Attached files

| file | filename |

|---|---|

| 10-Q - QUARTERLY REPORT - HEXION INC. | momentivespecchem10q2011q1.htm |

| EX-10.1 - MOMENTIVE PERFORMANCE MATERIALS HOLDINGS LLC 2011 INCENTIVE COMPENSATION PLAN - HEXION INC. | exhibit1012011q1.htm |

| EX-32.1 - SECTION 906 CEO AND CFO CERTIFICATION - HEXION INC. | exhibit3212011q1.htm |

| EX-31.1 (B) - SECTION 302 CFO CERTIFICATION - HEXION INC. | exhibit311b2011q1.htm |

| EX-31.1 (A) - SECTION 302 CEO CERTIFICATION - HEXION INC. | exhibit311a2011q1.htm |

Exhibit 10.2

AMENDMENT TWO TO SECOND AMENDED AND RESTATED NORCO SITE SERVICES, UTILITIES, MATERIALS AND FACILITIES AGREEMENT BETWEEN SHELL CHEMICAL LP

AND MOMENTIVE SPECIALTY CHEMICALS INC.

This Amendment Two (“Amendment”) to the Second Amended and Restated Norco Site Services, Utilities, Materials and Facilities Agreement Between Shell Chemical LP and Resolution Performance Products LLC, dated effective November 1, 2004, as amended by that certain Amendment One to Second Amended and Restated Norco Site Services, Utilities, Materials and Facilities Agreement between Shell Chemical LP and Hexion Specialty Chemicals, Inc. dated effective January 1, 2006 (the “SUMF Agreement”) is entered into between Momentive Specialty Chemicals Inc. (f/k/a Hexion Specialty Chemicals, Inc.) (“Momentive”) as successor-in-interest to Resolution Performance Products LLC and Shell Chemical LP (“Shell”). Shell and Momentive may be referred to individually as a “Party” and collectively as the “Parties”.

IN CONSIDERATION of the premises and mutual covenants contained herein, the Parties agree as follow:

ARTICLE ONE

DEFINITIONS

SECTION 1.1. Definitions in Other Instruments. Capitalized terms used herein and not defined herein have the meanings ascribed to them in the SUMF Agreement.

ARTICLE TWO

AMENDMENT TO THE SUMF AGREEMENT

All reference in the SUMF Agreement to “Hexion Specialty Chemicals,Inc” shall be replaced with “Momentive Specialty Chemicals Inc.”, and all references to “Hexion” shall be replaced with “Momentive”.

SECTION 2.1. Deletion and replacement of Schedule 3.2 C to the SUMF Agreement.

Schedule 3.2 C to the SUMF Agreement is hereby deleted and replaced to read in its entirety as set forth by Schedule 3.2 C (v2011), attached hereto as Exhibit A. All references to “Schedule 3.2 C” in the SUMF Agreement shall be replaced with “Schedule 3.2 C (v2011)”.

SECTION 2.2. Definition of Infrastructure Charge.

The definition of “Infrastructure Charge” is hereby deleted in its entirety and replaced with the following:

“Infrastructure Charge” means the charge related to infrastructure used to provide SUMF Items which is a charge in lieu of depreciation and capital required for the continuing operation of existing SUMF Assets. For the avoidance of doubt, capital required to comply with changes to Environmental Law that is not attributable to one Party under Article 12 of the SUMF Agreement shall be considered as being required for the continuing operation of existing SUMF Assets.

SECTION 2.3. Addition to Schedule 3.2 D to the SUMF Agreement.

The following paragraph is added to Schedule 3.2 D to the SUMF Agreement as Paragraph 6 (e):

In the event that the storm water ditches located throughout the West Site are inspected and waste and/or wastewater is discovered to be in the ditches, then the responsible Party will cease operation of any contributing activity and make best efforts to isolate and block in the source of such ingress. The responsible Party will then remove said material and be accountable for its contributive share of all defined costs related to cleaning up the specific incident.

ARTICLE THREE

MISCELLANEOUS

SECTION 3.1. Execution of Counterparts. This Amendment may be executed in counterparts, each of which shall be an original and all of which shall constitute but one and the same instrument.

SECTION 3.2. Applicability of the Original Agreement. Except as amended and supplemented by this Amendment, all of the provisions of the SUMF Agreement shall remain in full force and effect.

SECTION 3.3. Governing Law. This Amendment shall be governed by and construed in accordance with the law of the State of Louisiana, without regard to the conflict of law thereof.

SECTION 3.4. Effective Date. This Amendment shall be effective as of January 1, 2011.

1

IN WITNESS WHEREOF, the Parties hereto have caused this amendment to be executed by their duly authorized representatives.

MOMENTIVE SPECIALTY CHEMICALS INC.

