Attached files

Table of Contents

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

Form 10-K

(Mark One)

| þ | ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the fiscal year ended March 31, 2012

OR

| ¨ | TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

| For the transition period from to |

Commission file number 1-7872

BREEZE-EASTERN CORPORATION

(Exact name of registrant as specified in its charter)

| Delaware | 95-4062211 | |

| (State or other jurisdiction of incorporation or organization) |

(I.R.S. employer identification no.) | |

| 35 Melanie Lane Whippany, New Jersey |

07981 (Zip Code) | |

| (Address of principal executive offices) | ||

Registrant’s telephone number, including area code: (973)

602-1001

Securities registered pursuant to Section 12(b) of the Act:

| Common Stock, par value $0.01 | NYSE MKT | |

| (Title of class) | (Name of Exchange on Which Registered) |

Securities registered pursuant to Section 12(g) of the Act:

NONE

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes ¨ No þ

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act. Yes ¨ No þ

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes þ No ¨

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§ 229.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes þ No ¨

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. ¨

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, or a non-accelerated filer, or a smaller reporting company. See definition of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act. (Check one):

| Large accelerated filer ¨ | Accelerated filer ¨ | Non-accelerated filer ¨ | Smaller reporting company þ |

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Act). Yes ¨ No þ

The aggregate market value of the voting common equity held by non-affiliates of the registrant on September 30, 2011 (the last business day of the registrant’s most recently completed second fiscal quarter), based on the closing price of the registrant’s common stock on the NYSE MKT (formerly NYSE Amex) on such date, was $32,410,943. Shares of common stock held by executive officers and directors have been excluded since such persons may be deemed affiliates. This determination of affiliate status is not a determination for any other purpose.

As of May 7, 2012, the registrant had 9,490,151 shares of common stock outstanding.

DOCUMENTS INCORPORATED BY REFERENCE

The registrant’s Proxy Statement for the 2012 Annual Meeting of Stockholders is incorporated by reference into Part III of this Annual Report on Form 10-K. With the exception of those portions that are specifically incorporated by reference in this Annual Report on Form 10-K, such Proxy Statement shall not be deemed filed as part of this Report or incorporated by reference herein. Such proxy statement will be filed with the Securities and Exchange Commission within 120 days of the registrant’s fiscal year ended March 31, 2012.

Table of Contents

BREEZE-EASTERN CORPORATION

INDEX TO ANNUAL REPORT ON FORM 10-K

FOR THE YEAR ENDED MARCH 31, 2012

| PART I | ||||||

| Item 1. | 3 | |||||

| Item 1A. | 7 | |||||

| Item 1B. | 14 | |||||

| Item 2. | 15 | |||||

| Item 3. | 15 | |||||

| Item 4. | 15 | |||||

| PART II | ||||||

| Item 5. | Market for Registrant’s Common Equity, Related Stockholder Matters, and Issuer Purchases of Equity Securities | 16 | ||||

| Item 6. | 18 | |||||

| Item 7. | Management’s Discussion and Analysis of Financial Condition and Results of Operations |

18 | ||||

| Item 7A. | 27 | |||||

| Item 8. | 28 | |||||

| Item 9. | Changes in and Disagreements with Accountants on Accounting and Financial Disclosure |

55 | ||||

| Item 9A. | 55 | |||||

| Item 9B. | 55 | |||||

| PART III | ||||||

| Item 10. | 56 | |||||

| Item 11. | 56 | |||||

| Item 12. | Security Ownership of Certain Beneficial Owners and Management and Related Stockholder Matters | 56 | ||||

| Item 13. | Certain Relationships and Related Transactions, Director Independence |

56 | ||||

| Item 14. | 56 | |||||

| PART IV | ||||||

| Item 15. | 56 | |||||

2

Table of Contents

DISCLOSURE REGARDING FORWARD-LOOKING STATEMENTS

This report contains “forward-looking statements” within the meaning of Section 27A of the Securities Act of 1933, as amended, and Section 21E of the Securities Exchange Act of 1934, as amended. All statements other than statements of historical facts included or incorporated by reference in this report, including, without limitation, statements regarding our future financial position, business strategy, budgets, projected revenues, projected costs and plans and objective of management for future operations, are forward-looking statements. In addition, forward-looking statements generally can be identified by the use of forward-looking terminology such as “may,” “will,” “expects,” “intends,” “plans,” “projects,” “estimates,” “anticipates,” or “believes” or the negative thereof or any variation there on or similar terminology or expressions.

We have based these forward-looking statements on our current expectations and projections about future events. These forward-looking statements are not guarantees and are subject to known and unknown risks, uncertainties and assumptions about us that may cause our actual results, levels of activity, performance or achievements to be materially different from any future results, levels of activity, performance or achievements expressed or implied by such forward-looking statements. Important factors that could cause actual results to differ materially from our expectations include, but are not limited to: changes in business conditions, changes in applicable laws, rules and regulations affecting us in locations in which we conduct business, interest rate trends, a decline or redirection of the U.S. defense budget, the failure of Congress to approve a budget or continuing resolution, the termination of any contracts with the U.S. Government, changes in our sales strategy and product development plans, changes in the marketplace, continued services of our executive management team, competitive pricing pressures, security breaches, market acceptance of our products under development, delays in the development of products, changes in spending allocation or the termination, postponement, or failure to fund one or more significant contracts by the United States Government or other customers, determination by us to dispose of or acquire additional assets, events impacting the U.S. and world financial markets and economies, and statements of assumption underlying any of the foregoing, as well as other factors set forth under “Item 1A. Risk Factors” beginning on page 6 of this report and “Item 7 — Management’s Discussion and Analysis of Financial Condition and Results of Operations” below.

All subsequent written and oral forward-looking statements attributable to us, or persons acting on our behalf, are expressly qualified in their entirety by the foregoing. Except as required by law, we assume no duty to update or revise our forward-looking statements based on changes in internal estimates, expectations, or otherwise.

| ITEM 1. | BUSINESS |

Breeze-Eastern Corporation, a Delaware corporation, designs, develops, manufactures, sells and services sophisticated engineered mission equipment for specialty aerospace and defense applications. We were originally organized in 1962 as a California corporation and reincorporated in Delaware in 1986. Unless the context otherwise requires, references to the “Company,” the “Registrant,” “Breeze-Eastern,” “we” or “us” refer to Breeze-Eastern Corporation and its consolidated subsidiaries. All references to years in this report refer to the fiscal year ended March 31 of the indicated year unless otherwise specified. This report reflects all adjustments of a normal recurring nature, which are, in the opinion of management, necessary for fair presentation of the results of operations for the periods reflected. Certain prior fiscal year amounts may have been reclassified to conform to the current fiscal year presentation.

CORE BUSINESS

Our core business is aerospace and defense products. We believe we are a leading global designer, manufacturer, service provider, and supplier of mission-critical rescue hoists and cargo hook systems. We also manufacture weapons handling systems, cargo winches, and tie-down equipment. These products are sold primarily to military and civilian agencies and aerospace contractors. Our emphasis is on the engineering, assembly, testing, service, and support of our products.

3

Table of Contents

PRODUCTS AND SERVICES

Our products and related services aggregate into one reportable segment. The nature of the production process (assemble, inspect, and test), customers, and product distribution are similar for all products. We sell our products through internal marketing representatives and independent sales representatives and distributors.

PRODUCTS

Products include new equipment and spare parts sales and represented approximately 76%, 74%, and 72% of our total revenues in fiscal 2012, fiscal 2011, and fiscal 2010, respectively.

