Attached files

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

_______________

Form 10-K

ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF

THE SECURITIES EXCHANGE ACT OF 1934

For the Fiscal Year Ended January 3, 2010

Commission File No.: 001-33994

Interface, Inc.

(Exact name of registrant as specified in its charter)

|

Georgia

|

58-1451243

|

|

|

(State of incorporation)

|

(I.R.S. Employer Identification No.)

|

|

|

2859 Paces Ferry Road, Suite 2000

|

||

|

Atlanta, Georgia

|

30339

|

|

|

(Address of principal executive offices)

|

(zip code)

|

Registrant’s telephone number, including area code: (770) 437-6800

Securities Registered Pursuant to Section 12(b) of the Act:

|

Title of Each Class

|

Name of Each Exchange on Which Registered:

|

|

|

Class A Common Stock, $0.10 Par Value Per Share

|

Nasdaq Global Select Market

|

|

|

Series B Participating Cumulative Preferred Stock Purchase Rights

|

Nasdaq Global Select Market

|

Securities Registered Pursuant to Section 12(g) of the Act: None

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. YES o NO þ

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act. YES o NO þ

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. YES þ NO o

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Date File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). YES o NO o

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. o

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer or a smaller reporting company. See the definitions of “large accelerated filer,” “accelerated filer” and a “smaller reporting company” in Rule 12b-2 of the Securities Exchange Act of 1934. (Check one):

|

Large Accelerated Filer o

|

Accelerated Filer þ

|

Non-Accelerated Filer o

|

Smaller Reporting Company o

|

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act). YES o NO þ

Aggregate market value of the voting and non-voting stock held by non-affiliates of the registrant as of July 2, 2009 (assuming conversion of Class B Common Stock into Class A Common Stock): $339,520,732 (57,351,475 shares valued at the last sales price of $5.92 on July 2, 2009). See Item 12.

Number of shares outstanding of each of the registrant’s classes of Common Stock, as of March 1, 2010:

|

Class

|

Number of Shares | ||||

|

Class A Common Stock, $0.10 par value per share

|

56,721,192 | ||||

|

Class B Common Stock, $0.10 par value per share

|

6,596,352 | ||||

DOCUMENTS INCORPORATED BY REFERENCE

Portions of the Proxy Statement for the 2010 Annual Meeting of Shareholders are incorporated by reference into Part III.

1

PART I

ITEM 1. BUSINESS

Introduction and General

We are a worldwide leader in design, production and sales of modular carpet, and a manufacturer, marketer and servicer of select other floorcovering products for the commercial, institutional and residential markets. In recent years, modular carpet sales growth in the floorcovering industry has significantly outpaced the growth of the overall industry, as architects, designers and end users increasingly recognized the unique and superior attributes of modular carpet, including its dynamic design capabilities, greater economic value (which includes lower costs as a result of reduced waste in both installation and replacement), and installation ease and speed. Our Modular Carpet segment sales, which do not include modular carpet sales in our Bentley Prince Street segment, grew from $646.2 million to $765.3 million during the 2005 to 2009 period, representing a 4% compound annual growth rate.

Our Bentley Prince Street® brand is a leader in the high-end, designer-oriented sector of the broadloom market segment, where custom design and high quality are the principal specifying and purchasing factors.

As a global company with a reputation for high quality, reliability and premium positioning, we market products in over 110 countries under established brand names such as InterfaceFLOR®, Heuga®, Bentley Prince Street and FLOR® in modular carpet; Bentley Prince Street and Prince Street House and Home™ in broadloom carpet; and Intersept® in antimicrobial chemicals. Our principal geographic markets are the Americas, Europe and Asia-Pacific, where the percentages of our total net sales were approximately 58%, 30% and 12%, respectively, for fiscal year 2009.

Capitalizing on our leadership in modular carpet for the corporate office segment, we embarked on a market diversification strategy in 2001 to increase our presence and market share for modular carpet in non-corporate office market segments, such as government, education, healthcare, hospitality and retail space, which combined are almost twice the size of the approximately $1 billion U.S. corporate office segment. In 2003, we expanded our diversification strategy to target the approximately $11 billion U.S. residential market segment for carpet. As a result, our mix of corporate office versus non-corporate office modular carpet sales in the Americas shifted to 40% and 60%, respectively, for 2009 compared with 64% and 36%, respectively, in 2001. (Company-wide, our mix of corporate office versus non-corporate office sales was 55% and 45%, respectively, in 2009.) We believe the appeal and utilization of modular carpet is growing in each of these non-corporate office segments, and we are using our considerable skills and experience with designing, producing and marketing modular products that make us the market leader in the corporate office segment to support and facilitate our penetration into these new segments around the world.

In the fourth quarter of 2008, and particularly in November and December, the worldwide financial and credit crisis caused many corporations, governments and other organizations to delay or curtail spending on renovation and construction projects where our carpet is used. This downturn negatively impacted our performance. In the fourth quarter of 2008, we announced a restructuring plan pursuant to which we ceased manufacturing operations at our facility in Canada and reduced our worldwide employee base by a total of approximately 530 employees in the areas of manufacturing, sales and administration. In the first and second quarters of 2009, we announced further restructuring plans to further align our cost structure with market demand for our products, resulting in the reduction of an additional 370 employees worldwide. The employee reductions amounted to about 23% of our worldwide workforce. These plans have reduced costs across our worldwide operations, and more closely aligned our operations with the decreased demand levels that we have experienced since the fourth quarter of 2008.

Our Strengths

Our principal competitive strengths include:

Market Leader in Attractive Modular Carpet Segment. We are the world’s leading manufacturer of carpet tile. Modular carpet has become more prevalent across all commercial interiors markets as designers, architects and end users have become more familiar with its unique attributes. We continue to drive this trend with our product innovations and designs discussed below. According to the 2009 Floor Focus interiors industry survey of the top 250 designers in the United States, carpet tile was ranked as the number one “hot product” for the eighth consecutive year. We believe that we are well positioned to lead and capitalize upon the continued shift to modular carpet, both domestically and around the world.

2

Established Brands and Reputation for Quality, Reliability and Leadership. Our products are known in the industry for their high quality, reliability and premium positioning in the marketplace. Our established brand names in carpets are leaders in the industry. The 2009 Floor Focus survey ranked our InterfaceFLOR brand first or second in each of the survey categories of quality, performance, value, service and design. InterfaceFLOR also ranked second in the category of “best overall business experience” for carpet companies in this survey. On the international front, InterfaceFLOR and Heuga are well-recognized brand names in carpet tiles for commercial, institutional and residential use. More generally, as the appeal and utilization of modular carpet continues to expand into new market segments such as education, hospitality and retail space, our reputation as the pioneer of modular carpet — as well as our established brands and leading market position for modular carpet in the corporate office segment — will enhance our competitive advantage in marketing to the customers in these new markets.

Innovative Product Design and Development Capabilities. Our product design and development capabilities have long given us a significant competitive advantage, and they continue to do so as modular carpet’s appeal and utilization expand across virtually every market segment and around the globe. One of our best design innovations is our i2™ modular product line, which includes our popular Entropy® product for which we received a patent in 2005 on the key elements of its design. The i2 line introduced and features mergeable dye lots, and includes carpet tile products designed to be installed randomly without reference to the orientation of neighboring tiles. The i2 line offers cost-efficient installation and maintenance, interactive flexibility, and recycled and recyclable materials. Our i2 line of products, which now comprises approximately 40% of our total U.S. modular carpet business, represents a differentiated category of smart, environmentally sensitive and stylish modular carpet, and Entropy has been the fastest growing product in our history. The award-winning design firm David Oakey Designs had a pivotal role in developing our i2 product line, and our long-standing exclusive relationship with David Oakey Designs remains vibrant and augments our internal research, development and design staff. Another recent innovation is our patent-pending TacTiles® carpet tile installation system, which uses small squares of adhesive plastic film to connect intersecting carpet tiles, thus eliminating the need for traditional carpet adhesive and resulting in a reduction in installation time and waste materials.

