Attached files

| file | filename |

|---|---|

| 8-K - 8-K - C&J Energy Services, Inc. | cjes8-kinvestorpresentation.htm |

Management Presentation AUGUST 10, 2018 1

Important Disclaimer This presentation contains certain statements and information that may constitute “forward-looking statements” within the meaning of Section 27A of the Securities Act of 1933, as amended, and Section 21E of the Securities Exchange Act of 1934, as amended. All statements, other than statements of historical fact, that address activities, events or developments that we expect, believe or anticipate will or may occur in the future are forward-looking statements. The words “anticipate,” “believe,” “ensure,” “expect,” “if,” “once” “intend,” “plan,” “estimate,” “project,” “forecasts,” “predict,” “outlook,” “will,” “could,” “should,” “potential,” “would,” “may,” “probable,” “likely,” and similar expressions that convey the uncertainty of future events or outcomes, and the negative thereof, are intended to identify forward-looking statements. Forward-looking statements contained in this presentation, which are not generally historical in nature, include those that express a belief, expectation or intention regarding our future activities, plans and goals and our current expectations with respect to, among other things: our ability to successfully integrate the O-Tex cementing business with our own; our operating cash flows, the availability of capital and our liquidity; our future revenue, income and operating performance; our ability to sustain and improve our utilization, revenue and margins; our ability to maintain acceptable pricing for our services; future capital expenditures; our ability to finance equipment, working capital and capital expenditures; our ability to execute our long-term growth strategy; our ability to successfully develop our research and technology capabilities and implement technological developments and enhancements; and the timing and success of strategic initiatives and special projects. Forward-looking statements are not assurances of future performance and actual results could differ materially from our historical experience and our present expectations or projections. These forward-looking statements are based on management’s current expectations and beliefs, forecasts for our existing operations, experience, expectations and perception of historical trends, current conditions, anticipated future developments and their effect on us, and other factors believed to be appropriate. Although management believes the expectations and assumptions reflected in these forward-looking statements are reasonable as and when made, no assurance can be given that these assumptions are accurate or that any of these expectations will be achieved (in full or at all). Our forward-looking statements involve significant risks, contingencies and uncertainties, most of which are difficult to predict and many of which are beyond our control. Known material factors that could cause actual results to differ materially from those in the forward-looking statements include, but are not limited to, risks associated with the following: a decline in demand for our services, including due to declining commodity prices, overcapacity and other competitive factors affecting our industry; the cyclical nature and volatility of the oil and gas industry, which impacts the level of exploration, production and development activity and spending patterns by our customers; a decline in, or substantial volatility of, crude oil and gas commodity prices, which generally leads to decreased spending by our customers and negatively impacts drilling, completion and production activity; pressure on pricing for our core services, including due to competition and industry and/or economic conditions, which may impact, among other things, our ability to implement price increases or maintain pricing on our core services; the loss of, or interruption or delay in operations by, one or more significant customers; the failure by one or more of our significant customers to amounts when due, or at all; changes in customer requirements in markets or industries we serve; costs, delays, compliance requirements and other difficulties in executing our short-and long-term business plans and growth strategies; the effects of recent or future acquisitions on our business, including our ability to successfully integrate our operations and the costs incurred in doing so; business growth outpacing the capabilities of our infrastructure; operating hazards inherent in our industry, including the possibility of accidents resulting in personal injury or death, property damage or environmental damage; adverse weather conditions in oil or gas producing regions; the loss of, or interruption or delay in operations by, one or more of our key suppliers; the effect of environmental and other governmental regulations on our operations, including the risk that future changes in the regulation of hydraulic fracturing could reduce or eliminate demand for our hydraulic fracturing services; the incurrence of significant costs and liabilities resulting from litigation; the incurrence of significant costs and liabilities or severe restrictions on our operations or the inability to perform certain operations resulting from a failure to comply, or our compliance with, new or existing regulations; the effect of new or existing regulations, industry and/or commercial conditions on the availability of and costs for raw materials, consumables and equipment; the loss of, or inability to attract, key management personnel; a shortage of qualified workers; damage to or malfunction of equipment; our ability to maintain sufficient liquidity and/or obtain adequate financing to allow us to execute our business plan; and our ability to comply with covenants under our new credit facility. For additional information regarding known material factors that could affect our operating results and performance, please see our most recently filed Annual Report on Form 10-K, subsequent Quarterly Reports on Form 10-Q, and Current Reports on Form 8-K, which are available at the SEC’s website, http://www.sec.gov. Should one or more of these known material risks occur, or should the underlying assumptions change or prove incorrect, our actual results, performance, achievements or plans could differ materially from those expressed or implied in any forward-looking statement. Readers are cautioned not to place undue reliance on forward-looking statements, which speak only as of the date hereof. All subsequent written or oral forward-looking statements concerning us are expressly qualified in their entirety by the cautionary statements above. We undertake no obligation to publicly update or revise any forward-looking statements after the date they are made, whether as a result of new information, future events or otherwise, except as required by law. All information in this presentation is as of June 30, 2018 unless otherwise indicated. Non-GAAP Financial Measures: This presentation includes Adjusted EBITDA, a measure not calculated in accordance with generally accepted accounting principles in the U.S. ("U.S. GAAP"). Please see slide 24 for a reconciliation of net income (loss), the nearest measure calculated in accordance with U.S. GAAP, or pro forma net income (loss) prepared and presented in accordance with Article 11 of Regulation S-X, to Adjusted EBITDA. 2

Why Invest in C&J Energy Services?

