Attached files

| file | filename |

|---|---|

| 8-K - 8-K - Hi-Crush Inc. | a63015-earningsrelease8xk.htm |

| EX-99.1 - EXHIBIT 99.1 - Hi-Crush Inc. | exhibit991-earningsrelease.htm |

2ND QUARTER EARNINGS RELEASE AUGUST 6, 2015

Forward Looking Statements Some of the information included herein may contain forward-looking statements within the meaning of the federal securities laws. Forward- looking statements give our current expectations and may contain projections of results of operations or of financial condition, or forecasts of future events. Words such as “may,” “assume,” “forecast,” “position,” “predict,” “strategy,” “expect,” “intend,” “plan,” “estimate,” “anticipate,” “could,” “believe,” “project,” “budget,” “potential,” or “continue,” and similar expressions are used to identify forward-looking statements. They can be affected by assumptions used or by known or unknown risks or uncertainties. Consequently, no expected results of operations or financial condition or other forward-looking statements can be guaranteed. When considering these forward-looking statements, you should keep in mind the risk factors and other cautionary statements in Hi-Crush Partners LP’s (“Hi-Crush”) reports filed with the Securities and Exchange Commission (“SEC”), including those described under Item 1A, “Risk Factors” of Hi-Crush’s Annual Report on Form 10-K for the fiscal year ended December 31, 2014 and any subsequently filed Quarterly Report on Form 10-Q. Actual results may vary materially. You are cautioned not to place undue reliance on any forward-looking statements. You should also understand that it is not possible to predict or identify all such factors and should not consider the risk factors in our reports filed with the SEC or the following list to be a complete statement of all potential risks and uncertainties. Factors that could cause our actual results to differ materially from the results contemplated by such forward-looking statements include: the volume of frac sand we are able to sell; the price at which we are able to sell frac sand; the outcome of any pending litigation; changes in the price and availability of natural gas or electricity; changes in prevailing economic conditions; and difficulty collecting receivables. All forward-looking statements are expressly qualified in their entirety by the foregoing cautionary statements. Hi-Crush’s forward-looking statements speak only as of the date made and Hi-Crush undertakes no obligation to update or revise its forward-looking statements, whether as a result of new information, future events or otherwise. 2

Comparison to Prior Quarters 3 $ in 000s Q2 2015 Q1 2015 Q4 2014 Revenues $83,958 $102,111 $130,929 EBITDA $19,195 $29,581 $44,567 Earnings per unit (basic) $0.31 $0.61 $0.85 Earnings per unit (diluted) $0.31 $0.60 $0.85 Sales volumes (tons) 1,190,156 1,195,343 1,481,914 Production costs per ton $13.45 $16.28 $15.72 Distributions per unit1 $0.475 $0.675 $0.675 1 Represents distributions declared for the quarter. Volumes held flat despite further pressure on pricing in quarter • Decline in frac sand demand in Q2 2015 due to reduced well completions despite strong sand intensity trends • Working with our customers and vendors to lower delivered cost at terminal locations • Preserving capital and protecting our strong balance sheet for a recovery

Balance Sheet Remains Strong 4 $ in 000s As of June 30, 2015 Cash $ 6,923 Revolver1 $ 37,500 Term loan2 195,830 Other notes payable 3,676 Total debt $ 237,006 Net debt $ 230,083 Net debt / LTM EBITDA 1.68x Revolver availability1 $ 104.8 million 1 Revolving credit facility: $104.8mm available at L+2.75% ($150mm capacity less $37.5mm of borrowings and $7.7mm of LCs); includes accordion feature to increase capacity to $200mm 2 Senior secured term loan: $200mm original face value at L+3.75%; rated B2 and BB- by Moody’s and Standard & Poor’s, respectively; includes accordion feature to increase capacity to $300mm Low leverage Strong liquidity Financial flexibility