Made-to-Order and Global Manufacturing Capabilities. The success of our modernization and restructuring of operations over the past several years gives us a distinct competitive advantage in meeting two principal requirements of the specified products markets we primarily target — that is, providing custom samples quickly and on-time delivery of customized final products. We also can generate realistic digital samples that allow us to create a virtually unlimited number of new design concepts and distribute them instantly for customer review, while at the same time reducing sampling waste. Approximately 75% to 80% of our modular carpet products in the United States and Asia-Pacific markets are now made-to-order, and we are increasing our made-to-order production in Europe as well. Our made-to-order capabilities not only enhance our marketing and sales, they significantly improve our inventory turns. Our global manufacturing capabilities in modular carpet production are an important component of this strength, and give us an advantage in serving the needs of multinational corporate customers that require products and services at various locations around the world. Our manufacturing locations across four continents enable us to compete effectively with local producers in our international markets, while giving international customers more favorable delivery times and freight costs.

Recognized Global Leadership in Ecological Sustainability. Our long-standing goal and commitment to be ecologically “sustainable” — that is, the point at which we are no longer a net “taker” from the earth and do no harm to the biosphere — has emerged as a competitive strength for our business and remains a strategic initiative. It now includes Mission Zero®, our global branding initiative, which represents our mission to eliminate any negative impact our companies may have on the environment by the year 2020. Our acknowledged leadership position and expertise in this area resonate deeply with many of our customers and prospects around the globe, and provide us with a differentiating advantage in competing for business among architects, designers and end users of our products, who increasingly make purchase decisions based on “green” factors. The 2009 Floor Focus survey, which named our InterfaceFLOR business the top among “Green Leaders” and gave us the top honors for “Green Kudos”, found that 67% of the designers surveyed consider sustainability an added benefit and 30% consider it a “make or break” issue when deciding what products to recommend or purchase.

Strong Operating Leverage Position. Our operating leverage, which we define as our ability to realize profit on incremental sales, is strong and allows us to increase earnings at a higher rate than our rate of increase in net sales. Our operating leverage position is primarily a result of (1) the specified, high-end nature and premium positioning of our principal products in the marketplace, and (2) the mix of fixed and variable costs in our manufacturing processes that allow us to increase production of most of our products without significant increases in capital expenditures or fixed costs. For example, while net sales from our Modular Carpet segment increased from $646.2 million in 2005 to $930.7 million in 2007 (a period in which our industry and business were recovering from a prior downturn), our operating income from that segment increased from $77.4 million (12.0% of net sales) in 2005 to $133.7 million (14.4% of net sales) in 2007.

3

Experienced and Motivated Management and Sales Force. An important component of our competitive position is the quality of our management team and its commitment to developing and maintaining an engaged and accountable workforce. Our team is highly skilled and dedicated to guiding our overall growth and expansion into our targeted market segments, while maintaining our leadership in traditional markets and our high contribution margins. We utilize an internal marketing and predominantly commissioned sales force of approximately 700 experienced personnel, stationed at over 70 locations in over 30 countries, to market our products and services in person to our customers. We have also developed special features for our incentive compensation and our sales and marketing training programs in order to promote performance and facilitate leadership by our executives in strategic areas.

Our Business Strategy and Principal Initiatives

Our business strategy is (1) to continue to use our leading position in the modular carpet market segment and our product design and global made-to-order capabilities as a platform from which to drive acceptance of modular carpet products across several industry segments, while maintaining our leadership position in the corporate office market segment, and (2) to return to our historical profit levels in the high-end, designer-oriented sector of the broadloom carpet market. We will seek to increase revenues and profitability by capitalizing on the above strengths and pursuing the following key strategic initiatives:

Continue to Penetrate Non-Corporate Office Market Segments. We will continue our strategic focus on product design and marketing and sales efforts for non-corporate office market segments such as government, education, healthcare, hospitality, retail and residential space. We began this initiative as part of our market diversification strategy in 2001 (when our initial objective was reducing our exposure to the more severe economic cyclicality of the corporate office segment), and it has become a principal strategy generally for growing our business and enhancing profitability. We have shifted our mix of corporate office versus non-corporate office modular carpet sales in the Americas to 40% and 60%, respectively, for fiscal 2009 from 64% and 36%, respectively, in fiscal 2001. To implement this strategy, we:

|

·

|

introduced specialized product offerings tailored to the unique demands of these segments, including specific designs, functionalities and prices;

|

|

·

|

created special sales teams dedicated to penetrating these segments at a high level, with a focus on specific customer accounts rather than geographic territories; and

|

|

·

|

realigned incentives for our corporate office segment sales force generally in order to encourage their efforts, and where appropriate, to assist our penetration of these other segments.

|

As part of this strategy, we launched our FLOR and Prince Street House and Home lines of products in 2003 to focus on the approximately $11 billion U.S. residential carpet market segment. These products were specifically created to bring high style modular and broadloom floorcovering to the U.S. residential market. FLOR is offered by many specialty retailers, over the Internet and in a number of major retail catalogs. Through such direct and indirect retailing, FLOR sales have grown more than 50% from 2005 to 2009. Prince Street House and Home brings new colors and patterns to the high-end consumer market with a collection of broadloom carpet and rugs sold through hundreds of retail stores and interior designers. Through agreements between our FLOR brand and both Martha Stewart Living Omnimedia and the national homebuilder KB Home, we are further expanding our penetration of the U.S. residential market with a line of Martha Stewart-branded carpet tiles. Through our Heuga Home division, we have been increasing our marketing of modular carpet to the residential segment of international soft floorcovering markets, the size of which we believe to be approximately $2.3 billion in Western Europe alone.

Penetrate Expanding Geographic Markets for Modular Products. The popularity of modular carpet continues to increase compared with other floorcovering products across most markets, internationally as well as in the United States. While maintaining our leadership in the corporate office segment, we will continue to build upon our position as the worldwide leader for modular carpet in order to promote sales in all market segments globally. A principal part of our international focus – which utilizes our global marketing capabilities and sales infrastructure – is the significant opportunities in several emerging geographic markets for modular carpet. Some of these markets, such as China, India and Eastern Europe, represent large and growing economies that are essentially new markets for modular carpet products. Others, such as Germany and Italy, are established markets that are transitioning to the use of modular carpet from historically low levels of penetration. Each of these emerging markets represents a significant growth opportunity for our modular carpet business. Our initiative to penetrate these markets will include drawing upon our internationally recognized InterfaceFLOR and Heuga brands.

4

Continue to Minimize Expenses and Invest Strategically. We have steadily trimmed costs from our operations for several years through multiple and sometimes painful initiatives, which have made us leaner today and for the future. Our supply chain and other cost containment initiatives have improved our cost structure and yielded the operating efficiencies we sought. While we still seek to minimize our expenses in order to increase profitability, we will also take advantage of strategic opportunities to invest in systems, processes and personnel that can help us grow our business and increase profitability and value.

