Attached files

| file | filename |

|---|---|

| 8-K - 8-K - UNITED STATES STEEL CORP | form8-kxslidesandqaforearn.htm |

| EX-99.2 - EXHIBIT 99.2 - UNITED STATES STEEL CORP | external1q2015qafinal8kv.htm |

Exhibit 99.1 United States Steel Corporation First Quarter 2015 Earnings Conference Call and Webcast April 29, 2015 © 2011 United States Steel Corporation

2 Forward-looking Statements United States Steel Corporation This presentation contains information that may constitute “forward-looking statements” within the meaning of the Private Securities Litigation Reform Act of 1995. Generally, we have identified such forward-looking statements by using the words “believe,” “expect,” “intend,” “estimate,” “anticipate,” “project,” “target”, “forecast”, “aim,” “will” and similar expressions or by using future dates in connection with any discussion of, among other things, operating performance, trends, events or developments that we expect or anticipate will occur in the future, statements relating to volume growth, share of sales and earnings per share growth, and statements expressing general views about future operating results. However, the absence of these words or similar expressions does not mean that a statement is not forward-looking. Forward-looking statements are not historical facts, but instead represent only the Company’s beliefs regarding future events, many of which, by their nature, are inherently uncertain and outside of the Company’s control. It is possible that the Company’s actual results and financial condition may differ, possibly materially, from the anticipated results and financial condition indicated in these forward-looking statements. Management believes that these forward- looking statements are reasonable as of the time made. However, caution should be taken not to place undue reliance on any such forward-looking statements because such statements speak only as of the date when made. Our Company undertakes no obligation to publicly update or revise any forward- looking statements, whether as a result of new information, future events or otherwise, except as required by law. In addition, forward-looking statements are subject to certain risks and uncertainties that could cause actual results to differ materially from our Company's historical experience and our present expectations or projections. These risks and uncertainties include, but are not limited to the risks and uncertainties described in “Item 1A. Risk Factors” and “Supplementary Data - Disclosures About Forward-Looking Statements” in our Annual Report on Form 10-K for the year ended December 31, 2014, and those described from time to time in our future reports filed with the Securities and Exchange Commission.

Segment EBIT $ Millions Adjusted EBITDA $ Millions Adjusted Diluted EPS $ / Share 1Q 2015 3Q 2014 2Q 2014 2Q 2014 3Q 2014 4Q 2014 Note: For reconciliation of non-GAAP amounts see Appendix 3Q 2014 2Q 2014 4Q 2014 First Quarter 2015 Results 3 United States Steel Corporation Adjusted Net Income $ Millions 2Q 2014 3Q 2014 1Q 2015 Challenging environment reflected in results 4Q 2014 LTM 1Q 2015 LTM 4Q 2014 LTM 1Q 2015 LTM Market headwinds intensified in the first quarter Imports continued at historically high levels, driving spot prices significantly lower Oil prices remained low and rig counts declined rapidly US dollar continued to strengthen Note: LTM = latest twelve months

Cash from Operations $ Millions 4Q 2014 3Q 2014 2Q 2014 LTM 1Q 2015 Note: Cash from operations in 3Q 2014 includes a reduction in cash of $80 million from the deconsolidation of U. S. Steel Canada, Inc., a voluntary pension contribution of $140 million and a litigation settlement of $58 million Total Estimated Liquidity $ Millions 4Q 2014 3Q 2014 2Q 2014 1Q 2015 Strong Cash Position and Liquidity 4 United States Steel Corporation Cash and Cash Equivalents $ Millions Net Debt $ Millions Cash from operations remained positive in the face of multiple headwinds 2Q 2014 3Q 2014 4Q 2014 1Q 2015 2Q 2014 3Q 2014 4Q 2014 1Q 2015 Strong cash position and liquidity to weather tough market conditions Note: LTM = latest twelve months

