Attached files

| file | filename |

|---|---|

| 8-K - FORM 8-K - BIOHITECH GLOBAL, INC. | tm2025072d1_8k.htm |

Exhibit 99.1

Smart Disposal Technologies Driving Positive Environmental Change Investor Presentation July 2020 BioHiTech Global Nasdaq: BHTG

This presentation has been prepared by BioHiTech Global, Inc . (the ‘Company’) and includes information from other sources believed by management to be reliable . No representation or warranty, express or implied, is made as to the accuracy or completeness of any of the information set forth herein . This presentation may contain summaries of the terms of certain documents and agreements, but reference is made to the actual documents and agreements for the complete information contained herein . The information contained herein is as of the date hereof and is subject to change, completion or amendment without notice . Additionally, the COVID - 19 pandemic has created further risks and uncertainties, including disruptions to certain of our customer’s operations, which in turn has negatively impacted the Company’s operations as discussed in our filings with the U . S . Securities and Exchange Commission (“SEC”) . This presentation contains statements, estimates and projections with respect to the anticipated future performance of the company that may be deemed to be “forward - looking statements within the meaning of the “safe - harbor” provision of the Securities Litigation Reform Act of 1995 . ” These statements, estimates and projections reflect various assumptions made by the company concerning anticipated results, which may or may not prove to be correct . All statements contained in the presentation that address operating performance, future direction, management and control of company, events or developments that are expected to occur in the future (including statements related to earnings, expectations, sales of assets, capital expenditures, or statements expressing general optimism about future operating results) are forward - looking statements . Actual results could differ materially from those reflected in the forward - looking statements contained herein as a result of a variety of factors, many of which are beyond the Company’s control . Factors that could cause actual results result to differ materially from those described include, without limitation, those factors disclosed under “Item 1 . A . Risk Factors” in our Form 10 - K filed with the SEC on May 22 , 2020 for the year ended December 31 , 2019 . The Company undertakes no obligation to publicly update any forward - looking statement, whether as a result of new information, future events or otherwise . This presentation does not constitute an offer to sell or a solicitation of an offer to buy any security . Any such offer will be made solely to “accredited investors” or “qualified institutional buyers,” as defined by Rule 501 of Regulation D, or investors who are not “U . S . Person” as defined in Rule 902 (k) of Regulation S, each promulgated under the Securities Act of 1933 , as amended . This presentation is qualified in its entirety by our filings with the SEC, which contain more complete information about the Company and the risks of investing involving our Company . Safe Harbor 2

3 ▪ 79.9% of all non - recyclable waste generated ends up in landfills. 1 ▪ 14.1% of methane gas emissions come from landfills. 2 ▪ 30% to 40% of US food production is wasted. 3 ▪ 21.9% of total waste deposited in landfills is food. 1 ▪ 19.2% of total waste deposited in landfills are plastics. 1 ▪ 8 million metric tons of plastic end up in our oceans each year . 4 Key Statistics: The Problem: The United States is Behind the Curve on Sustainable Waste Disposal Corporate and Government leadership are seeking alternative solutions to change the outcome. 1 https://www.epa.gov/facts - and - figures - about - materials - waste - and - recycling/national - overview - facts - and - figures - materials 2 https://www.epa.gov/lmop/basic - information - about - landfill - gas 3 https://www.fda.gov/food/consumers/food - waste - and - loss 4 https://time.com/3707112/plastic - in - the - ocean/

4 ▪ Reducing or Eliminating Landfill Usage. ▪ Reducing Food Waste Generation with a Behavior Changing Data Analytics Platform. ▪ Lowering Carbon Emissions and other Harmful Greenhouse Gases. ▪ Helping to Keep Plastics from Our Oceans. BioHiTech changes the environmental outcome by: The Solution : Cost - Effective Technology Solutions for Sustainable Waste Management

