Attached files

| file | filename |

|---|---|

| EX-32.1 - EX-32.1 - DOUGLAS DYNAMICS, INC | plow-20161231ex321356de3.htm |

| EX-31.2 - EX-31.2 - DOUGLAS DYNAMICS, INC | plow-20161231ex312392c7a.htm |

| EX-31.1 - EX-31.1 - DOUGLAS DYNAMICS, INC | plow-20161231ex3117b3ae8.htm |

| EX-23.1 - EX-23.1 - DOUGLAS DYNAMICS, INC | plow-20161231ex2313335c1.htm |

| EX-21.1 - EX-21.1 - DOUGLAS DYNAMICS, INC | plow-20161231ex211067513.htm |

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10‑K

|

(Mark One) |

|

|

☒ |

Annual Report Pursuant to Section 13 or 15(d) of the Securities Exchange Act of 1934 |

|

For the fiscal year ended December 31, 2016 |

|

|

or |

|

|

☐ |

Transition Report Pursuant to Section 13 or 15(d) of the Securities Exchange Act of 1934 |

|

For the transition period from to |

|

Commission File No. 001‑34728

DOUGLAS DYNAMICS, INC.

(Exact name of registrant as specified in its charter)

|

Delaware |

134275891 |

|

7777 N 73rd Street |

53223 |

Registrant’s telephone number, including area code (414) 354‑2310

Securities registered pursuant to Section 12(b) of the Act:

|

Title of each class |

Name of each exchange on which registered |

|

Common Stock, $.01 Par Value |

New York Stock Exchange |

Securities registered pursuant to Section 12(g) of the Act: NONE

Indicate by check mark if the registrant is a well‑known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes ☐ No ☒.

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act. Yes ☐ No ☒.

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes ☒ No ☐.

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Website, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S‑T (232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes ☒ No ☐.

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S‑K is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10‑K or any amendment to this Form 10‑K. ☒

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non‑accelerated filer or a smaller reporting company. See definitions of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b‑2 of the Exchange Act. (Check one):

|

Large accelerated filer ☐ |

Accelerated filer ☒ |

Non‑accelerated filer ☐ |

Smaller reporting company ☐ |

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b‑2 of the Exchange Act). Yes ☐ No ☒.

At June 30, 2016, the aggregate market value of the voting stock of the Registrant held by stockholders who were not affiliates of the Registrant was approximately $579 million (based upon the closing price of Registrant’s Common Stock on the New York Stock Exchange on such date). At March 13, 2017, the Registrant had outstanding an aggregate of 22,590,897 shares of its Common Stock.

Documents Incorporated by Reference:

Portions of the Proxy Statement for the Registrant’s Annual Meeting of Shareholders to be held on May 2, 2017, which Proxy Statement will be filed with the Securities and Exchange Commission no later than 120 days after the close of the fiscal year ended December 31, 2016, are incorporated into Part III.

| 3 | ||

| 4 | ||

| 11 | ||

| 20 | ||

| 21 | ||

| 21 | ||

| 21 | ||

| 22 | ||

| 22 | ||

| 24 | ||

|

Management Discussion and Analysis of Financial Condition and Results of Operations |

26 | |

| 43 | ||

| 44 | ||

|

Changes In and Disagreements with Accountants on Accounting and Financial Disclosures |

44 | |

| 44 | ||

| 45 | ||

| 45 | ||

| 45 | ||

| 46 | ||

|

Security Ownership of Certain Beneficial Owners and Management and Related Shareholder Matters |

46 | |

|

Certain Relationships and Related Transactions, and Director Independence |

46 | |

| 46 | ||

| 46 | ||

| 46 | ||

| 46 | ||

|

|

|

|

| 47 | ||

| 48 | ||

|

F-1 |

||

2

Forward Looking Statements

This Annual Report on Form 10‑K contains “forward‑looking statements” made within the meaning of the Private Securities Litigation Reform Act of 1995. Words such as “anticipate,” “believe,” “intend,” “estimate,” “expect,” “continue,” “should,” “could,” “may,” “plan,” “project,” “predict,” “will” and similar expressions are intended to identify forward ‑ looking statements. In addition, statements covering our future sales or financial performance and our plans, performance and other objectives, expectations or intentions are forward‑looking statements, such as statements regarding our liquidity, debt, planned capital expenditures, and adequacy of capital resources and reserves. Factors that could cause our actual results to differ materially from those expressed or implied in such forward‑looking statements include, but are not limited to:

|

· |

Weather conditions, particularly lack of or reduced levels of snowfall and the timing of such snowfall; |

|

· |

A significant decline in economic conditions; |

|

· |

Our inability to maintain good relationships with our distributors; |

|

· |

Our inability to maintain good relationships with the original equipment manufacturers which whom we currently do significant business: |

|

· |

Lack of available or favorable financing options for our end‑users, distributors or customers; |

|

· |

Increases in the price of steel or other materials necessary for the production of our products that cannot be passed on to our distributors; |

|

· |

Increases in the price of fuel; |

|

· |

The inability of our suppliers to meet our volume or quality requirements; |

|

· |

Inaccuracies in our estimates of future demand for our products; |

|

· |

Our inability to protect or continue to build our intellectual property portfolio; |

|

· |

The effects of laws and regulations and their interpretations on our business and financial conditions; |

|

· |

Our inability to develop new products or improve upon existing products in response to end‑user needs; |

|

· |

Losses due to lawsuits arising out of personal injuries associated with our products; |

|

· |

Factors that could impact the future declaration and payment of dividends; |

|

· |

Our inability to compete effectively against our competition; and |

|

· |

Our inability to achieve the projected financial performance with the business of Henderson Enterprises Group, Inc. (“Henderson”) which we acquired in 2014 or with the assets of Dejana Truck & Utility Equipment Company, Inc. which we acquired in 2016 and unexpected costs or liabilities related to such acquisitions. |

We undertake no obligation to revise the forward‑looking statements included in this Annual Report on Form 10‑K to reflect any future events or circumstances. Our actual results, performance or achievements could differ materially from the results expressed in, or implied by, these forward‑looking statements. Factors in addition to those listed above that could cause or contribute to such differences are discussed in Item 1A, “Risk Factors” of the Annual Report on Form 10‑K.

3

Overview

Home to the best-selling brands in the industry, Douglas Dynamics, Inc. (the “Company,” “we,” “us,” “our”) is North America's premier manufacturer and up-fitter of commercial work truck attachments and equipment. For more than 65 years, the Company has been innovating products that enable end users to perform their jobs more efficiently and effectively, providing opportunities for businesses to increase profitability. Our commitment to continuous improvement enables us to consistently produce high quality products and drive shareholder value. The Douglas Dynamics portfolio of products and services is separated into two segments: First, the Work Truck Attachments segment, which includes manufactured snow and ice control attachments sold under the FISHER®, HENDERSON®, SNOWEX® and WESTERN® brands. Second, the Work Truck Solutions segment, which includes the up-fit of market leading attachments and storage solutions for commercial work vehicles under the DEJANA® brand and its related sub-brands. The Work Truck Solutions segment was established as a result of the acquisition of substantially all of the assets of Dejana Truck & Utility Equipment Company, Inc. and certain entities directly or indirectly owned by Peter Paul Dejana Family Trust Dated 12/31/98 (such assets, “Dejana”) in July 2016. For additional financial information regarding our reportable business segments, see Note 15 of the Notes to Consolidated Financial Statements of this report.