Sustain Leadership in Product Design and Development. As discussed above, our leadership position for product design and development is a competitive advantage and key strength, especially in the modular carpet market segment, where our i2 products and recent TacTiles installation system have confirmed our position as an innovation leader. We will continue initiatives to sustain, augment and capitalize upon that strength to continue to increase our market share in targeted market segments. Our Mission Zero global branding initiative, which draws upon and promotes our ecological sustainability commitment, is part of those initiatives and includes placing our Mission Zero logo on many of our marketing and merchandising materials distributed throughout the world.

Use Strong Free Cash Flow Generation to De-leverage Our Balance Sheet. Our principal businesses have been structured – including through our rationalization and repositioning initiatives over the past eight years – to yield high contribution margins and generate strong free cash flow (by which we mean cash available to apply towards debt service). Our historical investments in global manufacturing capabilities and mass customization techniques and facilities, which we have maintained, also contribute to our ability to generate substantial levels of free cash flow. We will use our strong free cash flow generation capability to continue to repay debt and strengthen our financial position. We will also continue to execute programs to reduce costs further and enhance free cash flow. In addition, our existing capacity to increase production levels without significant capital expenditures will further enhance our generation of free cash flow if and when demand for our products rises.

Challenges

In order to capitalize on our strengths and to implement successfully our business strategy and the principal initiatives discussed above, we will have to handle successfully several challenges that confront us or that affect our industry in general. As discussed in the Risk Factors in Item 1A of this Report, several factors could make it difficult for us, including:

|

|

•

|

|

sales of our principal products have been and may continue to be affected by adverse economic cycles in the renovation and construction of commercial and institutional buildings;

|

|

|

|

|

|

|

|

•

|

|

we compete with a large number of manufacturers in the highly competitive commercial floorcovering products market, and some of these competitors have greater financial resources than we do;

|

|

|

|

|

|

|

|

•

|

|

our success depends significantly upon the efforts, abilities and continued service of our senior management executives and our principal design consultant, and our loss of any of them could affect us adversely;

|

|

|

|

|

|

|

|

•

|

|

our substantial international operations are subject to various political, economic and other uncertainties that could adversely affect our business results;

|

|

|

|

|

|

|

|

•

|

|

large increases in the cost of petroleum-based raw materials could adversely affect us if we are unable to pass these cost increases through to our customers;

|

|

|

|

|

|

|

|

•

|

|

unanticipated termination or interruption of any of our arrangements with our primary third party suppliers of synthetic fiber could have a material adverse effect on us; and

|

|

|

|

|

|

|

|

•

|

|

we have a significant amount of indebtedness, which could have important negative consequences to us.

|

We believe our business model is strong enough, and our strategic initiatives are properly calibrated, for us to handle these and other challenges we will encounter in our business.

Floorcovering Products and Services

Interface is the world’s largest manufacturer and marketer of modular carpet. We also manufacture and sell broadloom carpet, which generally consists of tufted carpet sold primarily in twelve-foot rolls, under the Bentley Prince Street brand. Our broadloom operations focus on the high quality, designer-oriented sector of the U.S. broadloom carpet market and select international markets.

5

Modular Carpet

Our modular carpet system, which is marketed under the established global brands InterfaceFLOR and Heuga, and more recently under the Bentley Prince Street brand, utilizes carpet tiles cut in precise, dimensionally stable squares (usually 50 cm x 50 cm) or rectangles to produce a floorcovering that combines the appearance and texture of traditional soft floorcovering with the advantages of a modular carpet system. Our GlasBac® technology employs a fiberglass-reinforced polymeric composite backing that provides dimensional stability and reduces the need for adhesives or fasteners. We also make carpet tiles with a backing containing post-industrial and/or post-consumer recycled materials, which we market under the GlasBacRE brand. In 2008, we introduced the Convert™ collection of carpet tile designed and manufactured with yarn containing varying degrees of post-consumer nylon, depending on the style and color.

Our carpet tile has become popular for a number of reasons. Carpet tile incorporating this reinforced backing may be easily removed and replaced, permitting rearrangement of furniture without the inconvenience and expense associated with removing, replacing or repairing other soft surface flooring products, including broadloom carpeting. Because a relatively small portion of a carpet installation often receives the bulk of traffic and wear, the ability to rotate carpet tiles between high traffic and low traffic areas and to selectively replace worn tiles can significantly increase the average life and cost efficiency of the floorcovering. In addition, carpet tile facilitates access to sub-floor air delivery systems and telephone, electrical, computer and other wiring by lessening disruption of operations. It also eliminates the cumulative damage and unsightly appearance commonly associated with frequent cutting of conventional carpet as utility connections and disconnections are made. We believe that, within the overall floorcovering market, the worldwide demand for modular carpet is increasing as more customers recognize these advantages.

We use a number of conventional and technologically advanced methods of carpet construction to produce carpet tiles in a wide variety of colors, patterns, textures, pile heights and densities. These varieties are designed to meet both the practical and aesthetic needs of a broad spectrum of commercial interiors – particularly offices, healthcare facilities, airports, educational and other institutions, hospitality spaces, and retail facilities – and residential interiors. Our carpet tile systems permit distinctive styling and patterning that can be used to complement interior designs, to set off areas for particular purposes and to convey graphic information. While we continue to manufacture and sell a substantial portion of our carpet tile in standard styles, an increasing percentage of our modular carpet sales is custom or made-to-order product designed to meet customer specifications.

In addition to general uses of our carpet tile, we produce and sell a specially adapted version of our carpet tile for the healthcare facilities market. Our carpet tile possesses characteristics — such as the use of the Intersept antimicrobial, static-controlling nylon yarns, and thermally pigmented, colorfast yarns — which make it suitable for use in these facilities in place of hard surface flooring. Moreover, we launched our FLOR line of products to specifically target modular carpet sales to the residential market segment. Through our relationship with David Oakey Designs, we also have created modular carpet products (some of which are part of our i2 product line) specifically designed for each of the education, hospitality and retail market segments.

We also manufacture and sell two-meter roll goods that are structure-backed and offer many of the advantages of both carpet tile and broadloom carpet. These roll goods are often used in conjunction with carpet tiles to create special design effects. Our current principal customers for these products are in the education, healthcare and government market segments.

Broadloom Carpet

We maintain a significant share of the high-end, designer-oriented broadloom carpet segment by combining innovative product design and short production and delivery times with a marketing strategy aimed at interior designers, architects and other specifiers. Our Bentley Prince Street designs emphasize the dramatic use of color and multi-dimensional texture. In addition, we have launched the Prince Street House and Home collection of high-style broadloom carpet and area rugs targeted at design-oriented residential consumers. We received the 2007 Best of NeoCon Silver Award in the modular category for the Saturnia™ Collection, which is made up of carpet tile and broadloom products.

Other Products

We sell a proprietary antimicrobial chemical compound under the registered trademark Intersept. We incorporate Intersept in all of our modular carpet products and have licensed Intersept to another company for use in air filters. We also sell our TacTiles carpet tile installation system, along with a variety of traditional adhesives and products for carpet installation and maintenance that are manufactured by a third party. In addition, we continue to manufacture and sell our Intercell® brand raised/access flooring product in Europe.

6

Services

For several years, we provided or arranged for commercial carpet installation services, primarily through our Re:Source® service provider network. We decided to exit our owned Re:Source dealer businesses, and in 2005 we completed the exit activities related to the owned dealer businesses. In early 2006, we sold certain assets relating to our aligned non-owned dealer network, and have since discontinued its operations as well. We continue to provide “turnkey” project management services for national accounts and other large customers through our InterfaceSERVICES™ business.