Low Levels of Well Completions Felt in 2nd Quarter 5 Outlook for distribution increases dependent on length and depth of downturn • Return to growth in distributions to unitholders is a key priority • Distribution aligned to maintain near-term coverage (1) (2) (3) (3) (3) (3) 1 Actual coverage ratio was 1.0x including $0.525 per unit distribution paid on 4.25 million units issued in April 2014 2 Excludes impact of the August 15, 2014 conversion of Class B units to common units and related distribution paid upon conversion 3 Excludes the portion of DCF allocable to the Incentive Distribution Rights held by our Sponsor 1.12x 1.14x 1.24x 1.38x 1.15x 1.35x 1.40x 1.31x 1.00x 0.95x 0.0x 0.2x 0.4x 0.6x 0.8x 1.0x 1.2x 1.4x $ 0 $ 5 $ 10 $ 15 $ 20 $ 25 $ 30 $ 35 Q1 '13 Q2 '13 Q3 '13 Q4 '13 Q1 '14 Q2 '14 Q3 '14 Q4 '14 Q1 '15 Q2 '15 $mm Coverage (x) Declared Distributions (left axis) Coverage ratio (right axis)

Industry Backdrop

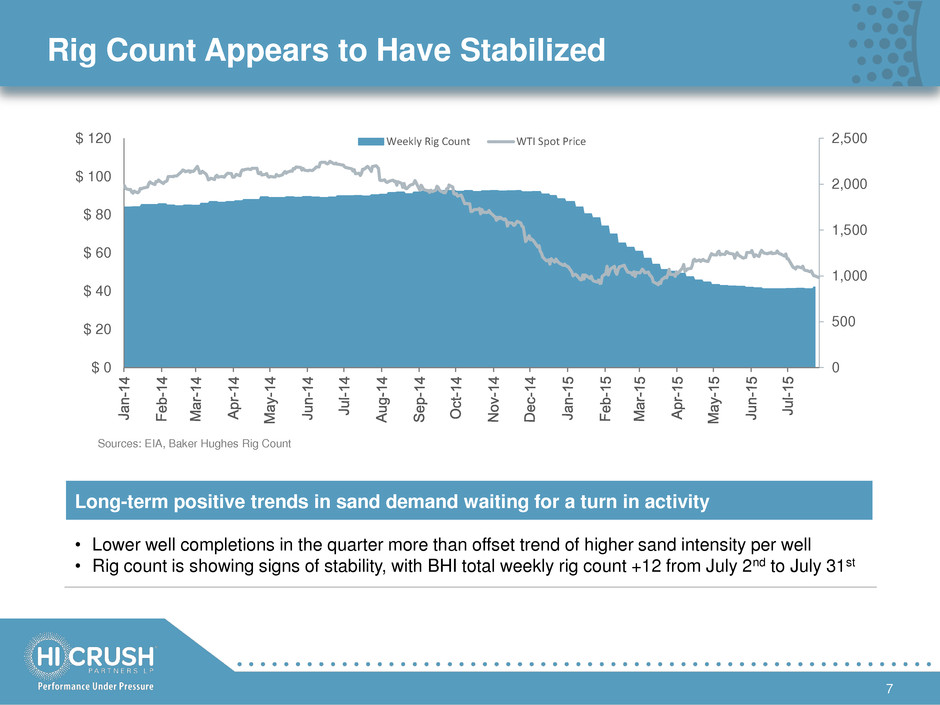

Rig Count Appears to Have Stabilized 7 Sources: EIA, Baker Hughes Rig Count Long-term positive trends in sand demand waiting for a turn in activity • Lower well completions in the quarter more than offset trend of higher sand intensity per well • Rig count is showing signs of stability, with BHI total weekly rig count +12 from July 2nd to July 31st 0 500 1,000 1,500 2,000 2,500 $ 0 $ 20 $ 40 $ 60 $ 80 $ 100 $ 120 Weekly Rig Count WTI Spot Price

