Attached files

| file | filename |

|---|---|

| 8-K - Q1 2013 EARNINGS RELEASE 8K - Noranda Aluminum Holding CORP | q12013earningsreleaseform8k.htm |

| EX-99.3 - EXHIBIT 99.3 DIVIDEND PRESS RELEASE Q1 2013 - Noranda Aluminum Holding CORP | q12013dividendreleaseexhib.htm |

| EX-99.1 - EXHIBIT 99.1 Q1 2013 EARNINGS RELEASE - Noranda Aluminum Holding CORP | a2013q1earningsreleaseexhi.htm |

TM 1st Quarter 2013 Earnings Conference Call Noranda Aluminum Holding Corp April 24, 2013 10:00 AM Eastern / 9:00 AM Central

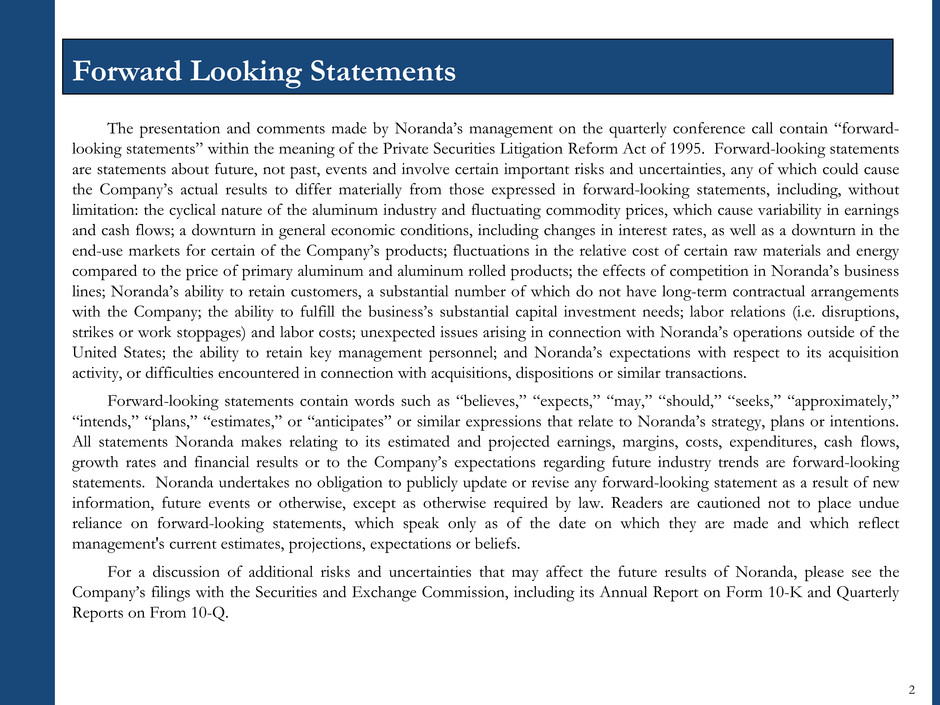

The presentation and comments made by Noranda’s management on the quarterly conference call contain “forward- looking statements” within the meaning of the Private Securities Litigation Reform Act of 1995. Forward-looking statements are statements about future, not past, events and involve certain important risks and uncertainties, any of which could cause the Company’s actual results to differ materially from those expressed in forward-looking statements, including, without limitation: the cyclical nature of the aluminum industry and fluctuating commodity prices, which cause variability in earnings and cash flows; a downturn in general economic conditions, including changes in interest rates, as well as a downturn in the end-use markets for certain of the Company’s products; fluctuations in the relative cost of certain raw materials and energy compared to the price of primary aluminum and aluminum rolled products; the effects of competition in Noranda’s business lines; Noranda’s ability to retain customers, a substantial number of which do not have long-term contractual arrangements with the Company; the ability to fulfill the business’s substantial capital investment needs; labor relations (i.e. disruptions, strikes or work stoppages) and labor costs; unexpected issues arising in connection with Noranda’s operations outside of the United States; the ability to retain key management personnel; and Noranda’s expectations with respect to its acquisition activity, or difficulties encountered in connection with acquisitions, dispositions