Attached files

| file | filename |

|---|---|

| EX-32.2 - EX-32.2 - WESTWATER RESOURCES, INC. | wwr-20191231ex322321e11.htm |

| EX-32.1 - EX-32.1 - WESTWATER RESOURCES, INC. | wwr-20191231ex321ce0a1d.htm |

| EX-31.2 - EX-31.2 - WESTWATER RESOURCES, INC. | wwr-20191231ex312c053e2.htm |

| EX-31.1 - EX-31.1 - WESTWATER RESOURCES, INC. | wwr-20191231ex311b085f8.htm |

| EX-23.1 - EX-23.1 - WESTWATER RESOURCES, INC. | wwr-20191231ex231fe1699.htm |

| EX-21.1 - EX-21.1 - WESTWATER RESOURCES, INC. | wwr-20191231ex211635930.htm |

| EX-4.1 - EX-4.1 - WESTWATER RESOURCES, INC. | wwr-20191231ex41901a544.htm |

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

WASHINGTON, D.C. 20549

FORM 10-K

|

(Mark One) |

|

|

☒ |

ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

|

For the fiscal year ended December 31, 2019 |

|

|

or |

|

|

☐ |

TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

|

For the transition period from to |

|

Commission file number 001‑33404

WESTWATER RESOURCES, INC.

(Exact name of Registrant as specified in its charter)

|

DELAWARE |

|

75‑2212772 |

|

(State of Incorporation) |

|

(I.R.S. Employer Identification No.) |

|

6950 S. Potomac Street, Suite 300 |

|

80112 |

|

(Address of principal executive offices) |

|

(Zip code) |

(303) 531‑0516

(Registrant’s telephone number, including area code)

Securities registered pursuant to Section 12(b) of the Act:

|

Title of Each Class |

|

Trading Symbol |

|

Name of Each Exchange on Which Registered |

|

Common Stock, par value $0.001 per share |

|

WWR |

|

Nasdaq Capital Market |

Securities registered pursuant to Section 12(g) of the Act: None

Indicate by check mark if the Registrant is a well‑known seasoned issuer as defined in Rule 405 of the Securities Act. Yes ☐ No ☒

Indicate by check mark if the Registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act. Yes ☐ No ☒

Indicate by check mark whether the Registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the Registrant was required to file such reports) and (2) has been subject to such filing requirements for the past 90 days. Yes ☒ No ☐

Indicate by check mark whether the Registrant has submitted electronically every Interactive Data File required to be submitted pursuant to Rule 405 of Regulation S‑T (§ 232.405 of this chapter) during the preceding 12 months (or for such shorter period that the Registrant was required to submit such files). Yes ☒ No ☐

Indicate by check mark whether the Registrant is a large accelerated filer, an accelerated filer, a non‑accelerated filer, a smaller reporting company or emerging growth company. See the definitions of “large accelerated filer”, “accelerated filer” “smaller reporting company” and “emerging growth company” in Rule 12b‑2 of the Exchange Act.

|

Large accelerated filer ☐ |

Accelerated filer ☐ |

Non‑accelerated filer ☒ |

Smaller reporting company ☒ |

|

|

|

|

Emerging growth company ☐ |

If an emerging growth company, indicate by check mark if the Registrant has elected not to use the extended transition period for complying with any new or revised financial accounting standards provided pursuant to Section 13(a) of the Exchange Act. ☐

Indicate by check mark whether the Registrant is a shell company (as defined in Rule 12b‑2 of the Exchange Act). Yes ☐ No ☒

The aggregate market value of the Common Stock held by non‑affiliates of the Registrant at June 30, 2019 was approximately $9,691,198. Number of shares of Common Stock, $0.001 par value, outstanding as of February 14, 2020 was 4,160,723 shares.

DOCUMENTS INCORPORATED BY REFERENCE

Portions of the definitive proxy statement relating to Registrant’s 2020 Annual Meeting of Stockholders are incorporated by reference into Part III of this Form 10‑K.

WESTWATER RESOURCES, INC.

ANNUAL REPORT ON FORM 10‑K

FOR THE FISCAL YEAR ENDED DECEMBER 31, 2019

| 3 | |

| 4 | |

| 4 | |

| 4 | |

| 5 | |

| 6 | |

| 6 | |

| 6 | |

| 6 | |

| 7 | |

| 10 | |

| 12 | |

| 13 | |

| 13 | |

| 13 | |

| 14 | |

| 17 | |

| 17 | |

| 20 | |

| 20 | |

| 31 | |

| 32 | |

| 32 | |

| 35 | |

| 38 | |

| 40 | |

| 55 | |

| 55 | |

| 55 | |

| 55 | |

| 55 | |

| 56 | |

| 56 | |

| 56 | |

| 56 | |

| 56 | |

| 56 | |

|

ITEM 7. MANAGEMENT’S DISCUSSION AND ANALYSIS OF FINANCIAL CONDITION AND RESULTS OF OPERATIONS |

57 |

| 57 | |

| 58 | |

| 60 | |

| 63 | |

|

ITEM 7A. QUANTITATIVE AND QUALITATIVE DISCLOSURES ABOUT MARKET RISK |

65 |

| 66 | |

|

ITEM 9. CHANGES IN AND DISAGREEMENTS WITH ACCOUNTANTS ON ACCOUNTING AND FINANCIAL DISCLOSURE. |

94 |

| 94 | |

| 94 | |

|

MANAGEMENT’S REPORT ON INTERNAL CONTROL OVER FINANCIAL REPORTING |

94 |

| 95 | |

| 95 | |

|

ITEM 10. DIRECTORS, EXECUTIVE OFFICERS AND CORPORATE GOVERNANCE |

95 |

| 99 | |

| 103 | |

|

ITEM 13. CERTAIN RELATIONSHIPS AND RELATED TRANSACTIONS, AND DIRECTOR INDEPENDENCE |

105 |

| 105 | |

| 106 | |

| 106 | |

| 108 | |

| 109 |

2

GLOSSARY OF CERTAIN ENERGY MINERALS INDUSTRY TERMS

|

Brine |

A naturally occurring fluid generally hosted in sedimentary rocks. Its chemical make-up is generally saline and may contain appreciable levels of potash (potassium chloride), magnesium and/or lithium. |

|

Claim |

A claim is a tract of land up to 20 acres in size, of which the right to mine is held under the federal General Mining Law of 1872 and applicable local laws. |

|

Concentrates |

A product from a mineral processing facility (including uranium). Uranium concentrates are commonly referred to as U3O8. |

|

Graphite |

A naturally occurring carbon material with electrical properties that enhance the performance of electrical storage batteries. |

|

Gross acres |

Total acreage of land under which we have mineral rights. May include unleased fractional ownership. |

|

In‑situ recovery (“ISR”) |

A mining method in which minerals may be extracted without physically removing rock from the ground. Groundwater fortified with oxygen and other solubilizing agents is pumped into a permeable ore body causing the uranium (or other mineral commodities) contained in the ore to dissolve. The resulting solution is pumped to the surface. The fluid‑bearing uranium is then circulated to an ion exchange column on the surface where uranium is extracted from the fluid onto resin beads. The fluid is then reinjected into the ore body. When the ion exchange column’s resin beads are loaded with uranium, they are removed and flushed with a salt‑water solution, which strips the uranium from the beads. This leaves the uranium in slurry, which is then dried and packaged for shipment as uranium powder, or yellowcake. |

|

Lithium |

A light metal used in the manufacture of lithium ion batteries for personal electronic devices, automotive and other transportation sectors. |

|

Mineral Resource |

A mineralized body which has been delineated by appropriately spaced drilling and/or underground sampling sufficient to support the estimate of tonnages and grade of the mineral deposit. Such a deposit does not qualify as a reserve, until a comprehensive evaluation based upon unit cost, grade, recoveries, and other material factors conclude legal and economic feasibility. |

|

Net acres |

Actual acres under lease which may differ from gross acres when fractional mineral interests are not leased. |

|

Ore |

Naturally occurring concentration of mineralization from which a mineral or minerals of economic value can be extracted at a reasonable profit. |

|

Probable reserves |

Reserves for which quantity and grade and/or quality are computed from information similar to that used for proven (measured) reserves, but the sites for inspection, sampling and measurement are farther apart or are otherwise less adequately spaced. The degree of assurance, although lower than that for proven (measured) reserves, is high enough to assume continuity between points of observation. |

|

Proven reserves |

Reserves for which (a) quantity is computed from dimensions revealed in outcrops, trenches, workings or drill-holes; grade and/or quality are computed from the results of detailed sampling and (b) the sites for inspection, sampling and measurement are spaced so closely and the geologic character is so well defined that size, shape, depth and mineral content of reserves are well‑established. |

|

Reclamation |

Reclamation involves the returning of the surface area of the mining and ISR wellfield operating areas to a condition similar to pre‑mining or ISR. |

3

|

Reserve |

That part of a mineral deposit which could be economically and legally extracted or produced at the time of the reserve determination. |

|

Restoration |

Restoration involves returning an aquifer to a condition consistent with our pre‑ISR use. The restoration of wellfield can be accomplished by flushing the ore zone with native ground water and/or using reverse osmosis to remove ions to provide clean water for reinjection to flush the ore zone. |

|

Spot price |

The price at which a mineral commodity may be purchased for delivery within one year. |

|

Surety obligations |

A bond, letter of credit, or financial guarantee posted by a party in favor of a beneficiary to ensure the performance of its or another party’s obligations, e.g., reclamation bonds, workers’ compensation bond, or guarantees of debt instruments. |

|

Tailings |

Waste material from a mineral processing mill after the metals and minerals of a commercial nature have been extracted; or that portion of the ore which remains after the valuable minerals have been extracted. |

|

Uranium or uranium concentrates |

U3O8 or triuranium octoxide. |

|

U3O8 |

Triuranium octoxide equivalent contained in uranium concentrates, referred to as uranium concentrate. |

|

Vanadium |

A metal used as a strengthening alloy in steelmaking, and in certain types of batteries. |

|

Waste |

Barren rock in a mine, or uranium in a rock formation that is too low in grade to be mined and milled at a profit. |

|

Yellowcake |

Uranium concentrate in powder form, the end‑result of the ISR mining or conventional milling process. |

In this Annual Report on Form 10‑K, unless the context otherwise requires, the terms “we”, “us”, “our”, “WWR”, “Westwater”, “Corporation”, or the “Company” refer to Westwater Resources, Inc. and its subsidiaries. The Company changed its name from “Uranium Resources, Inc.” to “Westwater Resources, Inc.” effective August 21, 2017.

The accounts of the Company are maintained in U.S. dollars. All dollar amounts referenced in this Annual Report on Form 10‑K and the consolidated financial statements are stated in U.S. dollars.

CAUTIONARY NOTE REGARDING FORWARD-LOOKING STATEMENTS

With the exception of historical matters, the matters discussed in this report are forward-looking statements that involve risks and uncertainties that could cause actual results to differ materially from projections or estimates contained herein. We intend such forward-looking statements to be covered by the safe harbor provisions for forward-looking statements contained in the Private Securities Litigation Reform Act of 1995. Such forward-looking statements include, without limitation, statements regarding the adequacy of funding, liquidity, the timing or occurrence of any future drilling or production from the Company’s properties, the ability of the Company to acquire additional properties or partner with other companies, the realization of expected benefits from recent business combinations and the Company’s anticipated cash burn rate and capital requirements. Words such as “may,” “could,” “should,” “would,” “believe,” “estimate,” “expect,” “anticipate,” “plan,” “forecast,” “potential,” “intend,” “continue,” “project” and variations of these words, comparable words and similar expressions generally indicate forward-looking statements. You are cautioned not to place undue reliance on forward-looking statements. Actual results may differ materially from those expressed or implied by

4

these forward-looking statements. Factors that could cause actual results to differ materially from these forward-looking statements include, among others:

the spot price and long‑term contract price of graphite, vanadium, lithium and uranium;

|

· |

the ability of WWR to enter into and successfully close acquisitions, dispositions or other material transactions; |

government regulation of the mining industry and the nuclear power industry in the United States;

operating conditions at our mining projects;

the world‑wide supply and demand of graphite, vanadium, lithium and uranium;

weather conditions;

unanticipated geological, processing, regulatory and legal or other problems we may encounter;

the results of our exploration activities, and the possibility that future exploration results may be materially less promising than initial exploration results;

any graphite, vanadium, lithium or uranium discoveries not being in high enough concentration to make it economic to extract the metals;

currently pending or new litigation or arbitration;

our ability to continue to satisfy the listing requirements of the Nasdaq Capital Market; and

our ability to maintain and timely receive mining and other permits from regulatory agencies.

