Attached files

| file | filename |

|---|---|

| EX-99.2 - EXHIBIT 99.2 - AUGUSTA GOLD CORP. | tm219403d1_ex99-2.htm |

| 8-K - FORM 8-K - AUGUSTA GOLD CORP. | tm219403d1_8k.htm |

Exhibit 99.1

|

Augusta Gold Corp. 555 – 999 Canada Place Vancouver, BC V6C-3E1 Phone: 604-687-1717

| |

|

NI

43-101 Technical Report Nye County, Nevada

| |

|

Effective Date: |

February 22, 2021 |

| Issue Date: | March 16, 2021 |

| Prepared by: | Kira L. Johnson, MMSA QP |

| |

|

350 Indiana Street, Suite 500 | Golden, CO 80401 Phone: 303-217-5700 | www.tetratech.com | |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

Table Of Contents

| 1. | EXECUTIVE SUMMARY | 1 | ||

| 1.1 | Location, Property Description & Ownership | 1 | ||

| 1.2 | Geology & Mineralization | 2 | ||

| 1.3 | Exploration, Drilling, Sampling & QA/QC | 4 | ||

| 1.3.1 | Exploration | 4 | ||

| 1.3.2 | Drilling | 4 | ||

| 1.3.3 | Sampling | 5 | ||

| 1.3.4 | QA/QC | 5 | ||

| 1.4 | Mineral Processing & Metallurgical Testing | 6 | ||

| 1.5 | Mineral Resource Estimation | 6 | ||

| 1.6 | Interpretations & Conclusions | 8 | ||

| 1.7 | Recommendations | 9 | ||

| 2. | INTRODUCTION | 10 | ||

| 2.1 | Units of Measure | 10 | ||

| 2.2 | Abbreviations | 11 | ||

| 3. | RELIANCE ON OTHER EXPERTS | 12 | ||

| 4. | PROPERTY DESCRIPTION AND LOCATION | 13 | ||

| 4.1 | NPX Assignment of Lands | 29 | ||

| 4.2 | Mojave Gold Option | 29 | ||

| 4.3 | Barrick Bullfrog Inc. Lease and Option | 29 | ||

| 4.4 | Lunar Landing Lease | 29 | ||

| 4.5 | Brown Claims | 30 | ||

| 4.6 | Barrick Claims (2020) | 30 | ||

| 4.7 | Abitibi Royalties Option | 31 | ||

| 4.8 | Other Property Considerations | 31 | ||

| 4.9 | Environmental and Permitting | 31 | ||

| 4.10 | Significant Risk Factors | 33 | ||

| 5. | ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY | 34 | ||

| 5.1 | Accessibility | 34 | ||

| 5.2 | Physiography, Climate and Vegetation | 34 | ||

| 5.3 | Local Resources and Infrastructure | 35 | ||

| 6. | HISTORY | 36 | ||

| 7. | GEOLOGICAL SETTING AND MINERALIZATION | 38 | ||

| 7.1 | Regional Geology | 38 | ||

| 7.2 | Local and Property Geology | 39 | ||

| 7.2.1 | Cenozoic Rocks | 42 | ||

| 7.2.2 | Pre-14 Ma Rocks | 42 | ||

| 7.2.3 | 14 to 11 Ma Rocks | 43 | ||

| Tetra Tech | February 2021 | i |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

| 7.2.4 | Post 11 Ma to 7.6 Ma Rocks | 45 | ||

| 7.2.5 | 10.6-10.0 Ma Rainbow Mountain Sequence (Trm, Tr11-16 and other units) | 46 | ||

| 7.3 | Deposit Geology | 47 | ||

| 7.4 | Mineralization and Veining | 48 | ||

| 7.4.1 | Bullfrog Deposit | 48 | ||

| 7.4.2 | Montgomery-Shoshone Deposit | 49 | ||

| 8. | DEPOSIT TYPES | 51 | ||

| 9. | EXPLORATION | 52 | ||

| 9.1 | M-S Area | 52 | ||

| 9.1.1 | North-East Extension | 52 | ||

| 9.1.2 | Down-Dip Polaris Vein | 52 | ||

| 9.1.3 | South Montgomery | 53 | ||

| 9.1.4 | East | 54 | ||

| 9.1.5 | Deep Potential | 54 | ||

| 9.1.6 | 2020 Drilling | 55 | ||

| 9.2 | West Bonanza Mountain | 55 | ||

| 9.3 | Western Exploration Targets | 55 | ||

| 9.3.1 | Rush Fault-Box Canyon | 55 | ||

| 9.3.2 | Ransome Fault | 56 | ||

| 9.3.3 | Original Bullfrog Mine | 56 | ||

| 10. | DRILLING | 57 | ||

| 10.1 | 2020 Drilling | 59 | ||

| 11. | SAMPLE PREPARATION, ANALYSES, AND SECURITY | 63 | ||

| 11.1 | St. Joe Minerals | 64 | ||

| 11.1.1 | RC Drilling | 64 | ||

| 11.1.2 | Core Drilling | 64 | ||

| 11.1.3 | Transport and Security | 65 | ||

| 11.1.4 | Duplicates | 65 | ||

| 11.1.5 | Field Duplicates | 65 | ||

| 11.1.6 | Visible Gold Sampling Protocol | 65 | ||

| 11.1.7 | Blanks | 65 | ||

| 11.1.8 | Certified Reference Material | 65 | ||

| 11.1.9 | Sample Recovery | 66 | ||

| 11.1.10 | RC Recovery | 66 | ||

| 11.1.11 | Laboratory Handling of Samples | 66 | ||

| 11.2 | 2020 Drilling Program | 66 | ||

| 11.2.1 | Standards: A74383, B74110, and C73909 | 67 | ||

| 11.2.2 | Blanks | 67 | ||

| 11.2.3 | Duplicates | 67 | ||

| 11.3 | Conclusions | 67 | ||

| 12. | DATA VERIFICATION | 68 | ||

| 13. | MINERAL PROCESSING AND METALLURGICAL TESTING | 69 | ||

| 13.1 | St. Joe | 69 | ||

| Tetra Tech | February 2021 | ii |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

| 13.1.1 | Large Column Leach Test | 69 | ||

| 13.1.2 | Bottle Roll Tests on UG Samples | 70 | ||

| 13.1.3 | Column Testing by Kappes Cassiday | 70 | ||

| 13.2 | Pilot Testing by Barrick | 72 | ||

| 13.3 | Conclusions for Heap Leaching | 72 | ||

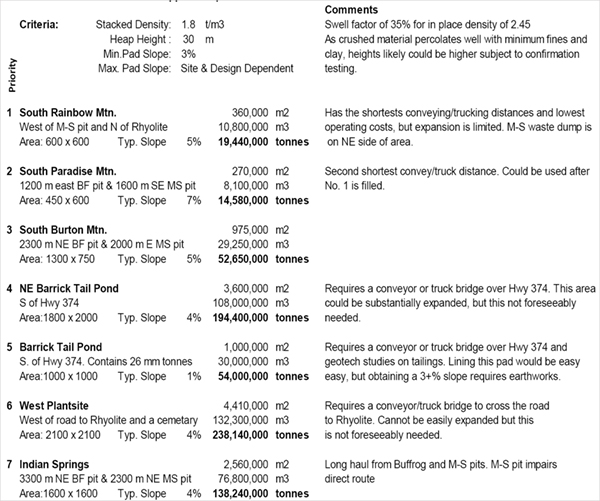

| 13.4 | Leach Pad Siting | 73 | ||

| 13.5 | Additional Testing | 74 | ||

| 14. | MINERAL RESOURCE ESTIMATES | 76 | ||

| 14.1 | Input Data | 77 | ||

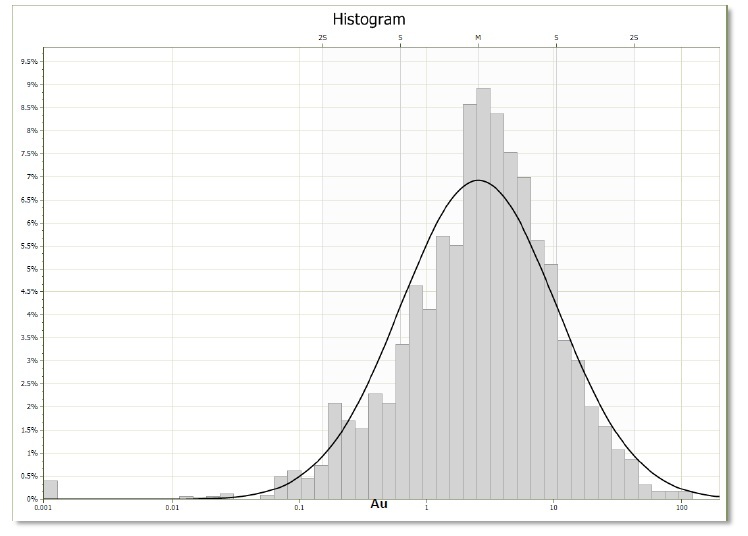

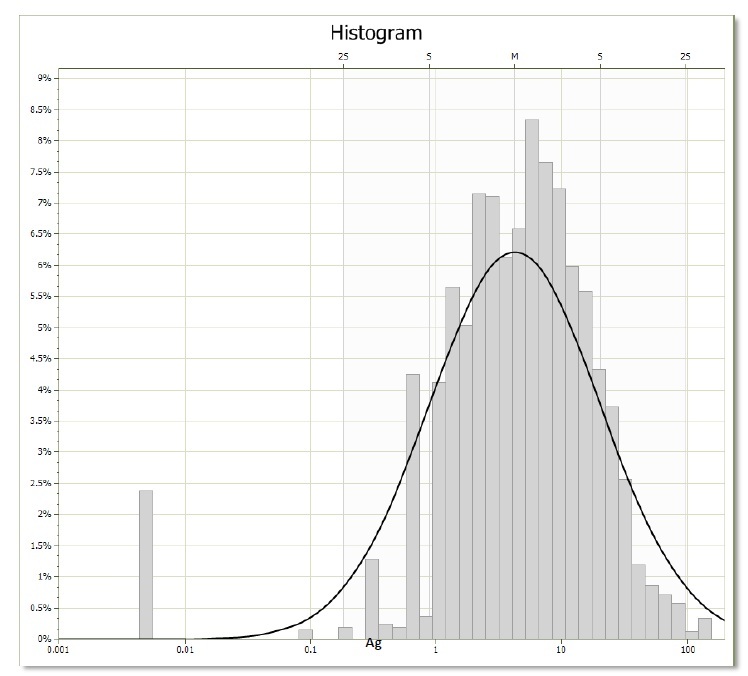

| 14.2 | Grade Capping | 78 | ||

| 14.3 | Compositing | 79 | ||

| 14.4 | Mineral Zone Modeling | 79 | ||

| 14.4.1 | Bullfrog Zone Modeling | 80 | ||

| 14.4.2 | Density Determination | 81 | ||

| 14.5 | Estimation Methods and Parameters | 82 | ||

| 14.5.1 | Variography and Search | 82 | ||

| 14.5.2 | Mineral Resource Classification | 85 | ||

| 14.5.3 | Cutoff Grade and Pit Shell Optimization | 86 | ||

| 14.6 | Model Verification | 89 | ||

| 14.7 | Heap Leap Run-of-Mine | 95 | ||

| 14.8 | Relevant Factors | 95 | ||

| 23. | ADJACENT PROPERTIES | 96 | ||

| 24. | OTHER RELEVANT DATA AND INFORMATION | 97 | ||

| 25. | INTERPRETATION AND CONCLUSIONS | 98 | ||

| 25.1 | Significant Risk Factors | 98 | ||

| 26. | RECOMMENDATIONS | 99 | ||

| 26.1 | Exploration | 99 | ||

| 26.2 | Baseline Studies | 99 | ||

| 26.3 | Additional Studies | 99 | ||

| 26.4 | Estimated Costs | 99 | ||

| 27. | REFERENCES | 100 | ||

| 28. | DATE AND SIGNATURE PAGE | 106 | ||

LIST OF TABLES

| Table 1-1: Project Drilling by Year | 4 |

| Table 1-2: 1994 Leach Test Results | 6 |

| Table 1-3: 1995 Pilot Heap Leach Test Results | 6 |

| Table 1-4: Mineral Resource Estimate for the Bullfrog Pit Area | 7 |

| Tetra Tech | February 2021 | iii |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