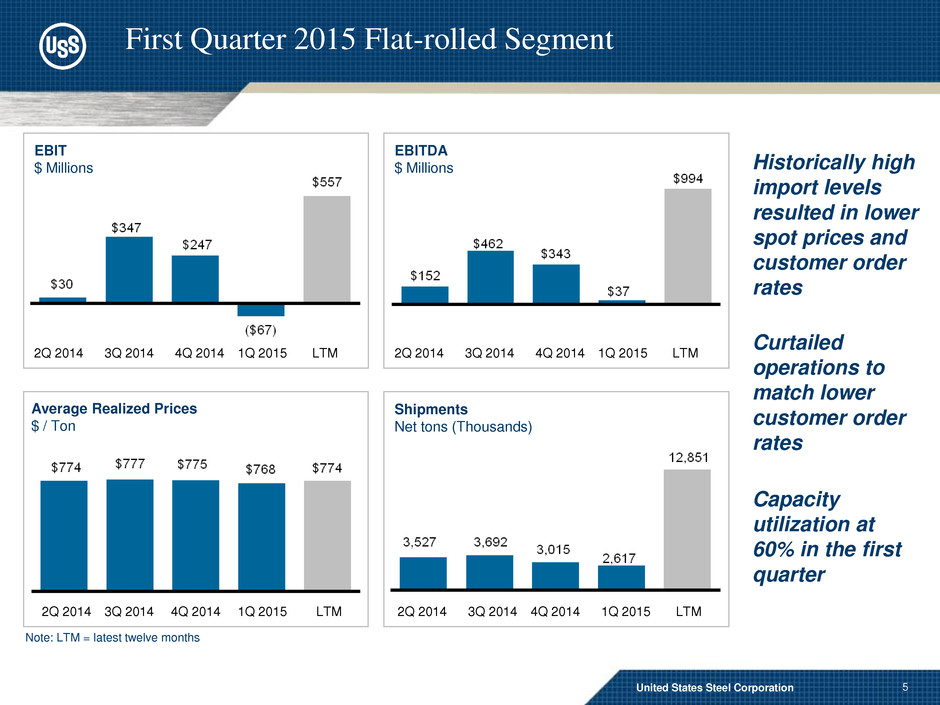

EBIT $ Millions Average Realized Prices $ / Ton 2Q 2014 3Q 2014 4Q 2014 First Quarter 2015 Flat-rolled Segment 2Q 2014 3Q 2014 4Q 2014 Shipments Net tons (Thousands) 2Q 2014 3Q 2014 1Q 2015 Historically high import levels resulted in lower spot prices and customer order rates 5 United States Steel Corporation EBITDA $ Millions 2Q 2014 3Q 2014 4Q 2014 Capacity utilization at 60% in the first quarter 1Q 2015 LTM 1Q 2015 LTM 1Q 2015 LTM 4Q 2014 LTM Curtailed operations to match lower customer order rates Note: LTM = latest twelve months

EBIT $ Millions Average Realized Prices $ / Ton 2Q 2014 3Q 2014 4Q 2014 First Quarter 2015 Tubular Segment 2Q 2014 3Q 2014 4Q 2014 Shipments Net tons (Thousands) 2Q 2014 3Q 2014 4Q 2014 U.S. rig counts have dropped 49% since the beginning of the year to 932 rigs 6 United States Steel Corporation EBITDA $ Millions 2Q 2014 3Q 2014 4Q 2014 Elevated import and inventory levels are delaying the recovery of order rates 1Q 2015 LTM 1Q 2015 LTM 1Q 2015 LTM 1Q 2015 LTM Note: LTM = latest twelve months

EBIT $ Millions Average Realized Prices $ / Ton 2Q 2014 3Q 2014 4Q 2014 First Quarter 2015 U. S. Steel Europe Segment 2Q 2014 3Q 2014 4Q 2014 Shipments Net tons (Thousands) 2Q 2014 3Q 2014 4Q 2014 Higher volumes and lower raw material costs help to offset lower selling prices 7 United States Steel Corporation EBITDA $ Millions 2Q 2014 3Q 2014 4Q 2014 Negatively impacted by strong U.S. dollar 1Q 2015 LTM 1Q 2015 LTM 1Q 2015 LTM 1Q 2015 LTM Note: LTM = latest twelve months

Carnegie Way Benefits1 – FY 2015 Impact $ Millions 8 Carnegie Way Continuing to Deliver 55% 12% United States Steel Corporation 1 Carnegie Way benefits are based on the incremental impact in 2015 as compared to 2014 as the base year.