For a more detailed discussion of such risks and other important factors that could cause actual results to differ materially from those in such forward-looking statements and forward-looking information, please see “Item 1A. Risk Factors” below in this Annual Report on Form 10‑K. Although we have attempted to identify important factors that could cause actual results to differ materially from those described in forward-looking statements and forward-looking information, there may be other factors that cause results not to be as anticipated, estimated or intended. There can be no assurance that these statements will prove to be accurate as actual results and future events could differ materially from those anticipated in the statements. Except as required by law, we assume no obligation to publicly update any forward-looking statements and forward-looking information, whether as a result of new information, future events or otherwise.

STATEMENT REGARDING THIRD PARTY INFORMATION

Certain information provided in this report has been provided to us by the third parties or is publicly available information published or filed with applicable securities regulatory bodies, including the SEC. WWR has not verified, and is not in a position to verify, and expressly disclaims any responsibility for, the accuracy, completeness or fairness of such third-party information and refers the reader to the information publicly published or filed by the third parties for additional information.

5

ITEM 1. DESCRIPTION OF BUSINESS.

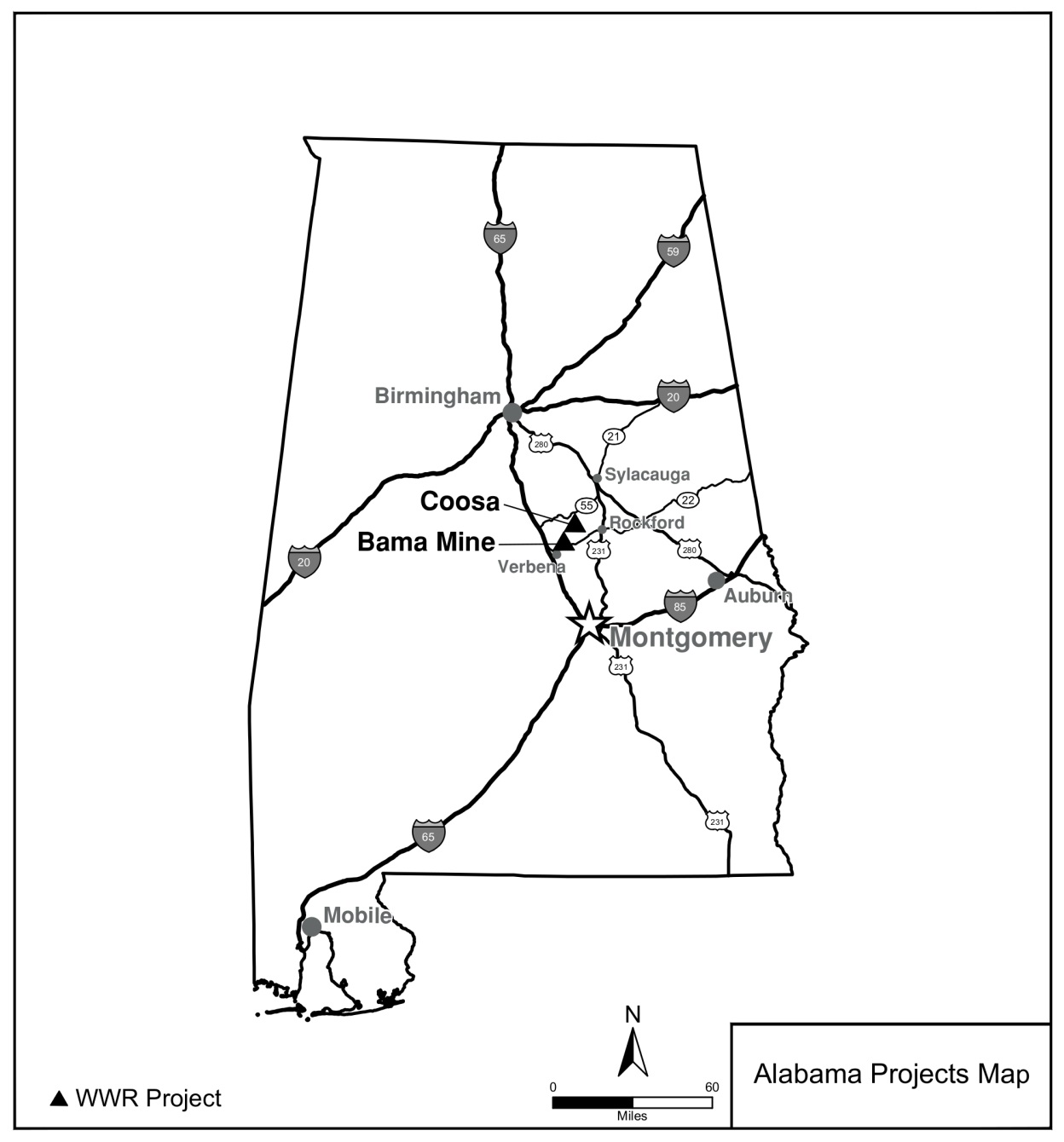

Westwater Resources, Inc. is a 40-year-old public company trading on the Nasdaq Capital Market (“Nasdaq”) under the symbol “WWR.” Originally incorporated in 1977 as Uranium Resources, Inc. to mine uranium in Texas, our company has been reborn as a diversified energy materials developer. Westwater now has a presence in uranium, lithium exploration, and battery-ready graphite materials after its acquisition of Alabama Graphite Corp. (“Alabama Graphite”) in April 2018. In addition, Westwater recently discovered significant vanadium concentrations at the Coosa Graphite Project (the “Coosa Project”) in Alabama and has an exploration plan available to further investigate the size and extent of those concentrations.

Westwater holds battery-ready graphite development properties in Alabama, exploration properties with lithium exploration potential in Nevada and Utah, two idled uranium production properties in Texas and several uranium properties in Texas and New Mexico. Westwater ceased uranium production in 2009 due to reductions in the price of uranium, although Westwater’s uranium properties and facilities in Texas can be restarted once the price of uranium recovers to acceptable levels.

Effective August 21, 2017, we amended our certificate of incorporation to change our name from Uranium Resources, Inc. to Westwater Resources, Inc. to reflect our broader focus on energy materials exploration and development. Our principal executive offices are located at 6950 South Potomac Street, Suite 300, Centennial, Colorado 80112, and our telephone number is (303) 531-0516. Our website is located at www.westwaterresources.net. Information contained on our website or that can be accessed through our website is not incorporated by reference into this report. As of February 14, 2020, the Company and its subsidiaries had 28 employees.

Our strategy is to increase shareholder value by expanding into the battery materials marketplace, while maintaining our uranium assets as an option on the future rising price of uranium. The acquisition of the Coosa Project graphite mineral properties from Alabama Graphite in April 2018, combined with the Company’s existing lithium exploration properties in Nevada and Utah, provides the Company with the opportunity to develop two critical raw materials utilized by the growing market for electric battery storage for automobiles, trucks and buses, as well as grid-based storage devices. In 2018, the global battery market consumed 182,400 tonnes of graphite, and was growing at an annual rate of 16.17% over the precious 10-year period.

Our goal for the graphite business is to develop a battery-graphite manufacturing business in Alabama that produces low-cost, high-quality, and high-margin graphite products for battery manufacturers. Subject to the availability of financing, we plan to begin operation of a pilot-scale processing plant in 2020, followed by construction of a commercial scale processing facility in 2022 that purifies readily available graphite flake concentrates from various sources to 99.95% pure carbon. Once purified, the graphite will be further processed into three advanced component products with enhanced conductivity performance needed by battery manufacturers. These advanced graphite products are purified micronized graphite, delaminated expanded graphite and coated spherical purified graphite. At the same time, subject to the availability of financing, we plan to begin developing the Coosa Graphite mine (planned for start-up in eight to ten years1) on our 40,000‑plus-acre mineral-rights holdings that can serve as a hedge against future feedstock costs and provide in-house quality assurance and quality control (“QA/QC”) for raw-material inputs.

6

We plan to continue geologic evaluation of our greenfield lithium exploration properties in Nevada and Utah. Significant exploration expenditures will be dependent on the availability of project-based or joint-venture based funding. We plan to continue to pursue and secure water rights for the two+- project areas, as water rights are a critical component of any future commercial development of the mineral properties and require relatively low capital expenditures.

