Attached files

| file | filename |

|---|---|

| EX-32.1 - CERTIFICATION PURSUANT TO SECTION 906 OF THE SARBANES-OXLEY ACT OF 2002 - TRANSCAT INC | transcat3266301-ex321.htm |

| EX-31.2 - CERTIFICATION OF CHIEF FINANCIAL OFFICER - TRANSCAT INC | transcat3266301-ex312.htm |

| EX-31.1 - CERTIFICATION OF CHIEF EXECUTIVE OFFICER - TRANSCAT INC | transcat3266301-ex311.htm |

| EX-23.1 - CONSENT OF FREED MAXICK CPAS, P.C. - TRANSCAT INC | transcat3266301-ex231.htm |

| EX-21.1 - SUBSIDIARIES - TRANSCAT INC | transcat3266301-ex211.htm |

UNITED

STATES

SECURITIES AND EXCHANGE

COMMISSION

Washington, D.C. 20549

______________

FORM 10-K

| (Mark one) | ||

| [✓] | ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 | |

|

For the fiscal year ended: March 25, 2017 | ||

|

or | ||

| [ ] | TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the transition period from ___________ to ___________

Commission File Number: 000-03905

TRANSCAT, INC.

(Exact name of registrant as

specified in its charter)

| Ohio | 16-0874418 | ||

| (State or other jurisdiction of | (I.R.S. Employer | ||

| incorporation or organization) | Identification No.) |

35 Vantage Point Drive,

Rochester, New York 14624

(Address of principal executive offices) (Zip Code)

(585) 352-7777

(Registrant’s telephone

number, including area code)

Securities registered pursuant to Section 12(b) of the Act:

| Title of each class | Name of each exchange on which registered |

| Common Stock, $0.50 par value | The NASDAQ Global Market |

Securities registered

pursuant to Section 12(g) of the Act:

None

Indicate by check mark if the

registrant is a well-known seasoned issuer, as defined in Rule 405 of the

Securities Act.

Yes [ ] No [✓]

Indicate by check mark if the

registrant is not required to file reports pursuant to Section 13 or Section

15(d) of the Act.

Yes [ ] No [✓]

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes [✓] No [ ]

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes [✓] No [ ]

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. [ ]

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, a smaller reporting company, or an emerging growth company. See the definitions of “large accelerated filer,” “accelerated filer,” “smaller reporting company” and “emerging growth company” in Rule 12b-2 of the Exchange Act.

| Large accelerated filer [ ] | Accelerated filer [ ] |

| Non-accelerated filer [ ] (Do not check if a smaller reporting company) | Smaller reporting company [✓] |

| Emerging growth company [ ] |

If an emerging growth company, indicate by check mark if the registrant has elected not to use the extended transition period for complying with any new or revised financial accounting standards provided pursuant to Section 13(a) of the Exchange Act. [ ]

Indicate by check mark whether

the registrant is a shell company (as defined in Rule 12b-2 of the

Act).

Yes [ ] No [✓]

The aggregate market value of the voting and non-voting common equity held by non-affiliates of the registrant on September 23, 2016 (the last business day of the registrant’s most recently completed second fiscal quarter) was approximately $68.8 million. The market value calculation was determined using the closing sale price of the registrant’s common stock on September 23, 2016, as reported on The NASDAQ Global Market.

The number of shares of common stock of the registrant outstanding as of June 14, 2017 was 7,108,620.

DOCUMENTS INCORPORATED BY REFERENCE

Portions of the registrant’s definitive proxy statement relating to the Annual Meeting of Shareholders to be held on September 13, 2017 have been incorporated by reference into Part III, Items 10, 11, 12, 13 and 14 of this report.

FORWARD-LOOKING STATEMENTS

This report contains “forward-looking statements” within the meaning of the Private Securities Litigation Reform Act of 1995. Forward-looking statements relate to expectations, estimates, beliefs, assumptions and predictions of future events and are identified by words such as “anticipates,” “believes,” “estimates,” “expects,” “projects,” “intends,” “could,” “may,” and other similar words. Forward-looking statements are not statements of historical fact and thus are subject to risks, uncertainties and other factors that could cause actual results to differ materially from historical results or those expressed in such forward-looking statements. You should evaluate forward-looking statements in light of important risk factors and uncertainties that may affect our operating and financial results and our ability to achieve our financial objectives. These factors include, but are not limited to, our reliance on one vendor to supply a significant amount of inventory purchases, the risks related to current and future indebtedness, the relatively low trading volume of our common stock, risks related to our acquisition strategy and the integration of the businesses we acquire, the impact of economic conditions, volatility in the oil and gas industry, the highly competitive nature of our two business segments, foreign currency rate fluctuations and cybersecurity risks. These risk factors and uncertainties are more fully described by us under the heading “Risk Factors” in Item IA. of Part I of this report. You should not place undue reliance on our forward-looking statements. Except as required by law, we undertake no obligation to update, correct or publicly announce any revisions to any of the forward-looking statements contained in this report, whether as a result of new information, future events or otherwise.

BUSINESS OVERVIEW

Transcat, Inc. (“Transcat”, the “Company”, “we” or “us”) is a leading provider of accredited calibration and laboratory instrument services and a value-added distributor of professional grade test, measurement and control instrumentation. We are focused on providing services and products to highly regulated industries, particularly the life science industry, which includes pharmaceutical, biotechnology, medical device and other FDA-regulated businesses. Additional industries served include industrial manufacturing; energy and utilities, including oil and gas and alternative energy; FAA-regulated businesses, including aerospace and defense; and other industries that require accuracy in their processes, confirmation of the capabilities of their equipment, and for which the risk of failure is very costly.

We conduct our business through two operating segments: service (“Service”) and distribution (“Distribution”). See Note 7 to our Consolidated Financial Statements in this report for financial information for these segments. We concentrate on attracting new customers in each segment, retaining existing customers in each segment and on cross-selling to customers to increase our total revenue. We serve approximately 20,000 and 22,000 customers through our Service and Distribution segments, respectively, with approximately 30% of those customers transacting with us through both of our business segments.

Through our Service segment, we offer calibration, repair, inspection, analytical qualifications, preventative maintenance, consulting and other related services, a majority of which are processed through our proprietary asset management system, CalTrak® (“CalTrak®”). Our Service model is flexible, and we cater to our customers’ needs by offering a variety of services and solutions including permanent and periodic on-site services, mobile calibration services, pickup and delivery and in-house services. As of our fiscal year ended March 25, 2017 (“fiscal year 2017”), we operated twenty-two calibration service centers (“Calibration Service Centers”) strategically located across the United States, Puerto Rico, and Canada. We also serve our customers on-site at their facility for daily, weekly or longer-term periods. In addition, we have several permanent customer-site locations where we provide calibration services, and in some cases other related services, exclusively for the customer where we reside and work every day. We also have a fleet of mobile calibration trailers that can provide service at customer sites which may not have the space or utility capabilities we require to service their equipment.

All of our Calibration Service Centers have obtained ISO/IEC 17025 scopes of accreditation. Our accreditations are the cornerstone of our quality program, which we believe is among the best in the industry. Our dedication to quality is highly valued by businesses that operate in the industries we serve, particularly those in life science and other FDA-regulated industries, and our accreditations provide our customers with confidence that they will receive a consistent and uniform service, regardless of which of our service centers completes the service.