Timing & Magnitude of Recovery Remain Unclear 8 From 2014 peak to end of July 2015, U.S. land rig count dropped ~55% • First 25 weeks of 2015 saw consecutive weekly declines in rig count (down 980+ rigs) • July 31st BHI rig count +2% above 2015 YTD weekly low set on July 17th Competition among oilfield service providers fierce • Some pressure pumpers bidding jobs at cash costs or below break-even to maintain market share • Lack of service company job visibility contributing to logistics & production planning challenges Inventory of drilled but uncompleted wells contributing to temporary drop in proppant demand • Limited number of well capitalized operators deferring completions for better economics • DUC inventory may be worked off at a slower pace but presents upside for frac sand demand

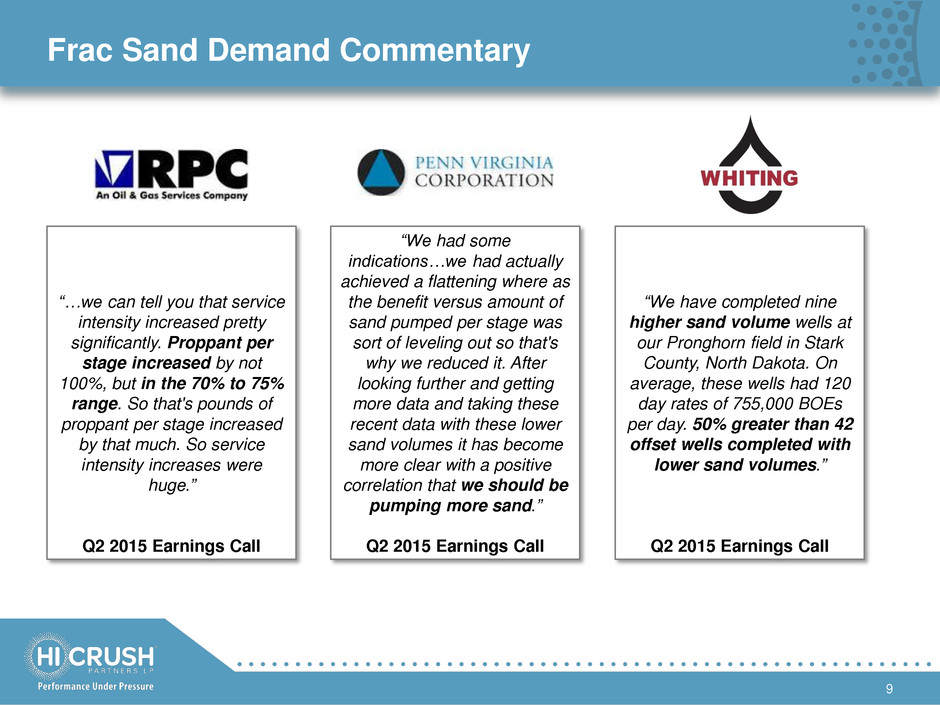

Frac Sand Demand Commentary 9 “…we can tell you that service intensity increased pretty significantly. Proppant per stage increased by not 100%, but in the 70% to 75% range. So that's pounds of proppant per stage increased by that much. So service intensity increases were huge.” Q2 2015 Earnings Call “We had some indications…we had actually achieved a flattening where as the benefit versus amount of sand pumped per stage was sort of leveling out so that's why we reduced it. After looking further and getting more data and taking these recent data with these lower sand volumes it has become more clear with a positive correlation that we should be pumping more sand.” Q2 2015 Earnings Call “We have completed nine higher sand volume wells at our Pronghorn field in Stark County, North Dakota. On average, these wells had 120 day rates of 755,000 BOEs per day. 50% greater than 42 offset wells completed with lower sand volumes.” Q2 2015 Earnings Call

Fundamentals Still Support Long-Term Demand 10 Targeting of shale & unconventional reservoirs Increased use of horizontal drilling More wells per rig Longer laterals More stages per lateral foot More proppant per stage Strong long-term proppant demand