As a pioneer of helicopter rescue hoist technology, we continue to develop sophisticated helicopter hoist and winch systems, including systems for the current generation of Blackhawk, Seahawk, Osprey, Chinook, Ecureuil, Dolphin, Merlin/Cormorant, Super Stallion, Changhe Z-11, Agusta A109, Agusta A119 and AgustaWestland AW139 helicopters. We also design, market, sell and service a broad line of hydraulic and electric aircraft cargo winch systems with capacities from 900 pounds to over 7,000 pounds. Sales of hoist and winch products accounted for approximately 56%, 57%, and 51% of our total revenues in fiscal 2012, fiscal 2011, and fiscal 2010, respectively.

Our external cargo hook systems are original equipment on leading military medium and heavy lift helicopters. These hook systems range from smaller 1,000-pound capacity models up to the largest 36,000-pound capacity hooks employed on the Super Stallion helicopter. Our latest designs incorporate load sensing and display technology and automatic load release features. We also manufacture cargo and aircraft tie-downs which are included in this product line. Sales of cargo hook products accounted for approximately 14%, 12%, and 14% of our total revenues in fiscal 2012, fiscal 2011, and fiscal 2010, respectively.

We make static-line retrieval and cargo winches for military cargo aircraft including the Boeing C-17, Alenia C-27J, and CASA CN-235, and CASA C-295. In addition, we have a contract with Airbus to develop and produce three products for the new cargo positioning and restraint system for the A400M cargo aircraft and expect to be the sole supplier of these products with anticipated delivery beginning in the later part of fiscal 2013.

Once our products are qualified and approved for use with a particular aircraft model, sales of products and services generally continue over the life of the aircraft model, which is usually decades. It is expensive and difficult for a second supplier’s product to become qualified and approved on the same aircraft.

Our weapons handling systems include weapons handling equipment for land-based rocket launchers and munitions hoists for loading missiles and other loads using electric power or exchangeable battery packs. We supply this equipment for the United States, Japanese, and European Multiple-Launch Rocket Systems (MLRS) and the United States High Mobility Artillery Rocket System (HIMARS). We also provide actuators and specialty gearboxes for specialty weapons applications. Sales of weapons handling products accounted for approximately 6%, 5%, and 7% of our total revenues in fiscal 2012, fiscal 2011, and fiscal 2010, respectively.

SERVICES

Services include overhaul and repair and engineering sales and represented 24%, 26%, and 28% of our total revenues in fiscal 2012, fiscal 2011, and fiscal 2010, respectively.

We perform overhaul, repair, and maintenance services for all of our products. Most of these services are performed at our Whippany, New Jersey facility. We have also licensed third-party vendors around the world to perform these services. Overhaul and repair represented 23%, 22%, and 24% of our total revenues in fiscal 2012, fiscal 2011, and fiscal 2010, respectively.

In addition to performing research and development to design new products, improve existing products, and add new features to our product line, we also provide engineering services to adapt our products to customer specific needs and aircraft models on a fee-for-service basis.

We discuss segment information in Note 14 of our “Notes to Consolidated Financial Statements” contained elsewhere in this report.

4

Table of Contents

MAJOR CUSTOMERS

We have four major customers: the U.S. Government, United Technologies Corporation, Finmeccanica SpA, and Transaero Inc. which accounted for 29%, 22%, 12%, and 11%, respectively, of the total consolidated net sales for fiscal 2012.

GOVERNMENT SALES

Our direct sales to the U.S. Government and sales for U.S. Government and foreign government end use represented 76%, 69%, and 67% of consolidated revenue during fiscal 2012, fiscal 2011, and fiscal 2010, respectively. U.S. Government sales, both direct and indirect, are generally made under standard government contracts including fixed price and cost plus. As a U. S. Government contractor, we are subject to routine audits and investigations by U. S. Government agencies.

In accordance with normal practice, contracts and orders with the U.S. Government are subject to partial or complete termination at any time, at the option of the customer. In the event of a termination for convenience by the government, there generally are provisions for recovery of our allowable incurred costs and a proportionate share of the profit or fee on the work completed, consistent with regulations of the U.S. Government.

BACKLOG

We measure backlog by the amount of products or services that customers committed by contract to purchase as of a given date. Backlog at March 31, 2012 was $111,184 as compared with $131,151 at March 31, 2011 as new orders exceeded shipments in fiscal 2011. Approximately $77,977 of our backlog at March 31, 2012 is not scheduled for shipment during the next twelve months. For additional discussion on our backlog, see “Item 7. Management’s Discussion and Analysis of Financial Condition and Results of Operations.”

COMPONENTS, RAW MATERIALS, AND SEASONALITY

The various component parts and, to some extent, assembly of components and subsystems by subcontractors used by us to produce our products are generally available from more than one source. In those instances where only a single source for any material or part is available, such items can generally be redesigned to accommodate materials or parts made by other suppliers, although this may lead to delays and higher costs in meeting customer requirements. In some cases, we stock an adequate supply of the single source materials or parts for use until a new supplier can be approved.

In recent years, our revenues in the second half of our fiscal year have generally exceeded revenues in the first half. The timing of U.S. Government awards, availability of U.S. Government funding, and product deliveries are among the factors affecting the periods in which revenues are recorded. Management expects this trend to continue in fiscal 2013.

EMPLOYEES

As of March 31, 2012, we had 182 salaried and hourly employees, and the United Auto Workers (UAW) represented 52 hourly employees at our facility. We reached a three-year collective bargaining agreement with the UAW in November 2010 and consider our relations, with both our union and non-union employees, to be generally satisfactory.

INTERNATIONAL OPERATIONS AND SALES

We currently have no operations based outside of the United States. We had export sales of $31,212, $28,598, and $27,912 in fiscal 2012, fiscal 2011, and fiscal 2010, respectively, representing 37%, 37%, and 40% of our consolidated net sales in each of those years. The risks and profitability of international sales are generally comparable with similar products sold by us in the United States. Net export sales by geographic area and customer domicile are set forth in Note 14 of our financial statements contained elsewhere in this report.

5

Table of Contents

COMPETITION

We compete in some markets with the hoist and winch business unit of the Goodrich Corporation, which as a whole is a larger corporation that has substantially greater financial and technical resources than us. Generally, competitive factors include design capabilities, product performance, delivery, and price. Our ability to compete successfully in these markets depends on our ability to develop and apply technological innovations and to expand our customer base and product lines. Technological innovation, development, and application requires significant investment and capital expenditures. While we make each investment with the intent of getting a good financial return, in some cases we may not fully recover the full investment through future sales of products or services.

RESEARCH AND DEVELOPMENT

We conduct extensive research and development activities, primarily for developing new or improved products, under customer-sponsored contracts and with our own funding. Research and development costs, which are charged to Engineering expense when incurred, amounted to $1,057, $1,347, and $1,848 for the years ended March 31, 2012, 2011, and 2010, respectively. Customer-sponsored research and development costs are charged to cost of sales when the associated revenue is recognized and were $2,096, $2,323, and $3,016 in fiscal 2012, fiscal 2011, and fiscal 2010, respectively.

INTELLECTUAL PROPERTY

We have been one of the market leaders since the initial development of rescue hoists for use on helicopters and have continually designed and manufactured rescue hoists since the 1940’s. Our intellectual property product knowledge enables us to continually evolve mission-critical products to meet our customers’ evolving needs. We generally retain the intellectual property rights to products we develop which typically lasts for the life of the product.