9 Carnegie Way transformation Phase 1: Earning the right to grow in search of: • Economic profits • Customer satisfaction and loyalty • Process improvements and focused investment Phase 2: Driving profitable growth with: • Innovation and Technology • Differentiated customer solutions • Focused M&A Strategic Approach United States Steel Corporation

10 United States Steel Corporation Business Update Short term actions taken are expected to reduce costs in the last three quarters of 2015 by at least $200 million Operating updates • Steelmaking facilities • Flat-rolled finishing facilities • Tubular facilities Strategic initiatives • Commercial entity management structure • Reliability centered maintenance • Operational excellence Recent activity

11 United States Steel Corporation Flat-rolled 2015 U.S. light vehicle sales forecast is up 3% year-over-year Recent OEM shipment forecasts indicate 3% - 5% growth in the appliance market versus 2014 Construction data points suggest better demand in 2015 Service center shipments YTD are approximately 2% lower year-over- year Imports remain a headwind for all of our flat-rolled markets U. S. Steel Europe V4* car production growth expected to outpace the average EU in 2015 Appliance growth in V4 expected to outperform average EU growth in 2015 EU construction output expected to grow slightly in 2015, with residential continuing to be the primary driver Tubular Imports remain challenging 1Q oil directed rig counts down 31% from 4Q 1Q natural gas directed rig counts down 15% from 4Q Oil prices remain uncertain Market Updates Major industry summary and market fundamentals * Visegrad Group – Czech Republic, Hungary, Poland and Slovakia

12 United States Steel Corporation 2015 Outlook Updated 2015 Adjusted EBITDA Guidance $0.7 to $0.9 billion Prior 2015 Adjusted EBITDA Guidance $1.1 to $1.4 billion Increased headwinds cannot be fully offset by improved tailwinds Headwinds intensified Spot and Index price decreases Imports remain at historically high levels Rig counts declined rapidly to very low levels U.S. dollar continued to strengthen and is approaching parity with the Euro Supply chain inventory rebalance delayed Tailwinds improved Carnegie Way benefits increasing Short term cost actions taking effect Energy and raw materials costs improved

United States Steel Corporation First Quarter 2015 Earnings Conference Call and Webcast Q & A April 29, 2015 © 2011 United States Steel Corporation United States Steel Corporation 13

© 2011 United States Steel Corporation Appendix 14 United States Steel Corporation