In our Work Truck Attachments segment, we offer a broad product line of snowplows and sand and salt spreaders for light and heavy duty trucks that we believe to be the most complete line offered in the U.S. and Canadian markets. We also provide a full range of related parts and accessories, which generates an ancillary revenue stream throughout the lifecycle of our snow and ice control equipment. We also provide customized turnkey solutions to governmental agencies such as Departments of Transportation (“DOTs”) and municipalities. For the years ended December 31, 2016, 2015 and 2014, 88%, 87% and 84% of our net sales in our Work Truck Attachments segment were generated from sales of snow and ice control equipment, respectively, and 12%, 13% and 16% of our net sales in our Work Truck Attachments segment were generated from sales of parts and accessories, respectively. While we measure sales of parts and accessories separately from snow and ice control equipment, they are integrated with one another and are not separable.

We sell our Work Truck Attachments products through a distributor network primarily to professional snowplowers who are contracted to remove snow and ice from commercial, municipal and residential areas. Over the last 50 years, we have engendered exceptional customer loyalty for our products because of our ability to satisfy the stringent demands of our customers for a high degree of quality, reliability and service. As a result, we believe our installed base is the largest in the light truck market with over 500,000 snowplows and sand and salt spreaders in service. Because sales of snowplows and sand and salt spreaders are primarily driven by the need of our core end‑user base to replace worn existing equipment, we believe our substantial installed base provides us with a high degree of predictable sales over any extended period of time.

We believe that our Work Truck Attachments segment has the snow and ice control industry’s most extensive distribution network worldwide, which consists of over 2,000 points of sale. Direct points of shipment are predominantly through North American truck equipment and lawn care equipment distributors. Most of our distributors are located throughout the snow belt regions in North America (primarily the Midwest, East and Northeast regions of the United States as well as all provinces of Canada). We have longstanding relationships with many of our distributors. We continually seek to grow and optimize our network by opportunistically adding high‑quality, well‑capitalized distributors in select geographic areas and by cross‑selling our industry‑leading brands within our distribution network. Beginning in 2005, we have extended our reach to international markets, establishing distribution relationships in Northern Europe and Asia, where we believe meaningful growth opportunities exist.

Created as a result of our acquisition of Dejana, our Work Truck Solutions segment offers a complementary line of up-fitting services and products. Our Work Truck Solutions products consist of truck and vehicle up-fits where we attach component pieces of equipment, truck bodies, racking, and storage solutions with varying levels of complexity to a vehicle chassis and are typically used by end users for work related purposes. Our Work Truck Solutions segment is a premier up-fitter of Class 4 - 6 trucks and other commercial work vehicles in the eastern United States. Additionally, we believe that our Work Truck Solutions segment is a leading specialized

4

manufacturer of storage solutions for trucks and vans and cable pulling equipment for trucks. We believe we are a regional market leader in the truck and vehicle up-fitting market. We believe that our Work Truck Solutions business possesses significant customer relationships comprised of over 1,500 customers across the truck equipment industry. We have longstanding relationships with many of our Work Truck Solutions customers. We continually seek to grow and strengthen our customer relationships by providing custom solutions to our customers’ evolving specialty up-fit needs. We are able to serve our Work Truck Solutions customers’ needs through our bailment and floor plan agreements with original equipment vehicle manufacturers who supply truck chassis, on which we perform custom up-fits for our customers.

We believe we are the industry’s most operationally efficient manufacturer due to our vertical integration, highly variable cost structure and intense focus on lean manufacturing. We continually seek to use lean principles to reduce costs and increase the efficiency of our manufacturing operations. During the year ended December 31, 2016 we manufactured our products and up-fitted vehicles in five facilities that we own in Milwaukee, Wisconsin; Rockland, Maine; Madison Heights, Michigan, Manchester, Iowa; and Huntley, Illinois. We also lease twelve manufacturing and up-fit facilities, located in Iowa, Maryland, Missouri, New Jersey, New York, Ohio, Pennsylvania, and Rhode Island. Furthermore, our manufacturing efficiency allows us to deliver desired products quickly to our customers, especially during times of sudden and unpredictable snowfall events when our customers need our products immediately.

Our Industry

Work Truck Attachments Segment.

Our Work Truck Attachments Segment participates primarily in the snow and ice control equipment industries in North America. These industries consist predominantly of domestic participants that manufacture their products in North America. The annual demand for snow and ice control equipment is driven primarily by the replacement cycle of the existing installed base, which is predominantly a function of the average life of a snowplow or spreader and is driven by usage and maintenance practices of the end‑user. We believe actively‑used snowplows are typically replaced, on average, every 9 to 12 years.

We believe that both light and heavy duty snow and ice control equipment are driven primarily by the replacement cycle of the existing installed base, which is predominantly a function of the average life of a snowplow or spreader and is driven by usage and maintenance practices of the end‑user. However, we believe that demand for heavy duty trucks is less elastic than light trucks. Heavy duty truck end users typically are comprised of local governments and municipalities which plan for and execute planned replacement of equipment over time.

The primary factor influencing the replacement cycle for snow and ice control equipment for light trucks is the level, timing and location of snowfall. Sales of snow and ice control equipment in any given year and region are most heavily influenced by local snowfall levels in the prior snow season. Heavy snowfall during a given winter causes equipment usage to increase, resulting in greater wear and tear and shortened life cycles, thereby creating a need for replacement equipment and additional parts and accessories.

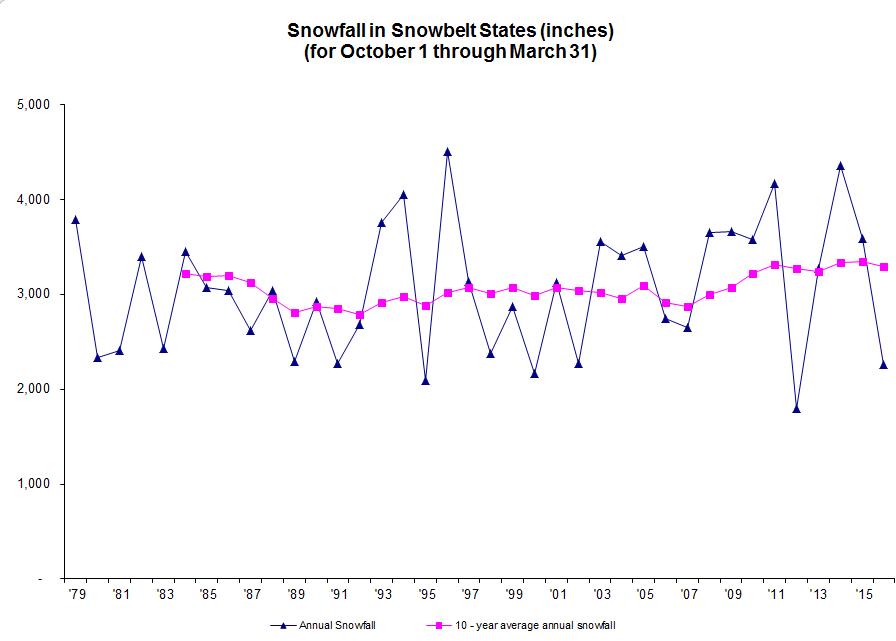

While snowfall levels vary within a given year and from year‑to‑year, snowfall, and the corresponding replacement cycle of snow and ice control equipment, is relatively consistent over multi‑year periods. The following chart depicts aggregate annual and ten‑year (based on the typical life of our snowplows) rolling average of the aggregate snowfall levels in 66 cities in 26 snow belt states across the Northeast, East, Midwest and Western United States where we monitor snowfall levels from 1980 to 2016. As the chart indicates, since 1984 aggregate snowfall levels in any given rolling ten‑year period have been fairly consistent, ranging from 2,782 to 3,345 inches.