or similar transactions. Forward-looking statements contain words such as “believes,” “expects,” “may,” “should,” “seeks,” “approximately,” “intends,” “plans,” “estimates,” or “anticipates” or similar expressions that relate to Noranda’s strategy, plans or intentions. All statements Noranda makes relating to its estimated and projected earnings, margins, costs, expenditures, cash flows, growth rates and financial results or to the Company’s expectations regarding future industry trends are forward-looking statements. Noranda undertakes no obligation to publicly update or revise any forward-looking statement as a result of new information, future events or otherwise, except as otherwise required by law. Readers are cautioned not to place undue reliance on forward-looking statements, which speak only as of the date on which they are made and which reflect management's current estimates, projections, expectations or beliefs. For a discussion of additional risks and uncertainties that may affect the future results of Noranda, please see the Company’s filings with the Securities and Exchange Commission, including its Annual Report on Form 10-K and Quarterly Reports on From 10-Q. Forward Looking Statements 2

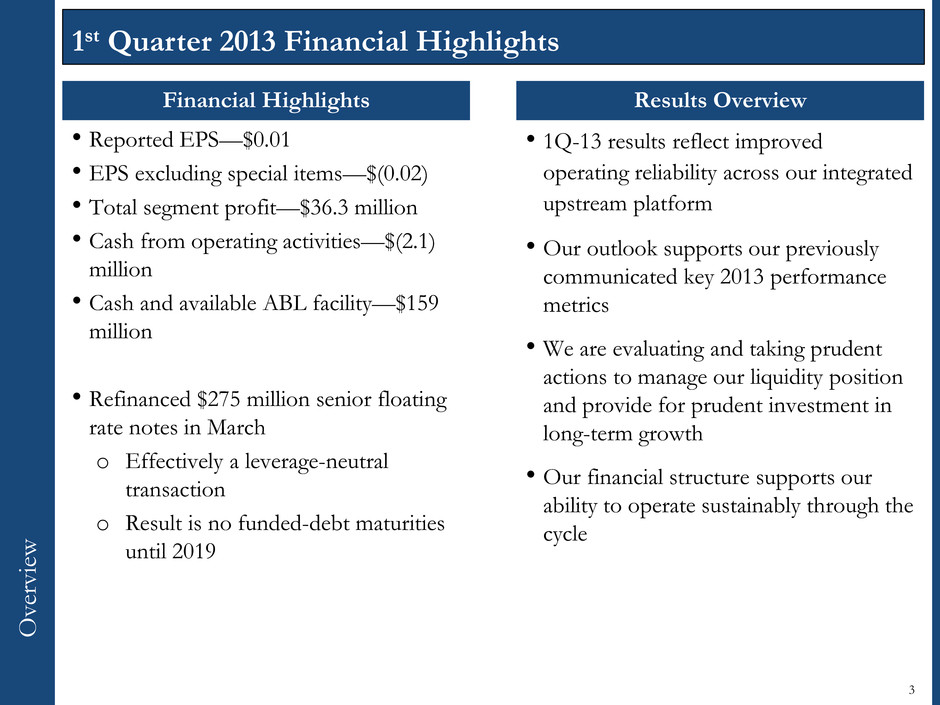

O v er v ie w Results Overview • 1Q-13 results reflect improved operating reliability across our integrated upstream platform • Our outlook supports our previously communicated key 2013 performance metrics • We are evaluating and taking prudent actions to manage our liquidity position and provide for prudent investment in long-term growth • Our financial structure supports our ability to operate sustainably through the cycle Financial Highlights • Reported EPS—$0.01 • EPS excluding special items—$(0.02) • Total segment profit—$36.3 million • Cash from operating activities—$(2.1) million • Cash and available ABL facility—$159 million • Refinanced $275 million senior floating rate notes in March o Effectively a leverage-neutral transaction o Result is no funded-debt maturities until 2019 1st Quarter 2013 Financial Highlights 3