5 ▪ Patented technology converts waste into an EPA recognized renewable fuel for use as an alternative to coal. ▪ Only company to utilize this proven and patented technology in the US. ▪ Reduces landfill usage by up to 80%. ▪ Addresses the non - recyclable plastics problem. ▪ Cost neutral to haulers or municipal customers. ▪ Aerobic digesters installed where food waste is generated. ▪ Converts food waste into a liquid that is safely discharged to any standard sewer line. ▪ Eliminates carbon emissions from transportation and landfill disposal. ▪ Reduces pest problems. ▪ Typically less costly than traditional waste disposal. ▪ Patented IoT technology differentiates BioHiTech from competitors. ▪ Provides actionable real - time supply chain management information. ▪ Information can help achieve behavioral change to reduce food waste generation. ▪ Generates reports to evidence regulatory compliance. Resource Recovery Facilities for Mixed Municipal Waste On - site Food Waste Disposal Technology Cloud - based Data Analytics Platform Changing the Outcome to Achieve Sustainability

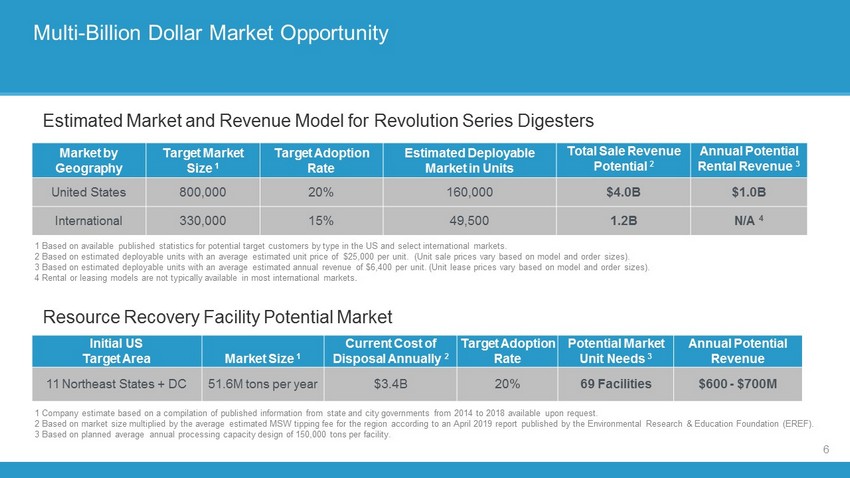

Market by Geography Target Market Size 1 Target Adoption Rate Estimated Deployable Market in Units Total Sale Revenue Potential 2 Annual Potential Rental Revenue 3 United States 800,000 20% 160,000 $4.0B $1.0B International 330,000 15% 49,500 1.2B N/A 4 Estimated Market and Revenue Model for Revolution Series Digesters Initial US Target Area Market Size 1 Current Cost of Disposal Annually 2 Target Adoption Rate Potential Market Unit Needs 3 Annual Potential Revenue 11 Northeast States + DC 51.6M tons per year $3.4B 20% 69 Facilities $600 - $700M Resource Recovery Facility Potential Market 1 Based on available published statistics for potential target customers by type in the US and select international markets. 2 Based on estimated deployable units with an average estimated unit price of $25,000 per unit. (Unit sale prices vary base d o n model and order sizes). 3 Based on estimated deployable units with an average estimated annual revenue of $6,400 per unit. (Unit lease prices vary ba sed on model and order sizes). 4 Rental or leasing models are not typically available in most international markets . 6 Multi - Billion Dollar Market Opportunity 1 Company estimate based on a compilation of published information from state and city governments from 2014 to 2018 availabl e u pon request. 2 Based on market size multiplied by the average estimated MSW tipping fee for the region according to an April 2019 report p ubl ished by the Environmental Research & Education Foundation (EREF). 3 Based on planned average annual processing capacity design of 150,000 tons per facility.