Marketing and Sales

We have traditionally focused our carpet marketing strategy on major accounts, seeking to build lasting relationships with national and multinational end-users, and on architects, engineers, interior designers, contracting firms, and other specifiers who often make or significantly influence purchasing decisions. While most of our sales are in the corporate office segment, both new construction and renovation, we also emphasize sales in other segments, including retail space, government institutions, schools, healthcare facilities, tenant improvement space, hospitality centers, residences and home office space. Our marketing efforts are enhanced by the established and well-known brand names of our carpet products, including the InterfaceFLOR, FLOR and Heuga brands in modular carpet and Bentley Prince Street brand in broadloom carpet. Our exclusive consulting agreement with the award-winning, premier design firm David Oakey Designs enabled us to introduce more than 25 new carpet designs in the United States in 2009 alone.

An important part of our marketing and sales efforts involves the preparation of custom-made samples of requested carpet designs, in conjunction with the development of innovative product designs and styles to meet the customer’s particular needs. Our mass customization initiative simplified our carpet manufacturing operations, which significantly improved our ability to respond quickly and efficiently to requests for samples. In most cases, we can produce samples to customer specifications in less than five days, which significantly enhances our marketing and sales efforts and has increased our volume of higher margin custom or made-to-order sales. In addition, through our websites, we have made it easy to view and request samples of our products. We also have technology which allows us to provide digital, simulated samples of our products, which helps reduce raw material and energy consumption associated with our samples.

We primarily use our internal marketing and sales force to market our carpet products. In order to implement our global marketing efforts, we have product showrooms or design studios in the United States, Canada, Mexico, Brazil, Denmark, England, Northern Ireland, France, Germany, Spain, Belgium, the Netherlands, India, Australia, Japan, Italy, Norway, United Arab Emirates, Russia, Singapore, Hong Kong and China. We expect to open offices in other locations around the world as necessary to capitalize on emerging marketing opportunities.

Manufacturing

We manufacture carpet at three locations in the United States and at facilities in the Netherlands, the United Kingdom, Australia and Thailand. In addition, we currently are constructing a new manufacturing facility in China that is expected to begin production in late 2010. Pursuant to our restructuring plan adopted in the fourth quarter of 2008, we have ceased manufacturing operations at our facility in Canada.

Having foreign manufacturing operations enables us to supply our customers with carpet from the location offering the most advantageous delivery times, duties and tariffs, exchange rates, and freight expense, and enhances our ability to develop a strong local presence in foreign markets. We believe that the ability to offer consistent products and services on a worldwide basis at attractive prices is an important competitive advantage in servicing multinational customers seeking global supply relationships. We will consider additional locations for manufacturing operations in other parts of the world as necessary to meet the demands of customers in international markets.

To the extent practicable, we seek to standardize our worldwide modular carpet manufacturing procedures. In connection with the implementation of this plan, we strive to establish global standards for our tufting equipment, yarn systems and product styling. We previously had changed our standard carpet tile size to be 50 cm x 50 cm, which we believe has allowed us to reduce operational waste and fossil fuel energy consumption and to offer consistent product sizing for our global customers.

7

We also implemented a new, flexible-inputs carpet backing line at our modular carpet manufacturing facility in LaGrange, Georgia. Using next generation thermoplastic technology, the custom-designed backing line dramatically improves our ability to keep reclaimed and waste carpet in the production “technical loop,” and further permits us to explore other plastics and polymers as inputs. This new process, which we call “Cool Blue™”, came on line for production of certain carpet styles in late 2005. In 2007, we implemented new technology that more cleanly separates the face fiber and backing of reclaimed and waste carpet, thus making it easier to recycle some of its components and providing a purer supply of inputs for the Cool Blue process. This technology, which is part of our ReEntry®2.0 carpet reclamation program, allows us to send some of the reclaimed face fiber back to our fiber supplier to be blended with virgin or other post-industrial materials and extruded into new fiber.

The environmental management systems of our floorcovering manufacturing facilities in LaGrange, Georgia, West Point, Georgia, City of Industry, California, Shelf, England, Northern Ireland, Australia, the Netherlands and Thailand are certified under International Standards Organization (ISO) Standard No. 14001.

Our significant international operations are subject to various political, economic and other uncertainties, including risks of restrictive taxation policies, foreign exchange restrictions, changing political conditions and governmental regulations. We also receive a substantial portion of our revenues in currencies other than U.S. dollars, which makes us subject to the risks inherent in currency translations. Although our ability to manufacture and ship products from facilities in several foreign countries reduces the risks of foreign currency fluctuations we might otherwise experience, we also engage from time to time in hedging programs intended to further reduce those risks.

Competition

We compete, on a global basis, in the sale of our floorcovering products with other carpet manufacturers and manufacturers of vinyl and other types of floorcoverings. Although the industry has experienced significant consolidation, a large number of manufacturers remain in the industry. We believe we are the largest manufacturer of modular carpet in the world. However, a number of domestic and foreign competitors manufacture modular carpet as one segment of their business, and some of these competitors have financial resources greater than ours. In addition, some of the competing carpet manufacturers have the ability to extrude at least some of their requirements for fiber used in carpet products, which decreases their dependence on third party suppliers of fiber.

We believe the principal competitive factors in our primary floorcovering markets are brand recognition, quality, design, service, broad product lines, product performance, marketing strategy and pricing. In the corporate office market segment, modular carpet competes with various floorcoverings, of which broadloom carpet is the most common. The quality, service, design, better and longer average product performance, flexibility (design options, selective rotation or replacement, use in combination with roll goods) and convenience of our modular carpet are our principal competitive advantages.

We believe we have competitive advantages in several other areas as well. First, our exclusive relationship with David Oakey Designs allows us to introduce numerous innovative and attractive floorcovering products to our customers. Additionally, we believe that our global manufacturing capabilities are an important competitive advantage in serving the needs of multinational corporate customers. We believe that the incorporation of the Intersept antimicrobial chemical agent into the backing of our modular carpet enhances our ability to compete successfully across all of our market segments generally, and specifically with resilient tile in the healthcare market.

In addition, we believe that our goal and commitment to be ecologically “sustainable” by 2020 is a brand-enhancing, competitive strength as well as a strategic initiative. Increasingly, our customers are concerned about the environmental and broader ecological implications of their operations and the products they use in them. Our leadership, knowledge and expertise in the area, especially in the “green building” movement and the related LEED certification program, resonate deeply with many of our customers and prospects around the globe, and these businesses are increasingly making purchase decisions based on “green” factors. Our modular carpet products historically have had inherent installation and maintenance advantages that translated into greater efficiency and waste reduction. We have further enhanced the “green” quality of our modular carpet in our highly successful i2 product line, and we are using raw materials and production technologies, such as our Cool Blue backing line and our ReEntry 2.0 reclaimed carpet separation process, that directly reduce the adverse impact of those operations on the environment and limit our dependence on petrochemicals.

8

To further raise awareness of our goal of becoming sustainable, we launched our Mission Zero global branding initiative, which represents our mission to eliminate any negative impact our companies may have on the environment by the year 2020. As part of this initiative, our Mission Zero logo appears on many of our marketing and merchandising materials distributed throughout the world. To further our Mission Zero goals, we partnered with other like-minded organizations to launch the website missionzero.org in 2008 to facilitate the sharing of ideas, best practices and resources in the area of sustainability.

Interior Fabrics

In July 2007, we sold our Fabrics Group business segment to a third party. This business designs, manufactures and markets specialty fabrics for open plan office furniture systems and other commercial interiors. In April 2006, we sold our European fabrics business to an entity formed by the business’s management team. Current and prior periods have been restated to include the results of operations and related disposal costs, gains and losses for these businesses as discontinued operations. In addition, assets and liabilities of these businesses have been reported in assets and liabilities held for sale for all reported periods.