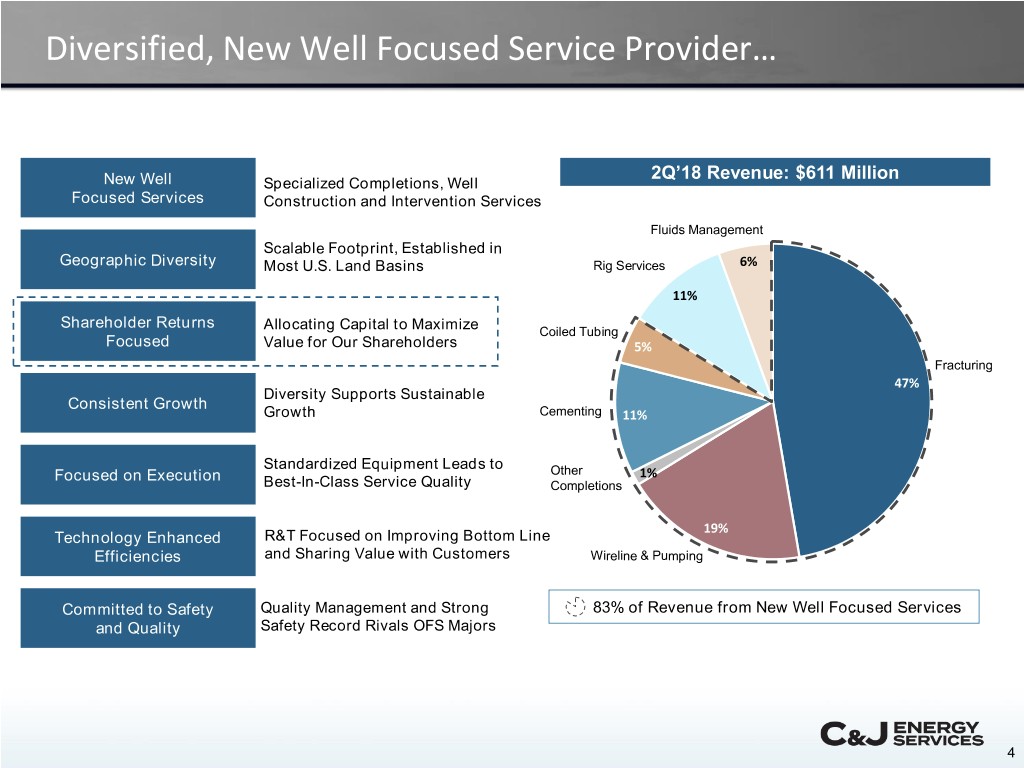

Diversified, New Well Focused Service Provider… 2Q’18 Revenue: $611 Million New Well Specialized Completions, Well Focused Services Construction and Intervention Services Fluids Management Scalable Footprint, Established in Geographic Diversity Most U.S. Land Basins Rig Services 6% 11% Shareholder Returns Allocating Capital to Maximize Coiled Tubing Focused Value for Our Shareholders 5% Fracturing 47% Diversity Supports Sustainable Consistent Growth Growth Cementing 11% Standardized Equipment Leads to Focused on Execution Other 1% Best-In-Class Service Quality Completions 19% Technology Enhanced R&T Focused on Improving Bottom Line Efficiencies and Sharing Value with Customers Wireline & Pumping Committed to Safety Quality Management and Strong 83% of Revenue from New Well Focused Services and Quality Safety Record Rivals OFS Majors 4

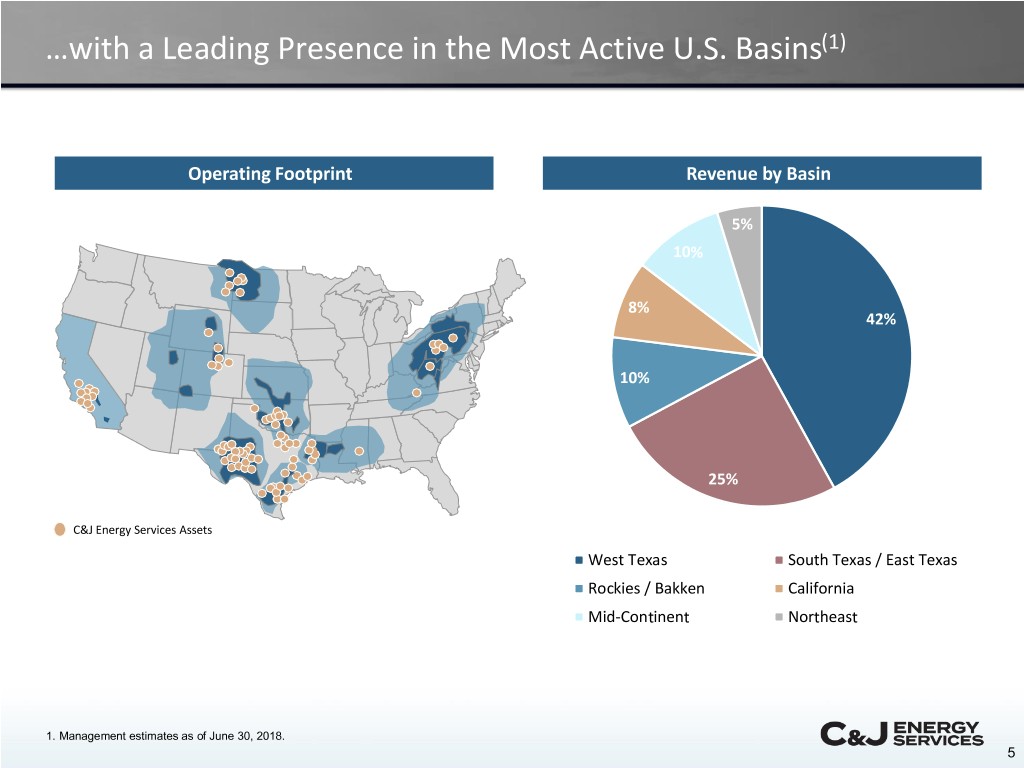

…with a Leading Presence in the Most Active U.S. Basins(1) Operating Footprint Revenue by Basin 5% 10% 8% 42% 10% 25% C&J Energy Services Assets West Texas South Texas / East Texas Rockies / Bakken California Mid-Continent Northeast 1. Management estimates as of June 30, 2018. 5

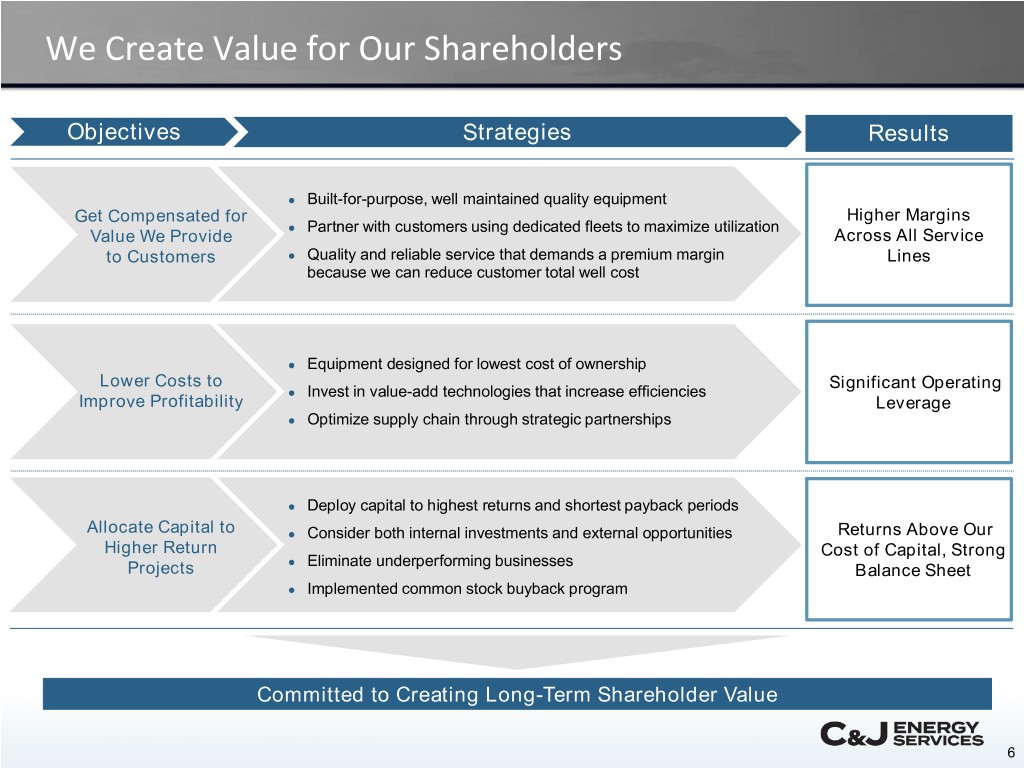

We Create Value for Our Shareholders Objectives Strategies Results ● Built-for-purpose, well maintained quality equipment Get Compensated for Higher Margins ● Partner with customers using dedicated fleets to maximize utilization Value We Provide Across All Service to Customers ● Quality and reliable service that demands a premium margin Lines because we can reduce customer total well cost ● Equipment designed for lowest cost of ownership Lower Costs to Significant Operating ● Invest in value-add technologies that increase efficiencies Improve Profitability Leverage ● Optimize supply chain through strategic partnerships ● Deploy capital to highest returns and shortest payback periods Allocate Capital to ● Consider both internal investments and external opportunities Returns Above Our Higher Return Cost of Capital, Strong ● Eliminate underperforming businesses Projects Balance Sheet ● Implemented common stock buyback program Committed to Creating Long-Term Shareholder Value 6