| Table 1-5: Mineral Resource Estimate for the M-S Pit Area | 7 |

| Table 1-6: Measured and Indicated Mineral Resource Summary for Project | 8 |

| Table 4-1: Lands Under the Control of Augusta Gold Corp | 14 |

| Table 4-2: Additional Minor Permits Required | 32 |

| Table 6-1: Bullfrog Project Production | 36 |

| Table 10-1: Drilling Totals by Type | 57 |

| Table 10-2: Active Years by Operator | 58 |

| Table 10-3: Location and depth of 2020 holes | 59 |

| Table 10-4: Drilling results from the 2020 program | 61 |

| Table 11-1: CRM Expected Values | 67 |

| Table 13-1: Typical Processing Statistics from 1989-1999 | 69 |

| Table 13-2: Leach Test Results | 70 |

| Table 13-3: Heap Leach Pilot Tests – Barrick | 72 |

| Table 13-4: Estimated Heap Leach Recovery | 72 |

| Table 13-5: Summary Metallurgical Results – Bottle Roll Tests | 74 |

| Table 14-1: Mineral Resource Estimate for the Bullfrog Pit Area | 76 |

| Table 14-2: Mineral Resource Estimate for the M-S Pit Area | 76 |

| Table 14-3: Measured and Indicated Resource Summary for Project | 77 |

| Table 14-4: Mineral Domain Information | 81 |

| Table 14-5: Block Model Setup Parameters | 85 |

| Table 14-6: Ordinary Kriging Pass Parameters | 85 |

| Table 14-7: Block Classification Parameters | 86 |

| Table 14-8: Cutoff Grade and Pit Optimization Assumptions | 86 |

| Table 26-1: Estimated costs | 99 |

LIST OF FIGURES

| Figure 1-1: Location Map (Scale bar is approximately 22.5 km long) | 2 |

| Figure 1-2: District Geology Map | 3 |

| Figure 4-1: Location Map | 13 |

| Figure 4-2: Property Map of the Bullfrog Project | 28 |

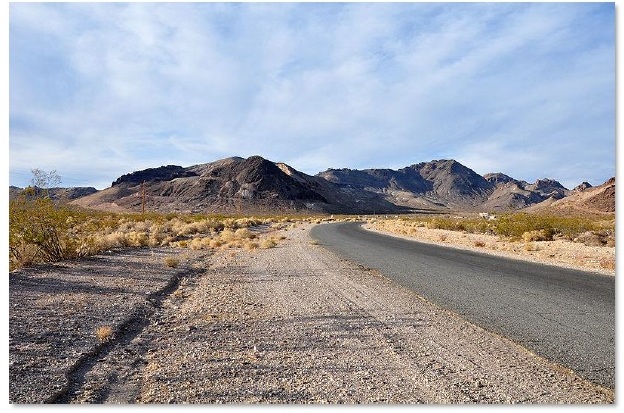

| Figure 5-1: Photo of Bullfrog Hills at Rhyolite | 34 |

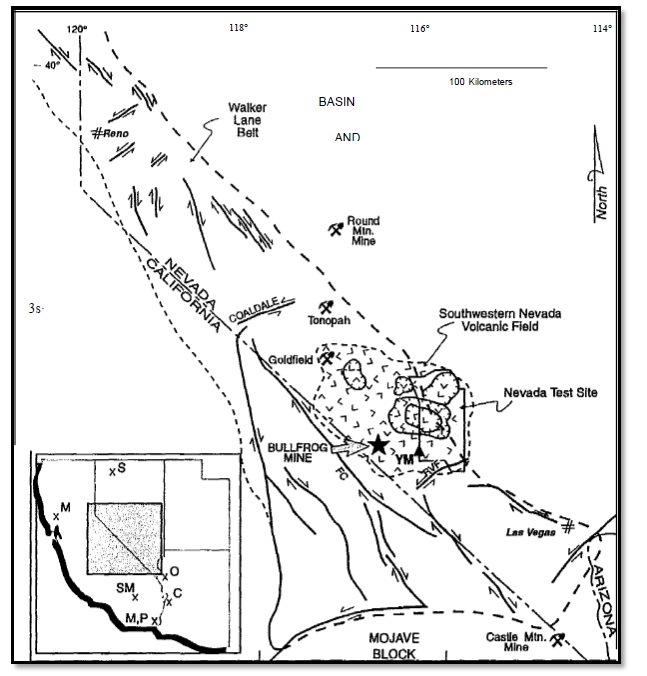

| Figure 7-1: Regional Setting of the Bullfrog Mine (Eng et al., 1996) | 38 |

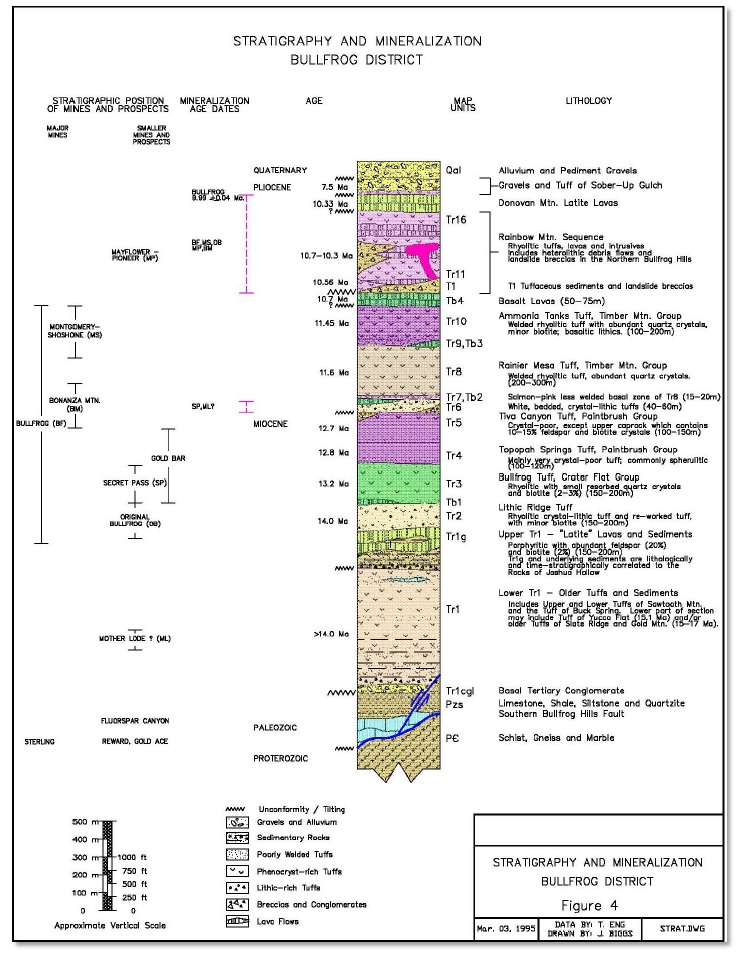

| Figure 7-2: Bullfrog District – Stratigraphy and Mineralization | 40 |

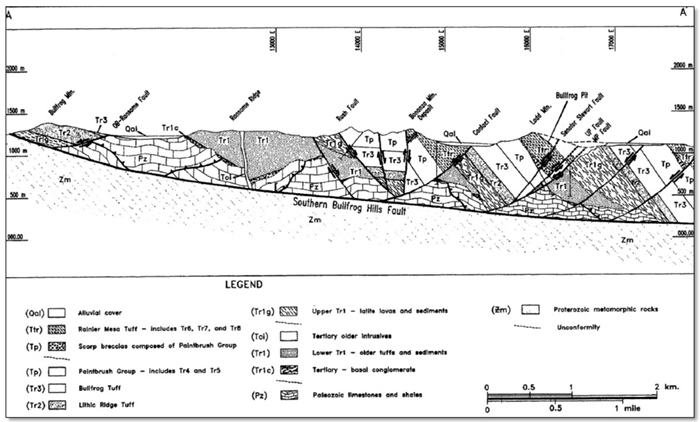

| Figure 7-3: Cross Section of the Bullfrog Project Area | 41 |

| Figure 7-4: Deposit Geology Map—Each Section is 1.6 km, or 1 mile square | 48 |

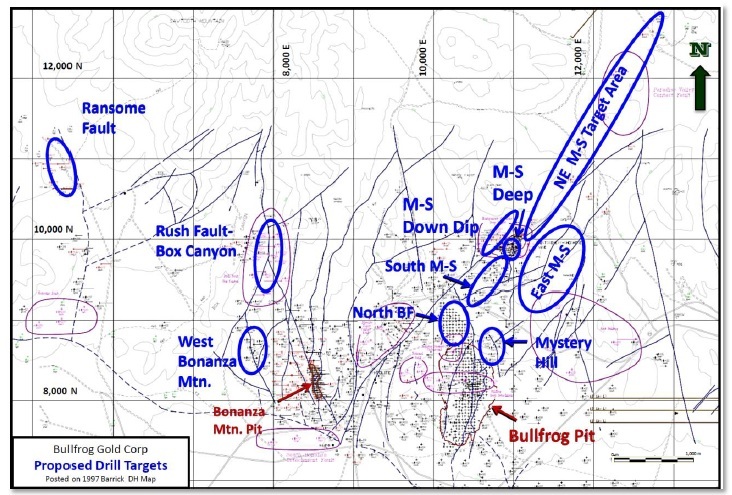

| Figure 9-1: Exploration and Mining Targets at the Bullfrog Project | 53 |

| Tetra Tech | February 2021 | iv |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

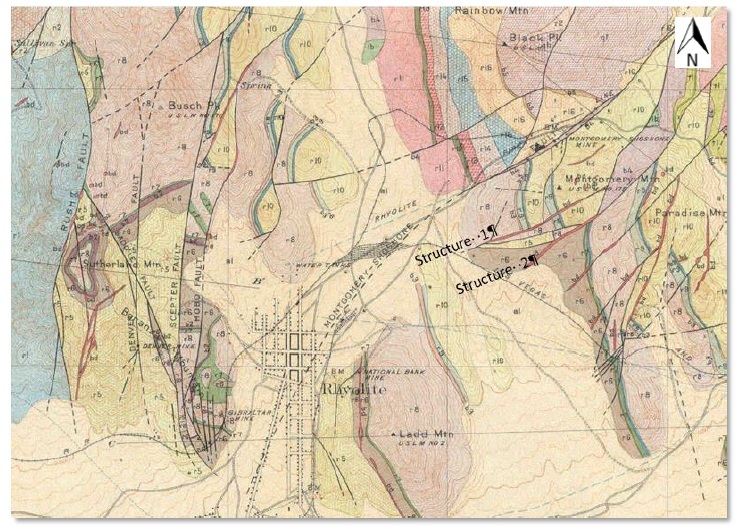

| Figure 9-2: Structure Map with Geology | 54 |

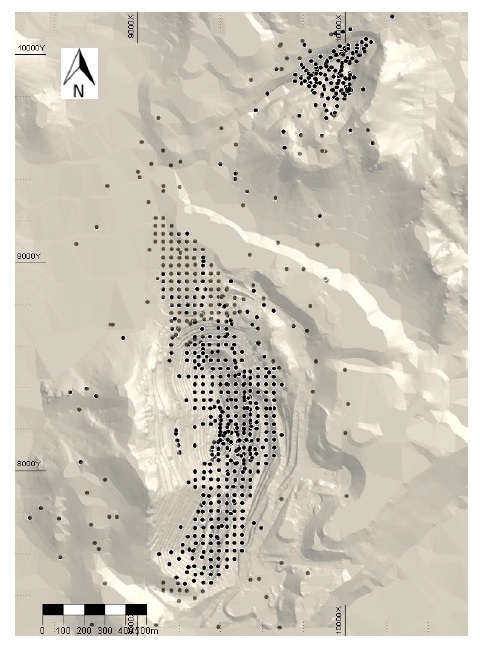

| Figure 10-1: Plan map of drill hole collars | 58 |

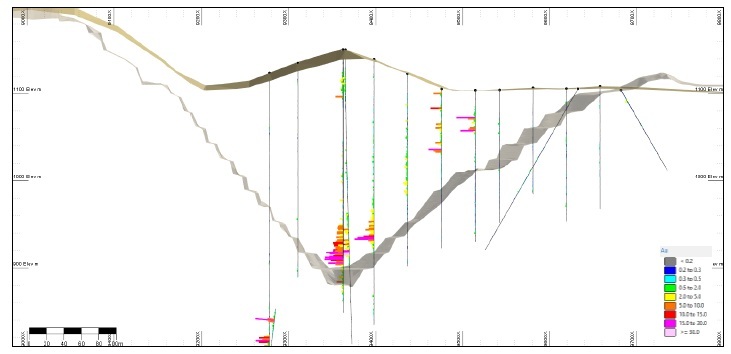

| Figure 10-2: Section in the Bullfrog Pit area looking North | 59 |

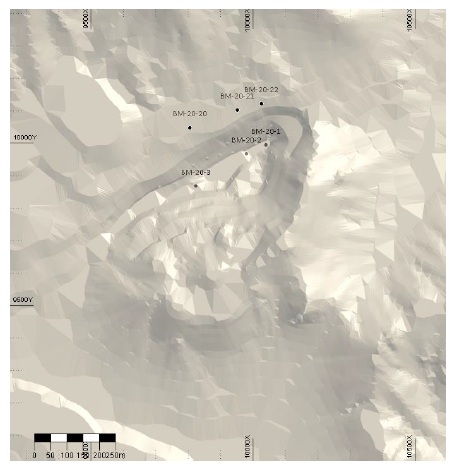

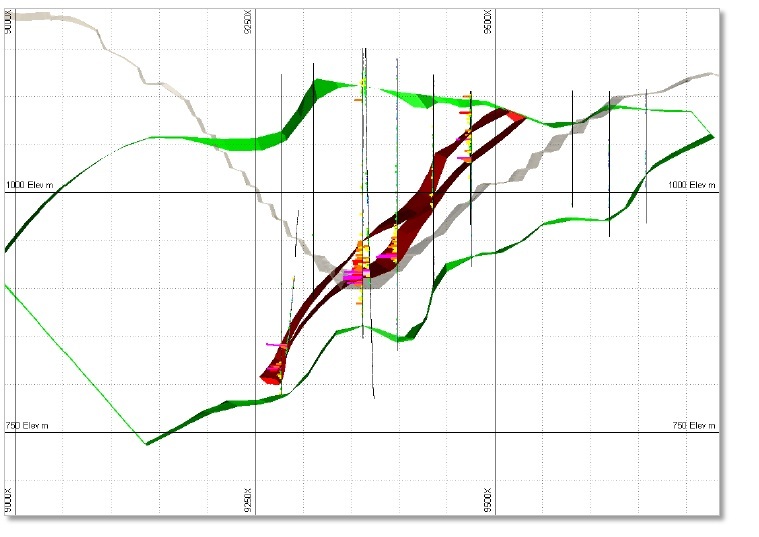

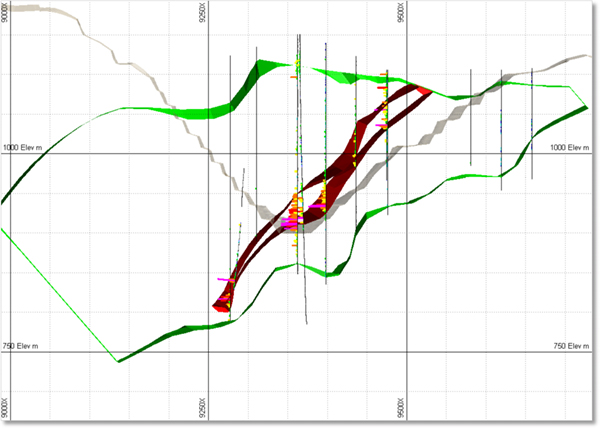

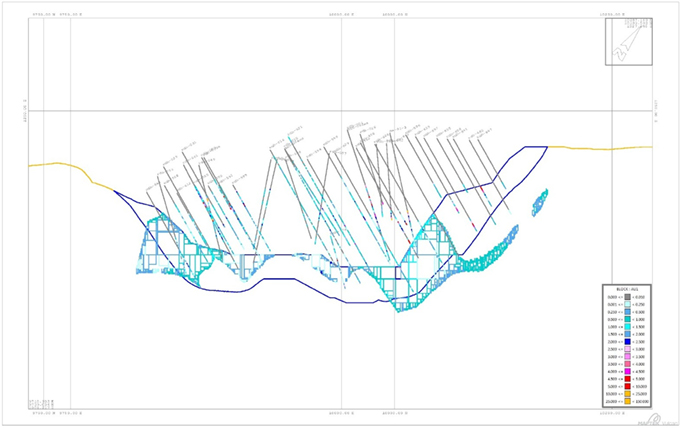

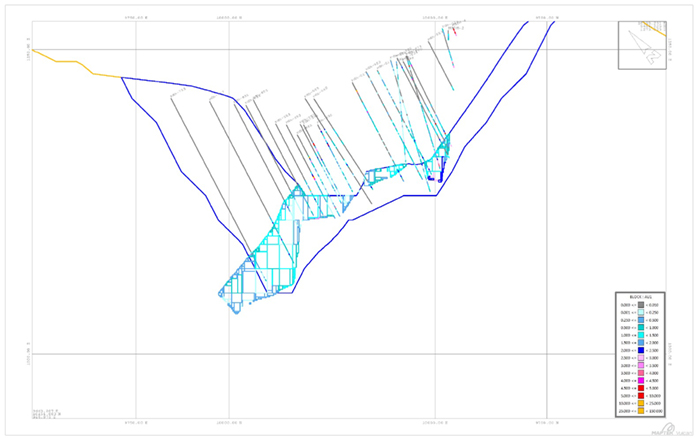

| Figure 10-3: Drilling in the Montgomery-Shoshone area from the 2020 drill campaign | 60 |