REGULATORY MATTERS

Aircraft Regulation

In the United States, our aircraft products are required to comply with Federal Aviation Administration regulations governing production and quality systems, airworthiness and installation approvals, repair procedures and continuing operational safety. Internationally, similar requirements exist for airworthiness, installation and operational approvals. These requirements are generally administered by the national aviation authorities of each country and, in the case of Europe, coordinated by the European Aviation Safety Agency (EASA).

Environmental Matters

We maintain compliance with federal, state, and local laws and regulations relating to materials used in production and to the discharge of wastes, and other laws and regulations relating to the protection of the environment. The costs of such compliance at our Whippany, New Jersey facility are not material to our operations.

We are subject to federal and state requirements for protection of the environment, including those for the remediation of contaminated sites relating to predecessor entities and previously-owned subsidiaries. At various times, we have been identified as a potentially responsible party pursuant to the Comprehensive Environmental Response, Compensation, and Liability Act of 1980 (CERCLA), and analogous state environmental laws, for the cleanup of contamination resulting from past disposals of hazardous wastes at certain former facilities and at sites to which we, among others, sent wastes in the past. CERCLA requires potentially responsible persons to pay for the cleanup of sites from which there has been a release or threatened release of hazardous substances. Courts have interpreted CERCLA to impose strict joint and several liability on all persons liable for cleanup costs. As a practical matter, however, at sites where there are multiple potentially responsible persons, the costs of cleanup typically are allocated among the parties according to a volumetric or other standard.

6

Table of Contents

Where appropriate, we have sought contribution to remediation costs from other potentially responsible parties and made claims under available insurance policies. We also periodically assess the amount of reserves held for environmental liabilities for these sites based upon current information. While there is an inherent uncertainty in assessing the potential total cost to investigate and remediate a given site, we make a determination as to the reasonable cost of investigation and remediation of each site based upon the information available to us at that time. Furthermore, the remediation efforts for a particular site may take place over a number of years and therefore a significant portion of the expenses represented by these reserves may not be incurred for some time. Factors that affect the actual liability for these sites include changes in federal and state environmental laws resulting in more stringent remediation requirements and actual operating results from remediation efforts which vary from estimated results.

Information concerning our specific environmental liabilities and reserves is contained in Note 13 of our “Notes to Consolidated Financial Statements” contained elsewhere in this report.

ADDITIONAL INFORMATION

We maintain a website at http://www.breeze-eastern.com. Our annual report on Form 10-K, quarterly reports on Form 10-Q, current reports on Form 8-K, and amendments to those reports, which we file with the Securities and Exchange Commission (SEC) are available on our web site, free of charge, as soon as reasonably practicable after they are electronically filed with or furnished to the SEC. Information that can be accessed through our website is not incorporated by reference in this Report and, accordingly, readers should not consider such information to be part of this Report. The reports noted above may also be obtained at the SEC’s public reference room at 100 F Street, NE, Washington, DC 20549. The SEC also maintains a web site at www.sec.gov that contains reports, proxy statements, and information regarding SEC registrants, including Breeze-Eastern.

| ITEM 1A. | RISK FACTORS |

An investment in our common stock involves risk. You should carefully consider the following risk factors in addition to other information in this Annual Report on Form 10-K before purchasing our common stock. The risks and uncertainties described below are those that we currently deem to be material and that we believe are specific to our company and our industry. In addition to these risks, our business may be subject to risks currently unknown to us. If any of these or other risks actually occurs, our business may be adversely affected, the trading price of our common stock may decline and you may lose all or part of your investment.

Risks Associated with our Business and/or Industry

A substantial amount of our revenue is derived from the U.S. Government, Finmeccanica SpA, United Technologies Corporation and Transaero Inc.; a termination or reduction in the volume of business with any of these customers would have a material adverse effect on our revenue and profits.

Approximately 29%, 22%, 12% and 11% of our consolidated net sales in fiscal 2012 were to the U.S. Government (direct), United Technologies Corporation, Finmeccanica SpA, and Transaero Inc., respectively. These sales are made principally for the benefit of the military services of the U.S. Department of Defense and defense organizations of other countries and are affected by, among other things, budget authorization and appropriation processes. In the event that defense expenditures are reduced for products we manufacture or services we provide and are not offset by revenues from additional foreign sales, new programs, or products or services that we currently manufacture or provide, we may experience a reduction in our revenues and earnings and a material adverse effect on our business, financial condition, and results of operations. Further, there can be no assurance that our significant customers will continue to buy our products and services at current or increased levels.

We depend heavily on government contracts that may not be fully funded or may be terminated, and the failure to receive funding or the termination of one or more of these contracts could reduce our sales and increase our costs.

Sales to the U.S. Government and its prime contractors and subcontractors represent a significant portion of our business. In fiscal 2012, sales under U.S. Government contracts represented approximately 63% of our total sales. Sales to foreign governments represented approximately 14% of our total sales. We expect that the

7

Table of Contents

percentage of our revenues from government contracts will continue to be substantial in the future. Government programs can be structured into a series of individual contracts. The funding of these programs is generally subject to annual congressional appropriations, and congressional priorities are subject to change. In addition, Congress may reduce expenditures for defense programs or terminate such programs any time. A decline in government expenditures or redirection of government funding may result in a reduction in the volume of contracts awarded to us. We have resources applied to specific government contracts and if any of those contracts were terminated, we may incur substantial costs redeploying those resources.

As a U.S. Government contractor, we are subject to a number of procurement rules and regulations and any non-compliance could subject us to fines, penalties or debarment.

We must comply with and are affected by laws and regulations relating to the award, administration, and performance of U.S. Government contracts. Government contract laws and regulations affect how we conduct business with our customers and, in some instances, impose added costs on our business. A violation of specific laws and regulations could result in fines and penalties, contract termination, or debarment from bidding on future contracts. These fines and penalties could be imposed for failing to follow procurement integrity and bidding rules, employing improper billing practices or otherwise failing to follow cost accounting standards, receiving or paying kickbacks, or filing false claims. We have been, and expect to continue to be, subjected to audits and investigations by government agencies. The failure to comply with the terms of government contracts could harm our business reputation and could also result in progress payments being withheld.

Our business could be adversely affected by a negative audit by the U.S. Government.

As a U.S. Government contractor, we are subject to routine audits and investigations by U.S. Government agencies, such as the Defense Contract Audit Agency (DCAA). These agencies review a contractor’s performance under its contracts, cost structure, and compliance with applicable laws, regulations, and standards. The DCAA also reviews the adequacy of a contractor’s compliance with its internal control systems and policies, including the contractor’s purchasing, property, estimating, compensation, and management information systems. Any costs found to be improperly allocated to a specific contract will not be reimbursed or must be refunded if already reimbursed. If an audit uncovers improper or illegal activities, we may be subject to civil and criminal penalties as well as administrative sanctions, which may include termination of contracts, forfeiture of profits, suspension of payments, fines, and suspension or prohibition from doing business with the U.S. Government. In addition, we could suffer serious reputational harm if allegations of impropriety were made against us.

The U.S. Government has the right to terminate or not renew any contract with us at any time and without notice. Any such action would have a material adverse effect on our results of operations.

In some instances, laws and regulations impose terms or rights that are more favorable to the government than those typically available to commercial parties in negotiated transactions. For example, the U.S. Government may terminate any government contract and, in general, subcontracts, at its convenience as well as for default based on performance. Upon termination for convenience of a fixed-price type contract, we normally are entitled to receive the purchase price for delivered items, reimbursement for allowable costs for work-in-process, and an allowance for profit on the contract or adjustment for loss if contract completion would have resulted in a loss. Upon termination for convenience of a cost-reimbursement contract, we normally are entitled to reimbursement of allowable costs plus a portion of the fee. Such allowable costs would normally include the cost to terminate agreements with our suppliers and subcontractors. The amount of the fee recovered, if any, is related to the portion of the work accomplished prior to termination and is determined by negotiation.