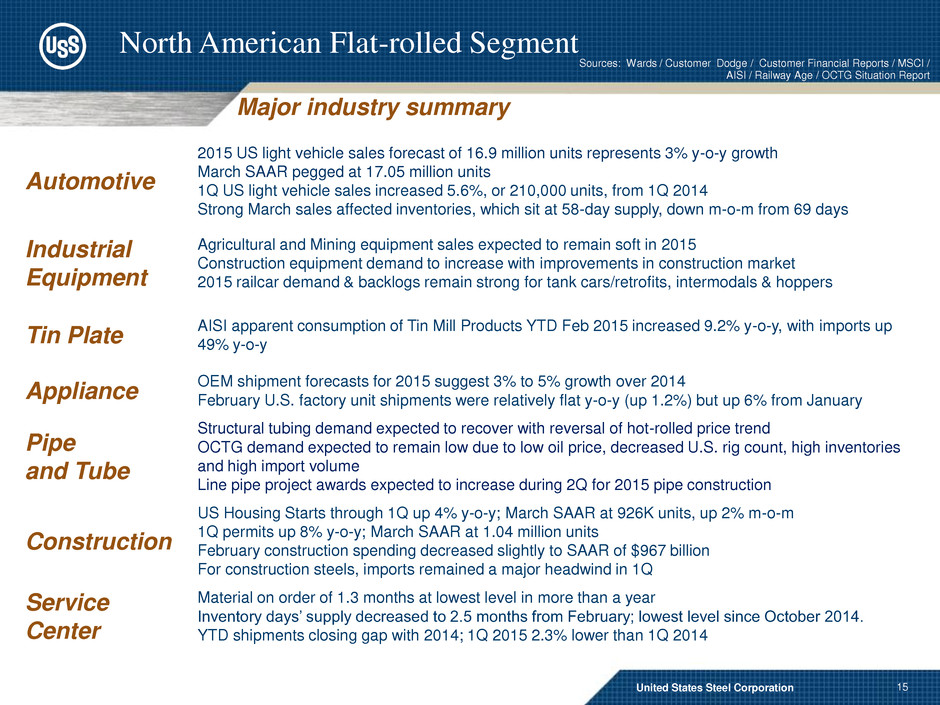

15 Major industry summary North American Flat-rolled Segment Automotive 2015 US light vehicle sales forecast of 16.9 million units represents 3% y-o-y growth March SAAR pegged at 17.05 million units 1Q US light vehicle sales increased 5.6%, or 210,000 units, from 1Q 2014 Strong March sales affected inventories, which sit at 58-day supply, down m-o-m from 69 days Industrial Equipment Agricultural and Mining equipment sales expected to remain soft in 2015 Construction equipment demand to increase with improvements in construction market 2015 railcar demand & backlogs remain strong for tank cars/retrofits, intermodals & hoppers Tin Plate AISI apparent consumption of Tin Mill Products YTD Feb 2015 increased 9.2% y-o-y, with imports up 49% y-o-y Appliance OEM shipment forecasts for 2015 suggest 3% to 5% growth over 2014 February U.S. factory unit shipments were relatively flat y-o-y (up 1.2%) but up 6% from January Pipe and Tube Structural tubing demand expected to recover with reversal of hot-rolled price trend OCTG demand expected to remain low due to low oil price, decreased U.S. rig count, high inventories and high import volume Line pipe project awards expected to increase during 2Q for 2015 pipe construction Construction US Housing Starts through 1Q up 4% y-o-y; March SAAR at 926K units, up 2% m-o-m 1Q permits up 8% y-o-y; March SAAR at 1.04 million units February construction spending decreased slightly to SAAR of $967 billion For construction steels, imports remained a major headwind in 1Q Service Center Material on order of 1.3 months at lowest level in more than a year Inventory days’ supply decreased to 2.5 months from February; lowest level since October 2014. YTD shipments closing gap with 2014; 1Q 2015 2.3% lower than 1Q 2014 United States Steel Corporation Sources: Wards / Customer Dodge / Customer Financial Reports / MSCI / AISI / Railway Age / OCTG Situation Report

16 Market industry summary Tubular Segment United States Steel Corporation Sources: Baker Hughes, US Energy Information Administration, Preston Publishing, Internal Oil Directed Rig Count The oil directed rig count averaged 1,090 during 1Q, a decrease of 31% over 4Q. There are currently 703 active oil rigs. Gas Directed Rig Count The natural gas directed rig count averaged 289 during 1Q, a decrease of 15% over 4Q. There are currently 225 active natural gas rigs. Natural Gas Storage Level Currently 1.6 Tcf, 83% above year-ago levels and 6% below the five year average. Oil Price The West Texas Intermediate oil price averaged $48.59 per barrel during 1Q, down $24 or 33% from 4Q. U.S. Energy Information Administration forecasts an average 2015 price of $52.48 per barrel. Natural Gas Price The Henry Hub natural gas price averaged $2.90 per million Btu during 1Q, down $0.89 or 23% from 4Q. The U.S. Energy Information Administration forecasts an average 2015 natural gas price of $3.07 per million Btu. Imports During 1Q, import share of OCTG apparent market demand is projected to exceed 60%. OCTG Inventory March 2015 OCTG inventory is estimated to be approximately 10 months of supply.