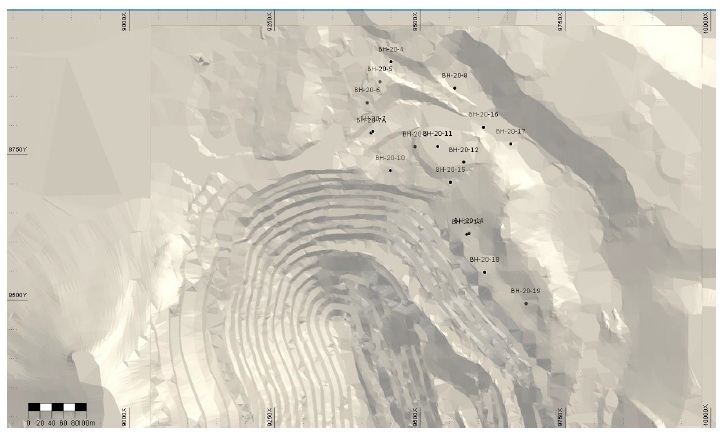

| Figure 10-4: Drilling in the Bullfrog area from the 2020 drill campaign | 61 |

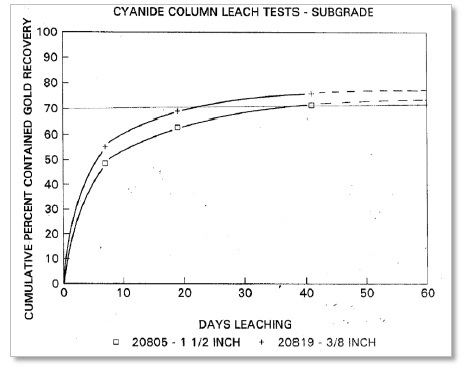

| Figure 13-1: Leach Test Results | 71 |

| Figure 13-2: Potential Leach Pad Sites & Approximate Capacities | 73 |

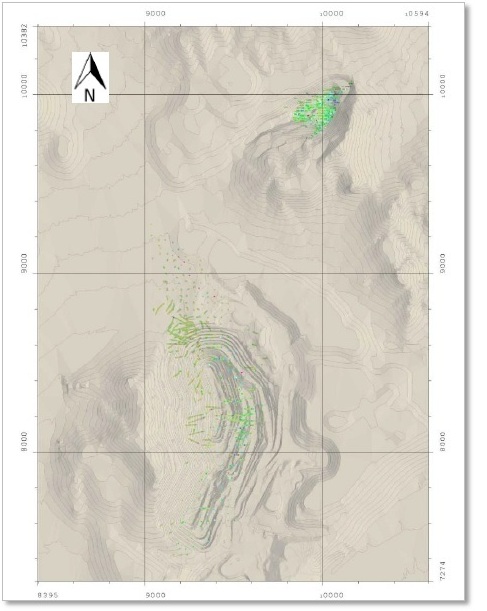

| Figure 14-1: Plan View Map of Project Drilling Composites used for Estimation | 77 |

| Figure 14-2: Histogram of Gold Grade values | 78 |

| Figure 14-3: Histogram of Silver Grade values | 79 |

| Figure 14-4: Cross-Section Mineral Domains at 8500 North | 80 |

| Figure 14-5: Montgomery and Polaris Veins at a Cross Section of 9980 North | 81 |

| Figure 14-6: Semivariogram Map Strike | 82 |

| Figure 14-7: Semivariogram Map Dip | 83 |

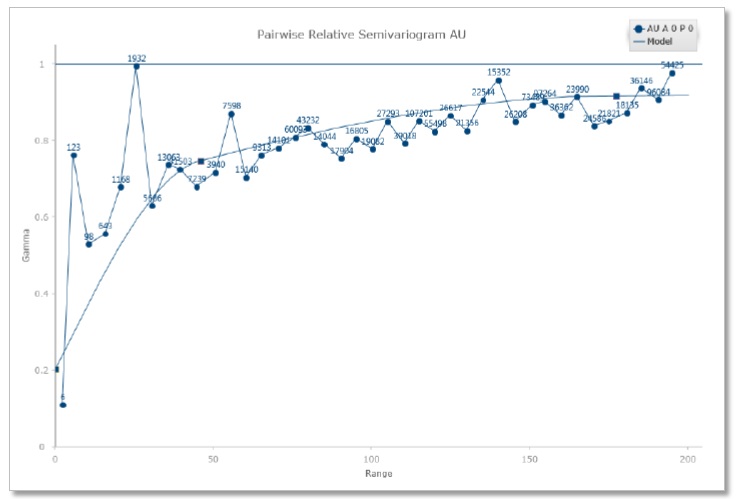

| Figure 14-8: Pairwise Relative Variography Au | 84 |

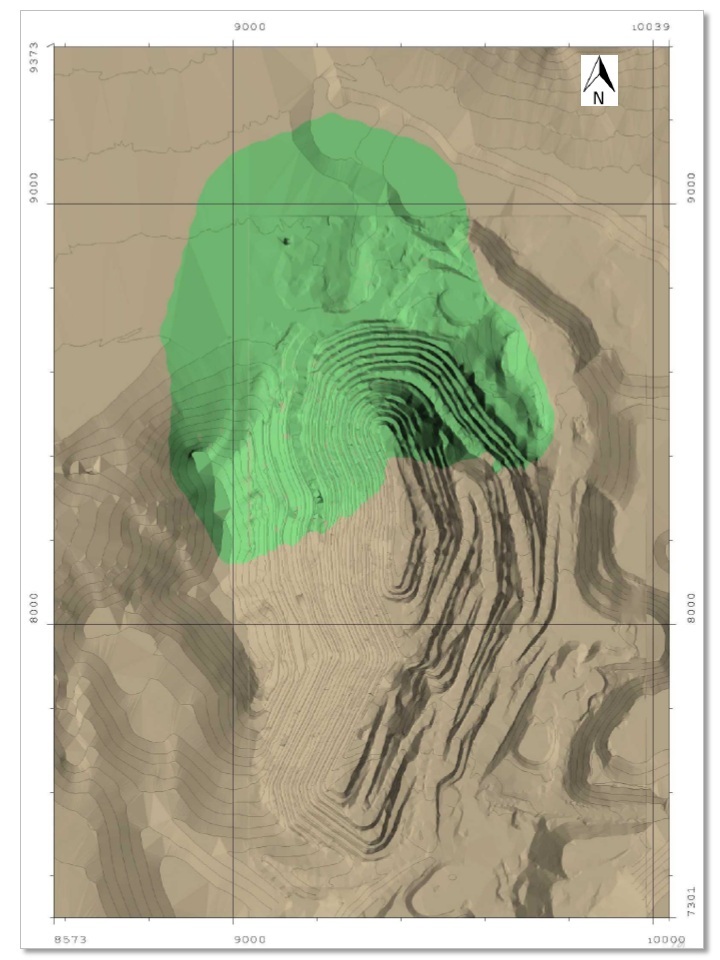

| Figure 14-9: Bullfrog Current Pit and Optimized Shell | 87 |

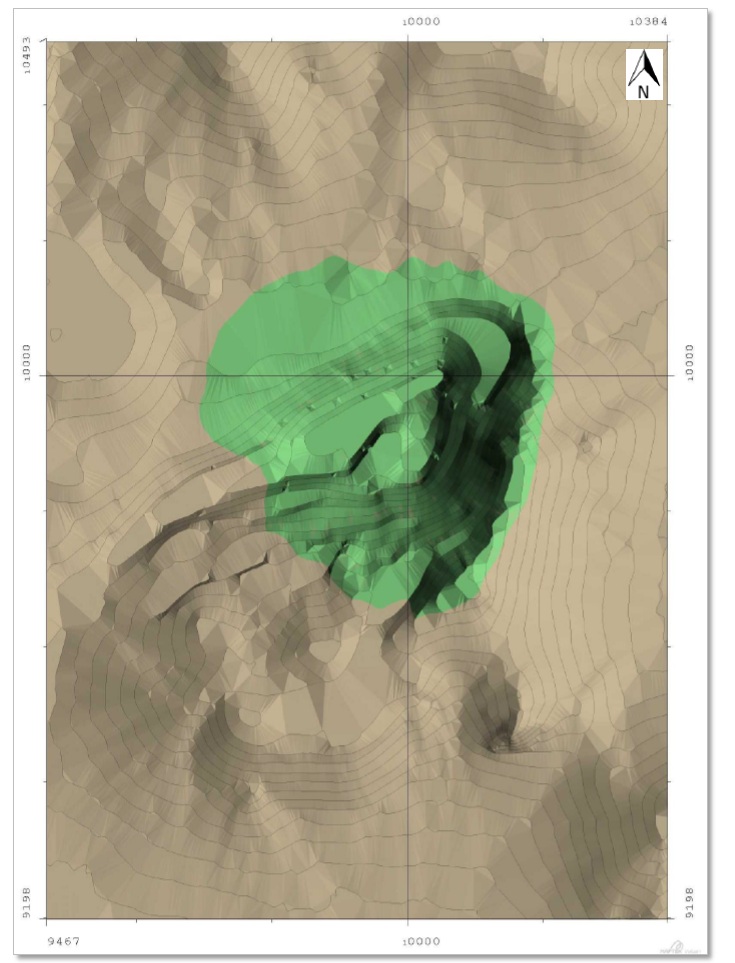

| Figure 14-10: M-S Current Pit and Optimized Shell | 88 |

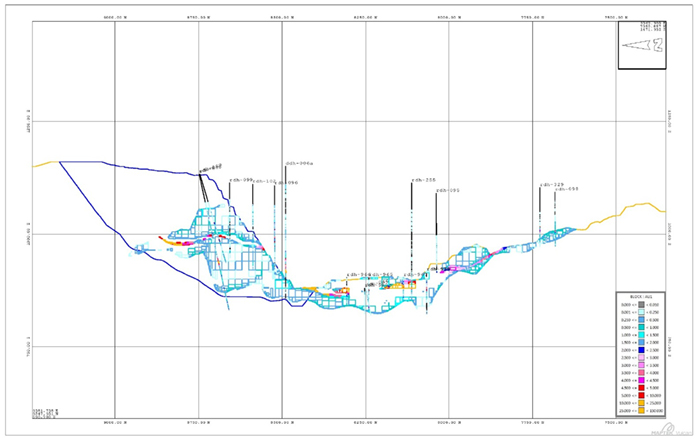

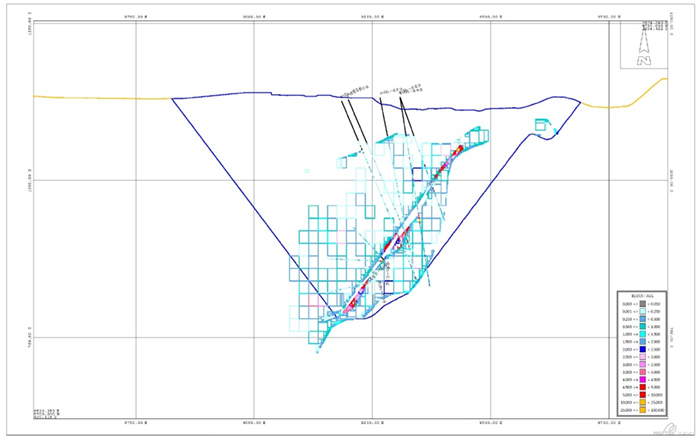

| Figure 14-11: Long Section of the Bullfrog Deposit | 90 |

| Figure 14-12: Cross Section of the Bullfrog Deposit at 8700 N | 91 |

| Figure 14-13: Cross Section of the Bullfrog Deposit at 8500 N | 92 |

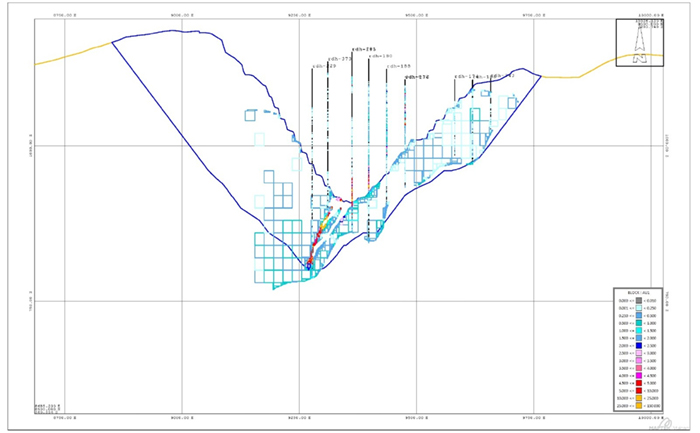

| Figure 14-14: Long Section of the M-S Deposit | 93 |

| Figure 14-15: Cross Section of the M-S Deposit | 94 |

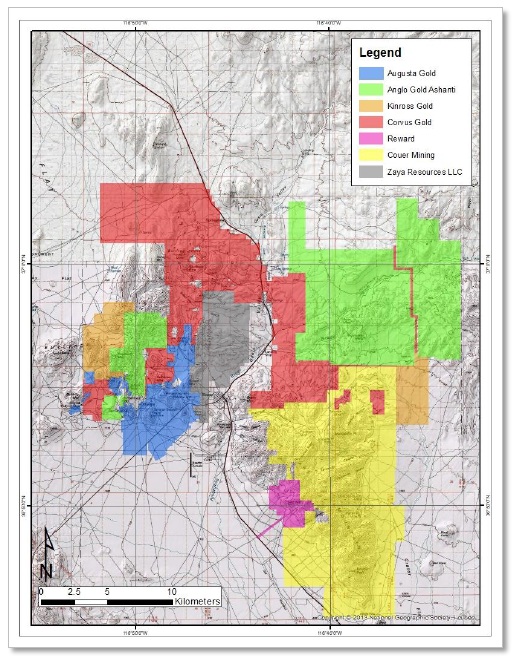

| Figure 23-1: Land Positions of the Bullfrog Project and Adjacent Properties | 96 |

| Tetra Tech | February 2021 | v |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

| 1. | EXECUTIVE Summary |

This technical report (TR or report) has been prepared for Augusta Gold Corp. (Augusta, or the Company) for the Bullfrog Gold Project (Project, project, or Bullfrog Project) in Nevada. Gold was produced from the Bullfrog Project by various companies, with Barrick Bullfrog Inc. being the most recent. The mine was exploited through open pit and underground methods and ore was processed in a conventional cyanidation mill.

This report has been prepared for the purposes of producing an independent estimation of mineral resources at the site. The report includes a description of additional and ongoing drilling completed during the period of 2020 to present. This included a review of the drilling data for the Project to date, including historical drilling.