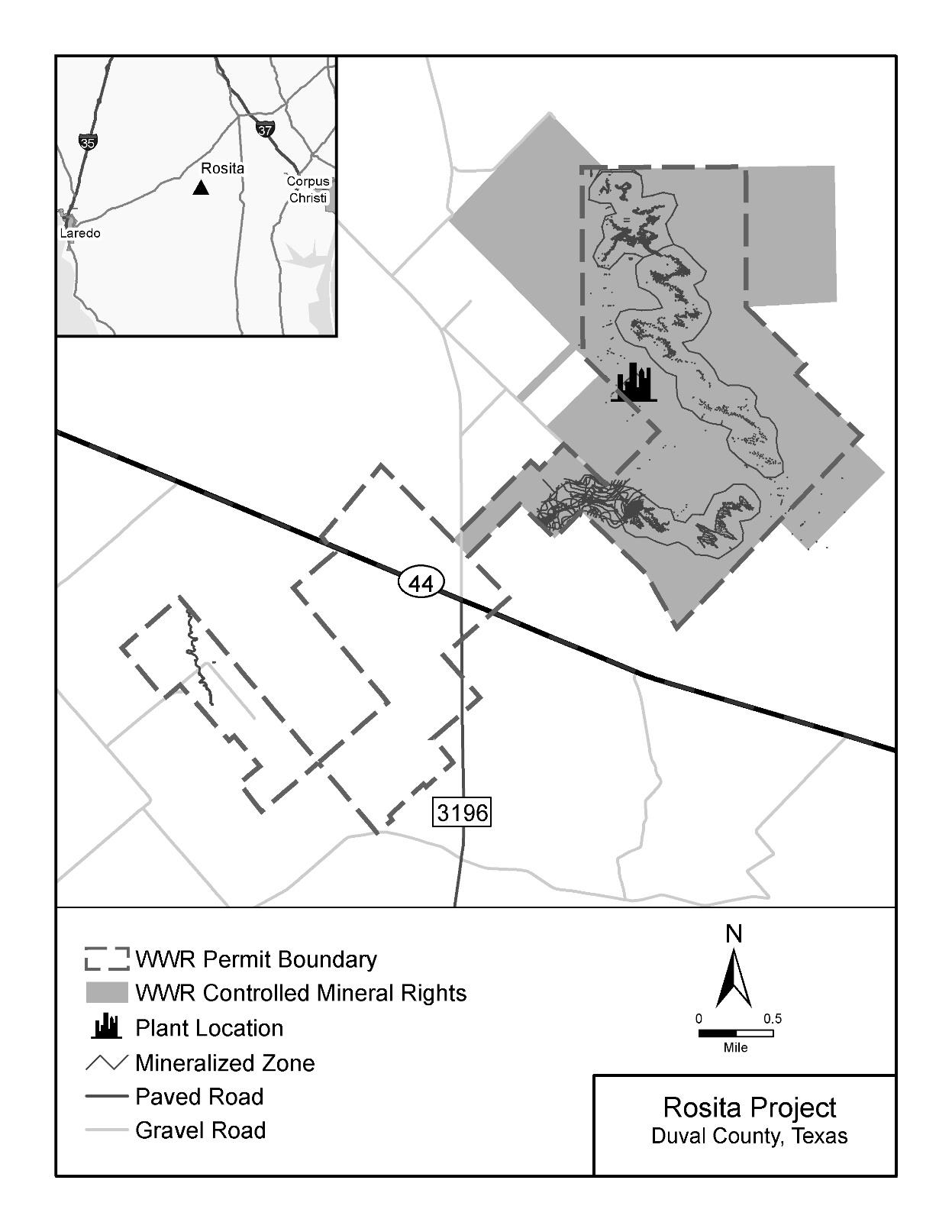

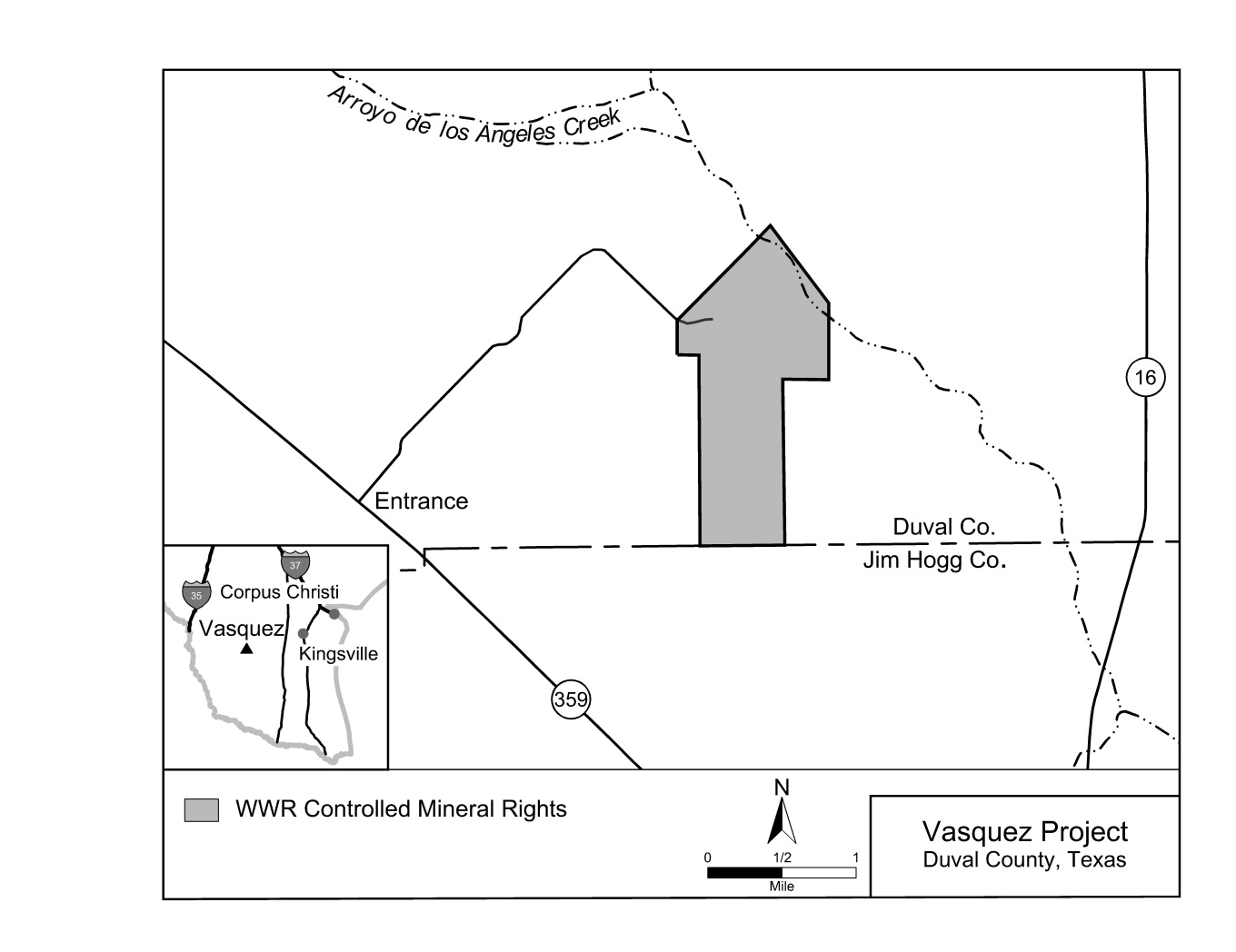

Amidst the prevailing low uranium price environment, we continue to balance cash conservation with maintaining readiness to fast track resumption of production at such time as uranium prices show sufficient improvement, as well as manage our assets opportunistically to take advantage of potential sales of property interests and royalties to maximize value for our shareholders. For our South Texas uranium projects, we plan to continue the focus on fulfilling our environmental obligations with proactive restoration of legacy wellfields while maintaining our processing facilities on standby for potential operating/processing agreements. During 2020, we anticipate completing the restoration requirements at the Vasquez Project and all non-production properties at the Rosita Project, and will seek bond release from the Texas Commission on Environmental Quality. In New Mexico, we continue to assess the potential for the development of our larger scale uranium projects on a stand-alone basis or with partners.

Our project pipeline is prioritized as near-term, mid-term and long-term projects, with a goal of achieving sustainable production over time with our graphite, lithium and uranium projects so as to take advantage of rising and/or high price environments for these minerals. We continually adjust near-term and long-term business priorities in accordance with market conditions.

Our broad base of mining, processing and manufacturing expertise from graphite, base and precious metals to energy materials is our key competitive advantage. Westwater possesses a unique combination of battery-materials knowledge and extensive project-execution experience, coupled with decades of capital markets expertise which makes our business a powerful presence in the new energy marketplace. We intend to advance the Company’s projects towards production when economics allow, while prudently managing our cash and liquidity position for financial flexibility.

KEY BUSINESS AND CORPORATE DEVELOPMENTS IN 2019

Graphite Product Development with Dorfner Anzaplan

Westwater announced on November 21, 2019 that it has engaged Dorfner Anzaplan of Hirschau, Germany to advance the development of processes needed to purify graphite concentrates and to produce the Company’s battery grade products: ULTRA-PMGTM, ULTRA-DEXDGTM and ULTRA-CSPGTM. Dorfner Anzaplan is an internationally recognized and highly regarded organization that specializes in high-purity industrial and strategic metals businesses. They employ state-of-the-art analytical methods and facilities and employ innovative processing technologies to provide effective solutions tailored to their clients’ requirements.

Dorfner Anzaplan is expected to collaborate with Westwater to scale up laboratory sample production to pilot scale production rates through new work anticipated to be executed through second quarter 2020 to:

|

· |

Define the method, equipment and operating parameters and requirements for graphite purification; |

|

· |

Define operating parameters and equipment for processes required to manufacture Westwater’s battery graphite products; and |

|

· |

Design Westwater’s pilot program. |

Westwater’s pilot scale program will utilize the 20 metric tons of graphite concentrate feedstock received from our supplier, with whom we have executed a long-term agreement to supply graphite concentrate under a cap and collar pricing arrangement. This graphite concentrate shipment to Westwater’s Sylacauga warehouse was previously announced in a October 15, 2019 press release. The pilot plant resulting from this work program with Dorfner Anzaplan will provide various product sizes of each of the Company’s three principal battery-grade conductivity enhancement products to potential clients to advance the prospective clients’ commodity evaluation and pre-qualification programs. This large-scale sample testing effort is the next step in the development schedule of the Coosa Graphite Project as it advances to a commercial production decision.

7

Purchase Agreement (“PA”) with Lincoln Park Capital Fund, LLC (“Lincoln Park”)

On June 6, 2019, the Company entered into the PA with Lincoln Park to place up to $10.0 million in the aggregate of the Company’s common stock on an ongoing basis when required by the Company over a term of 24 months. Westwater will control the timing and amount of any sales to Lincoln Park, and Lincoln Park is obligated to make purchases in accordance with the PA. Any common stock that is sold to Lincoln Park will occur at a purchase price that is based on an agreed upon fixed discount to the Company’s prevailing market prices at the time of each sale and with no upper limits to the price Lincoln Park may pay to purchase common stock. The PA may be terminated by Westwater at any time, in its sole discretion, without any additional cost or penalty.

The PA specifically provides that the Company may not issue or sell any shares of its common stock under the PA if such issuance or sale would breach any applicable rules of Nasdaq Capital Market. In particular, Nasdaq Listing Rule 5635(d) provides that the Company may not issue or sell more than 19.99% of the shares of the Company’s common stock outstanding immediately prior to the execution of the PA without shareholder approval. On August 6, 2019 the Company conducted a Special Meeting of Shareholders whereby the Company received such approval to sell up to 3,200,000 shares of common stock under the PA.

Lincoln Park has no right to require the Company to sell any shares of common stock to Lincoln Park, but Lincoln Park is obligated to make purchases as the Company directs, subject to certain conditions. In all instances, the Company may not sell shares of its common stock to Lincoln Park under the PA if it would result in Lincoln Park beneficially owning more than 9.99% of its common stock.

Following effectiveness of a registration statement on Form S-1 relating to the resale of the shares subject to the PA on June 18, 2019, the Company began selling shares of its common stock to Lincoln Park under the terms of the PA. On September 11, 2019 and October 28, 2019 we filed subsequent registration statements on Form S-1, which were declared effective on September 20, 2019 and November 7, 2019, respectively, registering for resale additional shares under the PA. Inception-to-date through December 31, 2019, the Company has sold 1,694,534 shares of common stock for gross proceeds of $5.8 million.

Securities Purchase Agreement with Lincoln Park

On May 24, 2019, Westwater entered into a securities purchase agreement, as amended by Amendment No. 1 thereto dated as of May 30, 2019 (as so amended, the “Securities Purchase Agreement”)2, with Lincoln Park, pursuant to which the Company agreed to issue and sell to Lincoln Park, and Lincoln Park agreed to purchase from the Company (i) 104,294 shares of the Company’s common stock, par value $0.001 per share and (ii) warrants to initially purchase an aggregate of up to 182,515 shares of common stock, at an exercise price of $5.062 per share. On May 30, 2019, the Company issued and sold the common shares and the warrants to Lincoln Park and received aggregate gross proceeds before expenses of $550,751. The warrants became exercisable on November 30, 2019 and may be exercised at any time thereafter until November 30, 2024.

8

On April 22, 2019, following the close of trading, Westwater effected a one-for-fifty reverse split of its common shares. The consolidated common shares began trading on a split-adjusted basis on April 23, 2019. On April 18, 2019, at the Annual Meeting of Stockholders, the Company received approval for a charter amendment permitting Westwater to effect a reverse split. The primary purpose of the reverse split was to bring Westwater into compliance with Nasdaq’s $1.00 minimum bid price requirement to maintain Westwater’s stock listing on the Nasdaq Capital Market.

The reverse split reduced the number of shares of Westwater’s outstanding common stock from 74,707,659 shares to 1,494,153 shares of common stock. No fractional shares were issued as a result of the reverse stock split. Any fractional shares that would have resulted were settled in cash. All share data herein has been retroactively adjusted for the reverse stock split.

Royalty and Promissory Note Sale

On March 5, 2019, Westwater entered into an asset purchase agreement to sell four royalty interests on uranium properties located in South Dakota, Wyoming and New Mexico and a promissory note due in 2020 (the “Laramide note”) to Uranium Royalty Corp. (“URC”) for $2.75 million, including $0.5 million paid at signing, which was credited against the purchase price at the closing of the transaction. On June 28, 2019, Westwater and URC entered into an amendment to the asset purchase agreement, which extended the date for closing under the asset purchase agreement from July 31, 2019 to August 30, 2019. In addition, URC delivered an additional $1,000,000 as deposit to the Company upon signing the amendment, increasing the total deposit credited against the purchase price to $1,500,000. The transaction closed on August 30, 2019, on which date the Company transferred ownership of the royalty interests and the Laramide note to URC in exchange for the final payment of $1.25 million.

Turkish Government Taking of Temrezli and Sefaatli Licenses and Westwater’s Arbitration Filing

In December 2018, Westwater filed a Request for Arbitration against the Republic of Turkey for its unlawful actions against the Company’s investments, most notably, the June 2018 illegal taking of its licenses for the Temrezli and Şefaatli uranium projects located in the Republic of Turkey, rendering both projects worthless. These two uranium projects were owned by Westwater’s wholly-owned, indirect Turkish subsidiary Adur Madencilik Limited Sirketi (“Adur”).

Since 2007, Adur has held the exclusive rights for the exploration and development of uranium at Temrezli and Şefaatli, two sites located around 200 kilometers from Ankara, which include the largest and highest-grade deposits of uranium known to be in Turkey. Through June 2018, Adur and its shareholders had invested substantially in these two projects, using their technical expertise and carrying out extensive drilling, testing and studies to move the projects towards production. Having successfully completed the exploration stage of the uranium mining process in 2013‑2014, Adur was granted a number of exploration and operating licenses by the Turkish government to develop the Temrezli mine. As a direct result of Adur’s efforts, Temrezli became the most advanced uranium project in Turkey and it was projected to be one of the lowest cost uranium mines in the world. Westwater acquired Adur in late 2015 for approximately $18 million in an all-stock acquisition of Adur’s parent company, Anatolia Energy Limited.

For many years, Adur and Westwater worked closely with the Turkish authorities and shared their technical expertise in uranium mining. However, Turkey’s most recent actions have undermined this longstanding relationship. In particular, in June 2018, the Turkish government cancelled all of Adur’s exploration and operating licenses with retroactive effect, rendering Westwater’s investment in Adur effectively worthless. While the Turkish authorities had variously issued, renewed and overseen these licenses for more than a decade, beginning in January 2018, they asserted that those licenses had been issued by mistake and that the Turkish government has a governmental monopoly over all uranium mining activities in Turkey, in violation of Westwater’s rights under both Turkish and international law. Westwater reached out on numerous occasions to the Turkish government to resolve this dispute amicably, to reinstate the licenses and to remedy Turkey’s unlawful actions, but to no avail.