Through our Distribution segment, we sell and rent national and proprietary brand instruments to customers globally. Through our website, in-house sales team and printed and digital marketing materials, we offer access to more than 100,000 test, measurement and control instruments, including products from approximately 540 leading manufacturers. Most instruments we sell and rent require calibration service to ensure that they maintain the most precise measurements. By having the capability to calibrate these instruments at the time of sale and at regular post-sale intervals, we can give customers a value-added service that most of our competitors are unable to provide. Calibrating before shipping means the customer can place their instruments into service immediately upon receipt, saving downtime. Other value-added options we offer through our Distribution segment include equipment kitting (which is especially valued in the alternative energy sector), equipment rentals and used equipment sales.

1

Our commitment to quality goes beyond the services and products we deliver. Our sales, customer service and support teams provide expert advice, application assistance and technical support to our customers. Since calibration is an intangible service, our customers rely on us to uphold high standards and provide integrity in our people and processes.

Our customers include leading manufacturers in the life science/pharmaceutical, energy, defense, aerospace and industrial process control sectors. We believe our customers do business with us because of our integrity and commitment to quality service, our broad range of product and service offerings and CalTrak®. In our fiscal year ended March 28, 2015 (“fiscal year 2015”) through fiscal year 2017, no customer or controlled group of customers accounted for 5% or more of our total revenue. The loss of any single customer would not have a material adverse effect on our business, cash flows, balance sheet, or results of operations.

Transcat was incorporated in Ohio in 1964. We are headquartered in Rochester, New York and employ more than 550 people, including approximately 150 in our corporate headquarters. Our executive offices are located at 35 Vantage Point Drive, Rochester, New York 14624. Our telephone number is 585-352-7777. Our website is www.transcat.com. We trade on The NASDAQ Global Market under the ticker symbol “TRNS”.

OUR STRATEGY

Our two operating segments are highly complementary in that their offerings are of value to customers within the same industries. Our strategy is to leverage the complementary nature of our operating segments in ways that add value for all customers who select Transcat as their source for test and measurement equipment and/or calibration and laboratory instrument services. We strive to differentiate ourselves within the markets we serve and build barriers to competitive entry by offering a broad range of products and services and by integrating our product and service offerings in a value-added manner to benefit our customers’ operations.

During fiscal year 2017, we made an important, strategic decision to commit capital and leadership investments to advance our “Operational Excellence” initiative. We expect this initiative to result in increased operational efficiency and further differentiation from our competitors as we invest in the information system and process improvements needed to improve our effectiveness and our customers’ experiences.

Within the Service segment, our strategy is to drive double-digit revenue growth both through organic expansion and acquisitions. We have adopted an integrated sales model to drive sales across the enterprise and capitalize on the cross-selling opportunities between our two segments, especially leveraging our Distribution relationships to develop new Service relationships. We leverage these relationships with our unique value proposition which resonates strongly with customers who rely on accredited calibration services and/or laboratory instrument services to maintain the integrity of their processes and/or meet the demands of regulated business environments. Our focused customer base values our superior quality programs and requires precise measurement capability in their processes to minimize risk, waste and defects. We execute this strategy by leveraging our quality programs, metrology expertise, multiple locations, qualified technicians, breadth of capabilities, and on-site and depot service options. All of which allows us to meet the most rigorous quality demands of our most highly regulated customers while simultaneously being nimble enough to meet their business needs.

We expect to continue to grow our Service business organically by taking market share from other third party providers and original equipment manufacturers (“OEMs”), as well as targeting the outsourcing of in-house calibration labs. We believe an important element in taking market share is our ability to expand into new technical capabilities that are in demand by our current and target customer base.

The other component to our Service growth strategy is acquisitions. There are three drivers of our acquisition strategy: infrastructure leverage, geographic expansion and increased capabilities. The majority of our acquisition opportunities are in the $500 thousand to $5 million annual revenue range, and we are disciplined in our approach to selecting target companies. A focus of our Operational Excellence initiative is to strengthen our acquisition integration process, allowing us to capitalize on acquired sales and cost synergies at a faster pace.

Our Distribution segment strategy is to be the premier distributor of leading handheld test and measurement equipment. Through our vendor relationships we have access to more than 100,000 products, which we market to our existing and prospective customers both with and without value-added service options that are unique to Transcat. In addition to offering pre-shipment value-added services, we offer our customers the options of renting selected test and measurement equipment or buying used equipment, furthering our ability to answer all of our customers’ test and measurement equipment needs. We continuously evaluate our offerings and add new in-demand vendors and products. In recent years we have expanded the number of SKU’s that we stock and the number of SKU’s that are sold with pre-shipment calibrations and have increased our focus on digital marketing to capitalize on the growing B2B ecommerce trend.

2

We see these various methods of meeting our Distribution customers’ needs as a way to differentiate ourselves and to diversify this segment’s customer base from its historically more narrow scope. This differentiation and diversification strategy has been deliberately instituted in recent years as a means to mitigate the effect of price-driven competition and to lessen the impact that any particular industry or market will have on the overall performance of this segment.

As part of our growth strategy, we completed a number of business acquisitions during our fiscal year ended March 26, 2016 (“fiscal year 2016”) and fiscal year 2017:

| ● |

On June 22, 2015, we acquired substantially all of the assets of Calibration Technologies, Inc. (“Calibration Technologies”), a regional provider of analytical instrument services including qualification, validation, repair and installation, headquartered in Morris Plains, New Jersey. |

| ● |

Effective August 24, 2015, we acquired Anmar Metrology, Inc. (“Anmar”), a calibration and repair service provider with significant focus on the life science and defense market, headquartered in San Diego, California. |

| ● |

On August 25, 2015, we acquired Nordcal Calibration Inc. (“Nordcal”), a provider of radio frequency and electronic calibration and repair services to the Canadian aerospace and defense market, located in Montreal, Quebec. |

| ● |

Effective December 31, 2015, we acquired substantially all of the assets of Spectrum Technologies, Inc. ("Spectrum"). Headquartered in Paxinos, Pennsylvania, Spectrum provides commercial calibrations, test equipment repair services and product sales throughout North America, primarily to companies in the life science and biomedical sectors. |

| ● |

Effective January 18, 2016, we acquired Dispersion Laboratory Inc. ("Dispersion"), headquartered near Montreal, Quebec. Dispersion provides fully accredited services for the calibration, repair and product sales of weights, balances, temperature instruments and liquid handling devices, primarily to the Canadian life science industry. |

| ● |

On April 1, 2016, we acquired substantially all of the assets of Excalibur Engineering, Inc. (“Excalibur”). Headquartered in Irvine, California, Excalibur is a provider of calibration services, new and used test equipment, and product rentals. |

