Attached files

| file | filename |

|---|---|

| EX-32.2 - EXHIBIT 32.2 - STONERIDGE INC | v457712_ex32-2.htm |

| EX-32.1 - EXHIBIT 32.1 - STONERIDGE INC | v457712_ex32-1.htm |

| EX-31.2 - EXHIBIT 31.2 - STONERIDGE INC | v457712_ex31-2.htm |

| EX-31.1 - EXHIBIT 31.1 - STONERIDGE INC | v457712_ex31-1.htm |

| EX-23.1 - EXHIBIT 23.1 - STONERIDGE INC | v457712_ex23-1.htm |

| EX-21.1 - EXHIBIT 21.1 - STONERIDGE INC | v457712_ex21-1.htm |

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10-K

ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934

For the fiscal year ended December 31, 2016

Commission file number: 001-13337

STONERIDGE, INC.

(Exact name of registrant as specified in its charter)

| Ohio | 34-1598949 | ||||

| (State or other jurisdiction of | (I.R.S. Employer | ||||

| incorporation or organization) | Identification No.) |

| 39675 MacKenzie Drive Suite 400, Novi, Michigan | 48377 | ||||

| (Address of principal executive offices) | (Zip Code) |

| (248) 489-9300 |

| Registrant’s telephone number, including area code |

Securities registered pursuant to Section 12(b) of the Act:

| Title of each class | Name of each exchange on which registered | |

| Common Shares, without par value | New York Stock Exchange |

Securities registered pursuant to section 12(g) of the Act: None

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act.

¨ Yes x No

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act.

¨ Yes x No

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days.

x Yes ¨ No

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Website, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§ 232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files).

x Yes ¨ No

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K (§ 229.405 of this chapter) is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K.

¨

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company. See definition of “large accelerated filer,” “accelerated filer,” and “smaller reporting company” in Rule 12b-2 of the Exchange Act. (Check one):

| Large accelerated filer ¨ | Accelerated filer x | Non-accelerated filer ¨ | Smaller reporting company ¨ |

| (Do not check if a smaller reporting company) | |||

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Act).

¨ Yes x No

As of June 30, 2016, the aggregate market value of the registrant’s Common Shares held by non-affiliates of the registrant was approximately $395.7 million. The closing price of the Common Shares on June 30, 2016 as reported on the New York Stock Exchange was $14.94 per share. As of June 30, 2016, the number of Common Shares outstanding was 27,842,883.

The number of Common Shares outstanding as of February 24, 2017 was 27,870,944.

DOCUMENTS INCORPORATED BY REFERENCE

Definitive Proxy Statement for the Annual Meeting of Shareholders to be held on May 9, 2017, into Part III, Items 10, 11, 12, 13 and 14.

INDEX

i

Forward-Looking Statements

Portions of this report on Form 10-K contain “forward-looking statements” under the Private Securities Litigation Reform Act of 1995. These statements appear in a number of places in this report and may include statements regarding the intent, belief or current expectations of the Company, with respect to, among other things, our (i) future product and facility expansion, (ii) acquisition strategy, (iii) investments and new product development, (iv) growth opportunities related to awarded business and (v) operational expectations. Forward-looking statements may be identified by the words “will,” “may,” “should,” “designed to,” “believes,” “plans,” “projects,” “intends,” “expects,” “estimates,” “anticipates,” “continue,” and similar words and expressions. The forward-looking statements are subject to risks and uncertainties that could cause actual events or results to differ materially from those expressed in or implied by the statements. Important factors that could cause actual results to differ materially from those in the forward-looking statements include, among other factors:

| · | the reduced purchases, loss or bankruptcy of a major customer; |

| · | the costs and timing of facility closures, business realignment, or similar actions; |

| · | a significant change in automotive, commercial, motorcycle, off-highway or agricultural vehicle production; |

| · | competitive market conditions and resulting effects on sales and pricing; |

| · | the impact on changes in foreign currency exchange rates on sales, costs and results, particularly the Brazilian real, euro, Argentinian peso, Mexican peso and Swedish krona; |

| · | our ability to achieve cost reductions that offset or exceed customer-mandated selling price reductions; |

| · | a significant change in general economic conditions in any of the various countries in which we operate; |

| · | labor disruptions at our facilities or at any of our significant customers or suppliers; |

| · | the ability of our suppliers to supply us with parts and components at competitive prices on a timely basis; |

| · | the amount of our indebtedness and the restrictive covenants contained in the agreements governing our indebtedness, including our revolving credit facility; |

| · | customer acceptance of new products; |

| · | capital availability or costs, including changes in interest rates or market perceptions; |

| · | the failure to achieve the successful integration of any acquired company or business; and |

| · | the items described in Part I, Item IA (“Risk Factors”). |

In addition, the forward-looking statements contained herein represent our estimates only as of the date of this filing and should not be relied upon as representing our estimates as of any subsequent date. While we may elect to update these forward-looking statements at some point in the future, we specifically disclaim any obligation to do so, whether to reflect actual results, changes in assumptions, changes in other factors affecting such forward-looking statements or otherwise.

ii

Overview

Founded in 1965, Stoneridge, Inc. (the “Company”) is a global designer and manufacturer of highly engineered electrical and electronic components, modules and systems for the automotive, commercial, motorcycle, off-highway and agricultural vehicle markets. Our products and systems are critical elements in the management of mechanical and electrical systems to improve overall vehicle performance, convenience and monitoring in areas such as emissions control, fuel efficiency, safety, security and infotainment. Our extensive footprint encompasses 25 locations in 12 countries and enables us to supply global and regional automotive, commercial, motorcycle, off-highway and agricultural vehicle markets.

Our custom-engineered products and systems are used to activate equipment and accessories, monitor and display vehicle performance and control, distribute electrical power and signals and provide vehicle security and convenience. Our product offerings consist of (i) sensors, (ii) application-specific actuators, switches and valves (iii) vehicle and driver information systems, (iv) vehicle management electronics, (v) power and switch distribution modules and telematics, (vi) security alarms and vehicle tracking devices and monitoring services and (vii) convenience accessories. We supply the majority of our products, predominantly on a sole-source basis, to many of the world’s leading commercial vehicle and automotive original equipment manufacturers (“OEMs”), agricultural manufacturers and select non-vehicle OEMs, as well as certain commercial vehicle and automotive tier one suppliers. Our customers are increasingly utilizing electronic technology to comply with more stringent regulations (particularly emissions and safety) and to meet end-user demand for improved vehicle performance and greater convenience. As a result, per-vehicle electronic content has been increasing. Our technology and our partnership-oriented approach to product design and development enables us to develop next-generation products.

Segments and Products

We conduct our business in three reportable business segments which are the same as our operating segments: Control Devices, Electronics and PST.

Control Devices. Our Control Devices segment designs and manufactures products that monitor, measure or activate specific functions within a vehicle. This segment includes product lines such as sensors, switches, valves and actuators. Sensor products are employed in major vehicle systems such as the emissions, safety, powertrain, braking, climate control, steering and suspension systems. Switches transmit signals that activate specific functions. Our switch technology is principally used in two capacities, user-activated and hidden. User-activated switches are used by a vehicle’s operator or passengers to manually activate, rear defrosters and other accessories. Hidden switches are not typically visible to vehicle operators or passengers and are engaged to activate or deactivate selected functions as part of normal vehicle operations, such as brake lights. In addition, our Control Devices segment designs and manufactures actuator products that enable OEMs to deploy power functions in a vehicle and can be designed to integrate switching and control functions including our shift by wire product. We sell these products principally to the automotive market. To a lesser exent, we sell these products to the commercial vehicle and agricultural markets.

