Attached files

| file | filename |

|---|---|

| EX-95 - MINE SAFETY DISCLOSURES - STILLWATER MINING CO /DE/ | swc-12x31x14x10xkex95.htm |

| EX-21.1 - LIST OF SUBSIDIARIES - STILLWATER MINING CO /DE/ | swc-12x31x14x10xkex211.htm |

| EX-32.1 - SECTION 1350 CERTIFICATION - STILLWATER MINING CO /DE/ | swc-12x31x14x10xkex321.htm |

| EX-31.2 - CERTIFICATION OF CFO, PURSUANT TO SECTION 302 OF THE SARBANES OXLEY ACT OF 2002 - STILLWATER MINING CO /DE/ | swc-12x31x14x10xkex312.htm |

| EX-32.2 - SECTION 1350 CERTIFICATION - STILLWATER MINING CO /DE/ | swc-12x31x14x10xkex322.htm |

| EX-31.1 - CERTIFICATION OF CEO, PURSUANT TO SECTION 302 OF THE SARBANES OXLEY ACT OF 2002 - STILLWATER MINING CO /DE/ | swc-12x31x14x10xkex311.htm |

| EX-23.2 - CONSENT OF BEHRE DOLBEAR & COMPANY, INC. - STILLWATER MINING CO /DE/ | swc-12x31x2014x10xkex232.htm |

| EXCEL - IDEA: XBRL DOCUMENT - STILLWATER MINING CO /DE/ | Financial_Report.xls |

| EX-23.1 - CONSENT OF KPMG LLP, INDEPENDENT REGISTERED PUBLIC ACCOUNTING FIRM - STILLWATER MINING CO /DE/ | swc-12x31x14x10xkex231.htm |

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10-K

ý ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 FOR THE FISCAL YEAR ENDED DECEMBER 31, 2014.

or

¨ TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 FOR THE TRANSITION PERIOD FROM ________ TO ________

Commission File Number 1-13053

STILLWATER MINING COMPANY

(Exact name of registrant as specified in its charter)

Delaware | 81-0480654 | |

(State or other jurisdiction of incorporation or organization) | (I.R.S. Employer Identification No.) | |

1321 Discovery Drive, Billings, Montana 59102

(Address of principal executive offices and zip code)

(Registrant’s telephone number, including area code) (406) 373-8700

Securities registered pursuant to Section 12(b) of the Act:

Title of each class | Name of each exchange on which registered | |

Common Stock, $0.01 par value | The New York Stock Exchange | |

Securities registered pursuant to Section 12(g) of the Act: None

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. ý YES ¨ NO

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act. ¨ YES ý NO

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. ý YES ¨ NO

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). ý YES ¨ NO

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. ¨

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company. See the definitions of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act. (Check one):

Large Accelerated Filer ý | Accelerated File ¨ | Non-Accelerated Filer ¨ | Smaller reporting company ¨ | |||

Indicate by check mark whether the registrant is a shell company (as defined in Exchange Act Rule 12b-2). ¨ YES ý NO

At June 30, 2014, the aggregate market value of the registrant's voting and non-voting common equity held by non-affiliates of the registrant (treating all executive officers and directors of the registrant and holders of 10% or more of the common shares outstanding, for this purpose, as if they may be affiliates of the registrant) was approximately $1.8 billion based on the closing sale price as reported on the New York Stock Exchange on such date.

There were 120,518,662 shares of common stock, par value $0.01 per share, outstanding on February 12, 2015.

1

DOCUMENTS INCORPORATED BY REFERENCE

Certain information required in Part III of this Annual Report on Form 10-K is incorporated herein by reference to the Registrant’s Proxy Statement for its 2015 Annual Meeting of Stockholders to be filed within 120 days of December 31, 2014.

2

TABLE OF CONTENTS

GLOSSARY OF SELECTED MINING TERMS | ||

ITEM 1A | ||

ITEM 3 | ||

ITEM 4 | ||

ITEM 5 | ||

ITEM 6 | ||

ITEM 7 | ||

ITEM 7A | ||

ITEM 8 | ||

ITEM 9A | ||

ITEM 10 | ||

ITEM 11 | ||

ITEM 12 | ||

ITEM 13 | ||

ITEM 14 | ||

ITEM 15 | ||

3

GLOSSARY OF SELECTED MINING TERMS

The following is a glossary of selected mining terms used in the United States and Canada and referenced in the Form 10-K that may be technical in nature:

Adit | A horizontal tunnel or drive, open to the surface at one end, which is used as an entrance or access to a mine. | |