▪ Models available to support various levels of customer food waste volumes. ▪ On - site aerobic digester converts food waste into a liquid that is safely discharged through any standard sewer line. ▪ Processing costs are often less expensive than traditional disposal. ▪ Complies with current food waste regulations. ▪ Provides real - time data analytics for supply chain management and to support Corporate Social Responsibility and Sustainability reporting. ▪ Attractive leasing model with no upfront costs or capital investment to the customer. Combining biology and technology to start a revolution in sustainable food waste disposal. Target markets include: 7 Restaurants Government Food Services Grocery/ Big Box Stores Maritime/ Cruise Industry Hotel/ Hospitality On - Site Food Waste Disposal Technology: Revolution Series Digesters

BioHiTech’s patented IoT software platform provides real - time data analytics on food waste generation. 8 Utilization Data Categorization Environmental Data Cost Savings Regulation Compliance REAL - TIME SUPPLY CHAIN ANALYTICS ▪ Measurement tools to quantify and qualify sources of waste. ▪ Enables the identification of patterns in the waste stream such as over - ordering or unreliable suppliers. ▪ Accurate measurement of food waste diversion helps with regulatory compliance. Real - time Information Can Help Effect Change. Reducing Food Waste Saves Money. ▪ It costs far more to purchase food than it does to dispose of it. ▪ Improved supply chain management generates less waste. Cloud - Based Data Analytics: Understanding the Problem is the Key to Solving it!

Received purchase contract from Carnival Corp in January 2020. ▪ Estimated $14 million of equipment purchases over the life of the agreement. ▪ Establishes our products as the standard for food waste disposal in the hospitality space. ▪ Provides validation of our business strategy to shift to larger market opportunities. ▪ Expected to generate significant revenue in 2020. Established lease financing arrangement with Crestmark and US Equity Funding for new digester rental contracts. ▪ Monetizes traditional 5 year rental agreement upfront for credit approved customers. ▪ Can significantly reduce capital needs for manufacturing product. ▪ Can substantially improve cash flow from operations. 9 Transforming the Digester Business for the Future

10 Select Digester Customers and Distributors

Facility Benefits: ▪ Reduces landfill usage by up to 80%. ▪ Produces an EPA recognized solid recovered fuel (SRF). ▪ Generates high EBITDA margins. ▪ No increased costs to haulers or municipalities. ▪ Outside environment is not exposed to waste. ▪ Waste is unloaded and processed inside facility. ▪ BioFilter removes odors and contaminants. ▪ Fully automated with no workers sorting or handling waste. ▪ Building design similar to a warehouse. BioHiTech controls the exclusive U.S. development rights to deploy facilities using the patented High Efficiency Biological Treatment (“HEBioT”) process in 11 Northeast states and DC. 11 Resource Recovery Facilities: Converting Waste into Renewable Fuel

The Martinsburg facility is the first mixed municipal solid waste processing facility in the U.S. to utilize the patented HEBioT process. ▪ Commenced operations in Q2 2019. ▪ Financed through $33 million in bond issuances by the West Virginia Economic Development Authority. ▪ 10 year contracts for both input and off - take support strong EBITDA margins. ▪ BioHiTech owns majority interest (partners include Kinderhook Industries and Entsorga Italia). 12 Location of Facility Martinsburg, W.Va Design Capacity 110,000 tons per year Waste Type Mixed Municipal Solid Waste/C&I Operational Availability 8,000 hours per year Stockpiling Availability 3,500 tons in bio - stabilization area 300 tons in receiving area Energy Produced Up to 50,000 tons per year Engineered Solid Recovered Fuel (SRF) Materials Recovered Up to 4,000 tons per year of Metals Residuals Landfilled Approximately 20,000 tons per year (20%) Estimated Annual Revenue $7 Million Flagship Resource Recovery Facility: Entsorga West Virginia