Electronics. Our Electronics segment designs and manufactures electronic instrument clusters, electronic control units and driver information systems. These products collect, store and display vehicle information such as speed, pressure, maintenance data, trip information, operator performance, temperature, distance traveled and driver messages related to vehicle performance. In addition, power distribution modules and systems regulate, coordinate, monitor and direct the operation of the electrical system within a vehicle. These products use state-of-the-art hardware, software and multiplexing technology and are sold principally to the commercial vehicle market or through both the OEM and aftermarket channels.

PST. Our PST segment, in which we have a 74% controlling interest, primarily serves the South American market and specializes in the design, manufacture and sale of in-vehicle audio and video devices, electronic vehicle security alarms, convenience accessories, vehicle tracking devices and monitoring services primarily for the automotive and motorcycle markets. This segment includes product lines such as alarms, convenience applications, vehicle monitoring and tracking devices and infotainment systems. These products improve the performance, safety and convenience features of our customers’ vehicles. PST sells its products through the aftermarket distribution channel, to factory authorized dealer installers, also referred to as original equipment services, direct to OEMs and through mass merchandisers.

| 1 |

| Segment | Product Category | 2016 | 2015 | 2014 | ||||||||||

| Control Devices | Sensors, switches, valves and actuators | 59 | % | 52 | % | 47 | % | |||||||

| Electronics | Electronic instrument clusters, electronic control units and driver information systems | 29 | 33 | 32 | ||||||||||

| PST | Security alarms, vehicle tracking devices and monitoring services and convenience accessories | 12 | 15 | 21 | ||||||||||

Our products and systems are sold to numerous OEM and tier one supplier customers, as well as aftermarket distributors and mass merchandisers, for use on many different vehicle platforms. We supply multiple parts to many of our principal OEM and tier one customers under requirements contracts for a particular vehicle model. These contracts range in duration from one year to the production life of the model, which commonly extends for three to seven years.

The following table sets forth for the periods indicated, the percentage of net sales derived from our principal end markets for the years ended December 31:

| Principal End Markets | 2016 | 2015 | 2014 | |||||||||

| Automotive | 50 | % | 42 | % | 37 | % | ||||||

| Commercial vehicle | 33 | 37 | 36 | |||||||||

| Aftermarket distributors and mass merchandisers | 12 | 15 | 21 | |||||||||

| Agricultural and other | 5 | 6 | 6 | |||||||||

For further information related to our reportable segments and financial information about geographic areas, see Note 13 to the consolidated financial statements.

Sale of Wiring Business

We sold the assets and liabilities of our Wiring business on August 1, 2014. As a result, the Wiring business has been classified as discontinued operations for all periods presented in the Company’s financial statements, and therefore has been excluded from continuing operations, segment results and other information herein for all periods presented. The Wiring business designed and manufactured wiring harness products and assembled instruments panels for sale principally to the commercial, agricultural and off-highway vehicle markets.

Production Materials

The principal production materials used in the Company’s manufacturing process are molded plastic components and resins, copper, precious metals and certain electrical components such as printed circuit boards, semiconductors, microprocessors, memory devices, resistors, capacitors, fuses, relays and infotainment devices. We purchase production materials pursuant to both annual contract and spot purchasing methods. Such materials are available from multiple sources, but we generally establish collaborative relationships with a qualified supplier for each of our key production materials in order to lower costs and enhance service and quality. As global demand for our production materials increases, we may have difficulties obtaining adequate production materials from our suppliers to satisfy our customers. Any extended period of time for which we cannot obtain adequate production material or which we experience an increase in the price of production material would materially affect our results of operations and financial condition.

| 2 |

Patents, Trademarks and Intellectual Property

We maintain and have pending various U.S. and foreign patents, trademarks and other rights to intellectual property relating to the reportable segments of our business, which we believe are appropriate to protect the Company's interests in existing products, new inventions, manufacturing processes and product developments. We do not believe any single patent is material to our business, nor would the expiration or invalidity of any patent have a material adverse effect on our business or ability to compete.

Industry Cyclicality and Seasonality

The markets for products in each of our reportable segments have been cyclical. Because these products are used principally in the production of vehicles for the automotive, commercial, motorcycle, off-highway and agricultural vehicle markets, revenues and therefore results of operations, are significantly dependent on the general state of the economy and other factors, like the impact of environmental regulations on our customers, which affect these markets. A significant decline in automotive, commercial, motorcycle, off-highway and agricultural vehicle production of our principal customers could adversely impact the Company. Our Electronics and Control Devices segments are typically not affected by seasonality, however the demand for our PST segment consumer products is typically higher in the second half of the year, the fourth quarter in particular.

Customers

We have several customers which account for a significant percentage of our sales. The loss of any significant portion of our sales to these customers, or the loss of a significant customer, would have a material adverse impact on our financial condition and results of operations. We supply numerous different products to each of our principal customers. Contracts with several of our customers provide for supplying their requirements for a particular model, rather than for manufacturing a specific quantity of products. Such contracts range from one year to the life of the model, which is generally three to seven years. These contracts are subject to potential renegotiation from time to time, which may affect product pricing and generally may be terminated by our customers at any time. Therefore, the loss of a contract for a major model or a significant decrease in demand for certain key models or group of related models sold by any of our major customers would have a material adverse impact on the Company. We may also enter into contracts to supply products, the introduction of which may then be delayed or cancelled. We also compete to supply products for successor models, and are therefore subject to the risk that the customer will not select the Company to produce products on any such model, which could have a material adverse impact on our financial condition and results of operations.

Due to the competitive nature of the markets we serve, we face pricing pressures from our customers in the ordinary course of business. In response to these pricing pressures we have been able to effectively manage our production costs by the combination of lowering certain costs and limiting the increase of others, the net impact of which has not been material. However, if we are unable to effectively manage production costs in the future to mitigate future pricing pressures, our results of operations would be adversely affected.

The following table presents our principal customers, as a percentage of net sales:

| Years ended December 31 | 2016 | 2015 | 2014 | |||||||||

| Ford Motor Company | 17 | % | 14 | % | 11 | % | ||||||

| General Motors Company | 7 | 5 | 5 | |||||||||

| Scania Group | 6 | 7 | 8 | |||||||||

| Daimler | 6 | 6 | 6 | |||||||||

| Volvo | 6 | 6 | 5 | |||||||||

| Other | 58 | 62 | 65 | |||||||||

| 3 |

Backlog

A substantial amount of the new business we are awarded by OEMs is granted well in advance of a program launch. These awards typically extend through the life of the given program. This backlog of new business does not represent firm orders, but instead estimated remaining projected volume under these programs over the following five years. Production scheduling and delivery for these orders could be changed or canceled by the customer on relatively short notice. Backlog was $3.0 billion and $2.7 billion at December 31, 2016 and 2015, respectively.

Competition

The markets for our products in our reportable segments are highly competitive. We compete based on technological innovation, price, quality, performance, service and delivery. We compete for new business both at the beginning of the development of new models and upon the redesign of existing models for OEM customers. New model development generally begins two to five years before the marketing of such models to the public. Once a supplier has been selected to provide parts for a new program, an OEM customer will usually continue to purchase those parts from the selected supplier for the life of the program, although not necessarily for any model redesigns. We compete for aftermarket and mass merchandiser sales based on price, product functionality, quality and service.

Our diversity in products creates a wide range of competitors, which vary depending on both market and geographic location. We compete based on strong customer relations and a fast and flexible organization that develops technically effective solutions at or below target price. We compete against the following companies:

Control Devices. Our primary competitors include Bosch, Continental AG, Delphi Automotive PLC, Denso Corporation, Electricfil, Hella KGaA Hueck & Co., Methode Electronics, Inc., NTK Technologies, Inc., TE Connectivity Ltd. and Sensata.

Electronics. Our primary competitors include Actia Group, Bosch, Continental AG, Delphi Automotive PLC, Dongfeng Electronics Technology Co., Ltd., Hella KGaA Hueck & Co., Magneti Marelli S.p.A. and Yazaki Corporation.