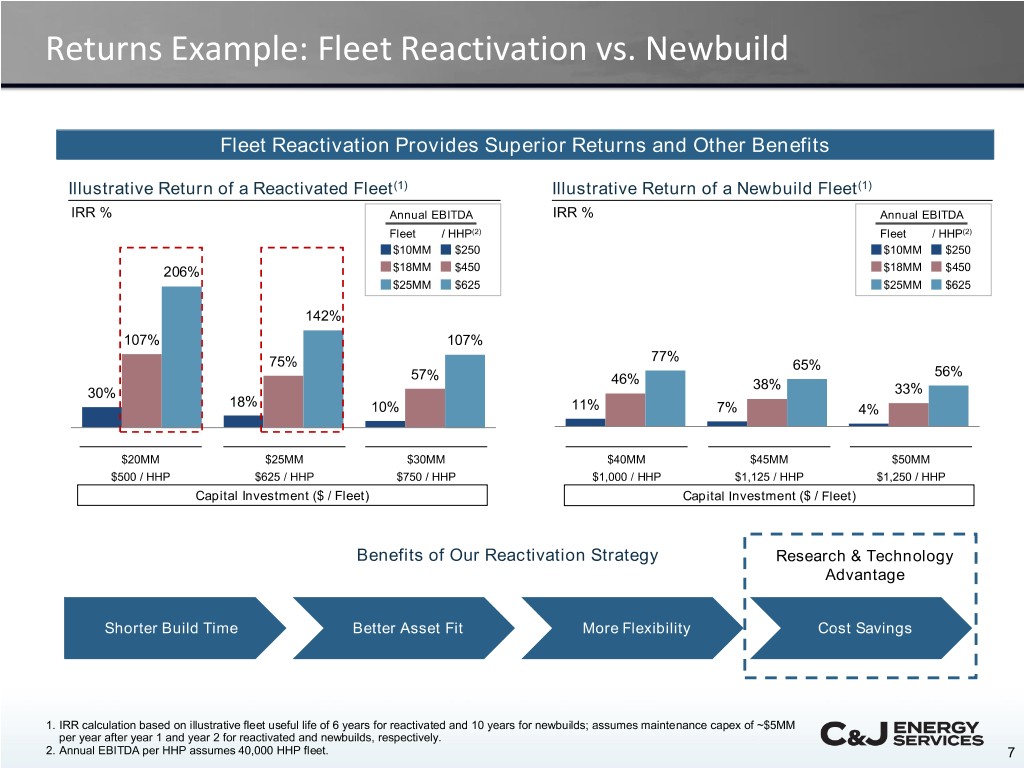

Returns Example: Fleet Reactivation vs. Newbuild Fleet Reactivation Provides Superior Returns and Other Benefits Illustrative Return of a Reactivated Fleet(1) Illustrative Return of a Newbuild Fleet(1) IRR % Annual EBITDA IRR % Annual EBITDA Fleet / HHP(2) Fleet / HHP(2) $10MM $250 $10MM $250 206% $18MM $450 $18MM $450 $25MM $625 $25MM $625 142% 107% 107% 77% 75% 65% 57% 56% 46% 38% 30% 33% 18% 10% 11% 7% 4% $20MM $25MM $30MM $40MM $45MM $50MM $500 / HHP $625 / HHP $750 / HHP $1,000 / HHP $1,125 / HHP $1,250 / HHP Capital Investment ($ / Fleet) Capital Investment ($ / Fleet) Benefits of Our Reactivation Strategy Research & Technology Advantage Shorter Build Time Better Asset Fit More Flexibility Cost Savings 1. IRR calculation based on illustrative fleet useful life of 6 years for reactivated and 10 years for newbuilds; assumes maintenance capex of ~$5MM per year after year 1 and year 2 for reactivated and newbuilds, respectively. 2. Annual EBITDA per HHP assumes 40,000 HHP fleet. 7

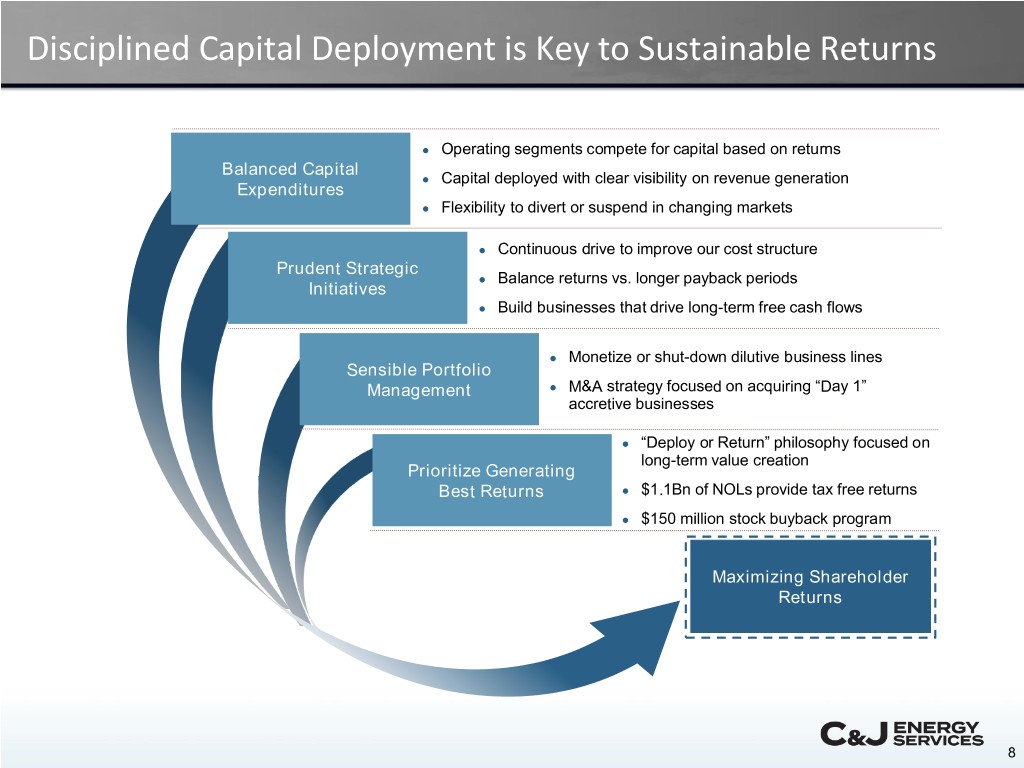

Disciplined Capital Deployment is Key to Sustainable Returns ● Operating segments compete for capital based on returns Balanced Capital ● Capital deployed with clear visibility on revenue generation Expenditures ● Flexibility to divert or suspend in changing markets ● Continuous drive to improve our cost structure Prudent Strategic ● Balance returns vs. longer payback periods Initiatives ● Build businesses that drive long-term free cash flows ● Monetize or shut-down dilutive business lines Sensible Portfolio Management ● M&A strategy focused on acquiring “Day 1” accretive businesses ● “Deploy or Return” philosophy focused on long-term value creation Prioritize Generating Best Returns ● $1.1Bn of NOLs provide tax free returns ● $150 million stock buyback program Maximizing Shareholder Returns 8