Specialty Products

In March 2007, we sold Pandel, Inc., our subsidiary that historically conducted our Specialty Products business segment. Pandel produces vinyl carpet tile backing and specialty mat and foam products.

Product Design, Research and Development

We maintain an active research, development and design staff of approximately 60 people and also draw on the research and development efforts of our suppliers, particularly in the areas of fibers, yarns and modular carpet backing materials. Our research and development costs were $12.7 million, $15.3 million and $15.8 million in 2009, 2008, and 2007, respectively.

Our research and development team provides technical support and advanced materials research and development for the entire family of Interface companies. The team assisted in the development of our NexStep® backing, which employs moisture-impervious polycarbite precoating technology with a chlorine-free urethane foam secondary backing, and also helped develop a post-consumer recycled content, polyvinyl chloride, or PVC, extruded sheet process that has been incorporated into our GlasBacRE modular carpet backing. Our post-consumer recycled content PVC extruded sheet exemplifies our commitment to “closing-the-loop” in recycling. More recently, this team developed our patent-pending TacTiles carpet tile installation system, which uses small squares of adhesive plastic film to connect intersecting carpet tiles. The team also helped implement our Cool Blue flexible inputs backing line and our ReEntry 2.0 reclaimed carpet separation technology and post-consumer recycling technology for nylon face fibers. With a goal of supporting sustainable product designs in floorcoverings applications, we continue to evaluate 100% renewable polymers based on corn-derived polylactic acid (PLA) for use in our products.

Our research and development team also is the coordinator of our QUEST and EcoSense initiatives (discussed below under “Environmental Initiatives”) and supports the dissemination, consultancies and technical communication of our global sustainability endeavors. This team also provides all biochemical and technical support to Intersept antimicrobial chemical product initiatives.

Innovation and increased customization in product design and styling are the principal focus of our product development efforts. Our carpet design and development team is recognized as an industry leader in carpet design and product engineering for the commercial and institutional markets.

David Oakey Designs provides carpet design and consulting services to our floorcovering businesses pursuant to a consulting agreement with us. David Oakey Designs’ services under the agreement include creating commercial carpet designs for use by our floorcovering businesses throughout the world, and overseeing product development, design and coloration functions for our modular carpet business in North America. The current agreement runs through April 2011. While the agreement is in effect, David Oakey Designs cannot provide similar services to any other carpet company. Through our relationship with David Oakey Designs, we introduced more than 25 new carpet designs in 2009 alone, and have enjoyed considerable success in winning U.S. carpet industry awards.

David Oakey Designs also contributed to our ability to efficiently produce many products from a single yarn system. Our mass customization production approach evolved, in major part, from this concept. In addition to increasing the number and variety of product designs, which enables us to increase high margin custom sales, the mass customization approach increases inventory turns and reduces inventory levels (for both raw materials and standard products) and their related costs because of our more rapid and flexible production capabilities.

9

Our i2 product line — which includes, among others, our patented Entropy modular carpet product — represents an innovative breakthrough in the design of modular carpet. The i2 line introduced and features mergeable dye lots, cost-efficient installation and maintenance, interactive flexibility and recycled and recyclable materials. Some of these products may be installed without regard to the directional orientation of the carpet tile, and their features also make installation, maintenance and replacement of modular carpet easier, less expensive and less wasteful.

Environmental Initiatives

In the latter part of 1994, we commenced a new industrial ecological sustainability initiative called EcoSense, inspired in part by the interest of customers concerned about the environmental implications of how they and their suppliers do business. EcoSense, which includes our QUEST waste reduction initiative, is directed towards the elimination of energy and raw materials waste in our businesses, and, on a broader and more long-term scale, the practical reclamation — and ultimate restoration — of shared environmental resources. The initiative involves a commitment by us:

|

•

|

to learn to meet our raw material and energy needs through recycling of carpet and other petrochemical products and harnessing benign energy sources; and

|

|

|

•

|

to pursue the creation of new processes to help sustain the earth’s non-renewable natural resources.

|

We have engaged some of the world’s leading authorities on global ecology as environmental advisors. The list of advisors includes: Paul Hawken, author of The Ecology of Commerce: A Declaration of Sustainability and The Next Economy, and co-author with Amory Lovins and Hunter Lovins of Natural Capitalism: Creating the Next Industrial Revolution; Mr. Lovins, energy consultant and co-founder of the Rocky Mountain Institute; John Picard, President of E2 Environmental Enterprises; Jonathan Porritt, director of Forum for the Future; Bill Browning, fellow and former director of the Rocky Mountain Institute’s Green Development Services; Dr. Karl-Henrik Robert, founder of The Natural Step; Janine M. Benyus, author of Biomimicry; Walter Stahel, Swiss businessman and seminal thinker on environmentally responsible commerce; and Bob Fox, renowned architect.

Our leadership, knowledge and expertise in this area, especially in the “green building” movement and the related LEED certification program, resonate deeply with many of our customers and prospects around the globe, and these businesses are increasingly making purchase decisions based on “green” factors. As more customers in our target markets share our view that sustainability is good business and not just good deeds, our acknowledged leadership position should strengthen our brands and provide a differentiated advantage in competing for business.

In 2006, we launched InterfaceRAISE™, our consulting business that helps clients imagine, plan and execute new ways of advancing business goals while responding to the needs of society and the environment. The operations of this business are not a significant percentage of our consolidated operations.

Backlog

Our backlog of unshipped orders was approximately $112.5 million at February 28, 2010, compared with approximately $100.3 million at March 1, 2009. Historically, backlog is subject to significant fluctuations due to the timing of orders for individual large projects and currency fluctuations. All of the backlog orders at February 28, 2010 are expected to be shipped during the succeeding six to nine months.

Patents and Trademarks

We own numerous patents in the United States and abroad on floorcovering products and on manufacturing processes. The duration of United States patents is between 14 and 20 years from the date of filing of a patent application or issuance of the patent; the duration of patents issued in other countries varies from country to country. We maintain an active patent and trade secret program in order to protect our proprietary technology, know-how and trade secrets. Although we consider our patents to be very valuable assets, we consider our know-how and technology even more important to our current business than patents, and, accordingly, believe that expiration of existing patents or nonissuance of patents under pending applications would not have a material adverse effect on our operations.

10

We also own many trademarks in the United States and abroad. In addition to the United States, the primary countries in which we have registered our trademarks are the United Kingdom, Germany, Italy, France, Canada, Australia, Japan, and various countries in Central and South America. Some of our more prominent registered trademarks include: Interface®, InterfaceFLOR, Heuga, Intersept, GlasBac, Bentley Prince Street, FLOR, Intercell, and Mission Zero. Trademark registrations in the United States are valid for a period of 10 years and are renewable for additional 10-year periods as long as the mark remains in actual use. The duration of trademarks registered in other countries varies from country to country.

Financial Information by Operating Segments and Geographic Areas

The Notes to Consolidated Financial Statements appearing in Item 8 of this Report set forth information concerning our sales, income and assets by operating segments, and our sales and long-lived assets by geographic areas. Additional information regarding sales by operating segment is set forth in Item 7, “Management’s Discussion and Analysis of Financial Condition and Results of Operations.”

Employees

At January 3, 2010, we employed a total of 3,099 employees worldwide. Of such employees, 1,697 were clerical, staff, sales, supervisory and management personnel and 1,402 were manufacturing personnel. We also utilized the services of 75 temporary personnel as of January 3, 2010.