PST. Our primary competitors include Autotrac, Clarion, Continental AG, Delphi Automotive PLC, FKS, Ituran, Kostal and Hinor, Lennox, M. Magneti Marelli S.p.A., Maxtrack, MultiLaser, Olympus, Pioneer Corporation, Quantum, Sascar, Suntech, Taramps and Tury.

Product Development

Our research and development efforts for our reportable segments are largely product design and development oriented and consist primarily of applying known technologies to customer requests. We work closely with our customers to solve customer requests using innovative approaches. The majority of our development expenses are related to customer-sponsored programs where we are involved in designing custom-engineered solutions for specific applications or for next generation technology. To further our vehicle platform penetration, we have also developed collaborative relationships with the design and engineering departments of key customers. These collaborative efforts have resulted in the development of new and complimentary products and the enhancement of existing products.

While our engineering and product development departments are organized by market, our segments interact and collaborate on new products. The product development operations are complimented by technology groups in Canton, Massachusetts; Lexington, Ohio; Stockholm, Sweden; Pune, India; Manaus, Brazil; São Paulo, Brazil; and Shanghai, China.

We use efficient and quality oriented work processes to address our customers’ high standards. Our product development technical resources include a full complement of computer-aided design and engineering (“CAD/CAE”) software systems, including (i) virtual three-dimensional modeling, (ii) functional simulation and analysis capabilities and (iii) data links for rapid prototyping. These systems enable us to expedite product design and the manufacturing process to shorten the development time and ultimately time to market.

| 4 |

We have further strengthened our electrical engineering competencies through investment in equipment such as (i) automotive electro-magnetic compliance test chambers, (ii) programmable automotive and commercial vehicle transient generators, (iii) circuit simulators and (iv) other environmental test equipment. Additional investment in 3-D printing product machining equipment has allowed us to fabricate new product samples in a fraction of the time required historically. Our product development and validation efforts are supported by full service, on-site test labs at most manufacturing facilities, thus enabling cross-functional engineering teams to optimize the product, process and system performance before tooling initiation.

We have invested, and will continue to invest heavily in technology to develop new products for our customers. Product development costs incurred in connection with the development of new products and manufacturing methods, to the extent not recoverable from the customer, are expensed as incurred. Such costs amounted to approximately $40.2 million, $38.8 million and $41.6 million for 2016, 2015 and 2014, respectively, or 5.8%, 6.0% and 6.3% of net sales for these periods.

We will continue to prioritize investment spending toward the design and development of new products over sustaining existing product programs for specific customers, which allows us to sell our products to multiple customers. The typical product development process takes three to five years to show tangible results. As part of our effort to evaluate our investment spending, we review our current product portfolio and adjust our spending to either accelerate or eliminate our investment in these products based on our position in the market and the potential of the market and product.

Environmental and Other Regulations

Our operations are subject to various federal, state, local and foreign laws and regulations governing, among other things, emissions to air, discharge to water and the generation, handling, storage, transportation, treatment and disposal of waste and other materials. We believe that our business, operations and facilities have been and are being operated in compliance, in all material respects, with applicable environmental and health and safety laws and regulations, many of which provide for substantial fines and criminal sanctions for violations.

Employees

As of December 31, 2016, we had approximately 4,200 employees, approximately 69% of whom were located outside the United States. Although we have no collective bargaining agreements covering U.S. employees, a significant number of employees located in Brazil, Estonia, Mexico, Sweden, and the United Kingdom either (i) are represented by a union and are covered by a collective bargaining agreement, or (ii) are covered by works council or other employment arrangements required by law. We believe that relations with our employees are good.

Joint Ventures

We form joint ventures in various global markets in order to achieve several strategic objectives including (i) diversifying our business by expanding in high-growth regions, (ii) employing complementary design processes, growth technologies and intellectual capital, and (iii) realizing cost savings from combined sourcing.

We have a 49% noncontrolling equity interest in Minda Stoneridge Instruments Ltd. (“Minda”) for the years ending December 31, 2016, 2015, and 2014. Based in India, Minda manufactures electromechanical/electronic instrumentation equipment and sensors primarily for the automotive, motorcycle and commercial vehicle markets. We leverage our investment in Minda by sharing our knowledge and expertise in electrical components and systems and expanding Minda’s product offering through the joint development of our products designed for the market in India.

| 5 |

Executive Officers of the Company

Each executive officer of the Company serves the Board of Directors at its pleasure. The Board of Directors appoints corporate officers annually. The following table sets forth the names, ages, and positions of the executive officers of the Company:

| Name | Age | Position | ||

| Jonathan B. DeGaynor | 50 | President, Chief Executive Officer and Director | ||

| Robert R. Krakowiak | 46 | Chief Financial Officer and Treasurer | ||

| George E. Strickler | 69 | Executive Vice President | ||

| Anthony L. Moore | 53 | Vice President of Operations | ||

| Thomas A. Beaver | 63 | Vice President of the Company and President of Global Sales | ||

| Michael D. Sloan | 60 | Vice President of the Company and President of the Control Devices Division | ||

| Peter Kruk | 48 | President of the Electronics Division | ||

| Sergio de Cerqueira Leite | 53 | Director President of PST Eletrônica Ltda. | ||

| Alisa A. Nagle | 49 | Chief Human Resources Officer | ||

| Robert J. Hartman Jr. | 50 | Chief Accounting Officer |

Jonathan B. DeGaynor, President, Chief Executive Officer and Director. Mr. DeGaynor was appointed as President and Chief Executive Officer in March 2015. He has served as a director since May 2015. Prior to joining Stoneridge, Mr. DeGaynor served as the Vice President of Strategic Planning and Innovation of Guardian Industries Corp., (“Guardian”), from October 2014 until March 2015. Mr. DeGaynor served as Vice President of Business Development, Managing Director Asia for SRG Global, Inc., a Guardian company from 2008 through September 2014. Mr. DeGaynor served as Chief Operating Officer, International for Autocam Corporation from 2005 to 2008. Prior to that, Mr. DeGaynor held positions of increasing responsibility with Delphi Corporation from 1993 to 2005.

Robert R. Krakowiak, Chief Financial Officer and Treasurer. Mr.Krakowiak was appointed as Chief Financial Officer and Treasurer in August 2016. Prior to joining Stoneridge, Mr. Krakowiak, served as Vice President, Treasurer and Investor Relations at Visteon Corporation from 2012 until August 2016. Prior to that, Mr. Krakowiak held the following positions at Owens Corning: from 2009 until 2012, Vice President of Finance (Composite Solutions Business); from 2008 until 2009, Vice President–Corporate Financial Planning and Analysis; from 2006 until 2008, Vice President and Controller (Roofing and Asphalt); and from 2005 until 2006, Assistant Treasurer.

George E. Strickler, Executive Vice President. In August 2016, Mr. Strickler relinquished his position of Chief Financial Officer and Treasurer but remained Executive Vice President supporting the Company’s growth initiatives. Mr. Strickler served as Executive Vice President and Chief Financial Officer from January 2006 to August 2016. Mr. Strickler was appointed Treasurer of the Company in February 2007. Prior to his employment with the Company, Mr. Strickler served as Executive Vice President and Chief Financial Officer for Republic Engineered Products, Inc. (“Republic”), from February 2004 to January 2006. Mr. Strickler also currently serves as Chairman of the Board of TCP International Holdings Ltd., a manufacturer and distributor of energy efficient lighting technologies.

Anthony L. Moore, Vice President of Operations. Mr. Moore was appointed as Vice President of Operations in May 2016. Prior to joining Stoneridge, he served as Global Vice President of Integrated Supply Chain and Operations at Ingersoll Rand, Compressed Air Systems from October 2015. Prior to that, Mr. Moore served as Chief Product Development and Supply Chain Officer at Remington Outdoor Company from May 2012 to September 2015. Before that, Mr. Moore was employed at Cooper Industries, Inc. where he held several leadership positions in the areas of supply chain, operations, and engineering from 2008.