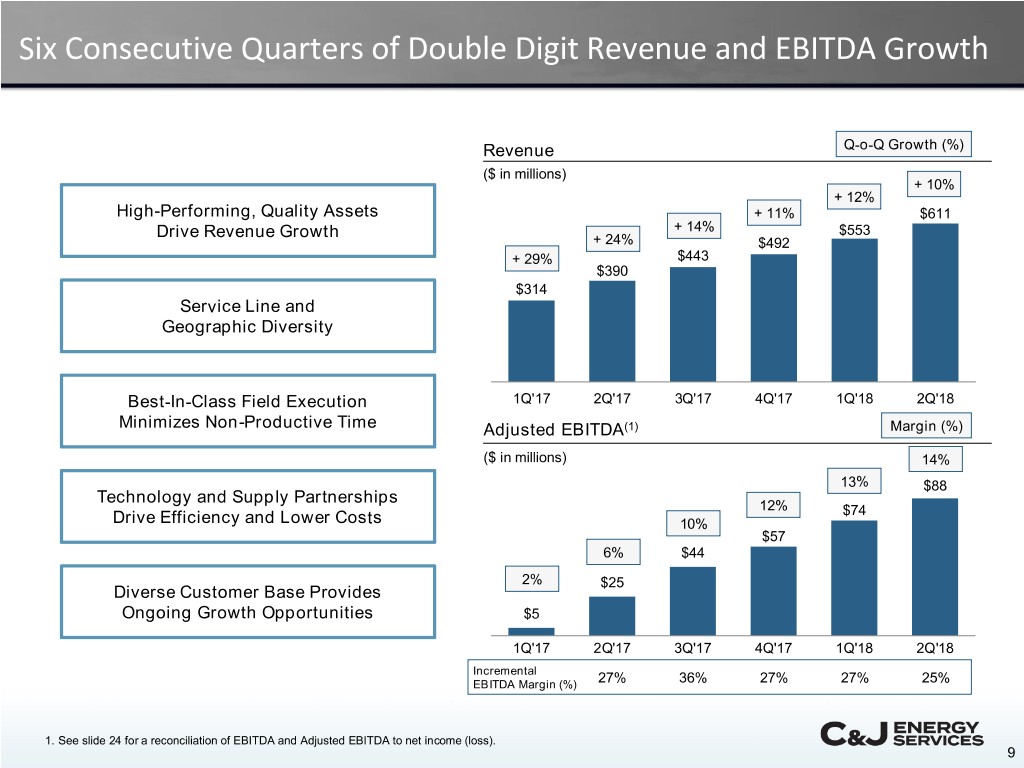

Six Consecutive Quarters of Double Digit Revenue and EBITDA Growth Revenue Q-o-Q Growth (%) ($ in millions) + 10% + 12% High-Performing, Quality Assets + 11% $611 Drive Revenue Growth + 14% $553 + 24% $492 + 29% $443 $390 $314 Service Line and Geographic Diversity Best-In-Class Field Execution 1Q'17 2Q'17 3Q'17 4Q'17 1Q'18 2Q'18 Minimizes Non-Productive Time Adjusted EBITDA(1) Margin (%) ($ in millions) 14% 13% $88 Technology and Supply Partnerships 12% $74 Drive Efficiency and Lower Costs 10% $57 6% $44 2% $25 Diverse Customer Base Provides Ongoing Growth Opportunities $5 1Q'17 2Q'17 3Q'17 4Q'17 1Q'18 2Q'18 Incremental EBITDA Margin (%) 27% 36% 27% 27% 25% 1. See slide 24 for a reconciliation of EBITDA and Adjusted EBITDA to net income (loss). 9

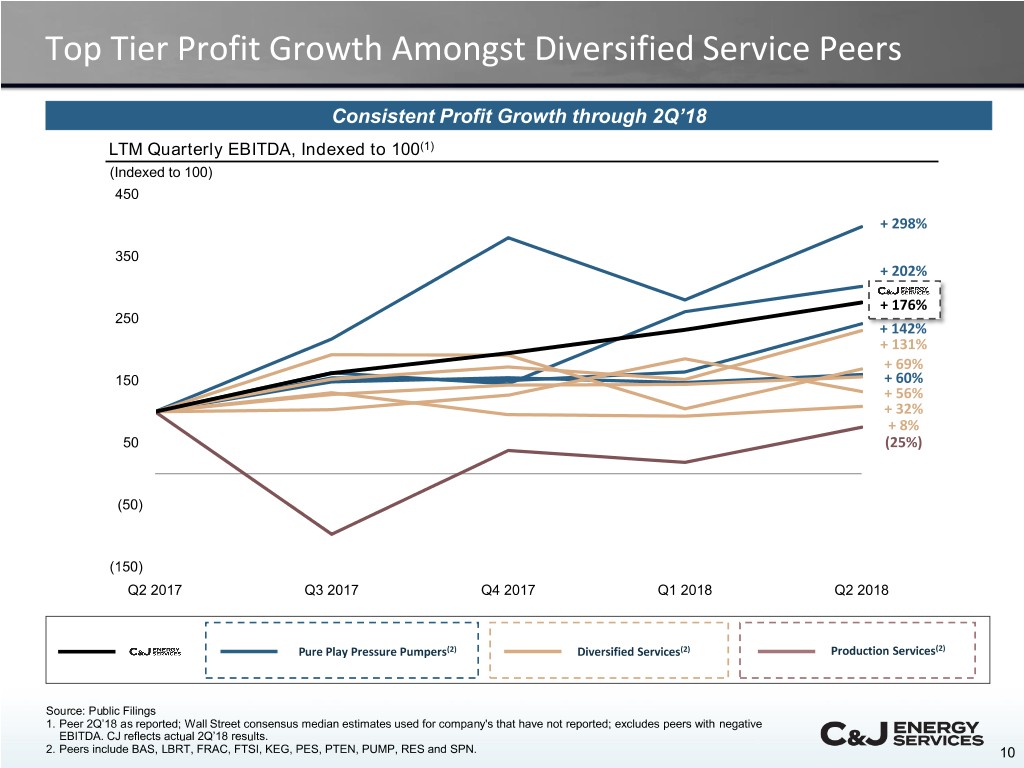

Top Tier Profit Growth Amongst Diversified Service Peers Consistent Profit Growth through 2Q’18 LTM Quarterly EBITDA, Indexed to 100(1) (Indexed to 100) 450 + 298% 350 + 202% + 176% 250 + 142% + 131% + 69% 150 + 60% + 56% + 32% + 8% 50 (25%) (50) (150) Q2 2017 Q3 2017 Q4 2017 Q1 2018 Q2 2018 Pure Play Pressure Pumpers(2) Diversified Services(2) Production Services(2) Source: Public Filings 1. Peer 2Q’18 as reported; Wall Street consensus median estimates used for company's that have not reported; excludes peers with negative EBITDA. CJ reflects actual 2Q’18 results. 2. Peers include BAS, LBRT, FRAC, FTSI, KEG, PES, PTEN, PUMP, RES and SPN. 10