A termination arising from default could expose us to liability and have a material adverse effect on our ability to compete for future contracts and orders. In addition, on those contracts for which we are teamed with others and are not the prime contractor, the U.S. Government could terminate a prime contract under which we are a subcontractor, irrespective of the quality of our services as a subcontractor.

In addition, our U.S. Government contracts typically span one or more base years and multiple option years. The U.S. Government generally has the right to not exercise option periods and may not exercise an option period if the U.S. Government is not satisfied with our performance on the contract.

8

Table of Contents

The aircraft manufacturing industry is heavily regulated, and if we fail to comply with applicable requirements, our results of operations could suffer.

Governmental agencies throughout the world, including the U.S. Federal Aviation Administration, or the FAA, prescribe standards and qualification requirements for aircraft components, including virtually all aviation products. Specific regulations vary from country to country, although compliance with FAA requirements generally satisfies regulatory requirements in other countries. We include, with some of the products we sell to our aircraft manufacturing customers, documentation certifying that each part complies with applicable regulatory requirements and meets applicable standards of airworthiness established by the FAA or the equivalent regulatory agencies in other countries. In order to sell our products, we and the products we manufacture must also be certified by our individual OEM customers. If any of the material authorizations or approvals qualifying us to supply our products is revoked or suspended, then the sale of the subject product would be prohibited by law, which would have an adverse effect on our business, financial condition, and results of operations.

From time to time, the FAA or equivalent regulatory agencies in other countries propose new regulations or changes to existing regulations, which are usually more stringent than existing regulations. If these proposed regulations are adopted and enacted, we may incur significant additional costs to achieve compliance, which could have a material adverse effect on our business, financial condition, and results of operations.

Cancellations, reductions, or delays in customer orders may adversely affect our results of operations.

Our overall operating results are affected by many factors, including the timing of orders from large customers and the timing of expenditures to manufacture parts and purchase inventory in anticipation of future sales of products and services. A large portion of our operating expenses are relatively fixed. Cancellations, reductions, or delays in customer orders could have a material adverse effect on our business, financial condition, and results of operations.

Engineering product development delays or customer engineering product development contract cancellations may adversely affect our results of operations.

Our new product development requires up-front engineering research & development expenditures that impact current income and qualification units that are capitalized as intangible assets on the balance sheet. These engineering research & development expenditures may not result in future revenue-generating products or may not become technically viable as a result of pre-production qualification testing. These research & development expenditures are generally incurred as a part of awarded new product development for customers’ aerospace platforms. If the product being designed does not meet customer technical specifications or timely delivery needs, we may need to write-off capitalized qualification units and reimburse customers for their costs that result from our product delivery delay.

Our backlog is subject to reduction and cancellation at any time without notice, which could negatively impact our future revenues and results of operations.

Backlog represents products or services that our customers have committed by contract to purchase from us. Backlog as of March 31, 2012 was $111,184. Backlog is subject to fluctuations and is not necessarily indicative of future sales. The U.S. Government may unilaterally modify or cancel its contracts with us. In addition, under certain of our commercial contracts, our customers may unilaterally modify or terminate their orders at any time for their convenience. Accordingly, certain portions of our backlog can be cancelled or reduced at the option of the U.S. Government and commercial customers. Our failure to replace cancelled or reduced backlog could negatively impact our revenues and results of operations.

We are subject to competition from entities which could have a substantial impact on our business.

We compete in some markets with entities that are larger and have substantially greater financial and technical resources than us. Generally, competitive factors include design capabilities, product performance, delivery, and price. Our ability to compete successfully in such markets will depend on our ability to develop and

9

Table of Contents

apply technological innovations and to expand our customer base and product lines. In addition, the development and application of technological innovations may mandate an expenditure of significant capital which may not be recovered through future sales of products or services. There can be no assurance that we will continue to successfully compete in any or all of the businesses discussed above. Our failure to compete successfully or to invest in technology where there is no recovery through product sales could have a materially adverse effect on our profitability.

Our potential tax benefits from net operating loss carry forwards are subject to a number of risks.

We have federal and state net operating loss carry forwards (“NOLs”) of approximately $9,023 and $489, respectively. Our NOLs may be used to offset future taxable income through their respective expiration dates and thereby reduce or eliminate our federal income taxes otherwise payable. If we do not generate adequate taxable earnings, some or all of our net operating loss carry forwards may not be realized. Additionally, changes to the federal income tax laws also could impact its ability to use the NOLs. The risks to realizing the tax benefit from NOLs are discussed in additional detail in Note 5 of our financial statements contained elsewhere in this report.

We are subject to liability under environmental laws.

Our business and facilities are subject to numerous federal, state, and local laws and regulations relating to the use, manufacture, storage, handling, and disposal of hazardous materials and other waste products. Environmental laws generally impose liability for investigation, remediation, and removal of hazardous materials and other waste products on property owners and those who dispose of materials at waste sites whether or not the waste was disposed of legally at the time in question. We are currently addressing environmental remediation at certain former facilities, and we have been named as a potentially responsible party along with other organizations in a number of environmental clean-up sites and may be named in connection with future sites. We are required to contribute to the costs of the investigation and remediation and have taken reserves in our financial statements for future costs deemed probable and estimable for these costs. Although we have estimated and reserved for future environmental investigation and remediation costs, the final resolution of these liabilities may significantly vary from our estimates and could potentially have an adverse effect on our results of operations and financial position. Our contingencies associated with environmental matters are described in Note 13 of “Notes to Consolidated Financial Statements” which is included elsewhere in this report.

Our sales to foreign countries expose us to risks and adverse changes in local legal, tax, and regulatory schemes.

In fiscal 2012, 37% of our consolidated sales were to customers outside the United States. We expect international export sales to continue to contribute to our earnings for the foreseeable future. The export sales are subject in varying degrees to risks inherent in doing business outside the United States. Such risks include, without limitation:

| • | The possibility of unfavorable circumstances arising from host country laws or regulations; Actual or anticipated fluctuations in our operating results; |

| • | Potential negative consequences from changes to significant taxation policies, laws, or regulations; changes in market valuations of other similarly situated companies; |

| • | Changes in tariff and trade barriers and import or export licensing requirements; and |

| • | Political or economic instability, insurrection, civil disturbance, or war. |

Government regulations could limit our ability to sell our products outside the United States and otherwise adversely affect our business.

In fiscal 2012, approximately 24% of our sales were subject to compliance with the United States Export Administration regulations. Our failure to obtain the requisite licenses, meet registration standards or comply with other government export regulations would hinder our ability to generate revenues from the sale of our products outside the United States. Compliance with these government regulations may also subject us to

10

Table of Contents

additional fees and operating costs. The absence of comparable restrictions on competitors in other countries may adversely affect our competitive position. In order to sell our products in European Union countries, we must satisfy certain technical requirements. If we are unable to comply with those requirements with respect to a significant quantity of our products, our sales in Europe would be restricted. Doing business internationally also subjects us to numerous U.S. and foreign laws and regulations, including, without limitation, regulations relating to import-export control, technology transfer restrictions, foreign corrupt practices and anti-boycott provisions. Failure by us or our sales representatives or consultants to comply with these laws and regulations could result in administrative, civil or criminal liabilities and could, in the extreme case, result in suspension or debarment from government contracts or suspension of our export privileges, which would have a material adverse effect on us.