Our acquisition strategy primarily targets service businesses that expand our geographic reach and leverage our infrastructure while also increasing the depth and/or breadth of our service capabilities and expertise. The table below illustrates the strategical drivers for each of the acquisitions executed during our fiscal year 2016 and fiscal year 2017:

| Geographic | Increased | Leveraged | |

| Expansion | Capabilities | Infrastructure | |

| Calibration | ✓ | ||

| Technologies | |||

| Anmar | ✓ | ||

| Nordcal | ✓ | ✓ | |

| Spectrum | ✓ | ✓ | |

| Dispersion | ✓ | ✓ | |

| Excalibur | ✓ | ✓ | ✓ |

3

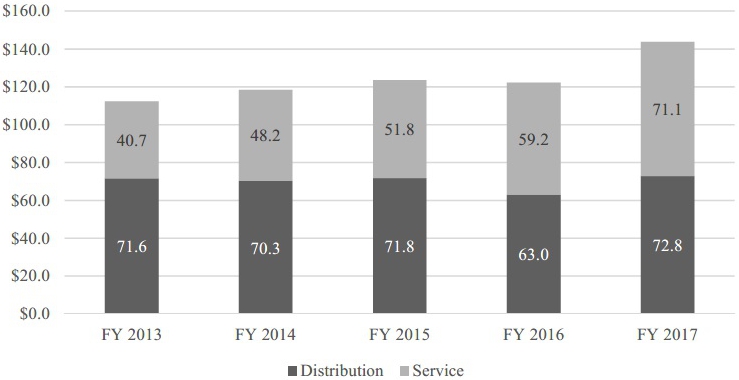

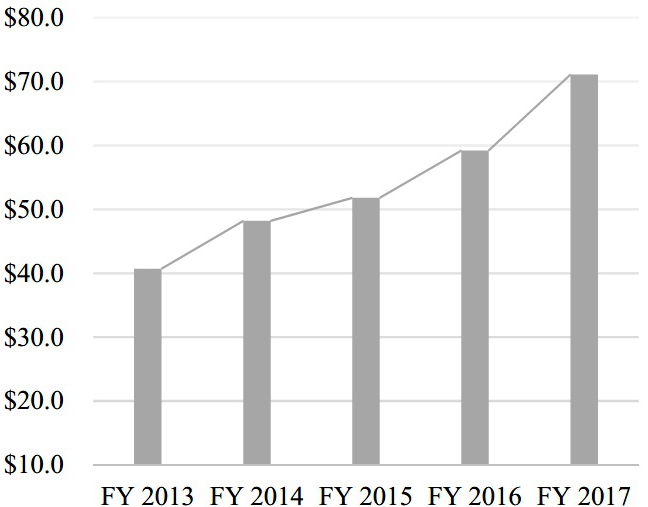

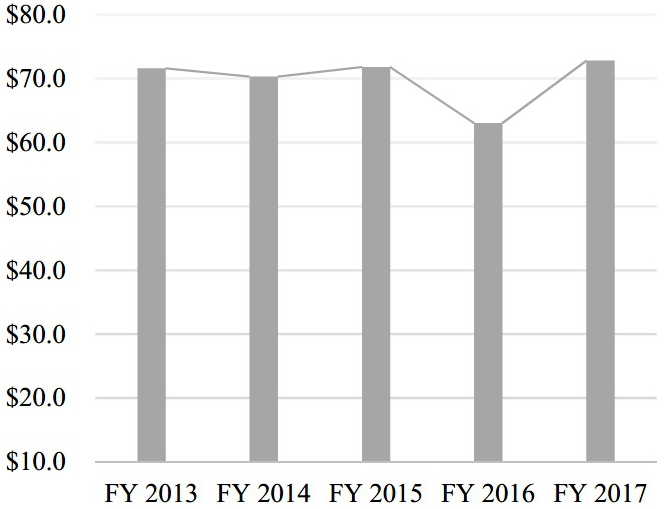

We believe our combined Service and Distribution segment offerings, experience, technical expertise and integrity create a unique and compelling value proposition for our customers, and we intend to continue to grow our business through organic revenue growth and business acquisitions. We consider the attributes of our Service segment which include higher gross margins and a recurring revenue streams to be more compelling and scalable than our legacy Distribution segment. For this reason, we expect our Service segment to be the primary source of revenue and earnings growth in future fiscal years. The charts below illustrate Service, Distribution and consolidated revenue over the past five years:

| Service Revenue Trend (in millions) | Distribution Revenue Trend (in millions) | |

|

| |

|

Consolidated Revenue (in millions) | ||

|

| ||

SEGMENTS

Service Segment

Calibration. Calibration is the act of comparing a unit or instrument of unknown value to a standard of known value and reporting the result in some specifically defined form. After the calibration has been completed, a decision is made, based on rigorously defined parameters, regarding what, if anything, should be done to the unit to conform to the required standards or specifications. The decision may be to adjust, optimize or repair a unit; limit the use, range or rating of a unit; scrap the unit; or leave the unit as is. The purpose of calibration is to significantly reduce the risk of product or process failures caused by inaccurate measurements. In addition to being an element of risk management, calibration improves an operation’s productivity and efficiency to optimal levels by assuring accurate, reliable instruments and processes.

4

The need for calibration is often driven by regulation, and we specifically target industries and companies that are regulated by the FDA, FAA or other regulatory bodies and, as a result, require quality calibration and laboratory instrument services as a critical component of their business operations. As a result of the various levels of regulation within our target industries, our customers’ calibration and laboratory instrument service sourcing decisions are generally made based on the provider’s quality systems, accreditation, reliability, trust, customer service and documentation of services. To maintain our competitive position in this segment, we maintain internationally recognized third-party accredited quality systems, further detailed in the section entitled “Quality” below, and provide our customers with access to proprietary asset management software solutions, which offer tools to manage their internal calibration programs and provide them with visibility to their service records.

Through our Service segment, we perform recurring periodic calibrations (typically ranging from three-month to twenty-four month intervals) on new and used instruments. We perform over 475,000 calibrations annually and can address a significant majority of the items requested to be calibrated with our in-house capabilities. For customers’ calibration needs in less common and highly specialized disciplines, we subcontract some calibrations to third-party vendors that have unique or proprietary capabilities. While typically representing approximately 15% of our Service segment revenue, we believe the management of these vendors is highly valued by our customers, and doing so has enabled us to continue our pursuit of having the broadest calibration offerings in these targeted markets.

Laboratory Instrument Services. Our laboratory instrument services (“LIS”) include analytical qualification, validation, remediation and preventative maintenance services. Our analytical qualification and validation services provide a comprehensive and highly specialized service offering focused on life science-related industries. Analytical qualifications and validation services include validations to specifically documented protocols that are commonly used in highly-regulated life science industries including installation qualification (“IQ”), operational qualification (“OQ”), and performance qualification (“PQ”). Most of the demand for our qualification, validation and preventative maintenance services comes from companies and institutions engaged in pharmaceutical manufacturing and research and development.

Our goal is to deliver specialized technical services with a quality assurance approach, which maximizes document accuracy and on-time job delivery. These industries demand knowledgeable contract services, and Transcat meets these demands with current good manufacturing practice (“cGMP”) and good laboratory practice (“GLP”) compliant services. Companies within these innovative and cutting-edge life science industries need a reliable alternative to the OEMs and the “generalist” service providers who cannot meet their industry-specific needs. We believe our value proposition to the life science industries is unique as a result of offering a comprehensive suite of both traditional calibration and laboratory instrument and other analytical services.

Analytical qualifications and preventative maintenance services are typically based on service agreements for periodic service, and tend to generate recurring revenue. Some validation services are based on certain customer processes. While some validation services may not be repeated, we generally develop relationships with these customers that lead to demand for additional unique validation services. Remediation services are based on specific regulatory actions and are generally project-based and required by a customer for a finite period of time. Remediation revenue is not recurring by its nature.

Other Services. We provide other services to our customers such as inspection, repair and consulting services, which appeal to customers across all sectors in our customer base. These are generally value-added services and allow us to provide “one-stop shopping” for our customers.

Service Value Proposition. Our calibration services strategy encompasses multiple ways to manage a customer’s calibration and laboratory instrument service needs:

| 1) | We offer an “Integrated Calibration Services Solution” that provides a complete wrap-around service, which can be delivered in the following ways: | ||

|

● |

permanent on-site services: Transcat establishes and manages a calibration service program within a customer’s facility; | ||

|

● |

periodic on-site services: Transcat technicians travel to a customer’s location and provide bench-top or in-line calibration or laboratory services on predetermined service cycles; | ||

|

● |

in-house services: services are performed at one of our twenty-two Calibration Service Centers (often accompanied by pick-up and delivery services); and | ||

|

● |

mobile calibration services: services are completed on a customer’s property within our mobile calibration unit. | ||

| 2) | For companies that maintain an internal calibration operation, we can provide: | ||

|

● |

calibration of primary standards; and | ||

|

● |

overflow capability, either on-site or at one of our Calibration Service Centers, during periods of high demand. | ||

Inclusive with all these services, we provide total program management including logistical, remediation and consultation services when needed.

