Attached files

| file | filename |

|---|---|

| 8-K - U. S. Premium Beef, LLC | esuspb8k.htm |

|

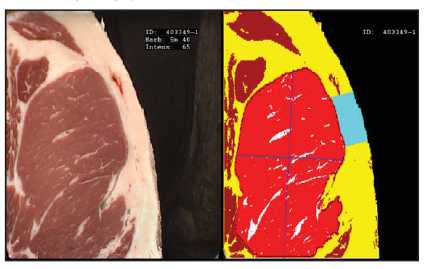

It is an objective method to measure and evaluate carcasses

How it Works By Brian Bertelsen, Vice President, Field Operations National Beef Packing Co. (National Beef) first started using instrument grading for the collection of individual animal carcass data (marbling, ribeye area and backfat) in 2005. The technology was then used to determine an in-house Yield Grade in 2008 and most recently, in 2009, the company began using it to determine the official USDA Quality Grade in its Kansas plants. In the Brawley plant camera grading is only used to determine Yield Grade, ribeye area and width.

Instrument grading is an objective method for measuring

and collecting important data used to determine carcass quality and

composition. It also generates data that is valuable to both producers

and plant personnel. Instrument grading uses a digital camera, linked to a sophisticated computer system in National Beef’s plants. It has also been referred to as the “Camera Vision System”. Here is a step-by-step look at how it works. First, a National Beef employee places the camera as shown in the photo below to capture the digital image of the ribeye interface where the carcass is cut, or “ribbed”, between the twelfth and thirteenth ribs for each side of the carcass. Then, the computer system immediately goes to work. It traces the ribeye muscle to determine the area, in square inches. Back- fat thickness is measured three fourths of the way up from the bottom of the ribeye (in the shaded area). The ribeye is divided into four quadrants and the marbling is estimated in each quadrant to then determine an overall marbling score. All of this is done in “real time” at chain speed in the plant. The photo below shows an example of an actual image together with the same image that has been measured and analyzed with the instrument grading system. This data is then linked with the hot carcass weight for each carcass that was collected on the slaughter floor.

In our Kansas plants, all of the data is matched up via the plant’s trolley tracking system which has a unique identity for every trolley, or hook, that each side of the carcass is hanging from. The two trolley identification numbers (ID) are linked to a carcass ID number, which producers ...continued on page 2

|

USPB FILES THIRD During the third quarter of fiscal year 2012, which ended September 29, 2012, U.S. Premium Beef, LLC (USPB) recorded a net income of approximately $5.0 million compared to a net income of $35.4 million for the thirteen-week period ended September 24, 2011. This was a decrease of approximately $30.4 million. For the fiscal year-to-date period, USPB had net income of approximately $5.5 million compared to net income of $129.5 million in the prior fiscal year, which was a decrease of approximately $124.0 million. The decrease in net income in both periods is primarily driven by two items, the Company’s sale of a majority of its ownership interest in Na‑ ...continued on page 2 USPB Extends ASV Premium USPB is extending its $35 per head age and source verified (ASV) premium for cattle delivered through March 30, 2013. USPB requires projections for ASV cattle. Please call our office at 866-877-2525 as soon as possible to let us know the approximate number of ASV cattle you, or your feedyard, plan on delivering between now and March 30, 2013, to ensure that your cattle have a reservation in our program. Even with a reservation, you will still need to have access to the necessary number of delivery rights. After March 30, 2013, the ASV premium will depend on the status of Japan’s export situation—either remaining open to U.S. beef products and our plants continuing to be approved for export to Japan, or the transition to 30-month cattle eligibility. We will update you as we have more information regarding Japan’s export requirements and resulting market conditions. ® Two Board positions up for election Annual Meeting Set for March 26, 2013 As a result of moving the company’s fiscal year to a calendar year, U.S. Premium Beef’s fiscal year 2012 annual meeting will be conducted in Kansas City, MO, at the Kansas City Airport Hilton on March 26, 2013. A pre-annual meeting reception will be held on the evening of March 25 at the Airport Hilton. There are two positions on USPB’s Board of Directors up for election. Jerry Bohn, Pratt, KS, and Duane Ramsey, Scott City, KS, currently hold these positions. Unitholders who want information on becoming a candidate for USPB’s Board should contact the USPB office at 866-877-2525. Applications are due December 26, 2012. Watch upcoming UPDATES for more information on the annual meeting. ®

|

Reproduction of any part of this newsletter is expressly forbidden without written permission of U.S. Premium Beef.

