Attached files

| file | filename |

|---|---|

| EX-14.1 - EXHIBIT 14.1 - BIMI International Medical Inc. | v434438_ex14-1.htm |

| EX-23.1 - EXHIBIT 23.1 - BIMI International Medical Inc. | v434438_ex23-1.htm |

| EX-32.2 - EXHIBIT 32.2 - BIMI International Medical Inc. | v434438_ex32-2.htm |

| EX-31.1 - EXHIBIT 31.1 - BIMI International Medical Inc. | v434438_ex31-1.htm |

| EX-32.1 - EXHIBIT 32.1 - BIMI International Medical Inc. | v434438_ex32-1.htm |

| EX-31.2 - EXHIBIT 31.2 - BIMI International Medical Inc. | v434438_ex31-2.htm |

| EX-21.1 - EXHIBIT 21.1 - BIMI International Medical Inc. | v434438_ex21-1.htm |

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10-K

x Annual Report Pursuant to Section 13 or 15(d) of the Securities Exchange Act of 1934

For the fiscal year ended: December 31, 2015

¨ Transition Report Pursuant to Section 13 or 15(d) of the Securities Exchange Act of 1934

For the transition period from ______________to ______________

Commission File Number 000-50155

NF ENERGY SAVING CORPORATION

(Exact Name of Registrant as Specified in Its Charter)

|

Delaware (State of Incorporation) |

02-0563302 (I.R.S. Employer ID Number) | |

|

3106, Tower C, 390 Qingnian Avenue, Heping District Shenyang, P. R. China (Address of Principal Executive Offices) |

110015 (Zip Code) |

(8624) 2560-9775

(Issuer’s Telephone Number, Including Area Code)

Securities registered pursuant to Section 12(b) of the Act:

| Title of Each Class Common stock, $0.001 par value |

Name of Each Exchange on Which Registered The NASDAQ Stock Market |

Securities registered pursuant to Section 12(g) of the Act:

None

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act.

Yes ¨ No x

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act.

Yes ¨ No x

Indicate by check mark whether the registrant: (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days.

Yes x No ¨

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files).

Yes x No ¨

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of the registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. x

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company. See definition of “accelerated filer”, “large accelerated filer”, and “smaller reporting company” in Rule 12b-2 of the Exchange Act. (Check One):

Large accelerated filer ¨ Accelerated filer ¨ Non-accelerated filer ¨ Smaller reporting company x

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act.).

Yes ¨ No x

As of June 30, 2015, the aggregate market value of the common equity held by non-affiliates of the registrant was $4,927,493 based on the price of $1.55 per share which the registrant’s common stock was last sold.

As of January 29, 2016, there were 6,553,289 shares of the registrant’s common stock outstanding.

NF ENERGY SAVING CORPORATION

FORM 10-K

TABLE OF CONTENTS

| 2 |

The Company

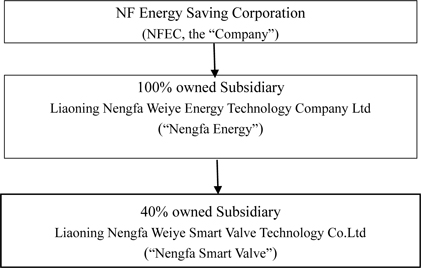

As used herein the terms “we”, “us”, “our,” “NFEC” and the “Company” means, NF Energy Saving Corporation, a Delaware corporation, formerly known as NF Energy Saving Corporation of America, Diagnostic Corporation of America, Global Broadcast Group, Inc., and Galli Process, Inc. These terms also include our subsidiaries, Liaoning Nengfa Weiye Energy Technology Company Ltd., a corporation organized and existing under the laws of the Peoples’ Republic of China (“PRC”), and Liaoning Nengfa Weiye Smart Valve Technology Co., Ltd., a limited liability corporation organized and existing under the laws of the PRC.

NF Energy Saving Corporation was incorporated under the laws of the State of Delaware under the name of Galli Process, Inc. on October 31, 2000 for the purpose of seeking and consummating a merger or acquisition with a business entity organized as a private corporation, partnership, or sole proprietorship. On December 31, 2001, Galli Process, Inc. became a majority owned subsidiary of City View TV, Inc., a Florida corporation (“City View”). On February 7, 2002, Galli Process, Inc. changed its name to Global Broadcast Group, Inc. On March 1, 2002, City View merged into Global Broadcast Group, Inc., which was the surviving entity. On November 12, 2004, the Company changed its name to Diagnostic Corporation of America. On March 15, 2007, we changed our name to NF Energy Saving Corporation of America, and on August 24, 2009, the Company further changed its name to NF Energy Saving Corporation, in both instances to more accurately reflect our business after the Plan of Exchange (see below). Our principal place of business is 3106, Tower C, 390 Qingnian Avenue, Heping District, Shenyang, P. R. China 110015. Our telephone number is (8624) 2560-9775.

On November 15, 2006, we executed a Plan of Exchange (“Plan of Exchange”), among the Company, Liaoning Nengfa Weiye Pipe Network Construction and Operation Co. Ltd. (“Nengfa”), the shareholders of Nengfa (the “Nengfa Shareholders”) and Gang Li, our Chairman and Chief Executive Officer (“Mr. Li”). At the closing of the Plan of Exchange, which occurred on November 30, 2006, we issued to the Nengfa Shareholders 12,000,000 shares of our common stock, or 89.4% of our then outstanding common stock, in exchange for all of the shares of capital stock of Nengfa owned by the Nengfa Shareholders. Immediately upon the closing, Nengfa became our 100% owned subsidiary, and the Company adopted and implemented the business plan of Nengfa.

On January 31, 2008, to better reflect our energy technology business, we changed the name of Nengfa to Liaoning Nengfa Weiye Energy Technology Company Ltd. (“Nengfa Energy”). Nengfa Energy’s area of business includes research and development, processing, manufacturing, marketing and distribution of energy saving flow control equipment; manufacturing, marketing and distribution of energy equipment, wind power equipment and fittings; energy saving technical reconstruction; and energy saving technology consulting services.

On August 26, 2009, the Company completed a 3 to 1 reverse share split of its common stock. As a result, the total number of shares of outstanding common stock changed from 39,872,704 pre-split to 13,291,387 post-split shares.

On September 15, 2010 the Company completed a 2.5 to 1 reverse share split of its common stock, the total number of shares of outstanding common stock changed from 13,315,486 pre-split to 5,326,501 post-split shares.

| 3 |

On October 4, 2010 our common stock commenced trading on the Nasdaq Global Market. On March 7, 2012, and upon approval by NASDAQ, our common stock transferred from the Nasdaq Global Market to the Nasdaq Capital Market, Our common stock trades on the Nasdaq Stock Market under the ticker symbol “NFEC”.

On November 26, 2015 , a new company devoting to intelligent products was set up which is named by ” Liaoning Nengfa Weiye Smart Valve Technology Co. Ltd”. (“Nengfa Smart Valve”).“Liaoning Nengfa Weiye Energy Technology Co. Ltd” owns approximately 40% of the shares in this new company.

The structure of our corporate organization is as follows:

Business Description

NFEC is dedicated to energy efficiency enhancement in two fields: (1) manufacturing large diameter energy efficient intelligent flow control systems for thermal and nuclear power generation plants, major national and regional water supply projects and municipal water, gas and heat supply pipeline networks; and (2) energy saving technology consulting, optimization design services, energy saving reconstruction of pipeline networks and contractual energy management services for China’s electric power, petrochemical, coal, metallurgy, construction, and municipal infrastructure industries.

