Attached files

| file | filename |

|---|---|

| EX-99.1 - EX-99.1 - NOVANTA INC | novt-ex991_6.htm |

| 8-K - 8-K - NOVANTA INC | novt-8k_20210718.htm |

Announcement Novanta to acquire ATI July 19, 2021 Exhibit 99.2

2 Safe Harbor Statement The statements in this presentation that relate to the anticipated ATI acquisition, including that the acquisition is expected to close in the third quarter of 2021; sources of funding for the ATI acquisition; the benefits of the ATI acquisition; future financial results; business opportunities; and future events or performance are forward-looking statements that involve risks and uncertainties, including risks associated with our ability to make and integrate acquisitions and realize expected benefits and synergies, business and economic conditions, failure to comply with the Food and Drug Administration regulations, customer and/or supplier contract cancellations, manufacturing risks, competitive factors, ability to successfully introduce new products, uncertainties pertaining to customer orders, demand for products and services, growth and development of markets for the Company's products and services, risks associated with the COVID-19 pandemic and other events outside our control, and other risks identified in our filings made with the Securities and Exchange Commission (“SEC”). Actual results, events and performance may differ materially from those anticipated in these forward-looking statements. Readers are cautioned not to place undue reliance on these forward-looking statements, which speak only as of the date of this presentation. The Company disclaims any obligation to update these forward-looking statements as a result of developments occurring after the date of this presentation. Readers are encouraged to refer to the risk disclosures included in the Company’s Form 10-K for the year ended December 31, 2020 and subsequent quarterly filings with the SEC, as applicable. Please see “Safe Harbor and Forward-Looking Information” in the Company’s most recent quarterly earnings release on Form 8-K for more information. The Company neither updates nor confirms any guidance regarding the future operating results of the Company which may have been given prior to this presentation.