Thomas A. Beaver, Vice President of the Company and President of Global Sales. Mr. Beaver has served as Vice President of the Company and President of Global Sales since May 2012. Prior to that, Mr. Beaver served as Vice President of the Company and Vice President of Global Sales and Systems Engineering from January 2005 to May 2012. From January 2000 to January 2005, Mr. Beaver served as Vice President of Stoneridge Sales and Marketing.

Michael D. Sloan, Vice President of the Company and President of the Control Devices Division. Mr. Sloan has served as President of the Control Devices Division since July 2009 and Vice President of the Company since December 2009. Prior to that, Mr. Sloan served as Vice President and General Manager of Stoneridge Hi-Stat from February 2004 to July 2009.

| 6 |

Peter Kruk, President of the Electronics Division. Mr. Kruk has served as President of the Electronics Division since August 2012. Mr. Kruk joined the Company in October 2009 as the Managing Director of Stoneridge Electronics – Europe. Prior to that, he served as President of HEXPOL Wheels and Managing Director of Stellana AB from 2007 to 2009.

Sergio de Cerqueira Leite, Director President of PST Eletrônica Ltda. Mr. Leite is a founding partner of PST. He has held the Director President position since 1997.

Alisa A. Nagle, Chief Human Resources Officer. Ms. Nagle has served as Chief Human Resources Officer since joining the Company in November 2015. From 2007 until her employment with the Company, Ms. Nagle served as Vice President of Human Resources – Global Aftermarket and Original Equipment Groups and Global Central Functions at Johnson Controls, Inc.

Robert J Hartman Jr., Chief Accounting Officer. Mr. Hartman was appointed as Chief Accounting Officer and to the role of principal accounting officer in July 2016. Prior to that, Mr. Hartman served as Corporate Controller of the Company since 2006 and prior to that as Stoneridge’s Director of Internal Audit from 2003.

Available Information

We make available, free of charge through our website (www.stoneridge.com), our Annual Report on Form 10-K (“Annual Report”), Quarterly Reports on Form 10-Q, Current Reports on Form 8-K, all amendments to those reports, and other filings with the U.S. Securities and Exchange Commission (“SEC”), as soon as reasonably practicable after they are filed with the SEC. Our Corporate Governance Guidelines, Code of Business Conduct and Ethics, Code of Ethics for Senior Financial Officers, Whistleblower Policy and Procedures and the charters of the Board of Director’s Audit, Compensation and Nominating and Corporate Governance Committees are posted on our website as well. Copies of these documents will be available to any shareholder upon request. Requests should be directed in writing to Investor Relations at Stoneridge, Inc., 39675 MacKenzie Drive, Suite 400, Novi, Michigan 48377.

The SEC maintains a website (www.sec.gov) that contains reports, proxy and information statements, and other information regarding issuers that file electronically with the SEC, including the Company. The public may also read and copy any materials we file with the SEC at the SEC’s Public Reference Room at 100 F. Street, NE, Washington, DC 20549. The public may obtain information on the operation of the Public Reference Room by calling the SEC at 1-800-SEC-0330.

Our business is cyclical and a downturn in the automotive, commercial, motorcycle, off-highway and agricultural vehicle markets as well as overall economic conditions could reduce the sales and profitability of our business.

The demand for products in our Control Devices and Electronics segments are largely dependent on the domestic and foreign production of automotive, commercial, motorcycle, off-highway and agricultural vehicles. The markets for our products have been cyclical, because new vehicle demand is dependent on, among other things, consumer spending and is tied closely to the overall strength of the economy. Because the majority of our products are used principally in the production of vehicles for the automotive, commercial, motorcycle, off-highway and agricultural vehicle markets, our net sales, and therefore our results of operations, are significantly dependent on the general state of the economy and other factors which affect these markets. A decline in commercial, automotive, agricultural, motorcycle and off-highway vehicle production, or a material decline in market share by our significant customers, could adversely affect our results of operations and financial condition.

In 2016, approximately 88% of our net sales were derived from automotive, commercial, motorcycle, off-highway and agricultural vehicle markets while approximately 12% were derived from aftermarket distributors, mass merchandisers and monitoring services markets.

| 7 |

We have foreign currency translation and transaction risks that may materially adversely affect our operating results, financial condition and liquidity.

The financial position and results of operations of our international subsidiaries are initially recorded in various foreign currencies and then translated into U.S. dollars at the applicable exchange rate for inclusion in our consolidated financial statements. The strengthening of the U.S. dollar against these foreign currencies ordinarily has a negative effect on our reported sales and operating margin (and conversely, the weakening of the U.S. dollar against these foreign currencies has a positive impact). The volatility of currency exchange rates may materially adversely affect our operating results, including foreign currency forward contracts. To mitigate a portion of our exposure to fluctuations in foreign currency exchange rates we use derivative financial instruments, including foreign currency contracts, to reduce the effect of such fluctuations on foreign currency denominated intercompany transactions, inventory purchases and other foreign currency exposures.

We are subject to risks related to our international operations.

Approximately 38% of our net sales in 2016 were derived from sales outside of North America. At December 31, 2016, significant concentrations of net assets outside of North America included $55.7 million in South America and $79.0 million in Europe and Other. Non-current assets outside of North America accounted for approximately 51% of our non-current assets as of December 31, 2016. International sales and operations are subject to significant risks, including, among others:

| · | political and economic instability; |

| · | restrictive trade policies; |

| · | economic conditions in local markets; |

| · | currency exchange controls; |

| · | labor unrest; |

| · | difficulty in obtaining distribution support and potentially adverse tax consequences; and |

| · | the imposition of product tariffs and the burden of complying with a wide variety of international and U.S. export laws |

We may not realize sales represented by awarded business.

We base our growth projections, in part, on business awards made by our customers. These business awards generally renew annually during a program life cycle. Failure of actual production orders from our customers to approximate these business awards could have a material adverse effect on our business, financial condition or results of operations.

The prices that we can charge some of our customers are predetermined and we bear the risk of costs in excess of our estimates, in addition to the risk of adverse effects resulting from general customer demands for cost reductions and quality improvements.

Our supply agreements with some of our customers require us to provide our products at predetermined prices. In some cases, these prices decline over the course of the contract and may require us to meet certain productivity and cost reduction targets. In addition, our customers may require us to share productivity savings in excess of our cost reduction targets. The costs that we incur in fulfilling these contracts may vary substantially from our initial estimates. Unanticipated cost increases or the inability to meet certain cost reduction targets may occur as a result of several factors, including increases in the costs of labor, components or materials. In some cases, we are permitted to pass on to our customers the cost increases associated with specific materials. However, cost overruns that we cannot pass on to our customers could adversely affect our business, financial condition or results of operations.

| 8 |

OEM customers have exerted and continue to exert considerable pressure on component suppliers to reduce costs, improve quality and provide additional design and engineering capabilities and continue to demand and receive price reductions and measurable increases in quality through their use of competitive selection processes, rating programs and various other arrangements. We may be unable to generate sufficient production cost savings in the future to offset required price reductions. Additionally, OEMs have generally required component suppliers to provide more design engineering input at earlier stages of the product development process, the costs of which have, in some cases, been absorbed by the suppliers. Future price reductions, increased quality standards and additional engineering capabilities required by OEMs may reduce our profitability and have a material adverse effect on our business, financial condition or results of operations.

Our business is very competitive and increased competition could reduce our sales and profitability.

The markets for our products are highly competitive. We compete based on technological innovation, price, quality, performance, service and delivery. Many of our competitors are more diversified and have greater financial and other resources than we do. In addition, with respect to certain products, some of our competitors are divisions of our OEM customers. We cannot assure that our business will not be adversely affected by competition or that we will be able to maintain our profitability if the competitive environment changes.