NFEC has received many awards and honors from China’s regulators, professional associations and renowned international organizations, including the ISO 9001:2008 certification from Det Norske Veritas Management System, the Liaoning Provincial Government’s Award of Innovative Enterprise with Best Investment Return Potentials, the Special Industrial Contribution Award of the ESCO Committee of China Energy Conservation Association, and the “Contract-abiding and credit enterprise” Award by the Liaoning State Local administrative bureau for industry and commerce. NFEC was awarded of “Hi-tech enterprise” by Liaoning Technology bureau in 2013.

NFEC enjoys a reputation as a leader and dedicated energy saving company in China for over 15 years. Its professional capacity as a provider of energy services is officially certified by China’s National Development and Reform Commission (NDRC). It has been a corporate member on the Board of the ESCO Committee of China Energy Conservation Association and a founding member of China Standardization and Technical Consortium for Energy Conservation and Emission.

| 4 |

As a certified energy service provider, NFEC is entitled to various tax breaks and energy saving awards created by Chinese governments at national, provincial and local levels. The major tax incentives by the central government include a two-year corporate income tax exemption plus a three-year reduction of corporation income tax for all energy performance based, profit sharing energy service projects. The government policy also incentivizes NFEC’s clients with tax refunds on goods and properties of the energy saving projects when NFEC transfers to them at the end of the energy service contracts.

The current principal development focus of NFEC is to renew the product, such as large intelligent flow control facility and to provide our Company with more advanced technology to supply high grade energy efficient and safety reliant products for high end markets.

Our corporate goal is to maintain our established position as a leading provider of energy efficiency flow control systems, a cutting edge innovator with clean energy and energy efficiency technologies, and a total energy efficiency solution and service provider dedicated to maximum returns to our investors, partners, clients and environment.

Products and Services

At present, our products and services include:

1. Provide the large-diameter smart flow control device for China’s electric power generation, water supply, heating supply and gas supply industries.

2. Provide the equipment related to desulfurization, denitration and dust removal for China’s electric power generation, metallurgy, petrochemical, steel, cement and heating supply industries.

3. Provide consulting services, such as energy efficiency optimization design, energy consuming equipment retrofit and engineering, equipment maintenance and services, energy management based on Energy Performance Contracts for China’s industrial enterprises.

Some landmark contracts the Company has completed include:

| ¨ | In 2007, Nengfa Energy received contracts for our products and services to be used in three sub-sections of the prominent “South to North Water Transfer and Supply Project.” The subsections were completed and passed inspection in 2008. |

| ¨ | In 2008, the Company received flow control equipment contracts from seven cities in Liaoning Province for their water supply systems. |

| ¨ | In 2009, the Company was awarded several flow control equipment supply contracts, including one for the Xijiang diversion project of Guangdong Province, and one for Phase 1 of Guangdong Yuedian Huilai Power Plant. |

| ¨ | In 2010, the Company received contracts for our products and services to be used in over 50 companies, including Chongqing Water Turbine Company, Chongqing Fangneng Electricity Power Company, Zhejiang Zheneng Jiahua Electricity Power Co. Ltd, and Shaoxing Binhai Thermal Power Company, and a project contract with a Fuxin inner-Mongolian county. |

| 5 |

| ¨ |

In 2011, the Company received contracts for our products, including from Jiangsu Changshu Electricity Power Ltd, India RODA Supercritical Coal Fired Power Station, India KAWAI Supercritical Coal Fired Power Station, Zhejiang Zheneng Zhongmei Zhoushan Coal and Electricity Company, Shenzhen Qinglinjing Water diversion project, Chongqing Yunneng Electricity Power Ltd, and Shenyang Mining Machinery Ltd.

|

| ¨ |

In 2012, the Company received contracts from Beijing South to North Water Diversion Operation and Management Center, Shanxi Kegong Longsheng Technology Ltd, Huaihu Coal Ltd, Chongqing Water-Turbine Ltd, Shenergy Company Limited, Shanghai Qingcaosha City-Environment Project (South Branch Project), Luanhe Power Station of China Guodian Corporation ,Qiangui Power Ltd , Guizhou Province, Guihang Nenghuan Refrigeration Engineering Ltd, Shanghai City , Electric Power Construction Corporation (Zambia’s project) , Shandong Province; Lu Electric International Trading corporation, and Shandong Province ( Philippines project).

|

|

In 2013, the Company received contracts from Zheneng Zhenhai Gas Thermal Power Co. Ltd; Chongqing Water Turbine Factory Ltd; Chongqing Wanliu Power Co., Ltd; Dalian Petrochemical Company of SenoPech; China National Electric Power Engineering Co. Ltd ; Xinyu Iron and Steel Ltd; Shandong Electric Power Corporation; Jiajie Gas-fired Cogeneration Branch of Shanxi New Energy Industry Group; and the Amedyan Power Co Ltd of the State Grid Company. . | |

|

In 2014, the Company received contracts from LXB Water Supply Co., Ltd. Shandong Luneng Huaneng Power International Trade Company of Taiyuan Dongshan Gas Turbine Thermal Power Co., Ltd., Beijing Sea of Inner Mongolia Coal Gangue Power Co., Ltd. and other companies. , At the same time, the Company has also completed the installation of desulfurization, denitration and dust removal systems at the 660T/h boiler room of the Chinese Aviation Company.

| |

| In 2015, the Company received contracts from Gansu Coal Group Co.Ltd, Nanning Tiefa Valve Co., Ltd, Weinan Dongnan Bureau , Shanxi Ruiguang power Co., Ltd and Harbin Binhe Technology Co., Ltd,,Chifeng Jianxi Shangrao water diversion project, Inner Mongolia Caisen hydropower station, Chifeng Xincheng thermal power co.,Ltd , Sinkiangr conservancy hub project and Italian Tecnedil International SRL, etc |

Production and Sales of Energy Saving Flow Control Equipment

The Company’s current principal business is the production and sales of energy-saving flow control equipment, and intelligent flow control equipment. This business accounts for the majority of the Company’s revenues.

Pipeline transport is one of the basic modes of transportation together with rail transport, road transport, air transport and water transport. Water, gas, oil, and heat rely on various kinds of pipelines and pipe networks to be transported to end users. In the case of water pipelines, such systems are also used for public health and safety, and waste and flood control.

| 6 |

The key to the efficiency and energy conservation of the pipeline transportation process is the valve and the flow control equipment. Having unique technology in this field, the Company has obtained four patents and holds fourteen utilization model patents in China for flow control devices, especially in the area of the bidirectional seal zero revelation installation system with its special characteristics. Using valves of this type can result in reduced energy consumption by 20% for customers compared to traditional valves. The reduced energy consumption thereby increases the efficiency of the pipeline system. It is widely used in the fields of electric power, hydro power, petroleum, and natural gas. The Company’s super intelligent flow-control device was awarded “Number One Energy Saving Valve of China” by the Chinese Energy Conservation Association. Our products are exported to the United States, Russia, Turkey, Italy, Bulgaria, South Korea, Vietnam, India, Thailand, South Africa, Iraq, and Afghanistan.

After the new facility was completed, the new large numerical control machine tool improved the manufactured quality of the Company’s products. The “M type high torque flow control device” providing for LXB project, the maximum output torque is 1.7 million N.m , 90 degrees of rotation and total ratio is 175:1. Not only improves the quality of product , but also reduces the cost such that has reached international advanced level.

