Attached files

| file | filename |

|---|---|

| 8-K - Cardinal Ethanol LLC | a8-krepavilionarticleandca.htm |

| EX-99.2 - Cardinal Ethanol LLC | casestudy.htm |

Plantwide Optimization Solutions in a Highly Volatile, Thin-Margin Commodity Market

Imagine that you run a multi-million dollar biofuels production plant which you are trying to operate as efficiently as possible. Your investment was based on strong research. You procured an excellent plant design and hired an experienced plant management staff to operate the plant with the highest standards and best practices. You hire qualified commodity strategists and risk managers because you want to run your plant for the long term, and not be caught on the wrong side of the investment. You know that the ethanol production business is very volatile and is affected by large swings in corn feed stock costs and fuel ethanol prices. This is the situation that Cardinal Ethanol faced shortly after starting up the plant in 2008.

Cardinal Ethanol LLC was formed by a group of local farmers and investors who set out clear mission goals from the early start. These goals were:

• | Maximize value of the facility through strategic and efficient plant operations |

• | Improve productivity of the fuel ethanol facility with best-in-class technologies |

• | Optimize overall production margin |

• | Fuel America's economic development |

Cardinal Ethanol is located in Union City, Ind. The $168 million facility processes over 36 million bushels of locally grown corn per year and has an annual production of 100 million gallons of ethanol and 320,000 tons of Dry Distillers Grain and Solubles (DDGS). Cardinal Ethanol is operated and managed by a staff of 49 highly skilled employees. The plant site has a CSX railroad mainline running parallel to ship DDGS and ethanol to the eastern U.S. markets. Cardinal's operation lies in the Midwest agricultural heartland. The plant produces more than ethanol, it's making the next generation of transportation fuel from crop fields grown locally in Indiana.

Cardinal's management and operations staff was tasked with ramping the plant up to capacity within a short time after the construction of the plant. In addition, this team was to focus on using value-adding technology to unearth greater value from the corn feedstock to maximize the economic margin that could be derived from operations.

The Challenge

Within the first nine months of operation, Cardinal had ramped-up its production to nameplate capacity. Just as Cardinal had reached its production targets, the economic downturn occurred, causing margins to become razor-thin. The new operating challenges posed by this economic climate were especially troubling to the new plant. To survive, the plant had to increase its operating margin. Cardinal looked at several capital projects to increase its margin.

But finding a solution to maximize operating margin proved especially difficult. Cardinal Ethanol's dry mill plant is highly integrated. All process units - from milling to fermentation, distillation and the dryer systems - are interconnected by energy or material flow, and the extensive process interactions between these units make it difficult to optimize the process. While existing proportional-integral-derivative (PID) controller strategies automate individual portions of plant, these simplified controls do not capture all interactions that can be adjusted to optimize the plant.

So even with well-trained operators, accurate lab measurements and best-in-class PID controls to control each part of the production process, there was still an undesired level of variation seen in key plant variables including slurry solids, fermenter yield, 200-proof product quality, DDGS product quality and energy-per-gallon. Each of these variables had gradual swings and a degree of inconsistency. It was clear

that an effective solution would need to capture, analyze and control all parts of the plant under a single, unified model.

Cardinal Ethanol found its solution in Pavilion8®-based Model Predictive Control (MPC) technology from Rockwell Automation. MPC has the ability to stabilize and drive peak efficiency with a single model of the entire plant. Best of all, the system could be built and then added as a supervisory control system without modifying existing process equipment. Cardinal was especially welcoming to learn that this technology had been implemented in over 30+ plants in the U.S. ethanol industry and had a track record of making significant margin gains in each operating facility. Having seen these proven results, Cardinal Ethanol chose to install this technology as a plantwide optimization solution for the entirety of its 100 million gallon-per-year plant.

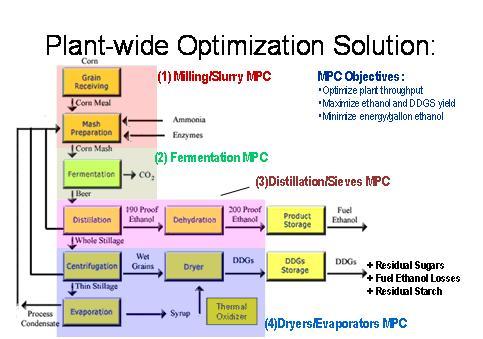

The Plantwide Optimization Solution

To install the Pavilion8-based MPC solution, Rockwell Automation application engineers came on-site to build non-linear dynamic response models and Soft Sensor® inferential models based on plant tests and historical data. Soft Sensor® models are inferential measurements that replace lab values; these are integrated into the solution to provide continuous control of key lab measurements. Soft Sensor® models were developed for properties including slurry solids, fermenter HPLC data, and syrup solids.