9

As a result, on December 13, 2018 Westwater filed a Request for Arbitration against the Republic of Turkey with the International Center for the Settlement of Investment Disputes (“ICSID”) pursuant to the Treaty between the United States of America and the Republic of Turkey (“Turkey”) concerning the Reciprocal Encouragement and Protection of Investments (the “Treaty”). On February 4, 2020, Westwater announced that it has submitted a Claimant’s Memorial (the “Memorial”) in its arbitration proceeding against Turkey. The Memorial sets out the details of Westwater’s claim against Turkey for its unlawful actions against Westwater’s investments at the Temrezli and Sefaatli uranium projects owned by Adur.

The Memorial sets forth the legal basis for Westwater’s claims under the Treaty and international law generally, as well as the basis for the jurisdiction of the tribunal constituted on May 1, 2019. The Memorial also explains the compensation owed by Turkey for breach of its international obligations towards Westwater, consisting of $36.5 million, plus costs and post-award interest. Accompanying the Memorial is an expert report analyzing the amount of compensation owed to Westwater.

Turkey has until March 9, 2020 to make a request for bifurcation of the proceedings so as to address issues of jurisdiction first. If it does not make such a request, it will proceed with filing a Counter-Memorial on or before June 15, 2020. Schedules for additional filings are dependent upon the approach taken by Turkey and the decision of the ICSID tribunal on any request for bifurcation. If bifurcation is requested and granted, a hearing on jurisdiction only will be scheduled for March 2021. If bifurcation is not requested, a hearing on the merits will be scheduled for May 2021. If bifurcation is requested and denied, a hearing on the merits will be scheduled for September 2021. Additional information regarding the ICSID arbitration proceeding is presented in Part II, Item 1 below.

Vanadium Target Identification

In late November 2018, Westwater announced the discovery of significant concentration of vanadium mineralization at several locations, hosted in the graphitic schists at the Company’s Coosa, Alabama Project. Westwater subsequently commenced the first of a four-phase exploration program designed to determine the extent, character and quality of the vanadium mineralization at Coosa. As announced by the Company on February 19, 2019, the first phase demonstrated widespread positive values for vanadium that extended beyond the Coosa graphite deposit, as defined in the 2015 Preliminary Economic Assessment for the Coosa Project.

Reclamation Success in Texas

Westwater has completed wellfield plugging at the Vasquez Project and the Texas Commission on Environmental Quality has approved this phase of reclamation. This paved the way for bond releases in 2019, including the release of a surety bond posted by the Company in the amount of $208,657 as announced by the Company on March 4, 2019. Reclamation of the waste disposal well and its associated pond, as well as the remainder of the surface, is planned for completion in early 2020.

At the Rosita Project, also located in Texas, the wellfield Production Areas 1 & 2 are plugged, and surface reclamation in those areas is planned for completion in 2020.

OVERVIEW OF THE BATTERY GRAPHITE INDUSTRY

Graphite is the name given to a common form of the element carbon. Occurring naturally as a mineral in numerous deposits around the world, graphite is used in many industrial applications. These end uses take advantage of the graphite’s natural characteristics of high lubricity, high resistance to corrosion, ability to withstand high temperatures while remaining highly stable, and excellent conductivity of heat and electricity.

In recent years, graphite has become an essential component in the production of all types of electrical storage batteries. This role will continue to be important as demand for these batteries increases, with the world’s growing electric-vehicle and energy-storage needs. Natural battery-ready graphite products are derived from flake graphite that has been

10

transformed through a series of specialty downstream processes into various battery graphite products. These processes include, but are not limited to:

Purification to battery-grade carbon as graphitic (Cg) content of ≥ 99.95%,

Micronization (sizing);

Intercalation (expansion), delamination (sheering);

Spheronization (shaping), classification (sorting); and

Surface treatment (carbon coating).

Natural flake graphite is increasingly supplanting the use of synthetic graphite in battery applications, for cost and performance reasons. Through a series of sophisticated and precise processing steps, flake-graphite concentrates are transformed into high-value end products for the battery industry, specifically purified micronized graphite and delaminated expanded graphite, used as conductivity-enhancement additives for the manufacture of cathodes for a number of battery material families, and coated spherical purified graphite for the manufacture of anodes in Li-ion batteries. Additional high-performance, battery-ready graphite materials can also be produced, using these three products as a starting point.

The global battery market consumed 182,400 tonnes in 2018 and was growing at a rate of 16.1% over the previous ten years (Roskill, 2019). The greatest share of this market is made up of four battery-market segments that require advanced battery-graphite products:

Li-ion batteries — these are rechargeable lithium-based batteries used in everything from cellphones and hand tools to laptop computers and electric vehicles.

Alkaline Power Cells — these are the most popular consumer batteries in the world, with more than 10 billion units produced worldwide each year (Roskill, 2019).

|

· |

Lead Acid batteries — these are the workhorse batteries used in automobiles and back-up power supplies and other energy-storage applications where weight is less important than capacity, and make up about 80% of the storage capacities in gigawatt hours (GWh) of all batteries presently sold worldwide (Sanders, 2018). |

|

· |

Primary Lithium batteries — these are non-rechargeable, lightweight lithium-based batteries like those used in flashlights, smoke detectors, and applications where long life and lightweight matters most. |

All of these batteries use graphite as a critical, non-substitutable constituent. According to analysts, batteries accounted for an estimated 182,400 tonnes of graphite consumption in 2018. Demand for batteries grew by a compound annual growth rate of 16.1% between 2008 and 2018 (Roskill, 2019). Based on Roskill’s base case scenario for electric vehicle demand, this rate of growth could almost double to 20.2% over the next decade, with graphite consumption in batteries reaching 1,900,000 tonnes in 2028. Consumption of graphite in Li-ion batteries currently accounts for around 84% of the battery market for graphite but this could rise to 95-98% by 2028. Competition between natural and synthetic graphite is expected to continue in Li-ion batteries with the choice coming down to price, performance and availability. Synthetic graphite consumption by anode manufacturers is expected to grow because of the concentration of the industry in China; however, natural flake graphite demand is forecast to grow at a higher rate because of natural graphite’s performance and cost efficiencies when compared to synthetic graphite.

Overall battery consumption is rising at an accelerated growth rate due to recent and robust developments in electric-automobile markets, personal electronic devices and electrical grid storage, an enabling technology for wind and solar power installation. The global shift towards low- and zero-emissions vehicles and power sources will continue to

11

drive increasing demand for graphite-battery materials for the foreseeable future. Recent developments in this sector include:

The United Kingdom and France have announced a prohibition on the sale of gasoline- and diesel-powered vehicles by 2040. Electric vehicles using battery storage are the only viable technology that can satisfy the demands for new cars mandated by these nations;

China, the largest new-car market in the world, has mandated that 8% of all new cars sold are to be plug-in hybrid, battery electric or fuel-cell powered;

Many major automobile companies have developed, or are developing, an electric-based technology to replace internal-combustion engines;

Governments around the world continue to incentivize electric-vehicle ownership through subsidies and other incentives;

The installed base of wind and solar power electrical-generating systems is increasing every year. Grid battery storage is the answer to increasing system reliability and unlocking the value of these power sources; and

As a result of these catalysts, and according to Roskill, the Li-ion battery market is expected to grow at a compounded annual growth rate of over 20%.

The real challenge for battery manufacturers is that the primary source of battery-grade graphite is China, presenting the global battery industry with significant risks, including supply chain management risks, economic risks and environmental unsustainability. Also, critical domestic production is absent in the United States. A recent Presidential Executive Order includes graphite on its list of minerals critical to the safety and security of the United States. With no domestic graphite production of any kind, the United States is presently required to source all of its battery graphite from China.

Westwater is developing graphite-purification technology and advanced product-development processes to meet the demands of these customers, as well as the large base of existing consumers for battery-graphite materials. Westwater is developing methodologies and facilities to produce high- purity, battery-graphite products in the State of Alabama. These products are designed to address all major battery sectors. In addition, the processes we intend to use are environmentally sustainable and permittable in the United States, where a robust regulatory environment complements our core values to reliably deliver safe, well-made products to our customers.

OVERVIEW OF THE VANADIUM INDUSTRY

Vanadium is a lightweight metal used in the construction industry, in high strength steel alloys, and in some large grid storage batteries. According to the United States Geological Survey (USGS), about 80,000 metric tonnes of vanadium (as V) per year were consumed worldwide in 2017, approximately 80% of which was utilized by the steel industry, where additions of the metal to conventional steel materials adds strength and corrosion resistance. Importantly for Westwater, demand for Vanadium Flow batteries is increasing as solar and wind power generators seek to make their installations more reliable electricity providers. Market research firm Roskill predicts that there will be a 45% increase in demand for vanadium, mostly in China.

Currently, about 85% of all vanadium is produced in South Africa, China and Russia. There is no significant production of vanadium currently in the United States.

12

OVERVIEW OF THE LITHIUM INDUSTRY

The primary use for lithium is a key ingredient in rechargeable batteries for electronic devices and electric vehicles. Lithium ion, or Li-ion, batteries, as they are known, have been adopted as the standard method of powering electronic devices such as smart phones and small, portable computers for some time, but it is the transportation market that is expected to drive growth for the next decade. Growth in consumption of lithium is expected to average over 6% annually between now and 2025, according to CRU International Limited, with the transportation sector accounting for much of this growth. According to industry studies, the transportation sector is expected to rise from 20% to 39% of total Li-ion battery demand over the next seven years.

At the same time, lithium prices have risen in response to increased demand. Lithium carbonate is one form used for battery manufacturing, and prices at year end 2019 are $8,750 per metric tonne for lithium carbonate. For lithium hydroxide, a second form of the material, prices are approximately $10,250/metric tonne – somewhat less than year end 2018.

Our lithium business objectives are to discover and produce lithium from lithium salts hosted in brines. This production method is typically the lowest cost type of lithium production. While the technologies are well known in some respects, it takes time for deposits to be discovered and developed, which should result in a supply deficit over the next few years. Expected higher prices will encourage investment in the sector and bring new sources of production online over time. CRU International Limited expects long term lithium prices to stabilize at approximately $6,400 per metric ton and $9,400 per metric ton for lithium carbonate and lithium hydroxide, respectively.

Westwater is targeting exploration and development of lithium brines because they are characteristically in the lowest operating cost quartile of production, and are more likely to be profitable in the markets described above.

OVERVIEW OF THE URANIUM INDUSTRY

The only significant commercial use for uranium is as a fuel for nuclear power plants for the generation of electricity. According to the World Nuclear Association (“WNA”), as of January 2020, there were 442 nuclear reactors operable worldwide, 53 reactors under construction, and 440 planned and/or proposed. Annual requirements for uranium amount to about 153 million pounds of uranium. While global nuclear power generation is expected to drive increased demand through 2030, especially in China, Russia, India and South Korea, UxC Consulting projects continued oversupply and low uncovered demand over the near-to-medium term due to higher inventory levels at utilities. During 2019, term contracting was weak and focused on shorter period mid-term contracts. This restrained the spot market as discretionary buying was also weak.

In 2010, the average spot price of uranium ended the year at approximately $24.50/lb, comparable with 2019. Some analysts project that uranium prices are expected to rise as higher cost mines are shut in and supplies dwindle.

There is global competition for graphite, lithium and uranium properties, capital, customers and the employment and retention of qualified personnel. We compete with multiple exploration companies for mineral properties and skilled personnel. In the production and marketing of graphite, lithium and uranium, there are a number of producing entities globally, some of which are government controlled and several of which are significantly larger and better capitalized than we are. Several of these organizations also have substantially greater financial, technical, manufacturing and distribution resources than we have.

Any future uranium production will also compete with uranium from secondary supplies, including the sale of uranium inventory held by the U.S. Department of Energy. In addition, there are numerous entities in the market that compete with us for properties and operate ISR facilities. If we are unable to successfully compete for properties, capital, customers or employees or with alternative uranium sources, it could have a materially adverse effect on our results of operations.

13

With respect to sales of graphite, lithium and uranium, the Company expects to compete primarily based on price. We will market graphite and lithium directly to users of the product, and uranium to utilities and commodity brokers. We are in direct competition with supplies available from various sources worldwide. We believe we compete with multiple graphite and lithium exploration and development companies, as well as operating uranium companies.