Another main business is the energy saving technology engineering and service, the Company will continue to develop comprehensive energy conservation and energy reduction equipment and services, and to pursue research development and improved manufacturing of flow control and clean energy related equipment.

Energy Saving Reconstruction Projects

1. Energy Efficiency Retrofitting Projects on Industrial Boilers and Furnaces

Our business also focuses on the reconstruction of various industrial boiler/furnace systems with the objective of modernization and improvement in the overall efficiency of existing systems. Efficiency can be expressed in several ways, such as lower operating costs, reduced energy consumption, recapture of by-products which can be used for other purposes, and pollution reduction.

China’s industrial boilers and furnaces are used mainly in the iron and steel, metallurgy, building materials, machinery manufacturing, chemical industry and other similar energy consumption industries. Their energy consumption accounts for about 10% of China’s total energy consumption. It is estimated that as many as half of the enterprises have outdated technology and equipment, and experience a significant waste of energy. Using our existing technology, we can reconstruct the boiler’s or furnace’s structure, its heat source system, combustion system, and control system, and thereby both improve the overall efficiency of the system and yield important conservation and pollution control benefits.

One of the most important opportunities for the Company is to undertake projects that refurbish or reconstruct industrial boilers and create cogeneration opportunities for coal fired boilers. It is estimated that as many as 95% of the industrial boilers in China use coal as fuel. These types of industrial boilers are very inefficient because: most industrial coal burning boilers are traditional traveling grate boilers. Only a small portion of the coal fired boilers are equipped with advanced technology, such as pulverized coal combustion or circulating fluidized bed. Due to their combustion type and low thermal efficiency, traditional coal fired boilers emit more CO2 and NOx, and they are typically under their manufacture rated operation life. Overall, it is estimated that these types of boilers are operating at about 60-70% of energy efficiency, which is approximately 20% below that of international best practice. The inefficiency, in part, results from their use of mixed sizes of coal particles in layer combustion. Among these types of boilers, about 60% of them are clockwise rotation boilers. The use of the differing sizes of the coal particles results in remarkable low combustion efficiency, due to poor ventilation and accumulation of dust which chokes the combustion. Therefore, coal is not totally burned and there is a loss of potential energy. The current methods of coal feed to the boilers and the current combustion cannot solve this problem. At present, there are approximately 0.3~0.4 million sets of traveling grate boilers in-use in China, the Company sees a significant opportunity to focus on boiler transformation technology and projects.

| 7 |

The Company’s solution is to redesign and reconstruct elements of an existing boiler or boiler system to improve its overall performance and increase its optimization rates. This is done in a number of different ways, such as the following:

The Company has mature technology and know-how to redesign and reconstruct elements of existing coal fired boiler and boiler system to improve their overall performance and optimize their energy efficiency and reduce their emissions. This can be done in a number of different ways, such as the following:

a) Traditional boilers using pulverized coal or with a clockwise rotation chain grate system can be refitted with circulating fluidized bed combustion technology. This change has the benefit of allowing the boiler to improve the thermal efficiency while using low grade coal. The ash from the fluidized bed combustion system can be used for making building materials, which is a valuable by-product and reduces pollution output.

b) The control system of a boiler can be either reconstructed or modified to improve the operations of the unit and system.

c) The coal feeding system of a boiler can be altered to provide more efficient coal layer arrangement according to different volume and nature of the coal. As a result, combustion rate of coal can be remarkably enhanced in the retrofitted boiler . This technology can effectively improve fuel use efficiency and lower emission and operation cost.

d) Another change that can be made to boilers is to improve the ventilation system by adding the right amount of fresh air and increase the turbulence based on computer aided calculation, which can result in increased fuel combustion efficiency and hence reducing the operating costs.

e) One of the most important improvements that the Company seeks to introduce into existing and new boiler systems are methods to reclaim discharged water. The Company designs recovery equipment which permits recovery of significant amounts of the waste water used in a traditional boiler. This recovery can also improve the capture of pollutants by the boiler system.

f) A boiler’s heat recovery can be improved, whether it is coal, natural gas or petroleum fueled. By-product heat can be used in a number of different ways, such as to create steam for other uses or localized heating of the factory. The capture and use of the residual heat reduces its emission into the atmosphere thereby reducing heat pollution. This can be an additional source of income or help reduce operating costs and pollution.

The Company is capable of designing and introducing steam thermal systems into existing systems with the effect of recovering the condensed water, eliminating the leakage losses due to faulty or worn steam trap valves and improving the heat preservation systems.

| 8 |

2. Motor Drive Reconstruction

In China, motor drive systems use about two thirds of the total electricity consumption of the country. About 90% of these motors are AC asynchronous motors. Nengfa Energy redesigns such systems to convert them so that they can be used for variable load fans and pumps through frequency conversion and speed regulation technology. Nengfa Energy focuses on the reconstruction and energy conservation of the fans of power station boilers, industrial furnaces and kilns, and the energy-saving pumps in the cold/hot water pipe system. As we analyze the whole industrial reconstruction projects, we can also provide power conservation reconstruction in solid material conveyor systems used in the mining, metallurgy, iron and steel industries.

It is estimated that approximately 12% of China’s electric power consumption is for lighting. As one of the most important energy-saving projects, the Chinese government plans to distribute 150 million energy-saving lamps throughout the country during the “Eleventh Five Year Plan” period through a fiscal subsidy in an effort to replace inefficient incandescent lamps and other lighting products. The government also plans to reduce the consumption of power by changing the use of lighting through a rational distribution of public lighting, improving the quality of power consumption and introducing on-demand controls.

3. Energy-Saving and Reconstruction of Steam Heat Energy System

As a high quality source of secondary energy, steam is widely used in petroleum, petrochemical, chemical, paper making, brewing, tobacco, steel, pharmaceutical, packaging, machinery, and electronics among other industries. The total energy efficiency of steam is directly determined by the system’s energy efficiency. The characteristics of the steam and condensation system are highly complex, due to factors such as the need for a condensation traps and vacuum breakers, the damage from water hammer, corrosion of the heat exchanger and leakage, condensation, pollution and purification, steam consumption’s imbalance in winter and summer, steam consumption’s mismatching between high and low pressures, the flash steam problem, and steam leakage. For a long time, due to the irrationality of system design, the complexity of the system itself, the negligence of owners, the imprecision of management, and the deficiency of maintenance, the overall energy efficiency of steam systems in China is very low. Therefore, the Company believes there is a significant opportunity for energy savings in steam systems:

1) Approximately 0.5 billion tons of standard coal is consumed annually in China, which is more than 1/3 of the total national consumption of fossil fuels of the country.

2) The overall energy efficiency of steam systems in China is only approximately 30%, which is 25% lower than that of industrialized countries.

3) The annual energy waste due to the low energy efficiency of steam systems is approximately 120 million ton of coal equivalent (tce), which is estimated to be worth over 120 billion RMB.

4) The annual waste due to inefficient transportation and distribution of steam systems is approximately 180 million tce.

5) Of the more than 1 million traps being used in steam systems in China, 60% of them have above average leakage, 30% of them have serious leakage, and only less than 10% work normally. The waste due to trap leakage is significant.