By: _________________________________

Title: _______________________________

Date: ________________________________

SHELL CHEMICAL LP

By: _________________________________

Title: _______________________________

Date: ________________________________

2

EXHIBIT A OF AMENDMENT TWO TO SECOND AMENDED AND RESTATED NORCO SITE SERVICES, UTILITIES, MATERIALS AND FACILITIES AGREEMENT

SCHEDULE 3.2 C (v2011)

1. | Biotreater System Services |

2. | Purchaser: Momentive |

Supplier: Shell

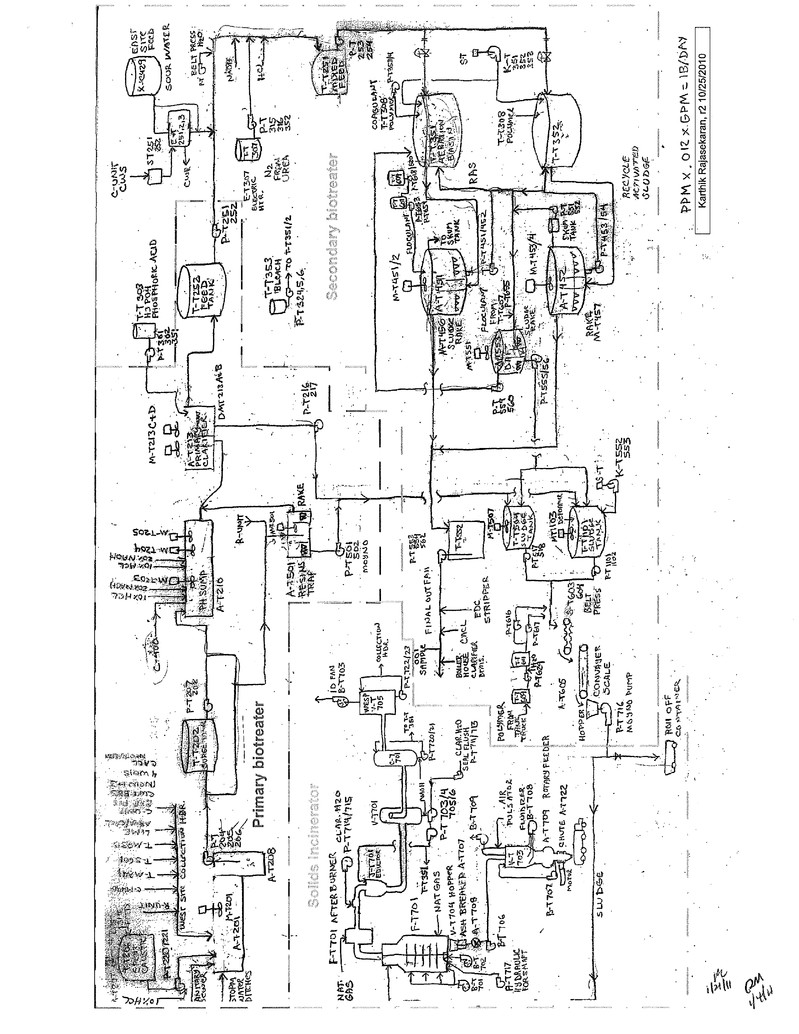

3. | “Biotreater System” shall mean all equipment utilized to receive, adjust and treat all waste water including the primary and secondary biotreaters, and the solid incinerator, in each case outside the first block valve off the supply header servicing a consuming unit, any buildings and structures used for the purpose of operating such equipment, and any modifications, additions or improvements thereto. A process flow diagram with demarcations of the systems collectively described as the primary and secondary biotreaters, and the solid incinerator, is included in Appendix A. |

4. | Specifications: |

The following is a list of plant components that may be discharged into the effluent system for treatment at the Biotreater System. In an effort to comply with the effluent treatment system capacity and environmental regulations, the corresponding maximum limits will be enforced. Shell shall notify Momentive of any additional or revised limits within a reasonable time before the changes are effective. Momentive and Shell agree to amend this schedule to incorporate such revised limits.

API BASIN**

PARAMETER | LIMIT* | |

AVERAGE | MAXIMUM | |

Isopropyl Alcohol (IPA) | 28 ppm | 450 ppm |

Methyl Ethyl Ketone (MEK) | 9.8 ppm | 450 ppm |

Methyl Isobutyl Ketone (MIBK) | 14 ppm | 144 ppm |

Epichlorohydrin (ECH) | 8.8 ppm | 150 ppm |

2,3 Dichloro 1-propanol (2,3 DCH) | 1 ppm | 75 ppm |

1,3 Dichloro 2-propanol (1,3 DCH) | 1 ppm | 75 ppm |

Toluene | 0.35 ppm | 6 ppm |

Ethylene Dichloride (EDC) | 0.70 ppm | 15 ppm |

Flow | 2,495 gpm | 2,495 gpm |

Temperature (annual average) | 85 deg F | |

ECH STRIPPER BOTTOMS

PARAMETER | LIMIT* | |

AVERAGE | MAXIMUM | |

Isopropyl Alcohol (IPA) | 0.15 ppm | 1.5 ppm |

Methyl Ethyl Ketone (MEK) | 0.22 ppm | 2.2 ppm |

Epichlorohydrin (ECH) | 13 ppm | 50 ppm |

2,3 Dichloro 1-propanol (2,3 DCH) | 15 ppm | 25 ppm |

1,3 Dichloro 2-propanol (1,3 DCH) | 25 ppm | 50 ppm |

Flow | 1,800 gpm | 2,127 gpm |

Temperature | 105 deg F | 119 deg F |

Total Organic Compounds (operational limit) | 24,000 lbs/day | |

3

HPRU EFFLUENT**

PARAMETER | LIMIT* | |

AVERAGE | MAXIMUM | |

Isopropyl Alcohol (IPA) | 500 ppm | 1000 ppm |

Methyl Ethyl Ketone (MEK) | 60 ppm | 902 ppm |

Methyl Isobutyl Ketone (MIBK) | 10 ppm | 2360 ppm |

Epichlorohydrin (ECH) | 30 ppm | 387 ppm |

2,3 Dichloro 1-propanol (2,3 DCH) | 3590 ppm | 3590 ppm |

1,3 Dichloro 2-propanol (1,3 DCH) | 3590 ppm | 3590 ppm |

Toluene | 60 ppm | 500 ppm |

Flow | 45 gpm | 50 gpm |

* The limits listed above are taken from Title V Permit 2889-V1, issued 11/26/07. Please note that all of the components included in the permit are not represented in the above tables, as some components are either not tested frequently or not known to cause a concern for source control limits. For a comprehensive list of all permitted components, refer to Permit No. 2889-V1.