OVERVIEW OF WESTWATER RESOURCES’ PROJECTS

Coosa Graphite Project (the “Coosa Project”)

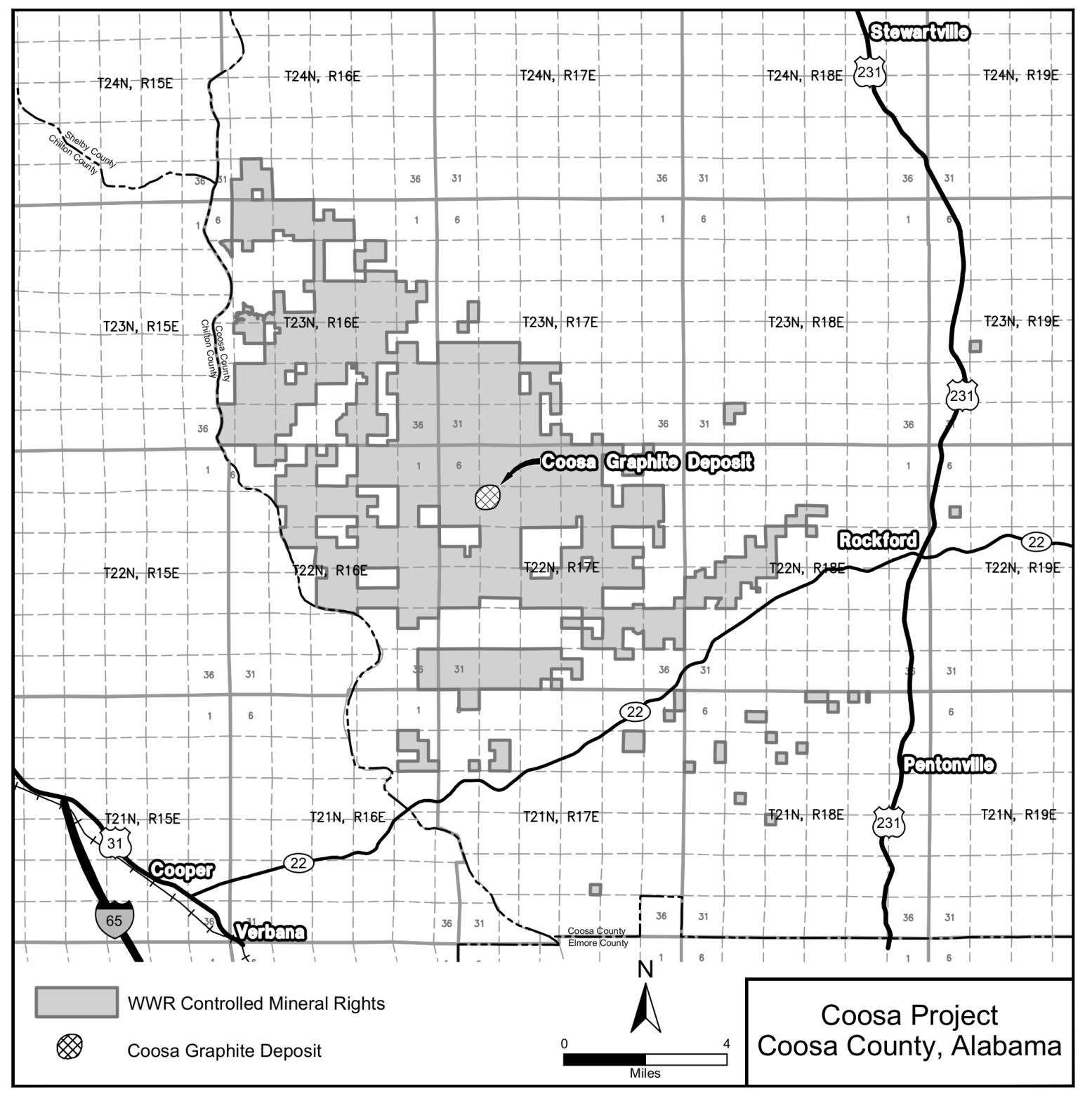

Westwater acquired Alabama Graphite in 2018 as part of a strategic decision to refocus the Company to supply battery manufacturers with low-cost, high-quality, and high-margin graphite products. As a result of that business transaction Westwater became the owner of the Coosa Graphite Project, which was the principal asset of Alabama Graphite. Westwater believes that graphite has an important strategic place in the global economy as a high-demand commodity as electrical storage systems for wind and solar power, and as the electrification of our transportation systems becomes more widespread. The principal asset acquired was the Coosa Project, which includes the Coosa graphite deposit located near Sylacauga, Alabama, 50 miles southeast of Birmingham. The Coosa deposit is located in an area that has been a past producer of graphite, utilizing a geology trend spanning tens of thousands of acres, known as the “Alabama Graphite Belt.” The State of Alabama remains a business-friendly jurisdiction, exemplified by the state successfully securing a $1 billion commitment from Daimler Benz to build a lithium-ion battery factory near its automobile assembly plant in the state. In addition, several other automobile manufacturers have sited plants in Alabama as a result of this favorable business climate.

Westwater’s graphite business plan will accelerate product development and market development by purchasing readily available graphite flake from qualified suppliers, for which a procurement contract is currently in place, to serve as plant feedstock while the Coosa graphite mine is being permitted and developed. Development of a mine at the Coosa graphite deposit, planned for start-up in the next eight to ten years, will serve as an in-house source of graphite feedstock, a hedge against future feedstock cost increases, and will provide in-house QA/QC for raw-material inputs. The Company plans to commence operation of a pilot-plant in 2020, subject to the availability of financing. Materials produced in the pilot-plant, presently targeted at 20-metric tonnes, will be used for customer development and product qualification, and pilot-plant operating data will serve as the foundation for the design and construction of a commercial scale processing facility. As part of the pilot plant, the graphite is purified, and then the material is further processed into the three advanced component products which provide graphite materials with enhanced conductivity performance for battery manufacturers: Purified Micronized Graphite, Delaminated Expanded Graphite, and Coated Spherical Purified Graphite. WWR is working with a number of potential customers, several of which have qualification samples in hand as a first step towards potential sales.

Description of the Graphite Deposit

The Coosa graphite deposit is located at the southern end of the Appalachian mountain range, in Coosa County, Alabama. The deposit area is approximately 52 miles south-southeast of the city of Birmingham, and 23 miles south-southwest of the town of Sylacauga. The project mineral tenure is comprised of approximately 41,965 acres of privately-owned mineral rights that the Company holds under a long-term lease.

The Coosa graphite deposit is hosted in high-grade metamorphic rocks. Graphitic material is present in two types of schist, a quartz-graphite schist that generally has grades greater than 1% Cg and a quartz-biotite-graphite-schist that has grades generally less than 1% Cg. The uppermost 60‑100 feet of the graphite-bearing rocks have been weathered and oxidized such that they could be easily mined by simple excavation equipment without any blasting. As currently defined, mining will mainly be centered on these weathered units.

A mineral resource estimate for the Coosa deposit, as set forth in a Preliminary Economic Assessment (PEA) completed by Alabama Graphite in 2015, demonstrated an overall concentration of non-reserve mineralized material of 157.8 million short tons averaging 2.48%, at a graphitic carbon cut- off grade of 1% Cg. This estimate is based on assay data from 69 core drill holes, totaling 20,414 feet.

14

Mining Method

The Coosa graphite deposit is expected to be mined by conventional small-scale open-pit mining methods through several shallow pits (less than 100 feet deep each) that will be developed over life of the project. At full-scale production, the mining rate will be approximately 577,000 short tons per annum, at an average grade of 3.2% Cg. Mine operations will employ small conventional loading and haulage equipment, including a 6.0 cubic yard excavator and 45‑ton articulated haul trucks. Mineralized material will be ripped with a bulldozer to prepare the mineralized material for mining with the excavator. Additional support to the mine and plant will be provided by graders and smaller dozers to maintain access roads, stockpiles and overburden storage areas.

Concentrate Plant

Mineralized material from the Coosa Project mine is projected to have an average grade of 3.2% Cg, and will contain impurities consisting of quartz, muscovite, iron oxides and calcite. Most of the impurities are present on the surfaces of the graphite flakes and can be easily removed during a metallurgical process known as flotation. Flotation processing maximizes the removal of these impurities while avoiding degradation of graphite flakes.

The concentration plant will consist of two-stage crushing, rod and ball-mill grinding, and multi-stage flotation units. The plant will operate 24 hours per day, 7 days per week, 52 weeks per year. The concentrator operating availability will be on the order of 93%. The concentrator plant capacity has been planned to handle approximately 577,000 short tons of material to produce 16,500 tonnes per annum of final concentrated product, with minimum 95% Cg and a 90% graphite recovery rate. The flotation concentrate will be transported to a purification plant for secondary processing and cleaning to produce the ultra-pure final products.

Purification and Post-Processing Activities

The purification of the graphite concentrate is expected to be performed using industry standard processes presently being tested by Dorfner Anaplan, and are expected to be the subject of the pilot plant study in 2020 to verify application to our graphite and that of the purchased feedstock we intend to use until the mine starts production, expected in the next eight to ten years. The operation of the pilot process will further inform the design of the full-scale purification process to be built in 2021. Once the graphite is purified to a minimum graphite carbon content of 99.95%, we will then process it through a combination of sizing, expansion and spheronization to the advanced graphite products we intend to sell.

Products and Business Development

The Company is working to develop products for all potential major battery markets. Unlike many of its peers, the Company believes that all of the battery markets should not be ignored, as is often the case with most publicity currently focused on Li-ion batteries. Lead-acid, alkaline and primary-lithium battery manufacturers have significantly shorter and less onerous qualification requirements compared to large-scale Li-ion battery applications.

The advanced graphite products which the Company intends to develop and sell are:

Purified Micronized Graphite. Conductivity enhancement materials for both the rechargeable and single use Li-ion, Primary-Lithium, Lead-Acid, and Alkaline battery markets;

Delaminated Expanded Graphite. Conductivity enhancement materials for both the rechargeable and single use Li-ion, Primary-Lithium, Lead-Acid, and Alkaline battery markets;

Coated Spherical Purified Graphite. For Li-ion battery anodes. 95% of a Li-ion battery’s anode is coated spherical purified graphite and there is 10‑30 times more specialty anode graphite required for the production of these batteries than there is Lithium in a Li-ion battery.

15

The Company has initiated discussions with several battery manufacturers (including automobile manufacturers) for the purposes of evaluating the Company’s battery-graphite products, with the goal of executing multi-year supply agreements. To date, the Company has executed more than two-dozen Non-Disclosure Agreements with potential customers and has conveyed evaluation samples to several battery manufacturers and potential end users.

Lithium Projects

We commenced our program to acquire and explore lithium-enriched brine targets in the western United States in 2016. As a consequence of our in-house geological reconnaissance program we identified three prospective project areas for which we have acquired mineral rights: the Columbus Basin project in western Nevada, the Railroad Valley project in east-central Nevada and the Sal Rica Project in northwestern Utah. The Company has since allowed the Railroad Valley project claims to lapse to facilitate focus on the remaining projects.