The loss or insolvency of any of our principal customers would adversely affect our future results.

We are dependent on several principal customers for a significant percentage of our net sales. In 2016, our top five customers were Ford Motor Company, General Motors, Scania Group, Daimler and Volvo which comprised 17%, 7%, 6%, 6% and 6% of our net sales, respectively. In 2016, our top ten customers accounted for 55% of our net sales. The loss of any significant portion of our sales to these customers would have a material adverse effect on our results of operations and financial condition. The contracts we have entered into with many of our customers provide for supplying the customers’ requirements for a particular model, rather than for manufacturing a specific quantity of products. Such contracts range from one year to the life of the model. These contracts are subject to renegotiation, which may affect product pricing and generally may be terminated by our customers at any time. Therefore, the loss of a contract for a major model or a significant decrease in demand for certain key models or any group of related models sold by any of our major customers could have a material adverse effect on our results of operations and financial condition by reducing cash flows and our ability to spread costs over a larger revenue base. We also compete to supply products for successor models and are subject to the risk that the customer will not select us to produce products on any such model, which could have a material adverse impact on our business, financial condition or results of operations. In addition, we have significant receivable balances related to these customers and other major customers that would be at risk in the event of their bankruptcy.

The discontinuation of, loss of business or lack of commercial success, with respect to a particular vehicle model for which the Company is a significant supplier could reduce the Company’s sales and harm its profitability.

Although the Company has purchase orders from many of its customers, these purchase orders generally provide for the supply of a customer’s annual requirements for a particular vehicle model and assembly plant, or in some cases, for the supply of a customer’s requirements for the life of a particular vehicle model, rather than for the purchase of a specific quantity of products. In addition, it is possible that customers could elect to manufacture components internally that are currently produced by outside suppliers, such as the Company. The discontinuation of, the loss of business with respect to or a lack of commercial success of a particular vehicle model for which the Company is a significant supplier, could reduce the Company’s sales and harm the Company’s profitability.

We are dependent on the availability and price of raw materials and other supplies.

We require substantial amounts of raw materials and other supplies, and substantially all such materials we require are purchased from outside sources. The availability and prices of raw materials and other supplies may be subject to curtailment or change due to, among other things, new laws or regulations, suppliers’ allocations to other purchasers and interruptions in production by suppliers, weather emergencies, natural disasters, commercial disputes, acts of terrorism or war, changes in exchange rates and worldwide price levels. If demand for raw materials increases, we may have difficulties obtaining adequate raw materials and other supplies from our suppliers to satisfy our customers. At times, we have experienced difficulty obtaining adequate supplies of semiconductors and memory chips for our Control Devices, Electronics and PST segments. In addition, there have been challenges at times in obtaining timely supply of nylon and resins for our Control Devices segment and audio component parts for our PST segment. If we cannot obtain adequate raw materials and other supplies, or if we experience an increase in the price of raw materials and other supplies, our business, financial condition or results of operations could be materially adversely affected.

We use a variety of commodities, including copper, zinc, resins and certain other commodities. Increasing commodity costs could have a negative impact on our results. We have sought at times to alleviate the effect of increasing costs by selectively hedging a portion of our exposure. The inability to effectively hedge them may have a material adverse effect on our business, financial condition or results of operations.

| 9 |

We rely on independent dealers and distributors to sell certain products in the aftermarket sales channel and a disruption to this channel would harm our business.

Because we sell certain products such as security accessories and driver information products to independent dealers and distributors, we are subject to many risks, including risks related to their inventory levels and support for our products. If dealers and distributors do not maintain sufficient inventory levels to meet customer demand, our sales could be negatively impacted.

Our dealer network also sells products offered by our competitors. If our competitors offer our dealers more favorable terms, those dealers may de-emphasize or decline to carry our products. In the future, we may not be able to retain or attract a sufficient number of qualified dealers and distributors. If we are unable to maintain successful relationships with dealers and distributors, or to expand our distribution channels, our business will suffer.

We must implement and sustain a competitive technological advantage in producing our products to compete effectively.

Our products are subject to changing technology, which could place us at a competitive disadvantage relative to alternative products introduced by competitors. Our success will depend on our ability to continue to meet customers’ changing specifications with respect to technological innovation, price, quality, performance, service and delivery by implementing and sustaining competitive technological advances. Our business may, therefore, require significant recurring additional capital expenditures and investment in product development and manufacturing and management information systems. We cannot assure that we will be able to achieve the technological advances or introduce new products that may be necessary to remain competitive. Our inability to continuously improve existing products, to develop new products and to achieve technological advances could have a material adverse effect on our business, financial condition or results of operations.

PST’s Global Positioning Systems (“GPS”) products depend upon satellites maintained by the United States Department of Defense. If a significant number of these satellites become inoperable, unavailable or are not replaced, or if the policies of the United States government for the use of the GPS without charge are changed, our business will suffer.

The GPS is a satellite-based navigation and positioning system consisting of a constellation of orbiting satellites. The satellites and their ground control and monitoring stations are maintained and operated by the United States Department of Defense. The Department of Defense does not currently charge users for access to the satellite signals. These satellites and their ground support systems are complex electronic systems subject to electronic and mechanical failures and possible sabotage.

If a significant number of satellites were to become inoperable, unavailable or are not replaced, it would impair the current utility of our GPS products and the growth of market opportunities. In addition, there can be no assurance that the U.S. government will remain committed to the operation and maintenance of GPS satellites over a long period, or that the policies of the U.S. government that provide for the use of the GPS without charge and without accuracy degradation will remain unchanged. Because of the increasing commercial applications of the GPS, other U.S. government agencies may become involved in the administration or the regulation of the use of GPS signals. Any of the foregoing factors could affect the willingness of buyers of our products to select GPS-based products instead of products based on competing technologies, which could adversely affect our operational revenues, financial condition and results of operation.

We may incur material product liability costs.

We may be subject to product liability claims in the event that the failure of any of our products results in personal injury or death and we cannot assure that we will not experience material product liability losses in the future. We cannot assure that our product liability insurance will be adequate for liabilities ultimately incurred or that it will continue to be available on terms acceptable to us. In addition, if any of our products prove to be defective, we may be required to participate in government-imposed or customer OEM-instituted recalls involving such products. A successful claim brought against us that exceeds available insurance coverage or a requirement to participate in any product recall could have a material adverse effect on our business, financial condition or results of operations.

| 10 |

Increased or unexpected product warranty claims could adversely affect us.

We typically provide our customers a warranty covering workmanship, and in some cases materials, on products we manufacture. Our warranty generally provides that products will be free from defects and adhere to customer specifications. If a product fails to comply with the warranty, we may be obligated or compelled, at our expense, to correct any defect by repairing or replacing the defective product. We maintain warranty reserves in an amount based on historical trends of units sold and payment amounts, combined with our current understanding of the status of existing claims. To estimate the warranty reserves, we must forecast the resolution of existing claims, as well as expected future claims on products previously sold. The amounts estimated to be due and payable could differ materially from what we may ultimately be required to pay. An increase in the rate of warranty claims or the occurrence of unexpected warranty claims could have a material adverse effect on our customer relations, our financial condition or results of operations. Our customers are increasingly seeking to hold suppliers responsible for product warranties, which could negatively impact our exposure to these costs.

If we fail to protect our intellectual property rights or maintain our rights to use licensed intellectual property or are found liable for infringing the rights of others, our business could be adversely affected.

Our intellectual property, including our patents, trademarks, copyrights, trade secrets and license agreements, are important in the operation of our businesses, and we rely on the patent, trademark, copyright and trade secret laws of the United States and other countries, as well as nondisclosure agreements, to protect our intellectual property rights. We may not, however, be able to prevent third parties from infringing, misappropriating or otherwise violating our intellectual property, breaching any nondisclosure agreements with us, or independently developing technology that is similar or superior to ours and not covered by our intellectual property. Any of the foregoing could reduce any competitive advantage we have developed, cause us to lose sales or otherwise harm our business. We cannot assure that any intellectual property will provide us with any competitive advantage or will not be challenged, rejected, cancelled, invalidated or declared unenforceable. In the case of pending patent applications, we may not be successful in securing issued patents, or securing patents that provide us with a competitive advantage for our businesses. In addition, our competitors may design products around our patents that avoid infringement and violation of our intellectual property rights.

