Attached files

| file | filename |

|---|---|

| 8-K - U. S. Premium Beef, LLC | es8k.htm |

|

Remodel improves product quality, consistency and plant efficiency National Beef |

|

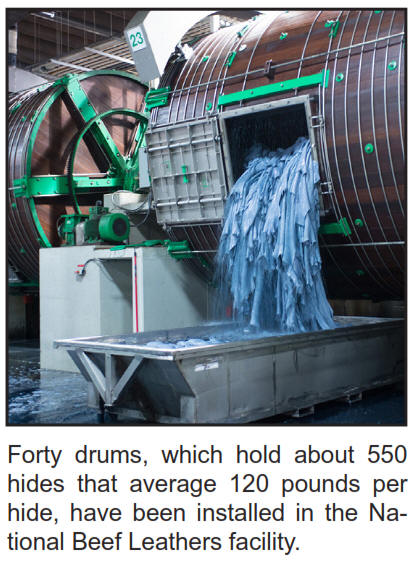

National Beef is nearing completion of a six year renovation of its National Beef Leathers tannery in St. Joseph, MO. “We’ve got some work to do on the final phase of this renovation, which has to do with hide folding and stacking machinery,” explains Carey Hoskinson, vice president and general manager of National Beef Leathers. “But in terms of equipment, processes and technology that enables us to produce consistent, high quality blue-tanned hides, we’re there today. “Our recipe for tanning is unique in the industry,” he points out. “For example, removing hair from the hides with minimal damage to the grain can be a big problem. Our process does a much better job of hair removal than conventional processes.” “In my opinion, this tannery is the best plant on the globe, as far as wet blue tanning,” Robert Hein, senior vice president of National Beef Leathers, adds. “The process we use, from when hides enter the plant through final packaging and shipment to the customer, is second to none. But we still have room to improve, especially in terms of the quality of hides that come to our facility.” (See Hide Quality is a Lifetime Event on page two.)

“We source all of our hides from our Dodge City and Liberal

processing plants and when we’re at full capacity, we should be able to process

60,000 hides per week,” Front start to finish, a hide spends between 50 and 55 hours in the tannery before being packaged in a unique container that provides up to a year in storage without loss of hide quality. That’s important when you consider that National Beef exports most of its hides to countries around the world including Italy, China, Korea, Tai- |

|

|

|

...continued on page 2 |

|

FY 2014 Annual Meeting To Be Held on March 27, 2015 U.S. Premium Beef’s fiscal year 2014 annual meeting will be held in Kansas City, MO, at the Kansas City Airport Hilton on Friday, March 27, 2015. A reception will be held on the evening of March 26 at the Airport Hilton. There are two positions on USPB’s Board of Directors up for election. Rex McCloy, Morse, TX and Jeff Sternberger, Ingalls, KS, currently hold these positions. Unitholders who want information on becoming a candidate for USPB’s Board should contact the our office at 866-877-2525. Applications are due December 27, 2014. Watch upcoming UPDATES for more information on the annual meeting.♦ Qualified Seedstock Suppliers Schedule Fall Sales The following USPB Qualified Seedstock Suppliers (QSS) will conduct sales during October through December. Go to USPB’s Qualified Custom Feedyards and Seedstock Suppliers link on our web page, then scroll down to the supplier you are interested in for sale times and locations.♦ |

||

|

Lyons Influence Feeder Calf Sales |

10/15 & 11/5 |

|

|

Heartland Simmental and Angus Heifer Sale |

10/26 |

|

|

Fink Beef Genetics Bull Sale |

|

10/29 |

|

Downey Ranch, Inc., Bull and Female Sale |

|

11/7 |

|

Kniebel Farms & Cattle, Inc., Bull and Female Sale 11/7 |

||

|

Dalebanks Angus Bull Sale |

|

11/22 |

|

Marshall & Fenner Female Sale |

|

12/5 |

|

In addition, the following USPB QSS members are selling bulls at private treaty during the Fall: Cow Camp, Inc., Dalebanks Angus, Inc., Gardiner Angus Ranch, Harms Plainview Ranch, McCurry Brothers Angus, Oleen Brothers.♦ Did You Know... üIf you have delivery rights you do not plan on using in delivery year 2015, which ends August 29, and would like USPB to help you get them leased to other producers, please call our office at 866.877.2525.♦ |

||

Reproduction of any part of this newsletter is expressly forbidden without written permission of U.S. Premium Beef.