Committed, High Quality Customers Diverse Customer Base ─ No Individual Why Customers Choose C&J? Exposure Greater than 10% of 2017 Revenues High Quality Assets and Execution Service Line and Geographic Diversity Value-Added Technology Reputation for Safety and Service Quality Logos from next few pages Recent Customer Award Congratulations to C&J Well Services, Inc. 2017 Top Business Partner V&V Conformance 11

Our Service Lines

Our New Well Business Has Strong Economics Today Fracturing Wireline & Pumping Coiled Tubing Cementing 2Q’18 Revenue 47% 19% 5% 11% $289MM $115MM $30MM $69MM Current Performance ● 19 horizontal equivalent ● One of our most profitable ● High demand for large ● Growing market share, frac fleets deployed business lines, enhanced by diameter coiled tubing units particularly in West Texas ● Currently operating in six internally manufactured perf ● Increasing utilization and ● Continue to benefit from U.S. basins with mostly guns and switches pricing integration of O-Tex dedicated customers ● Recently realized all-time high revenue per truck Strong Outlook ● 2H’18 frac calendar continues ● Tight marketplace and high ● New agreements for ● Cementing pricing, to strengthen from June lows demand for our services dedicated units in South especially in West Texas, ● Focused on increasing ● Deploying technologies to and West Texas continues to improve dedicated fleets to large, increase efficiencies ● Two newbuild large ● Expanding presence, “blue-chip” customers diameter units deployed targeting long lateral work in 2Q’18 with higher margins Compelling Current Payback Economics(1) < 1 1 – 1.5 < 1 < 1 < 1 Year Years Year Year Years Fracturing Wireline & Pumping Coiled Tubing Cementing 2017 2018E 1. Target payback periods shown on cash basis based on current leading edge EBITDA generation. 13

Hydraulic Fracturing Is Our Biggest Business Line Fleet Reactivations Drive Attractive Returns 2018 Strategy and Reactivation Plan Frac Revenue Q-o-Q Growth (%) ($ in millions) + 7% ● Focused on committed customers who appreciate + 9% + 14% $289 the value we provide + 18% $269 + 41% $247 ● Best-in-class execution and technology enhanced $216 + 47% $184 efficiencies attract “blue-chip” customers $131 ● Will resume redeployment of remaining 120,000 stacked HHP when customer demand dictates 1Q'17 2Q'17 3Q'17 4Q'17 1Q'18 2Q'18 Active Horizontal Equivalent Fleets Adjusted Frac EBITDA Margin (%) ($ in millions) 22% 21% 19 17% 18 22% $59 16 $53 15 20% $47 $49 $36 10 14% $18 YE'16 YE'17 1Q'18 2Q'18 3Q'18E 1Q'17 2Q'17 3Q'17 4Q'17 1Q'18 2Q'18 14

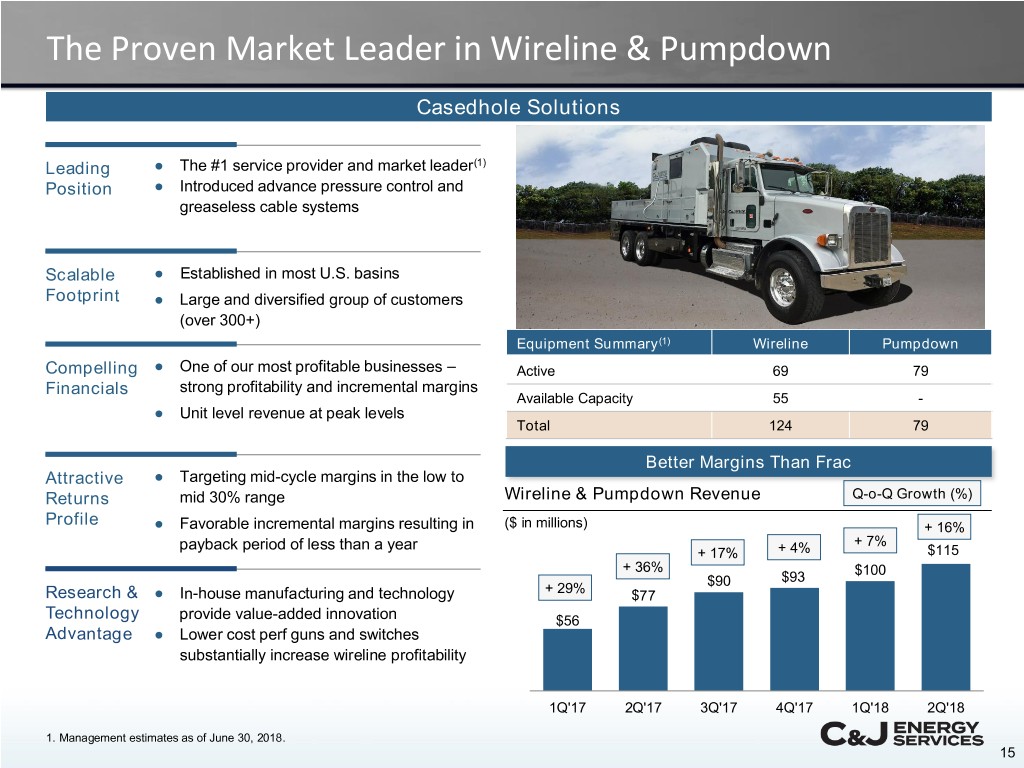

The Proven Market Leader in Wireline & Pumpdown Casedhole Solutions Leading ● The #1 service provider and market leader(1) Position ● Introduced advance pressure control and greaseless cable systems Scalable ● Established in most U.S. basins Footprint ● Large and diversified group of customers (over 300+) Equipment Summary(1) Wireline Pumpdown Compelling ● One of our most profitable businesses – Active 69 79 Financials strong profitability and incremental margins Available Capacity 55 - ● Unit level revenue at peak levels Total 124 79 Better Margins Than Frac Attractive ● Targeting mid-cycle margins in the low to Returns mid 30% range Wireline & Pumpdown Revenue Q-o-Q Growth (%) Profile ● Favorable incremental margins resulting in ($ in millions) + 16% payback period of less than a year + 7% + 17% + 4% $115 + 36% $100 $90 $93 Research & ● In-house manufacturing and technology + 29% $77 Technology provide value-added innovation $56 Advantage ● Lower cost perf guns and switches substantially increase wireline profitability 1Q'17 2Q'17 3Q'17 4Q'17 1Q'18 2Q'18 1. Management estimates as of June 30, 2018. 15