While we believe our control systems are effective, there are inherent limitations in all control systems, and misstatements due to error or fraud may occur and not be detected.

We continue to take action to assure compliance with the internal controls, disclosure controls, and other requirements of the Sarbanes-Oxley Act of 2002. Our management, including our Chief Executive Officer and Chief Financial Officer, cannot guarantee that our internal controls and disclosure controls will prevent all possible errors or all fraud. A control system, no matter how well conceived and operated, can provide only reasonable, not absolute, assurance that the objectives of the control system are met. In addition, the design of a control system must reflect the fact that there are resource constraints, and the benefit of controls must be relative to their costs. Because of the inherent limitations in all control systems, no system of controls can provide absolute assurance that all control issues and instances of fraud, if any, within the Company have been detected. These inherent limitations include the realities that judgments in decision-making can be faulty and that breakdowns can occur because of simple error or mistake. Further, controls can be circumvented by individual acts of some persons, by collusion of two or more persons, or by management override of the controls. The design of any system of controls also is based in part upon certain assumptions about the likelihood of future events, and there can be no assurance that any design will succeed in achieving its stated goals under all potential future conditions. Over time, a control may become inadequate because of changes in conditions or the degree of compliance with policies or procedures may deteriorate. Because of inherent limitations in a cost-effective control system, misstatements due to error or fraud may occur and may not be detected.

The terms of our credit agreement may restrict our current and future operating and financial flexibility.

The credit agreement that is in effect with respect to our debt includes covenants that, among other things, restrict our ability to:

| • | engage in mergers, consolidations and asset dispositions; |

| • | redeem or repurchase stock; |

| • | create, incur, assume or guarantee additional indebtedness; |

| • | create, incur, assume or permit any liens on any asset; |

| • | make loans and investments; |

| • | engage in transactions with affiliates; |

| • | enter into sale and leaseback transactions; |

| • | issue additional shares of our capital stock; |

| • | change our organizational documents; and |

| • | change the nature of our business. |

Our credit agreement also contains covenants that require us to:

| • | maintain a leverage ratio of consolidated total debt to consolidated EBITDA not to exceed 2.50:1.00; and |

| • | maintain a fixed charge coverage ratio of at least 1.25:1.00. |

11

Table of Contents

We may be unable to comply with the covenants under our credit agreement in the future. A failure to comply with the covenants under our credit agreement could result in an event of default. In the event of a default our lender could elect to declare all borrowings, accrued and unpaid interest and other fees outstanding, due and payable, and require us to apply all of our available cash to repay these borrowings.

We are subject to financing and interest rate exposure risks that could adversely affect our business and operating results.

Changes in the availability, terms and cost of capital, increases in interest rates or a reduction in credit rating could cause the cost of doing business to increase, limit the ability to fund the development of products, and place us at a competitive disadvantage. The current contraction in credit markets could impact our ability to finance our operations.

Our operations are conducted at a single location.

The risk that substantial impairment of our facility as a consequence of a natural disaster or other event could have a material adverse effect on operations.

We depend on component availability, subcontractor performance, and key suppliers to manufacture and deliver our products and services.

We are dependent upon the delivery of component parts by suppliers and, to some extent, the assembly of components and subsystems used by us in manufacturing our products in a timely and satisfactory manner and to remain in full compliance with applicable terms and conditions. We are generally subject to specific procurement requirements, which may, in effect, limit the suppliers and subcontractors we may utilize. In some instances, we are dependent on sole-source suppliers. If any of these suppliers or subcontractors fails to meet our needs, the development of alternatives could cause delays and increased costs in meeting customer requirements. While we may enter into long-term or volume purchase agreements with certain suppliers and take other actions to ensure the availability of needed materials, components and subsystems, we cannot be sure that such items will be available in the quantities we require, if at all. If we experience a material supplier or subcontractor problem, the ability to satisfactorily and timely meet customer obligations could be negatively impacted, which could result in reduced sales, termination of contracts, and damage to our reputation and customer relationships. We could also incur additional costs in addressing such a problem. Any of these events could have a negative impact on our results of operations and financial condition.

Our operating results and financial condition may be adversely impacted by the current worldwide economic conditions.

We currently generate operating cash flows, which combined with access to the credit markets, provides discretionary funding capacity. However, current uncertainty in the global economic conditions resulting from the recent disruption in credit markets poses a risk to the overall economy that could impact consumer and customer demand for our products, as well as our ability to manage normal commercial relationships with our customers, suppliers, and creditors. If the current economic situation deteriorates significantly, our business could be negatively impacted, including such areas as reduced demand for our products from a slow-down in the general economy, or supplier or customer disruptions resulting from tighter credit markets.

Our future growth and continued success is dependent upon retaining key employees.

Our success is dependent upon the efforts of our senior management personnel and our ability to attract and retain other highly qualified management personnel. We face competition for management from other companies and organizations, and therefore may not be able to retain our existing management personnel or fill new management positions or vacancies created by expansion or turnover at existing compensation levels. We have entered into change of control agreements with some members of senior management and have made efforts to reduce the effect of the loss of senior management personnel through management succession planning. The loss of senior managers could have a material and adverse effect on our business. In addition, competition for qualified technical personnel in our industry is intense, and management believes that our future growth and success will depend upon the ability to attract, train, and retain such personnel.

12

Table of Contents

Our profitability could be negatively affected if we fail to maintain satisfactory labor relations.

Approximately 29% of our workforce is employed under a collective bargaining agreement with the United Auto Workers (UAW), which from time to time is subject to renewal and negotiation. Although we have historically enjoyed satisfactory relations with both our unionized and non-unionized employees, if we are subject to labor actions, we may experience an adverse impact on our operating results.

Our failure to adequately protect our intellectual property could have an adverse effect on our business.

Intellectual property is important to our success. We rely upon confidentiality procedures and contractual provisions to protect our business and proprietary technology. Our general policy is to enter into confidentiality agreements with our employees and consultants, and nondisclosure agreements with all other parties to whom we disclose confidential information. We may apply for legal protection for certain of our other intellectual property in the future. These patents, trademarks and any additional legal protection we may obtain in the future may be challenged by others or invalidated through administrative process or litigation. As a result, our means of protecting our proprietary technology and brands may be inadequate. Furthermore, despite our efforts, we may be unable to prevent third parties from infringing upon or misappropriating our intellectual property. Any such infringement or misappropriation could have a material adverse effect on our business, financial condition and results of operations.

Our business could be negatively impacted by security threats, including cybersecurity threats, and other disruptions.

As a defense contractor, we face various security threats, including cybersecurity threats to gain unauthorized access to sensitive information; threats to the security of our facility and infrastructure; and threats from terrorist acts. Although we utilize various procedures and controls to monitor these threats and mitigate our exposure to such threats, there can be no assurance that these procedures and controls will be sufficient in preventing security threats from materializing. If any of these events were to materialize, they could lead to losses of sensitive information, critical infrastructure, personnel or capabilities, essential to our operations and could have a material adverse effect on our reputation, financial position, results of operations, or cash flows.

Cybersecurity attacks in particular are evolving and include but are not limited to, malicious software, attempts to gain unauthorized access to data, and other electronic security breaches that could lead to disruptions in mission critical systems, unauthorized release of confidential or otherwise protected information and corruption of data. These events could damage our reputation and lead to financial losses from remedial actions, loss of business or potential liability.