5

We strive to provide the broadest accredited calibration offering to our targeted markets, which includes certification of our technicians pursuant to the American Society for Quality standards, complete calibration management encompassing the entire metrology function, and access to our complementary service and product offerings. We believe our calibration services are of the highest technical and quality levels, with broad ranges of accreditation.

Our LIS strategy is to identify and establish long-term relationships with life science research and development and manufacturing customers who require analytical qualifications, validation, remediation and/or preventative maintenance services. In most cases, these customers are life science companies, including pharmaceutical and biotechnology companies engaged in research and development and manufacturing, which are subject to extensive government regulation. The services we provide to these regulated customers are typically a critical component of the customer’s overall compliance program. Because many laboratory instrument service customers operate in regulated industries, these same customers typically also require accredited calibration services. This requirement allows a natural synergy between our laboratory instrument and calibration services. Our strategy includes cross-selling our services within our customer accounts to maximize our revenue opportunities with each customer.

Proprietary Asset Management Software. CalTrak® is our proprietary documentation and asset management software which is used to integrate and manage both the workflow of our Calibration Service Centers and our customers’ assets. With CalTrak®, we are able to provide our customers with timely and consistent calibration service while optimizing our own efficiencies. CalTrak® has been validated to U.S. federal regulations 21 CFR Part 820.75 and 21 CFR Part 11, as applicable. This validation is important to pharmaceutical and other FDA-regulated industries where federal regulations can be particularly stringent.

Additionally, CalTrak® Online provides our customers with web-based asset management capability and a safe and secure off-site archive of calibration and other service records that can be accessed 24 hours a day through our secure password-protected website.

Our newly developed cloud-based customer portal and asset management tool (“C3®”) is scheduled to replace CalTrak® Online in our fiscal year 2018. C3® stands for Compliance, Control and Cost, and at Transcat we see these as the major areas of focus for our clients within the regulatory environment as it relates to instrument calibration. We specifically designed C3® to assist our customers in increasing efficiency, driving compliance to quality systems and enhancing control of instrumentation, all while bringing their overall metrology costs down. Understanding the regulated environments that our clients operate within, we customized the platform to allow for single system of record utilization via capabilities that allow clients to track and manage instruments maintained internally in addition to instruments supported by Transcat. C3® is validated to 21 CFR Part 820.75 and 21 CFR Part 11 to meet stringent FDA requirements.

Through CalTrak® and CalTrak® Online and C3®, each customer calibration is tracked and automatically cross-referenced to the assets used to perform the calibration, providing traceability.

Service Marketing and Sales. Under our integrated sales model, we have both inside and outside sales teams that seek to acquire new customers in our targeted markets by leveraging our unique value proposition, including our broad geographic footprint and comprehensive suite of services. We target regulated, enterprise customers with multiple manufacturing operations throughout North America. We leverage our ability to manage the complete life cycle of instrumentation from purchase of calibrated equipment to long-term service and maintenance requirements. Connecting all the dots by using new and used product sales, rentals, and repair and calibration services is the goal of our marketing and sales initiatives. We also have a team of account managers focused on servicing the needs of our existing customers. We utilize print media, trade shows and web-based initiatives to market our services to customers and prospective customers with a strategic focus in the highly regulated industries including life science and other FDA-regulated industries, aerospace and defense, energy and utilities, and chemical manufacturing. We also target industrial manufacturing and other industries that appreciate the value of quality calibrations.

6

The approximate percentage of our Service revenue by industry type for the periods indicated are as follows:

| FY 2017 | FY 2016 | FY 2015 | ||||

| Life Science/FDA-regulated | 43% | 39% | 32% | |||

| Industrial Manufacturing | 21% | 24% | 29% | |||

| Energy/Utilities | 7% | 7% | 8% | |||

| Chemical Manufacturing | 6% | 6% | 7% | |||

| Other | 23% | 24% | 24% | |||

| Total | 100% | 100% | 100% |

Service Competition. The calibration services industry is highly fragmented and is composed of companies ranging from internationally recognized and accredited OEM’s, to non-accredited sole proprietors as well as companies that perform their own calibrations in-house, resulting in a tremendous range of service levels and capabilities. A large percentage of calibration companies are small businesses that generally do not have a range of capabilities as broad as ours. There are also several companies with whom we compete that have national or regional operations.

We differentiate ourselves from our competitors by demonstrating our commitment to quality, having a wide range of capabilities that are tailored to the markets we serve, having a geographical footprint that spans North America and by providing a comprehensive suite of services that spans many manufacturers and is not limited to certain product lines or brands. Our unique ability to bundle our products with our LIS and calibration services also provides a high level of differentiation from our competitors. As one of the only North American LIS and calibration service providers who also distributes product, our customers can seamlessly replace instruments that cannot be calibrated or are otherwise deemed to be at end of life. Our close knowledge of the products we distribute also allows our service staff to consult and advise customers on what products are best suited for their in-house calibration needs. We also believe that our proprietary software is a key differentiator from our competitors. CalTrak Online® and C3® are utilized by our customers in an integrated manner, providing a competitive barrier as customers realize synergies and efficiencies as a result of this integration.

In fiscal year 2017, we further expanded our range of capabilities by making significant capital and human resource investments in reference-level radio frequency/microwave calibration capabilities that have allowed us to further expand our offerings and compete for additional market share in FAA-regulated sectors, including aerospace and defense industries, and in the medical device and telecommunication industries.

Competition for laboratory instrument services is composed of both small local and regional service providers and large multinational OEMs. We believe we are generally financially stronger, service a larger customer base and are typically able to offer a larger suite of services than many of the small local and regional competitors. The large OEMs may offer specialized services and brand-specific expertise which we do not offer, but they are generally focused on providing specialized services only for their proprietary brands and product lines, rather than servicing an array of brands and product lines as we do. We believe our competitive advantages in the laboratory instrument services market are our financial and technical resources, turnaround time, and flexibility to react quickly to customers’ needs. The breadth of our suite of laboratory instrument service, combined with our calibration service offerings, also differentiates us from our competitors by allowing us to be our customers’ one-source accredited services provider for their entire calibration and compliance programs.

Service Quality. The accreditation process is the only system currently in existence that validates measurement competence. To ensure that the quality and consistency of our calibrations are consistent with the global metrology network, designed to standardize measurements worldwide, we have sought and achieved international levels of quality and accreditation to provide uniformity across all locations with advanced levels of training for our technical staff. Our Calibration Service Centers are accredited to ISO/IEC 17025:2005 by National Voluntary Laboratory Accreditation Program (“NVLAP”) and other accrediting bodies. These accrediting bodies are signatories to the International Laboratory Accreditation Cooperation (“ILAC”), are proficient in the technical aspects of the chemistry and physics that underlie metrology, and provide an objective, third-party, internationally accepted evaluation of the quality, consistency, and competency of our calibration processes. Accreditation also requires that all measurement standards used for accredited measurements have a fully documented path, known as Metrological Traceability, through the National Institute of Standards and Technology or the National Research Council (the National Measurement Institutes for the United States and Canada, respectively), or to other national or international standards bodies, or to measurable conditions created in our Calibration Service Center, or accepted fundamental and/or natural physical constants, ratio type of calibration, or by comparison to consensus standards, all inclusive of measurement uncertainties.