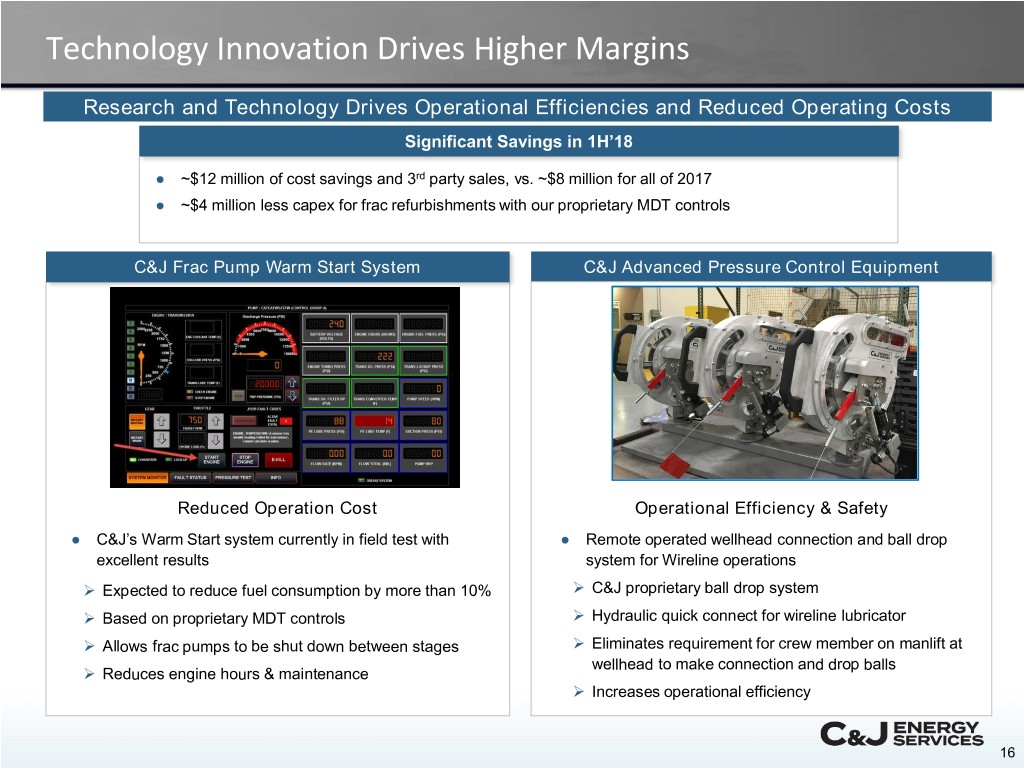

Technology Innovation Drives Higher Margins Research and Technology Drives Operational Efficiencies and Reduced Operating Costs Significant Savings in 1H’18 ● ~$12 million of cost savings and 3rd party sales, vs. ~$8 million for all of 2017 ● ~$4 million less capex for frac refurbishments with our proprietary MDT controls C&J Frac Pump Warm Start System C&J Advanced Pressure Control Equipment Reduced Operation Cost Operational Efficiency & Safety ● C&J’s Warm Start system currently in field test with ● Remote operated wellhead connection and ball drop excellent results system for Wireline operations ➢ ➢ Expected to reduce fuel consumption by more than 10% C&J proprietary ball drop system ➢ ➢ Based on proprietary MDT controls Hydraulic quick connect for wireline lubricator ➢ ➢ Allows frac pumps to be shut down between stages Eliminates requirement for crew member on manlift at wellhead to make connection and drop balls ➢ Reduces engine hours & maintenance ➢ Increases operational efficiency 16

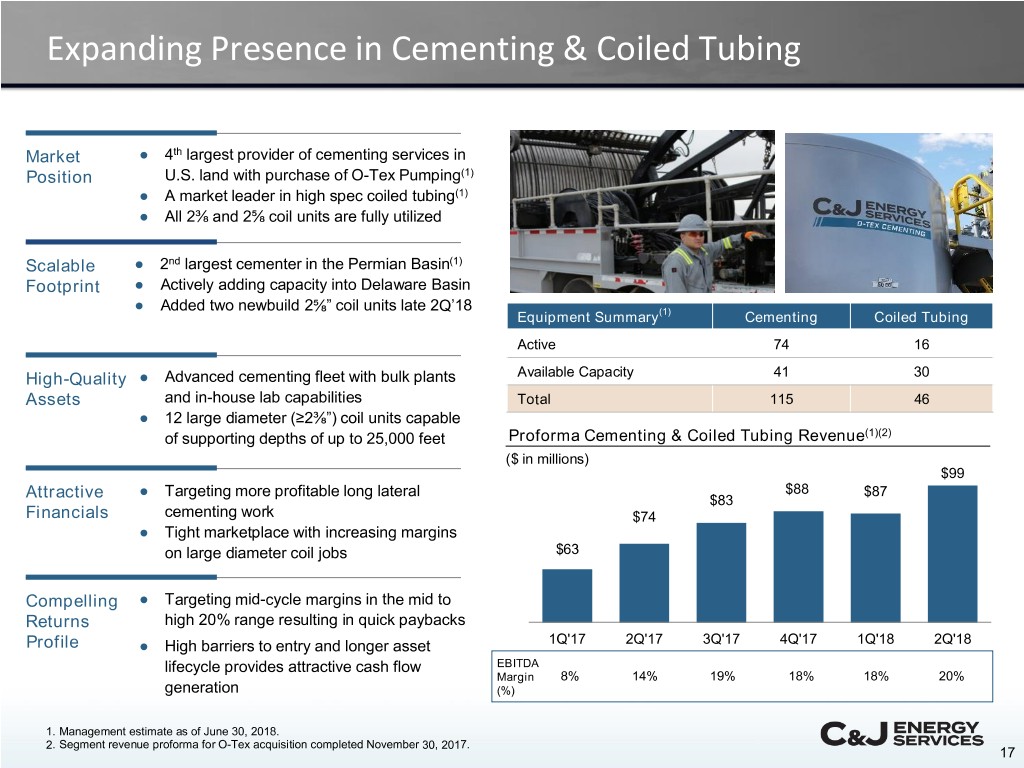

Expanding Presence in Cementing & Coiled Tubing Market ● 4th largest provider of cementing services in Position U.S. land with purchase of O-Tex Pumping(1) ● A market leader in high spec coiled tubing(1) ● All 2⅜ and 2⅝ coil units are fully utilized Scalable ● 2nd largest cementer in the Permian Basin(1) Footprint ● Actively adding capacity into Delaware Basin ● Added two newbuild 2⅝” coil units late 2Q’18 Equipment Summary(1) Cementing Coiled Tubing Active 74 16 High-Quality ● Advanced cementing fleet with bulk plants Available Capacity 41 30 Assets and in-house lab capabilities Total 115 46 ● 12 large diameter (≥2⅜”) coil units capable of supporting depths of up to 25,000 feet Proforma Cementing & Coiled Tubing Revenue(1)(2) ($ in millions) $99 ● Targeting more profitable long lateral $88 $87 Attractive $83 Financials cementing work $74 ● Tight marketplace with increasing margins on large diameter coil jobs $63 Compelling ● Targeting mid-cycle margins in the mid to Returns high 20% range resulting in quick paybacks Profile ● High barriers to entry and longer asset 1Q'17 2Q'17 3Q'17 4Q'17 1Q'18 2Q'18 lifecycle provides attractive cash flow EBITDA Margin 8% 14% 19% 18% 18% 20% generation (%) 1. Management estimate as of June 30, 2018. 2. Segment revenue proforma for O-Tex acquisition completed November 30, 2017. 17

Established Provider of Well Support Services ● Top 2 well services company in the U.S. Market (1) Position with a proven brand name ● Top 10 customers are majors and large independents – recurring and stable Diversified ● Strong operating presence in California, Footprint & Rockies, Permian and South Texas Scale ● ~62% class 4+ rigs capable of the most complex jobs Equipment Summary(1) Rigs Trucks SWDs ● Improved to double-digit segment EBITDA Attractive Active 139 633 23 Financial generation in 2Q’18 Idle & Stacked 213 351 - Returns ● Limited capital investment needed to drive cash flow improvement Total 352 984 23 A Leading Provider of Service Rigs(1)(2) Well Support Services Revenue(3) ($ in millions) 363 ✓ #2 rig position in the U.S. Total Service Rigs ✓ Over 62% of the rig fleet is $96 226 high-spec Capable of $87 $89 HZ Services $85 $85 $82 KEG CJ BAS SPN Forbes PES Ranger Nine 1Q'17 2Q'17 3Q'17 4Q'17 1Q'18 2Q'18 Conventional High Spec 1. Management estimate as of June 30, 2018. 2. Conventional rigs: 100 – 400 HP rigs; High Spec: 400+ HP. 3. Shown proforma for Canadian rig services and artificial lift divestitures in November 2017 and July 2018, respectively. 18