** For the avoidance of doubt, the limits listed above for the API Basin and the HPRU Effluent shall only apply to the equipment numbered A-T201 and A-T501, respectively, and not to the streams entering into these vessels.

Per the LPDES LA #0005762 water permit, a pH specification range of 6-9 is applicable for the effluent stream(s) of the Biotreater System. Both Parties will proactively monitor their various feed streams to the Biotreater System, communicate pH excursions, and collaborate to control, mitigate and recover from these excursions.

Except as otherwise set forth below, the following limits apply for purposes of compliance with 40 CFR 63 Subpart DD, National Emission Standard for Hazardous Air Pollutants from Off-Site Waste and Recovery Operations (OSWRO MACT).

STREAM | LIMIT* |

TiCl4 Abatement Unit | < 500 ppm total volatile organic hazardous air pollutants (VOHAP) on an annual, flow weighted average as measured at meter F5623. A listing of VOHAPs is included in Section 7 (k) below. |

HPRU Effluent | HPRU wastewaters are subject to and must meet the control standards specified in 40 CFR 63 Subpart FFFF, MON MACT. Shell facilities are exempt from the monitoring requirements in OSWRO MACT per 40 CFR 63.683(b)(2)(i) as there are no longer any Group 1 process wastewater streams from HPRU routed to Shell. |

C Unit Effluent | C Unit wastewaters are subject to and must meet the control standards specified in 40 CFR 63 Subparts G, HON MACT. Therefore, as per 40 CFR 63.680(b)(2)(v)(A), this stream does not meet the definition of offsite waste in OSWRO MACT. |

* The limits above are based on the treatment of the East Side feed stream at an average flow rate of 2,200 gpm. The parameters are subject to change if applicable regulations change.

5. Firm Capacity Reservation and Biotreater System capacity:

a) | Primary Biotreater (flow): Momentive Firm Capacity Reservation, annualized = 1,576,800 Kgal; Primary Biotreater (flow) max capacity = 5000 gpm; Momentive Firm Capacity Reservation share = 60.00% |

b) | Primary Biotreater (solids): Momentive Firm Capacity Reservation, annualized = 15,200 Klbs; Primary Biotreater (solids) max capacity = 126 Klbs/day; Momentive Firm Capacity Reservation share = 33.05% |

c) | Secondary Biotreater: Momentive Firm Capacity Reservation, annualized = 6950 Klbs; Secondary Biotreater (TOC) max capacity = 38.16 Klbs/day; Momentive Firm Capacity Reservation share = 49.90% |

d) | Solids Incinerator: Momentive Firm Capacity Reservation, annualized = 104,200 Klbs (wet basis); Solids Incinerator max capacity = 392.64 Klbs/day (wet basis); Momentive Firm Capacity Reservation share = 72.71% |

6. Curtailment: Consistent with Article 7 of the SUMF agreement.

4

7. Delivery Terms and Conditions:

(a) | Momentive acknowledges that hazardous materials contained in its waste materials delivered to the Biotreater System shall be owned by Momentive at all times. |

(b) | In the event Biotreater System capacity is increased, de-rated or otherwise decreased on a long term basis at Shell's sole discretion, Momentive's Firm Capacity Reservation will remain the same except in the case where Momentive elects to fund Improvement Capital that expands Biotreater System capacity, as provided in Article 12 of the SUMF agreement and as defined in Paragraph 8(c) below. In the event that Momentive elects to fund (in whole or in part) Improvement Capital, Momentive's Firm Capacity Reservation per Paragraph 5 of this Schedule will be adjusted to reflect such changes in Biotreater System capacity, the results of such change to be documented and appended to this Schedule. Should Biotreater System capacity be increased, de-rated or otherwise decreased on a long term basis at the Parties' mutual agreement, Momentive's Firm Capacity Reservation per Paragraph 5 of this Schedule will be adjusted to reflect such changes in the Biotreater System capacity, the results of such change to be documented and appended to this Schedule. |

(c) | After review and consultation with Momentive, Shell shall not refuse to store, handle, treat or dispose of any Momentive hazardous materials that, as of the date hereof are currently being handled if such hazardous materials (i) are being generated on site by Momentive Facilities and (ii) are not in excess of the Momentive's Firm Capacity Reservation. Correspondingly, except after consultation and review with Momentive, Shell will not store, handle, treat or dispose of any Shell hazardous materials that as of the date hereof are not currently being handled if such hazardous materials (i) are not being generated on site by the Shell Facilities or by any facilities of Shell or its Affiliates, or (ii) are not being evaluated by the same criteria as hazardous waste is being evaluated for Momentive. |