ATI OVERVIEW 3 Confidential and Proprietary

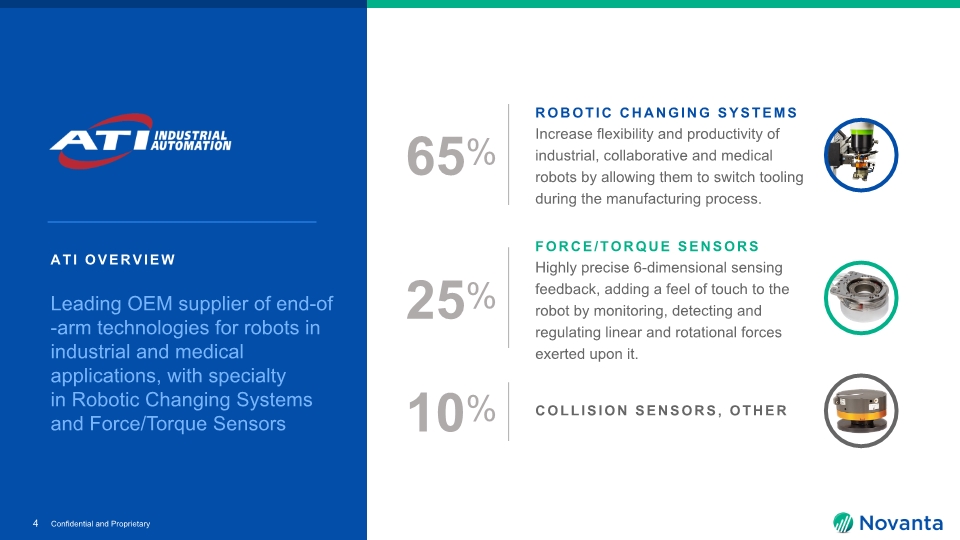

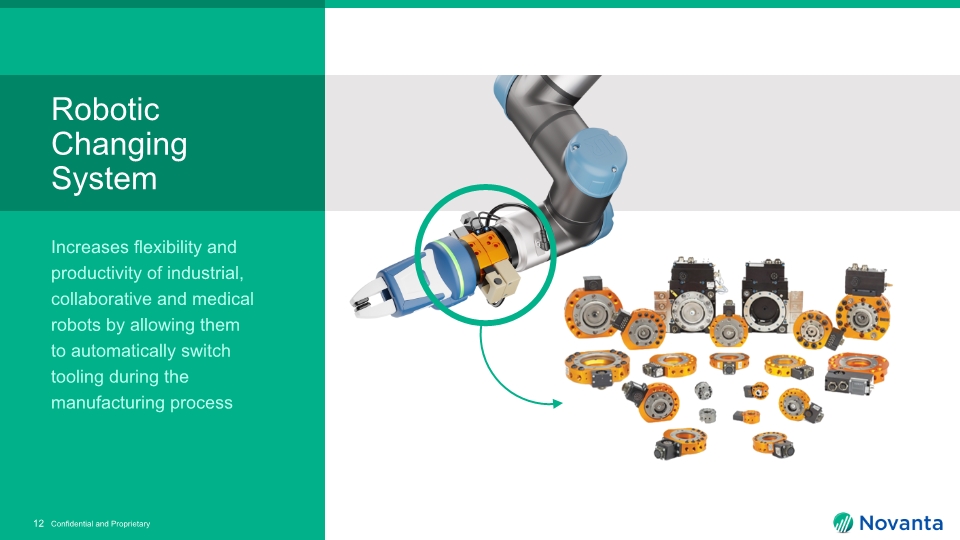

Leading OEM supplier of end-of-arm technologies for robots in industrial and medical applications, with specialty in Robotic Changing Systems and Force/Torque Sensors ATI OVERVIEW Robotic Changing SysteMs Increase flexibility and productivity of industrial, collaborative and medical robots by allowing them to switch tooling during the manufacturing process. 65% 25% 10% Force/Torque Sensors Highly precise 6-dimensional sensing feedback, adding a feel of touch to the robot by monitoring, detecting and regulating linear and rotational forces exerted upon it. Collision Sensors, OTHER 4 Confidential and Proprietary

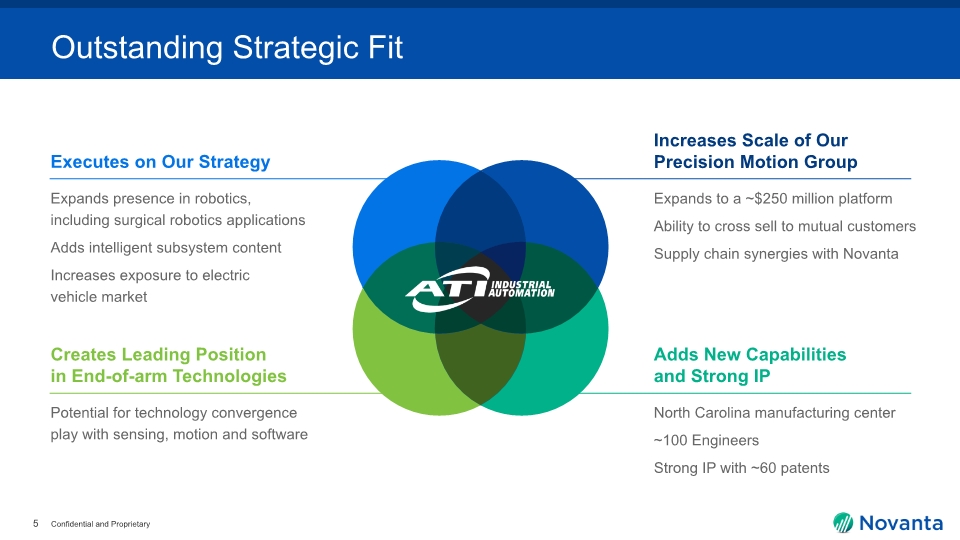

Creates Leading Position in End-of-arm Technologies Potential for technology convergence play with sensing, motion and software Executes on Our Strategy Expands presence in robotics, including surgical robotics applications Adds intelligent subsystem content Increases exposure to electric vehicle market Increases Scale of Our Precision Motion Group Expands to a ~$250 million platform Ability to cross sell to mutual customers Supply chain synergies with Novanta Adds New Capabilities and Strong IP North Carolina manufacturing center ~100 Engineers Strong IP with ~60 patents 5 Outstanding Strategic Fit