17 Major industry summary United States Steel Corporation Automotive In 2Q, EU car production is expected to amount to 4.47 million units, an increase of 0.6% y-o-y. In 2015, total EU car production is forecasted to grow by 2.3% to roughly 17.20 million units. V4 car production is anticipated to decrease by 1.4% y-o-y in 2Q and for 2015 we expect growth of 5.7% y-o-y with 3.18 million produced units. Significant growth is expected mainly at Opel Poland, Audi Hungary and Suzuki Hungary. Appliance The appliance sector is expected to rise in the EU as a whole in 2Q by 2% y-o-y and by 5% y-o-y in V4. The EU appliance market this year is projected to rise by 2.4% y-o-y and by 4% y-o-y in the V4 market. The V4 appliance market in 2015 is driven mainly by Slovakia (Whirlpool – washing machines, Tatramat - heaters ) and Poland (Samsung, LG, BSH). Tin Plate Consumption is anticipated to increase by 15% q-o-q in 2Q. The positive trend in consumption should continue until the end of 3Q. Overall consumption in 2015 is expected to grow by 2.5% y-o-y; after growing 2.8% in 2014. Construction From 2Q onwards, construction activity is expected to improve across the EU. New and renovation projects in the residential sector will likely be the main drivers of growth activity in 2015. Construction in Poland will likely remain largely driven by infrastructure projects. Continued weakness in France and Italy is projected to limit growth of EU construction activity to around 1.2% in 2015. Service Centers 2Q inventory levels likely will remain overall balanced with sales; Southern Europe slightly higher than normal. U. S. Steel Europe Segment Sources: Eurofer, USSK Marketing, EASSC, IHS, Euroconstruct, ESTA, ACEA