Current Environment 11 Consolidation, Efficiencies & Pricing Coordination • Oilfield service providers seeking efficiencies through supply chain enhancements • Sand suppliers working with customers to lower all-in pricing at well head through better origin/destination matching, increasing unit trains, & more in-basin services • Service providers continuing to consolidate vendors down to key partners, capable of delivering large quantities, efficiently and on time Potential of Refrac Activity • Potential for refracs in early stages • Could accelerate pace of proppant demand increase during a market recovery • Operators testing results using comparable amounts of frac sand as original frac job Positive Forward Signals • Weekly total rig count up 12 from July 2nd to July 31st (horizontal rigs up 7) • Waiting to see the potential decrease in drilled but uncompleted wells backlog

Managing the Downturn 12 Temporary measures to address contract customer market factors • Offered pricing discounts to certain contract customers, in certain circumstances in exchange for additional term and/or volume • Extended price discounts through 2015; time-based discounts revert back to contract terms Spent majority of 2015 capex budget of $35-55 million in 1H 2015 • Two new terminal facilities being developed in DJ and Permian • DJ Basin terminal set to open later in 2015, with new Permian terminal in Spring 2016 Building Blair facility at Sponsor • Construction on pace for end of 2015 completion • Located directly on Canadian National Railway Focused on internal cost reductions • Key focus is on managing logistics costs • Optimizing production to lowest cost plant while factoring in freight and logistics costs • Reducing headcount for more efficient operations • Pushing for discounts and efficiency from vendors and suppliers

Hi-Crush Operations

Hi-Crush’s Competitive Advantages 14 Long-Term Contracted Cash Flow 4.01 average years remaining Low-Cost Producer 7.5 million tons of 20/100 capacity, including Sponsor’s Whitehall facility2 Long-Lived High Quality Reserves Long-term Northern White frac sand demand Prime Portfolio of Assets Key strategic network in Marcellus / Utica; expanding in Permian and DJ Basin Focused Strategy Strong balance sheet, leverage ratio below 1.7x1 Visible Avenues to Growth Future drop downs of Sponsor’s Whitehall and Blair facilities 1 As of June 30, 2015 2 Sponsor’s Blair facility will bring 20/100 capacity to 10.5 million tons

Hi-Crush Ranks Among Largest in Industry 15 #1 in Wisconsin #4 in World Largest production capacity of frac sand in Wisconsin Fourth largest production capacity of frac sand in the world2 Source: Internal estimates 7.5 million tons current capacity1 1 20/100 mesh capacity, including Sponsor’s Whitehall facility 2 With completion of Blair at the Sponsor level, total capacity will rank 2nd in world

Logistics Flexibility Critical 16 Sandstone Formations Sponsor’s Whitehall Facility • Access to all major U.S. oil and gas basins • Direct loading and unloading of unit trains • Multiple in-basin terminals across Marcellus and Utica shales and one located in Permian Basin • 5,400 railcars under management (~2,900 owned/leased by Hi-Crush as of 6/30/15) • Strong relationships with multiple Class-1 and short- line railroads HCLP Sand Facilities Sponsor Sand Facility Existing Distribution Terminals Basin Play Terminals Under Development1 1 New Permian Basin and DJ Basin terminals expected to be operational early 2016 and late 2015, respectively Sponsor Sand Facility Under Development

Our Business Model – Q2 2015 Operating Results 17 Sold FOB plant direct to customer Sand delivered to terminal via rail Customer truck delivers to well site Sold at terminal to customer Freight costs Class-1 and short-line rail Production cost/ton: $13.45 Tons sold: 1,190,156 Terminal locations 42% 58% FOB Plant Terminal 42% 58% FOB Plant Terminal

A Strategy for the Current Market 18 • Northern White in highest demand relative to other proppant types • Migration to in-basin sales as a way for customers to lower supply chain costs • Organic growth of distribution network • Dropdown of Sponsor’s Whitehall facility when the timing is right • Blair facility being constructed by Sponsor ‒ Positioned to capture long-term market share during recovery • Focused on managing costs while preserving flexibility