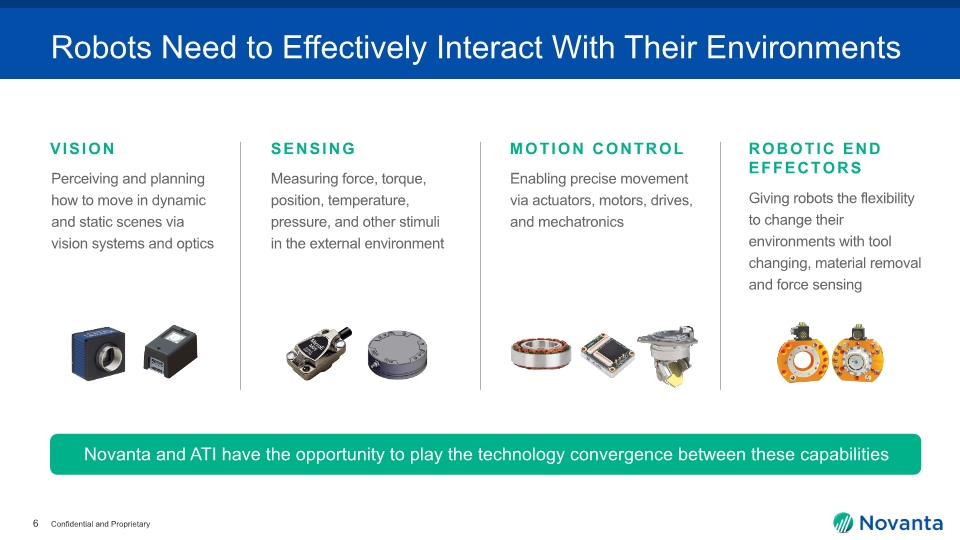

Perceiving and planning how to move in dynamic and static scenes via vision systems and optics Measuring force, torque, position, temperature, pressure, and other stimuli in the external environment Enabling precise movement via actuators, motors, drives, and mechatronics VISION SENSING MOTION CONTROL Giving robots the flexibility to change their environments with tool changing, material removal and force sensing ROBOTIC END EFFECTORS 6 Novanta and ATI have the opportunity to play the technology convergence between these capabilities Robots Need to Effectively Interact With Their Environments

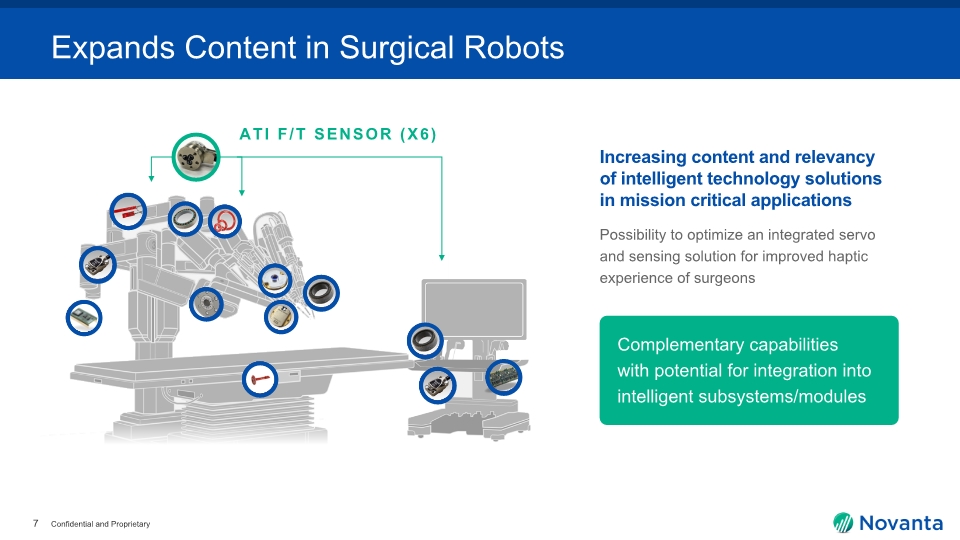

7 Expands Content in Surgical Robots ATI F/T Sensor (x6) Increasing content and relevancy of intelligent technology solutions in mission critical applications Possibility to optimize an integrated servo and sensing solution for improved haptic experience of surgeons

8 Strong Presence in Robotics Robotics is a key enabler to Factory 4.0 goals of automating to improve safety, quality and productivity Portfolio of highly engineered, intelligent end-effector technologies Well-positioned to capture growth in automation and robotics Differentiated technologies, which could be further enhanced through Novanta’s offering

Headquartered outside of Raleigh, North Carolina 138,000 sq. ft. modern manufacturing facility Dedicated labs for R&D, Electronics, Mechanical Assembly, Sensor Calibration Long tenured technical workforce FACILITY >350 employees, with ~100 engineers Strong emphasis on Continuous Improvement and Lean (many employees have yellow belt) High commonality with Novanta manufacturing capabilities and know-how Close collaboration with customer R&D and engineering teams US revenue ~45% of total sales CAPABILITIES Adds New Talent and Capabilities 9