(d) | Shell shall be responsible for notifying Governmental Authorities regarding all aspects of the Biotreater System operation. If a release at Shell is caused by Momentive, then Momentive will assist Shell in all follow-up requirements in such a manner that will allow Shell to provide agency reports in the allotted timeframe. This includes the notification of the Shell Site Supervisor promptly after Momentive becomes aware that it may be responsible for such release. If an odor from the Biotreater System is detected of unknown origin, Momentive will assist Shell in determining the responsible Party. Each Party will assist the other in all routine environmental reporting activities as needed. |

(e) | Unit source control limits will be developed based on the control limits for the Biotreater System or other Environmental Law. Momentive and Shell will each monitor these limits in their respective unit labs. |

(f) | If any new chemicals are introduced into any part of Momentive that may be introduced into the waste water, Momentive will be required to alert the Shell Biotreater System Technical Department and the Shell Environmental Department to determine the treatability and permit impacts of this new chemical in the Biotreater System. This includes, but is not limited to, any new process materials, any new chemicals introduced into the cooling water system, and any new waste material. This notification to Shell must be made 12 months in advance or as soon as practicable. In no case will Momentive commence the use of this new material prior to written concurrence from Shell, which consent will not be unreasonably withheld. |

(g) | Samples run at the Biotreater System for Momentive exclusively will be at Momentive's expense. |

(h) | In the event of an unusual excursion from normal operating parameters resulting in repair and/or clean up costs, including costs to provide temporary services and equipment, the Party responsible for such excursion shall pay all such defined costs related to such unusual excursion. The root cause(s) for the excursion must be directly and wholly attributable to one Party, and the incremental defined costs must be greater in sum than a deminimus amount of $50,000, for this clause to take effect. Both Parties must agree on the cause of such an excursion, and on the incremental repair and/or clean up costs associated with any such excursion. Written notification of said event and resulting costs must be made by Shell within 60 days of the unusual excursion event. Any disputes and dispute resolution proceedings shall be handled pursuant to Article 18 of the SUMF agreement. |

(i) | Since the start-up of the 400 section of the ECH unit could adversely affect the Biotreater System, the following start-up schedule with respect to the ECH unit will be enforced: |

5

Start-up rates for <12 hours shutdown

GPM to loops | Duration |

30 | For 12 hours |

40 | After 12 hours |

Max | After 24 hours |

Start-up rates for 12-24 hours shutdown

GPM to loops | Duration |

25 | For 8 hours |

30 | After 8 hours |

35 | After 16 hours |

40 | After 24 hours |

45 | After 32 hours |

Max | After 40 hours |

Start-up rates for 24-48 hours shutdown

GPM to loops | Duration |

20 | For 8 hours |

25 | After 8 hours |

30 | After 16 hours |

35 | After 24 hours |

40 | After 32 hours |

45 | After 40 hours |

Max | After 48 hours |

Start-up rates for 48-96 hours shutdown

GPM to loops | Duration |

15 | For 12 hours |

20 | After 12 hours |

25 | After 24 hours |

30 | After 36 hours |

35 | After 48 hours |

40 | After 60 hours |

45 | After 72 hours |

50 | After 85 hours |

55 | After 96 hours |

Max | After 108 hours |

6

Start-up rates for >96 hours shutdown

GPM to loops | Duration |

15 | For 18 hours |

20 | After 18 hours |

25 | After 36 hours |

30 | After 54 hours |

35 | After 72 hours |

40 | After 90 hours |

45 | After 108 hours |

Max | After 126 hours |

The above rates may be accelerated depending on the state of the Biotreater System. There will be no alterations to the rate schedule without the approval of the Shell Utilities Production Unit Manager.

(j) | Meters that are used to characterize feeds to the Biotreater System include: |

F9046 from C-Unit Effluent Pit to the Primary Biotreater

F9076 from the Solvent Recovery Column (HPRU) to the Primary Biotreater

F1004 from ECH stripper bottoms to the Primary Biotreater

F1006 from CaCl tank to the LPDES 001 outfall

F5623 from TiCl Abatement Unit

F0998 from the Solvent Recovery Column (HPRU) to the Primary Biotreater

(k) | The determination of the annual, flow-weighted average concentration of VOHAPs for wastewaters from the TiCl4 Abatement Unit will be made by Shell per 40 CFR 63.683(b)(1)(iii). |

1. | A written sampling plan shall be maintained on-site in the Shell plant site operating records. |

2. | Sampling shall be done for all of the VOHAPs listed in table 1 of 40 CFR 63 Subpart DD reproduced below and expected to be present unless otherwise noted. |

CAS | OSWRO VOHAP CHEMICAL | Possible present in wastewater basis Process Knowledge? |