7

The importance of this international oversight to our customers is the assurance that our service documentation will be accepted worldwide, removing one of the barriers to trade that they may experience if using a non-ILAC traceable calibration service provider. To provide the widest range of services to our customers in our target markets, our ISO/IEC 17025:2005 accreditations extend across many technical disciplines, including working-level and reference-level capabilities. We believe our scope of accreditation to ISO/IEC 17025:2005 to be the broadest for the industries we serve.

Acquired calibration labs might use other quality registration systems. We continually evaluate when to integrate acquired quality systems with the focus on minimizing business disruptions and disruptions to our customers.

Our scopes of accreditation can be found at http://www.transcat.com/calibration-services/accreditation/calibration-lab-certificates.

Distribution Segment

Distribution Summary. We distribute professional grade test, measurement and control instrumentation throughout North America and internationally. Our customers use test and measurement instruments to ensure that their processes, and ultimately their end products, are within specification. Utilization of such diagnostic instrumentation also allows for continuous improvement processes to be in place, increasing the accuracies of their measurements. The industrial test and measurement instrumentation market, in those geographic areas where we predominately operate, has historically been serviced by broad-based national equipment distributors and niche or specialty-focused organizations such as Transcat. We offer value-added services such as calibration/certification of equipment purchases, equipment rentals, used equipment for sale, and equipment kitting. In recent years, online-based distributors have become more prevalent. To more effectively compete with these online-based distributors, we have continued to make improvements to our digital platform, including enhanced e-commerce capabilities.

We believe that a customer chooses a distributor based on a number of different criteria, including product availability, price, ease of doing business, timely delivery and accuracy of orders, consistent product quality, technical competence of the representative serving them and availability of value-added services. The decision to buy is generally made by plant engineers, quality managers, or their purchasing personnel, and products are typically obtained from one or more distributors as replacements, upgrades, or for expansion of manufacturing and research and development facilities. As a result, sales to Distribution customers are somewhat unpredictable and potentially non-recurring. Our on-line presence, including our website and e-newsletters; Master Catalog; supplemental mailings and other sales and marketing activities are designed to create demand and maintain a constant presence in front of our customers to ensure we receive the order when they are ready to purchase.

We provide our customers with value-added services including technical support, to ensure our customers receive the right product for their application, and more comprehensive instrument suitability studies to customers in regulated industries who are concerned about the technical uncertainties that their testing or in-process instruments may bring to a process. We consider our biggest value-added service for our Distribution customers is the option to have calibration service performed on their new product purchases prior to shipment, allowing them to place newly acquired equipment directly into service upon receipt, saving downtime. We also offer online procurement, credit card payment options, same day shipment of in-stock items, kitted products, the option to rent, training programs and a variety of custom product offerings. Items are regularly added to and deleted from our product offerings on the basis of customer demand, recommendations of suppliers, sales volumes and other factors. Because of the breadth of our product and service offerings, we are often a “one-stop shop” for our customers who gain operational efficiency by dealing with just one distributor for most or all of their test and measurement instrumentation needs.

In fiscal year 2017, our Distribution segment rebounded from a decline in sales in fiscal year 2016. We attributed the fiscal year 2016 sales decline to continued competitive pressures as well as the recessionary conditions experienced in U.S. industrial output in general and in the oil and gas industry in particular. To mitigate the impact of competition and recessionary market conditions, we expanded the number of new equipment items on which we offer pre-shipment calibration, grew our organic rental business and through the acquisition of Excalibur, forayed into the used equipment sales market and rental market for higher-end electronics. We will continue to use these and other efforts to bolster sales in the Distribution segment in an effort to stabilize the recent unpredictability and uncertainty of the Distribution segment.

Distribution Marketing and Sales. We market, create demand and sell to our customers through multiple direct sales channels including our website, digital and print advertising, proactive outbound sales and an inbound call center. Our outbound and inbound sales teams are staffed with technically trained personnel who are available to help guide product selection. Our website serves as a sales channel for our products and services, and provides search capability, detailed product information, in-stock availability, selection guides, demo videos and downloadable product specification sheets. We have made investments in our website to implement the latest marketing technologies which allow us to provide an intuitive customer experience, with simple product comparison and quoting, ease at checkout and automated post-order follow-up. We also operate and maintain several industry-specific service websites, obtained through recent business acquisitions.

8

We use a multichannel approach to reach our customers and prospective customers including our Master Catalog, periodic supplemental catalogs, website, e-newsletters, and other direct sales and marketing programs. Our digital marketing strategy includes ongoing investment in search engine optimization, application-specific digital content, pay-per-click search engine advertising, and product listings on online marketplaces such as Amazon and Google Shopping. We continue to invest in back-end technologies designed to provide a seamless customer experience across all our marketing channels. During fiscal year 2017, we proactively communicated with our customers and prospective customers through direct mail catalogs, email newsletters, vertical email drip campaigns, retargeting ads, educational webinars, and outbound sales calls. Some of the key factors that determine the marketing materials a customer may receive include relevancy of new product introductions, current promotions, purchase history, the customer’s market segment, and the contact’s job function.

As a result of strong relationships with our product vendors and our historical performance of effectively marketing, we have the opportunity to carry out co-branded marketing initiatives, aimed at our existing customers and our prospective customer base, for which we receive cooperative advertising support. These co-branded marketing initiatives typically feature specific vendors, new products or targeted product categories and take the form of direct mailers, web-based initiatives or outbound sales efforts.

In fiscal year 2017, the acquisition of Excalibur brought us a network of experienced independent sales representatives who are currently focused on selling new and used equipment and equipment rentals, but who also have the ability to sell our comprehensive suite of calibration services.

Distribution Competition. The distribution market for industrial test and measurement instrumentation is fragmented and highly competitive. Our competitors range from large national distributors and manufacturers that sell directly to customers to small local distributors, and in recent years, online distributors. Key competitive factors typically include customer service and support, quality, lead time, inventory availability, brand recognition and price. To address our customers’ needs for technical support and product application assistance, we employ a staff of highly trained technical sales specialists. In order to maintain this competitive advantage, technical training is an integral part of developing our sales staff. To differentiate ourselves from competitors, we offer pre-shipment calibration or performance data reports which allow customers to receive our products and immediately place them into service, saving them downtime and money.

In recent years, online distributors, including Amazon for lower price-point products, have become prominent competitors for sales of handheld test and measurement equipment, competing primarily on price. While online competitors lack the value-added services we offer in our Distribution segment, they have been successful in capturing some market share in the worldwide market for test and measurement instruments. To stay ahead of growing competition from these online distributors and the general trend of increased use of e-commerce, we have invested in our digital platform including a well-indexed website with improved design and functionality. In addition, we have diversified our offerings by expanding the brands and product lines that we offer and adding higher gross margin equipment rentals and used equipment sales, which we believe makes Transcat unique among our competitors.

Distribution Suppliers and Purchasing. We believe that effective purchasing is a key element to maintaining and enhancing our position as a provider of high quality test and measurement instruments. We frequently evaluate our purchase requirements and suppliers’ offerings to obtain products at the best possible cost. We obtain our products from over 430 suppliers of brand name and private-labeled equipment. In fiscal year 2017, our top 10 vendors accounted for approximately 59% of our aggregate Distribution business. Approximately one-quarter of our product purchases on an annual basis are from Fluke Electronics Corporation (“Fluke”), which we believe to be consistent with Fluke’s share of the markets we serve.