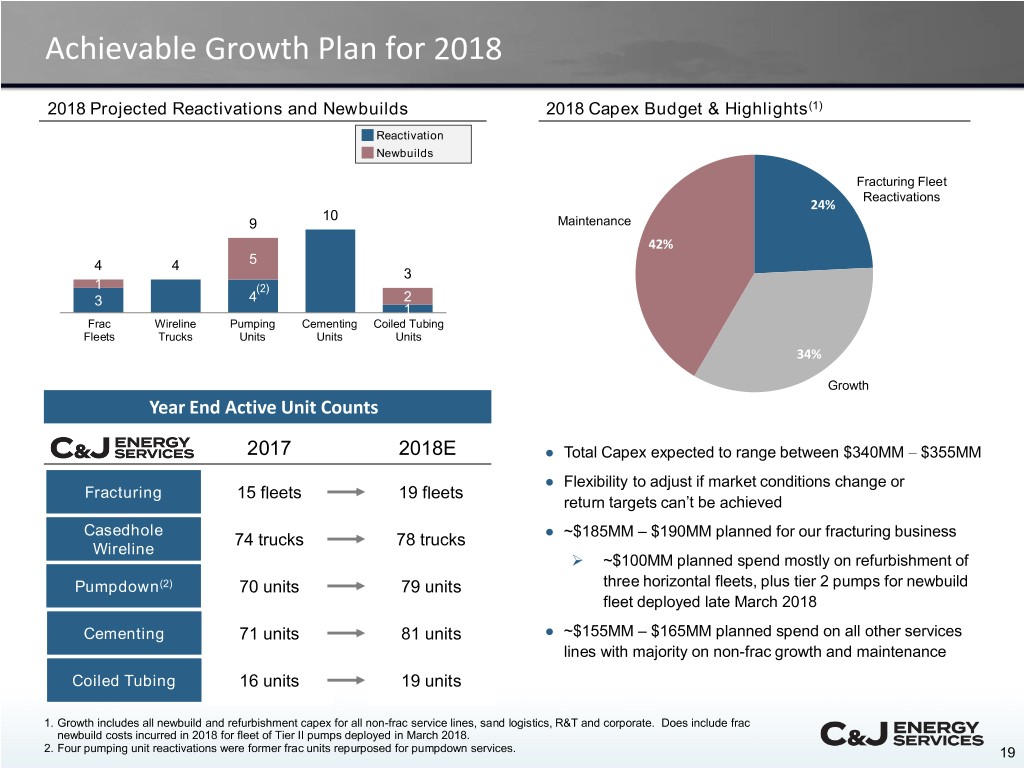

Achievable Growth Plan for 2018 2018 Projected Reactivations and Newbuilds 2018 Capex Budget & Highlights(1) Reactivation Newbuilds Fracturing Fleet Reactivations 24% 10 9 Maintenance 42% 4 4 5 3 1 (2) 3 4 2 1 Frac Wireline Pumping Cementing Coiled Tubing Fleets Trucks Units Units Units 34% Growth Year End ActiveYear Units End Active Unit Counts 2017 2018E ● Total Capex expected to range between $340MM – $355MM ● Flexibility to adjust if market conditions change or Fracturing 15 fleets 19 fleets return targets can’t be achieved Casedhole 74 trucks 78 trucks ● ~$185MM – $190MM planned for our fracturing business Wireline ➢ ~$100MM planned spend mostly on refurbishment of Pumpdown(2) 70 units 79 units three horizontal fleets, plus tier 2 pumps for newbuild fleet deployed late March 2018 Cementing 71 units 81 units ● ~$155MM – $165MM planned spend on all other services lines with majority on non-frac growth and maintenance Coiled Tubing 16 units 19 units 1. Growth includes all newbuild and refurbishment capex for all non-frac service lines, sand logistics, R&T and corporate. Does include frac newbuild costs incurred in 2018 for fleet of Tier II pumps deployed in March 2018. 2. Four pumping unit reactivations were former frac units repurposed for pumpdown services. 19

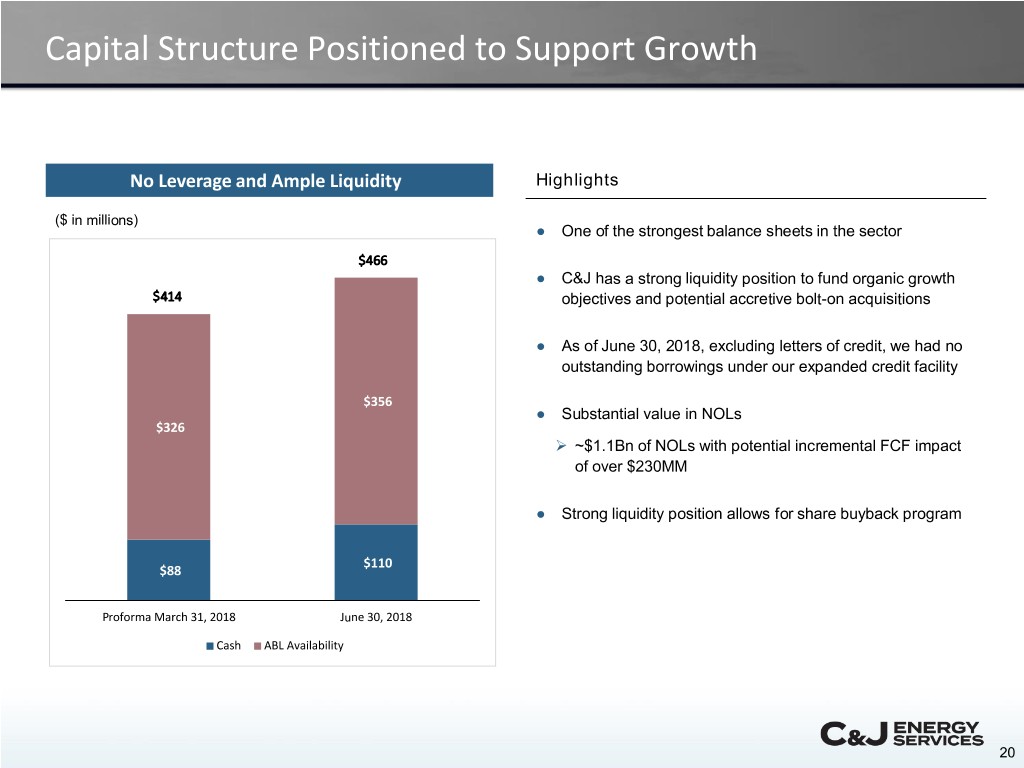

Capital Structure Positioned to Support Growth No Leverage and Ample Liquidity Highlights ($ in millions) ● One of the strongest balance sheets in the sector $466 ● C&J has a strong liquidity position to fund organic growth $414 objectives and potential accretive bolt-on acquisitions ● As of June 30, 2018, excluding letters of credit, we had no outstanding borrowings under our expanded credit facility $356 ● Substantial value in NOLs $326 ➢ ~$1.1Bn of NOLs with potential incremental FCF impact of over $230MM ● Strong liquidity position allows for share buyback program $110 $88 Proforma March 31, 2018 June 30, 2018 Cash ABL Availability 20