6) Current condensation systems are generally designed in such a way as to be inappropriate to the system, resulting in the average recovery rate being less than 30% thus; causing large waste of heat energy and water.

| 9 |

Working with energy saving experts in steam systems in China, the Company has built a steam system department. This department has an R&D and design team, which can provide energy conservation solutions for efficient and the long lasting energy saving results. Under normal conditions, the reduction of steam energy cost is generally between 10% and 25%.

Our energy conservation solutions improve energy efficiency in steam systems in five principal ways, covering the entire process of the steam and condensation system: steam generation, steam transportation and distribution, steam consumption, and condensation recovery and condensation purification.

| 1) | Steam generation stage |

Our energy saving measures include: using the boiler’s long-term stable heat sink resources to fully absorb low temperature waste heat and reduce fuel consumption; correctly designing the generator in order to reduce the steam consumption of the deoxygenizing process and increasing the efficiency of the boiler; controlling boiler blowdown and fully utilizing the waste heat of blowdown water; adjusting the steam load with steam accumulator; and improving the quality of steam.

| 2) | Steam transportation and distribution stage |

Our energy saving measures include: designing the most economical flow speed of steam, reducing leakage, draining condensation correctly, filtering dirt and debris, reducing pressure drop loss, improving steam quality, and avoiding water hammer. The most serious problems to be addressed are water hammer, big drops in steam pressure, high steam humidity and low steam quality caused by errors in the design of the condensation trapping system.

| 3) | Steam consumption stage |

In this stage, we improve the energy efficiency of the steam system by studying the difference in details between designed and actual steam consumption of each heat exchanger, and looking for the root causes of excessive energy consumption; consuming lower pressure steam as far as possible when meeting the process’s demands; equipping the system with a vacuum breaker and air valve in beehive heat exchangers; designing a condensation trapping system correctly to avoid waterlogging; controlling temperatures automatically in the heating process; installing a separator for steam and vaporous water in the inlet of important equipment to ensure steam quality; optimizing the condensation pipe system according to the residual pressure of each heat exchanger; and enhancing daily inspection and maintenance.

| 4) | Condensation recovery stage |

In this stage, we improve steam efficiency by optimizing the overall condensation piping system and deploying decentralized, cutting-edge pressure pump recovery technology; comprehensive treatment on flash steam; comprehensive utilization of heat sink resources; and limit water hammer. The key to optimizing the overall condensation piping system is to identify different condensations according to the residual pressure as “strong”, “mainstream” and “weak”, thus minimizing the mutual interference between different residual pressures.

| 10 |

| 5) | Condensation purification stage |

The Company’s “solvent impregnated resin oil desorption technology” can separate emulsified oil molecules and dissolved oil molecules from high temperature condensation directly through the resin’s lipophilicity and hydrophobicity. Before separation, “emulsification breaking”, “capturing” and “enriching” are completed automatically. When the oil molecules adsorbed in the face of the resin reaches a certain saturation level, the enriched oil will be separated from the resin as large oil-drops through the flow impact of condensation water inside the tank. After separation the oil-drops float into an oil-water separator and the off-oil resin will start to work automatically. In the oil-water separator the oils will separate from water automatically.

Nengfa Energy’s condensation iron deprivation technology is called “Powder Ion Exchange Resin Coverage and Filtration Technology”.. We utilize this technology to separate excessive metal oxides, colloids and iron ion (Fe3+ & Fe2+) from high temperature condensation. The technical principles are filtration, adsorption, and ion replacement; the processes are film formation, operating, toggling, back-washing and film formation again.

We estimate the energy saving market for steam systems is very large in China. We believe the annual consumption of steam systems is approximately 0.5 billion tce. The overall energy efficiency of steam systems in China is only approximately 30%, which is 25% lower than well developed countries. The annual energy waste due to low energy efficiency of steam systems is approximately 120 million tce, which is worth over 120 billion RMB. If all the energy saving projects in steam systems were operated under a EPC (Energy Performance Contract) model, and the average profit were to equal three years of energy-saved we estimate, the value of the energy-saving market for steam system in China would be approximately 360 billion RMB.

Patents and Technology

Nengfa Energy currently has been issued four invention patents and has applied for fourteen utility model patents in the PRC. We will strive to maintain the innovation of our products in order to maintain our leading position in the market.

The invention patents include the following:

1. Processing technology of butterfly valve seal (ZL2006 1 0152644.8), which expires on September 26, 2026;

2. Butterfly valve body dynamic seal ring pointing device (ZL2007 1 0159250.X), which expires on December 28, 2027;

3. The closing and locking equipment for valves (ZL2009 1 0011939.7), which expires on June 11, 2029; and

4. Valve body active seal circle position monitor equipment (ZL2009 2 0014504.3), which expires on July 21, 2030.

The utility model patents that we have applied for include the following:

5. An energy-saving heat-sink used in heating (ZL2008 2 0218146.3), with an application date of September 23, 2008

| 11 |

6. A device used in energy-saving boiler combustion (ZL2008 2 0218145.9) , with an application date of September 23, 2008;

7. Butterfly valve sealing ring instruction device (ZL2007 2 0185293.0) , with an application date of December 12, 2007;

8. Butterfly valve with block for opening butterfly plate (ZL2007 2 0185289.4), with an application date of December 12, 2007;

9. Piston flow-adjusting valve with removable piston sealing ring (ZL2007 2 0185288.X), with an application date of December 12, 2007;

10. J-shapes large dimension butterfly valve hard sealing ring (ZL2007 2 0185292.6), with an application date of December 12, 2007;

11. Composite valve sealing ring (ZL2007 2 0185290.7), with an application date of December 12, 2007;

12. Multi-level buffering full oriented valve fuel tank (ZL2007 2 0185287.5), with an application date of December 12, 2007;

13. Fluid control valve on-off speed control device (ZL2007 2 0185286.0), with an application date of December 12, 2007;

14. T-shaped large dimension butterfly valve rubber sealing ring (ZL2007 2 0185291.1), with an application date of December 12, 2007;

15. Butterfly valve with butterfly plate adjusting device (ZL2008 2 0231340.5), with an application date of September 23, 2008;

16. Two-way sealed butterfly valve (ZL 2009 2 0014504.3), with an application date of June 11, 2009;

17. Energy-saving electric valve (ZL2011 2 0393230.0) with an application date of October 14, 2011; and

18. Radial fixed valve seal butterfly valve (ZL2011 2 0393135.0) with an application date of October 14, 2011.

In addition to the patent protection that we seek, we also rely on the confidentiality of our operations, proprietary know-how and business secrets. Although we do not have formal agreements with our employees, we do consider our employees’ work to be proprietary and owned by the Company. Where necessary, we will take steps to protect our intellectual property interests under the laws of the PRC. There can be no assurance that we will be able to enforce our rights if they are improperly taken by our employees or adopted by our competitors outside of sanctioned use and royalty agreements with the Company.

Certain of our service offerings will not be patentable or otherwise be capable of being registered as intellectual property. Therefore, the Company will rely solely on such services being proprietary. As such the Company will have to rely on the services being more advanced or better than its competitors’ offerings or rely on trade secret laws and protections. Such protections in the PRC are considered rather weak and are difficult if not impossible to enforce. Consequently, it may be possible for our competitors to obtain our information and to copy, adopt or adapt our methods, services and technical aspects to their own business with no assurance that we will be able to prevent them from using the intellectual property in competition with us.

| 12 |

The Company does not have any significant trademarks in use at this time. As our business develops, we will consider the advantage of developing specific trademarks for our products and services and have registered those marks with the PRC government authorities for trademark protection.