We plan our product mix and inventory stock to best serve the anticipated needs of our customers, whose individual purchases vary in size. We can usually ship our top selling products to our customers the same day they are ordered.

Distribution Vendor Rebates. We have agreements with certain product vendors that provide for rebates based on meeting a specified cumulative level of purchases and/or incremental distribution sales. These rebates are recorded as a reduction of cost of distribution sales. Purchase rebates are calculated and recorded quarterly based upon our volume of purchases with specific vendors during the quarter. Point of sale rebate programs that are based on year-over-year sales performance on a calendar year basis are recorded as earned, on a quarterly basis, based upon the estimated level of annual achievement. Point of sale rebate programs that are based on year-over-year sales performance on a quarterly basis are recorded as earned in the respective quarter.

Distribution Operations. Our Distribution operations primarily take place at our 37,250 square-foot facility in Rochester, New York and a 12,600 square-foot facility in Portland, Oregon. The Rochester location also serves as our corporate headquarters, houses our customer service, sales and administrative functions, and is a Calibration Service Center. The Portland location also is a Calibration Service Center. In fiscal year 2017, we shipped approximately 33,000 product orders, in the aggregate, from both locations. We also have two smaller warehouse facilities in Wisconsin that fulfill orders for certain large industrial scales and a location in Irvine, California, added in fiscal year 2017 with the Excalibur acquisition, that stocks used equipment and rental equipment and fulfills those orders.

9

Distribution Backlog. Distribution orders include orders for instruments that we routinely stock in our inventory, customized products, and other products ordered less frequently, which we do not stock. Pending product shipments are primarily backorders, but also include products that are requested to be calibrated in one of our Calibration Service Centers prior to shipment, orders required by the customer to be shipped complete or at a future date, and other orders awaiting final credit or management review prior to shipment. Our total backlog was $3.6 million and $3.0 million as of March 25, 2017 and March 26, 2016, respectively.

CUSTOMER SERVICE AND SUPPORT

Key elements of our customer service approach are our field business development sales team, outbound sales team, account management team, inbound sales and customer service organization. To ensure the quality of service provided, we frequently monitor our customer service through customer surveys, call monitoring and daily statistical reports.

|

Customers may place orders via: | |

| ● |

Mail to Transcat, Inc., 35 Vantage Point Drive, Rochester, NY 14624; |

| ● |

Fax at 1-800-395-0543; |

| ● |

Telephone at 1-800-828-1470; |

| ● |

Email at sales@transcat.com; or |

| ● |

Online at transcat.com. |

INFORMATION REGARDING EXPORT SALES

In fiscal years 2015 through 2017, approximately 10% of our total revenue resulted from sales to customers outside the United States. Of those export sales in fiscal year 2017, approximately 14% were denominated in U.S. dollars and the remaining 86% were in Canadian dollars. Our revenue is subject to the customary risks of operating in an international environment, including the potential imposition of trade or foreign exchange restrictions, tariff and other tax increases, fluctuations in exchange rates and unstable political situations, any one or more of which could have a material adverse effect on our business, cash flows, balance sheet or results of operations. See “Foreign Currency” in Item 7A. of Part II and Note 7 to our Consolidated Financial Statements in this report for further details.

INFORMATION SYSTEMS

We utilize a turnkey enterprise software solution from Infor, Inc. (“Infor”) called Application Plus to manage our business and operations segments. This software includes a suite of fully integrated modules to manage our business functions, including customer service, warehouse management, inventory management, financial management, customer relations management and business intelligence. This solution is a fully mature business package and has been subject to more than 20 years of refinement. We utilize customer relationship management (“CRM”) software offered by SalesForce.com, Inc., which is strategically partnered with Infor, allowing us to fully integrate the CRM software with our Infor enterprise software.

We also utilize CalTrak®, our proprietary document and asset management system, to manage documentation, workflow and customers’ assets within and amongst most of our Calibration Service Centers. In addition to functioning as an internal documentation, workflow, and asset management system, CalTrak®, through CalTrak® Online and C3®, provides customers with web-based calibration cycle management service and access to documentation relating to services completed by Transcat. Certain recent acquisitions utilize either third-party or their own proprietary calibration management systems. We continually evaluate when to integrate these acquired systems with a focus on obtaining operational synergies while imposing minimal disruption to customers.

INTELLECTUAL PROPERTY

We have federally registered trademarks for Transcat®, CalTrak® and C3®, which we consider to be of material importance to our business. The registrations for these trademarks encompass multiple classes, and the registrations are in good standing with the U.S. Patent & Trademark Office. Our CalTrak® trademark is also registered in Canada for one class with the Canada Intellectual Property Office. Our trademark registrations must be renewed at various times, and we intend to renew our trademarks, as necessary, for the foreseeable future.

We have filed an application with the U.S. Patent & Trademark Office to trademark in one class the brand name “Procision” in the United States. The U.S. Patent & Trademark Office is currently examining the application.

10

In addition, we own www.transcat.com and www.transcat.ca. As with phone numbers, we do not have and cannot acquire any property rights to an Internet address. The regulation of domain names in the United States and in other countries is also subject to change. Regulatory bodies could establish additional top-level domains, appoint additional domain name registrars or modify the requirements for holding domain names. As a result, we might not be able to maintain our domain names or obtain comparable domain names, which could harm our business.

SEASONALITY

Our business has certain historical seasonal factors. Historically, our fiscal third and fourth quarters have been stronger than our fiscal first and second quarters due to the operating cycles of our industrial sector customers.

ENVIRONMENTAL MATTERS

We believe that we are in compliance with federal, state, and local provisions relating to the protection of the environment, and that continued compliance will not have any material effect on our capital expenditures, earnings, or competitive position.

EMPLOYEES

At the end of fiscal year 2017, we had 585 employees, including 27 part-time employees, compared with 537 employees, including 11 part-time employees, at the end of fiscal year 2016.

MANAGEMENT TEAM

The following table presents certain information regarding our management team, including our executive officers and certain key employees as of March 25, 2017:

| Name | Age | Position | ||

| Lee D. Rudow | 52 | President and Chief Executive Officer | ||

| Michael J. Tschiderer | 57 | Vice President of Finance and Chief Financial Officer | ||

| Robert A. Flack | 47 | Vice President of Service Sales and Operations | ||

| Jennifer J. Nelson | 46 | Vice President of Human Resources | ||

| Michael W. West | 46 | Vice President of Inside Sales and Marketing | ||

| Benjamin P. Hawley | 60 | Vice President of Operational Excellence | ||

| Scott D. Deverell | 51 | Corporate Controller and Principal Accounting Officer |

AVAILABLE INFORMATION

We are subject to the informational requirements of the Securities Exchange Act of 1934, as amended, and, therefore, we file periodic reports, proxy statements and other information with the United States Securities and Exchange Commission (“SEC”). Such reports may be read and copied at the Public Reference Room of the SEC at 100 F Street NE, Washington, D.C. 20549. Information on the operation of the Public Reference Room may be obtained by calling the SEC at (800) SEC-0330. Additionally, the SEC maintains a website (sec.gov) that contains reports, proxy statements and other information for registrants that file electronically.

We maintain a website at transcat.com. We make available, free of charge, in the Investor Relations section of our website, documents we file with or furnish to the SEC, including our Annual Reports on Form 10-K, Quarterly Reports on Form 10-Q, Current Reports on Form 8-K and any amendments to those reports. We make this information available as soon as reasonably practicable after we electronically file such materials with, or furnish such information to, the SEC. The other information found on our website is not part of this or any other report we file with, or furnish to, the SEC.