Levers for Further Performance 19

Financial Results

2nd Quarter 2015 Summary 21 Unaudited Condensed Consolidated Statements of Operations (Amounts in thousands, except per unit amounts) Three Months Ended June 30, 2015 2014 Revenues $ 83,958 $ 82,724 Cost of goods sold (including depreciation, depletion and amortization) 63,698 43,859 Gross profit 20,260 38,865 Operating costs and expenses: General and administrative expenses 5,749 6,679 Accretion of asset retirement obligation 84 66 Income from operations 14,427 32,120 Other income (expense): Interest expense (2,979 ) (2,315 ) Net income 11,448 29,805 Loss (income) attributable to non-controlling interest 2 (264 ) Net income attributable to Hi-Crush Partners LP $ 11,450 $ 29,541 Earnings per unit: Common units - basic $ 0.31 $ 0.77 Subordinated units - basic $ 0.31 $ 0.77 Common units - diluted $ 0.31 $ 0.75 Subordinated units - diluted $ 0.31 $ 0.75

YTD 2015 Summary 22 Unaudited Condensed Consolidated Statements of Operations (Amounts in thousands, except per unit amounts) Six Months Ended June 30, 2015 2014 (a) Revenues $ 186,069 $ 153,302 Cost of goods sold (including depreciation, depletion and amortization) 132,337 88,025 Gross profit 53,732 65,277 Operating costs and expenses: General and administrative expenses 11,967 13,104 Accretion of asset retirement obligation 167 123 Income from operations 41,598 52,050 Other income (expense): Interest expense (6,296 ) (3,725 ) Net income 35,302 48,325 Income attributable to non-controlling interest (167 ) (412 ) Net income attributable to Hi-Crush Partners LP $ 35,135 $ 47,913 Earnings per unit: Common units - basic $ 0.92 $ 1.32 Subordinated units - basic $ 0.92 $ 1.32 Common units - diluted $ 0.91 $ 1.25 Subordinated units - diluted $ 0.91 $ 1.25 (a) Financial information has been recast to include the financial position and results attributable to Hi -Crush Augusta LLC.

2nd Quarter 2015 Summary 23 (a) Maintenance and replacement capital expenditures, including accrual for reserve replacement, were determined based on an estimated reserve replacement cost of $1.35 per ton produced and delivered during the period. Such expenditures include those associated with the replacement of equipment and sand reserves, to the extent that such expenditures are made to maintain our long-term operating capacity. The amount presented does not represent an actual reserve account or requirement to spend the capital. (b) The Partnership's historical financial information has been recast to consolidate Augusta for all periods presented. For purposes of calculating distributable cash flow attributable to Hi-Crush Partners LP, the Partnership excludes the incremental amount of recasted distributable cash flow earned during the periods prior to the acquisition by the Partnership on April 28, 2014 of substantially all of the remaining equity interests in Hi-Crush Augusta LLC (the "Augusta Contribution"). Three Months Ended June 30, 2015 2014 Reconciliation of distributable cash flow to net income: Net income $ 11,448 $ 29,805 Depreciation and depletion expense 4,035 2,428 Amortization expense 733 1,067 Interest expense 2,979 2,315 EBITDA $ 19,195 $ 35,615 Less: Cash interest paid (2,564 ) (2,010 ) Less: Loss (income) attributable to non-controlling interest 2 (264 ) Less: Maintenance and replacement capital expenditures, including accrual for reserve replacement (a) (1,120 ) (1,288 ) Add: Accretion of asset retirement obligation 84 66 Add: Unit based compensation 1,053 353 Distributable cash flow $ 16,650 $ 32,472 Adjusted for: Distributable cash flow attributable to Hi-Crush Augusta LLC, net of intercompany eliminations, prior to the Augusta Contribution (b) — (3,010 ) Distributable cash flow attributable to Hi-Crush Partners LP 16,650 29,462 Less: Distributable cash flow attributable to holders of incentive distribution rights — (2,453 ) Distributable cash flow attributable to common and subordinated unitholders $ 16,650 $ 27,009 Unaudited EBITDA and Distributable Cash Flow (in thousands)