This mineral resource report has been prepared by Tetra Tech (Tt) and is based on the previously published TR issued on August 9, 2017. It includes the mineral resources estimated in 2017 and additional information from the 2020-2021 drilling program. Tetra Tech has also updated sections on metallurgical research.

| 1.1 | Location, Property Description & Ownership |

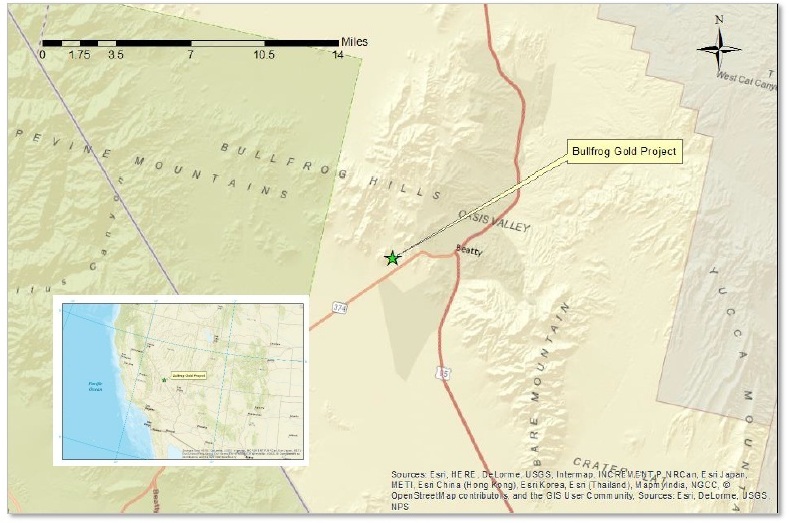

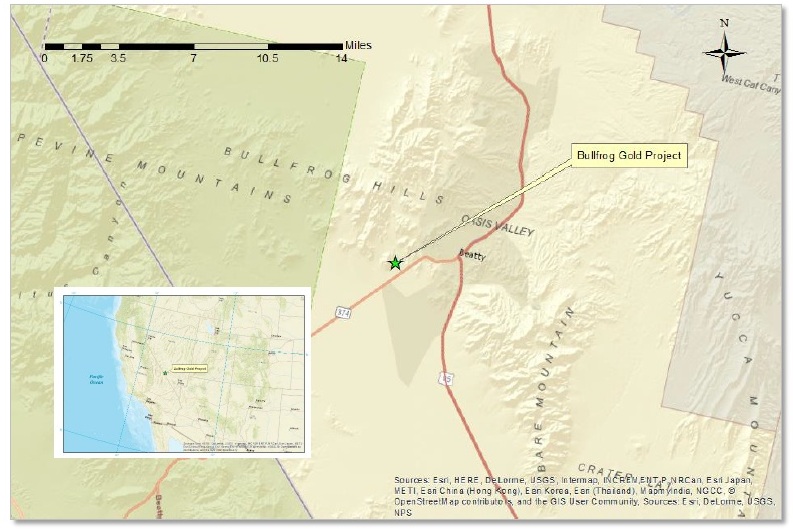

The Company’s wholly-owned Bullfrog Gold Project is located in the Bullfrog Hills of Nye County, Nevada and in the southern half of the Bullfrog Mining District (Figure 1-1). Basic amenities are available in the town of Beatty, which is situated 6.5 km (4 miles) east of the Project. Las Vegas is the largest regional city with full services and is a 260 km drive to the site. Project properties are located in Sections 25, 26, 35 and 36 of T11S, R46E and Sections 1, 2, 3, 4, 5, 6, 8 9, 10, 11, 12, 13, 14, 15, 16, 17, and 23 of T12S, R46E, Mt. Diablo Meridian.

| Tetra Tech | February 2021 | 1 |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

Figure 1-1: Location Map

(Scale bar is approximately 22.5 km long)

| 1.2 | Geology & Mineralization |

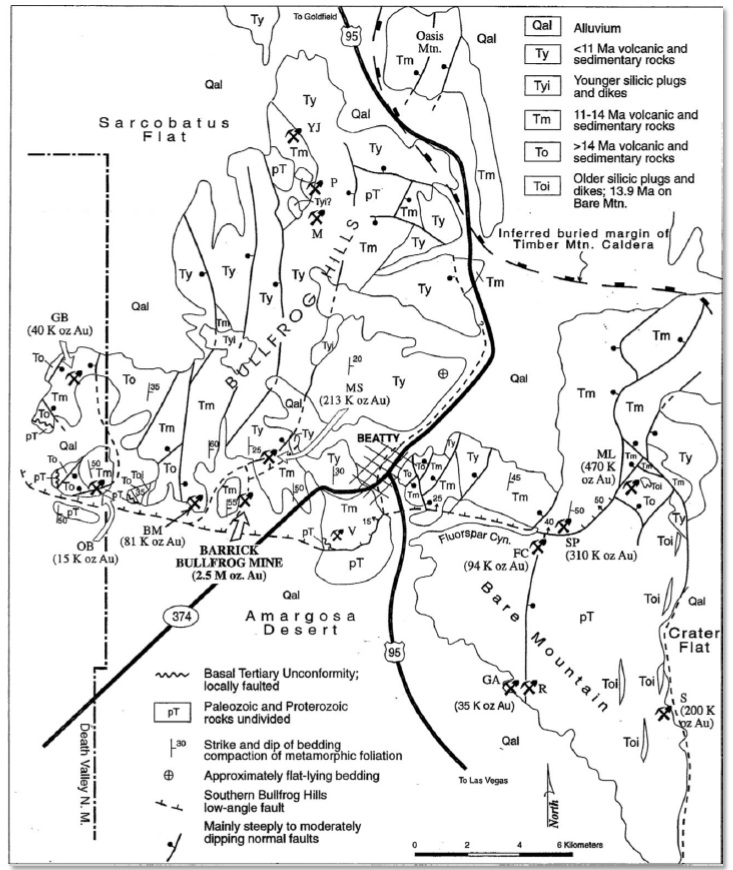

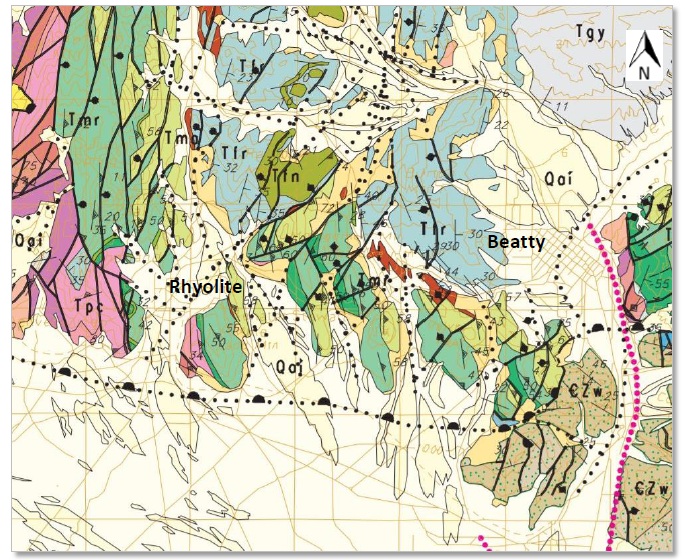

The Project is in the southern Walker Lane trend within brittle upper-plate volcanic host rocks that were severely broken from dominant detachment faulting and associated dip-slip and strike-slip displacements. Epithermal solutions permeated the broken host rocks in the Montgomery-Shoshone (M-S) and Bullfrog deposits precipitating micron-sized and relatively high-grade gold (Au) within major quartz-calcite veins and disseminated gold in associated stock-works. The veins contain gangue minerals other than quartz, such as calcite and manganese oxides, the latter of which contributes associated silver (Ag) recoveries and gold. The district geology map is shown below.

| Tetra Tech | February 2021 | 2 |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

Figure 1-2: District Geology Map

The highest grades in the Bullfrog deposit typically correlate with zones of black manganese-rich material, where much of the early manganiferous calcite has been leached out, rendering the vein a rubble zone of quartz, calcite, and wad. Veins continue up dip and down dip, but the gold grades and thicknesses diminish rapidly above and below these elevations. The veins and breccia veins associated with the mineralization are generally associated with the MP Fault and its immediate hanging wall. Mineralization also occurs in upper and lower stockwork zones that are subparallel to the high-grade brecciated vein within the main fault structure.

| Tetra Tech | February 2021 | 3 |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

| 1.3 | Exploration, Drilling, Sampling & QA/QC |

| 1.3.1 | Exploration |

The Company’s exploration activities to date have focused on the following:

| ▪ | Acquiring, organizing, digitizing and vetting electronic and paper data bases obtained from Barrick mainly related to drill data, metallurgy and project infrastructure; and |

| ▪ | Maintaining and expanding the land holdings. |

| 1.3.2 | Drilling |

The project drilling includes 1,287 holes, for a total of 254,542 meters completed between 1983 and 2020. The holes were drilled using both core and reverse circulation methods, as detailed in the drilling section of this report. Table 1-1 summarizes the project drilling by year.

Table 1-1: Project Drilling by Year

| Year | Holes | Length (m) | ||

| 1983 | 6 | 975 | ||

| 1984 | 37 | 3,560 | ||

| 1985 | 3 | 303 | ||

| 1986 | 29 | 3,364 | ||

| 1987 | 163 | 29,479 | ||

| 1988 | 321 | 66,325 | ||

| 1989 | 71 | 12,285 | ||

| 1990 | 154 | 37,114 | ||

| 1991 | 79 | 22,954 | ||

| 1992 | 23 | 4,907 | ||

| 1993 | 9 | 387 | ||

| 1994 | 210 | 31,362 | ||

| 1995 | 99 | 22,370 | ||

| 1996 | 58 | 15,254 | ||

| 2020 | 25 | 3,903 | ||

| Total | 1,287 | 254,542 |

25 Reverse Circulation holes were drilled by Augusta in 2020. The purpose of this drilling program was to further define resources and ultimate limits of the Bullfrog and Montgomery-Shoshone pits, and have not been included in the mineral resource estimate in this report. The program also fulfilled a final work commitment for the Company to purchase a 100% interest in lands under lease from Barrick by mid-September 2020. Two holes were drilled at the Paradise Ridge Target. Section 10 of this report details the results of the 2020 drilling program.

| Tetra Tech | February 2021 | 4 |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

Additional potential has been shown in the drilling results and the drilling was completed in proximity of the resource estimate from 2017. A delineation drilling program should be completed to further define the resource.

| 1.3.3 | Sampling |

Drilling and coring information used in this resource estimate was obtained from several drill programs that began in 1983 with St. Joe Minerals, continued with Bond Gold and Lac Minerals, and ended by Barrick in late 1996. Of 1,262 total holes drilled in the area, 147 holes included core and 1,243 holes were drilled using reverse circulation methods. Most of the cored holes included intervals of core plus RC segments. Percent recovery and RQD measurements were made on all core intervals. An assessment was made of the quality of the orientation data and the core was marked accordingly. The core was then logged, recording lithological, alteration, mineralization, and structural information including the orientation of faults, fault lineation’s, fractures, veins, and bedding. With few exceptions, the entire lengths of the holes were sampled. Sample intervals were 5 feet and occasionally based on the geological logging, separating different lithologies and styles of mineralization and alteration. Samples were marked and tagged in the core box before being photographed, after which the core was sawed in half, with one half sent for assay and one half retained for future reference. Each sample interval was bagged separately and shipped to the lab for analysis.

Cuttings from nearly all reverse circulation drill programs were divided into two streams, one was sampled and the other was disposed during the reclamation of each drill site. Using a Jones splitter, the sample stream was further divided into two sample bags, one designated for assaying and the second duplicate designated as a field reject. Samples were collected at five-foot intervals and bagged at the drill site. Each five-foot sample was sealed at the drill site and not opened until it reached the analytical lab. At each 20-foot rod connection, the hole was blown clean to eliminate material that had fallen into the hole during the connection. The designated assay samples for each five-foot interval were collected by the site geologist and moved to a secure sample collection area for shipment to accredited laboratories off site. When duplicate samples were collected, they were retained at the drill site as a reference sample, if needed. If the duplicate samples were not used, they were blended with site materials during site reclamation.

Additional holes were drilled by the Company in 2020 that are not included in this mineral resource estimate. The sampling for this program is described in Section 11 of this report.

| 1.3.4 | QA/QC |

The sampling QA/QC program was originally established by St. Joe Minerals. Subsequent owners followed the procedures with any necessary updates to meet quality assurance standards of the time. The standard practices included the supervision of drilling, logging of core, as well as in-stream sample submittal for blanks, certified standards, and duplicate testing to ensure laboratory performance. All assay testing was completed by outside laboratories, such as Skyline, Legend, Iron King, Barringer, American Assay, and Chemex. Assay certificates are available and have been electronically scanned to complete the project drilling database.

| Tetra Tech | February 2021 | 5 |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

| 1.4 | Mineral Processing & Metallurgical Testing |

Metallurgical testing programs that are relevant to the development plans of the Project are summarized below.

In 1986 St. Joe American performed two large column tests on 20 t (22 short tons) composites of M-S samples and recovered 56% of the gold after 59 days of leaching material grading 0.034 opt and crushed to -19 mm (-3/4 inch). The other column recovered 49% of the gold after 59 days of leaching minus 304.8 mm (-12-inch) material grading 0.037 opt. Projected 90-day recoveries were 61% and 54% respectively.

Results from leach tests performed in 1994 by Kappes Cassiday of Reno, Nevada on 250 kg of sub-grade material from the Bullfrog mine are shown below:

Table 1-2: 1994 Leach Test Results

| Bottle | Column | Column | ||||

| Size, mesh, & mm (inch) | -100 mesh | -38 mm (-1.5”) | -9.5 mm (-3/8”) | |||

| Calc. Head, opt Au | 0.029 | 0.035 | 0.029 | |||

| Rec % | 96.6 | 71.4 | 75.9 | |||

| Leach time, days | 2.0 | 41 | 41 | |||

| NaCN, kg/t (lb/short ton) | 0.5 (0.1) | 0.385 (0.77) | 5.35 (10.7) | |||

| Lime, kg/t (lb/short ton | 1.0 (2.0) | 0.155 (0.31) | 1.75 (0.35) |

In 1995 Barrick performed pilot heap leach tests on 765t (844 short tons) of BF subgrade material and 730 t (805 short tons) from the M-S pit. Both composites were crushed to 0.8 mm (-1/2 inch). Results are shown below.

Table 1-3: 1995 Pilot Heap Leach Test Results

| BF Low-Grade | M-S Ore | |||

| Calc. Head, opt Au | 0.019 | 0.048 | ||

| Calc. Head, opt Ag | 0.108 | 0.380 | ||

| Projected Au Rec % | 67 | 74 | ||

| Projected Ag Rec % | 9 | 32 | ||

| Leach Time, days | 41 | 37 | ||

| NaCN, kg/t (lb/short ton) | 0.10 (0.20) | 0.125 (0.25) | ||

| Lime, kg/t (lb/short ton) | Nil (Nil) | Nil (Nil) |

In 2020, cyanidation bottle rolls tests were conducted on 14 variability composites from the Bullfrog project. Details of this testing can be found in Section 13 of this report.

| 1.5 | Mineral Resource Estimation |

Mineral resources have been estimated for the Bullfrog deposit using a block model to fit the deposit strike for each of the areas. Two separate block models were created, one for the Bullfrog Pit (BF) area, and one of the Montgomery-Shoshone (M-S) area. Sub-blocking was used to help define the vein system. Two wireframe domains were built for the Bullfrog deposit, one for the high grade and one for the low-grade gold. Vein solids were created for Polaris and Montgomery veins in the M-S pit area. Au and Ag grades were estimated using Ordinary Kriging on blocks independently within and outside of wireframe constrained domains. Reporting of estimated blocks has been constrained by a base case pit optimization using input parameters deemed reasonable.

| Tetra Tech | February 2021 | 6 |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

Although the mineral resources are pit constrained using reasonable cost assumptions, detailed costing and economic evaluations have not been performed. The pit optimizations only consider ounces on lands controlled by Augusta, but the pit has been allowed to extend onto non controlled land for planning purposes. The pit optimizations include mineral resources that have not demonstrated economic value and include inferred mineral resources that are too speculative for the definition of mineral reserves.