Some of our production employees in Australia and the United Kingdom are represented by unions. In the Netherlands, a Works Council, the members of which are Interface employees, is required to be consulted by management with respect to certain matters relating to our operations in that country, such as a change in control of Interface Europe B.V. (our modular carpet subsidiary based in the Netherlands), and the approval of the Council is required for some of our actions, including changes in compensation scales or employee benefits. Our management believes that its relations with the Works Council, the unions and all of our employees are good.

Environmental Matters

Our operations are subject to laws and regulations relating to the generation, storage, handling, emission, transportation and discharge of materials into the environment. The costs of complying with environmental protection laws and regulations have not had a material adverse impact on our financial condition or results of operations in the past and are not expected to have a material adverse impact in the future. The environmental management systems of our floorcovering manufacturing facilities in LaGrange, Georgia, West Point, Georgia, City of Industry, California, Shelf, England, Northern Ireland, Australia, the Netherlands and Thailand are certified under ISO Standard No. 14001.

Executive Officers of the Registrant

Our executive officers, their ages as of January 3, 2010, and their principal positions with us are set forth below. Executive officers serve at the pleasure of the Board of Directors.

|

Name

|

Age

|

Principal Position(s)

|

|

Daniel T. Hendrix

|

55

|

President and Chief Executive Officer

|

|

Robert A. Coombs

|

51

|

Senior Vice President

|

|

Patrick C. Lynch

|

40

|

Senior Vice President and Chief Financial Officer

|

|

Lindsey K. Parnell

|

52

|

Senior Vice President

|

|

John R. Wells

|

48

|

Senior Vice President

|

|

Raymond S. Willoch

|

51

|

Senior Vice President-Administration, General Counsel and Secretary

|

|

Maria C. Davlantes

|

41

|

Chief Marketing Officer

|

Mr. Hendrix joined us in 1983 after having worked previously for a national accounting firm. He was promoted to Treasurer in 1984, Chief Financial Officer in 1985, Vice President-Finance in 1986, Senior Vice President in October 1995, Executive Vice President in October 2000, and President and Chief Executive Officer in July 2001. He was elected to the Board in October 1996 and has served on the Executive Committee of the Board since July 2001.

11

Mr. Coombs originally worked for us from 1988 to 1993 as a marketing manager for our Heuga carpet tile operations in the United Kingdom and later for all of our European floorcovering operations. In 1996, Mr. Coombs returned to us as Managing Director of our Australian operations. He was promoted in 1998 to Vice President-Sales and Marketing, Asia-Pacific, with responsibility for Australian operations and sales and marketing in Asia, which was followed by a promotion to Senior Vice President, Asia-Pacific. He was promoted to Senior Vice President, European Sales, in May 1999 and Senior Vice President, European Sales and Marketing, in April 2000. In February 2001, he was promoted to President and Chief Executive Officer of Interface Overseas Holdings, Inc. with responsibility for all of our floorcoverings operations in both Europe and the Asia-Pacific region, and he became a Vice President of Interface. In September 2002, Mr. Coombs relocated back to Australia, retaining responsibility for our floorcovering operations in the Asia-Pacific region while Mr. Parnell (see below) assumed responsibility for floorcovering operations in Europe. Mr. Coombs was promoted to Senior Vice President of Interface in July 2008.

Mr. Lynch joined us in 1996 after having previously worked for a national accounting firm. He became Assistant Corporate Controller in 1998 and Assistant Vice President and Corporate Controller in 2000. Mr. Lynch was promoted to Vice President and Chief Financial Officer in July 2001. Mr. Lynch was promoted to Senior Vice President in March 2007.

Mr. Parnell was the Production Director for Firth Carpets (our former European broadloom operations) at the time it was acquired by us in 1997. In 1998, Mr. Parnell was promoted to Vice President, Operations for the United Kingdom, and in 1999 he was promoted to Senior Vice President, Operations for our entire European floorcovering division. In September 2002, he was promoted to President and Chief Executive Officer of our floorcovering operations in Europe, and became a Vice President of Interface in October 2002. Mr. Parnell was promoted to Senior Vice President of Interface in July 2008.

Mr. Wells joined us in February 1994 as Vice President-Sales of Interface Flooring Systems, Inc. (now InterfaceFLOR, LLC), our principal U.S. modular carpet subsidiary. Mr. Wells was promoted to Senior Vice President-Sales & Marketing of Interface Flooring Systems in October 1994. He was promoted to Vice President of Interface and President of Interface Flooring Systems in July 1995. In March 1998, Mr. Wells was also named President of both Prince Street Technologies, Ltd. and Bentley Mills, Inc., making him President of all three of our U.S. carpet mills at that time. In November 1999, Mr. Wells was named Senior Vice President of Interface, and President and Chief Executive Officer of Interface Americas Holdings, LLC (formerly Interface Americas, Inc.), thereby assuming operations responsibility for all of our floorcovering businesses in the Americas.

Mr. Willoch, who previously practiced with an Atlanta law firm, joined us in June 1990 as Corporate Counsel. He was promoted to Assistant Secretary in 1991, Assistant Vice President in 1993, Vice President in January 1996, Secretary and General Counsel in August 1996, and Senior Vice President in February 1998. In July 2001, he was named Senior Vice President-Administration and assumed corporate responsibility for various staff functions.

Ms. Davlantes joined us in May 2008 as Senior Vice President of Marketing for FLOR, our residential carpet tile business. In November 2009, she was promoted to Chief Marketing Officer of Interface, Inc., while still maintaining her responsibilities at FLOR. Prior to joining us, Ms. Davlantes had acquired 17 years of marketing experience with Spiegel, McKinsey & Company, Charcol and BP.

Available Information

We make available free of charge on or through our Internet website our annual report on Form 10-K, quarterly reports on Form 10-Q, current reports on Form 8-K and amendments to those reports filed or furnished pursuant to Section 13(a) or 15(d) of the Securities Exchange Act of 1934 as soon as reasonably practicable after we electronically file such material with, or furnish it to, the SEC. Our Internet address is http://www.interfaceglobal.com.

12

Forward-Looking Statements

This report on Form 10-K contains “forward-looking statements” within the meaning of the Securities Act of 1933, and the Securities Exchange Act of 1934, and the Private Securities Litigation Reform Act of 1995. Words such as “believes,” “anticipates,” “plans,” “expects” and similar expressions are intended to identify forward-looking statements. Forward-looking statements include statements regarding the intent, belief or current expectations of our management team, as well as the assumptions on which such statements are based. Any forward-looking statements are not guarantees of future performance and involve a number of risks and uncertainties that could cause actual results to differ materially from those contemplated by such forward-looking statements. We undertake no obligation to update or revise forward-looking statements to reflect changed assumptions, the occurrence of unanticipated events or changes to future operating results over time. Important factors currently known to management that could cause actual results to differ materially from those in forward-looking statements include risks and uncertainties associated with economic conditions in the commercial interiors industry as well as the risks and uncertainties discussed in Item 1A, “Risk Factors”.

ITEM 1A. RISK FACTORS

You should carefully consider the following factors, in addition to the other information included in this Annual Report on Form 10-K and the documents incorporated herein by reference, before deciding whether to purchase our common stock. Any or all of the following risk factors could have a material adverse effect on our business, financial condition, results of operations and prospects.

Sales of our principal products have been and may continue to be affected by adverse economic cycles in the renovation and construction of commercial and institutional buildings.