We cannot be certain that we have rights to use all intellectual property used in the conduct of our businesses or that we have complied with the terms of agreements by which we acquire such rights, which could expose us to infringement, misappropriation or other claims alleging violations of third party intellectual property rights. Third parties have asserted and may assert or prosecute infringement claims against us in connection with the services and products that we offer, and we may or may not be able to successfully defend these claims. Litigation, either to enforce our intellectual property rights or to defend against claims regarding intellectual property rights of others, could result in substantial costs and a diversion of our resources. Any such claims and resulting litigation could require us to enter into licensing agreements (if available on acceptable terms or at all), pay damages and cease making or selling certain products and could result in a loss of our intellectual property protection. Moreover, we may need to redesign some of our products to avoid future infringement liability. We also may be required to indemnify customers or other third parties at significant expense in connection with such claims and actions. Any of the foregoing could have a material adverse effect on our business, financial condition or results of operations.

| 11 |

Our debt obligations could limit our flexibility in managing our business and expose us to risks.

As of December 31, 2016, there was $67.0 million in borrowings outstanding on our revolving credit facility (the “Credit Facility”). In addition, we are permitted under our Credit Facility to incur additional debt, subject to specified limitations. Our leverage and the terms of our indebtedness may have important consequences including the following:

| · | we may have difficulty satisfying our obligations with respect to our indebtedness, and if we fail to comply with these requirements, an event of default could result; |

| · | we may be required to dedicate a substantial portion of our cash flow from operations to required payments on indebtedness, thereby reducing the availability of cash flow for working capital, capital expenditures and other general corporate activities; |

| · | covenants relating to our debt may limit our ability to obtain additional financing for working capital, capital expenditures and other general corporate activities; |

| · | covenants relating to our debt may limit our flexibility in planning for, or reacting to, changes in our business and the industry in which we operate; |

| · | we may be placed at a competitive disadvantage against any less leveraged competitors |

These and other consequences of our leverage and the terms of our indebtedness could have a material adverse effect on our business, financial condition or results of operations.

Covenants in our Credit Facility may limit our ability to pursue our business strategies.

Our Credit Facility limits our ability to, among other things:

| · | incur additional debt and guarantees; |

| · | pay dividends and repurchase our shares; |

| · | make other restricted payments, including investments; |

| · | create liens; |

| · | sell or otherwise dispose of assets, including capital shares of subsidiaries; |

| · | enter into agreements that restrict dividends from subsidiaries; |

| · | consolidate, merge or sell or otherwise dispose of all or substantially all of our assets; and |

| · | substantially change the nature of our business. |

The agreement governing our Credit Facility requires us to maintain a maximum leverage ratio of 3.00 to 1.00, and a minimum interest coverage ratio of 3.50 to 1.00 and places a maximum annual limit on capital expenditures. Our ability to comply with these covenants as well as the negative covenants under the terms of our indebtedness, may be affected by events beyond our control.

A breach of any of the negative covenants under our indebtedness or our inability to comply with the leverage and interest ratio requirements in the Credit Facility could result in a default. If a default occurs, the lenders under the Credit Facility could elect to declare all outstanding borrowings, together with accrued interest and other fees, to be immediately due and payable and terminate any commitments they have to provide further borrowings, and the Credit Facility lenders could pursue foreclosure and other remedies against us and our assets.

| 12 |

We have limited or no redundancy for certain of our manufacturing facilities, and therefore damage or disruption to those facilities could interrupt our operations, increase our costs of doing business and impair our ability to deliver our products on a timely basis.

If certain of our existing production facilities become incapable of manufacturing products for any reason, we may be unable to meet production requirements, we may lose revenue and we may not be able to maintain our relationships with our customers. Without operation of certain existing production facilities, we may be limited in our ability to deliver products until we restore the manufacturing capability at the particular facility, find an alternative manufacturing facility or arrange an alternative source of supply. Although we carry business interruption insurance to cover lost revenue and profits in an amount we consider adequate, this insurance does not cover all possible situations and may be insufficient. Also, our business interruption insurance would not compensate us for the loss of opportunity and potential adverse impact on relations with our existing customers resulting from our inability to produce products for them.

A failure of our information technology (IT) networks and systems, or the inability to successfully implement upgrades to our enterprise resource planning (ERP) systems, could adversely impact our business and operations.

We rely upon information technology networks and systems to process, transmit and store electronic information, and to manage or support a variety of business processes and/or activities. The secure operation of these information technology networks and systems and the proper processing and maintenance of this information are critical to our business operations. Despite the implementation of security measures, our IT systems are at risk to damages from computer viruses, unauthorized access, cyber-attack and other similar disruptions. The occurrence of any of these events could compromise our networks, and the information stored there could be accessed, publicly disclosed or lost. Any such access, disclosure, loss of information or disruption of our operations could cause significant damage to our reputation, affect our relationships with our customers, suppliers and employees, lead to claims against the company and ultimately harm our business. We may be required to incur significant costs to protect against damage caused by these disruptions or security breaches in the future.

Also, we continually expand and update our IT networks and systems in response to the changing needs of our business and periodically upgrade our ERP systems. Should our networks or systems not be implemented successfully, or if the systems do not perform in a satisfactory manner once implementation is complete, our business and operations could be disrupted and our results of operations could be adversely affected, including our ability to report accurate and timely financial results.

Compliance with environmental and other governmental regulations could be costly and require us to make significant expenditures.

Our operations are subject to various federal, state, local and foreign laws and regulations governing, among other things:

| · | the discharge of pollutants into the air and water; |

| · | the generation, handling, storage, transportation, treatment, and disposal of waste and other materials; |

| · | the cleanup of contaminated properties; and |

| · | the health and safety of our employees. |

Our business, operations and facilities are subject to environmental and health and safety laws and regulations, many of which provide for substantial fines for violations. The operation of our manufacturing facilities entails risks and we cannot assure you that we will not incur material costs or liabilities in connection with these operations. In addition, potentially significant expenditures could be required in order to comply with evolving environmental, health and safety laws, regulations or requirements that may be adopted or imposed in the future. Changes in environmental, health and safety laws, regulations and requirements or other governmental regulations could increase our cost of doing business or adversely affect the demand for our products.

| 13 |

Our annual effective tax rate could be volatile and materially change as a result of changes in the mix of earnings and other factors including changes in the recognition and/or release of valuation allowances against deferred tax assets.

Our overall effective tax rate is computed by dividing our total tax expense (benefit) by our total earnings (loss) before tax. However, tax expense and benefits are not recognized on a global basis, but rather on a jurisdictional or legal entity basis. Losses in certain jurisdictions may not provide a current financial statement tax benefit as a result of the need to maintain a valuation allowance against the associated deferred tax asset. Also, management periodically evaluates the realizability of our deferred tax assets which may result in the recognition and/or release of valuation allowances. As a result, changes in the mix of earnings between jurisdictions and changes in the recognition and/or release of valuation allowances, among other factors, could have a significant effect on our overall effective tax rate.

The impact of potential changes in tax and trade policies in the United States and the potential corresponding actions by other countries in which we do business could adversely affect our financial performance.