5

Note:The 10‑year rolling average snowfall is not presented prior to 1984 for purposes of the calculation due to lack of snowfall data prior to 1975. Snowfall data in this chart is not adjusted for snowfall outside of the 66 cities in the 26 states reflected.

Source:National Oceanic and Atmospheric Administration’s National Weather Service.

The demand for snow and ice control equipment can also be influenced by general economic conditions in the United States, as well as local economic conditions in the snow‑belt regions in North America. In stronger economic conditions, our end‑users may choose to replace or upgrade existing equipment before its useful life has ended, while in weak economic conditions, our end‑users may seek to extend the useful life of equipment, thereby increasing the sales of parts and accessories. However, since snow and ice control management is a non‑discretionary service necessary to ensure public safety and continued personal and commercial mobility in populated areas that receive snowfall, end‑users cannot extend the useful life of snow and ice control equipment indefinitely and must replace equipment that has become too worn, unsafe or unreliable, regardless of economic conditions. While our parts and accessories yield slightly higher gross margins than our snow and ice control equipment, they yield significantly lower revenue than equipment sales, which adversely affects our results of operations. See “Management’s Discussion and Analysis of Financial Condition and Results of Operations—Seasonality and Year‑to‑Year Variability.”

Long‑term growth in the overall snow and ice control equipment market also results from geographic expansion of developed areas in the snow belt regions of North America, as well as consumer demand for technological enhancements in snow and ice control equipment and related parts and accessories that improves efficiency and reliability. Continued construction in the snow belt regions in North America increases the aggregate area requiring snow and ice removal, thereby growing the market for snow and ice control equipment. In addition, the development and sale of more reliable, more efficient and more sophisticated products have contributed to an approximate 2% to 4% average unit price increase in each of the past five years.

6

Work Truck Solutions Segment.

Our Work Truck Solutions Segment primarily participates in the truck and vehicle up-fitting industry in the United States. This industry consists predominantly of domestic participants that up-fit work trucks and vehicles. Specifically, there are regional market leaders that operate in close proximity to the original equipment vehicle manufacturers’ facilities and vehicle ports of entry. In addition to the regional market leaders, there exist smaller up-fit businesses. Our Work Truck Solutions segment competes against both the other regional market leaders and the smaller market participants. The annual demand for up-fit vehicles is subject to the general macro-economic environment trends.

We believe our Work Truck Solutions segment is a regional market leasder. We serve a variety of different customers that include dealers who typically sell to end users and to large national customers who purchase fleets of up-fitted vehicles. We believe that approximately half of our revenues are derived from dealer customers, while approximately 40% of our revenues are fleet sales.

Long term growth in the truck and vehicle up-fit market will depend on technological advances in the component products and advances in the original equipment manufacturer’s vehicles, as well customer demand for such products. Along with technological advancements, end users are demanding more specialized vehicles specifically related to their unique work related needs, which we expect will further increase demand. Along with technological advancements, products become more complex in the marketplace, thus increasing the importance of the role of the truck up-fitter in the value chain.

Our Competitive Strengths

We compete solely with other North American manufacturers and up-fitters who do not benefit from our manufacturing efficiencies, depth and breadth of products, extensive distributor network and customer relationships. As the market leader in the industries we serve, we enjoy a set of competitive advantages versus smaller competitors, which allows us to generate robust cash flows in all market environments and to support continued investment in our products, distribution capabilities and brand regardless of annual volume fluctuations. We believe these advantages are rooted in the following competitive strengths and reinforces our industry leadership over time.

Exceptional Customer Loyalty and Brand Equity. Our brands enjoy exceptional customer loyalty and brand equity in the snow and ice control equipment and truck up-fitting industries with both end‑users and distributors, which have been developed through over 50 years of superior innovation, productivity, reliability and support, consistently delivered year after year. We believe past brand experience, rather than price, is the key factor impacting our brands.

Broadest and Most Innovative Product Offering. In our Work Truck Attachments segment, we provide the industry’s broadest product offering with a full range of snowplows, sand and salt spreaders and related parts and accessories. We believe we maintain the industry’s largest and most advanced in‑house new product development program, historically introducing several new and redesigned products each year. Our broad product offering and commitment to new product development is essential to maintaining and growing our leading market share position as well as continuing to increase the profitability of our business. Meanwhile at our Work Truck Solutions segment, each up-fit is customized to the specific needs of our customers.

Extensive North American Distributor Network. With over 2,000 points of sale at our Work Truck Attachments segment, we benefit from having what we believe to be the most extensive distributor network in the light truck and heavy duty snow and ice control equipment industry, providing a significant competitive advantage over our peers. Our distributors function not only as sales and support agents (providing access to parts and service), but also as industry partners providing real‑time end‑user information, such as retail inventory levels, changing consumer preferences or desired functionality enhancements, which we use as the basis for our product development efforts.

Leader in Operational Efficiency. We believe we are a leader in operational efficiency in our industries, resulting from our application of lean manufacturing principles and a highly variable cost structure. By utilizing lean principles, we are able to adjust production levels easily to meet fluctuating demand, while controlling costs in slower periods. This operational efficiency is supplemented by our highly variable cost structure, driven in part by our access

7

to a sizable temporary workforce (comprising approximately 10‑15% of our total workforce during average snowfall years), which we can quickly adjust, as needed. These manufacturing efficiencies enable us to respond rapidly to urgent customer demand during times of sudden and unpredictable snowfalls, allowing us to provide exceptional service to our existing customer base and capture new customers from competitors that we believe cannot service their customers’ needs with the same speed and reliability.

Strong Cash Flow Generation. We are able to generate significant cash flow as a result of relatively consistent high profitability, low capital spending requirements and predictable timing of our working capital requirements. Our cash flow results will also benefit substantially from approximately $31.0 million of annual tax‑deductible intangible and goodwill expense over the next two years, which has the impact of reducing our corporate taxes owed by approximately $11.8 million on an annual basis during this period, in the event we have sufficient taxable income to utilize such benefit. Additionally, we expect to have substantial benefits of tax deductible intangible and goodwill amortization expense beyond the next two years with at least $10.0 million for the twelve years beyond 2018, which we expect to have the impact of reducing our corporate taxes owed by approximately $3.8 million on an annual basis during this period. Our significant cash flow has allowed us to reinvest in our business, pay down long term debt, and pay substantial dividends on a pro rata basis to our stockholders.

Experienced Management Team. We believe our business benefits from an exceptional management team that is responsible for establishing our leadership in light truck and heavy duty the snow and ice control equipment and truck up-fitting industries. Our senior management team, consisting of four officers, has an average of approximately 26 years of weather‑related industry experience and an average of over sixteen years with our company. James Janik, our Chairman, President and Chief Executive Officer, has been with us for over 24 years and in his role as President and Chief Executive Officer since 2000, and through his strategic vision, we have been able to expand our distributor network and grow our market leading position.