Weight Loss of 30% to 35% Mechanical Pre - Screening Biological Process Refinement and Sorting Traditional Disposal Method Recycled Metals 3% to 5% Solid Recovered Fuel 40% to 50% Inert Materials 8% to 10% Other Residual for Landfill 15% to 20% LANDFILL Collection Vehicles Aggregated (manual sorting ) 95% plus Transfer Station Same Tipping Fee Per Truck 13 Patented Waste Conversion Process Residual for Landfill 95%+ Recycled Metals 3% to 5% BioHiTech Solution 20% or Less x Reduces CO2 1 and Methane Emissions x Multiple Revenue Streams x High EBITDA Margins Resource Recovery Solution vs. Traditional Disposal Method Potential uses – Fill or other industrial 2 1 CO2 reduction expected to be attained through reduced long - haul trucking of waste to landfills. 2 Inert materials are currently landfllled with the Company exploring other potential uses.

▪ Martinsburg Facility commissioned in 2019 with first full year of revenue in 2020. ▪ New York Facility in late stage permitting process expected to be under construction in 2021. ▪ Several identified locations in planning stage. ▪ Active discussions with several municipal authorities for additional locations. ▪ Potential for numerous relationships to accelerate growth including co - development, licensing, and operations management. ▪ Targeting to bring 1 - 2 new facilities online per year. Resource Recovery Roadmap: Building Value through Commercialization

15 Altapure Opportunity – Environmentally Friendly Disinfection in a Post - COVID World ▪ BioHiTech has established itself as a trusted technology provider to customers in the cruise, hotel, hospitality, hospital/assisted living, grocery, and education markets, all of which have all been affected by COVID - 19. ▪ To assist our customers with post - COVID reopening challenges, the BioHiTech team sought out additional environmentally friendly technologies to meet specific needs in health and safety. ▪ BioHiTech entered into a distribution agreement in May 2020 with Altapure , a disinfectant technology company, to help its customers create a healthy and safe environment through automated, high level disinfection.

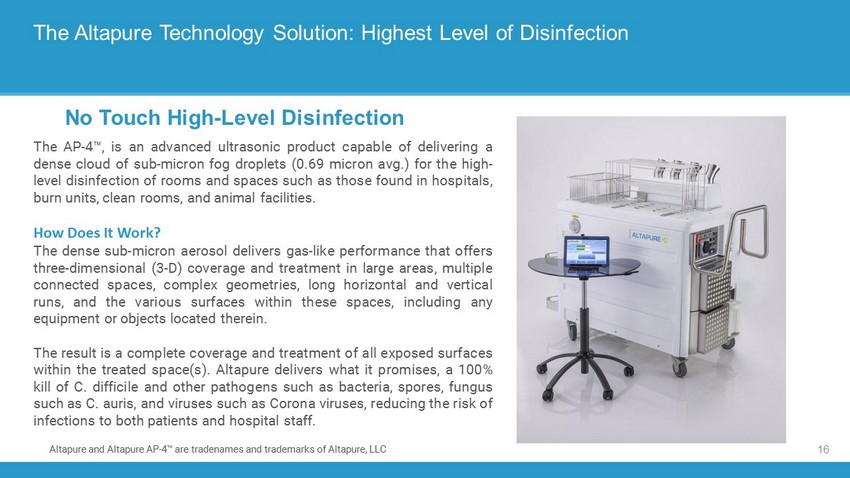

16 The Altapure Technology Solution: Highest Level of Disinfection No Touch High - Level Disinfection The AP - 4 ™, is an advanced ultrasonic product capable of delivering a dense cloud of sub - micron fog droplets ( 0 . 69 micron avg . ) for the high - level disinfection of rooms and spaces such as those found in hospitals, burn units, clean rooms, and animal facilities . How Does It Work? The dense sub - micron aerosol delivers gas - like performance that offers three - dimensional ( 3 - D) coverage and treatment in large areas, multiple connected spaces, complex geometries, long horizontal and vertical runs, and the various surfaces within these spaces, including any equipment or objects located therein . The result is a complete coverage and treatment of all exposed surfaces within the treated space(s) . Altapure delivers what it promises, a 100 % kill of C . difficile and other pathogens such as bacteria, spores, fungus such as C . auris , and viruses such as Corona viruses, reducing the risk of infections to both patients and hospital staff . Altapure and Altapure AP - 4™ are tradenames and trademarks of Altapure , LLC