Markets and Customers

The transport of water and fluid energy, such as oil, gas, steam and hot water depends on pipelines. The intelligent flow control device supplied by NF Energy is an important part in the fluid energy transportation systems. According to “the 12th Five-Year) National Strategic Emerging Industry Development Plan”, China will invest 4 trillion yuan in the next 5-10 years into the South-North Water Diversion Projects.. Since it was founded in 2006, the Company has supplied its products to many projects of this national water works, including the middle and northern Guangxi Xijiang River Water Diversion Project, Shenzhen Water Supply Project, Shanghai Water Diversion Project, and the 7 urban water supply projects in Liaoning Province, three curved water diversion projects in Dandong, and other major domestic water diversion projects. We have the best industry performance in water supply projects. At the same time, we also provide flow control devices and equipment for supercritical thermal power plants and ultra-supercritical coal-fired power plants as well as domestic hydro power generation market which are dominated by China’s state-owned five big power groups. More than 80% of the Company’s annual revenues come from these markets and customers.

In connection with its work on the water diversion project and some of the power plant projects, the Company has a preferred provider agreement with Nengfa Weiye Tieling Valve Joint Stock Co., Ltd. (“Tieling Valve”) under which Nengfa Energy is the preferred provider of the valves and other related flow control equipment that Tieling Valve requires in its own work on the water diversion project. The agreement is in the manner of a right of first refusal whereby Tieling Valve is obliged to offer supply opportunities to Nengfa Energy within its scope of product offerings and expertise, but Tieling Valve is not prohibited from developing other supply arrangements. Tieling Valve and Nengfa Energy have agreed to cooperate to develop and market their respective technologies, equipment, products and services for their respective and mutual benefit, and will work together to examine and expand their respective businesses. Under the agreement, each party retains full right to their respective intellectual property. The agreement terminates in 2021, but by its terms will automatically extend for additional one year terms unless notice of termination is given by one party to the other at least six months prior to the then termination date.

The Company will focus its marketing to the wind power generation and the boiler/furnace industry through participation in and addressing government organizations and industry associations related to energy conservation and emission reduction. Marketing will also focus on equipment suppliers and end-users such as the larger and medium sized high energy consumption enterprises that provide or use the kinds of products and services that the Company currently offers or plans to offer. The focus will not only be to sell the products and services, but also to learn of the customer’s needs so that the Company can develop and adapt its products and services to the needs of its customer base. Another important aspect of the marketing strategy will be to participate directly in the consulting and reconstruction services of energy conservation projects organized by government agencies. Nevertheless, the Company plans to continue to participate in the bidding process for government projects, in an effort to enhance its market position.

| 13 |

The Company’s marketing and sales strategy also relies on the use of exclusive agents throughout China who act as marketing agents and after sale service providers. The Company currently has 23 exclusive distributing agents national wide. At certain times each year, the Company provides and organizes training sessions for these agents and their personnel. These sessions provide the Company with a valuable opportunity to gather feedback and to foster an exchange of technical ideas. These agents have agreements with the Company to sell NF flow control equipment and systems. The Company evaluates the performance of these exclusive agents annually, based on how well they achieve the annual sales target established by the Company. The Company typically will terminate its agreement with those agents that miss the sales targets for two consecutive years without good reasons.

Raw Materials

The major raw materials for our production are pig iron, steel, copper, and plastic. We source our materials locally in China. Nengfa Energy is located in Liaoning Province which is China’s largest production base for iron and steel. We have stable long term supply arrangements for our principal raw material suppliers based on long standing business relationships. Since we are located close to the supplies of many of our essential raw materials, we enjoy price and transportation cost advantages over our competitors and competing users. Through our advanced technology and our management of raw materials, we are able to manage and improve our consumption rates of the raw materials we use in production, which results in lower operating expense and extension of our inventories.

Regulatory Compliance

The Company’s products are subject to regulatory standards and enforcement codes which typically require that these products meet stringent performance criteria. Standards are established by industry testing and certification organizations such as the Ministry of Industry and Information Technology of China, the American Society of Mechanical Engineers (A.S.M.E.), the Canadian Standards Association (C.S.A.), the Japanese Standards Association (J.S.A.), the International Association of Plumbing and Mechanical Officials (I.A.P.M.O.), Factory Mutual (F.M.), and Underwriters Laboratory (U.L.). These standards are incorporated into state and municipal plumbing and heating, building and fire protection codes in China.

We maintain stringent quality control and testing procedures at our manufacturing facility in order to manufacture products in compliance with code requirements. Our production management is certified to conform to the ISO 9001 standards by the Det Norske Veritas Management System.

Competition

The Company holds a leading position in the super diameter energy efficient flow control system market in China. The Company has an extensive competitive advantage over Chinese domestic manufactures in this field. Other manufactures that are focusing on the development of different and smaller valve products may enter this field. Our major potential competitor in this field is China Valve Technology.

| 14 |

In the other areas of the Company’s business, there are many different competitors with differing focuses and strengths. To some extent, boilers and furnaces are specialized to particular industries and output requirements. This specialization engenders specialization in the design, manufacture and installation of new equipment and retrofit solutions. Therefore, there are many engineering and manufacturing companies that focus on certain types of boilers and furnaces resulting in a relatively fragmented market for these services. The same is true for the retrofit and reconstruction of other industrial systems for improved energy efficiency, as well as for the localized projects for energy conservation and biomass utilization, and similar projects. Therefore, the competition that the Company faces tends to be localized companies with no dominant players at this time.

The utilization of gasified biomass energy is matured in China. Although the technology is widely used in China, it is still at a stage of individual household build gas digesters, rather with a large scale piped gas supply system. The county-city level gas supply project the Company concentrates on will generate a local area monopoly business operation. There is no direct competition in short term.

We plan to compete based on our ability to address a wide spectrum of solutions in our various market areas. We believe our competitive advantages result from our patented technologies, our strategic relationships with engineering companies, our marketing and our business relationships. We plan to continue to expand these aspects of our business to further grow our core businesses and provide solutions for the energy savings and green energy projects. We intend to participate actively in the government sponsored projects and government contracting.

Research and Development

The research and development expenses are to develop new products or new production technologies. The research and development expenses include the materials and labor costs, application fees for patents and significant improvements to existing products. We incurred $105,168 and $107,872 of research and development expenses in 2015 and 2014, respectively.

Employees

As of December 31, 2015, there were 220 employees including 31 technical staff working in our subsidiaries located in China. We believe we have a good relationship with our employees.

Others

Our internet website address is http://www.nfenergy.com. Through our website, we make available, free of charge, our annual report on Form 10-K, quarterly reports on Form 10-Q, current reports on Form 8-K and any amendments to those reports, proxy statement and registration statements, and all of our insider Section 16 reports, as soon as reasonably practicable after such material is electronically filed with, or furnished to, the Securities and Exchange Commission, or SEC. These SEC reports can be accessed through the “Investors” section of our website.

Investors should carefully consider the following risk factors, in addition to other information included in this annual report, in evaluating NF Energy Saving Corporation and our business. If any of the following risks occur, our business, financial condition and operating results could be materially adversely affected.

| 15 |

Risks Related to Our Business

We have incurred a net loss in each of the past two years and there are no assurances that such losses may not continue.

We incurred a net loss of $969,442 for 2015 and $617,291 for 2014. Our ability to generate net income is dependent upon generating sufficient revenues. If we are unable to generate sufficient revenues, our results of operations and financial condition may be adversely affected.