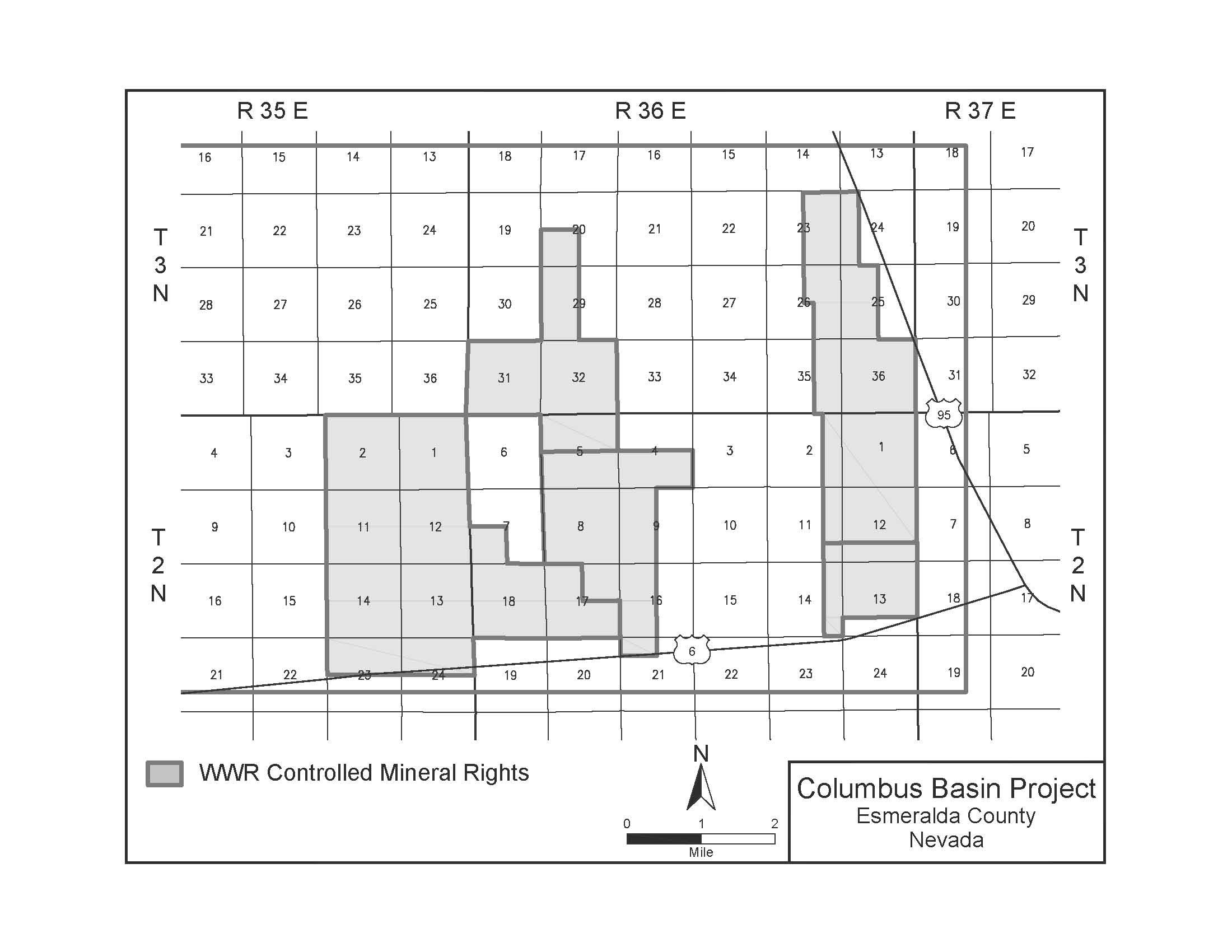

Columbus Basin Project

Our Columbus Basin project is located in western Nevada and is comprised of two blocks of unpatented placer claims that we staked in July and September of 2016. These claims, which are owned by the Company, cover portions of a closed drainage basin that has geological characteristics that may be permissive for hosting lithium-enriched brines. Our exploration efforts on the project thus far have included reconnaissance-scale and detailed geochemical sampling, and the completion of three exploration drill holes. The Columbus Basin project encompasses approximately 14,200 acres, split into two significant blocks of placer mineral claims, and a third contiguous block for which rights were acquired through purchase from a third-party in 2018.

Water rights for the Columbus Basin project are owned by Westwater.

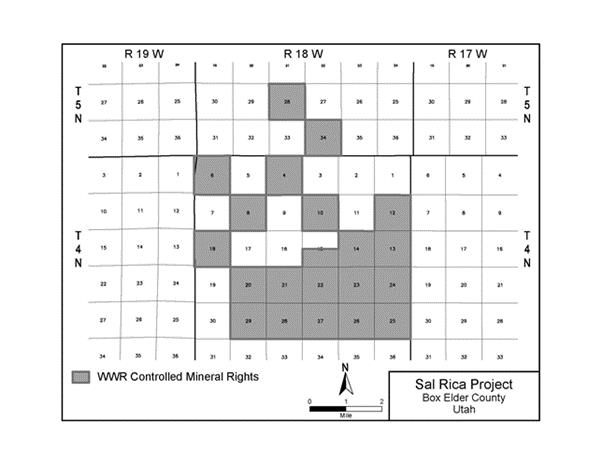

Sal Rica Project

Our Sal Rica project is situated in the area of a closed drainage basin that was once part of the Great Salt Lake/Lake Bonneville area of western Utah. We hold a large group of unpatented placer claims that we acquired in part from Mesa Exploration Corporation (“Mesa Exploration”) and adjoining placer claims that we staked in 2016. The project area was explored previously by Quintana Petroleum for potash-enriched brines, and as part of their shallow drilling program they identified anomalous levels of lithium-enriched brines at depths of less than 50 feet from the surface. Our activities at the Sal Rica project thus far have been limited to geologic reconnaissance and geochemical characterization sampling. The Sal Rica project encompasses approximately 13,260 acres of federal placer mineral claims.

Water rights for the Sal Rica project are owned by Westwater.