We use estimates when competing for contracts. Variances between actual and estimates could affect our profitability and overall financial position.

The competitive bidding process requires judgment relative to assessing risks, estimating contract revenues and costs, and making assumptions for schedule and technical issues. Due to the size and nature of many of our contracts, the estimation of total revenues and costs at completion is complicated and subject to many variables. For example, assumptions have to be made regarding the length of time to complete the contract because costs also include expected increases in wages and prices for materials. Similarly, assumptions have to be made regarding the future impact of efficiency initiatives and cost reduction efforts. Incentives, awards, price escalations, or penalties related to performance on contracts are considered in estimating revenue and profit rates and are recorded when there is sufficient information to assess anticipated performance. Because of the significance of the judgments and estimation processes described above, it is possible that materially different amounts could be obtained if different assumptions were used or if the underlying circumstances were to change. Changes in underlying assumptions, circumstances, or estimates may have a material adverse effect upon future period financial reporting and performance.

Risks Related to our Common Stock

Our common stock is thinly traded and subject to volatility.

Although our common stock is traded on the NYSE MKT (formerly NYSE Amex), it may remain relatively illiquid, or “thinly traded,” which can increase volatility in the share price and make it difficult for investors to

13

Table of Contents

buy or sell shares in the public market without materially affecting the quoted share price. Further, investors seeking to buy or sell a certain quantity of our shares in the public market may be unable to do so within one or more trading days. If limited trading in our stock continues, it may be difficult for holders to sell their shares in the public market at any given time at prevailing prices.

The prevailing market price of our common stock may fluctuate significantly in response to a number of factors, some of which are beyond our control, including the following:

| • | Actual or anticipated fluctuations in operating results; |

| • | Changes in market valuations of other similarly situated companies; |

| • | Announcements by us or our competitors of significant technical innovations, contracts, acquisitions, strategic partnerships, joint ventures, or capital commitments; |

| • | Additions or departures of key personnel; |

| • | Future sales of common stock; |

| • | Any deviations in net revenues or in losses from levels expected by the investment community; |

| • | Trading volume fluctuations; and |

| • | Business pressures on any of our large shareholders resulting from their holdings in other unrelated businesses. |

Our share ownership is highly concentrated.

Our directors, officers, and principal stockholders, and certain of their affiliates, beneficially own approximately 63% of our common stock and will continue to have significant influence over the outcome of all matters submitted to the stockholders for approval, including the election of our directors.

We have adopted a shareholder rights plan which could make it more difficult for a third-party to acquire the Company.

We adopted a shareholders rights plan which is intended to protect us from efforts to obtain control of the Company that are inconsistent with the best interests of the Company and its stockholders. The rights will be exercisable ten days following the earlier of the public announcement that a stockholder has acquired 10% or more of our common stock without Board approval or the announcement of a tender offer which results in the ownership of 10% or more of our common stock. The rights also will become exercisable if a person or group that already owns 10% or more of the Company’s common stock, without Board approval, acquires any additional shares (other than pursuant to the Company’s employee benefit plans). If the rights become exercisable, all rights holders (other than the person triggering the rights) will be entitled to acquire Company securities at a substantial discount. Because the rights may substantially dilute the stock ownership of a person or group attempting to take over the Company without the approval of the Board of Directors, the rights plan could make it more difficult for a third-party to acquire the Company or a significant percentage of the outstanding capital stock, without first negotiating with the Board of Directors.

We do not anticipate paying dividends in the foreseeable future.

Any payment of cash dividends in the future will depend upon our earnings (if any), financial condition and capital requirements. We do not have any plans at this time to pay dividends in the foreseeable future. Accordingly, any potential investor who anticipates the need for current dividends from its investment should not purchase any of our securities.

| ITEM 1B. | UNRESOLVED STAFF COMMENTS |

None.

14

Table of Contents

| ITEM 2. | PROPERTIES |

The following table sets forth certain information concerning our sole operating facility as of March 31, 2012:

| Location |

Use of Premises |

Owned or Leased |

Sq. Ft | |||||||

| Whippany, New Jersey |

Executive offices and manufacturing plant |

Leased | 115,335 | |||||||

In February, 2008, we sold our headquarters and manufacturing facility located in Union, New Jersey. The sale agreement and amended lease agreement permitted us to lease the facility through May 1, 2010, pending our relocation to a new site. In May, 2009, we executed a 10-year lease, at market terms, for a facility in Whippany, New Jersey, which is better suited to our current and expected future needs. We completed our relocation to the Whippany site in the first quarter of fiscal 2011 and no longer maintain a facility in Union, New Jersey.

Our current business has only been conducted at our previous Union, New Jersey and current Whippany, New Jersey facilities. The properties in Pennsylvania, New York, and New Jersey were operated by one or more of our predecessor affiliates or parent company, TransTechnology Corporation. Our contingencies associated with environmental liabilities are discussed in Note 13 of “Notes to Consolidated Financial Statements” contained elsewhere in this report.

We also own properties in Saltzburg, Pennsylvania and Irvington, New Jersey that are carried on the books at zero value and are not used in operations.

We also own a property in Glen Head, New York which is not used in our operations and is subject to a sale agreement at a price of $4,000. This property is carried on our books as an asset held for sale for $3,800, which includes estimated disposal costs. Closing on the property is subject to the buyer receiving development approvals and us completing environmental obligations and reviews. The buyer has indicated to us its intent to build residential housing on the property and has been engaged in the lengthy process of securing the municipal approvals necessary to redevelop this industrial site for residential purposes.

| ITEM 3. | LEGAL PROCEEDINGS |

We are engaged in various legal proceedings incidental to our business. Our management, after taking into consideration information provided by our outside legal counsel, believes that these matters will have no material effect on our consolidated financial position or the results of operations or cash flows in future periods.

We are subject to federal and state requirements for protection of the environment, including those for discharge of hazardous materials and remediation of contaminated sites. As a result, we are a party to or have our former property subject to various lawsuits or proceedings involving environmental protection matters. Due in part to their complexity and pervasiveness, such requirements have resulted in us being involved with related legal proceedings, claims, and remediation obligations. The extent of our financial exposure cannot in all cases be reasonably estimated at this time. For information regarding these matters, including current estimates of the amounts that we believe are required for remediation or clean-up to the extent estimable, see Note 13 in the “Notes to Consolidated Financial Statements” contained elsewhere in this report.

| ITEM 4. MINE | SAFETY DISCLOSURES |

None.

15

Table of Contents

| ITEM 5. MARKET | FOR REGISTRANT’S COMMON EQUITY, RELATED STOCKHOLDER MATTERS, AND ISSUER PURCHASES OF EQUITY SECURITIES |

Our common stock, par value $0.01, is listed for trading on the NYSE MKT (formerly NYSE Amex) under the trading symbol BZC. The following table sets forth the range of high and low sale prices of our common stock as reported on the NYSE MKT for the periods indicated.

| High | Low | |||||||

| Fiscal 2011 |

||||||||

| First Quarter |

$ | 6.88 | $ | 5.82 | ||||

| Second Quarter |

7.20 | 5.76 | ||||||

| Third Quarter |

7.25 | 6.58 | ||||||

| Fourth Quarter |

9.29 | 6.96 | ||||||

| Fiscal 2012 |

||||||||

| First Quarter |

$ | 11.19 | $ | 8.36 | ||||

| Second Quarter |

11.13 | 8.16 | ||||||

| Third Quarter |

9.25 | 7.90 | ||||||

| Fourth Quarter |

8.95 | 7.77 | ||||||

Holders

As of May 7, 2012, the number of stockholders of record of the Company’s common stock was 1,305. On May 7, 2012, the closing sales price of a share of common stock was $8.30 per share.