Our Business Strategy

Our business strategy is to capitalize on our competitive strengths to maximize cash flow to pay dividends, reduce indebtedness and reinvest in our business to create stockholder value. We have also developed a management system called the Douglas Dynamics Management System that is intended to assist in value creation and enhanced customer service. The building blocks of our strategy are:

Continuous Product Innovation. We believe new product innovation is critical to maintaining and growing our market‑leading position in the snow and ice control equipment industry. We will continue to focus on developing innovative solutions to increase productivity, ease of use, reliability, durability and serviceability of our products and on incorporating lean manufacturing concepts into our product development process, which has allowed us to reduce the overall cost of development and, more importantly, to reduce our time‑to‑market by nearly one‑half.

Distributor Network and Customer Optimization. At our Work Truck Attachment segment, we will continually seek opportunities to continue to expand our extensive distribution network by adding high‑quality, well‑capitalized distributors in select geographic areas and by cross‑selling our industry‑leading brands within our distribution network to ensure we maximize our ability to generate revenue while protecting our industry leading reputation, customer loyalty and brands. We will also focus on optimizing this network by providing in‑depth training, valuable distributor support and attractive promotional and incentive opportunities. As a result of these efforts, we believe a majority of our distributors choose to sell our products exclusively. We believe this sizable high quality network is unique in the industry, providing us with valuable insight into purchasing trends and customer preferences, and would be very difficult to replicate. At our Work Truck Solutions segment, we have well developed customer relationships resulting from being responsive to the needs of our customers. We will seek opportunities to continue to expand our customer group by increasing throughput allowing us to grow our customer base and continuing to be responsive to our customers’ specialized up-fit needs.

Aggressive Asset Management and Profit Focus. We will continue to aggressively manage our assets in order to maximize our cash flow generation despite seasonal and annual variability in snowfall levels that affect our

8

Work Truck Attachments segment. We believe our ability is unique in our industry and enables us to achieve attractive margins in all snowfall environments. Key elements of our asset management and profit focus strategies include:

|

· |

employment of a highly variable cost structure, which allows us to quickly adjust costs in response to real‑time changes in demand; |

|

· |

use of enterprise‑wide lean principles, which allow us to easily adjust production levels up or down to meet demand; |

|

· |

implementation of a pre‑season order program, which incentivizes distributors to place orders prior to the retail selling season and thereby enables us to more efficiently utilize our assets; and |

|

· |

development of a vertically integrated business model, which we believe provides us cost advantages over our competition. |

Additionally, although modest, our capital expenditure requirements and operating expenses can be temporarily reduced in response to anticipated or actual lower sales in a particular year to maximize cash flow.

Flexible, Lean Enterprise Platform. We will continue to utilize lean principles to maximize the flexibility, efficiency and productivity of our manufacturing operations while reducing the associated costs, enabling us to increase distributor and end‑user satisfaction. For example, in an environment where shorter lead times and near‑perfect order fulfillment are important to our distributors, we believe our lean processes have helped us to improve our shipping performance and build a reputation for providing industry leading shipping performance.

Our Growth Opportunities

Opportunistically Seek New Products and New Markets. On July 15, 2016, we completed our acquisition of Dejana, which we believe significantly strengthens our position as a premier manufacturer and up-fitter of vehicle attachments and equipment. Adding the Dejana business is expected to diversify our revenue streams and reduce the influence of weather on the overall business going forward. On December 31, 2014, we completed our acquisition of Henderson, which gave us Henderson’s full line of product offerings and access to its network of dealers. We plan to continue to evaluate other acquisition opportunities within our industry that can help us expand our distribution reach, enhance our technology and as a consequence improve the breadth and depth of our product lines. We also consider diversification opportunities in adjacent markets that complement our business model and could offer us the ability to leverage our core competencies to create stockholder value.

Increase Our Industry Leading Market Share. In our Work Truck Attachments segment, we plan to leverage our industry leading position, distribution network and new product innovation capabilities to capture market share in the North American snow and ice control equipment market, focusing our primary efforts on increasing penetration in those North American markets where we believe our overall market share is less than 50%, including the heavy duty truck market. We also plan to continue growing our presence in the snow and ice control equipment market outside of North America, particularly in Asia and Europe, which we believe could provide significant growth opportunities in the future. At our Work Truck Solutions segment, we plan to leverage our regional market leading position and utilize our Douglas Dynamics Management System to further penetrate up-fit markets and to grow our customer base.

Employees

As of December 31, 2016, we employed 1,633 employees on a full‑time basis. None of our employees are represented by a union and we are not party to any collective bargaining agreements.

Financing program

We are party to a financing program in which certain distributors may elect to finance their purchases from us through a third party financing company. We provide the third party financing company recourse against us

9

regarding the collectability of the receivable under the program due to the fact that if the third party financing company is unable to collect from the distributor the amounts due in respect of the product financed, we would be obligated to repurchase any remaining inventory related to the product financed and reimburse any legal fees incurred by the financing company. During the years ended December 31, 2016, 2015 and 2014, distributors financed purchases of $7.6 million, $7.6 million and $5.6 million through this financing program, respectively. At both December 31, 2016 and December 31, 2015, there were no uncollectible outstanding receivables related to sales financed under the financing program. The amount owed by our distributors to the third party financing company under this program at December 31, 2016 and 2015 was $6.8 million and $2.8 million, respectively. We were required to repurchase no repossessed inventory for the years ended December 31, 2016, 2015 and 2014.

In the past, minimal losses have been incurred under this agreement. However, an adverse change in distributor retail sales could cause this situation to change and thereby require us to repurchase repossessed units. Any repossessed units are inspected to ensure they are current, unused product and are restocked and resold.

Intellectual Property

We maintain patents relating to snowplow mounts, assemblies, hydraulics, electronics and lighting systems, brooms, sand, salt and fertilizer spreader assemblies, reel handlers and carriers and shelving systems. Patents are valid for the longer period of 17 years from issue date or 20 years from filing date. The duration of the patents we currently possess range between less than one year and 18 years of remaining life. Our patent applications date from 1997 through 2016.

We rely on a combination of patents, trade secrets and trademarks to protect certain of the proprietary aspects of our business and technology. We hold approximately 46 U.S. registered trademarks (including the trademarks WESTERN®, FISHER®, DEJANA®, BLIZZARD®, SNOWEX®, TURFEX®, SWEEPEX®, HENDERSON® and BRINEXTREME®) 13 Canadian registered trademarks, 5 European trademarks, 74 U.S. issued patents, 11 Canadian patents and 5 Chinese and 2 Mexican trademarks.

We rely upon a combination of patents, trade secrets and trademarks to protect certain of the proprietary aspects of our business and technology. In the year ended December 31, 2016, we received a settlement resulting from an ongoing lawsuit with one of our competitors relating to our intellectual property. Under the settlement agreement we received $10.1 million as part of defending our intellectual property. Our competitor has exhausted all appeals related to this matter and has paid us both awarded damages of $10.0 million and accrued interest of $0.1 million.

Raw Materials

During 2016, we experienced slightly less favorable commodity costs compared to the favorable prices paid for commodities in 2015. Historically, we have mitigated, and we currently expect to continue to mitigate, commodity cost increases in part by engaging in proactive vendor negotiations, reviewing alternative sourcing options, substituting materials, engaging in internal cost reduction efforts, and increasing prices on some of our products, all as appropriate.

Most of the components of our products are also affected by commodity cost pressures and are commercially available from a number of sources. In 2016, we experienced no significant work stoppages because of shortages of raw materials or commodities. The highest raw material and component costs are generally for steel, which we purchase from several suppliers.