We are subject to the risks of any growing enterprise, any one of which could limit our growth and our product and market development.

Our operating history makes it difficult to predict how our businesses will develop and where the Company will find success. This is especially true in respect of our expansion into areas other than flow valve technology and their design, sales and installation. Accordingly, we face all of the risks and uncertainties encountered by companies in similar stages of development, such as: (i) uncertain and continued market acceptance for our product extensions and our services; (ii) the evolving nature of the wind energy equipment industry in the PRC, where significant consolidation may occur, leading to the formation of companies which may be better able to compete with us than is currently the case; (iii) the fragmented nature of the boiler and furnace business which may limit our ability to penetrate the market and provide comprehensive solutions on a sufficiently wide basis to make the business profitable; (iv) changing competitive conditions, technological advances or customer preferences could adversely effect the sales of our products or services; (v) maintaining our competitive position in the PRC and competing with Chinese and international companies, many of which have longer operating histories and greater financial resources than us; (vi) continuing to offer commercially successful products to attract and retain a larger base of direct customers and ultimate users; (vii) maintaining effective control of our costs and expenses; and (viii) retaining our management and skilled technical staff and recruiting additional key employees.

If we are not able to meet the challenges of building our businesses and managing our growth, the likely result will be slower growth, lower margins, additional operational costs and lower income.

We may be unable to generate sufficient cash flow from operations or obtain financing in the future to support our operations and expansion.

Having access to sufficient operating funds and capital funds for expansion will affect our ability to execute our business plan. We finance our business mainly through internally generated funds, short-term bank loans and, from time to time, selling equity securities to raise additional capital. There is no guarantee that we will always have internal funds available for our future development or that we will be able to raise capital from investor financing and loans granted by investors and financial institutions in the future. In addition, there may be delays in the process of selling our securities, which may require us to cut back on our operations or expansion activities. Our access to debt or equity financing depends on the investors’ and banks’ willingness to lend to and invest in us, our financial condition and on general conditions in the capital markets. We may not be able to secure additional sources of financing on commercially acceptable terms, if at all. Any shortfall in our cash flow and capital needs may result in our having to curtail our business plans or have an adverse effect on our financial condition.

| 16 |

We believe that we need to raise additional capital for the expansionary elements of our business plan, which financing may not be available or available on terms favorable to us.

During the next phase of our business development, as we complete Phase II of our new manufacturing facility and continue our planned expansion into manufacture of energy-saving equipment and other aspects of the energy savings industry, including steam energy, we believe that we will need to raise additional capital from outside sources during the next year or two. We cannot be certain that we will be able to obtain additional financing on favorable terms, if at all. One possible impediment to raising capital is the tightening credit policies of the Chinese banks and the continued effects of tightening in the global credit markets as a result of the recent economic financial crisis. If we cannot raise additional capital on acceptable terms, we may not be able to develop or enhance our products or services, take advantage of future opportunities or respond to competitive pressures or unanticipated requirements. We cannot be sure that we will be able to secure all the financing we will require, or that it will be available on favorable terms. If we are unable to obtain any necessary additional financing, we will be required to substantially curtail our approach to implementing our business objectives. Additional financing may be debt, equity or a combination of debt and equity. If equity is used, it could result in significant dilution to our shareholders.

Efforts to protect our intellectual property rights and to defend against claims against us can increase our costs and will not always succeed. Any failures could adversely affect our sales and results of operations or restrict our ability to conduct our business.

Intellectual property rights are important to many aspects of our business. We actively pursue patent protection in our flow valve business, and we expect to pursue intellectual property rights in our other business endeavors as we develop unique solutions to business demands. We, however, may be unable to obtain protection for our intellectual property. Even if protection is obtained, competitors may raise legal challenges to our rights or illegally infringe on our rights, including through means that may be difficult to prevent, detect or defend. In addition, because of the rapid pace of technological change and the confidentiality of patent applications in some jurisdictions, competitors may be issued patents from applications that were unknown to us prior to issuance. The patents of others could reduce the value of our commercial or pipeline of products or, to the extent they cover key technologies on which we have unknowingly relied, require that we seek to obtain licenses at a financial cost to us or cease using the technology, no matter how valuable the patents may be to our business. We cannot assure you we would be able to obtain such licenses on acceptable terms. Also, litigation may be necessary to enforce our intellectual property rights, protect our trade secrets or determine the validity and scope of our and the proprietary rights of others. There is a risk that the outcome of such litigation will not be in our favor. Such litigation may be costly and may divert management attention as well as expend other resources which could otherwise have been devoted to our business. An adverse determination in any such litigation will impair our intellectual property rights and may harm our business, prospects and reputation. In addition, we have no insurance coverage against litigation costs and would have to bear all costs arising from such litigation to the extent we are unable to recover such costs from other parties. The occurrence of any of the foregoing may harm our business, results of operations and financial condition.

Finally, implementation of PRC intellectual property-related laws has historically been limited, primarily because of ambiguities in the PRC laws and difficulties in enforcement. Accordingly, intellectual property rights and confidentiality protections in China may not be as effective as in the United States or other countries, which increases the risk that we may not be able to adequately protect our intellectual property.

| 17 |

For aspects of our business we rely on strategic relationships, and there is no assurance that we will be able to renew these arrangements.

We have several strategic relationships which provide us with access to technology and provide us with a competitive advantage. These include the relationships with Shanghai Electric Co., LTD., Sichuan Eastern Electric Co., LTD, Harbin Electric Co., LTD, China Datang Corporation, China Huadian Group, China Huaneng Group and China Guodian Group. There is no guarantee that any of these agreements and arrangements will provide the benefits that we hope will result or that the relationships will be renewed on substantially similar terms or at all. Moreover, there is no assurance that any steps we have already taken or might take in the future will ensure the successful renewal of any or all our rights or the granting of further new rights or that the terms of any renewals would not be significantly less favorable to us than the terms of our current agreements. The loss of such arrangements or diminution of the rights may have an adverse impact on our business development, including product offerings, research and development and competitive position.

We derive a substantial part of our revenues from several major customers, therefore if we lose any of these customers or they reduce the amount of business they do with us in the future, our revenues may be affected

Our largest customer, Nengfa Weiye Tieling Valve Joint Stock Co. Ltd, accounted for 83 % of our revenues for the year ended December 31, 2015, Our second largest customer, Italian Tecnedil International SRL accounted for 5% of our revenue in the year ended December 31, 2015. As of December 31, 2015, these two customers accounted for 88% in our total revenue. These customers may not maintain the same volume of business with us in the future. If we lose any of these customers or they reduce the amount of business they do with us, our revenues may be materially and adversely affected. Although we have a strategic partnership with our second largest customer and a preferred provider agreement with our largest customer, there can be no assurance that these customers will continue to provide the current level of demand or will not seek to modify or terminate their respective agreements.

Our technology may not satisfy the changing needs of our customers.

With any technology, including the technology of our current and proposed products, there are risks that the technology may not successfully address our customers’ needs. Certain of our product offerings in relation to the wind energy equipment will be new for the Company. While we have already established successful relationships with our customers, their needs may change or vary. This may affect the ability of our present or proposed products to address all of our customers’ ultimate technology needs in an economically feasible manner.

We may not be able to keep pace with rapid technological changes and competition in our industry.