260 288 289 271 261 276 0 50 100 150 200 250 300 350 Q4-11 Q1-12 Q2-12 Q3-12 Q4-12 Q1-13 K m ts CGA External SGA External SGA Intercompany 76 93 102 98 87 94 0 20 40 60 80 100 120 140 Q4-11 Q1-12 Q2-12 Q3-12 Q4-12 Q1-13 Po un ds in m ill io ns Primary Aluminum Shipments Bauxite Shipments 4 Quarterly Shipment Information Flat-Rolled Product Shipments 146 142 147 139 145 142 2 4 60 80 100 120 140 160 Q4-11 Q1-12 Q2- 2 Q3-12 Q4-12 Q1-13 Po un ds in m illi on s Value-Added External sow Intercompany Alumina Shipments 1,271 1,145 1,16 1,267 1,185 1,209 0 300 600 90 1,200 1,500 Q4-11 Q1-12 Q2-12 Q3-12 Q4-12 Q1-13 K m ts Internal ExternalD e man d

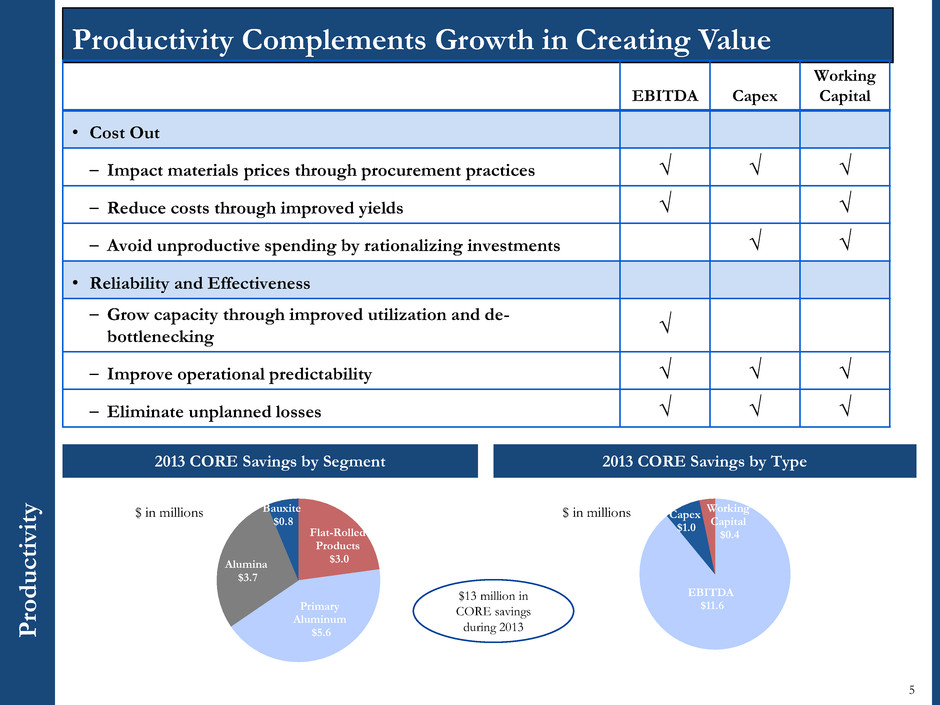

Productivity Complements Growth in Creating Value P rodu c ti v it y 5 EBITDA Capex Working Capital • Cost Out – Impact materials prices through procurement practices – Reduce costs through improved yields – Avoid unproductive spending by rationalizing investments • Reliability and Effectiveness – Grow capacity through improved utilization and de- bottlenecking – Improve operational predictability – Eliminate unplanned losses Flat-Rolled Products $3.0 Primary Aluminum $5.6 Alumina $3.7 Bauxite $0.8 Corporate $- $ in millions EBITDA $11.6 Capex $1.0 Working Capital $0.4 $ in millions 2013 CORE Savings by Segment 2013 CORE Savings by Type $13 million in CORE savings during 2013