C&J Tenants: The Differentiated U.S. Oilfield Services Company Leading Diversified Modern, High-Quality Service Provider in most 1 2 Asset Base U.S. Land Basins Established and Growing Focused on Quality, Safe Relationships with 3 and Reliable Execution 4 “Blue-Chip” Customer Base Operating Model Focused Capitalized for Growth – on Durable Returns and Low Leverage and Ample 5 6 Delivering Value to Liquidity Shareholder Committed to Creating Long-Term Shareholder Value 21

APPENDIX A: Financial Review

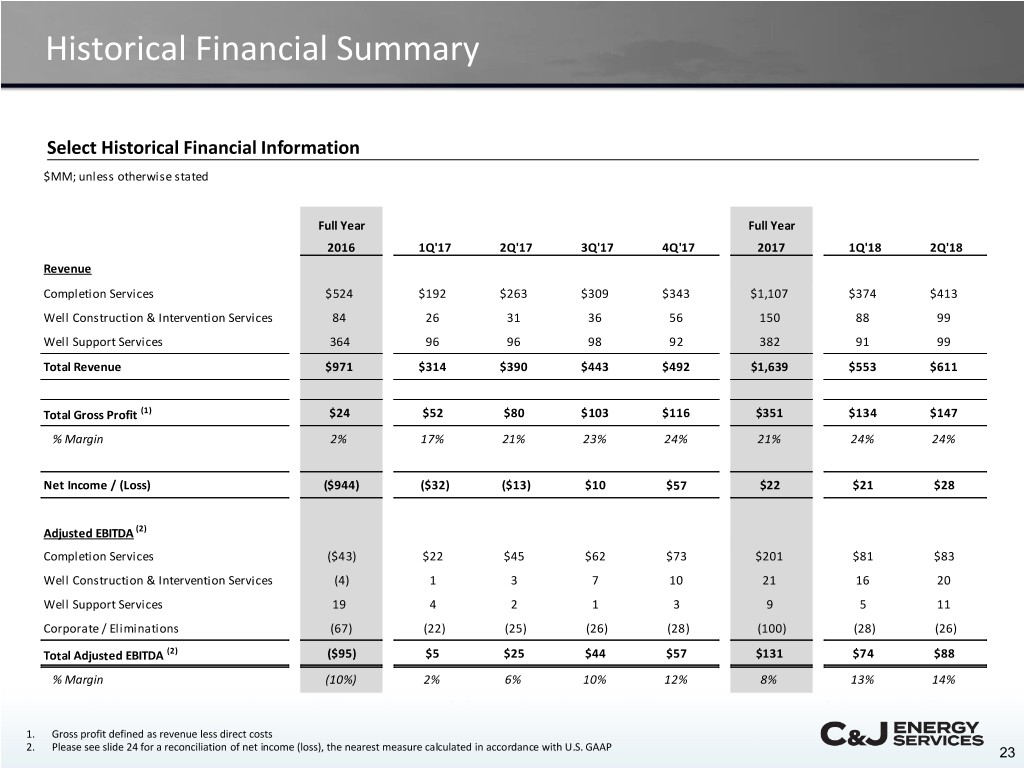

Historical Financial Summary Select Historical Financial Information $MM; unless otherwise stated Full Year Full Year 2016 1Q'17 2Q'17 3Q'17 4Q'17 2017 1Q'18 2Q'18 Revenue Completion Services $524 $192 $263 $309 $343 $1,107 $374 $413 Well Construction & Intervention Services 84 26 31 36 56 150 88 99 Well Support Services 364 96 96 98 92 382 91 99 Total Revenue $971 $314 $390 $443 $492 $1,639 $553 $611 Total Gross Profit (1) $24 $52 $80 $103 $116 $351 $134 $147 % Margin 2% 17% 21% 23% 24% 21% 24% 24% Net Income / (Loss) ($944) ($32) ($13) $10 $57 $22 $21 $28 Adjusted EBITDA (2) Completion Services ($43) $22 $45 $62 $73 $201 $81 $83 Well Construction & Intervention Services (4) 1 3 7 10 21 16 20 Well Support Services 19 4 2 1 3 9 5 11 Corporate / Eliminations (67) (22) (25) (26) (28) (100) (28) (26) Total Adjusted EBITDA (2) ($95) $5 $25 $44 $57 $131 $74 $88 % Margin (10%) 2% 6% 10% 12% 8% 13% 14% 1. Gross profit defined as revenue less direct costs 2. Please see slide 24 for a reconciliation of net income (loss), the nearest measure calculated in accordance with U.S. GAAP 23

Non-GAAP Reconciliation Adjusted EBITDA Reconciliation* $MM Full Year Full Year 2016 1Q'17 2Q'17 3Q'17 4Q'17 2017 1Q'18 2Q'18 Net income / (loss) ($944) ($32) ($13) $10 $57 $22 $21 $28 Interest expense, net 157 1 0 0 0 2 0 2 Income tax expense / (benefit) (129) (3) (2) (3) (31) (40) (0) (1) Depreciation and amortization 217 32 33 36 40 141 46 54 Other (income) / expense, net (10) (2) 1 (1) 1 (0) (1) 1 (Gain) / loss on disposal of assets 3 (6) (3) (1) (21) (31) (0) 0 Impairment expense 436 - - - - - - - Restructuring costs 31 - 8 2 2 11 1 2 Reorganization costs 55 - - - - - - - Inventory write-down 35 - - - - - - - Acquisition-related and other transaction costs 11 - - 1 3 4 1 0 Severance and business divestiture costs 34 - 1 - 5 7 6 0 Share-based compensation expense acceleration 8 15 - - - 15 - - Adjusted EBITDA ($95) $5 $25 $44 $57 $131 $74 $88 Note: *We present Adjusted EBITDA, because management believes that the disclosure of Adjusted EBITDA as a measure of the Company’s operating performance allows investors to make a direct comparison to competitors, without regard to differences in capital and financing structure and the incurrence of other charges that impact comparability of our results of operations to those of our competitors. Investors should be aware, however, that there are limitations inherent in using Adjusted EBITDA as a measure of overall profitability because it excludes significant expense items. An improving trend in Adjusted EBITDA may not be indicative of an improvement in the Company’s profitability. To compensate for the limitations in utilizing Adjusted EBITDA as an operating measure, management also uses U.S. GAAP measures of performance, including operating income (loss) and net income (loss), to evaluate performance. As required under Regulation G and Item 10(e) of Regulation S-K, the table above provides a reconciliation of Adjusted EBITDA, a non-GAAP financial measure, from net income (loss), which is the nearest comparable U.S. GAAP financial measure for the years ended December 31, 2017 and 2016 and for their interim periods. We generally define Adjusted EBITDA as net income (loss) before interest expense, income taxes, depreciation and amortization, other income (expense), gain or loss on the disposal of assets and other items that our management considers to be extraordinary, such as impairment expenses, acquisition-related costs, costs and charges associated with severance, facility closures, write-offs of bad debts and similar charges. Additionally, for the years ended December 31, 2017 and 2016 and for their interim periods, we have added back in calculating Adjusted EBITDA several categories of expenses and charges incurred in connection with our Chapter 11 proceedings which are detailed in the table above. 24