While we believe that we have hired or engaged personnel and outside consultants who have the experience and ability necessary to keep pace with advances in technology, and while we continue to seek out and develop “next generation” technology through our research and development efforts, there is no guarantee that we will be able to keep pace with technological developments and market demands in this evolving industry and market. In addition, our industry is competitive in various aspects. Although we believe that we have developed strategic relationships to best penetrate the Chinese market, we face competition from other manufacturers of products similar to our products and services. Some of these companies have significant advantages over us with respect to their products, marketing and services, and their financial resources and customer relationships.

| 18 |

We may experience high accounts receivable balances from time to time, which may have an adverse effect on our operating profitability and cash flow and financing needs.

Although we generally have a 90 to 270 day accounts receivable period, if our customers extend the period in which they pay, we will experience a reduced cash flow, which could have an adverse effect on our ability to fund our operations and growth. One result may be that we will have to obtain outside financing and our operating expenses will increase. Extension of the accounts receivable period may also result in reduced collections, which will adversely affect our operations and profitability.

To the extent that we depend on government projects, our business is dependent on government policy and, to some extent, government funding and government contracts.

Although we do not characterize our business as a government contractor, some aspects of our business are indirectly dependent on government policy, government funding, and government contracts. For example, the South to North Water Diversion Project is largely a government funded project, and our customers are contractors with the government. Similarly, our energy-saving projects and adjustments of our products and services are dependent on the policies issued by the government. As a consequence, it is possible that our requirements based on the products and services to be provided will be diminished resulting in a decrease in our revenue. Much of the pollution control and green industries are dependent on government policy to implement societal improvements. Our business has a number of aspects that are dependent on the government and our products, services and revenues are dependent on policies that can change if the government officials determine to redirect attention and investment to other aspects of society and industrial development.

Additionally, as a number of our customers are dependent on the government for their revenues through the provision of products and services on government contracts or government funded projects, there may be delays in our receiving payment for our products and services.

Fluctuation in the availability and cost of our raw materials may have an adverse effect on our operations and results of operations.

A portion of the inventory of raw materials and parts may be affected by fluctuations in the availability of the items and the price. Such things may include steel, electronic components, power systems, paints and welding rods. We do not generally have long term supply contracts with our suppliers, but rely on long standing relationships. To the extent that we are not able to obtain the required materials and parts necessary to enable us to fabricate our products, or we are required to pay more for such items, then there could be an adverse effect on our operations and our results of operations.

We may be unable to effectively manage our growth.

As we expand our business into several different areas of energy savings and green industry, we will need to manage our growth effectively, which may entail devising and effectively implementing business plans, training and managing our growing workforce, managing our costs, and implementing adequate control in our reporting systems in a timely manner. We may not be able to successfully manage our growth. Our failure to do so could affect our success in executing our business plan and adversely affect our revenues, profitability and results of operations.

| 19 |

If we fail to successfully manage our planned expansion of operations, our growth prospects will be diminished and our operating expenses could exceed budgeted amounts.

Our ability to offer our products and services in an evolving market and in different markets requires effective planning and management process. This rapid growth places significant demand on our managerial and operational resources and our internal training capabilities. In addition, we plan to increase our total work force. This growth will place a substantial burden on our management team. To manage growth effectively, we must implement and improve our operational, financial and other systems, procedures and controls on a timely basis and expand, train and manage our workforce, particularly our sales and marketing and support organizations. We cannot be certain that our systems, procedures and controls will be adequate to support our current or future operations or that our management will be able to handle such expansion and still achieve the execution necessary to meet our growth expectations. Failure to manage our growth effectively could diminish our growth prospects and could result in lost opportunities as well as operating expenses exceeding the amount budgeted.

If we fail to establish and maintain an effective system of internal control, we may not be able to report our financial results accurately or to prevent fraud. Any inability to report and file our financial results accurately and timely could harm our business and adversely impact the trading price of our common stock.

We are required to establish and maintain internal controls over financial reporting, disclosure controls, and to comply with other requirements of the Sarbanes-Oxley Act and the rules promulgated by the SEC thereunder. Our management, including our Chief Executive Officer and Chief Financial Officer, cannot guarantee that our internal controls and disclosure controls will prevent all possible errors or all fraud. A control system, no matter how well conceived and operated, can provide only reasonable, not absolute, assurance that the objectives of the control system are met. In addition, the design of a control system must reflect the fact that there are resource constraints and the benefit of controls must be relative to their costs. Because of the inherent limitations in all control systems, no system of controls can provide absolute assurance that all control issues and instances of fraud, if any, within the Company have been detected. These inherent limitations include the realities that judgments in decision-making can be faulty and that breakdowns can occur because of simple error or mistake. Further, controls can be circumvented by individual acts of some persons, by collusion of two or more persons, or by management override of the controls. The design of any system of controls also is based in part upon certain assumptions about the likelihood of future events, and there can be no assurance that any design will succeed in achieving its stated goals under all potential future conditions. Over time, a control may become inadequate because of changes in conditions or the degree of compliance with policies or procedures may deteriorate. Because of inherent limitations in a cost-effective control system, misstatements due to error or fraud may occur and may not be detected.

Our operations are vulnerable to natural disasters or other events.

Our operating income may be reduced by natural disasters, in locations where we own and/or operate significant manufacturing facilities or are working on significant projects. Some types of losses, such as from earthquake, severe winter storms and environmental hazards, may be either uninsurable or too expensive to justify insuring against. Should an uninsured loss or a loss in excess of insured limits occur, we could lose all or a portion of the capital we have invested in any particular property, as well as any anticipated future revenue from such property.

| 20 |

Our products may contain defects, which could adversely affect our reputation and cause us to incur significant costs.

Despite numerous testing and quality controls, defects may be found in existing or new products. Any such defects could cause us to incur significant return and exchange costs, re-engineering costs, divert the attention of our engineering personnel from product development efforts, and cause significant customer relations and business reputation problems. Any such defects could force us to undertake a product recall program, which could cause us to incur significant expenses and could harm our reputation and that of our products. If we deliver products with defects, our credibility and the market acceptance and sales of our products could be harmed.

Our business could be subject to environmental liabilities.

We use certain hazardous substances in our operations. Currently we do not anticipate any material adverse effect on our business, revenues or results of operations, as a result of compliance with Chinese environmental laws and regulations. However, the risk of environmental liability and charges associated with maintaining compliance with environmental laws is inherent in the nature of our business, and there is no assurance that material environmental liabilities and compliance charges will not arise in the future.

We have limited business insurance coverage in China

The insurance industry in China is still at an early stage of development. Insurance companies in China offer limited business insurance products. As a result, we do not have any business liability or disruption insurance coverage for our operations in China. Any business disruption, litigation or natural disaster might result in substantial costs and diversion of resources.

Because our funds are held in banks in the PRC that do not provide insurance, the failure of any bank in which we deposit our funds could affect our ability to continue in business.

Banks and other financial institutions in the PRC do not provide insurance for funds held on deposit. A portion of our assets are in the form of cash deposited with banks in the PRC, and in the event of a bank failure, we may not have access to our funds on deposit. Depending upon the amount of money we maintain in a bank that fails, our inability to have access to our cash could impair our operations, and, if we are not able to access funds to pay our suppliers, employees and other creditors, we may be unable to continue in business.

We substantially depend on a few key personnel who, if not retained, could cause declines in productivity and operational results and loss of our strategic guidance, all of which would diminish our business prospects and value to investors.