Estimated mineral resources within the base case pit constraint are shown in Table 1-4 for the Bullfrog Pit area. Estimated mineral resources within the base case pit constraint is shown in Table 1-5 for the M-S Pit area. Historically mined ounces were flagged and removed from the model before calculating the mineral resource numbers. A total of ounces for both deposits can be found in Table 1-6.

Table 1-4: Mineral Resource Estimate for the Bullfrog Pit Area

| Classification | Cutoff Au g/t | Tonnes (M) | Au g/t | Ag g/t | Au oz (1000) | Ag oz (M) | ||||||

| Measured | 0.36 | 2.05 | 0.88 | 2.35 | 58 | 0.15 | ||||||

| Indicated | 0.36 | 12.9 | 1.04 | 2.52 | 431 | 1.04 | ||||||

| Measured + Indicated | 0.36 | 14.95 | 1.02 | 2.50 | 489 | 1.2 | ||||||

| Inferred | 0.36 | 2.8 | 1.2 | 2.58 | 109 | 0.24 |

| NOTES: |

| (1) | Cutoff grade calculated using a metal price of $1,200 per troy ounce of Au and a recovery of 72% for Au. |

| (2) | Mineral Resources have been pit shell constrained using the Lerch Grossman algorithm |

| (3) | Metal prices do not exceed three-year trailing average as of the end of December 2016, per SEC guidance. |

Table 1-5: Mineral Resource Estimate for the M-S Pit Area

| Classification | Cutoff Au g/t | Tonnes (M) | Au g/t | Ag g/t | Au oz (1000) | Ag oz (M) | ||||||

| Measured | 0.36 | 0.41 | 1.03 | 4.53 | 13.7 | 0.06 | ||||||

| Indicated | 0.36 | 0.71 | 0.99 | 3.72 | 22.7 | 0.09 | ||||||

| Measured + Indicated | 0.36 | 1.12 | 1.00 | 4.02 | 36.4 | 0.15 | ||||||

| Inferred | 0.36 | 0.045 | 1.17 | 5.53 | 1.69 | 0.008 |

| NOTES: |

| (1) | Cutoff grade calculated using a metal price of $1,200 per troy ounce of Au and a recovery of 72% for Au. |

| (2) | Mineral Resources have been pit shell constrained using the Lerch Grossman algorithm |

| (3) | Metal prices do not exceed three-year trailing average as of the end of December 2016, per SEC guidance. |

| Tetra Tech | February 2021 | 7 |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

Table 1-6: Measured and Indicated Mineral Resource Summary for Project

| Classification | Cutoff Au g/t | Tonnes (M) | Au g/t | Ag g/t | Au oz (1000) | Ag oz (M) | ||||||

| Bullfrog | 0.36 | 14.95 | 1.02 | 2.50 | 489 | 1.2 | ||||||

| M-S | 0.36 | 1.12 | 1.00 | 4.02 | 36.4 | 0.15 | ||||||

| Total | 0.36 | 16.07 | 1.02 | 2.61 | 525.4 | 1.35 |

| NOTES: |

| (1) | Cutoff grade calculated using a metal price of $1,200 per troy ounce of Au and a recovery of 72% for Au. |

| (2) | Mineral Resources have been pit shell constrained using the Lerch Grossman algorithm |

| (3) | Metal prices do not exceed three-year trailing average as of the end of December 2016, per SEC guidance. |

Additional upside material can be provided by evaluating the low gold grade material between a 0.2 and 0.36 gold cutoff grades. This information is discussed in detail in Section 14. Instead of being stored in the waste rock facility, it is possible to heap leach this uncrushed material to recover additional gold and silver.

| 1.6 | Interpretations & Conclusions |

Drill hole samples were collected and analyzed using industry standard methods and practices at the time they were drilled, and based on the assay certifications, are sufficient to characterize grade and thickness and support the estimation of mineral resources set out in this report.

The Bullfrog project and deposit have several beneficial attributes that provide opportunities to justify further investigation by way of a PEA:

| ▪ | The Project is in a jurisdiction amenable to mining. Local permitting authorities and the community are accustomed to mine development and the potential economic benefits. |

| ▪ | The Town of Beatty with a population of approximately 1,000 is 6.4 km (4 miles) away and has adequate amenities and services. |

| ▪ | The Project is near infrastructure, including power lines on site, a paved highway to the site, water below the Bullfrog pit, a network of roads on site, and pit ramps that are in place. |

| ▪ | Years of production data and comprehensive heap leach tests have demonstrated acceptable heap leach recoveries at various crushed and run-of-mine sizes. |

| ▪ | The Project has potential to expand resources around the pits as well as exploration upside in the District. |

| ▪ | Extensive drilling helps defines several targets for expanding the pits and providing exploration upside. |

| ▪ | After 20+ years, existing pit walls remain stable up to 53 degrees. |

Project risks include:

| ▪ | Potential permitting and environmental issues may be a concern. |

| ▪ | Mineral resources have been constrained by an optimized pit shell; however, scoping study-level costing for mining and processing have not been undertaken. |

| Tetra Tech | February 2021 | 8 |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

| 1.7 | Recommendations |

Current estimation of mineral resources indicate the Bullfrog Project warrants further advancement to the Preliminary Economic Assessment (PEA) or Pre-Feasibility Study (PFS) stage. Tetra Tech also recommends updating the resource with the following considerations:

| ▪ | Land acquired since the 2017 resource report |

| ▪ | 2020-2021 drilling programs |

| ▪ | Gold prices |

| ▪ | Revaluate cutoff grade to include new metallurgical test work |

The Project acquired additional land in 2020. It is recommended to calculate the resource to include the newly acquired land package.

It is also recommended that a local environmental consulting firm, experienced in the area of permitting and societal issues in the area, be retained to assist in baseline and background work that will be required as inputs into the feasibility and mine planning process. Some existing Baseline Studies already exist, due to the historic mining, but updates will be required for a minimum of:

| ▪ | Geochemical characterization of the waste rock. |

| ▪ | Hydrologic characterization of the water in the Bullfrog Pit and in existing wells. |

| ▪ | Plant and wildlife surveys, mainly concerning the Desert Tortoise and bats. |

| ▪ | Meteorological Data. |

| ▪ | Cultural Surveys |

Additional exploration holes are recommended to confirm resource estimations and condemn areas ultimately selected for siting Project facilities. These recommendations have an estimated cost of $19.9 million.

| Tetra Tech | February 2021 | 9 |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

| 2. | Introduction |

This report has been prepared for Augusta Gold Corp. for the Bullfrog Gold Project in Nevada with the purpose of detailing drilling data collected by multiple companies during the exploration and exploitation of the deposit in the past and to detail the results of an independent estimation of mineral resources calculated by Tetra Tech. This update to the 2017 resource report also includes the newly acquired land and ownership.

Technical information, including locations, orientations, mapping, and analytical data has been supplied by Augusta. Information pertaining to title, environment, permitting and access has also been supplied by Augusta, and the author of this report have relied on the experts supplying this information. Introductory summaries pertaining to infrastructure, location, geology, and mineralization have been primarily sourced from the historical reports from past producers and by Augusta.

The project site was inspected by Geologist Kira Johnson on August 25, 2020.

| 2.1 | Units of Measure |

All references to dollars in this report are to U.S. dollars (US$) unless otherwise noted. Distances, areas, volumes, and masses are expressed in the metric system unless indicated otherwise. Historic data is expressed in English units, such as feet and tons.

For the purpose of this report, common measurements are given in metric units. All tonnages shown are in Tonnes (t) of 1,000 kilograms, and precious metal grade values are given in grams per tonne (g/t), precious metal quantity values are given in troy ounces (toz). To convert to English units, the following factors should be used:

| ▪ | 1 short ton = 0.907 tonne (T) |

| ▪ | 1 troy ounce = 31.1035 grams (g) |

| ▪ | 1 troy ounce/short ton = 34.286 grams per tonne (g/t) |

| ▪ | 1 foot = 30.48 centimeters (cm) = 0.3048 meters (m) |

| ▪ | 1 mile = 1.61 kilometer (km) |

| ▪ | 1 acre = 0.405 hectare (ha) |

| Tetra Tech | February 2021 | 10 |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

| 2.2 | Abbreviations |

The following is a list of the abbreviations used in this report:

| Abbreviation | Unit or Term |

| 2D | two-dimensional |

| 3D | three-dimensional |

| Ag | silver |

| Au | gold |

| cm | centimeter |

| cm3 | cubic centimeters |

| g | gram |

| g/t | grams per tonne |

| g/cm3 | grams per cubic centimeter |

| ha | hectare |

| kg | kilogram |

| km | kilometer |

| km2 | square kilometers |

| km/h | kilometers per hour |

| kw-h | kilowatt per hour |

| m | meter |

| M | million |

| Mm | millimeter |

| mm/yr | millimeters per year |

| Mya | million years before present |

| NDEP | Nevada Department of Environmental Projection |

| NI 43-101 | Canadian Securities Administrators’ National Instrument 43-101 |

| NSR | Net Smelting Return |

| Pb | lead |

| PEA | Preliminary Economic Assessment |

| ppm | parts per million |

| QA/QC | quality assurance/quality control |

| T | metric ton |

| toz | Troy ounces |

| T/d | Tonnes per day |

| US$ | United States dollars |

| Tetra Tech | February 2021 | 11 |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

| 3. | Reliance on Other Experts |

The author relied on statements by Augusta concerning legal and environmental matters mainly included in Section 4.0 and 5.0 of this report.

The author are relying on statements and documents provided by Augusta regarding:

| ▪ | Permitting requirements to initiate mining, |

| ▪ | Location of the land holdings, |

| ▪ | Status of the land holdings, |

| ▪ | Surface access per the agreements and US mining law, |

| ▪ | Royalty and purchase agreements relating to the land holdings concessions. |

| Tetra Tech | February 2021 | 12 |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

| 4. | Property Description and Location |

The Project is located in the Bullfrog Hills of Nye County, Nevada (Figure 4-1). Augusta’s property covers approximately 3,157 hectares of patented and unpatented lode mining claims in Sections 25, 26, 35 and 36 of T11S, R46E and Sections 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 14, 15, 16, 17, and 23 of T12S, R46E, Mt. Diablo Meridian. The Project is accessible via a 2¼ hour (260 km) drive north of Las Vegas, Nevada along US Highway 95. Las Vegas is serviced by a major international airport and is the closest major hub for providing equipment, supplies, services, and other support to the Project. The Project lies 4 miles west of the Town of Beatty, Nevada, which has a population of approximately 1,000 and contains most basic services, including motels, gasoline stations, schools, and a variety of stores and services. Access around the Project is provided by a series of reasonably good gravel roads that extend to the existing mines and important exploration areas.

Figure 4-1: Location Map

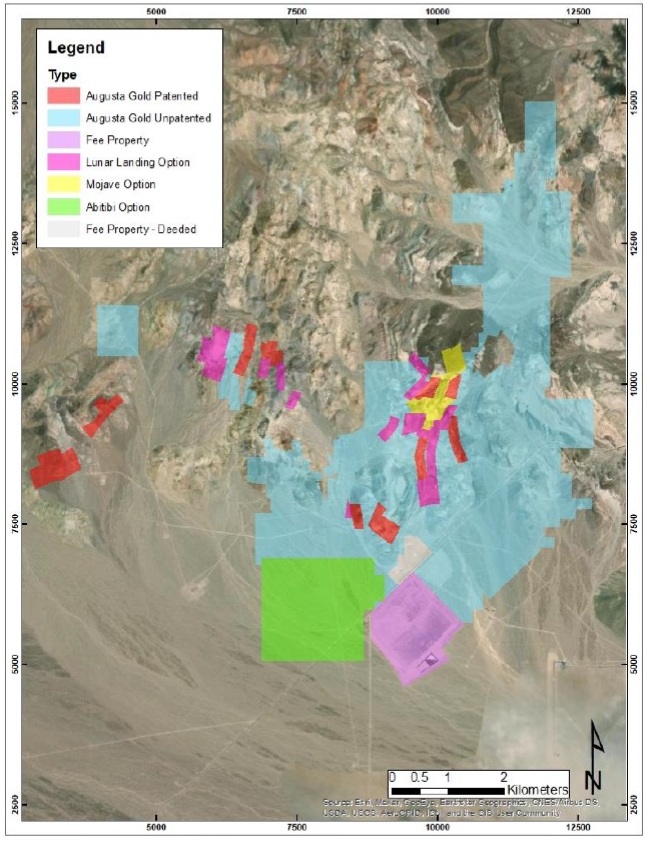

Augusta has four option/lease/purchase agreements in place and has located 61 claims that give it control of 435 unpatented lode mining claims and mill site claims, and 86 patented. These lands are listed in Table 4-1. A property map with the locations shown in detail can be seen below in Figure 4-2. The claims do not have an expiration date, as long as the fees and obligations are maintained.

| Tetra Tech | February 2021 | 13 |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

Table 4-1: Lands Under the Control of Augusta Gold Corp.