Uranium Projects

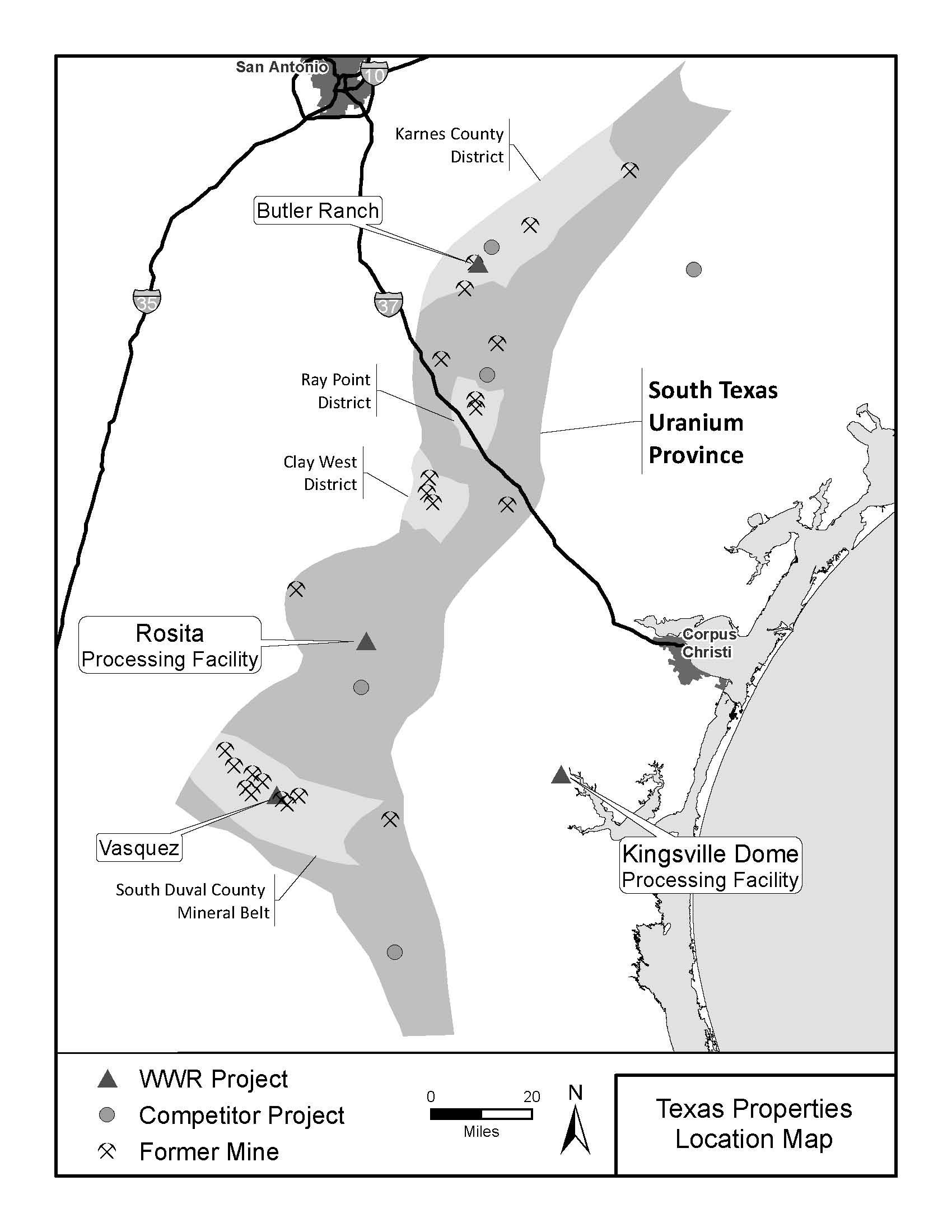

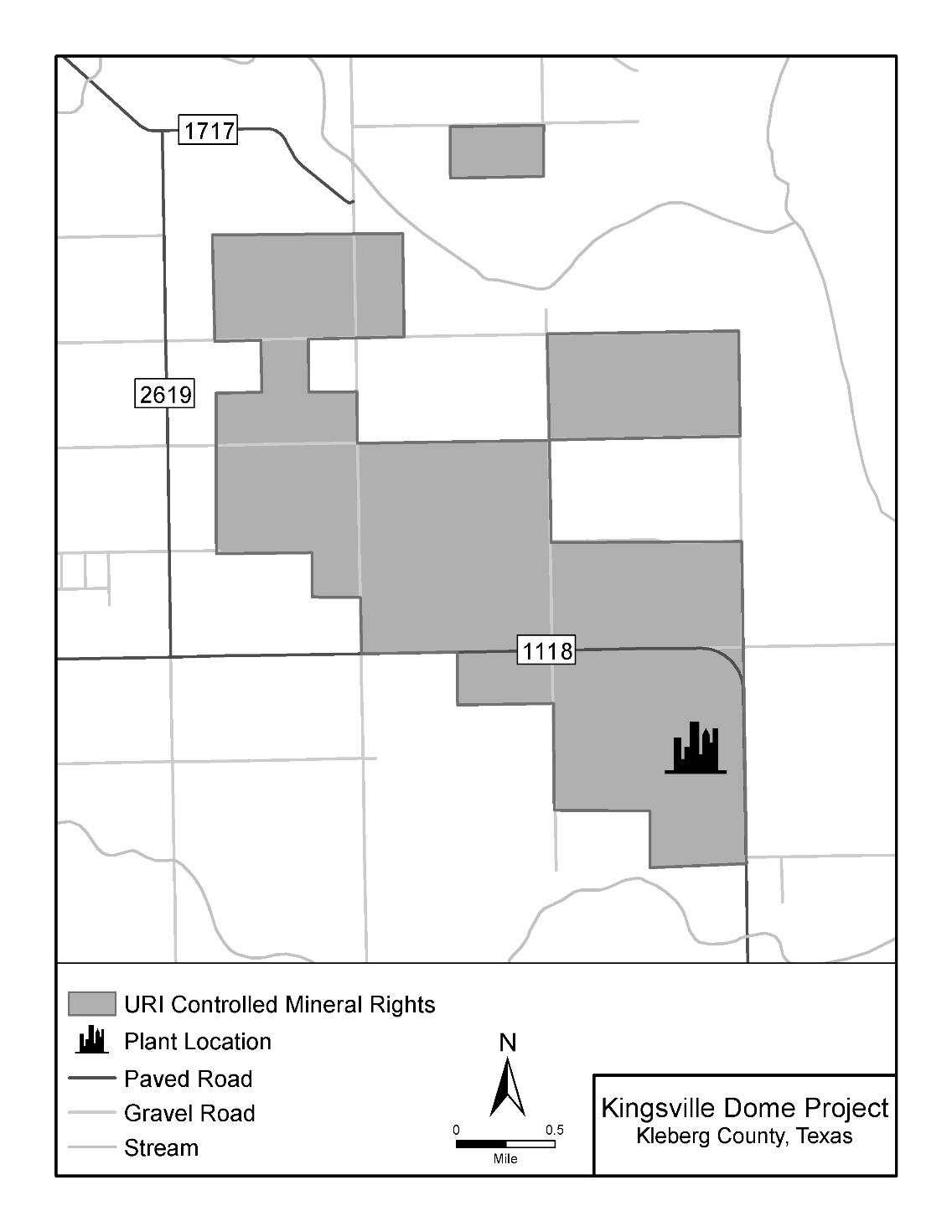

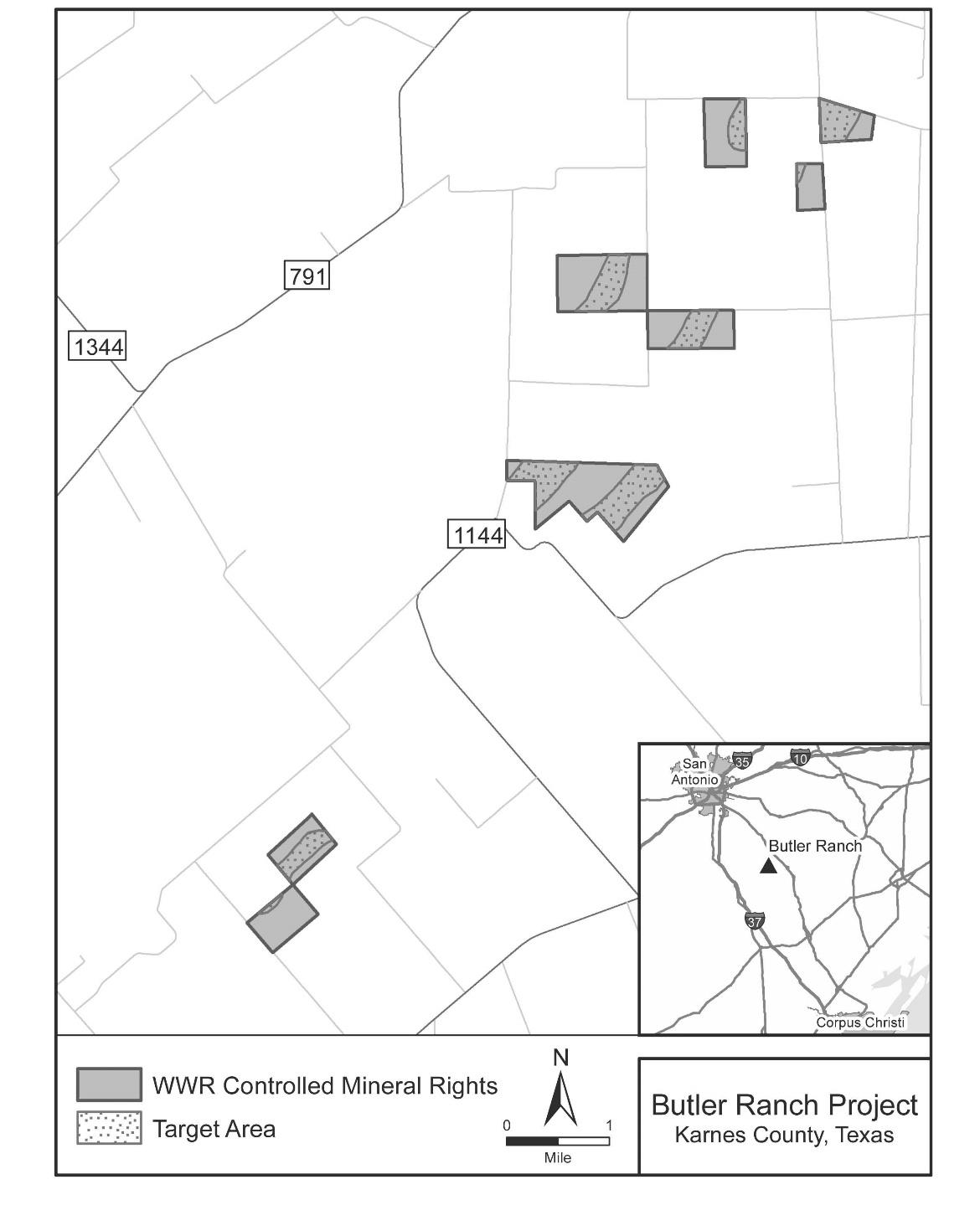

Texas

In Texas, WWR has the Kingsville Dome and Rosita licensed processing facilities and approximately 11,000 acres of prospective ISR projects and historical production assets. These wellfields and the processing facilities are on standby for a restart of production when there is a sustained improvement in the uranium market. Key operational elements of WWR’s plan for its Texas properties include (1) positioning the Company to return to sustainable production by continuing to evaluate potential brownfield and greenfield exploration opportunities and evaluating synergistic opportunities from existing resources held by other entities; and (2) continuing reclamation activities in South Texas in accordance with the Company’s existing agreements and regulatory requirements.

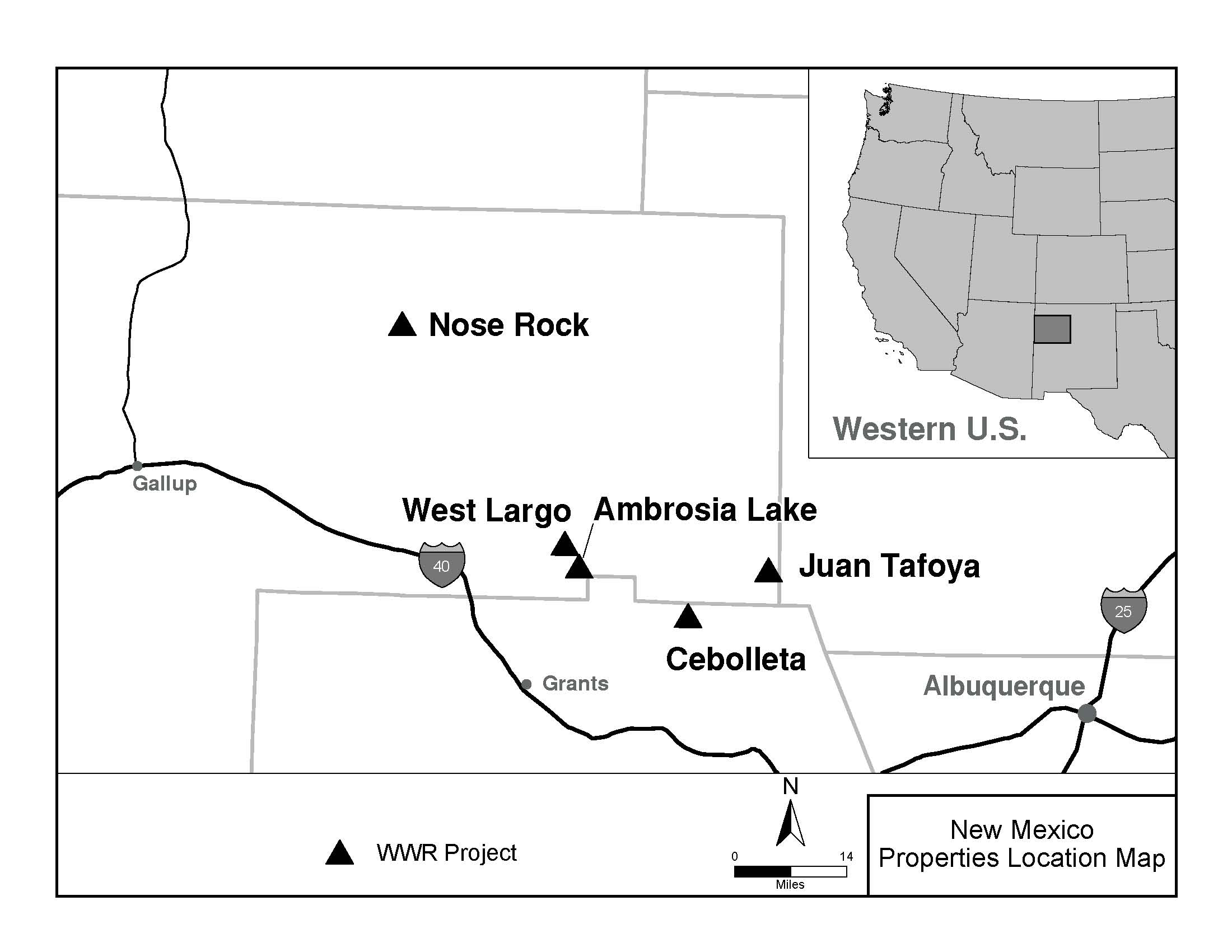

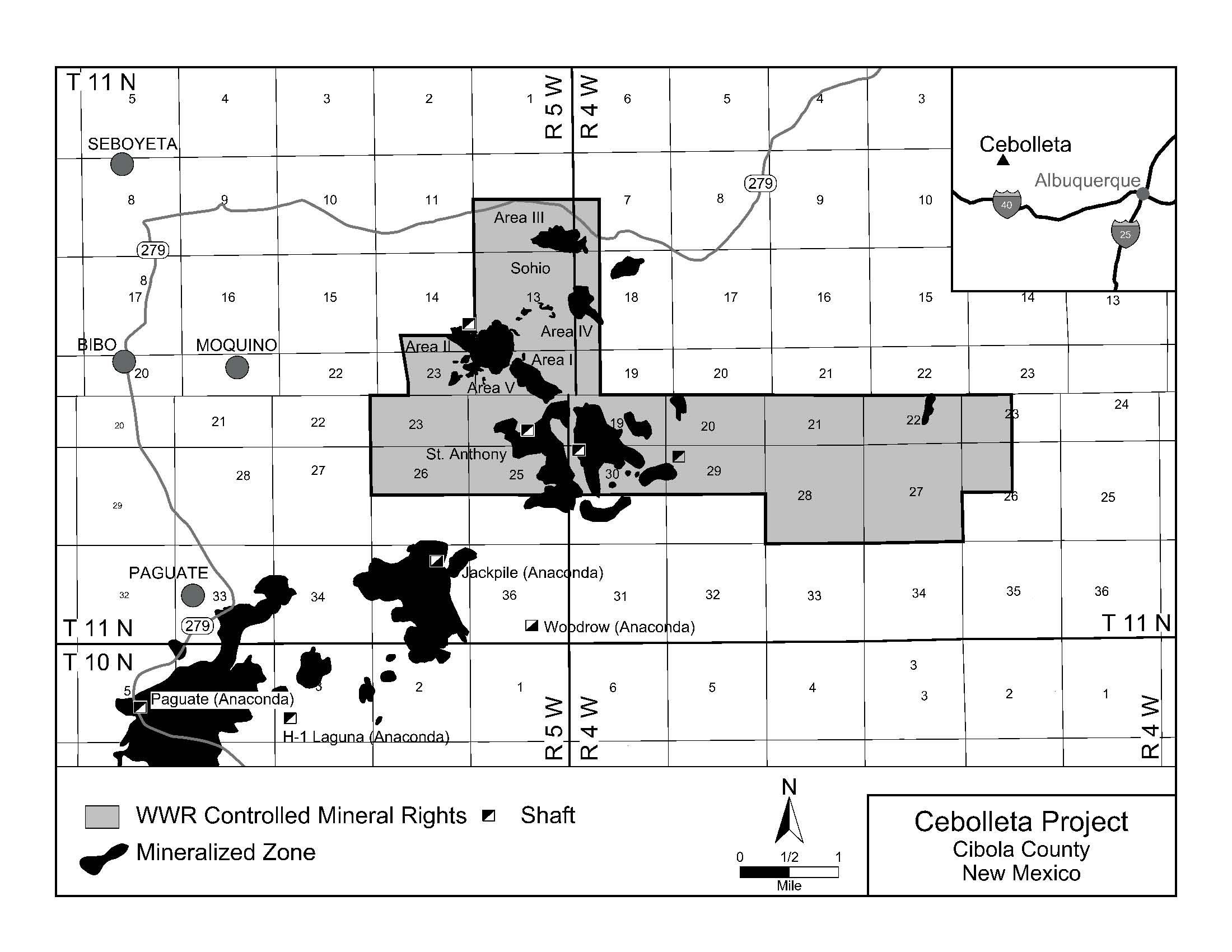

New Mexico

In New Mexico, the Company controls minerals rights encompassing approximately 188,700 acres in the west-central part of the State. WWR holds substantial non-reserve mineralized material at several of its properties in the prolific Grants Mineral Belt, which is one of the largest known concentrations of sandstone-hosted uranium deposits in the world.

16

The ISR (in-situ recovery) process is dramatically different from conventional mining techniques. The ISR technique avoids the extraction (mining) and milling of significant quantities of rock and ore and also eliminates the creation of mill tailing waste associated with more traditional mining methods. It is generally more cost‑effective and environmentally sensitive than conventional mining and processing. Historically, the majority of U.S. uranium production resulted from either open pit surface mines or underground mining.

The ISR process was initially developed for the production of uranium in the mid‑1960s, and was first utilized at a commercial‑scale project in South Texas in 1975. It became a routinely utilized recovery method in the South Texas uranium district by the late 1970s, where it was employed in about twenty commercial projects, including two operated by us.

In the ISR process, groundwater fortified with oxygen and carbon dioxide is pumped into a permeable uranium mineralized zone within a wellfield, causing the uranium contained in the deposit to dissolve. A wellfield consists of a series of injection wells, production (extraction) wells and monitoring wells drilled in specified patterns. The design of a wellfield pattern is crucial to minimizing costs and maximizing efficiencies of production. The resulting solutions from the wellfields are pumped to the surface, where the uranium‑bearing water is circulated through an ion exchange column, and uranium is precipitated from the fluid onto resin beads. The uranium‑depleted fluid is then re‑injected into the subsurface uranium deposit. When the ion exchange column’s resin beads are loaded with uranium, they are removed and flushed with a salt‑water solution, which liberates the uranium from the beads. This process results in uranium residing in a slurry, which is then dried and packaged for shipment as a uranium concentrate. In order to achieve greater operating efficiencies and reducing capital expenditures when developing new wellfields, we employ a wellfield‑ specific remote ion exchange process as opposed to a central processing plant, as we had done historically. Instead of piping the solutions over long distances through large diameter pipelines, and mixing the waters of several wellfields together, each wellfield is produced using a dedicated satellite ion exchange facility. This allows ion exchange to take place at the wellfield instead of at the central plant. The satellite facilities allow recovery of uranium from each wellfield using its own native groundwater, thus avoiding the introduction of foreign mineral complexes and the attendant complications of doing so.