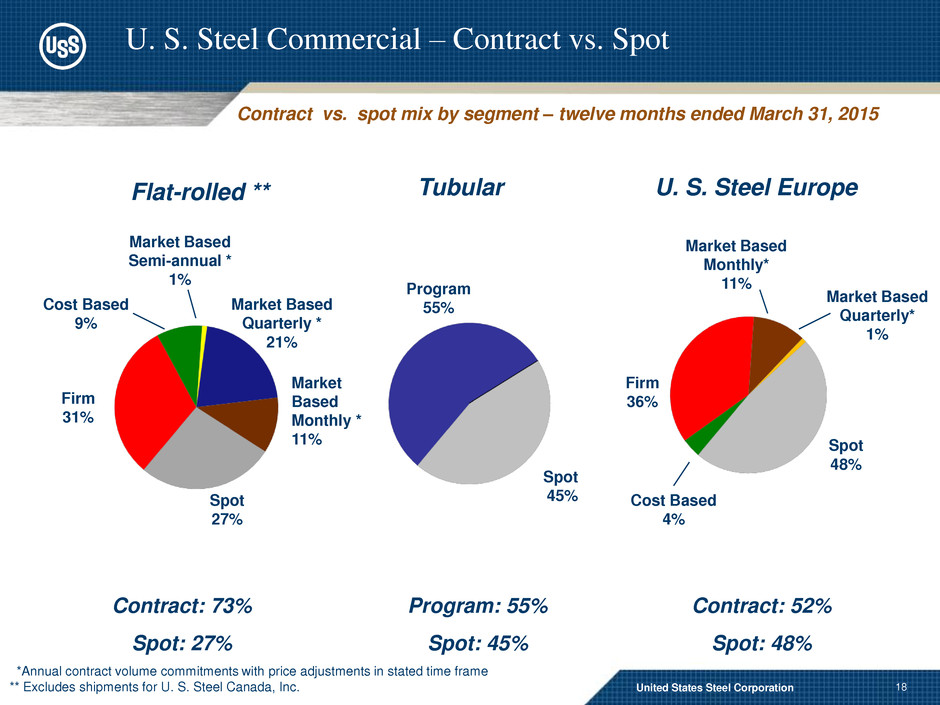

U. S. Steel Commercial – Contract vs. Spot Contract vs. spot mix by segment – twelve months ended March 31, 2015 Firm 31% Market Based Quarterly * 21% Flat-rolled ** Market Based Monthly * 11% Tubular U. S. Steel Europe Spot 27% Cost Based 9% Contract: 73% Spot: 27% Firm 36% Market Based Quarterly* 1% Spot 48% Cost Based 4% Program 55% Contract: 52% Spot: 48% Market Based Monthly* 11% Spot 45% Program: 55% Spot: 45% United States Steel Corporation 18 Market Based Semi-annual * 1% *Annual contract volume commitments with price adjustments in stated time frame ** Excludes shipments for U. S. Steel Canada, Inc.

19 United States Steel Corporation Other Items Capital Spending First quarter actual $172 million, 2015 estimate $550 million Depreciation, Depletion and Amortization First quarter actual $144 million, 2015 estimate $585 million Pension and Other Benefits Costs First quarter actual $62 million, 2015 estimate $240 million Pension and Other Benefits Cash Payments (excluding any VEBA contributions and voluntary pension contributions) First quarter actual $82 million, 2015 estimate $300 million

20 Safety Performance Rates Frequency of Injuries (per 200,000 manhours) Data for 2010 forward includes Lone Star Tubular Operations, Bellville Tubular Operations, Rig Site Services, Tubular Processing Houston, Offshore Operations Houston, and Wheeling Machine Products. Data for 2011 forward includes Transtar. Data for 2010 through 2011 includes U. S. Steel Serbia © 2015 United States Steel Corporation