|

Instrument Grading... |

continued from page 1 |

|

see on their carcass data reports, and the carcass ID is assigned a National Beef lot number. In the Brawley plant, the data is matched to the carcass ID assigned at the hot scale. Almost immediately, all of the data is available. The camera operator has a screen to show him if he captured a good image. Then, just a few feet down the chain, a USDA Grader has a screen as well. The Graders compares the information on the screen to what they sees on the carcass. They also look at what the camera does not “see” such as lean color and physiological maturity and have the authority to override the instrument grade, if necessary. Lean color refers to dark cutters or those that have “partially dark” lean, or meat color. Physiological maturity is estimated by several factors, primarily by ossification, or how much cartilage has turned to bone, in the spinal column as the animal ages. Both lean color and skeletal maturity are factors that can affect the final Quality Grade. If, for any reason, no image is captured, or it is not a good quality image, then the USDA Grader can determine the Quality Grade as they did before instrument grading was implemented. Before the carcass leaves the USDA Grader, they will either stamp the carcass as Prime, Choice or Select or they can withhold the stamp if it is “Ungraded”. This applies to carcasses that are Hardbones , Dark Cutters or those with low marbling, below Select (Standard Quality Grade). Next, a National Beef Carcass Merchandiser evaluates the carcass. This person also has a video screen with all of the instrument grading data, plus the hide color that was collected on the slaughter floor. The Carcass Merchandiser, under the supervision of USDA, decides how each carcass will be merchandised, based on a variety of factors including Quality Grade, Yield Grade, weight range, ribeye area, breed type and branded beef requirements. Instrument Grading is not only an objective, unbiased, consistent system for grading carcasses and collecting carcass data for producers, but it is also a valuable tool for our processing company. “The implementation of Camera Vision Grading has simplified the grading process,” National Beef’s vice president of Grading Services, Steve Crable explains. “Quality Grade and Yield Grade placement is consistent day in and day out. “Vision Grading also gives us the means to “re-visit” real time data and images to understand why a particular lot of cattle performed better or worse than predicted,” Crable adds. “With Vision Grading we now have the means to query data and images a week later, if necessary, to substantiate or answer any questions that may arise. |

|

|

“Historical data can also be queried to ensure that we are merchandising every carcass to their greatest potential based on breed type, Quality and Yield Grade, ribeye area, and weight range,” he concludes. ® |

||||

| USPB Files Third Quarter Results... |

continued from page 1 |

|||

|

tional Beef Packing Company, LLC (NBP), to Leucadia National Corporation, and lower gross margins at NBP. Although demand for beef products remained strong during the thirteen and twenty-six week periods, gross margins were lower. ® |

||||

|

Did You Know... PIf you have delivery rights you do not plan on using in delivery year 2013, USPB would like to help you get them leased to other producers. Please call our office at 866-877-2525 to put your excess delivery rights on our lease list. ® |

||||

|

BENCHMARK PERFORMANCE DATA TABLE |

||||

|

Base Grid Cattle Harvested in KS Plants 10/14/12 to 11/10/12 |

||||

| Base Grid | ||||

|

(Numbers |

ALL | Top 25% | ||

|

Yield |

65.03 |

65.47 |

||

|

Prime |

3.68 |

6.24 |

||

|

CH & PR |

68.61 |

81.96 |

||

|

CAB |

17.94 |

26.06 |

||

|

BCP |

16.75 |

20.40 |

||

|

Ungraded |

1.55 |

0.78 |

||

|

Hard Bone |

0.60 |

0.30 |

||

|

YG1 |

14.52 |

9.91 |

||

|

YG2 |

39.75 |

37.69 |

||

|

YG3 |

35.50 |

39.94 |

||

|

YG4 |

9.25 |

11.15 |

||

|

YG5 |

0.99 |

1.30 |

||

|

Light Weight |

0.23 |

0.11 |

||

|

Heavy Weight |

2.52 |

1.83 |

||

|

Average Grid Premiums/Discounts ($/Head) |

||||

|

Quality Grade |

$40.60 |

$69.34 |

||

|

Yield Benefit |

$37.19 |

$49.73 |

||

|

Yield Grade |

-$3.64 |

-$6.02 |

||

|

Out Weight |

-$3.80 |

-$2.71 |

||

|

ASV |

$3.87 |

$10.20 |

||

|

Natural |

$2.75 |

$9.09 |

||

|

Total Premium |

$76.97 |

$129.63 |

||