We also post on our website our board of directors’ committee charters (audit committee, compensation committee and corporate governance and nominating committee) and Code of Ethics. Copies of such documents are available in print at no charge to any shareholder who makes a request. Such requests should be made to our corporate secretary at our corporate headquarters, 35 Vantage Point Drive, Rochester, New York 14624.

11

You should consider carefully the following risks and all other information included in this report. The risks and uncertainties described below and elsewhere in this report are not the only ones facing our business. If any of the following risks were to actually occur, our business, financial condition or results of operations would likely suffer. In that case, the trading price of our common stock could fall and you could lose all or part of your investment.

We depend on manufacturers to supply inventory to our Distribution segment and rely on one vendor to supply a significant amount of our inventory purchases. If our vendor fails to provide desired products to us, increases prices, or fails to timely deliver products, our revenue and gross profit could suffer. A significant amount of our inventory purchases are made from one vendor, Fluke. Our reliance on this vendor leaves us vulnerable to having an inadequate supply of required products, price increases, late deliveries, and poor product quality. Like other distributors in our industry, we occasionally experience supplier shortages and are unable to purchase our desired volume of products. If we are unable to enter into and maintain satisfactory distribution arrangements with leading manufacturers, if we are unable to maintain an adequate supply of products, or if manufacturers do not regularly invest in, introduce to us, and/or make new products available to us for distribution, our Distribution segment sales could suffer considerably. Finally, we cannot provide any assurance that particular products, or product lines, will be available to us, or available in quantities sufficient to meet customer demand. This is of particular significance to our Distribution segment business because the products we sell are often only available from one source. Any limits to product access could materially and adversely affect our Distribution segment business.

Volatility in the oil and gas industry has had and could continue to have a negative impact on our operating results. A portion of our products and services customer base is directly or indirectly related to the oil and gas industry. As a result, demand for some of our products is dependent on the level of expenditures by the oil and gas industry. In addition to the more significant impact on our Distribution segment, an extended downturn in the oil and gas industry or continued volatility in oil and gas prices could impact customers’ demand for some of our services (generally excluding life sciences, our largest industry customer sector), which could have a material adverse effect on our financial condition, results of operations and cash flows.

Our future success may be affected by our current and future indebtedness. Under our credit agreement, as of March 25, 2017, we owed $27.3 million to our secured creditor, a commercial bank, including $8.7 million we borrowed on April 1, 2016 via a $10.0 million term loan to fund an acquisition and provide us additional working capital. We may borrow additional funds in the future to support our growth and working capital needs. We are required to meet financial tests on a quarterly basis and comply with other covenants customary in secured financings. Although we believe that we will continue to comply with such covenants, if we do not remain in compliance with such covenants, our lender may demand immediate repayment of amounts outstanding. Changes in interest rates may have a significant effect on our payment obligations and operating results. Furthermore, we are dependent on credit from manufacturers of our products to fund our inventory purchases. If our debt burden increases to high levels, such manufacturers may restrict our credit. Our cash requirements will depend on numerous factors, including the rate of growth of our revenues, the timing and levels of products purchased, payment terms, and credit limits from manufacturers, the timing and level of our accounts receivable collections and our ability to manage our business profitably. Our ability to satisfy our existing obligations, whether or not under our secured credit facility, will depend upon our future operating performance, which may be impacted by prevailing economic conditions and financial, business, and other factors described in this report, many of which are beyond our control.

The relatively low trading volume of our common stock may limit your ability to sell your shares. Although our shares of common stock are listed on The NASDAQ Global Market, we have historically experienced a relatively low trading volume of less than 10,000 shares a day. If our low trading volume continues in the future, holders of our shares may have difficulty selling shares of our common stock in the manner or at a price that they desire.

If significant existing shareholders sell large numbers of shares of our common stock, our stock price could decline. The market price of our common stock could decline if a large number of our shares are sold in the public market by our existing shareholders or holders of stock options or as a result of the perception that these sales could occur. Due to the relatively low trading volume of our common stock, the sale of a large number of shares of our common stock may significantly depress the price of our common stock.

We expect that our quarterly results of operations will fluctuate. Such fluctuation could cause our stock price to decline. A large portion of our expenses for our Service segment, including expenses for facilities, equipment and personnel are relatively fixed. Accordingly, if revenues decline or do not grow as we anticipate, we may not be able to correspondingly reduce our operating expenses in any particular quarter. Our quarterly revenues and operating results have fluctuated in the past and are likely to do so in the future. Historically, our fiscal third and fourth quarters have been stronger than our fiscal first and second quarters due to industrial operating cycles. Fluctuations in industrial demand for products we sell and services we provide could cause our revenues and operating results to fluctuate. If our operating results in some quarters fail to meet the expectations of stock market analysts and investors, our stock price may decline.

12

|

Our stock price may be volatile. The stock market, from time to time, has experienced significant price and volume fluctuations that are both related and unrelated to the operating performance of companies. Our stock may be affected by market volatility and by our own performance. The following factors, among others, may have a significant effect on the market price of our common stock: | |

| ● |

Developments in our relationships with current or future manufacturers of products we distribute; |

| ● |

Announcements by us or our competitors of significant acquisitions, strategic partnerships, joint ventures or capital commitments; |

| ● |

Litigation or governmental proceedings or announcements involving us or our industry; |

| ● |

Economic and other external factors, such as disasters or other crises; |

| ● |

Sales of our common stock or other securities in the open market; |

| ● |

Repurchases of our common stock on the open market or in privately-negotiated transactions; |

| ● |

Period-to-period fluctuations in our operating results; and |

| ● |

Our ability to satisfy our debt obligations. |

Our business acquisitions or future business acquisition efforts, which are important to our growth, may not be successful, which may limit our growth or adversely affect our results of operations and financial condition. Business acquisitions have been an important part of our growth to date. As part of our business strategy, we may make additional acquisitions of companies that could complement or expand our business, augment our market coverage, provide us with important relationships or otherwise offer us growth opportunities. If we identify an appropriate acquisition candidate, we may not be able to successfully negotiate terms or finance the acquisition. If we fail to successfully acquire businesses, our growth and results of operations could be adversely affected.

|

We may not successfully integrate business acquisitions. We completed a total of six business acquisitions during fiscal years 2016 and 2017. If we fail to accurately assess and successfully integrate any recent or future business acquisitions, we may not achieve the anticipated benefits, which could result in lower revenues, unanticipated operating expenses, reduced profitability and dilution of our book value per share. Successful integration involves many challenges, including: | |

| ● |

The difficulty of integrating acquired operations and personnel with our existing operations; |

| ● |

The difficulty of developing and marketing new products and services; |

| ● |

The diversion of our management’s attention as a result of evaluating, negotiating and integrating acquisitions; |

| ● |

Our exposure to unforeseen liabilities of acquired companies; and |

| ● |

The loss of key employees of an acquired operation. |

|

In addition, an acquisition could adversely impact cash flows and/or operating results, and dilute shareholder interests, for many reasons, including: | |

| ● |

Charges to our income to reflect the impairment of acquired intangible assets, including goodwill; |

| ● |

Interest costs and debt service requirements for any debt incurred in connection with an acquisition or new business venture; and |

| ● |

Any issuance of securities in connection with an acquisition or new business venture that dilutes or lessens the rights of our current shareholders. |

If the integration of any or all of our acquisitions or future acquisitions is not successful, it could have a material adverse impact on our operating results and stock price.