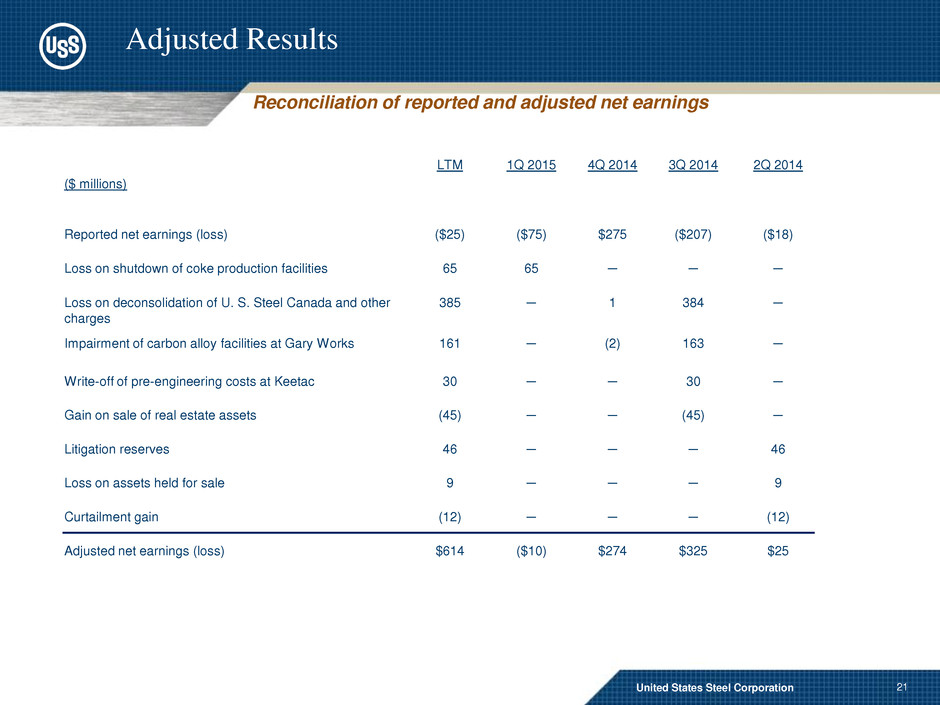

21 United States Steel Corporation Adjusted Results ($ millions) LTM 1Q 2015 4Q 2014 3Q 2014 2Q 2014 Reported net earnings (loss) ($25) ($75) $275 ($207) ($18) Loss on shutdown of coke production facilities 65 65 ─ ─ ─ Loss on deconsolidation of U. S. Steel Canada and other charges 385 ─ 1 384 ─ Impairment of carbon alloy facilities at Gary Works 161 ─ (2) 163 ─ Write-off of pre-engineering costs at Keetac 30 ─ ─ 30 ─ Gain on sale of real estate assets (45) ─ ─ (45) ─ Litigation reserves 46 ─ ─ ─ 46 Loss on assets held for sale 9 ─ ─ ─ 9 Curtailment gain (12) ─ ─ ─ (12) Adjusted net earnings (loss) $614 ($10) $274 $325 $25 Reconciliation of reported and adjusted net earnings

22 United States Steel Corporation Adjusted Results ($ per share) LTM 1Q 2015 4Q 2014 3Q 2014 2Q 2014 Reported diluted EPS (LPS) ($0.23) ($0.52) $1.83 ($1.42) ($0.12) Loss on shutdown of coke production facilities 0.45 0.45 ─ ─ ─ Loss on deconsolidation of U. S. Steel Canada and other charges 2.55 ─ 0.01 2.54 ─ Impairment of carbon alloy facilities at Gary Works 1.06 ─ (0.02) 1.08 ─ Write-off of pre-engineering costs at Keetac 0.21 ─ ─ 0.21 ─ Gain on sale of real estate assets (0.30) ─ ─ (0.30) ─ Litigation reserves 0.31 ─ ─ ─ 0.31 Loss on assets held for sale 0.06 ─ ─ ─ 0.06 Curtailment gain (0.08) ─ ─ ─ (0.08) Additional dilutive effects of securities 0.05 ─ ─ 0.05 ─ Adjusted diluted EPS (LPS) $4.08 ($0.07) $1.82 $2.16 $0.17 Reconciliation of reported and adjusted diluted EPS

23 United States Steel Corporation Adjusted Results ($ millions) LTM 1Q 2015 4Q 2014 3Q 2014 2Q 2014 Reported (loss) earnings before interest and income taxes (EBIT) $104 ($187) $397 ($141) $35 Depreciation expense 605 144 138 158 165 EBITDA 709 (43) 535 17 200 Loss on shutdown of coke production facilities 153 153 ─ ─ ─ Loss on deconsolidation of U. S. Steel Canada and other charges 416 ─ 3 413 ─ Impairment of carbon alloy facilities at Gary Works 195 ─ (4) 199 ─ Write-off of pre-engineering costs at Keetac 37 ─ ─ 37 ─ Gain on sale of real estate assets (55) ─ ─ (55) ─ Litigation reserves 70 ─ ─ ─ 70 Loss on assets held for sale 14 ─ ─ ─ 14 Curtailment gain (19) ─ ─ ─ (19) Adjusted EBITDA $1,520 $110 $534 $611 $265 Reconciliation of adjusted EBITDA

24 United States Steel Corporation Adjusted Results Net Debt ($ millions) 1Q 2015 4Q 2014 3Q 2014 2Q 2014 Short-term debt and current maturities of long-term debt $378 $378 $336 $20 Long-term debt, less unamortized discount 3,124 3,120 3,162 3,605 Total Debt $3,502 $3,498 $3,498 $3,625 Less: Cash and cash equivalents 1,266 1,354 1,257 1,471 Net Debt $2,236 $2,144 $2,241 $2,154 Reconciliation of net debt