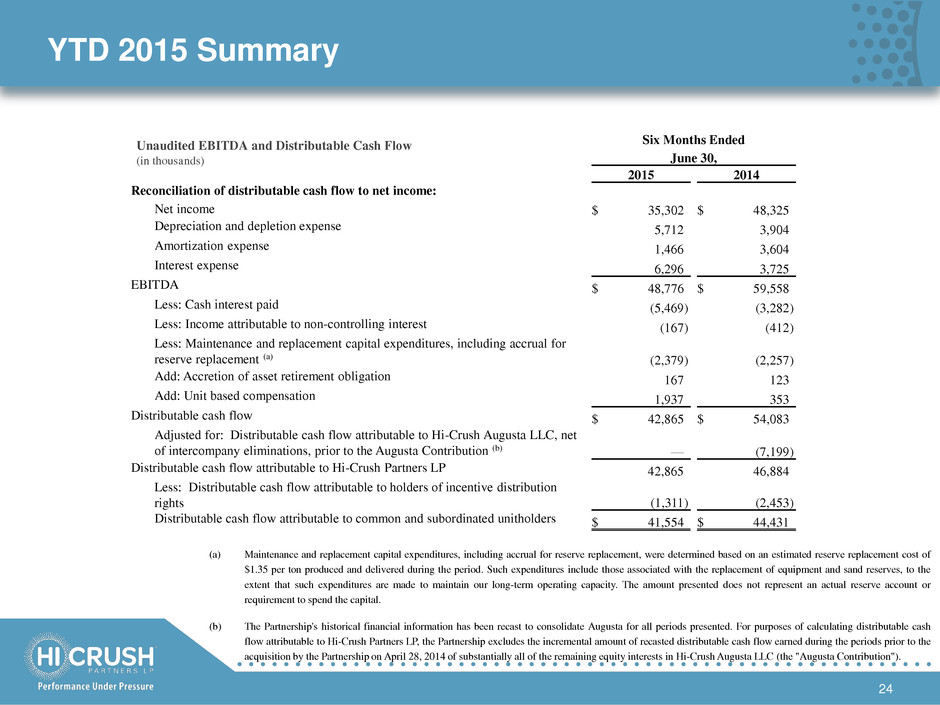

YTD 2015 Summary 24 (a) Maintenance and replacement capital expenditures, including accrual for reserve replacement, were determined based on an estimated reserve replacement cost of $1.35 per ton produced and delivered during the period. Such expenditures include those associated with the replacement of equipment and sand reserves, to the extent that such expenditures are made to maintain our long-term operating capacity. The amount presented does not represent an actual reserve account or requirement to spend the capital. (b) The Partnership's historical financial information has been recast to consolidate Augusta for all periods presented. For purposes of calculating distributable cash flow attributable to Hi-Crush Partners LP, the Partnership excludes the incremental amount of recasted distributable cash flow earned during the periods prior to the acquisition by the Partnership on April 28, 2014 of substantially all of the remaining equity interests in Hi-Crush Augusta LLC (the "Augusta Contribution"). Six Months Ended June 30, 2015 2014 Reconciliation of distributable cash flow to net income: Net income $ 35,302 $ 48,325 Depreciation and depletion expense 5,712 3,904 Amortization expense 1,466 3,604 Interest expense 6,296 3,725 EBITDA $ 48,776 $ 59,558 Less: Cash interest paid (5,469 ) (3,282 ) Less: Income attributable to non-controlling interest (167 ) (412 ) Less: Maintenance and replacement capital expenditures, including accrual for reserve replacement (a) (2,379 ) (2,257 ) Add: Accretion of asset retirement obligation 167 123 Add: Unit based compensation 1,937 353 Distributable cash flow $ 42,865 $ 54,083 Adjusted for: Distributable cash flow attributable to Hi-Crush Augusta LLC, net of intercompany eliminations, prior to the Augusta Contribution (b) — (7,199 ) Distributable cash flow attributable to Hi-Crush Partners LP 42,865 46,884 Less: Distributable cash flow attributable to holders of incentive distribution rights (1,311 ) (2,453 ) Distributable cash flow attributable to common and subordinated unitholders $ 41,554 $ 44,431 Unaudited EBITDA and Distributable Cash Flow (in thousands)