Over the course of the project, the Cardinal Ethanol operators were fully-trained in the MPC technology, and the system was gradually given the entire degree of freedom to make optimum control, margin and energy decisions. The plantwide optimization solution was given full reign of the 100-million gallon/year plant.

Milling and Slurry Control Application

The Milling and Slurry Control application reduced the variation of feed quality to the fermenters and helped the plant to safely run at mill amperage limits without tripping the hammermills. In addition, the application improved the water balance of the plant. (Water balance is critical because it impacts the economy of the operation. More water in the plant units results in higher energy costs.) The application helps ensure that the slurry to the fermenters had a consistent quality. This, in turn, improved the batch fermentation performance as seen with a 54-percent reduction in standard deviation of ethanol from the fermenters.

The application links the milling and slurry process units with the distillation sieves and the dryer/evaporators process units. It anticipated constraints and ran at higher energy efficiency and higher capacity (increased production by 7.2 percent).

Batch Fermentation Control Application

The Batch Fermentation Control application adjusted the temperature conditions and helped to ensure that enzyme levels are added using the optimal dynamic ratio to feedstock and the best trajectories that respond to changes in feedstock quality. The average of residual sugars was reduced by more than 40 percent. In addition, the standard deviation was reduced in excess of 70 percent. The plant now produces 2.2 percent more ethanol from each bushel of corn. This higher conversion of starch to ethanol, on a consistent basis, essentially yielded more ethanol for the same amount of corn. This was the key factor in the increase of overall margin.

Distillation and Dehydration (Molecular Sieves) Control Application

Cardinal Ethanol was inefficiently using energy to separate and purify ethanol. The Distillation and Dehydration Control application reduced the variability of energy use by over 50 percent. By optimizing the energy trade-offs between the sieve and distillation operations (within the evaporator energy constraints), energy was reduced. The application also enabled the ethanol to be tightly controlled to the desired moisture specification.

Evaporation and Drying Control, and Optimization Application

Dryer and evaporator process units remove moisture out of the stillage to form DDGS, a high protein feed ingredient. This application controlled evaporator solids and dryer moisture while managing stillage inventory and syrup usage. It also controlled the DDGS quality and yield. Since the evaporators are connected to distillation by material and heat, the application considers these interactions and minimized energy use within the process requirements and equipment constraints. The combined energy reduction resulting from optimization of both Distillation and Dehydration, and Evaporation and Drying was approximately 7.7 percent - each of these major sections contributing 50 percent of the energy improvements.

Value Methodology

Both Rockwell Automation and Cardinal Ethanol insisted that the results of the plantwide optimization solution be measureable and clear. To achieve this, the ValueFirst engagement methodology was used. The ValueFirst methodology entails: (a) completing a process assessment and establishing the potential gains from the project, (b) evaluating if the project met Cardinal's investment criteria and (c) auditing the results achieved with the customer.

Results

The magnitude of improvements achieved with plantwide optimization was unanticipated since Cardinal Ethanol was a very well-run plant. The Pavilion8-based MPC solution greatly improved overall plant

stability and reduced variability on all key process variables - especially the batch fermentation operations. A summary of the key results that made the project successful includes:

1. | Ethanol yield increase of 2.2 percent |

2. | Ethanol production increase of 7.2 percent |

3. | Energy/gallon reduction of 7.7 percent |

4. | Increased stability on all key process variables and reductions in standard deviation between 40-70 percent |

5. | Great operator acceptance |

6. | Payback in less than 12 months |

Overall, the project met and exceeded the expectations of Cardinal Ethanol and the management learned some key lessons through the implementation of the project. The joint work by

Rockwell Automation and Cardinal Ethanol throughout the project helped uncover and resolve complex process factors to enable higher production, yield and energy efficiency.

Cardinal Ethanol has also contracted with Rockwell Automation for sustained solution support, which is a service that includes remote monitoring and 1-2 site visits per year. This service helps ensure that the application sustains its value and is evergreen. Through the sustained support agreement, minor changes to the plant configuration will be incorporated into the plantwide optimization solution. Today, the service factor of the system exceeds 99 percent for all variables.

The significant commercial increase in the operating margin of the facility has ensured that Cardinal Ethanol is not only a well-positioned low-cost producer of ethanol, but that its carbon footprint is much lower than the industry average.

Pavillion8 is a trademark of Rockwell Automation.

By: Maina Macharia, Biofuels industry manager, Rockwell Automation

mmacharia@ra.rockwell.com