71-55-6 | 1,1,1-Trichloroethane (Methyl chloroform) | NO |

79-34-5 | 1,1,2,2-Tetrachloroethane | NO |

79-00-5 | 1,1,2-Trichloroethane (Vinyl trichloride) | NO |

120-82-1 | 1,2,4-Trichlorobenzene | NO |

12/8/1996 | 1,2-Dibromo-3-chloropropane | NO |

106-88-7 | 1,2-Epoxybutane | NO |

75-55-8 | 1,2-Propylenimine (2-Methyl aziridine) | NO |

106-99-0 | 1,3-Butadiene | NO |

542-75-6 | 1,3-Dichloropropene | NO |

106-46-7 | 1,4-Dichlorobenzene | NO |

123-91-1 | 1,4-Dioxane (1,4-Diethyleneoxide) | NO |

540-84-1 | 2,2,4-Trimethylpentane | NO |

95-95-4 | 2,4,5-Trichlorophenol | NO |

6/2/1988 | 2,4,6-Trichlorophenol | NO |

94-75-7 | 2,4-D, salts and esters | NO |

51-28-5 | 2,4-Dinitrophenol | NO |

121-14-2 | 2,4-Dinitrotoluene | NO |

7

79-46-9 | 2-Nitropropane | NO |

75-07-0 | Acetaldehyde | NO |

5/8/1975 | Acetonitrile | NO |

98-86-2 | Acetophenone | NO |

2/8/107 | Acrolein | NO |

107-13-1 | Acrylonitrile | NO |

5/1/107 | Allyl chloride | NO |

71-43-2 | Benzene (includes benzene in gasoline) | YES |

7/7/1998 | Benzotrichloride (isomers and mixture) | YES |

100-44-7 | Benzyl chloride | YES |

92-52-4 | Biphenyl | NO |

542-88-1 | Bis(chloromethyl)ether | NO |

75-25-2 | Bromoform | NO |

75-15-0 | Carbon disulfide | NO |

56-23-5 | Carbon tetrachloride | NO |

43-58-1 | Carbony sulfide | NO |

133-90-4 | Chloramben | NO |

108-90-7 | Chlorobenzene | YES |

67-66-3 | Chloroform | NO |

107-30-2 | Chloromethyl methyl ether | NO |

126-99-8 | Chloroprene | NO |

98-82-8 | Cumene | NO |

334-88-3 | Diazomethane | NO |

132-64-9 | Dibenzofurans | NO |

111-44-4 | Dichloroethyl ether (Bis(2-chloroethyl ether) | NO |

64-67-5 | Diethyl sulfate | NO |

79-44-7 | Dimethyl carbamoyl chloride | NO |

77-78-1 | Dimethyl sulfate | NO |

106-89-8 | Epichlorohydrin (1-Chloro-2,3-epoxypropane) | NO |

140-88-5 | Ethyl acrylate | NO |

100-41-4 | Ethyl benzene | YES |

75-00-3 | Ethyl chloride (Chloroethane) | YES |

106-93-4 | Ethylene dibromide (Dibromoethane) | NO |

6/2/107 | Ethylene dichloride (1,2-Dichloroethane) | NO |

151-56-4 | Ethylene imine (Aziridine) | NO |

75-21-8 | Ethylene oxide | NO |

75-34-3 | Ethylidene dichloride (1,1-Dichloroethane) | NO |

Glycol ethers {d} that have a Henry's Law constant value equal to or greater than 0.1 Y/X (1.8 x 10[6] atm/gm-mole/m[3]) at 25ºC | NO | |

8

118-74-1 | Hexachlorobenzene | NO |

87-68-3 | Hexaclorobutadiene | NO |

67-72-1 | Hexachloroethane | NO |

110-54-3 | Hexane | NO |

78-59-1 | Isophorone | NO |

58-89-9 | Lindane (all isomers) | NO |

67-56-1 | Methanol | NO |

74-83-9 | Methyl bromide (Bromomethane) | NO |

74-87-3 | Methl chloride (Chloromethane) | NO |

78-93-3 | Methyl ethyl ketone (2-Butanone) | NO |

74-88-4 | Methyl iodide (Iodomethane) | NO |

10/1/108 | Methyl isobutyl ketone (Hexone) | NO |

624-83-9 | Methyl isocyanate | NO |

80-62-6 | Methyl methacrylate | NO |

4/4/1634 | Methyl tert butyl ether | NO |

9/2/1975 | Methylene chloride (Dichloromethane) | NO |

121-69-7 | N,N-Dimethylaniline | NO |

91-20-3 | Naphthalene | NO |

98-95-3 | Nitrobenzene | NO |

95-53-4 | o-Toluidine | NO |

82-68-8 | Pentachloronitrobenzene (Quintobenzene) | NO |

87-86-5 | Pentachlorophenol | NO |

75-44-5 | Phosgene | NO |

123-38-6 | Propionaldehyde | NO |

78-87-5 | Propylene dichloride (1,2-Dichloropropane) | NO |

75-56-9 | Propylene oxide | NO |

100-42-5 | Styrene | NO |

9/3/1996 | Styrene oxide | NO |

127-18-4 | Tetrachloroethylene (Perchloroethylene) | NO |

108-88-3 | Toluene | YES |

1/6/1979 | Trichloroethylene | NO |

121-44-8 | Triethylamine | NO |

5/4/108 | Vinyl acetate | NO |

593-60-2 | Vinyl bromide | NO |

1/4/1975 | Vinyl chloride | NO |

75-35-4 | Vinylidene chloride (1,1-Dichloroethylene) | NO |

1330-20-7 | Xylenes (sum of isomers and mixture) | YES |

This table applies only to TiCL4 abatement. The HPRU is no longer subject to the OSWRO VOHAP rule.