Other Information

We were formed as a Delaware corporation in 2004. We maintain a website with the address www.douglasdynamics.com. We are not including the information contained on our website as part of, or incorporating it by reference into, this report. We make available free of charge (other than an investor’s own Internet access charges) through our website our Annual Report on Form 10‑K, quarterly reports on Form 10‑Q and current

10

reports on Form 8‑K, and amendments to these reports, as soon as reasonably practicable after we electronically file such material with, or furnish such material to, the Securities and Exchange Commission (“SEC”). For further information regarding our geographic areas see the Summary of Significant Accounting Policies as discussed in Note 2 to our audited consolidated financial statements included elsewhere in this Annual Report on Form 10‑K.

The Company operates in an environment that involves numerous known and unknown risks and uncertainties. Our business, prospects, financial condition and operating results could be materially adversely affected by any of these risks, as well as other risks not currently known to us or that we currently consider immaterial. The risks described below highlight some of the factors that have affected, and in the future could affect our operations.

Our results of operations for our Work Truck Attachments segment depend primarily on the level, timing and location of snowfall. As a result, a decline in snowfall levels in multiple regions for an extended time could cause our results of operations to decline and adversely affect our ability to pay dividends.

As a manufacturer through our Work Truck Attachments segment of snow and ice control equipment for both light and heavy duty trucks, and related parts and accessories, our sales depend primarily on the level, timing and location of snowfall in the regions in which we offer our products. A low level or lack of snowfall in any given year in any of the snow‑belt regions in North America (primarily the Midwest, East and Northeast regions of the United States as well as all provinces of Canada) will likely cause sales of our Work Truck Attachments products to decline in such year as well as the subsequent year, which in turn may adversely affect our results of operations and ability to pay dividends. See “Management’s Discussion and Analysis of Financial Condition and Results of Operations—Seasonality and Year‑to‑Year Variability.” A sustained period of reduced snowfall events in one or more of the geographic regions in which we offer our products could cause our results of operations to decline and adversely affect our ability to pay dividends.

The year‑to‑year variability of our Work Truck Attachments segment can cause our results of operations and financial condition to be materially different from year‑to‑year; whereas the seasonality of our Work Truck Attachments segment can cause our results of operations and financial condition to be materially different from quarter‑to‑quarter.

Because our Work Truck Attachments segment depends on the level, timing and location of snowfall, our results of operations vary from year‑to‑year. Additionally, because the annual snow season typically only runs from October 1 through March 31, our distributors typically purchase our Work Truck Attachments products during the second and third quarters. As a result, we operate in a seasonal business. We not only experience seasonality in our sales, but also experience seasonality in our working capital needs. Consequently, our results of operations and financial condition of our Work Truck Attachments segment can vary from year‑to‑year, as well as from quarter‑to‑quarter, which could affect our ability to pay dividends. If we are unable to effectively manage the seasonality and year‑to‑year variability of our Work Truck Attachments segment, our results of operations, financial condition and ability to pay dividends may suffer.

If economic conditions in the United States continue to remain weak or deteriorate further, or if spending by governmental agencies is limited or reduced, our results of operations, financial condition and ability to pay dividends may be adversely affected.

Historically, demand for snow and ice control equipment for light and heavy duty trucks as well as up-fitted vehicles has been influenced by general economic conditions in the United States, as well as local economic conditions in the snow‑belt regions in North America. During the last few years, economic conditions throughout the United States have been weak and spending by governmental agencies such as DOTs and municipalities has been constrained. Although conditions have improved from 2011 through 2016, this trend may not continue in the foreseeable future. Weakened economic conditions and limited or reduced government spending may cause both our Work Truck Attachments and Work Truck Solutions end‑users to delay purchases of replacement snow and ice control equipment and up-fit vehicles and instead repair their existing equipment and vehicles, leading to a decrease in our sales of new equipment and up-fitted vehicles. Specific to our Work Truck Attachments segment, weakened economic conditions

11

and limited or reduced governmental spending may also cause our end‑users to delay their purchases of new light and heavy duty trucks. Because our end‑users tend to purchase new snow and ice control equipment concurrent with their purchase of new light or heavy duty trucks, their delay in purchasing new light or heavy duty trucks can also result in the deferral of their purchases of new snow and ice control equipment. The deferral of new equipment purchases during periods of weak economic conditions or limited or reduced government spending may negatively affect our results of operations, financial condition and ability to pay dividends.

Weakened economic conditions or limited or reduced government spending may also cause both our Work Truck Attachments and Work Truck Solutions end‑users to consider price more carefully in selecting new snow and ice control equipment and up-fit vehicles, respectively. Historically, considerations of quality and service have outweighed considerations of price, but in a weak economy, or an environment of constrained government spending, price may become a more important factor. Any refocus away from quality in favor of cheaper equipment could cause end‑users to shift away from our products to less expensive competitor products, or to shift away from our more profitable products to our less profitable products, which in turn would adversely affect our results of operations and our ability to pay dividends.

Our failure to maintain good relationships with our customers and distributors, the loss or consolidation of our distributor base or the actions or inactions of our distributors could have an adverse effect on our results of operations and our ability to pay dividends.

We depend on a network of truck equipment distributors to sell, install and service our products and up-fitted vehicles. Nearly all of these sales and service relationships are at will, so almost all of our distributors could discontinue the sale and service of our products and up-fitted vehicles at any time, and those distributors that primarily sell our products and up-fitted vehicles may choose to sell competing products or vehicles at any time. Further, difficult economic or other circumstances could cause any of our distributors to discontinue their businesses. Moreover, if our distributor base were to consolidate or if any of our distributors were to discontinue their business, competition for the business of fewer distributors would intensify. If we do not maintain good relationships with our distributors and customers, or if we do not provide product or up-fit offerings and pricing that meet the needs of our distributors and customers, we could lose a substantial amount of our distributor and customer base. A loss of a substantial portion of our distributor and customer base could cause our sales to decline significantly, which would have an adverse effect on our results of operations and ability to pay dividends.

In addition, our distributors may not provide timely or adequate service to our end‑users. If this occurs, our brand identity and reputation may be damaged, which would have an adverse effect on our results of operations and ability to pay dividends.

Lack of available financing options for our end‑users or distributors may adversely affect our sales volumes.

Our end‑user base in our Work Truck Attachments segment is highly concentrated among professional snowplowers, who comprise over 50% of our end‑users, many of whom are individual landscapers who remove snow during the winter and landscape during the rest of the year, rather than large, well‑capitalized corporations. These end‑users often depend upon credit to purchase our Work Truck Attachments products. If credit is unavailable on favorable terms or at all, these end‑users may not be able to purchase our Work Truck Attachments products from our distributors, which would in turn reduce sales and adversely affect our results of operations and ability to pay dividends.

In addition, because our distributors, like our end‑users, rely on credit to purchase our products, if our distributors are not able to obtain credit, or access credit on favorable terms, we may experience delays in payment or nonpayment for delivered products. Further, if our distributors are unable to obtain credit or access credit on favorable terms, they could experience financial difficulties or bankruptcy and cease purchases of our products altogether. Thus, if financing is unavailable on favorable terms or at all, our results of operations and ability to pay dividends would be adversely affected.

12

The price of steel, a commodity necessary to manufacture our products, is highly variable. If the price of steel increases, our gross margins could decline.