| Augusta Gold Corp. Patented Claims | ||

| Standard Gold | ||

| Patent Name | Mineral Survey No. | |

| Providence | 2470 | |

| Aurium | 2654 | |

| Augusta Gold Corp. Patented Claims | ||

| Mojave Gold Mining | ||

| Patent Name | Mineral Survey No. | |

| Polaris Fraction | 2426 | |

| Inaugural Fraction | 2426 | |

| Three Peaches | 2426 | |

| Little Fraction | 2471A | |

| Indian Johnnie | 2471A | |

| Shoshone | 2471A | |

| Del Monte Fraction | 2501A | |

| Shoshone Two | 2471A | |

| Shoshone Three | 2471A | |

| Oro Grande | 2470 | |

| Shoshone Extension | 2470 | |

| Greenhorn | 2470 | |

| Augusta Gold Corp. Patented Claims | ||

| Brown Claims | ||

| Patent Name | Mineral Survey No. | |

| Crystal | 2418 | |

| Oliver | 2340 | |

| Augusta Gold Corp. Patented Claims | ||

| Lunar Landing Claims | ||

| Patent Name | Mineral Survey No. | |

| Elkhorn | 2736 | |

| Red Bluff | 2540 | |

| Black Bull | 2425 | |

| Bell Boy Fraction | 2425 | |

| South Fraction | 2425 | |

| Lookout | 2461 | |

| Molly Gibson #1 | 3043 | |

| Molly Gibson # 2 | 3043 | |

| Molly Gibson #3 | 3043 | |

| Tetra Tech | February 2021 | 14 |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

| Molly Gibson #4 | 3043 | |

| Molly Gibson #5 | 3043 | |

| Rand | 2784 | |

| Rand #1 | 2784 | |

| Rand #2 | 2784 | |

| Rand #3 | 2784 | |

| Rand Fraction | 2784 | |

| Early Bird | 2491 | |

| Unexpected | 2735 | |

| Scorpion | 2411 | |

| St. Anthony | 2734 | |

| Eva Bell | 2576 | |

| Gem Fraction | 2377 | |

| Quartzsite Fraction | 2422 | |

| Annex | 2715 | |

| Augusta Gold Corp. Unpatented Claims | ||

| Claim Name | BLM Serial Number | |

| BFGC 1 | NMC1147851 | |

| BFGC 2 | NMC1147852 | |

| BFGC 3 | NMC1147853 | |

| BFGC 4 | NMC1147854 | |

| BFGC 5 | NMC1147855 | |

| BFGC 6 | NMC1147856 | |

| BFGC 8 | NMC1147857 | |

| BFGC 9 | NMC1147858 | |

| BFGC 10 | NMC1147859 | |

| BFGC 11 | NMC1147860 | |

| BFGC 12 | NMC1147861 | |

| BFGC 13 | NMC1147862 | |

| BFGC 14 | NMC1147863 | |

| BFGC 15 | NMC1147864 | |

| BFGC 16 | NMC1147865 | |

| BFGC 17 | NMC1147866 | |

| BFGC 18 | NMC1147867 | |

| BFGC 19 | NMC1147868 | |

| BFGC 20 | NMC1147869 | |

| BFGC 21 | NMC1147870 | |

| BFGC 22 | NMC1147871 | |

| BFGC 23 | NMC1147872 | |

| BFGC 24 | NMC1147873 | |

| BFGC 25 | NMC1147874 | |

| Tetra Tech | February 2021 | 15 |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

| BFGC 26 | NMC1147875 | |

| BFGC 27 | NMC1147876 | |

| BFGC 28 | NMC1147877 | |

| BFGC 29 | NMC1147878 | |

| BFGC 30 | NMC1147879 | |

| BFGC 31 | NMC1147880 | |

| BFGC 32 | NMC1147881 | |

| BFGC 33 | NMC1147882 | |

| BFGC 34 | NMC1147883 | |

| BFGC 35 | NMC1147884 | |

| BFGC 36 | NMC1147885 | |

| BFGC 37 | NMC1147886 | |

| BFGC 38 | NMC1147887 | |

| BFGC 39 | NMC1147888 | |

| BFGC 40 | NMC1147889 | |

| BFGC 41 | NMC1147890 | |

| BFGC 42 | NMC1147891 | |

| BFGC 43 | NMC1147892 | |

| BFGC 44 | NMC1147893 | |

| BFGC 45 | NMC1147894 | |

| BFGC 46 | NMC1147895 | |

| BFGC 47 | NMC1147896 | |

| BFGC 48 | NMC1147897 | |

| BFGC 49 | NMC1147898 | |

| BFGC 50 | NMC1147899 | |

| BFGC 51 | NMC1147900 | |

| BFGC 52 | NMC1147901 | |

| BFGC 53 | NMC1147902 | |

| BFGC 54 | NMC1147903 | |

| BFGC 55 | NMC1147904 | |

| BFGC 56 | NMC1147905 | |

| BFGC 57 | NMC1147906 | |

| BFGC 58 | NMC1147907 | |

| BFGC 59 | NMC1147908 | |

| BFGC 60 | NMC1147909 | |

| BFGC 61 | NMC1147910 | |

| BFGC 62 | NMC1147911 | |

| BFGC 7 | NMC1154057 | |

| BFGC 63 | NMC1154058 | |

| BFGC 64 | NMC1154059 | |

| BFGC 65 | NMC1154060 |

| Tetra Tech | February 2021 | 16 |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

| BFGC 66 | NMC1154061 | |

| BFGC 67 | NMC1154062 | |

| BFGC 68 | NMC1154063 | |

| BFGC 69 | NMC1154064 | |

| BFGC 70 | NMC1154065 | |

| BFGC 71 | NMC1154066 | |

| BFGC 72 | NMC1154067 | |

| BFGC 73 | NMC1154068 | |

| BFGC 74 | NMC1154069 | |

| BFGC 75 | NMC1154070 | |

| BFGC 76 | NMC1154071 | |

| BFGC 77 | NMC1154072 | |

| BFGC 78 | NMC1154073 | |

| BFGC 79 | NMC1154074 | |

| BFGC 80 | NMC1154075 | |

| BFGC 81 | NMC1154076 | |

| BFGC 82 | NMC1154077 | |

| BFGC 83 | NMC1154078 | |

| BFGC 84 | NMC1154079 | |

| BFGC 85 | NMC1154080 | |

| BFGC 86 | NMC1154081 | |

| BFGC 87 | NMC1154082 | |

| BFGC 88 | NMC1154083 | |

| BFGC 89 | NMC1177609 | |

| BFGC 90 | NMC1177610 | |

| BFGC 91 | NMC1177611 | |

| BFGC 92 | NMC1177612 | |

| BFGC 93 | NMC1177613 | |

| BFGC 94 | NMC1177614 | |

| BFGC 95 | NMC1177615 | |

| BFGC 96 | NMC1177616 | |

| BFGC 97 | NMC1177617 | |

| BFGC 98 | NMC1177618 | |

| BFGC 99 | NMC1177619 | |

| BFGC 100 | NMC1177620 | |

| BFGC 101 | NMC1177621 | |

| BFGC 102 | NMC1177622 | |

| BFGC 103 | NMC1177623 | |

| BFGC 104 | NMC1177624 | |

| BFGC 105 | NMC1177625 | |

| BFGC 106 | NMC1177626 |

| Tetra Tech | February 2021 | 17 |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

| BFGC 107 | NMC1177627 | |

| BFGC 108 | NMC1177628 | |

| BFGC 109 | NMC1177629 | |

| BFGC 110 | NMC1177630 | |

| BFGC 111 | NMC1177631 | |

| BFGC 112 | NMC1185280 | |

| BFGC 113 | NMC1185281 | |

| BFGC 114 | NMC1185282 | |

| BFGC 115 | NMC1185283 | |

| BFGC 116 | NMC1185284 | |

| BFGC 117 | NMC1185285 | |

| BFGC 118 | NMC1185286 | |

| BFGC 119 | NMC1185287 | |

| BFGC 120 | NMC1185288 | |

| BFGC 121 | NMC1185289 | |

| BFGC 122 | NMC1185290 | |

| BFGC 123 | NMC1185291 | |

| BFGC 124 | NMC1185292 | |

| BFGC 125 | NMC1185293 | |

| BFGC 126 | NMC1185294 | |

| BFGC 127 | NMC1185295 | |

| BFGC 128 | NMC1185296 | |

| BFGC 129 | NMC1185297 | |

| BFGC 130 | NMC1185298 | |

| BFGC 131 | NMC1185299 | |

| BFGC 132 | NMC1185300 | |

| BFGC 133 | NMC1185301 | |

| BFGC 134 | NMC1185302 | |

| BEATTY CON # 1 | NMC109662 | |

| LUCKY QUEEN | NMC109667 | |

| BC # 8 BABINGTON | NMC109697 | |

| BC # 9 CORNELL | NMC109698 | |

| BC # 10 FLIN FLON 2 | NMC109699 | |

| BVD 6 | NMC987963 | |

| BVD 5 | NMC987964 | |

| BVD 324 | NMC987965 | |

| BVD 323 | NMC987966 | |

| BVD 322 | NMC987967 | |

| BVD 321 | NMC987968 | |

| BVD 317 | NMC987969 | |

| BVD 316 | NMC987970 |

| Tetra Tech | February 2021 | 18 |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

| BVD 315 | NMC987971 | |

| BVD 314 | NMC987972 | |

| BVD 303 | NMC987973 | |

| BVD 302 | NMC987974 | |

| BVD 301 | NMC987975 | |

| BVD 300 | NMC987976 | |

| BVD 207 | NMC987977 | |

| BVD 206 | NMC987978 | |

| BVD 205 | NMC987979 | |

| BVD 204 | NMC987980 | |

| BVD 203 | NMC987981 | |

| BVD 202 | NMC987982 | |

| BVD 201 | NMC987983 | |

| BVD 200 | NMC987984 | |

| BVD 107 | NMC987985 | |

| BVD 106 | NMC987986 | |

| BVD 105 | NMC987987 | |

| BVD 41 | NMC987988 | |

| BVD 40 | NMC987989 | |

| BVD 32 | NMC987990 | |

| BVD 31 | NMC987991 | |

| BVD 30 | NMC987992 | |

| BVD 29 | NMC987993 | |

| BVD 36 | NMC987994 | |

| BVD 35 | NMC987995 | |

| BVD 34 | NMC987996 | |

| BVD 33 | NMC987997 | |

| BVD 28 | NMC987998 | |

| BVD 27 | NMC987999 | |

| BVD 26 | NMC988000 | |

| BVD 25 | NMC988001 | |

| BVD 19 | NMC988002 | |

| BVD 18 | NMC988003 | |

| BVD 17 | NMC988004 | |

| BVD 16 | NMC988005 | |

| BVD 24 | NMC988006 | |

| BVD 23 | NMC988007 | |

| BVD 22 | NMC988008 | |

| BVD 21 | NMC988009 | |

| BVD 20 | NMC988010 | |

| BVD 15 | NMC988011 |

| Tetra Tech | February 2021 | 19 |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

| BVD 14 | NMC988012 | |

| BVD 13 | NMC988013 | |

| BVD 12 | NMC988014 | |

| BVD 11 | NMC988015 | |

| BVD 39 | NMC988016 | |

| BVD 38 | NMC988017 | |

| BVD 37 | NMC988018 | |

| BVD 10 | NMC988019 | |

| BVD 9 | NMC988020 | |

| BVD 8 | NMC988021 | |

| BVD 7 | NMC988022 | |

| BVD 4 | NMC988023 | |

| BVD 3 | NMC988024 | |

| BVD 2 | NMC988025 | |

| BVD 1 | NMC988026 | |

| BVD 401 | NMC992989 | |

| BVD 402 | NMC992990 | |

| BVD 403 | NMC992991 | |

| BVD 404 | NMC992992 | |

| BVD 405 | NMC992993 | |

| BVD 406 | NMC992994 | |

| BVD 407 | NMC992995 | |

| BVD 408 | NMC992996 | |

| BVD 409 | NMC992997 | |

| BVD 410 | NMC992998 | |

| Augusta Gold Corp. Unpatented Claims | ||

| Abitibi Option | ||

| Claim Name | BLM Serial Number | |

| AR 1 | 1209019 | |

| AR 2 | 1209020 | |

| AR 3 | 1209021 | |

| AR 4 | 1209022 | |

| AR 5 | 1209023 | |

| AR 6 | 1209024 | |

| AR 7 | 1209025 | |

| AR 8 | 1209026 | |

| AR 9 | 1209027 | |

| AR 10 | 1209028 | |

| AR 11 | 1209029 | |

| AR 12 | 1209030 | |

| Tetra Tech | February 2021 | 20 |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

| AR 13 | 1209031 | |

| AR 14 | 1209032 | |

| AR 15 | 1209033 | |

| AR 16 | 1209034 | |

| AR 17 | 1209035 | |

| AR 18 | 1209036 | |

| AR 19 | 1209037 | |

| AR 20 | 1209038 | |

| AR 21 | 1209039 | |

| AR 22 | 1209040 | |

| AR 23 | 1209041 | |

| AR 24 | 1209042 | |

| AR 25 | 1209043 | |

| AR 26 | 1209044 | |

| AR 27 | 1209045 | |

| AR 28 | 1209046 | |

| AR 29 | 1209047 | |

| AR 30 | 1209048 | |

| AR 31 | 1209049 | |

| AR 32 | 1209050 | |

| AR 33 | 1209051 | |

| AR 34 | 1209052 | |

| AR 35 | 1209053 | |

| AR 36 | 1209054 | |

| AR 37 | 1209055 | |

| AR 38 | 1209056 | |

| AR 39 | 1209057 | |

| AR 40 | 1209058 | |

| AR 41 | 1209059 | |

| AR 42 | 1209060 | |

| AR 43 | 1209061 | |

| Augusta Gold Corp. Patented Claims | ||

| Barrick Claims | ||

| Claim Name | Patent Number | |

| EMERALD | 44862 | |

| RUBY | 44862 | |

| NORTHSTAR | 45830 | |

| LOUISVILLE | 35256 | |

| DENVER FRACTION | 45316 | |

| TRAMP NO. 2 | 46191 | |

| SIDEWINDER | 45387 | |

| Tetra Tech | February 2021 | 21 |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

| TIGER | 45387 | |

| TRAMP EXTENSION | 46171 | |

| TRAMP NO. 1 | 46171 | |

| HOBO | 45253 | |

| VIRGINIA | 529024 | |

| DIAMOND HITCH | 46187 | |

| COMET | 46182 | |

| LE ROI | 46181 | |

| UGLY DUCKLING | 46180 | |

| LE ROI FRACTION | 46179 | |

| DEL MONTE | 46173 | |

| POLARIS | 46173 | |

| DENVER NO. 2 | 45348 | |

| VENTURE | 45348 | |

| DENVER NO. 3 | 77975 | |

| SUNSET NO. 1 | 45371 | |

| SUNSET NO. 2 | 45371 | |

| CHIEF | 45815 | |

| PRINCE | 45815 | |

| S.L. | 46223 | |

| SPEARHEAD | 46223 | |

| SUMMIT | 46223 | |

| AURORA | 47481 | |

| GRAND PRIZE | 47481 | |

| QUARTETTE | 47481 | |

| H071 TRACT 37 PATENT | ||

| BULL FROG NO. 2 | 44644 | |

| BULLFROG | 44644 | |

| BULLFROG FRACTION LODE | 45120 | |

| DELAWARE NO. 1 | 46263 | |

| ETHEL | 46263 | |

| JUMBO | 46263 | |

| NEVADA | 88070 | |

| ROOSEVELT | 88070 | |

| TEDDY | 88070 | |

| TEDDY FRACTION | 88070 | |

| PACIFIC PLACER | 952102 | |

| NEVADA PLACER | 952102 | |

| PARIAN PLACER | 952102 | |

| Augusta Gold Corp. Unpatented Claims | ||

| Barrick Claims | ||

| Tetra Tech | February 2021 | 22 |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

| Mine Claims | ||

| Claim Name | BLM Serial Number | |

| Shorty 1 | NMC 1058705 | |

| Shorty 2 | NMC 1058706 | |

| Shorty 3 | NMC 1058707 | |

| Shorty 4 | NMC 1058708 | |

| Shorty 5 | NMC 1058709 | |

| Shorty 6 | NMC 1058710 | |

| Shorty 7 | NMC 1058711 | |

| Shorty 8 | NMC 1058712 | |

| Shorty 10 | NMC 1058713 | |

| Shorty 11 | NMC 1058714 | |

| Shorty 12 | NMC 1058715 | |

| ACE NUMBER 1 | NMC 112229 | |

| ACE NO. 2* | NMC 112230 | |

| ACE NO. 3* | NMC 112231 | |

| RHYOLITE NO. 1 | NMC 128702 | |

| RHYOLITE NO. 5 | NMC 128705 | |

| WEST SIDE RHYOLITE | NMC 128708 | |

| EAST SIDE | NMC 128709 | |

| YANKEE GIRL # 2 | NMC 128710 | |

| FROG EXTENSION | NMC 128711 | |

| FROG NO. 1 | NMC 128712 | |

| BOLIVAR NO. 1 | NMC 128713 | |

| CASH BOY | NMC 128714 | |

| GOLDEN EAGLE # 2* | NMC 298788 | |

| GOLDEN EAGLE # 3* | NMC 298789 | |

| GOLDEN AGE # 1* | NMC 298790 | |

| GOLDEN AGE # 2* | NMC 298791 | |

| GOLDEN AGE # 3* | NMC 298792 | |

| GOLDEN AGE # 4* | NMC 298793 | |

| GOLDEN AGE # 5* | NMC 298794 | |

| GOLDEN AGE # 15* | NMC 298802 | |

| GOLDEN AGE # 16* | NMC 298803 | |

| BEV # 43 | NMC 350754 | |

| BEV # 44 | NMC 350755 | |

| BEV # 45 | NMC 350756 | |

| BEV # 46 | NMC 350757 | |

| BEV # 53 | NMC 350764 | |

| BEV # 54 | NMC 350765 | |

| BEV # 65 | NMC 350776 | |

| Tetra Tech | February 2021 | 23 |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