The U.S. government has recently proposed comprehensive tax and trade reform. These proposals are designed to encourage increased production in the United States and include a border tax on imports, an increase in customs duties and the renegotiation of U.S. trade agreements. Reflective of the automotive industry, our vehicle parts manufacturing facilities in the United States and Mexico are highly dependent on trade within the North American Free Trade Agreement (“NAFTA”) region. Our facility in Mexico represents a critical component of our supply chain and that of our customers. We have significant imports into the United States, and the imposition of a border tax or an increase in customs duties with respect to these imports could negatively impact our financial performance. If such taxes or customs duties are implemented, it also may cause our trading partners to take actions with respect to U.S. imports or U.S. investment activities in their respective countries. Any potential changes in tax and trade policies in the United States and the potential corresponding actions by other countries in which we do business could adversely affect our financial performance.

We may not be able to successfully integrate acquisitions into our business or may otherwise be unable to benefit from pursuing acquisitions.

Failure to successfully identify, complete and/or integrate acquisitions could have a material adverse effect on us. A portion of our growth in sales and earnings has been generated from acquisitions and subsequent improvements in the performance of the businesses acquired. We expect to continue a strategy of selectively identifying and acquiring businesses with complementary products. We cannot assure you that any business acquired by us will be successfully integrated with our operations or prove to be profitable. We could incur substantial indebtedness in connection with our acquisition strategy, which could significantly increase our interest expense.

We anticipate that acquisitions could occur in foreign markets in which we do not currently operate. As a result, the process of integrating acquired operations into our existing operations may result in unforeseen operating difficulties and may require significant financial resources that would otherwise be available for the ongoing development or expansion of existing operations. Any failure to successfully integrate such acquisitions could have a material adverse effect on our business, financial condition or results of operations.

Item 1B. Unresolved Staff Comments.

None.

| 14 |

At December 31, 2016, the Company and its joint venture currently owned or leased 10 manufacturing facilities, which together contain approximately 1.0 million square feet of manufacturing space. Of these manufacturing facilities, four are used by our Control Devices reportable segment, three are used by our Electronics reportable segment, one is used by our PST reportable segment and two are used by our joint venture, Minda. The following table provides information regarding our facilities:

| Owned/ | Square | |||||||

| Location | Leased | Use | Footage | |||||

| Control Devices | ||||||||

| Lexington, Ohio | Owned | Manufacturing/Division Office | 219,612 | |||||

| Juarez, Mexico (A) | Owned | Manufacturing | 189,327 | |||||

| Canton, Massachusetts | Owned | Manufacturing | 132,560 | |||||

| Suzhou, China (A) | Leased | Manufacturing | 77,253 | |||||

| El Paso, Texas (A) | Leased | Warehouse | 57,000 | |||||

| Lexington, Ohio | Leased | Warehouse | 15,000 | |||||

| Lexington, Ohio | Leased | Warehouse | 2,700 | |||||

| Electronics | ||||||||

| Tallinn, Estonia (B) | Leased | Manufacturing | 85,911 | |||||

| Orebro, Sweden | Leased | Manufacturing | 77,472 | |||||

| Stockholm, Sweden | Leased | Engineering Office/Division Office | 39,600 | |||||

| Dundee, Scotland | Leased | Manufacturing/Sales Office/Engineering Office | 34,605 | |||||

| Bayonne, France | Leased | Sales Office/Warehouse | 9,655 | |||||

| Lomersheim, Germany | Leased | Sales Office/Warehouse | 5,597 | |||||

| Shanghai, China (B) | Leased | Sales Office | 5,034 | |||||

| Madrid, Spain | Leased | Sales Office/Warehouse | 1,545 | |||||

| PST | ||||||||

| Manaus, Brazil | Owned | Manufacturing | 102,247 | |||||

| São Paulo, Brazil | Owned | Engineering Office/Division Office | 45,467 | |||||

| São Paulo, Brazil | Leased | Sales Office | 9,246 | |||||

| Buenos Aires, Argentina | Leased | Sales Office | 5,798 | |||||

| Corporate and Other | ||||||||

| Novi, Michigan | Leased | Headquarters | 37,713 | |||||

| Warren, Ohio | Leased | Data Center | 3,020 | |||||

| Stuttgart, Germany | Leased | Sales Office/Engineering Office | 1,000 | |||||

| Seoul, South Korea | Leased | Sales Office | 330 | |||||

| Joint Venture | ||||||||

| Pune, India | Owned | Manufacturing/Engineering Office/Sales Office | 80,000 | |||||

| Chennai, India | Leased | Manufacturing | 25,629 | |||||

(A) This facility is also used in the Electronics reportable segment.

(B) This facility is also used in the Control Devices reportable segment.

| 15 |

We are involved in certain legal actions and claims primarily arising in the ordinary course of business. Although it is not possible to predict with certainty the outcome of these matters, we do not believe that any of the litigation in which we are currently engaged, either individually or in the aggregate, will have a material adverse effect on our business, consolidated financial position or results of operations. We are subject to a tax assessment in Brazil related to value added taxes on vehicle tracking and monitoring services for which the likelihood of loss is not probable although it may take years to resolve. In addition, we are subject to litigation regarding patent infringement. See additional details of these matters in Note 10 to the consolidated financial statements.

Item 4. Mine Safety Disclosure.

Not Applicable.

Item 5. Market for Registrant’s Common Equity, Related Stockholder Matters and Issuer Purchases of Equity Securities.

Our shares are listed on the New York Stock Exchange (“NYSE”) under the symbol “SRI.” As of February 24, 2017, we had 27,870,944 Common Shares, without par value, outstanding which were owned by approximately 200 registered holders, including Common Shares held in the names of brokers and banks (so-called “street name” holdings) who are record holders with approximately 2,600 beneficial owners.

Since the Company’s initial public offering in 1997, we have not paid or declared dividends, which are restricted under the Credit Facility. We may only pay cash dividends on our Common Shares of up to $7.0 million annually if immediately prior to and immediately after the payment is made, no event of default under our Credit Facility shall have occurred. We currently intend to use cash flows from our earnings for acquisitions, working capital, capital expenditures, general corporate purposes and reduction in outstanding indebtedness. Accordingly, we do not expect to pay cash dividends for the foreseeable future.

High and low sales prices for our Common Shares for each quarter ended during 2016 and 2015 are as follows:

| Quarter Ended | High | Low | ||||||

| 2016 | ||||||||

| March 31 | $ | 15.17 | $ | 10.51 | ||||

| June 30 | $ | 16.99 | $ | 13.57 | ||||

| September 30 | $ | 19.20 | $ | 14.84 | ||||

| December 31 | $ | 18.62 | $ | 13.42 | ||||

| 2015 | ||||||||

| March 31 | $ | 13.26 | $ | 10.83 | ||||

| June 30 | $ | 13.23 | $ | 11.18 | ||||

| September 30 | $ | 13.12 | $ | 10.18 | ||||

| December 31 | $ | 15.74 | $ | 11.70 | ||||

There were no repurchases of Common Shares made by us during the years ended December 31, 2016 or 2015, other than the repurchase of Common Shares of 126,539 and 241,537, respectively, to satisfy employee tax withholdings associated with the vesting of restricted Common Shares.

| 16 |

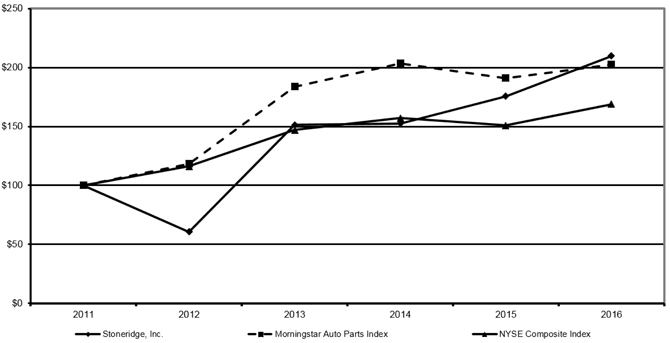

Performance Graph

Set forth below is a line graph comparing the cumulative total return of a hypothetical investment in our Common Shares with the cumulative total return of hypothetical investments in the Morningstar Auto Parts Industry Group Index and the NYSE Composite Index based on the respective market price of each investment as of December 31, 2011, 2012, 2013, 2014, 2015, and 2016 assuming in each case an initial investment of $100 on December 31, 2011, and reinvestment of dividends.

| 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | |||||||||||||||||||

| Stoneridge, Inc. | $ | 100 | $ | 61 | $ | 151 | $ | 153 | $ | 176 | $ | 210 | ||||||||||||

| Morningstar Auto Parts Index | $ | 100 | $ | 118 | $ | 184 | $ | 204 | $ | 191 | $ | 202 | ||||||||||||

| NYSE Composite Index | $ | 100 | $ | 116 | $ | 147 | $ | 157 | $ | 151 | $ | 169 | ||||||||||||

For information on “Related Stockholder Matters” required by Item 201(d) of Regulation S-K, refer to Item 12 of this report.

| 17 |

Item 6. Selected Financial Data.

