Attached files

| file | filename |

|---|---|

| 8-K - 8-K - McEwen Mining Inc. | a13-12064_28k.htm |

Exhibit 99.1

New Approach to Drilling Protects the

Environment, Reduces Costs & Accelerates

Permitting Time Frames in Mexico!

The impact of exploration drilling is typically visible for months after the work has been completed. Roads, drill pads and holes dug into the ground to capture drill fluids, were required to complete a hole.

In 2010, McEwen Mining’s (then US Gold) team at the El Gallo Complex in Mexico saw the need for real change and an opportunity to become proactive in minimizing this impact. The belief: it should be possible to drill an exploration hole with zero impact or discharge. Zero. The idea was that there would be no impact to the area’s natural landscape or the release of drilling fluids into the natural environment.

In order to accomplish this feat, the team first had to find a way to eliminate the need for new roads. Traditionally, dirt roads were built in order to move the drill to its required location. In addition to creating a surface disturbance, this took time and money. McEwen Mining began researching suppliers that could provide a drill which could be carried to its desired location and assembled. Energold Drilling from Vancouver filled this need perfectly. Since switching to “man portable drills” three years ago, the need for exploration roads has been completely eliminated.

McEwen Mining also wanted to find a way to reduce the size of the drill pads and ensure that these left no visual impact. Through an ongoing dialogue with the drill contractor, McEwen Mining was able to reduce the size of its drill pads by 95% to just 3 x 3 meters. This helps ensure that no trees are removed and that the drill’s footprint remains small. In order to achieve almost zero surface impact, the company began building raised platforms where the drill could be stationed (Fig 1.). These platforms are built of wood and are raised approximately 0.5 meters off the ground. This provides a safe and solid drill station and eliminates almost all earthworks activities that were previously required.

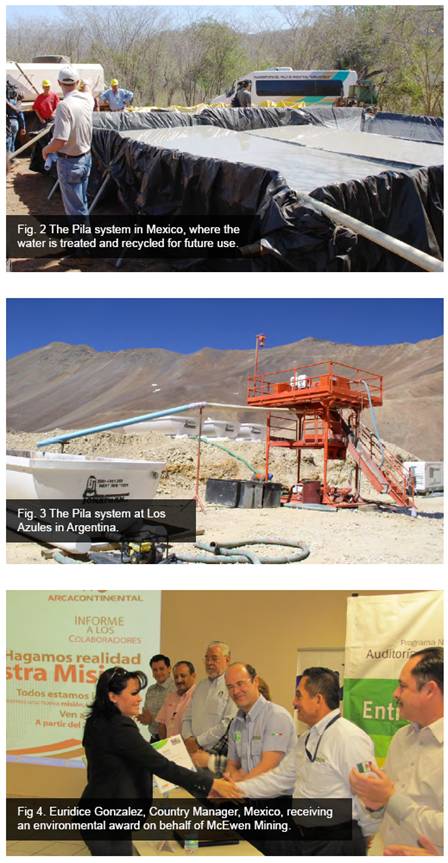

In order to keep the drills well lubricated and cool, water is added to the drill process. This water is circulated into the hole, which then has to be captured as it exits. The typical method is to dig a hole in the ground, cover it with a plastic liner and then burying the liner once the hole has been filled with water. McEwen Mining’s geologists developed a “Pila” system, which is essentially an above ground sewer system, which pipes the water from

Jenya Meshcheryakova | info@mcewenmining.com | 1.866.441.0690

the drill to several large collection areas that resemble above ground swimming pools (Fig. 2). Here the water is treated and then recycled back to the drill for future use. This system has several advantages. First, drill fluid is never discharged into the environment. Second, our above ground pools eliminate the need for holes in the ground with plastic liners, and third, the water used in the process is recycled, reducing the need for fresh water by approximately 70%.

This system has been very successful in Mexico and last fall, McEwen Mining began implementing the Pila system at the Los Azules Copper project in Argentina. The system was modified due to the large drills used at Los Azules. However, after some innovative thinking, the Argentinian team was able to develop a system that ensured the same environmental protection that was being achieved in Mexico (Fig 3). The company also believes this is the first time such a system has been used successfully in the high Andes.

In Mexico, McEwen Mining’s innovative approach to environmental protection has also allowed it to substantially reduce the drill permitting process given the lack of environmental impact. The company has also been the recipient of various environmental awards and acknowledgments (Fig. 4). By thinking outside the normal course, McEwen Mining has been able to protect the environment, reduce costs and accelerate the normal timelines associated with permitting. We hope we are helping to establish a new standard for the industry. Contact us if you want to know more about our methods and how they might help your company.