9

3. | Sampling frequencies and analysis should be done at intervals deemed appropriate as agreed by Shell and Momentive, to meet the requirements of 40 CFR 63.694. |

4. | Momentive will grant Shell access to Momentive process areas as needed to procure any required samples. Shell will follow all Momentive-required notification and permitting requirements for access to such areas. |

5. | A summary of all sample results and associated calculations shall be sent to Momentive within 30 days following the sampling event. Momentive and Shell will in good faith take all necessary steps to reduce flow/concentration of the wastewater until the annual average, flow-weighted VOHAP concentration is projected to be < 500 ppmw for the 12-month period. |

8. Pricing:

(a) | (1) Variable Cost: Momentive will be charged Variable Costs based on its utilization-based allocation of each and all Biotreater Systems. Momentive shall pay for its utilization-based share of solids disposal as a Variable Cost. Momentive shall also pay for its utilization-based share of chemicals usage as a Variable Cost. Momentive's utilization-based allocation of Variable Cost charges, with calculation/estimation basis drawn from actual usage data, is detailed in Appendix B, for each Biotreater System, as defined in Appendix A, and is summarized below. |

Primary biotreater (flow) = 91.50%

Primary biotreater (solids) = 100.0%

Primary biotreater, composite, weighted by 40% flow and 60% solids = 96.60%

Secondary biotreater (TOC) = 78.95%

Solids incinerator (solids, dry) = 95.11%

(2) These Variable Cost allocation percentages are applied to the various categories of Variable Costs as follows.

Variable Cost Category | Momentive variable cost allocation, % | Basis for allocation |

Natural Gas | 95.11 | Used to fire solids incinerator |

Nitrogen | 10.00 | Primarily used in nitrogen sweep for TT-206 for East Site feed to the primary biotreater (90%), plus intermittent decon use in all areas (10%) |

Electricity | 88.94 | Used in all areas, weighted 20-40-40 for primary biotreater-secondary biotreater-solids incinerator |

Air | 88.94 | Used in all areas, weighted 20-40-40 for primary biotreater-secondary biotreater-solids incinerator |

Steam | 88.94 | Used in all areas, weighted 20-40-40 for primary biotreater-secondary biotreater-solids incinerator |

Water | 95.60 | Used in primary biotreater and solids incinerator (firewater, potable water, desuperheating water), weighted 33-67 for primary biotreater-solids incinerator |

Cooling Water | — | From C Unit cooling water tower, used for East Site feed cooling |

Flare | — | Used primarily for butylene sphere venting |

Acid/Caustic | 59.4 | Mutually agreed number based upon 2004 and 2006 primary biotreater firm capacity reservation percentages |

Process Chemicals | 88.94 | Comprising settling chemicals (secondary biotreater), filter press polymer (solids incinerator), urea and phosphoric acid (primary/secondary biotreater), weighted 20-40-40 primary biotreater-secondary biotreater-solids incinerator |

Solids Disposal | 95.11 | Alternative to solids incineration, hence tied to solids incinerator |

10

(3) The Parties agree to review, and revise as necessary, the utilization patterns and premises, as described in Appendix B, used to determine these Variable Cost allocations. In turn, these Variable Cost allocation percentages will be changed upon mutual agreement of the Parties, the results of such change to be documented and appended to this Schedule. This review shall take place whenever there is a material and sustained shift in utilization patterns, or annually upon the effective date of this Schedule, whichever is sooner.

(4) If it becomes necessary to employ the services of a Third Party to handle any streams outlined in this Schedule, Momentive will share the cost of the Third Party based on its utilization-based Variable Cost percentage for that Biotreater System which would ordinarily process/treat the affected stream. Shell shall review and consult with Momentive prior to employing such Third Parties if the Third Party is to handle Momentive's Hazardous Substances.

(b) | (1) Fixed Costs: Momentive will be charged $289,358 per month as the Fixed Costs Charge, subject to escalation each year as described in Paragraph 9 below. |

(2) In addition, any fines or other environmental remediation costs paid by Shell as a result of non specification feedstocks shall be charged to Momentive as additional Fixed Costs, but only if Shell demonstrates such fines or other environmental remediation costs result from or are caused by the non specification feedstock of Momentive.

(c) | Capital Costs: Momentive will be charged $68,069 per month as the Infrastructure Charge. Capital expenditure that expands capacity or increases capability and that is not required for the continuing operation of existing assets or related to regulatory change is defined as “Improvement Capital” which either Party can choose to decline to participate under Article 12 of the SUMF Agreement. Consistent with Paragraph 7(b) of this Schedule and only for this category of capital expenditure, Momentive's Firm Capacity Reservation to the system or systems that are to be affected by the Improvement Capital expenditure will be modified and any corresponding cost recovery formulas including, but not limited to, those related to Variable Costs, Infrastructure Charges, and Fixed Operating Costs, may be renegotiated. |

(d) | Exceedance Costs: In the event Momentive's usage of any of the Biotreater System services described in Paragraph 5 above in any calendar year exceeds its Firm Capacity Reservation for such service for such year, then Momentive shall pay, in addition to the other charges set forth in this Schedule, an additional amount of Fixed Costs for such year, determined in the following manner: |

a. | If the exceedance is 105% or less: by multiplying the percentage by which Momentive's usage of such service exceeds 100% of its Firm Capacity Reservation for such service times 80% of the total Fixed Costs Charge for such year as set out in clause b (1) above times Y where in the case of 5(a) Y = 10%; 5(b) Y=10%; 5(c) Y=40%; and 5(d) Y=40%. |

b. | If the exceedance is greater than 105%: by multiplying the percentage by which Momentive's usage of such service exceeds 100% of its Firm Capacity Reservation for such service times the total Fixed Costs Charge for such year as set out in clause b (1) above times Y where in the case of 5(a) Y = 10%; 5(b) Y=10%; 5(c) Y=40%; and 5(d) Y=40%. |