Demand Factors • Projected consumption CAGR through 2017(1) – Global—5.9% with China; 3.7% outside China – United States—3.1% • Global, emerging market drivers(2) – Strong working age population income growth – Low base level of aluminum consumption per capita – Urbanization & Industrialization • US demand drivers(2) – Auto demand–growth & increased sector penetration – Building & construction recovery – Return of working age population growth Supply Factor and Macroeconomic Factors • Supply Factors – World production/consumption balance(1) • 0.4 million MT surplus for 2012 • 0.3 million MT surplus for 2013 – Curtailments and disruptions since 3Q-11(1) • 2.8 million MT curtailed; 1.9 million MT disrupted – LME warehouse inventories—5.2 million MT(3) • Macroeconomic Factors(2) – Europe’s ability to regain economic footing and escape manufacturing contraction – Growth rate for China’s economy – Strength/Weakness of U.S. dollar Quarterly Average LME(3) $1.33 $0.62 $0.82 $0.91 $0.50 $0.60 $0.70 $0.80 $0.90 $1.00 $1.10 $1.20 $1.30 $1.40 Q1-2 0 0 7 Q2-2 0 0 7 Q3-2 0 0 7 Q4-2 0 0 7 Q1-2 0 0 8 Q2-2 0 0 8 Q3-2 0 0 8 Q4-2 0 0 8 Q1-2 0 0 9 Q2-2 0 0 9 Q3-2 0 0 9 Q4-2 0 0 9 Q1-2 0 1 0 Q2-2 0 1 0 Q3-2 0 1 0 Q4-2 0 1 0 Q1-2 0 1 1 Q2-2 0 1 1 Q3-2 0 1 1 Q4-2 0 1 1 Q1-2 0 1 2 Q2-2 0 1 2 Q3-2 0 1 2 Q4-2 0 1 2 Q1-2 0 1 3 LME Levels Were Flat Sequentially, Still Below Equilibrium Sna p shot o f Alumi n um Fundam e nta ls 6 Sources: (1) CRU (2) Harbor (3) LME

R esu lts O ve rv ie w TTM MWTP $1.13 $1.01 $1.00 $0.80 $0.90 $1.00 $1.10 $1.20 $1.30 Q1-12 Q4-12 Q1-13 $ pe r p ou nd TTM Revenue TTM Net Cash Cost $224 $135 $126 $0 $50 $100 $150 $200 $250 Q1-12 Q4-12 Q1-13 $ i n m illi on s Key Performance Indicators – Trailing Twelve Months (“TTM”) 7 $0.78 $0.81 $0.82 $0.20 $0.30 $0.40 $0.50 $0.60 $0.70 $0.80 $0.90 Q1-12 Q4-12 Q1-13 $ p er p ou nd TTM Segment Profit $1,519 $1,395 $1,380 $900 $1,000 $1,100 $1,200 $1,300 $1,400 $1,500 ,6 0 $1,700 Q1-12 4-12 Q1-13 $ i n m illi on s