Sales of our principal products are related to the renovation and construction of commercial and institutional buildings. This activity is cyclical and has been affected by the strength of a country’s or region’s general economy, prevailing interest rates and other factors that lead to cost control measures by businesses and other users of commercial or institutional space. The effects of cyclicality upon the corporate office segment tend to be more pronounced than the effects upon the institutional segment. Historically, we have generated more sales in the corporate office segment than in any other market. The effects of cyclicality upon the new construction segment of the market also tend to be more pronounced than the effects upon the renovation segment. The adverse cycle during the years 2001 through 2003 significantly lessened the overall demand for commercial interiors products, which adversely affected our business during those years. These effects may recur and could be more pronounced if the current global economic conditions do not improve or are further weakened.

The ongoing worldwide financial and credit crisis could have a material adverse effect on our business, financial condition and results of operations.

The ongoing worldwide financial and credit crisis has reduced the availability of liquidity and credit to fund the continuation and expansion of many business operations worldwide. This shortage of liquidity and credit, combined with recent substantial losses in worldwide equity markets, could lead to an extended worldwide economic recession and result in a material adverse effect on our business, financial condition and results of operations. Specifically, the limited availability of credit and liquidity adversely affects the ability of customers and suppliers to obtain financing for significant purchases and operations. Consequently, customers may defer, delay or cancel renovation and construction projects where our carpet is used, resulting in decreased orders and sales for us, and they also may not be able to pay us for those products and services we already have provided to them. For the same reasons, suppliers may not be able to produce and deliver raw materials and other goods and services that we have ordered from them, thus disrupting our own manufacturing operations. In addition, our ability to obtain funding from capital markets may be severely restricted at a time when we would like, or need, to access those markets. This inability to obtain that funding could prevent us from pursuing important strategic growth plans, from reacting to changing economic and business conditions, and from refinancing existing debt (which in turn could lead to a default on our debt). The financial and credit crisis also could have an impact on the lenders under our credit facilities, causing them to fail to meet their obligations to provide us with loans and letters of credit, which are important sources of liquidity for us.

Our domestic revolving credit facility matures in December 2012, our outstanding 11 3/8% Senior Secured Notes mature in November 2013, and our outstanding 9.5% Senior Subordinated Notes mature in February 2014. We cannot assure you that we will be able to renegotiate or refinance any of this debt on commercially reasonable terms, or at all, especially given the ongoing worldwide financial and credit crisis.

13

We compete with a large number of manufacturers in the highly competitive commercial floorcovering products market, and some of these competitors have greater financial resources than we do.

The commercial floorcovering industry is highly competitive. Globally, we compete for sales of floorcovering products with other carpet manufacturers and manufacturers of other types of floorcovering. Although the industry has experienced significant consolidation, a large number of manufacturers remain in the industry. Some of our competitors, including a number of large diversified domestic and foreign companies who manufacture modular carpet as one segment of their business, have greater financial resources than we do.

Our success depends significantly upon the efforts, abilities and continued service of our senior management executives and our principal design consultant, and our loss of any of them could affect us adversely.

We believe that our success depends to a significant extent upon the efforts and abilities of our senior management executives. In addition, we rely significantly on the leadership that David Oakey of David Oakey Designs provides to our internal design staff. Specifically, David Oakey Designs provides product design/production engineering services to us under an exclusive consulting contract that contains non-competition covenants. Our current agreement with David Oakey Designs extends to April 2011. The loss of any of these key persons could have an adverse impact on our business because each has a great deal of knowledge, training and experience in the carpet industry – particularly in the areas of sales, marketing, operations, product design and management – and could not easily or quickly be replaced.

Our substantial international operations are subject to various political, economic and other uncertainties that could adversely affect our business results, including by restrictive taxation or other government regulation and by foreign currency fluctuations.

We have substantial international operations. In 2009, approximately 49% of our net sales and a significant portion of our production were outside the United States, primarily in Europe and Asia-Pacific. Our corporate strategy includes the expansion and growth of our international business on a worldwide basis. As a result, our operations are subject to various political, economic and other uncertainties, including risks of restrictive taxation policies, changing political conditions and governmental regulations. We also make a substantial portion of our net sales in currencies other than U.S. dollars (approximately 47% of 2009 net sales), which subjects us to the risks inherent in currency translations. The scope and volume of our global operations make it impossible to eliminate completely all foreign currency translation risks as an influence on our financial results.

Large increases in the cost of petroleum-based raw materials could adversely affect us if we are unable to pass these cost increases through to our customers.

Petroleum-based products comprise the predominant portion of the cost of raw materials that we use in manufacturing. While we attempt to match cost increases with corresponding price increases, continued volatility in the cost of petroleum-based raw materials could adversely affect our financial results if we are unable to pass through such price increases to our customers.

Unanticipated termination or interruption of any of our arrangements with our primary third party suppliers of synthetic fiber could have a material adverse effect on us.

The unanticipated termination or interruption of any of our supply arrangements with our current suppliers of synthetic fiber (nylon), which typically are not pursuant to long-term agreements, could have a material adverse effect on us because we do not have the capability to manufacture our own fiber for use in our carpet products. If any of our supply arrangements with our primary suppliers of synthetic fiber is terminated or interrupted, we likely would incur increased manufacturing costs and experience delays in our manufacturing process (thus resulting in decreased sales and profitability) associated with shifting more of our synthetic fiber purchasing to another synthetic fiber supplier.

14

We have a significant amount of indebtedness, which could have important negative consequences to us.

Our significant indebtedness could have important negative consequences to us, including:

|

·

|

making it more difficult for us to satisfy our obligations with respect to such indebtedness;

|

|

·

|

increasing our vulnerability to adverse general economic and industry conditions;

|

|

·

|

limiting our ability to obtain additional financing to fund capital expenditures, acquisitions or other growth initiatives, and other general corporate requirements;

|

|

·

|

requiring us to dedicate a substantial portion of our cash flow from operations to interest and principal payments on our indebtedness, thereby reducing the availability of our cash flow to fund capital expenditures, acquisitions or other growth initiatives, and other general corporate requirements;

|

|

·

|

limiting our flexibility in planning for, or reacting to, changes in our business and the industry in which we operate;

|

|

·

|

placing us at a competitive disadvantage compared to our less leveraged competitors; and

|

|

·

|

limiting our ability to refinance our existing indebtedness as it matures.

|

The terms of our primary revolving credit facility in the U.S. and the indentures governing our 9.5% Senior Subordinated Notes due 2014 and our 11 3/8% Senior Secured Notes due 2013 govern our ability and the ability of our subsidiaries to, among other things, incur additional indebtedness, pay dividends or make certain other restricted payments or investments in certain situations, consummate certain asset sales, enter into certain transactions with affiliates, create liens, merge or consolidate with any other person, or sell, assign, transfer, lease, convey or otherwise dispose of all or substantially all of our assets. They also require us to comply with certain other reporting, affirmative and negative covenants and, at times, meet certain financial tests. If we fail to satisfy these tests or comply with these covenants, a default may occur, in which case the lenders could accelerate the debt as well as any other debt to which cross-acceleration or cross-default provisions apply. We cannot assure you that we would be able to renegotiate, refinance or otherwise obtain the necessary funds to satisfy these obligations.

The market price of our common stock has been volatile and the value of your investment may decline.

The market price of our Class A common stock has been volatile in the past and may continue to be volatile going forward. Such volatility may cause precipitous drops in the price of our Class A common stock on the Nasdaq Global Select Market and may cause your investment in our common stock to lose significant value. As a general matter, market price volatility has had a significant effect on the market values of securities issued by many companies for reasons unrelated to their operating performance. We thus cannot predict the market price for our common stock going forward.