ENVIRONMENTAL CONSIDERATIONS AND PERMITTING

United States

Graphite, lithium and uranium extraction is regulated by the federal government, states and, in some cases, by Indian tribes (only on lands for which they have control). Compliance with such regulation has a material effect on the economics of our operations and the timing of project development. Our primary regulatory costs have been related to obtaining licenses and operating permits from federal and state agencies before the commencement of production activities, as well as the cost for maintaining compliance with licenses and permits once they have been issued. The current environmental and technical regulatory requirements for the ISR industry are well established. Many ISR projects have gone a full life cycle without any significant environmental impact. However, the regulatory process can make permitting difficult and timing unpredictable.

U.S. regulations pertaining to ISR mining continually evolve in the U.S. However, at this time we do not anticipate any adverse impact from these regulations that would be unique to our operations.

Radioactive Material License

Before commencing ISR uranium operations in Texas and either ISR or conventional uranium mining activity in New Mexico, we must obtain a radioactive material license. Under the federal Atomic Energy Act, the NRC has primary jurisdiction over the issuance of a radioactive material license. However, the Atomic Energy Act also allows for states with regulatory programs deemed satisfactory by NRC to take primary responsibility for issuing the radioactive material license. NRC has ceded jurisdiction for such licenses to Texas, but not to New Mexico. Such ceding of jurisdiction by NRC is hereinafter referred to as the “granting of primacy.”

17

The Texas Commission of Environmental Quality (“TCEQ”) is the administrative agency with jurisdiction in Texas over the radioactive material license. For operations in New Mexico, radioactive material licensing is handled directly by the Nuclear Regulatory Commission (“NRC”).

See Item 2, “Properties” for the status of our radioactive material license for Texas.

Uranium Underground Injection Control (“UIC”) Permits

The federal Safe Drinking Water Act creates a nationwide regulatory program protecting groundwater. This law is administered by the United States Environmental Protection Agency (the “EPA”). However, to avoid the burden of dual federal and state regulation, the Safe Drinking Water Act allows for the UIC permits issued by states to satisfy the UIC permit required under the Safe Drinking Water Act under two conditions. First, the state’s program must have been granted primacy. Second, the EPA must have granted, upon request by the state, an aquifer exemption. The EPA may delay or decline to process the state’s application if the EPA questions the state’s jurisdiction over the ISR site.

Texas has been granted primacy for its UIC programs, and the TCEQ administers UIC permits. The TCEQ also regulates air quality and surface deposition or discharge of treated wastewater associated with the ISR process.

New Mexico has also been granted primacy for its UIC program. Properties located in “Indian Country,” as that term is defined in federal law, remain subject to the jurisdiction of the EPA. Some of our properties are located in areas that some alleged to be in Indian Country. The Navajo Nation has been determined eligible for treatment as a state, but it has not requested the grant of primacy from the EPA for uranium related UIC activity. Until the Navajo Nation has been granted primacy, ISR activities that may fall within Indian Country will require a UIC permit from the EPA. Despite some procedural differences, the substantive technical requirements of the Texas, New Mexico and EPA underground injection control programs are very similar.

See Item 2, “Properties” and Item 3, “Legal Proceedings” for a description of the status of our UIC permits in Texas and New Mexico.

Mining Permits

All uranium producing states have regulations governing the development licensing or permitting, operation and closure of conventional and ISR mines. In New Mexico, the Mining and Minerals Division of the Energy, Minerals and Natural Resources Department is responsible for issuing permits under the authority of the New Mexico Mining Act of 1978. Well established regulations specify what information is necessary to support mine permit applications and set forth a well‑defined application review process. The primary focus of the agency’s review is to ensure that the proposed mine will protect the environment surrounding the mine area, comply with relevant environmental standards, and be reclaimed to a self‑sustaining ecosystem or other approved post‑mine land use. Application reviews require consultation with other state agencies, public notice and public hearing opportunities. In addition to mine permits, a discharge permit must be obtained from the New Mexico Environmental Department for mine facilities such as ore pads, waste rock piles and tailings impoundments.

In Texas, the TCEQ regulates uranium mining and issues the necessary license and permits. Our subsidiary URI, Inc. holds a radioactive material license which covers the Kingsville Dome, Rosita and Vasquez sites, and that license is in timely renewal. Each site has operated under a class III injection permit also issued by the TCEQ. Rosita and Vasquez permits were renewed in 2014. The Kingsville mining permit application was withdrawn, without prejudice to refiling, in June 2016. Within each area’s permit, the TCEQ also issues production area authorizations (“PAAs”). Kingsville holds three PAAs, Rosita holds four PAAs, and Vasquez holds two PAAs. Each site also has class I non-hazardous injection permits for operation of waste disposal wells on site, which are regulated by the TCEQ as well. The permits for the disposal wells at Kingsville Dome and Vasquez are active. The permit for the disposal well at Rosita is currently in the renewal process and is being reviewed by the TCEQ. The disposal well permit for Kingsville was renewed and approved on January 28, 2019. In addition to the required state permits, the EPA regulates the underground aquifers and requires areas with uranium mineralization to have that portion of the aquifer exempted before state mining permits are issued. The aquifer exemptions for all three Texas sites have been issued.

18

Graphite Mining

Graphite Mining in Alabama requires a mine permit in accordance with the Alabama Surface Mining Act of 1969. It is administrated by the Alabama Department of Labor (“DoL”). DoL issues mining permits, ensures that mine sites are properly bonded for reclamation purposes, and makes periodic inspections. A streamlined permit application process reduces the start-up time for new operations, and expedites permit renewals. Mining permit is filed by completing the “Application for Surface Mining Permit and Comprehensive Reclamation Plan” along with the $250 permit fee. The applicant must also post a cash, surety or negotiable bond in the amount of $2,500 per acre area to be disturbed payable to “Commissioner, Alabama Department of Labor”. The Coosa graphite mine may be subject to the US NEPA process, with potential review by various federal agencies that may include USEPA, the Army Corp of Engineers, and others.

Lithium-enriched brines

Lithium-enriched brines on public lands, which are managed by either the U.S. Bureau of Land Management (“BLM”) or the U.S. Forest Service, in Nevada and Utah can be acquired by staking placer mining claims. Production of lithium-enriched brines in Nevada is regulated in part by the Nevada Division of Water Resources as brine is considered to be a water resource and the Nevada Bureau of Mining Regulation and Reclamation, as well as by the relevant federal land management agency in a manner similar to the requirements for a hard-rock mine.

Other

In order for a licensee to receive final release from further radioactive material license obligations after all of its ISR and post‑production reclamation have been completed, approval must be issued by the TCEQ for Texas properties along with concurrence from NRC and for properties in New Mexico by the NRC.

In addition to the costs and responsibilities associated with obtaining and maintaining permits and the regulation of production activities, we are subject to environmental laws, including but not limited to the Comprehensive Environmental Response, Compensation and Liability Act, commonly known as Superfund or CERCLA, and regulations applicable to the ownership and operation of real property in general, including, but not limited to, the potential responsibility for the activities of prior owners and operators.

Uranium Reclamation and Restoration Costs and Bonding Requirements

At the conclusion of ISR or conventional mining, a site is decommissioned and reclaimed, and each well field is restored. Restoration involves returning the aquifer to its pre‑development use. Restoration can be accomplished by flushing the ore zone with native ground water and/or using reverse osmosis to remove ions, minerals and salts to provide clean water for reinjection to flush the ore zone. Reclamation involves repairing surface disturbances caused by mining and mineral processing. Decommissioning and reclamation entails dismantling and removing the structures, equipment and materials used at the site during the ISR and restoration activities.

The Company is required by the regulatory agencies in the State of Texas to obtain financial surety relating to certain of its future restoration and reclamation obligations. The Company has provided performance bonds issued for the benefit of the Company in the amount of $9.1 million to satisfy such regulatory requirements. The performance bonds relate primarily to our operations at our Kingsville Dome, Rosita and Vasquez projects.

In February 2013, the Company secured a new source to satisfy its financial surety obligations for the Texas regulatory agencies. Previously, the Company had met its financial surety obligations through a combination of bank issued letters of credit (the “LOCs”) and bonds issued for the benefit of the Company. These financial surety arrangements required the Company to fully collateralize the face amount of the LOC’s and the bonds with short term investment vehicles. This requirement resulted in the Company posting $9.1 million in cash that was restricted for the purpose of collateralizing these obligations. The Company’s financial surety arrangements are currently provided by Lexon Insurance Company (“Lexon”) in the form of bonds issued for the benefit of the Company. The amount of the bonds written by Lexon total $9.2 million at December 31, 2019 and the collateral requirements of these bonds require the Company to maintain approximately 40% of the value of the bonds in the form of restricted cash.

19

We estimate that our restoration and reclamation liabilities for prior operations at the Kingsville Dome, Vasquez and Rosita sites as of December 31, 2019, are about $7.9 million, with a carrying value of $6.2 million recorded as a liability on our balance sheet as of December 31, 2019.The Company’s financial surety obligations are reviewed and revised periodically by the Texas regulatory agencies. In New Mexico surety bonding will be required before commencement of uranium recovery operations and will be subject to annual review and revision by NRC and the State of New Mexico or the EPA.

Water Rights

Water is essential to the ISR process. It is readily available in South Texas, where water is subject to capture and we do not have to acquire water rights through a state administrative process. In New Mexico, water rights are administered through the office of the New Mexico State Engineer (the “State Engineer”) and can be subject to Indian tribal jurisdictional claims in some instances. Also, in New Mexico, new water rights or changes in purpose or place of use or points of diversion of existing water rights, such as those in the San Juan and Gallup Basins where our properties are located, must be obtained by permit from the State Engineer. Applications may be approved subject to conditions that govern exercise of the water rights.

Water rights are also an essential component for the production of lithium from brine sources. In the case of Nevada, application for water rights must be submitted to the Division of Water Resources, a state agency that holds responsibility for administration of surface and ground water in the State. The state has a well-established process for application to acquire water rights and protection of existing water rights. As is the case in most of the western states, Nevada’s water rights administration includes the evaluation of applications for new water rights, the availability of groundwater within a specific locality, point(s) of diversion and use of granted water rights for beneficial use. The State of Utah has a similar water right application and administration processes, managed under the Utah Division of Water Rights.

In Alabama, any surface or groundwater withdrawals are managed through the Alabama Water Use Reporting Program. The Alabama Water Resources Act and associated regulations establish the requirements for water withdrawals. The process begins with the submittal of an application form called a “Declaration of Beneficial Use” and other required information to the Office of Water Resources (“OWR”) within the Alabama Department of Economic and Community Affairs. Once application information is reviewed and determined to be complete, OWR will issue what is called a Certificate of Use (“COU”) that lists the applicant’s name and information concerning all registered surface and/or groundwater withdrawal points and their withdrawal information. Entities with a capacity to withdraw more than 100,000 gallons per day are required to register with OWR and obtain a COU. The COU certify that proposed water use will not interfere with an existing water use and is beneficial.

Our internet website address is www.westwaterresources.net. Our Annual Report on Form 10‑K, quarterly reports on Form 10‑Q, current reports on Form 8‑K, and amendments to those reports filed or furnished pursuant to section 13(a) of 15(d) of the Exchange Act, are available free of charge through our website under the tab “Investor Relations” as soon as reasonably practicable after they are electronically filed with, or furnished to, the SEC. We also make available on our website copies of materials regarding our corporate governance policies and practices, including our Code of Ethics, Nominating and Governance Committee Charter, Audit Committee Charter and Compensation Committee Charter. You may read and copy any materials we file with the Securities and Exchange Commission (“SEC”) at the SEC’s website at http://www.sec.gov. You may also obtain a printed copy of the foregoing materials by sending a written request to: Westwater Resources, Inc., 6950 S. Potomac Street, Suite 300, Centennial, Colorado 80112, Attention: Information Request, or by calling 303.531.0516. The information found on our internet website is not part of this or any report filed or furnished to the SEC.

Our business activities are subject to significant risks, including those described below. Every investor or potential investor in our securities should carefully consider these risks. If any of the described risks actually occurs, our business,

20

financial position and results of operations could be materially adversely affected. Such risks are not the only ones we face and additional risks and uncertainties not presently known to us or that we currently deem immaterial may also affect our business.

Risks Related to Our Business

There is substantial doubt about our ability to continue as a going concern.