| BEV # 73 | NMC 350784 | |

| RACHAEL # 3 | NMC 400293 | |

| RACHAEL # 4 | NMC 400294 | |

| RACHAEL # 5 | NMC 400295 | |

| MIKE 9 | NMC 415141 | |

| MIKE 10 | NMC 415142 | |

| IRBF # 5 | NMC 418634 | |

| IRBF # 6 | NMC 418635 | |

| IRBF # 8 | NMC 418637 | |

| IRISH EYES # 2 | NMC 436850 | |

| CHERYL MARIE # 3 | NMC 436852 | |

| GOLDEN SLIVER | NMC 436855 | |

| TOTO # 1 | NMC 436856 | |

| TOTO # 2 | NMC 436857 | |

| TOTO # 3 | NMC 436858 | |

| TOTO # 4 | NMC 436859 | |

| TOTO # 5 | NMC 436860 | |

| TOTO # 6 | NMC 436861 | |

| TOTO # 7 | NMC 436862 | |

| OVERSIGHT | NMC 436870 | |

| ERICA ANN # 1 | NMC 436876 | |

| DINY F | NMC 443898 | |

| DOUG'S DESPAIR # 1 | NMC 453427 | |

| LITTLE BEV # 7 | NMC 462038 | |

| BEV NO. 17 | NMC 507261 | |

| BEV NO. 18 | NMC 507262 | |

| BEV NO. 19 | NMC 507263 | |

| BEV NO. 20 | NMC 507264 | |

| BEV NO. 55 | NMC 507277 | |

| BEV NO. 66 | NMC 507287 | |

| BEV NO. 67 | NMC 507288 | |

| LITTLE BEV # 9 | NMC 523201 | |

| BROTHER 1 | NMC 551789 | |

| BROTHER 2 | NMC 551790 | |

| GOLDEN AGE # 6 | NMC 583381 | |

| GOLDEN AGE # 7* | NMC 583382 | |

| GOLDEN AGE # 8* | NMC 583383 | |

| GOLDEN AGE # 9* | NMC 583384 | |

| GOLDEN AGE # 12* | NMC 583385 | |

| GOLDEN AGE # 13* | NMC 583386 | |

| GOLDEN AGE # 14* | NMC 583387 |

| Tetra Tech | February 2021 | 24 |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

| GOLDEN AGE # 17* | NMC 583388 | |

| BEV 47 A | NMC 819978 | |

| BEV 48 A | NMC 819979 | |

| Augusta Gold Corp. Millsite Claims | ||

| Barrick Claims | ||

| Claim Name | BLM Serial Number | |

| BFMS NO. 1 | NMC 519933 | |

| BFMS NO. 2 | NMC 519934 | |

| BFMS NO. 3 | NMC 519935 | |

| BFMS NO. 4 | NMC 519936 | |

| BFMS NO. 5 | NMC 519937 | |

| BFMS NO. 6 | NMC 519938 | |

| BFMS NO. 7 | NMC 519939 | |

| BFMS NO. 8 | NMC 519940 | |

| BFMS NO. 9 | NMC 519941 | |

| BFMS NO. 10 | NMC 519942 | |

| BFMS 11 | NMC 519943 | |

| BFMS NO. 12 | NMC 519944 | |

| BFMS NO. 13 | NMC 519945 | |

| BFMS NO. 14 | NMC 519946 | |

| BFMS NO. 15 | NMC 519947 | |

| BFMS NO. 16 | NMC 519948 | |

| BFMS NO. 17 | NMC 519949 | |

| BFMS NO. 18 | NMC 519950 | |

| BFMS NO. 19 | NMC 519951 | |

| BFMS NO. 20 | NMC 519952 | |

| BFMS NO. 21 | NMC 519953 | |

| BFMS NO. 22 | NMC 519954 | |

| BFMS NO. 23 | NMC 519955 | |

| BFMS NO. 24 | NMC 519956 | |

| BFMS NO. 25 | NMC 519957 | |

| BFMS NO. 26 | NMC 519958 | |

| BFMS NO. 27 | NMC 519959 | |

| BFMS NO. 28 | NMC 519960 | |

| BFMS NO. 29 | NMC 519961 | |

| BFMS NO. 30 | NMC 519962 | |

| BFMS NO. 31 | NMC 519963 | |

| BFMS NO. 32 | NMC 519964 | |

| BFMS NO. 33 | NMC 519965 | |

| BFMS NO. 36 | NMC 519968 | |

| BFMS NO. 37 | NMC 519969 | |

| Tetra Tech | February 2021 | 25 |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

| BFMS NO. 38 | NMC 519970 | |

| BFMS 41 | NMC 519973 | |

| BFMS NO. 42 | NMC 519974 | |

| BFMS NO. 43 | NMC 519975 | |

| BFMS NO. 46 | NMC 519978 | |

| BFMS NO. 48 | NMC 519980 | |

| BFMS NO. 49 | NMC 519981 | |

| BFMS NO. 50 | NMC 519982 | |

| BFMS NO. 51 | NMC 519983 | |

| BFMS NO. 52 | NMC 519984 | |

| BFMS NO. 53 | NMC 519985 | |

| BFMS NO. 56 | NMC 519988 | |

| BFMS NO. 57 | NMC 519989 | |

| BFMS NO. 58 | NMC 519990 | |

| BFMS NO. 59 | NMC 519991 | |

| BFMS NO. 60 | NMC 519992 | |

| BFMS NO. 61 | NMC 519993 | |

| BFMS NO. 63 | NMC 519995 | |

| BFMS NO. 64 | NMC 519996 | |

| BFMS NO. 65 | NMC 519997 | |

| BFMS NO. 66 | NMC 519998 | |

| BFMS NO. 67 | NMC 519999 | |

| BFMS NO. 71 | NMC 528590 | |

| BFMS 72 | NMC 528591 | |

| BFMS NO. 73 | NMC 528592 | |

| BFMS NO. 92 | NMC 528611 | |

| BFMS NO. 93 | NMC 528612 | |

| BFMS NO. 94 | NMC 528613 | |

| BFMS NO. 95 | NMC 528614 | |

| BFMS NO. 96 | NMC 528615 | |

| BFMS NO. 97 | NMC 528616 | |

| BFMS NO. 98 | NMC 528617 | |

| BFMS NO. 101 | NMC 528620 | |

| BFMS NO. 104 | NMC 528623 | |

| BFMS NO. 105 | NMC 528624 | |

| BFMS NO. 106 | NMC 528625 | |

| BFMS NO. 107 | NMC 528626 | |

| BFMS NO. 110 | NMC 528629 | |

| BFMS NO. 111 | NMC 528630 | |

| BFMS NO. 114 | NMC 528633 | |

| BFMS NO. 115 | NMC 528634 |

| Tetra Tech | February 2021 | 26 |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

| BFMS NO. 116 | NMC 528635 | |

| BFMS NO. 119 | NMC 528638 | |

| BFMS NO. 205 | NMC 528724 | |

| BFMS NO. 206 | NMC 528725 | |

| BFMS NO. 207 | NMC 528726 | |

| BFMS NO. 208 | NMC 528727 | |

| BFMS NO. 209 | NMC 528728 | |

| BFMS NO. 250 | NMC 528769 | |

| BFMS NO. 251 | NMC 528770 | |

| BFMS NO. 252 | NMC 528771 | |

| BFMS NO. 253 | NMC 528772 | |

| BFMS NO. 254 | NMC 528773 | |

| BFMS NO. 255 | NMC 528774 | |

| BFMS NO. 256 | NMC 528775 | |

| BFMS 257 | NMC 528776 | |

| BGMW NO. 1 | NMC 551064 | |

| BGMW NO. 3 | NMC 551065 | |

| BGMW NO. 11 | NMC 551066 | |

| BGMW NO. 13 | NMC 551067 | |

| BFMS 47 A | NMC 817723 |

| Tetra Tech | February 2021 | 27 |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

Figure 4-2: Property Map of the Bullfrog Project

| Tetra Tech | February 2021 | 28 |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

| 4.1 | NPX Assignment of Lands |

In September 2011 the Company issued 14.4 million shares of the Company to the shareholders of Standard Gold Corp. (SGC) to acquire 100% of SGC and its assets. SGC is a private Nevada corporation and now wholly owned by the Company. Concurrently, NPX Metals, Inc. (NPX) and Bull Frog Holding, Inc. (BHI) assigned all title and interests in 79 claims and two patents to Standard Gold Corp. (SGC). The Company granted a production royalty of 3% NSR on the property to NPX and BHI, plus an aggregate 3% NSR cap on any acquired lands within one mile of the 2011 boundary. Thus, NPX and BHI would not receive any royalty on acquisitions having a 3% or greater NSR.

| 4.2 | Mojave Gold Option |

In March 2014, the Company formed Rocky Mountain Minerals Corp. (RMMC), a private Nevada corporation, as a wholly owned subsidiary specifically for holding and acquiring assets. On October 29, 2014, RMMC exercised an option to purchase from Mojave Gold Mining Co. 12 patents west and adjacent to the Company’s initial property and that cover the NE half of the M-S pit. Mojave was paid 750,000 shares of BFGC plus $16,000. RMMC agreed to make annual payments totaling $180,000 over nine years to fully exercise the option, and expend as a minimum work commitment for the benefit of the Property $100,000 per year and a total of $500,000 over five years on the Properties and surrounding lands within one-half mile of the 12 Mojave patents. Alternatively, RMMC can pay cash to Mojave at 50% of the difference between the minimum required and the actual expenditures. Mojave retained a sliding scale Net Smelter Return royalty ranging from 1% for gold prices below $1,200/ounce and up to 4% for gold prices above $3,200 per ounce. For reference, Barrick terminated a lease on the 12 Mojave patents in mid-2000 (then known as the Dees group) and all residual access rights in 2010.

| 4.3 | Barrick Bullfrog Inc. Lease and Option |

On March 23, 2015, Bullfrog Mines LLC (Bullfrog Mines), the successor by conversion of Barrick Bullfrog Inc., and RMMC, among others, entered into a lease and option to purchase agreement (the Lease and Option Agreement) dated March 23, 2015 for RMMC to acquire six patents, 20 unpatented claims, and eight mill site claims from Bullfrog Mines. The Lease and Option Agreement terminated upon execution of the Membership Interest Purchase Agreement (MIPA).

| 4.4 | Lunar Landing Lease |

On July 1, 2017, RMMC entered a lease with Lunar Landing LLC on 24 patents in the Bullfrog District:

| ▪ | Two patents are adjacent and west of the M-S pit that could allow potential expansion of the pit down dip of the Polaris vein and stock work system. |

| ▪ | Ten patents have provided the Company with contiguous and connecting lands between the M-S and Bullfrog pits. These patents will also allow further expansions of the Bullfrog pit to the north and east. |

| ▪ | Four patents are within 0.5 to 1.2 miles west of the Bullfrog pit in the vicinity of the Bonanza Mountain open pit mine. |

| ▪ | Eight patents are in an exploration target area located about 1.5 miles NW of the Bullfrog pit and where the Company has owned the Aurium patent since 2011. |

| Tetra Tech | February 2021 | 29 |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

The lease includes the following:

| ▪ | The Company paid $26,000 on signing and is scheduled to annually pay $16,000 for years 2-5, $21,000 for years 6-10, $25,000 for years 11-15, $30,000 for years 16-20, $40,000 for years 21-25 and $45,000 for years 26-30. |

| ▪ | Production royalty of 5% net smelter returns with the right to buy-down to 2.5%. |

| ▪ | The Company is to expend as a work commitment not less than $50,000 per year and $500,000 in total to maintain the lease. |

| ▪ | The Company has rights to commingle ores and the flexibility to operate the Project as a logical land and mining unit. |

| 4.5 | Brown Claims |

On January 29, 2018, RMMC purchased the two patented claims, thereby eliminating minor constraints to expand the Bullfrog pit to the north. As partial consideration for the Brown Claims, RMMC granted the sellers of the Brown Claims a 5% net smelter returns royalty on the Brown Claims, of which 2.5% can be purchased by RMMC for aggregate consideration of US$37,500.

| 4.6 | Barrick Claims (2020) |

On October 26, 2020, the Company completed its acquisition of Bullfrog Mines pursuant to the MIPA with Homestake Mining Company of California (Homestake) and Lac Minerals (USA) LLC (Lac Minerals and together with Homestake, the Barrick Parties).

Pursuant to the MIPA, the Company purchased from the Barrick Parties all of the equity interests (the Equity Interests) in Bullfrog Mines for aggregate consideration of (i) 54,600,000 units of the Company, each unit consisting of one share of common stock of the Company and one four-year warrant purchase one share of common stock of the Company at an exercise price of C$0.30, (ii) a 2% net smelter returns royalty (the Barrick Royalty) granted on all minerals produced from all of the patented and unpatented claims (subject to the adjustments set out below), pursuant to a royalty deed, dated October 26, 2020 by and among Bullfrog Mines and the Barrick Parties (the Royalty Deed), (iii) the Company granting indemnification to the Barrick Parties pursuant to an indemnity deed, dated October 26, 2020 by and among the Company, the Barrick Parties and Bullfrog Mines, and (iv) certain investor rights, including anti-dilution rights, pursuant to the investor rights agreement, dated October 26, 2020, by and among the Company, Augusta Investments Inc., and Barrick.

Through the Company’s acquisition of the Equity Interests, the Company acquired rights to the 1,500 acres of claims adjoining the Company’s Bullfrog Gold deposit.

Pursuant to the Royalty Deed, the Barrick Royalty is reduced to the extent necessary so that royalties burdening any individual parcel or claim included in the Barrick Properties on October 26, 2020, inclusive of the Barrick Royalty, would not exceed 5.5% in the aggregate, provided that the Barrick Royalty in respect of any parcel or claim would not be less than 0.5%, even if the royalties burdening a parcel or claim included in the Barrick Properties would exceed 5.5%.

| Tetra Tech | February 2021 | 30 |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

| 4.7 | Abitibi Royalties Option |

On December 9, 2020, Bullfrog Mines entered into a mining option agreement with Abitibi Royalties (USA) Inc. (Abitibi) granting Bullfrog Mines the option (the Abitibi Option) to acquire forty-three unpatented lode mining claims to the south of the Bullfrog deposit. Bullfrog Mines made an initial payment to Abitibi of C$25,000 and can exercise the Abitibi Option by:

| ▪ | Paying to Abitibi C$50,000 in cash or shares of Company common stock by December 9, 2021; |

| ▪ | Paying to Abitibi C$75,000 in cash or shares of Company common stock by December 9, 2022; and |

| ▪ | Granting to Abitibi a 2% net smelter royalty on the claims subject to the Abitibi Option by December 9, 2022, of which Bullfrog Mines would have the option to purchase 0.5% for C$500,000 on or before December 9, 2030. |

In order to exercise the Abitibi Option, Bullfrog Mines is also required to keep the underlying claims in good standing.

| 4.8 | Other Property Considerations |

All the unpatented lode mining claims are on U.S. public land administered by the Bureau of Land Management (“BLM”) and, therefore, are subject to exploration and development permits as required by the several current regulations. The unpatented lode mining claims require annual payments of $155 per claim to the BLM and $12 per claim to Nye County.