Any impairment of goodwill or other intangible assets could negatively impact our results of operations. Our goodwill and other intangible assets are subject to an impairment test on an annual basis and are also tested whenever events and circumstances indicate that goodwill and/or intangible assets may be impaired. Any excess goodwill and/or indefinite-lived intangible assets value resulting from the impairment test must be written off in the period of determination. Intangible assets (other than goodwill and indefinite-lived intangible assets) are generally amortized over the useful life of such assets. In addition, from time to time, we may acquire or make an investment in a business that will require us to record goodwill based on the purchase price and the value of the acquired tangible and intangible assets. We may subsequently experience unforeseen issues with the businesses we acquire, which may adversely affect the anticipated returns of the business or value of the intangible assets and trigger an evaluation of the recoverability of the recorded goodwill and intangible assets for such business. Future determinations of significant write-offs of goodwill or intangible assets because of an impairment test or any accelerated amortization of other intangible assets could have a material negative impact on our results of operations and financial condition. We have completed our annual impairment analysis for goodwill and indefinite-lived intangible assets, in accordance with the applicable accounting guidance, and have concluded that we do not have any impairment of goodwill or other intangible assets as of March 25, 2017.

13

The financing of any future acquisitions we might make may result in dilution to your stock ownership and/or could increase our leverage and our risk of defaulting on our bank debt. Our business strategy includes expansion into new markets and enhancement of our position in existing markets, including through acquisitions. In order to successfully complete targeted acquisitions, we may issue additional equity securities that could dilute your stock ownership. We may also incur additional debt if we acquire another company, which could increase our leverage and our risk of default under our existing credit facility.

Adverse changes in general economic conditions or uncertainty about future economic conditions could adversely affect us. We are subject to the risks arising from adverse changes in general economic market conditions. Uncertainty about future economic conditions could negatively affect our current and prospective customers causing them to delay the purchase of necessary services or test and measurement instruments. Poor economic conditions could harm our business, financial condition, operating results and cash flow.

The U.S. Congress and Trump administration may make substantial changes to fiscal, tax, regulation and other federal policies that may adversely affect our business. The Trump administration has called for substantial changes to U.S. fiscal and tax policies, which may include comprehensive corporate and individual tax reform. In addition, the Trump administration has called for significant changes to U.S. trade, healthcare, immigration, foreign, and government regulatory policy. To the extent the U.S. Congress or Trump administration implements changes to U.S. policy, those changes may impact, among other things, the U.S. and global economy, international trade and relations, unemployment, immigration, corporate taxes, healthcare, the U.S. regulatory environment, inflation and other areas. Although we cannot predict the impact, if any, of these changes to our business, they could adversely affect our business. Until we know what policy changes are made and how those changes impact our business and the business of our competitors over the long term, we will not know if, overall, we will benefit from them or be negatively affected by them.

The industries in which we compete are highly competitive, and we may not be able to compete successfully. Within our Service segment, we provide calibration services and compete in an industry that is highly fragmented and is composed of companies ranging from internationally recognized and accredited corporations to non-accredited sole proprietors, resulting in a tremendous range of service levels and capabilities. Also, within our Service segment, we provide compliance services and compete in an industry that is composed of both small local and regional service providers and large multi-national companies who are also OEMs. Within our Service segment, some of our larger competitors may have broader service capabilities and may have greater name recognition than us. Some manufacturers of the products we sell may also offer calibration and compliance services for their products.

Within our Distribution segment, we compete with numerous companies, including several major manufacturers and distributors. Most of our products are available from several sources and our customers tend to have relationships with several distributors. Competitors in the product distribution industry could also obtain exclusive rights to market particular products, which we would then be unable to market. Manufacturers could also increase their efforts to sell directly to end-users and bypass distributors like us. Industry consolidation among distributors, the unavailability of products, whether due to our inability to gain access to products or interruptions in supply from manufacturers, or the emergence of new competitors could also increase competition and adversely affect our business or results of operations.

In each of the industries in which we compete, some of our competitors have greater financial and other resources than we do, which could allow them to compete more successfully. In the future, we may be unable to compete successfully and competitive pressures may reduce our sales.

Our Service segment has a concentration of customers in the life science and other FDA-regulated and industrial manufacturing industries. A number of our Service segment customers operate in the pharmaceutical and other FDA-regulated or industrial manufacturing industries. This concentration of our customer base affects our overall risk profile, since a significant portion of our customers would be similarly affected by changes in economic, political, regulatory, and other industry conditions. We anticipate that our Service segment will continue to grow and comprise a greater percentage of our total revenue, which could increase our exposure to fluctuations in the life science and other FDA-regulated or industrial manufacturing industries. An abrupt or unforeseen change in conditions in these industries could adversely affect customer demand for our services, which could have a material adverse effect on our financial results.

Competition in our Distribution segment is changing with an increase in web-based distributors. We may not be able to compete successfully. We face substantial and increased competition throughout the world, especially in our Distribution segment where, until an upturn in revenues in fiscal year 2017, we had experienced a gradual decline in sales. The competition is changing, with web-based distributors becoming more prevalent and increasing their market share. Some of our competitors are much larger than us. Changes in the competitive landscape pose new challenges that could adversely affect our ability to compete. Entry or expansion of other vendors into this market may establish competitors that have larger customer bases and substantially greater financial and other resources with which to pursue marketing and distribution of products. Their current customer base and relationships, as well as their relationships and ability to negotiate with manufacturers, may also provide them with a competitive advantage. If we are unable to effectively compete with our current and future competitors, our ability to sell products could be harmed and could result in a negative impact on our Distribution segment. Any erosion of our competitive position could have a material adverse effect on our business, results of operations, and financial condition.

14

Cybersecurity incidents could adversely affect our business by causing a disruption to our operations, a compromise or corruption of our confidential information and/or damage to our business relationships, all of which could negatively impact our business, results of operations or financial condition. Global cybersecurity threats can range from uncoordinated individual attempts to gain unauthorized access to our information technology (“IT”) systems to sophisticated and targeted measures known as advanced persistent threats. While we employ comprehensive measures to prevent, detect, address and mitigate these threats (including access controls, data encryption, vulnerability assessments, management training, continuous monitoring of our IT networks and systems and maintenance of backup and protective systems), cybersecurity incidents, depending on their nature and scope, could potentially result in the misappropriation, destruction, corruption or unavailability of critical data or proprietary information and the disruption of business operations. The potential consequences of a material cybersecurity incident include reputational damage, litigation with third parties, and increased cybersecurity protection and remediation costs, which in turn could adversely affect our business and results of operations.

Our enterprise resource planning system is aging and we may experience issues from any implementation of a new enterprise resource planning system. We have an enterprise resource planning system (“ERP” or “Application Plus”) to assist with the collection, storage, management and interpretation of data from our business activities to support future growth and to integrate significant processes. Although we use current versions of software and have support agreements in place, due to the age of our ERP, we anticipate that a new ERP will be required to be implemented in the future. ERP implementations are complex and time-consuming and involve substantial expenditures on system software and implementation activities, as well as changes in business processes. Our ERP system is critical to our ability to accurately maintain books and records, record transactions, provide important information to our management and prepare our consolidated financial statements. ERP implementations also require the transformation of business and financial processes in order to reap the benefits of the ERP system; any such transformation involves risks inherent in the conversion to a new computer system, including loss of information and potential disruption to our normal operations. Any disruptions, delays or deficiencies in the design and implementation of a new ERP system could adversely affect our ability to process orders, provide services and customer support, send invoices and track payments, fulfill contractual obligations or otherwise operate our business. Additionally, if the ERP system does not operate as intended, the effectiveness of our internal control over financial reporting could be adversely affected or our ability to assess it adequately could be delayed.