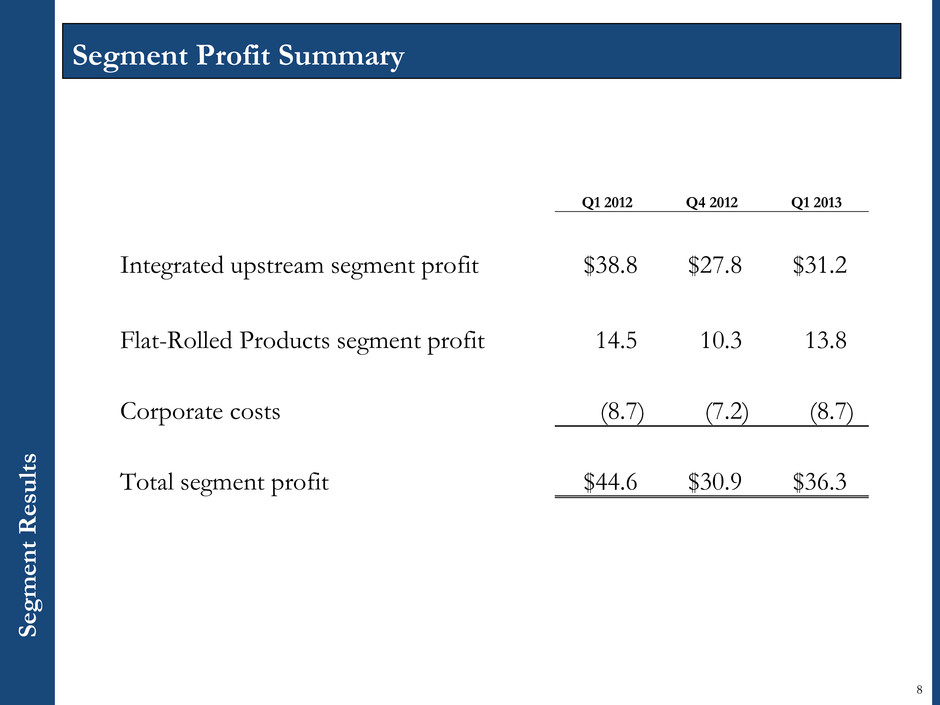

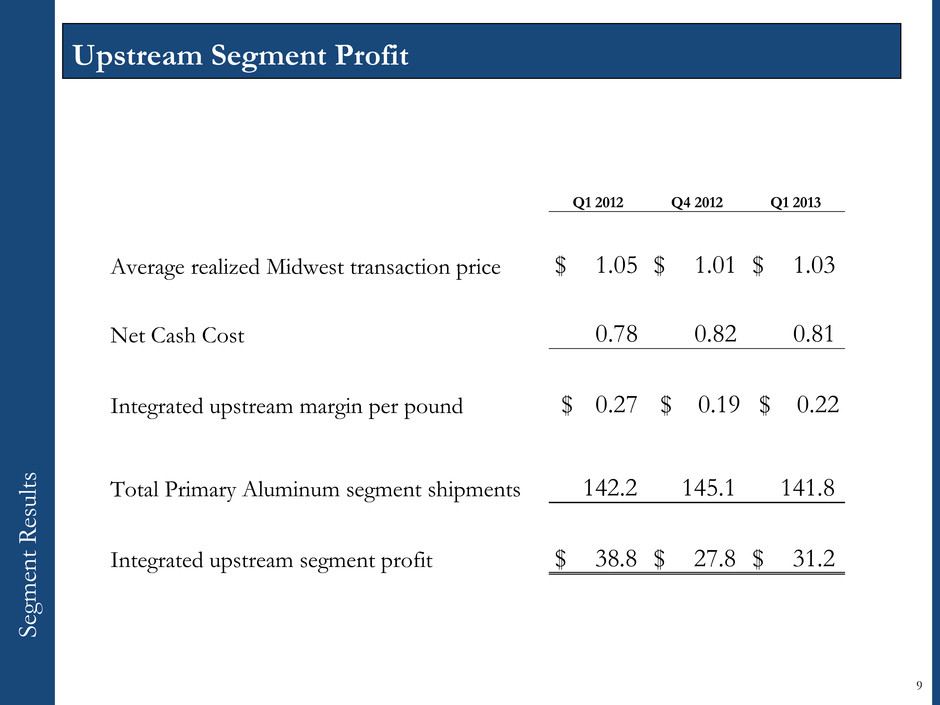

Se g men t R esu lt s 8 Segment Profit Summary Q1 2012 Q4 2012 Q1 2013 Integrated upstream segment profit $38.8 $27.8 $31.2 Flat-Rolled Products segment profit 14.5 10.3 13.8 Corporate costs (8.7) (7.2) (8.7) Total segment profit $44.6 $30.9 $36.3