Dividends

We have not paid any cash dividends on our common stock since fiscal 2001. We currently intend to retain earnings, if any, to fund our operations and reduce debt. The payment of future cash dividends, if any, will be reviewed periodically by our Board of Directors and will depend upon the results of operations, financial condition, contractual and legal restrictions and other factors the board of directors deem relevant.

16

Table of Contents

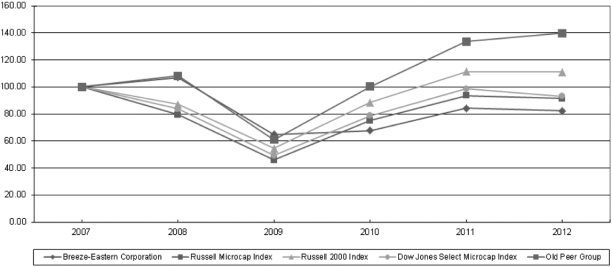

Stock Performance Graph

The following Performance Graph and related information shall not be deemed “soliciting material” or to be “filed” with the Securities and Exchange Commission, nor shall such information be incorporated by reference into any future filing under the Securities Act of 1933 or Securities Exchange Act of 1934, each as amended, except to the extent that the Company specifically incorporates such information by reference into such filing.

This stock performance graph compares the Company’s total cumulative stockholder return on its common stock during the period from April 1, 2007 through March 31, 2012, with the cumulative return on a Peer Issuer Group Index. Beginning in fiscal 2012, we established a new peer group to reflect better comparability based on the Company’s market capitalization. The previous peer group in previous filings includes Curtiss-Wright Corp., Ducommun Inc., HEICO Corp., Ladish Co. Inc., Moog Inc., SIFCO Industries Inc., and Triumph Group, Inc. The graph assumes a $100 investment on April 1, 2007.

Comparison of 5 Year Cumulative Total Return

Assumes Initial Investment of $100

March 2012

| Years Ended March 31, | ||||||||||||||||||||||||

| 2007 | 2008 | 2009 | 2010 | 2011 | 2012 | |||||||||||||||||||

| Breeze-Eastern Corporation |

$ | 100.00 | $ | 106.88 | $ | 64.72 | $ | 67.76 | $ | 84.13 | $ | 82.36 | ||||||||||||

| Russell Microcap Index |

100.00 | 79.31 | 45.79 | 75.07 | 93.52 | 91.48 | ||||||||||||||||||

| Russell 2000 Index |

100.00 | 87.01 | 54.38 | 88.50 | 111.34 | 111.12 | ||||||||||||||||||

| Dow Jones Select Microcap Index |

100.00 | 83.62 | 49.29 | 78.76 | 98.66 | 93.15 | ||||||||||||||||||

| Old Peer Group |

100.00 | 108.24 | 61.03 | 100.28 | 133.52 | 139.77 | ||||||||||||||||||

17

Table of Contents

| ITEM 6. SELECTED | FINANCIAL DATA |

The following table sets forth selected financial data for each of the five years in the period ended March 31, 2012 (amounts in thousands, except per share amounts). This financial data should be read together with our consolidated financial statements and related notes, Management’s Discussion and Analysis of Financial Condition and Results of Operations, and other financial data appearing elsewhere in this report.

| Years Ended March 31, | ||||||||||||||||||||

| 2012 | 2011 | 2010 | 2009 | 2008 | ||||||||||||||||

| Results from Operations |

||||||||||||||||||||

| Net sales |

$ | 84,942 | $ | 78,200 | $ | 69,027 | $ | 75,427 | $ | 75,974 | ||||||||||

| Gross profit |

35,214 | 30,952 | 20,651 | 30,090 | 32,517 | |||||||||||||||

| Operating income (loss) |

7,022 | 9,457 | (6,723 | ) | 11,353 | 13,027 | ||||||||||||||

| Interest expense |

396 | 694 | 891 | 1,462 | 3,395 | |||||||||||||||

| Loss on debt extinguishment |

— | — | — | 551 | — | |||||||||||||||

| Gain on sale of facility |

— | — | — | — | 6,811 | |||||||||||||||

| Net income (loss) |

3,776 | 5,026 | (6,043 | ) | 5,760 | 9,442 | ||||||||||||||

| Net income (loss) per share: |

||||||||||||||||||||

| Basic |

$ | 0.40 | $ | 0.53 | $ | (0.64 | ) | $ | 0.62 | $ | 1.01 | |||||||||

| Diluted |

0.39 | 0.53 | (0.64 | ) | 0.61 | 1.00 | ||||||||||||||

| Shares outstanding at year-end |

9,490 | 9,429 | 9,397 | 9,365 | 9,339 | |||||||||||||||

| Financial Position |

||||||||||||||||||||

| Total assets |

$ | 79,851 | $ | 78,148 | $ | 76,108 | $ | 76,705 | $ | 76,190 | ||||||||||

| Working capital |

39,805 | 32,376 | 25,188 | 32,322 | 28,544 | |||||||||||||||

| Long-term debt |

8,215 | 11,500 | 14,786 | 18,071 | 19,849 | |||||||||||||||

| Stockholders’ equity |

38,152 | 33,433 | 27,820 | 33,327 | 26,892 | |||||||||||||||

| Book value per share at year end |

4.02 | 3.55 | 2.96 | 3.56 | 2.88 | |||||||||||||||

| Ratios |

||||||||||||||||||||

| Current ratio |

3.41 | 3.11 | 2.72 | 2.84 | 2.48 | |||||||||||||||

| ITEM 7. MANAGEMENT’S | DISCUSSION AND ANALYSIS OF FINANCIAL CONDITION AND RESULTS OF OPERATIONS |

This Management’s Discussion and Analysis of Financial Condition And Results of Operation and other parts of this Annual Report on Form 10-K contain forward-looking statements that involve risks and uncertainties. All forward-looking statements included in this Annual Report on Form 10-K are based on information available to us on the date hereof, and except as required by law, we assume no obligation to update any such forward-looking statements. Our actual results may differ materially from those anticipated in these forward-looking statements as a result of a number of factors, including those set forth under the caption “Risk Factors” beginning on page 6 of this report and elsewhere herein. The following should be read in conjunction with our annual financial statements, including the notes thereto, contained elsewhere in this report. All references to years in this Management’s Discussion and Analysis of Financial Condition and Results of Operations refer to the fiscal year ended March 31 of the indicated year unless otherwise specified.

OVERVIEW

We design, develop, manufacture, sell, and service sophisticated engineered mission equipment for specialty aerospace and defense applications. We have long been recognized a leading global designer, manufacturer, service provider, and supplier of mission-critical rescue hoists. We also manufacture weapons-handling systems, cargo winches, cargo hook systems and tie-down equipment. Our products are designed to be efficient and reliable in extreme operating conditions and are used to complete rescue operations and military insertion/extraction operations, move and transport cargo, and load weapons onto aircraft and ground-based launching systems.

18

Table of Contents

Our primary strategy is to continue to expand our position as a market leader in the design, development, and service of sophisticated mission equipment for specialty aerospace and defense applications. We intend to maintain our position by continuing to focus on our principal customers and on geographic areas where we have developed our reputation as a premier provider of aircraft hoist and lift equipment, and by expanding both our customer base and product lines. We believe that continued spending on research and development to improve the quality of our product offerings and remaining on the leading edge of technological advances in our chosen markets is also crucial to our business. In this regard, we will continue to commit resources to product research and development.