|

National Beef Renovates Tannery... |

continued from page 1 |

“Branding costs the U.S. cattle and hide industry in excess of $200 million dollars per year,” Hein adds. “Moving brands to the hip would reduce that loss significantly. Between 70% and 80% of the hides we process carry at least one brand, so there’s room for improvement.”♦ |

||

|

wan, Vietnam, Indonesia, the Dominican Republic and Mexico. “Since there is no USDA grading system for hides, delivering hides that are consistently the quality our customers want, sorted and packaged so there are no surprises in every container, is what we have to do to compete in this market,” Hein points out. “Our reputation is what will enable us to grow this business. “Our upper end product goes into high quality brands like Coach purses, Timberland hiking boots, and BMW, Mercedes, Lexus and Chrysler upholstery,” Hein adds. “Because hide costs to our customers have gone up 70% in the last six years, it’s really important that we help them become more efficient. How we process, grade, sort, package and deliver a consistent product lets them spend less time at their facilities sorting and matching hides for their various needs. This facility enables us to produce the best wet blue tanned hides in the world.”♦ Hide Quality is a Lifetime Event “Producing high quality hides doesn’t just happen at the plant,” Carey Hoskinson, vice president and general manager of National Beef Leathers, says. “Scratches on hides from barb wire fences or facilities and even thorns on brush that cut a young calf’s hide, stay with that hide forever. Bites from parasites also damage the hide. And, muddy pens, especially when that mud freezes to the hide, causes damage as that frozen mud and manure is removed in the plant. “Probably one half of one percent of the hides that go into our packing plants never get to our tannery because of scarring and other damage which makes them a number 3 (lower quality) hide,” Hoskinson says. “We can’t do anything at the tannery to salvage them, so they get sold for a discounted price out of the packing plant. So having good facilities, parasite control and clean pens can really make a difference in hide quality.” And then there is branding. “Our hides can compete in the world market on a quality basis except for damage due to the branding that we do in the U.S.,” Robert Hein, senior vice president of National Beef Leathers, says. “I understand that producers aren’t going to stop branding, and in some states are required to brand, but it would make a significant difference if people used smaller brands and put them high on the hip area.

|

||||

|

BENCHMARK PERFORMANCE DATA TABLE |

||||

|

Base Grid Cattle Harvested in KS Plants 9/07/14 to 10/04/14 |

||||

|

(Numbers in Percent) |

Base Grid |

|||

|

All |

Top 25% |

|||

|

Yield |

64.25 |

64.84 |

||

|

Prime |

2.64 |

4.46 |

||

|

CH & PR |

71.41 |

78.87 |

||

|

CAB |

23.79 |

30.24 |

||

|

BCP |

18.17 |

19.07 |

||

|

Ungraded |

1.78 |

1.12 |

||

|

Hard Bone |

0.25 |

0.18 |

||

|

YG1 |

6.83 |

5.88 |

||

|

YG2 |

32.45 |

29.26 |

||

|

YG3 |

44.02 |

45.32 |

||

|

YG4 |

15.20 |

17.62 |

||

|

YG5 |

1.50 |

1.92 |

||

|

Light Weight |

0.24 |

0.18 |

||

|

Heavy Weight |

1.26 |

1.03 |

||

|

Average Grid Premiums/Discounts ($/Head) |

||||

|

Quality Grade |

$22.80 |

$36.72 |

||

|

Yield Benefit |

$22.80 |

$42.15 |

||

|

Yield Grade |

-$1.75 |

-$4.55 |

||

|

Out Weight |

-$2.02 |

-$1.64 |

||

|

Natural |

$2.83 |

$7.05 |

||

|

Total Premium |

$44.66 |

$79.73 |

||

Hoskinson notes. We’re almost

there right now but the completion of the last phase of our renovation will get

us there on a consistent basis.”

Hoskinson notes. We’re almost

there right now but the completion of the last phase of our renovation will get

us there on a consistent basis.”