9 Upstream Segment Profit Q1 2012 Q4 2012 Q1 2013 Average realized Midwest transaction price $ 1.05 $ 1.01 $ 1.03 Net Cash Cost 0.78 0.82 0.81 Integrated upstream margin per pound $ 0.27 $ 0.19 $ 0.22 Total Primary Aluminum segment shipments 142.2 145.1 141.8 Integrated upstream segment profit $ 38.8 $ 27.8 $ 31.2 Se gm ent R es u lt s

In te g ra te d Net Cash Cos t 10 Segment Profit and Net Cash Cost Bridge $0.81 $0.02 $0.05 $0.02 $0.02 $0.02 $0.82 $0.50 $0.55 $0.60 $0.65 $0.70 $0.75 $0.80 $0.85 $0.90 Q4 2012 Net Cash Cost Value Added Premium/ Bauxite Price Improved Bauxite/ Alumina Operations Commodity Prices (Natural Gas) Electricity Eliminations Q1 2013 Cash Cost $ pe r p o u n d $36.3 $3.6 $3.3 $2.6 $1.9 $5.7 $7.3 $30.9 $- $10 $20 $30 $40 $50 Q4 2012 LME / MWP Price Impact Value Added & Fabrication Premiums Improved Bauxite/ Alumina Operations Commoditiy Prices (Natural Gas) Electricity Eliminations Q1 2013 $ in m illi o n s

Ne t In c ome (Los s) , E x c ludin g Sp e cia l It e m s 11 Bridge of Segment Profit to Net Income, Excluding Special Items Q1 2012 Q4 2012 Q1 2013 Segment profit $ 44.6 $ 30.9 $ 36.3 LIFO/LCM 4.9 (4.6) (0.8) Other recurring non-cash items (1.3) (4.1) (4.0) EBITDA, excluding special items 48.2 22.2 31.5 Depreciation and amortization (22.9) (25.0) (23.2) Interest expense, net (6.5) (8.9) (10.1) Pre-tax income (loss), excluding special items 18.8 (11.7) (1.9) Income tax (expense) benefit (6.1) 3.9 0.6 Net income (loss), excluding special items $ 12.7 $ (7.8) $ (1.3)