Our business is affected by global economic and geo-political conditions. In particular, as the U.S. military activity in Iraq and Afghanistan is reduced, reductions and redirection of United States defense spending could have a material impact on revenues and earnings in future periods. Similarly, if European governments significantly reduce their military and other government spending, that could have a material impact on revenues and earnings in future periods. However, we believe that the primary missions that drive procurement and the use of our equipment (search and rescue, special operations, and cargo delivery) will continue to get a relatively high funding priority.

As our OEM customers’ development timetables have been extended, we have experienced corresponding product development schedule slippage and increased investment. We have not seen, nor do we currently anticipate, any program cancellations and still expect all of our current product development projects to lead to production and aftermarket services which support our current and expected investments. As an example, developing the Airbus A400M military transport aircraft has taken longer than was originally expected, but flight testing is now underway, and we expect revenues related to this project starting in calendar 2013. Our engineering expense is reported net of reimbursements from Airbus, and we anticipate gross engineering costs to continue at a high level.

CRITICAL ACCOUNTING POLICIES

The preparation of our consolidated financial statements is in conformity with accounting principles generally accepted in the United States of America and requires us to make estimates, judgments, and assumptions. We believe that the estimates, judgments, and assumptions upon which we rely are reasonable based upon information available at the time that these estimates, judgments, and assumptions are made. These estimates, judgments, and assumptions can affect the reported amounts of assets and liabilities as of the date of the financial statements, as well as the reported amounts of revenues and expenses during the periods presented. To the extent that there are material differences between these estimates, judgments, or assumptions and actual results, our financial statements will be affected. We believe the following critical accounting policies are affected by significant estimates, assumptions, and judgments used in the preparation of our consolidated financial statements.

Inventory. We purchase parts and materials to assemble and manufacture components for use in our products and for use by our engineering and repair and overhaul departments. The decision to purchase a set quantity of a particular material is influenced by several factors including current and projected cost, future estimated availability, production lead time, existing and projected contracts to produce certain items, and the estimated needs for our overhaul and repair business.

We value inventories using the lower of cost or market on a first-in, first-out (FIFO) basis. We reduce the carrying amount of these inventories to net realizable value based on our assessment of inventory that is considered excess or obsolete based on the backlog of sales orders and historical usage. Since all of our products are produced to meet specific customer requirements, the reserve focus is on purchased and manufactured parts.

We relocated our headquarters and manufacturing facility in the fourth quarter of fiscal 2010. As a part of this relocation and prior to our move to the new location, we determined that approximately $2,198 of inventory would not be moved to the new location because it would cost more to relocate and restock this inventory than its current or projected future market value or utility. These items were physically scrapped before the end of the fiscal year.

19

Table of Contents

Because the amount of the inventory scrapped was higher than expected, as evidenced by the dollar value of inventory scrapped being higher than the existing inventory reserves, we reassessed the methodology previously used for estimating inventory obsolescence and determined that a modification was warranted. The previous method for estimating inventory obsolescence was based on estimates of future potential usage based on current usage for each item in inventory.

We determined that a better method of estimating inventory obsolescence is to identify specific items based on the age of inventory and to establish a general reserve based on annual purchases. Analyzing inventory by age, based on the purchase date for raw materials or the completion date for manufactured items, showed little movement once items aged five years, and historical trends showed that 1.1% of purchases would eventually be scrapped. Accordingly, we established a 100% reserve for all inventory on hand at March 31, 2010 that was purchased or manufactured more than five years earlier and for 1.1% of purchases for each of the last five years. Therefore, each $1,000 of inventory purchased will result in an increase of $11 in inventory reserves. Management periodically reviews this methodology to ensure it is reasonably accurate and will make future adjustments as necessary through current earnings.

In fiscal 2010, the change in methodology resulted in a non-cash adjustment to increase the inventory reserves by $3,311, including the $2,198 discussed above, during the fourth quarter of fiscal 2010. The total amount of the inventory reserve change for fiscal 2010 was $3,533 which included increases to inventory reserves in earlier quarters of fiscal 2010. In fiscal 2011 we increased the inventory reserve by $569, and in fiscal 2012 we increased the inventory reserve by $496.

Inventories are discussed further in Notes 1 and 2 of “Notes to Consolidated Financial Statements” contained elsewhere in this report.

Qualification Units. We capitalize as intangible assets engineering qualification units, which are pre-production product units that are tested as a part of becoming qualified on an aircraft. Aerospace government regulations stipulate that a product cannot be installed on aircraft until it becomes qualified. The qualification testing destroys the units, making them unsalable, and as a result the units become intangible assets.

Engineering qualification units are ultimately expensed. There can be an extended timing difference between incurring the engineering qualification unit cost and realizing the resulting revenues. Thus, immediately expensing engineering qualification units would not best represent the project economics. Under the matching principle, we amortize the qualification unit costs to expense over future equipment unit shipments. If product testing results in engineering changes, then the technically obsolete qualification units are expensed in the current period. During fiscal 2012, we expensed $3,165 of costs for impairment of qualification units that became technically obsolete.

Revenue Recognition. Revenue related to equipment sales is recognized when title and risk of loss have been transferred, collectability is reasonably assured, and pricing is fixed or determinable. Revenue related to repair and overhaul sales is recognized when the related repairs or overhaul are complete and the unit is shipped to the customer. Revenue related to contracts in which we are reimbursed for costs incurred plus an agreed upon profit are recorded as costs are incurred.

Environmental Reserves. We provide for a best estimate of environmental liability reserves when, after consultation with internal and external counsel and other environmental consultants, we determine that a liability is both probable and estimable. In many cases, we do not fix or cap the liability for a particular site when first recorded. Factors that affect the recorded amount of the liability in future years include our participation percentage due to a settlement by, or bankruptcy of, other potentially responsible parties, a change in the environmental laws resulting in more stringent requirements, a change in the estimate of future costs that will be incurred to remediate the site, and changes in technology related to environmental remediation. Current estimated exposures related to environmental claims are discussed further in Note 13 of our “Notes to Consolidated Financial Statements” contained elsewhere in this report.

Deferred Tax Asset. See Note 5 of “Notes to Consolidated Financial Statements” contained elsewhere in this report.

Stock-Based Compensation. See Note 9 of “Notes to Consolidated Financial Statements” contained elsewhere in this report.

20

Table of Contents

RESULTS OF OPERATIONS

Fiscal 2012 Compared with Fiscal 2011

| Fiscal Year Ended | Increase/ (Decrease) |

|||||||||||||||

| March 31, | March 31, | |||||||||||||||

| 2012 | 2011 | $ | % | |||||||||||||

| Products |

$ | 64,147 | $ | 58,086 | $ | 6,061 | 10.4 | % | ||||||||

| Services |

20,795 | 20,114 | 681 | 3.4 | ||||||||||||

|

|

|

|

|

|

|

|||||||||||

| Net sales |

84,942 | 78,200 | 6,742 | 8.6 | ||||||||||||

|

|

|

|

|

|

|

|||||||||||

| Products |

36,488 | 33,434 | 3,054 | 9.1 | ||||||||||||

| Services |

13,240 | 13,814 | (574 | ) | (4.2 | ) | ||||||||||

|

|

|

|

|

|

|

|||||||||||

| Cost of sales |

49,728 | 47,248 | 2,480 | 5.2 | ||||||||||||

|

|

|

|

|

|

|

|||||||||||