Steel is a significant raw material used to manufacture our products. During 2016, 2015 and 2014, our steel purchases were approximately 12%, 15% and 13% of our revenue, respectively. The steel industry is highly cyclical in nature, and steel prices have been volatile in recent years and may remain volatile in the future. Steel prices are influenced by numerous factors beyond our control, including general economic conditions domestically and internationally, the availability of raw materials, competition, labor costs, freight and transportation costs, production costs, import duties and other trade restrictions. Steel prices are volatile and may increase as a result of increased demand from the automobile and consumer durable sectors. If the price of steel increases, our variable costs may increase. We may not be able to mitigate these increased costs through the implementation of permanent price increases or temporary invoice surcharges, especially if economic conditions remain weak and our distributors and end‑users become more price sensitive. If we are unable to successfully mitigate such cost increases in the future, our gross margins could decline.

If petroleum prices increase, our results of operations could be adversely affected.

Petroleum prices have fluctuated significantly in recent years. Prices and availability of petroleum products are subject to political, economic and market factors that are outside of our control. Political events in petroleum‑producing regions as well as hurricanes and other weather‑related events may cause the price of fuel to increase. If the price of fuel increases, the demand for our products may decline, which would adversely affect our financial condition and results of operations.

We depend on outside suppliers who may be unable to meet our volume and quality requirements, and we may be unable to obtain alternative sources.

We purchase certain components essential to our snowplows and sand and salt spreaders from outside suppliers, including off‑shore sources. Most of our key supply arrangements can be discontinued at any time. A supplier may encounter delays in the production and delivery of such products and components or may supply us with products and components that do not meet our quality, quantity or cost requirements. Additionally, a supplier may be forced to discontinue operations. Any discontinuation or interruption in the availability of quality products and components from one or more of our suppliers may result in increased production costs, delays in the delivery of our products and lost end‑user sales, which could have an adverse effect on our business and financial condition.

We have continued to increase the number of our off‑shore suppliers. Our increased reliance on off‑shore sourcing may cause our business to be more susceptible to the impact of natural disasters, war and other factors that may disrupt the transportation systems or shipping lines used by our suppliers, a weakening of the dollar over an extended period of time and other uncontrollable factors such as changes in foreign regulation or economic conditions. In addition, reliance on off‑shore suppliers may make it more difficult for us to respond to sudden changes in demand because of the longer lead time to obtain components from off‑shore sources. We may be unable to mitigate this risk by stocking sufficient materials to satisfy any sudden or prolonged surges in demand for our products. If we cannot satisfy demand for our products in a timely manner, our sales could suffer as distributors can cancel purchase orders without penalty until shipment.

We do not sell our products under long‑term purchase contracts, and sales of our products are significantly impacted by factors outside of our control; therefore, our ability to estimate demand is limited.

We do not enter into long‑term purchase contracts with our distributors and the purchase orders we receive may be cancelled without penalty until shipment. Therefore, our ability to accurately predict future demand for our products is limited. Nonetheless, we attempt to estimate demand for our products for purposes of planning our annual production levels and our long‑term product development and new product introductions. We base our estimates of demand on our own market assessment, snowfall figures, quarterly field inventory surveys and regular communications with our distributors. Because wide fluctuations in the level, timing and location of snowfall, economic conditions and other factors may occur, each of which is out of our control, our estimates of demand may not be accurate. Underestimating demand could result in procuring an insufficient amount of materials necessary for the production of our products, which may result in increased production costs, delays in product delivery, missed

13

sale opportunities and a decrease in customer satisfaction. Overestimating demand could result in the procurement of excessive supplies, which could result in increased inventory and associated carrying costs.

If we are unable to enforce, maintain or continue to build our intellectual property portfolio, or if others invalidate our intellectual property rights, our competitive position may be harmed.

Our patents relating to snowplow mounts, assemblies, hydraulics, electronics and lighting systems, brooms, sand, salt and fertilizer spreader assemblies, reel handlers and carriers and shelving systems. Patents are valid for the longer period of 17 years from issue date or 20 years from filing date. The duration of the patents we currently possess range between less than one year and 18 years of remaining life. Our patent applications date from 1997 through 2016.

We rely on a combination of patents, trade secrets and trademarks to protect certain of the proprietary aspects of our business and technology. We hold approximately 46 U.S. registered trademarks (including the trademarks WESTERN®, FISHER®, DEJANA®, BLIZZARD®, SNOWEX®, TURFEX®, SWEEPEX®, HENDERSON® and BRINEXTREME®) 13 Canadian registered trademarks, 5 European trademarks, 74 U.S. issued patents, 11 Canadian patents and 5 Chinese and 2 Mexican trademarks. Although we work diligently to protect our intellectual property rights, monitoring the unauthorized use of our intellectual property is difficult, and the steps we have taken may not prevent unauthorized use by others. In addition, in the event a third party challenges the validity of our intellectual property rights, a court may determine that our intellectual property rights may not be valid or enforceable. An adverse determination with respect to our intellectual property rights may harm our business prospects and reputation. Third parties may design around our patents or may independently develop technology similar to our trade secrets. The failure to adequately build, maintain and enforce our intellectual property portfolio could impair the strength of our technology and our brands, and harm our competitive position. Although we have no reason to believe that our intellectual property rights are vulnerable, previously undiscovered intellectual property could be used to invalidate our rights.

If we are unable to develop new products or improve upon our existing products on a timely basis, it could have an adverse effect on our business and financial condition.

We believe that our future success depends, in part, on our ability to develop on a timely basis new technologically advanced products or improve upon our existing products in innovative ways that meet or exceed our competitors’ product and up-fit offerings. Continuous product innovation ensures that our consumers have access to the latest products and features when they consider buying snow and ice control equipment and truck up-fits. Maintaining our market position will require us to continue to invest in research and development and sales and marketing. Product development requires significant financial, technological and other resources. We may be unsuccessful in making the technological advances necessary to develop new products or improve our existing products to maintain our market position. Industry standards, end‑user expectations or other products may emerge that could render one or more of our products less desirable or obsolete. If any of these events occur, it could cause decreases in sales, a failure to realize premium pricing and an adverse effect on our business and financial condition.

We face competition from other companies in our industry, and if we are unable to compete effectively with these companies, it could have an adverse effect on our sales and profitability. Price competition among our distributors and customers could negatively affect our market share.

In our Work Truck Attachments segment, we primarily compete with regional manufacturers of snow and ice control equipment for light and heavy duty trucks. While we are the most geographically diverse company in our industry, we may face increasing competition in the markets in which we operate. Additionally, in our Work Truck Solutions segment, we compete with other market leaders in the truck up-fit industry. In saturated markets, price competition may lead to a decrease in our market share or a compression of our margins, both of which would affect our profitability. Moreover, current or future competitors may grow their market share and develop superior service and may have or may develop greater financial resources, lower costs, superior technology or more favorable operating conditions than we maintain. As a result, competitive pressures we face may cause price reductions for our products, which would affect our profitability or result in decreased sales and operating income. Additionally, saturation of the markets in which we compete or channel conflicts among our brands and shifts in consumer preferences may increase these competitive pressures or may result in increased competition among our distributors and affect our sales and profitability. In addition, price competition among the distributors that sell our products could lead to significant

14

margin erosion among our distributors, which could in turn result in compressed margins or loss of market share for us. Management believes that, after ourselves, the next largest competitors in the market for snow and ice control equipment for light trucks are Northern Star Industries, Inc. (the manufacturer of the Boss brand of snow and ice control equipment) and Meyer Products LLC, and accordingly represent our primary competitors for light truck market share for our Work Truck Attachments segment. Management believes that, after ourselves, the next largest competitors in the market for snow and ice control equipment for heavy trucks are Monroe and Viking, and accordingly represent our primary competitors for heavy truck market share for our Work Truck Attachments segment. Management believes that, other regional market leaders in the truck up-fitting industry are Knapheide, Reading, Palfleet and Autotruck, and accordingly represent our primary competitors for market share for our Work Truck Solutions segment.