9. Escalation: The Fixed Costs Charge will be adjusted beginning April 1, 2012, and annually thereafter on the anniversary of such date, according to the following formula. (For avoidance of doubt, the following formula shall be used for the adjustment to be made on April 1, 2012. Adjustments on the anniversary dates of April 1, 2012 shall be made using the same formula, with the variables adjusted to correspond to the calendar year for which the adjustment is to be made. The Example Hypothetical Calculation is provided for the purpose of illustration based on an April 1, 2013 adjustment using hypothetical numbers.)

ADJUSTMENT(2012) =

(0.75 * WAGE(2011)) + 0.25 * {(NELSON(2011) - NELSON(2010))}

NELSON(2010)

CHARGES(2012) = CHARGES(2011) + {ADJUSTMENT(2012)*CHARGES(2011)}

The numeric value of the ADJUSTMENT and CHARGES shall be rounded to four decimal places.

Where:

ADJUSTMENT(2012) is the 2012 adjustment to the Fixed Costs Charge.

CHARGES(2012) is the annual Fixed Costs Charge for 2012.

CHARGES (2011) is the annual Fixed Costs Charge for 2011.

WAGE(2011) is Shell's Norco 2011 average annual non-union staff salary percentage increase expressed as a decimal.

11

NELSON is the Nelson Refining Construction Index published in the Oil and Gas Journal.

NELSON(2011) is the average monthly value of NELSON for 2011.

NELSON (2010) is the average monthly value of NELSON for 2010.

EXAMPLE hypothetical calculation for April 1, 2013

WAGE(2012) = 4.5%

NELSON(2012) = 410

NELSON (2011) = 400

CHARGES(2012) = $4.2640 mln$

ADJUSTMENT(2013) = 0.75*0.045 + 0.25*{(410-400)/400} = 0.0400

CHARGES(2013) = 4.2640 mln$ + (4.2640 mln$ * 0.0400) = 4.4346 mln$

10. Term: This Schedule 3.2 C (v2011) shall terminate without further notice on December 31, 2015 at 11:59:59 pm; provided, however, that Momentive and Shell shall meet no later than June 1, 2015 to attempt to agree on the terms and conditions for renewing this Schedule. Neither Party shall be obligated to reach agreement on the terms and conditions of such renewal and may reject any terms or conditions for renewal for any reason at its sole discretion, including, but not limited to, renewing the terms of this Schedule without change. If for any reason Momentive and Shell are unable to agree on the terms of renewal of this Schedule by December 31, 2015 then the terms of this Schedule will continue on a month-to-month basis until a new agreement is reached, subject to the following modification: the Escalation formula in Paragraph 9 will be suspended.

12

APPENDIX A

PROCESS FLOW DIAGRAM

DEMARCATING BOUNDARIES FOR

SUMF AGREEMENT DEFINED

BIOTREATER SYSTEMS

13

14

APPENDIX B

CALCULATION BASIS USED TO DETERMINE

VARIABLE COST ALLOCATION PERCENTAGES

Units of Measure

All mass flow rates are corrected to a dry basis and are in Klbs/day, or 1,000 lbs/day.

All volumetric flow rates are in gallons per minute.

Primary Biotreater

Refer to Appendix A for the grouping of equipment included in this system. The boundaries are drawn such that the Primary Biotreater begins with the API basin, and ends at the discharge of

P-T216/217/501/502/251/252.

FIRM CAPACITY

• | Maximum flow capacity - Estimated at 5,000 gpm, based upon the historical maximum for Primary Biotreater flow. This includes storm water flow from the West Site. This flow is measured using F2018.TU, which records flow from T-T252 to the mix tank |

• | T-T251. |

• | Maximum solids capacity - 126 Klbs/day. A-T213's underflow pumps have a documented design capacity of 150 gpm. The average solids concentration of this underflow (WSBTPRIMUN!NONE!TSS_VSSWS TSS@limsnrc) is 7%, based upon lab data from October 2008 to September 2010. |

150 gpm (8.34 lb/gal)(60 min/ 1hr)(24 hrs/ 1 day)*0.07 = 126 Klbs/day

USAGE

• | East Site (Shell) flow - The East Site has only one metered stream to the Primary Biotreater, F2051.TU, which measures spent caustic flow to the Primary Biotreater. Average spent caustic flow from the East Site between October 2008 and September 2010 is 35 gpm. |

• | West Site (Shell) flow - 220 gpm. Contributions from the West Site groundwater wells and the T-Unit control room sanitary sewer are estimated to total 20 gpm. Since Shell has facilities or assets located on approximately 25% of the land on the West Site, and West Site storm water flow is estimated to be 800 gpm (on average), Shell's proportion of storm water flow to the Primary Biotreater is an estimated 200 gpm. |

• | West Site (Momentive) flow - 2,745 gpm. This is derived mathematically by subtracting Shell flows from both the East and West sites from the total flow to the Primary Biotreater, F2018.TU. The average flow recorded by F2018.TU between October 2008 and September 2010 is 3,000 gpm. This flow data is compiled only from periods of time when the C-Unit is operational. |