17 AP - 4™ Distribution Opportunity ▪ Initially leverage customer opportunities in current markets serviced including: ▪ Cruise. ▪ Hotel/Hospitality. ▪ Hospital/Assisted Living. ▪ Education. ▪ Collaborate with existing stakeholders to introduce additional opportunities in government and long - term care markets. ▪ Potential to expand relationship beyond distribution.

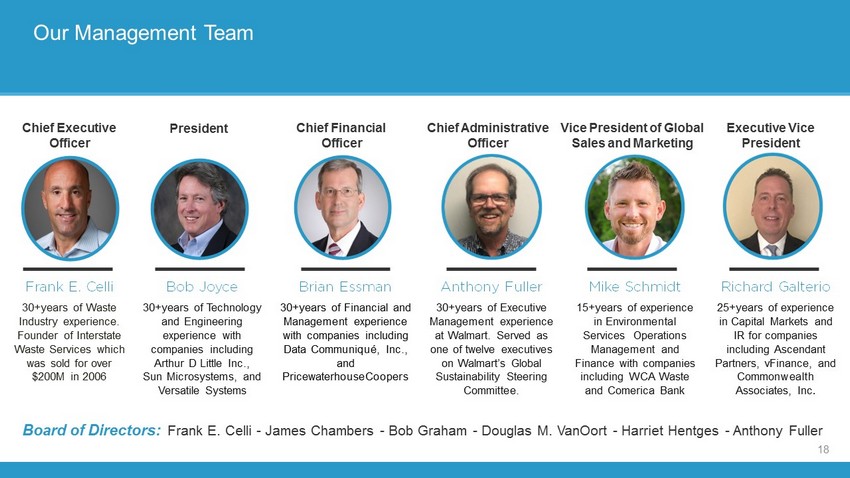

18 Frank E. Celli 30+years of Waste Industry experience. Founder of Interstate Waste Services which was sold for over $200M in 2006 Bob Joyce 30+years of Technology and Engineering experience with companies including Arthur D Little Inc., Sun Microsystems, and Versatile Systems Mike Schmidt 15+years of experience in Environmental Services Operations Management and Finance with companies including WCA Waste and Comerica Bank Brian Essman 30+years of Financial and Management experience with companies including Data Communiqué, Inc., and PricewaterhouseCoopers Anthony Fuller 30+years of Executive Management experience at Walmart. Served as one of twelve executives on Walmart’s Global Sustainability Steering Committee. Board of Directors: Frank E. Celli - James Chambers - Bob Graham - Douglas M. VanOort - Harriet Hentges - Anthony Fuller Chief Executive Officer President Vice President of Global Sales and Marketing Chief Financial Officer Chief Administrative Officer Richard Galterio 25+years of experience in Capital Markets and IR for companies including Ascendant Partners, vFinance , and Commonwealth Associates, Inc . Executive Vice President Our Management Team

19 Why BioHiTech ▪ Cost - effective proprietary technologies with first mover advantage. ▪ Large target markets in early stage of adoption represent a significant high - margin growth opportunity. ▪ Corporate social responsibility and government regulatory efforts are beginning to accelerate demand for sustainable disposal technologies. ▪ Environmental benefits include reduced landfill usage and food waste generation as well as the reduction of harmful carbon and methane emissions. ▪ Growing customer base includes Fortune 500 companies and government. ▪ New opportunity in post - COVID disinfecting. ▪ Proven management team with successful track record.

20 BioHiTech Global NASDAQ: BHTG Corporate Office 80 Red Schoolhouse Road Suite 101 Chestnut Ridge, NY 10977 Tel: 845.262.1081 Contact Information Richard Galterio rgalterio@biohitech.com www.biohitech.com