Our success depends to a large extent upon the continued service of a few executive officers and key employees, including, Mr. Gang Li, our Chairman, Chief Executive Officer and President. The loss of the services of one or more of our key employees would have an adverse effect on us and our PRC operating subsidiaries, as these individuals play a significant role in developing and executing our overall business plan and maintaining customer relationships and proprietary technology systems. While none of our key personnel is irreplaceable, the loss of the services of any of these individuals would be disruptive to our business. We believe that our overall future success depends in large part upon our ability to attract and retain highly skilled managerial and marketing personnel. There is no assurance that we will be successful in attracting and retaining such personnel on terms acceptable to the Company or the employee. Inadequate personnel will limit our growth, and will be seen as a detriment to our prospects, leading potentially to a loss in value for investors.

| 21 |

We are controlled by a small group of our existing stockholders, whose interests may differ from other stockholders.

Our Chairman, Chief Executive Officer and President, Mr. Gang Li, beneficially owns approximately 41.19% of the outstanding shares of our common stock and is our largest single stockholder. Together with, Ms. Lihua Wang, who is our Chief Financial Officer, they own 51.49% of the outstanding shares of our common stock. Accordingly these stockholders acting together will have significant influence in determining the outcome of any corporate transaction or other matter submitted to the stockholders for approval, including mergers, consolidations, the sale of all or substantially all of our assets, election of directors and other significant corporate actions. They will also have significant influence in preventing or causing a change in control. In addition, without the consent of these stockholders, we may be prevented from entering into certain transactions which may be beneficial to our other stockholders. The interests of these stockholders may differ from the interests of the other stockholders.

We are responsible for the indemnification of our officers and directors.

Delaware law and our Bylaws provide for the indemnification of our directors, officers, employees, and agents, under certain circumstances, against costs and expenses incurred by them in any litigation to which they become a party arising from their association with or activities on our behalf. Consequently, we may be required to expend substantial funds to satisfy these indemnity obligations. Any payment in respect of these indemnification rights could have an adverse effect on our cash flow and our results of operations.

If we fail to implement effective internal controls required by the Sarbanes-Oxley Act of 2002, or remedy any material weaknesses in our internal controls that we may identify, such failure could result in material misstatements in our financial statements, cause investors to lose confidence in our reported financial information and have a negative effect on the trading price of our common stock.

Section 404 of the Sarbanes-Oxley Act of 2002 requires management of public companies to develop and implement internal controls over financial reporting and evaluate the effectiveness thereof. A material weakness is a deficiency or a combination of deficiencies, in internal control over financial reporting such that there is a reasonable possibility that a material misstatement of our annual interim financial statement will not be prevented or detected on a timely basis. Due to the Company’s limited resources, the Company does not have accounting personnel with extensive experience in maintaining books and records and preparing financial statements in accordance with US GAAP which could lead to untimely identification and resolution of accounting matters inherent in the Company’s financial transactions in accordance with US GAAP.

Any failure to complete our assessment of our internal controls over financial reporting, to remediate any material weaknesses that we may identify, including the one identified above, or to implement new or improved controls, could harm our operating results, cause us to fail to meet our reporting obligations or result in material misstatements in our financial statements. Inadequate disclosure controls and procedures and internal controls over financial reporting could also cause investors to lose confidence in our public disclosures and reported financial information, which could have a negative effect on the trading price of our common stock.

The inability to inspect may prevent the PCAOB from regularly evaluating our auditor’s audits and its quality control procedures since our auditors come from Hong Kong rather than United States.

Public company auditors are required by law to undergo regular Public Company Accounting Oversight Board, or PCAOB, inspections to assess their compliance with U.S. law and professional standards in connection with their audits of public company financial statements filed with the SEC. Due to the position taken by the authorities in China, the PCAOB was prevented from conducting inspections of certain registered firms in Hong Kong to the extent that their audit clients had operations in China.

| 22 |

The inability of the PCAOB to conduct inspections of auditors in the PRC makes it more difficult to evaluate the effectiveness of our independent registered public accounting firm’s audit procedures or quality control procedures as compared to auditors outside of the PRC that are subject to PCAOB inspections, which could cause investors and potential investors in our stock to lose confidence in our audit procedures and reported financial information and the quality of our financial statements.

The Company’s auditor HKCMCPA Company Limited, Certified Public Accountants is subject to PCAOB inspection. The auditor was inspected in 2008 and the corresponding inspection report was issued under the name of Zhong Yi (Hong Kong) Company Limited. The most recent inspection report has been issued in 2014.

Because our auditor is located in Hong Kong and we have operations in China, in the event that PCAOB becomes unable to inspect the audit work and practices of our auditor, our investors in U.S. markets who rely on audit reports from our auditor will be unable to factor the publicly reported findings of regular recurring PCAOB inspections of audit firms and their quality control practices into their decision making processes.

Risks Related to Our Company’s Common Stock

Future sales of our common stock could adversely affect our stock price.

We have a substantial amount of outstanding shares held by persons that are able to sell or will be able to sell in the near future under Rule 144.The holders of these shares subject to Rule 144 include our significant shareholders and a number of investors. If our shareholders sell substantial amounts of our common stock in the public market, the market price of our common stock could be adversely affected. In addition, the sale of these shares could impair our ability to raise capital through the sale of additional equity or equity based securities.

Trading volume of our common stock has fluctuated from time to time, which may make it difficult for investors to sell their shares at times and prices that investors feel are appropriate.

To date, the trading volume of our common stock has fluctuated. Generally, lower trading volumes adversely effects the liquidity of our common stock, not only in terms of the number of shares that can be bought and sold at a given price, but also through delays in the timing of transactions and reduction in security analysts’ and the media’s coverage of us. This may result in lower prices for our common stock than might otherwise be obtained and could also result in a larger spread between the bid and asked prices for our common stock.

The Nasdaq Capital Market imposes listing standards on our common stock that we may not be able to fulfill, thereby leading to a possible delisting of our common stock.

As a listed Nasdaq Capital Market company, we are subject to rules covering, among other things, certain major corporate transactions, the composition of our Board of Directors and committees thereof, minimum bid price of our common stock and minimum stockholders equity. The failure to meet the Nasdaq Capital Market requirements may result in the de-listing of our common stock from the Nasdaq Capital Market, which could adversely affect the liquidity and market price thereof.

| 23 |

The closing bid price of our common stock has been below $1.00 for more than 30 consecutive business days. Nasdaq notified us on January 11, 2016 that we have a 180 day grace period to re-gain compliance before being subject to de-listing. We cannot be sure that the closing bid price of our common stock will comply with the Nasdaq requirements for continued listing nor can we assure that our common stock will not be de-listed. If our common stock were to be de-listed, selling our common stock could be more difficult because smaller quantities of shares would likely be bought and sold, transactions could be delayed, and security analysts’ coverage of us may be reduced. In addition, in the event our common stock is de-listed, broker-dealers have certain regulatory requirements imposed upon them, which may discourage broker-dealers from effecting transactions in our common stock, further limiting the liquidity thereof. These factors could result in lower prices for shares of our common stock and/or limit an investor’s ability to execute a transaction. In addition delisting from Nasdaq could also greatly impair our ability to raise additional necessary capital through equity or debt financing, and could lead to significant dilution to our stockholders caused by our issuing equity in financing or other transactions at a price per share significantly below the then market price.

We believe that period-to-period comparisons of our financial results will not necessarily be indicative of our future performance.