Our earnings in a future period could be adversely affected by non-cash adjustments to goodwill, if a future test of goodwill assets indicates a material impairment of those assets.

As prescribed by accounting standards governing goodwill and other intangible assets, we undertake an annual review of the goodwill asset balance reflected in our financial statements. Our review is conducted during the fourth quarter of the year, unless there has been a triggering event prescribed by applicable accounting rules that warrants an earlier interim testing for possible goodwill impairment. In the past, we have had non-cash adjustments for goodwill impairment as a result of such testings ($61.2 million in 2008, $44.5 million in 2007, and $20.7 million in 2006). A future goodwill impairment test may result in a future non-cash adjustment, which could adversely affect our earnings for any such future period.

Our Chairman currently has sufficient voting power to elect a majority of our Board of Directors.

Our Chairman, Ray C. Anderson, beneficially owns approximately 54% of our outstanding Class B common stock. The holders of the Class B common stock are entitled, as a class, to elect a majority of our Board of Directors. Therefore, Mr. Anderson has sufficient voting power to elect a majority of the Board of Directors. On all other matters submitted to the shareholders for a vote, the holders of the Class B common stock generally vote together as a single class with the holders of the Class A common stock. Mr. Anderson’s beneficial ownership of the outstanding Class A and Class B common stock combined is approximately 6%.

15

Our Rights Agreement could discourage tender offers or other transactions for our stock that could result in shareholders receiving a premium over the market price for our stock.

Our Board of Directors has adopted a Rights Agreement pursuant to which holders of our common stock will be entitled to purchase from us a fraction of a share of our Series B Participating Cumulative Preferred Stock if a third party acquires beneficial ownership of 15% or more of our common stock without our consent. In addition, the holders of our common stock will be entitled to purchase the stock of an Acquiring Person (as defined in the Rights Agreement) at a discount upon the occurrence of triggering events. These provisions of the Rights Agreements could have the effect of discouraging tender offers or other transactions that could result in shareholders receiving a premium over the market price for our common stock.

ITEM 1B. UNRESOLVED STAFF COMMENTS

None.

ITEM 2. PROPERTIES

We maintain our corporate headquarters in Atlanta, Georgia in approximately 20,000 square feet of leased space. The following table lists our principal manufacturing facilities and other material physical locations (some locations are comprised of multiple buildings), all of which we own except as otherwise noted:

|

Location

|

Segment

|

Floor Space(Sq. Ft.)

|

||||

|

Bangkok, Thailand(1)

|

Modular Carpet

|

275,946 | ||||

|

Craigavon, N. Ireland(2)

|

Modular Carpet

|

80,986 | ||||

|

LaGrange, Georgia

|

Modular Carpet

|

539,545 | ||||

|

LaGrange, Georgia(2)

|

Modular Carpet

|

209,337 | ||||

|

Picton, Australia

|

Modular Carpet

|

98,774 | ||||

|

Scherpenzeel, the Netherlands

|

Modular Carpet

|

245,420 | ||||

|

Scherpenzeel, the Netherlands(2)

|

Modular Carpet

|

121,515 | ||||

|

Shelf, England

|

Modular Carpet

|

206,882 | ||||

|

West Point, Georgia

|

Modular Carpet

|

250,000 | ||||

|

City of Industry, California(2)

|

Bentley Prince Street

|

558,596 | ||||

__________

|

(1)

|

Owned by a joint venture in which we have a 70% interest.

|

|

(2)

|

Leased.

|

We maintain marketing offices in over 70 locations in over 30 countries and distribution facilities in approximately 40 locations in six countries. Most of our marketing locations and many of our distribution facilities are leased. We are currently constructing a modular carpet manufacturing facility in Taicang, China, which we anticipate will be completed in 2010. This will be a leased facility comprised of approximately 54,000 square feet. We also have a 78,389 square foot manufacturing facility in Belleville, Canada, where we have ceased operations.

We believe that our manufacturing and distribution facilities and our marketing offices are sufficient for our present operations. We will continue, however, to consider the desirability of establishing additional facilities and offices in other locations around the world as part of our business strategy to meet expanding global market demands. Substantially all of our owned properties in the United States, Europe and Australia are subject to mortgages, which secure borrowings under our debt instruments.

ITEM 3. LEGAL PROCEEDINGS

We are subject to various legal proceedings in the ordinary course of business, none of which is required to be disclosed under this Item 3.

ITEM 4. RESERVED

16

PART II

|

ITEM 5.

|

MARKET FOR THE REGISTRANT’S COMMON EQUITY, RELATED STOCKHOLDER MATTERS AND ISSUER PURCHASES OF EQUITY SECURITIES

|

Our Class A Common Stock is traded on the Nasdaq Global Select Market under the symbol IFSIA. Our Class B Common Stock is not publicly traded but is convertible into Class A Common Stock on a one-for-one basis. As of March 1, 2010, we had 671 holders of record of our Class A Common Stock and 67 holders of record of our Class B Common Stock. We estimate that there are in excess of 6,500 beneficial holders of our Class A Common Stock. The following table sets forth, for the periods indicated, the high and low intraday prices of the Company’s Class A Common Stock on the Nasdaq Global Select Market as well as dividends paid during such periods.

|

High

|

Low

|

Dividends Per Share

|

||||||||||

|

2010

|

||||||||||||

|

First Quarter (through March 1, 2010)

|

$ | 9.15 | $ | 7.05 | -- | |||||||

|

2009

|

||||||||||||

|

Fourth Quarter

|

$ | 8.99 | $ | 6.90 | $ | 0.0025 | ||||||

|

Third Quarter

|

9.01 | 5.22 | 0.0025 | |||||||||

|

Second Quarter

|

7.02 | 3.08 | 0.0025 | |||||||||

|

First Quarter

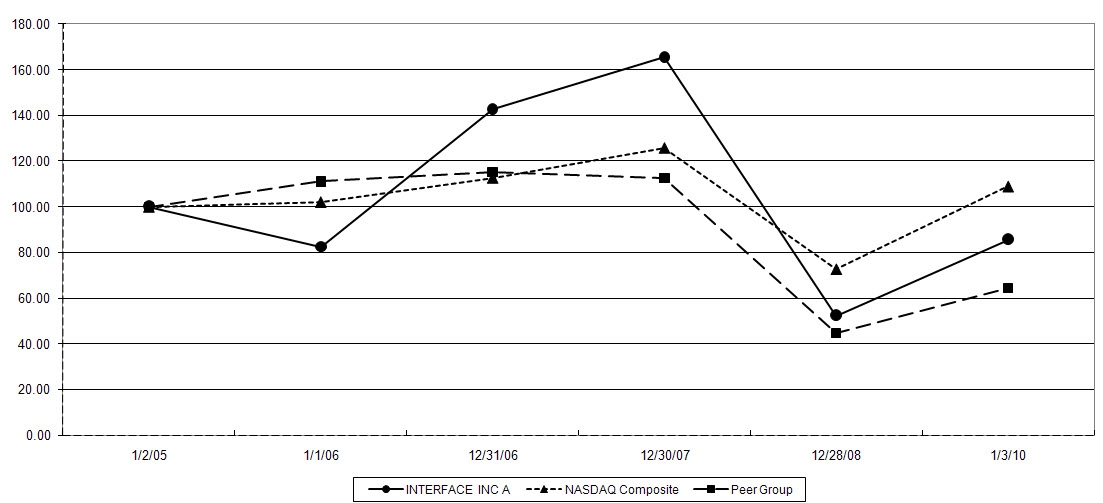

|