We are subject to complex laws and regulations, including environmental and safety regulations that can adversely affect the cost, manner or feasibility of doing business.

Our operations are subject to certain federal, state and local laws and regulations relating to, among other things, the generation, storage, handling, emission, transportation, disposal and discharge of hazardous and non‑hazardous substances and materials into the environment, the manufacturing of motor vehicle accessories and employee health and safety. We cannot be certain that existing and future laws and regulations and their interpretations will not harm our business or financial condition. We currently make and may be required to make large and unanticipated capital expenditures to comply with environmental and other regulations, such as:

|

· |

Applicable motor vehicle safety standards established by the National Highway Traffic Safety Administration; |

|

· |

Reclamation and remediation and other environmental protection; and |

|

· |

Standards for workplace safety established by the Occupational Safety and Health Administration. |

While we monitor our compliance with applicable laws and regulations and attempt to budget for anticipated costs associated with compliance, we cannot predict the future cost of such compliance. In 2016, the amount expended for such compliance was insignificant, but we could incur material expenses in the future in the event of future legislation changes or unforeseen events, such as a workplace accident or environmental discharge, or if we otherwise discover we are in non‑compliance with an applicable regulation. In addition, under these laws and regulations, we could be liable for:

|

· |

Product liability claims; |

|

· |

Personal injuries; |

|

· |

Investigation and remediation of environmental contamination and other governmental sanctions such as fines and penalties; and |

|

· |

Other environmental damages. |

Our operations could be significantly delayed or curtailed and our costs of operations could significantly increase as a result of regulatory requirements, restrictions or claims. We are unable to predict the ultimate cost of compliance with these requirements or their effect on our operations.

Financial market conditions have had a negative impact on the return on plan assets for our pension plans, which may require additional funding and negatively impact our cash flows.

Our pension expense and required contributions to our pension plan are directly affected by the value of plan assets, the projected rate of return on plan assets, the actual rate of return on plan assets and the actuarial assumptions we use to measure the defined benefit pension plan obligations. Despite modest recent market recoveries, the funding status of our pension plans remain impacted by the financial market downturn over the last several years, which had

15

severely impacted the funded status of our pension plans. As of December 31, 2016, our pension plans were underfunded by approximately $10.2 million. In 2016, contributions to our defined benefit pension plans were approximately $1.7 million. If plan assets perform below expectations, future pension expense and funding obligations will increase, which would have a negative impact on our cash flows. Moreover, under the Pension Protection Act of 2006, it is possible that losses of asset values may necessitate accelerated funding of our pension plans in the future to meet minimum federal government requirements.

The statements regarding our industry, market positions and market share in this filing are based on our management’s estimates and assumptions. While we believe such statements are reasonable, such statements have not been independently verified.

Information contained in this Annual Report on Form 10‑K concerning the snow and ice control equipment and truck up-fitting industries, our general expectations concerning these industries and our market positions and other market share data regarding the industries are based on estimates our management prepared using end‑user surveys, anecdotal data from our distributors and distributors that carry our competitors’ products, our results of operations and management’s past experience, and on assumptions made, based on our management’s knowledge of this industry, all of which we believe to be reasonable. These estimates and assumptions are inherently subject to uncertainties, especially given the year‑to‑year variability of snowfall and the difficulty of obtaining precise information about our competitors, and may prove to be inaccurate. In addition, we have not independently verified the information from any third‑party source and thus cannot guarantee its accuracy or completeness, although management also believes such information to be reasonable. Our actual operating results may vary significantly if our estimates and outlook concerning the industry, snowfall patterns, our market positions or our market shares turn out to be incorrect.

We are subject to product liability claims, product quality issues, and other litigation from time to time that could adversely affect our operating results or financial condition.

The manufacture, sale and usage of our products expose us to a risk of product liability claims. If our products are defective or used incorrectly by our end‑users, injury may result, giving rise to product liability claims against us. If a product liability claim or series of claims is brought against us for uninsured liabilities or in excess of our insurance coverage, and it is ultimately determined that we are liable, our business and financial condition could suffer. Any losses that we may suffer from any liability claims, and the effect that any product liability litigation may have upon the reputation and marketability of our products, may divert management’s attention from other matters and may have a negative impact on our business and operating results. Additionally, we could experience a material design or manufacturing failure in our products, a quality system failure or other safety issues, or heightened regulatory scrutiny that could warrant a recall of some of our products. A recall of some of our products could also result in increased product liability claims. Any of these issues could also result in loss of market share, reduced sales, and higher warranty expense.

We are heavily dependent on our Chief Executive Officer and management team.

Our continued success depends on the retention, recruitment and continued contributions of key management, finance, sales and marketing personnel, some of whom could be difficult to replace. Our success is largely dependent upon our senior management team, led by our Chief Executive Officer and other key managers. The loss of any one or more of such persons could have an adverse effect on our business and financial condition.

Our indebtedness could adversely affect our operations, including our ability to perform our obligations and pay dividends.

As of December 31, 2016, we had approximately $316 million of senior secured indebtedness, no outstanding borrowings under our revolving credit facility and $90 million of borrowing availability under the revolving credit

16

facility. We may also be able to incur substantial indebtedness in the future, including senior indebtedness, which may or may not be secured.

Our indebtedness could have important consequences, including the following:

|

· |

We could have difficulty satisfying our debt obligations, and if we fail to comply with these requirements, an event of default could result; |

|

· |

We may be required to dedicate a substantial portion of our cash flow from operations to required payments on indebtedness, thereby reducing the cash flow available to pay dividends or fund working capital, capital expenditures and other general corporate activities; |

|

· |

Covenants relating to our indebtedness may restrict our ability to make distributions to our stockholders; |

|

· |

Covenants relating to our indebtedness may limit our ability to obtain additional financing for working capital, capital expenditures and other general corporate activities, which may limit our flexibility in planning for, or reacting to, changes in our business and the industry in which we operate; |

|

· |

We may be more vulnerable to general adverse economic and industry conditions; |

|

· |

We may be placed at a competitive disadvantage compared to our competitors with less debt; and |

|

· |

We may have difficulty repaying or refinancing our obligations under our senior credit facilities on their respective maturity dates. |

If any of these consequences occur, our financial condition, results of operations and ability to pay dividends could be adversely affected. This, in turn, could negatively affect the market price of our common stock, and we may need to undertake alternative financing plans, such as refinancing or restructuring our debt, selling assets, reducing or delaying capital investments or seeking to raise additional capital. We cannot assure you that any refinancing would be possible, that any assets could be sold, or, if sold, of the timing of the sales and the amount of proceeds that may be realized from those sales, or that additional financing could be obtained on acceptable terms, if at all.

Our variable rate indebtedness subjects us to interest rate risk, which could cause our debt service obligations to increase significantly and could impose adverse consequences.