3,000 gpm - 35 gpm - 220 gpm = 2,745 gpm

• | East Site (Shell) solids - Insignificant and estimated to be zero in all East Site streams to the Primary Biotreater. |

• | West Site (Shell) solids - Contribution from Shell operations at the West Site is estimated to be zero. |

• | West Site (Momentive) solids - This is derived mathematically by subtracting the biomass generated by Momentive's TOC load in the Secondary Biotreater (as documented below) from total Momentive solids fed to the Solids Incinerator (as documented below). Per the original biotreater design, 1 lb of TOC produces approximately 0.5 lb of biomass. |

42.0 Klbs/day - 16.2 Klbs TOC/day (0.5 lb biomass/ 1 lb TOC) = 33.9 Klbs/day

• | Momentive Usage Percentage - For the Primary Biotreater, this percentage is derived by dividing the quantity of Momentive usage by the total quantity used. The percentage usage related to flow forms 40% of the overall usage, and the percentage usage related to solids froms 60% of the overall usage. Hence Momentive's usage percentage for the Primary Biotreater is calculated to be: |

2745 gpm/ 3000 gpm * 40% + 33.9 Klbs/day / 33.9 Klbs/day * 60% = 96.60%

15

Secondary Biotreater

Refer to Appendix A for the grouping of equipment included in this system. The boundaries are drawn such that the Secondary Biotreater begins at the discharge of P-T251/252, and ends at the final outfall and the discharge of P-T716.

FIRM CAPACITY

• | Maximum TOC (Total Organic Carbon) capacity - 38.16 Klbs/day, based upon the biotreater design specifications. |

USAGE

• | East Site (Norco) TOC loading - This is calculated using the average TOC content of the East Site stream (A002-TU-SX-NET-ES_FEED_11AM,TOC,LOG,SAMPLE,ENVIRO@otterhdc) and the average flow rate of the same stream, as measured by F2000.TU. TOC data recorded between May 2010 and September 2010 is used to establish the average East Site feed TOC content of 200 ppm, excluding periods in 2009-2010 when East Site feed composition was not representative due to large unit outages. The average flow rate of the East Site feed stream (1800 gpm) is from this same May-September 2010 timeframe, so as to preserve data consistency. |

200 ppm TOC x 1,800 gpm x 0.012 x 1Klb/1000 lb = 4.32 Klbs/day

• | West Site (Shell) TOC loading - Contribution from Shell operations at the West Site is estimated to be zero. |

• | West Site (Momentive) TOC loading - This is calculated using the average TOC content of the West Site stream (OTR146198 .. A002-TU-A-T213_5,TOC,LOG,SAMPLE,ENVIRO@otterhdc) and the average flow rate of the same stream, as measured by F2018.TU. Data is compiled from 2009-2010 operations, excluding periods when the C-Unit was shutdown. The average TOC concentration is 450 ppm, and the average flow rate is 3,000 gpm. |

450 ppm TOC x 3,000 gpm x 0.012 x 1Klb/1000 lb = 16.2 Klbs/day

• | Momentive Usage Percentage - For the Secondary Biotreater, this percentage is derived by dividing the quantity of Momentive usage by the total quantity used. |

16.2 Klbs/day / (16.2 + 4.32 ) Klbs/day * 100% = 78.95%

Solids Incinerator

Refer to Appendix A for the grouping of equipment included in this system. The boundaries are drawn such that the Solids Incinerator begins at the discharge of P-T716 and ends at the roll-off containers or the incinerator stack.

FIRM CAPACITY

• | Maximum incineration capacity - 90.31 Klbs/day, on a dry basis. This is calculated by multiplying 392.64 Klbs/day (the incineration capacity on a wet basis, per the environmental compliance limit) by the average solids content of the biotreater feed (23%), as referenced below. |

USAGE

• | East Site (Shell) solids loading - This is calculated using the total East Site TOC loading, and assumes there are zero inorganic solids included. Per the original biotreater design, 1 lb of TOC produces approximately 0.5 lb of biomass. |

4.32 Klbs TOC/day ( 0.5 lb biomass / 1 lb TOC ) = 2.16 Klbs/day solids (dry basis)

• | West Site (Shell) solids loading - Contribution from Shell operations at the West Site is estimated to be zero. |

• | West Site (Momentive) solids loading - This is calculated by subtracting the East Site and West Site solids loading attributable to Shell from the total amount of solids fed to the solids incinerator, as measured by F7030.TU. The resultant quantity represents the sum total of solids loading attributable to Momentive. The average flow measured by F7030.TU between May 2009 and September 2010 was 4 tons/hr. The average solids concentration was 23%, recorded between October 2008 and September 2010 (WSBTBLTPCK!NONE!SOLIDSPCT Percent Solids@limsnrc). |

4 tons/hr ( 2Klb / 1 ton)( 24 hrs / 1 day ) (0.23) - 2.16 Klbs/day = 42.0 Klbs/day solids (dry basis)

• | Momentive Usage Percentage - For the Solids Incinerator, this percentage is derived by dividing the quantity of Momentive usage by the total quantity used. |

42.0 Klbs/day / (42.0 + 2.16 ) Klbs/day * 100% = 95.11%

16