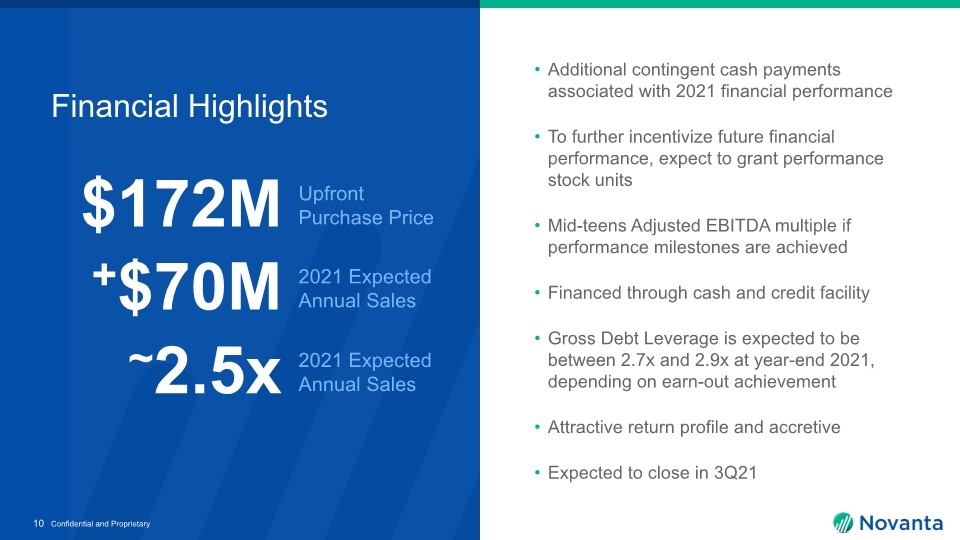

Additional contingent cash payments associated with 2021 financial performance To further incentivize future financial performance, expect to grant performance stock units Mid-teens Adjusted EBITDA multiple if performance milestones are achieved Financed through cash and credit facility Gross Debt Leverage is expected to be between 2.7x and 2.9x at year-end 2021, depending on earn-out achievement Attractive return profile and accretive Expected to close in 3Q21 $172M Upfront Purchase Price +$70M 2021 Expected Annual Sales ~2.5x 2021 Expected Annual Sales 10 Confidential and Proprietary Financial Highlights

Appendix 11

Increases flexibility and productivity of industrial, collaborative and medical robots by allowing them to automatically switch tooling during the manufacturing process Robotic Changing System 12 Confidential and Proprietary

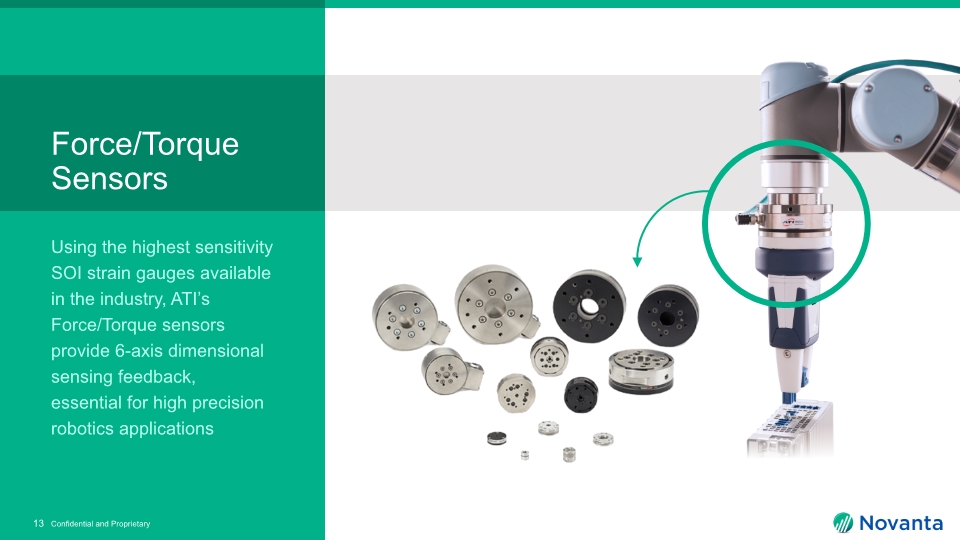

Using the highest sensitivity SOI strain gauges available in the industry, ATI’s Force/Torque sensors provide 6-axis dimensional sensing feedback, essential for high precision robotics applications Force/Torque Sensors 13 Confidential and Proprietary

Thank You