Total fees paid in 2020 for the lode and mill site claims was $26,739. Nye County property taxes paid in 2020 was approximately $1,781.

In summary, the lands controlled by Augusta are in good standing with no significant liens, encumbrances, or title adversities.

| 4.9 | Environmental and Permitting |

The author is not aware of any outstanding environmental, reclamation or permitting issues that would impact future exploration work. Future exploration work will require a Plan of Operations to be filed with the BLM and the Nevada Department of Environmental Protection.

The following outlines the general framework for permitting a mine in Nevada and the required permits. Many of the permits discussed herein apply to the construction stage and are not currently being pursued.

Exploration activities on Federal mining claims on BLM lands requires a Plan of Operations rather than a Notice of Intent to Drill due to the area being designated desert tortoise habitat. A Plan of Operations is also required with the Nevada Department of Environmental Protection (NDEP) to fulfill the State of Nevada permitting obligations on private and public lands, respectively. Reclamation bonds related to environmental liabilities need to be calculated and posted to cover activities on the Project. Additional permits and bonding will be required for developing, constructing, operating, and reclaiming the Project.

Additional Baseline Studies will be required to update the historical studies completed by Barrick. This will include geochemistry, hydrologic studies of the in-pit water and water in existing wells, plant and wild life surveys, meteorological information, and cultural surveys.

| Tetra Tech | February 2021 | 31 |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

Major permits, not inclusive of the Plan of Operations above, that will be required include:

| ▪ | Water Pollution Control Permits (WPCP): The WPCP application must address the open pit, heap leach pad, mining activities and water management systems with respect to potentially degrading of the waters of Nevada. Sufficient engineering, design and modeling data must be included in the WPCP. A Tentative Permit Closure Plan must be submitted to the NDEP-BMRR in conjunction with the WPCP. A Final Permanent Closure Plan will be needed two years prior to Project closure. |

| ▪ | Air Quality: An application for a Class II Air Quality Permit must be prepared using Bureau of Air Pollution Control (BAPC) forms. The application must include descriptions of the facilities, a detailed emission inventory, plot plans, process flow diagrams and a fugitive dust control plan for construction and operation of the Project. A Mercury Operating Permit and a Title V Operating permit will also be necessary for processing loaded carbon or electro-winning precipitates. |

| ▪ | Water Right: Additional water rights will need to be acquired from third parties or obtained from the Nevada Division of Water Resources (NDWR) for producing Project water. |

| ▪ | Industrial Artificial Pond: Water storage ponds, which are part of the water management systems, will require Industrial Artificial Pond permits (IAPP) from the Nevada Department of wildlife. Approval from the Nevada State Engineer’s Office is also required if embankments exceed specified heights. |

Additional minor permits will be required for the project to advance to production and are listed in Table 4-2 below.

Table 4-2: Additional Minor Permits Required

| Notification/Permit | Agency | |

| Mine Registry | Nevada Division of Minerals | |

| Mine Opening Notification | State Inspector of Mines | |

| Solid Waste Landfill | Nevada Bureau of Waste Management | |

| Hazardous Waste Management Permit | Nevada Bureau of Waste Management | |

| General Storm Water Permit | Nevada Bureau of Water Pollution Control | |

| Hazardous Materials Permit | State Fire Marshall | |

| Fire and Life Safety | State Fire Marshall | |

| Explosives Permit | Bureau of Alcohol, Tobacco, Firearms & Explosives | |

| Notification of Commencement of Operation | Mine Safety and Health Administration | |

| Radio License | Federal Communications Commission | |

| Public Water Supply Permit | NV Division of Environmental Protection | |

| MSHA Identification Number and MSHA Coordination | U.S. Department of Labor Mine Safety and Health Administration (MSHA) | |

| Septic Tank | NDEP-Bureau of Water Pollution Control | |

| Petroleum Contaminated Soils | NV Division of Environmental Protection |

| Tetra Tech | February 2021 | 32 |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

| 4.10 | Significant Risk Factors |

The author is not aware of any outstanding environmental, reclamation or permitting issues that would impact future exploration work.

The author is unaware of any other significant risk factors that may affect access, title, or right or ability to perform work on the property.

| Tetra Tech | February 2021 | 33 |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

| 5. | Accessibility, Climate, Local Resources, Infrastructure and Physiography |

| 5.1 | Accessibility |

The Bullfrog Project is accessible via a 2½ hour (120 mile) drive north of Las Vegas, Nevada on US Highway 95. Las Vegas, the largest city in Nevada, is serviced by a major international airport, and has ample equipment, supplies and services to support many of the Project’s needs. The Project is 4 miles west of the Town of Beatty, Nevada via a paved highway. Beatty has a population of approximately 1,000 and can provide basic housing, services, and supplies. Access around the Project is by a series of reasonably good gravel roads that extend to the open pit mines and most of the significant exploration areas.

| 5.2 | Physiography, Climate and Vegetation |

Figure 5-1: Photo of Bullfrog Hills at Rhyolite

The Bullfrog Project is in Western Nevada’s high desert, which receives about 15 cm of precipitation per year, mostly as modest snowfall in the winter and thunderstorms in the summer. Temperatures typically range from -12°C (10°F) in winter to 43.3°C (110°F) in the summer. Due to the relatively mild climate at the Project, the operating season is year-round.

The hills at the Project are covered with sparse low brush including creosote, four-wing saltbush, rabbit brush, and Nevada ephedra. The Project is in the Basin and Range province, but the local topographic relief is only a few hundred feet. Elevations in the main Project areas range from 1,035 m in the valleys to 1,270 m at the peak of Ladd Mountain and 1,320 m at the peak of Montgomery Mountain. Most of the Project is characterized by low hills separated by modest width valleys. Although the U.S. Fish and Wildlife Service has designated the area as habitat for desert tortoise—a threatened and endangered species—Barrick and others have successfully coped with this designation, and the rough terrain is not conducive for these species. Additional studies may be required to meet requirements regarding the tortoise habitat.

| Tetra Tech | February 2021 | 34 |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

| 5.3 | Local Resources and Infrastructure |

Augusta maintains sufficient surface rights to support mining operations, including areas for potential waste disposal, tailings storage, heap leach pads and potential mill sites. The Company recently located additional mining claims and is pursuing the acquisition of other lands in the area. Most claim blocks are contiguous, and the water rights that Barrick held through Bullfrog Mines were indirectly acquired by Augusta as part of its acquisition of Bullfrog Mines.

The towns of Beatty, Pahrump and Tonopah in Nye County have populations that support mining operations in the area.

Valley Electric Association based in Pahrump, Nevada owns a 138 KV transmission line and a 24.9 KV distribution line that remain on-site and serviced mining at the site previously. The substation connected to the 24.9 KV line remains on-site, but the transformers and switchgear have been removed. Current monthly demand and energy rates are $4.00/kw and $0.096/kw-h, respectively.

Pumping from relatively shallow wells completed near the bottom of the Bullfrog pit is required to access deeper mineralization and could produce most of the Project water needs. Water may also be available from Barrick’s production wells located a few miles south of Highway 374, possibly from the Town of Beatty wellfield in Section 2, and to a limited extent from deepening the M-S pit.

| Tetra Tech | February 2021 | 35 |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

| 6. | History |

The original Bullfrog deposit was discovered in 1904 by Frank “Shorty” Harris and Ernest Cross. This deposit is located 3.5 miles WSW of the Montgomery Shoshone (M-S) mine and initially had un-recorded but minor production. In 1904 the M-S deposit was discovered, and an underground mine was developed to the 700-foot level. A 300-tpd cyanidation mill was constructed for processing the mined material. The M-S operation recovered 67,000 gold equivalent ounces from 141,000 tons or 0.48 gold ounce/ton (opt) during the period 1907 to 1911. The mine was shut down in late 1910 due to declining grades and operating issues at depth. The adjacent Polaris mine produced 4,900 ounces of gold from 9,500 tons, or an average recovery of 0.52 gold opt.

Through 1911 the District produced 94,000 ounces of gold, but thereafter only minor exploration, development, and production activities occurred until St. Joe American successfully initiated modern exploration programs in 1982. In July 1987, Bond International Gold acquired St. Joe and constructed a nominal 9,000-tpd cyanidation mill in July 1989. In November 1989, Lac Minerals acquired Bond’s interest. In September 1994, Lac was acquired by Barrick. Recorded Project gold production from 1989 to 1999 is summarized in Table 6-1.

Table 6-1: Bullfrog Project Production

| Year | Mined Tons | Gold Rec. OPT | Gold Rec. Oz | Silver Rec. Oz | Source Report | |||||

| 1989 | 1,025,000 | 0.060 | 56,771 | 35,752 | Bond Gold | |||||

| 1990 | 3,036,000 | 0.080 | 220,192 | 228,647 | Bond Gold | |||||

| 1991 | 2,988,000 | 0.073 | 198,863 | 188,824 | Lac Min. | |||||

| 1992 | 3,173,000 | 0.111 | 323,825 | 313,100 | Lac Min. | |||||

| 1993 | 3,080,000 | 0.125 | 354,900 | 469,899 | Lac Min. | |||||

| 1994 | 3,093,000 | 0.105 | 301,000 | NR | Barrick | |||||

| 1995 | 3,110,100 | 0.062 | 176,307 | NR | Barrick | |||||

| 1996 | 3,008,600 | 0.073 | 205,300 | NR | Barrick | |||||

| 1997 | 3,070,700 | 0.073 | 206,571 | NR | Barrick | |||||

| 1998 | 3,213,000 | 0.070 | 208,123 | NR | Barrick | |||||

| 1999 | From Stockpiles | 77,000 | NR | NV G.S. | ||||||

| Total/Avg. | 28,797,400 | 0.081 | 2,328,852 | 2,493,591 est. | ||||||

| Mine | Ore Tonnes | G Gold/T Ore | Gold Oz Rec. | Years Mined | ||||||

| BF Pit | 18,428,840 | 2.44 | 1,346,852 | 1989 – 1994 | ||||||

| BF UG | 2,782,077 | 8.30 | 690,000 | 1992 – 1998 | ||||||

| M-S Pit | 3,504,309 | 2.10 | 220,000 | 1994 – 1997 | ||||||

| Bonanza Pit | 1,416,715 | 1.70 | 72,000 | 1995 – 1996 | ||||||

| 26,131,942 | 2.98 | 2,328,852 |

| Tetra Tech | February 2021 | 36 |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

Open pit mine production began in 1989 and underground mine production started in 1992 in the Bullfrog deposit. Bullfrog pit operations were terminated in late 1994, with the underground mine scheduled to produce the remaining Bullfrog reserves. The M-S deposit was open pit mined between 1994 and 1997, during which time the Bonanza Mountain deposit was also mined. Underground operations were shut down in late 1998 due to adverse economic conditions and depletion of remaining reserves. During the last years of mill operations, all remaining low- and high-grade stockpiles, grading +0.5 gold g/t, were blended with underground ores. For reference, gold prices averaged less than $290 per ounce during 1998 and 1999 and hit a multi-year low of $252/oz in August 1999.

By December 2000 Barrick completed all major reclamation and closure requirements, and subsequently removed all mine and processing equipment and buildings. Per Barrick’s permit requirements, the deep north part of the Bullfrog pit has now been backfilled with alluvium to an elevation of 927 meters to cover the gradually rising water table, which currently is at an elevation of 906 m. There has been no backfilling in the M-S pit. Since 2000 no significant activities in the south half of the Bullfrog Mining District have been performed, other than reclamation by Barrick.

The Company’s initial land position in 2011 consisted of 79 unpatented mining claims and two patented claims located adjacent to Barrick and covering 648 hectares. Since then the Company has acquired several additional land parcels, ultimately acquiring Lac and Homestake from Barrick on 2020.

On October 26, 2020, Augusta acquired Bullfrog Mines LLC (the successor by conversion of Barrick Bullfrog Inc.) from certain wholly owned subsidiaries of Barrick Gold Corporation. This transaction added additional land claims to the project.

| Tetra Tech | February 2021 | 37 |

Bullfrog Gold Project – Nye County, Nevada NI 43-101 Technical Report Mineral Resource Estimate |

|

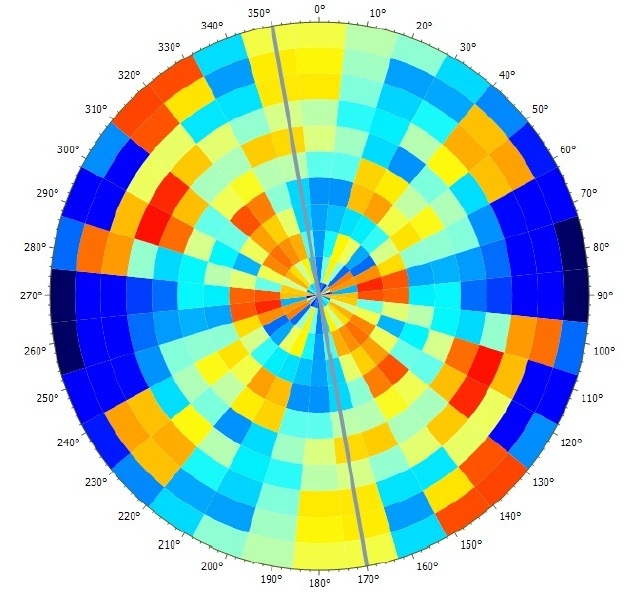

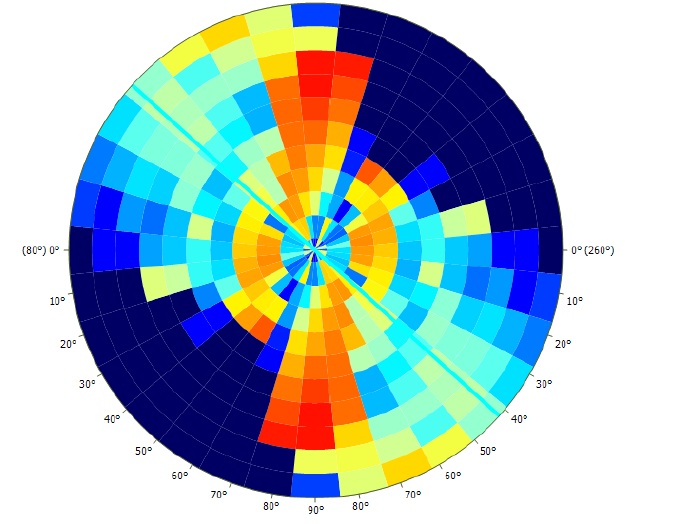

| 7. | Geological Setting and Mineralization |