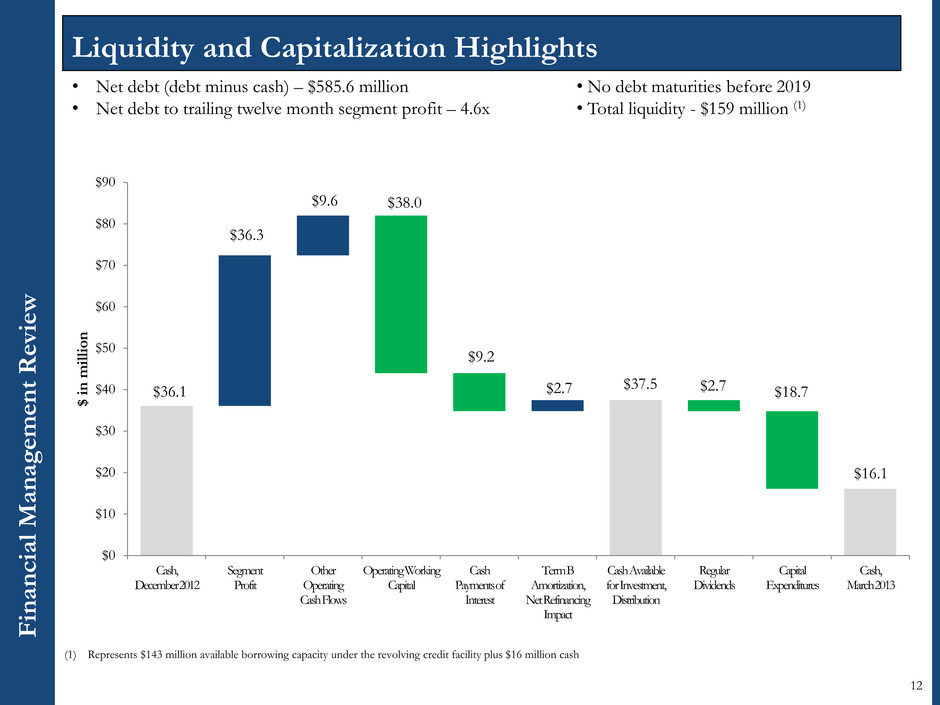

Financia l Mana g em e nt Revie w 12 Liquidity and Capitalization Highlights $38.0 $9.2 $2.7 $18.7 $36.3 $9.6 $2.7 $36.1 $37.5 $16.1 $0 $10 $20 $30 $40 $50 $60 $70 $80 $90 Cash, December 2012 Segment Profit Other Operating Cash Flows Operating Working Capital Cash Payments of Interest Term B Amortization, Net Refinancing Impact Cash Available forInvestment, Distribution Regular Dividends Capital Expenditures Cash, March 2013 $ in m illi o n (1) Represents $143 million available borrowing capacity under the revolving credit facility plus $16 million cash • Net debt (debt minus cash) – $585.6 million • Net debt to trailing twelve month segment profit – 4.6x • No debt maturities before 2019 • Total liquidity - $159 million (1)

Transa c ti on Over v ie w Debt Maturity Profile 13 No funded debt maturities until 2019 Weighted Average Maturity--6.1 years Weighted Average Maturity--4.2 years $275.3 $323.9 $0 $150 $300 $450 2013 2014 2015 2016 2017 2018 2019 2020 $609.2 $0 $150 $300 $450 $600 $750 2013 2014 2015 2016 2017 2018 2019 2020 Pre- Transaction Maturity Profile Post- Transaction Maturity Profile Summary: Repaid $275 million senior floating rate notes due 2015 with proceeds from $110 million addition to Term B loan, and $175 million senior fixed rate notes due 2019

1Q-13 results reflect improved operating reliability across our integrated upstream platform – Key performance metrics were consistent with previously communicated expectations – Stable overall demand across integrated platform – Improved value-added and fabrication premiums for key aluminum products Our outlook supports previously communicated key 2013 operating metrics – Modest year-over-year volume improvement supported by stable overall customer demand and our productivity and reliability programs – Prices for key input costs remain flat, except natural gas We are evaluating and taking prudent actions to manage our liquidity position and provide for prudent investment in long-term growth – Near-term, reviewing actions to preserve liquidity – Planning to move forward with previously announced capital projects, supported by options for project-specific financing – Have begun to obtain customer commitments for a significant portion of the additional capacity beginning in 2015 Our financial structure supports our ability to operate sustainably through the cycle – Completed refinancing of senior floating rate notes, extending maturities to 2019 – No maintenance covenants other than minimum ABL availability requirement – Approximately $159 million of total liquidity as of end of 1Q-13 Key Takeaways 14 1 2 Summa ry 3 4

Non-GAAP Measure: Disclaimer No n -GA A P M ea sure: Disclaim er This presentation contains non-GAAP financial measures as defined by SEC rules. We believe these measures are helpful to investors in measuring our financial performance and comparing our performance to our peers. However, our non-GAAP financial measures may not be comparable to similarly titled non- GAAP financial measures used by other companies. These non-GAAP financial measures have limitations as an analytical tool and should not be considered in isolation or as a substitute for U.S. GAAP financial measures. To the extent we disclose any non-GAAP financial measures, a reconciliation of each measure to the most directly comparable U.S. GAAP measure is available in the Press Release included as an exhibit to the Current Report on Form 8-K to which this presentation is also an exhibit. As such, this presentation should be read in conjunction with our Press Release. 15

TM