Certain of our borrowings, including our term loan and any revolving borrowings under our senior credit facilities, are at variable rates of interest and expose us to interest rate risk. In addition, the interest rate on any revolving borrowings is subject to an increase in the interest rate if the average daily availability under our revolving credit facility falls below a certain threshold. If interest rates increase, our debt service obligations on the variable rate indebtedness would increase even though the amount borrowed remained the same, and our net income and cash flows would correspondingly decrease.

Our senior credit facilities impose restrictions on us, which may also prevent us from capitalizing on business opportunities and taking certain corporate actions. One of these facilities also includes minimum availability requirements, which if unsatisfied, could result in liquidity events that may jeopardize our business.

Our senior credit facilities contain, and future debt instruments to which we may become subject may contain, covenants that limit our ability to engage in activities that could otherwise benefit our company. Under the credit facilities, these covenants include restrictions on our ability to:

|

· |

incur, assume or permit to exist additional indebtedness or contingent obligations; |

|

· |

incur liens and engage in sale and leaseback transactions; |

|

· |

make loans and investments in excess of agreed upon amounts; |

17

|

· |

declare dividends, make payments or redeem or repurchase capital stock in excess of agreed upon amounts and subject to certain other limitations; |

|

· |

engage in mergers, acquisitions and other business combinations; |

|

· |

prepay, redeem or purchase certain indebtedness or amend or alter the terms of our indebtedness; |

|

· |

sell assets; |

|

· |

make further negative pledges; |

|

· |

create restrictions on distributions by subsidiaries; |

|

· |

change our fiscal year; |

|

· |

engage in activities other than, among other things, incurring the debt under our new senior credit facilities and the activities related thereto, holding our ownership interest in DDI LLC, making restricted payments, including dividends, permitted by our senior credit facilities and conducting activities related to our status as a public company; |

|

· |

amend or waive rights under certain agreements; |

|

· |

transact with affiliates or our stockholders; and |

|

· |

alter the business that we conduct. |

Our amended revolving credit facility also includes limitations on capital expenditures and requires that if we fail to maintain the greater of $12,500,000 and 12.5% of the revolving commitments in borrowing availability, we must comply with a fixed charge coverage ratio test. In addition, if a liquidity event occurs because our borrowing availability is less than the greater of $15,000,000 and 15% of the aggregate revolving commitments (or an event of default occurs and is continuing), subject to certain limited cure rights, all proceeds of our accounts receivable and other collateral will be applied to reduce obligations under our amended revolving credit facility, jeopardizing our ability to meet other obligations. Our ability to comply with the covenants contained in our senior credit facilities or in the agreements governing our future indebtedness, and our ability to avoid liquidity events, may be affected by events, or our future performance, which are subject to factors beyond our control, including prevailing economic, financial, industry and weather conditions, such as the level, timing and location of snowfall and general economic conditions in the snowbelt regions of North America. A failure to comply with these covenants could result in a default under our senior credit facilities, which could prevent us from paying dividends, borrowing additional amounts and using proceeds of our inventory and accounts receivable, and also permit the lenders to accelerate the payment of such debt. If any of our debt is accelerated or if a liquidity event (or event of default) occurs that results in collateral proceeds being applied to reduce such debt, we may not have sufficient funds available to repay such debt and our other obligations, in which case, our business could be halted and such lenders could proceed against any collateral securing that debt. Further, if the lenders accelerate the payment of the indebtedness under our senior credit facilities, our assets may not be sufficient to repay in full the indebtedness under our senior credit facilities and our other indebtedness, if any. We cannot assure you that these covenants will not adversely affect our ability to finance our future operations or capital needs to pursue available business opportunities or react to changes in our business and the industry in which we operate.

18

Provisions of Delaware law and our charter documents could delay or prevent an acquisition of us, even if the acquisition would be beneficial to you.

Provisions in our certificate of incorporation and bylaws may have the effect of delaying or preventing a change of control or changes in our management. These provisions include:

|

· |

the absence of cumulative voting in the election of our directors, which means that the holders of a majority of our common stock may elect all of the directors standing for election; |

|

· |

the ability of our Board of Directors to issue preferred stock with voting rights or with rights senior to those of our common stock without any further vote or action by the holders of our common stock; |

|

· |

the division of our Board of Directors into three separate classes serving staggered three‑year terms; |

|

· |

the ability of our stockholders to remove our directors is limited to cause and only by the vote of at least 662/3% of the outstanding shares of our common stock; |

|

· |

the prohibition on our stockholders from acting by written consent and calling special meetings; |

|

· |

the requirement that our stockholders provide advance notice when nominating our directors or proposing business to be considered by the stockholders at an annual meeting of stockholders; and |

|

· |

the requirement that our stockholders must obtain a 662/3% vote to amend or repeal certain provisions of our certificate of incorporation. |

We are also subject to Section 203 of the Delaware General Corporation Law, which, subject to certain exceptions, prohibits us from engaging in any business combination with any interested stockholder, as defined in that section, for a period of three years following the date on which that stockholder became an interested stockholder. This provision, together with the provisions discussed above, could also make it more difficult for you and our other stockholders to elect directors and take other corporate actions, and could limit the price that investors might be willing to pay in the future for shares of our common stock.

Our dividend policy may limit our ability to pursue growth opportunities.

If we continue to pay dividends at the level contemplated by our dividend policy, as in effect on the date of this filing, or if we increase the level of our dividend payments in the future, we may not retain a sufficient amount of cash to finance growth opportunities, meet any large unanticipated liquidity requirements or fund our operations in the event of a significant business downturn. In addition, because a significant portion of cash available will be distributed to holders of our common stock under our dividend policy, our ability to pursue any material expansion of our business, including through acquisitions, increased capital spending or other increases of our expenditures, will depend more than it otherwise would on our ability to obtain third party financing. We cannot assure you that such financing will be available to us at all, or at an acceptable cost. If we are unable to take timely advantage of growth opportunities, our future financial condition and competitive position may be harmed, which in turn may adversely affect the market price of our common stock.

Security breaches and other disruptions could compromise our information and expose us to liability, which would cause our business and reputation to suffer.

In the ordinary course of our business, we collect and store sensitive data, including our proprietary business information and that of our customers, suppliers and business partners, as well as personally identifiable information of our customers and employees, in our data centers and on our networks. The secure processing, maintenance and transmission of this information is critical to our operations and business strategy. Despite our security measures, our information technology and infrastructure may be vulnerable to malicious attacks or breached due to employee error, malfeasance or other disruptions, including as a result of rollouts of new systems. Any such breach could compromise our networks and the information stored there could be accessed, publicly disclosed, lost or stolen. Any such access,

19

disclosure or other loss of information could result in legal claims or proceedings and/or regulatory penalties, disrupt our operations, damage our reputation, and/or cause a loss of confidence in our products and services, which could adversely affect our business.

We may be unable to identify, complete or benefit from strategic transactions.

Our long‑term growth strategy includes building value for our company through a variety of methods. These methods may include acquisition of, investment in, or joint ventures involving, complementary businesses. We cannot assure that we will be able to identify suitable parties for these transactions. If we are unable to identify suitable parties for strategic transactions we may not be able to capitalize on market opportunities with existing and new customers, which could inhibit our ability to gain market share. Even if we identify suitable parties to participate in these transactions, we cannot assure that we will be able to make them on commercially acceptable terms, if at all.