The following table sets forth selected historical financial data and should be read in conjunction with the consolidated financial statements and notes related thereto and other financial information included elsewhere herein. The selected historical data was derived from our consolidated financial statements.

| Years ended December 31 | 2016 | 2015 | 2014 | 2013 | 2012 | |||||||||||||||

| (in thousands, except per share data) | ||||||||||||||||||||

| Statement of Operations Data: | ||||||||||||||||||||

| Net sales: | ||||||||||||||||||||

| Control Devices | $ | 408,132 | $ | 333,010 | $ | 306,658 | $ | 291,145 | $ | 267,860 | ||||||||||

| Electronics | 205,256 | 216,544 | 214,141 | 189,809 | 164,196 | |||||||||||||||

| PST | 82,589 | 95,258 | 139,780 | 178,532 | 180,410 | |||||||||||||||

| Total net sales | $ | 695,977 | $ | 644,812 | $ | 660,579 | $ | 659,486 | $ | 612,466 | ||||||||||

| Gross profit | $ | 195,439 | $ | 176,978 | $ | 190,874 | $ | 205,955 | $ | 185,267 | ||||||||||

| Operating income (loss) | ||||||||||||||||||||

| Control Devices | $ | 61,815 | $ | 44,690 | $ | 35,387 | $ | 32,331 | $ | 20,945 | ||||||||||

| Electronics | 14,798 | 13,784 | 17,444 | 20,732 | 15,851 | |||||||||||||||

| PST (C) | (3,462 | ) | (7,542 | ) | (59,587 | ) | 7,211 | 583 | ||||||||||||

| Unallocated Corporate (F) | (29,069 | ) | (23,117 | ) | (19,067 | ) | (17,871 | ) | (17,474 | ) | ||||||||||

| Total operating income (loss) | $ | 44,082 | $ | 27,815 | $ | (25,823 | ) | $ | 42,403 | $ | 19,905 | |||||||||

| Equity in earnings of investees | $ | 1,233 | $ | 608 | $ | 815 | $ | 476 | $ | 760 | ||||||||||

| Income (loss) before income taxes from continuing operations | $ | 39,185 | $ | 20,230 | $ | (53,060 | ) | $ | 23,326 | $ | (3,810 | ) | ||||||||

| Income (loss) from continuing operations (A) (B) (C) (D) | $ | 75,574 | $ | 20,777 | $ | (51,204 | ) | $ | 20,529 | $ | (3,777 | ) | ||||||||

| Income (loss) from discontinued operations (E) | - | (210 | ) | (9,387 | ) | (4,021 | ) | 7,525 | ||||||||||||

| Net income (loss) | 75,574 | 20,567 | (60,591 | ) | 16,508 | 3,748 | ||||||||||||||

| Net income (loss) attributable to noncontrolling interest (A)(B)(C)(D) | (1,887 | ) | (2,207 | ) | (13,483 | ) | 1,377 | (1,613 | ) | |||||||||||

| Net income (loss) attributable to Stoneridge, Inc. | $ | 77,461 | $ | 22,774 | $ | (47,108 | ) | $ | 15,131 | $ | 5,361 | |||||||||

| Basic earnings (loss) per share from continuing operations attributable to Stoneridge, Inc. | $ | 2.79 | $ | 0.84 | $ | (1.40 | ) | $ | 0.72 | $ | (0.08 | ) | ||||||||

| Diluted earnings (loss) per share from continuing operations attributable to Stoneridge, Inc. | $ | 2.74 | $ | 0.82 | $ | (1.40 | ) | $ | 0.70 | $ | (0.08 | ) | ||||||||

| Basic earnings (loss) per share attributable to discontinued operations | $ | - | $ | (0.01 | ) | $ | (0.35 | ) | $ | (0.15 | ) | $ | 0.28 | |||||||

| Diluted earnings (loss) per share attributable to discontinued operations | $ | - | $ | (0.01 | ) | $ | (0.35 | ) | $ | (0.14 | ) | $ | 0.28 | |||||||

| Basic earnings (loss) per share attributable to Stoneridge, Inc. | $ | 2.79 | $ | 0.83 | $ | (1.75 | ) | $ | 0.57 | $ | 0.20 | |||||||||

| Diluted earnings (loss) per share attributable to Stoneridge, Inc. | $ | 2.74 | $ | 0.81 | $ | (1.75 | ) | $ | 0.56 | $ | 0.20 | |||||||||

| Other Continuing Operations Data: | ||||||||||||||||||||

| Design and development | $ | 40,212 | $ | 38,792 | $ | 41,609 | $ | 40,372 | $ | 38,945 | ||||||||||

| Capital expenditures | $ | 24,476 | $ | 28,735 | $ | 23,516 | $ | 21,576 | $ | 22,909 | ||||||||||

| Depreciation and amortization (G) | $ | 23,258 | $ | 22,274 | $ | 27,105 | $ | 29,286 | $ | 29,405 | ||||||||||

| Balance Sheet Data (as of December 31): | ||||||||||||||||||||

| Working capital (C) | $ | 128,184 | $ | 123,859 | $ | 125,197 | $ | 215,880 | $ | 157,585 | ||||||||||

| Total assets (C) | $ | 394,529 | $ | 364,252 | $ | 398,751 | $ | 588,322 | $ | 592,691 | ||||||||||

| Long-term debt, net of current portion | $ | 75,060 | $ | 104,458 | $ | 110,651 | $ | 185,045 | $ | 181,311 | ||||||||||

| Shareholders' equity (D) | $ | 192,077 | $ | 106,429 | $ | 113,806 | $ | 188,534 | $ | 193,834 | ||||||||||

| 18 |

| (A) | The Company recorded the release of a valuation allowance associated with its U.S. federal, certain state and foreign deferred tax assets of $49.6 million for the year ended December 31, 2016. |

| (B) | The Company recorded a full valuation allowance on PST’s net deferred tax assets of $1,237 for the year ended December 31, 2015 of which $322 was attributable to noncontrolling interest. |

| (C) | The Company recorded a goodwill impairment of $51,458 related to PST during the year ended December 31, 2014 of which $11,304 was attributable to noncontrolling interest. |

| (D) | The Company recorded a loss on extinguishment of debt of $10,607 related to the redemption of the 9.5% senior notes during the year ended December 31, 2014. |

| (E) | The Company sold its Wiring business during the year ended December 31, 2014. As such, for all periods presented the Company reported this business as discontinued operations in the Company’s consolidated financial statements. |

| (F) | Unallocated corporate expenses include, among other items, accounting, finance, legal, information technology costs as well as share-based compensation. |

| (G) | These amounts represent depreciation and amortization on fixed and certain finite-lived intangible assets. |

| 19 |

Item 7. Management’s Discussion and Analysis of Financial Condition and Results of Operations.

The following discussion and analysis should be read in conjunction with the consolidated financial statements and notes related thereto and other financial information included elsewhere herein.

Segments