Concentrate | A mineral processing product that generally describes the material that is produced after crushing and grinding ore, effecting significant separation of gangue (waste) minerals from the metal and / or metal minerals, and discarding the waste and minor amounts of metal and / or metal minerals. The resulting “concentrate” of metal and/or metal minerals typically has an order of magnitude higher content of metal and / or metal minerals than the beginning ore material. | |

Cut-off grade | The lowest grade of mineralized material that qualifies as ore in a given deposit. The grade above which minerals are considered economically mineable considering the following parameters: estimates over the relevant period of mining costs, ore treatment costs, smelting and refining costs, process and refining recovery rates, royalty expenses, by-product credits, general and administrative costs and PGM prices. | |

Dilution | An estimate of the percentage of waste or low-grade mineralized rock which is included with the ore as part of normal mining practices in extracting an ore body. | |

Developed state | The portion of proven and probable ore reserves that are fully accessible and ready to mine at any point in time. | |

ETF | An exchange- traded fund is a security that tracks an underlying index, commodity or basket of assets like an index fund, but trades continuously like a stock on an exchange. | |

Exploration stage | The earliest stage of mineral commercialization, in which a potential mineral asset is being investigated, explored, defined and evaluated, but for which no decision has yet been reached to actively prepare it for commercial development. | |

Grade | The average metal content, as determined by assay of a volume of ore. For precious metals, grade is normally expressed as troy ounces per ton of ore or as grams per metric tonne of ore. One troy ounce per short ton is equivalent to approximately 34.3 grams per tonne. | |

Mill | A processing plant that produces a concentrate of the valuable minerals or metals contained in an ore. The concentrate must then be treated in some other type of plant, such as a smelter, to effect recovery of the pure metal. Term used interchangeably with concentrator. | |

MSHA | Mine Safety and Health Administration is the U.S. federal regulatory agency charged with overseeing and enforcing regulations pertaining to the safety and health of workers in the nation's mines. The Company's mining properties fall under MSHA jurisdiction. | |

Mineral deposit | Geologic term measuring an aggregate of a mineral or metal in an unusually high concentration. The term deposit does not distinguish whether the mineral can be extracted economically. | |

Mineralization | The concentration of metals and their compounds in rocks, and the processes involved therein. | |

Mineralized material | A mineralized body which has been delineated by appropriately spaced drilling and / or sampling to support a general estimate of available tonnage and average grade of metals. Such a deposit does not qualify as a reserve until a comprehensive evaluation based upon unit cost, grade, recoveries, and other material factors conclude legal and economic feasibility. | |

OSHA | Occupational Safety and Health Administration is the U.S. federal regulatory agency charged with overseeing and enforcing regulations pertaining to workplace health and safety. The Company's processing facilities in Columbus, Montana fall under OSHA jurisdiction. | |

Ore | That part of a mineral deposit which could be economically and legally extracted or produced at the time of reserve determination. | |

PGM | The platinum group metals collectively and in any combination of palladium, platinum, rhodium, ruthenium, osmium, and iridium. Reference to PGM grades for the Company’s mine operations include measured quantities of palladium and platinum only. References to PGM grades associated with recycle materials typically include palladium, platinum and rhodium. | |

PGM-rich matte | Matte is an intermediate product of smelting, an impure metallic sulfide mixture made by melting sulfide ore concentrates. PGM-rich matte is a matte with an elevated level of platinum group metals. | |

4

Probable reserves | Reserves for which quantity and grade and / or quality are computed from information similar to that used for proven reserves, but the sites for inspection, sampling, and measurement are farther apart or are otherwise less adequately spaced. The degree of assurance, although lower than that for proven reserves, is high enough to assume continuity between points of observation. | |

Proven reserves | Reserves for which (a) quantity is computed from dimensions revealed in outcrops, trenches, workings or drill holes; grade and / or quality are computed from the results of detailed sampling; and (b) the sites for inspection, sampling and measurement are spaced so closely and the geologic character is so well defined that size, shape, depth and mineral content of reserves are well established. | |

Recovery | The percentage of contained metal actually extracted from ore in the course of processing such ore. | |

Reef | A layer precipitated within the Stillwater Layered Igneous Complex enriched in platinum group metal-bearing minerals, chalcopyrite, pyrrhotite, pentlandite, and other sulfide materials. The J-M Reef, which the Company mines, occurs at a regular stratigraphic position within the Stillwater Complex. Note: this use of “reef” is uncommon and originated in South Africa where it is used to describe the PGM-bearing Merensky, Upper Group 2, and other similar layers in the Bushveld Complex. | |

Refining | The final stage of metal production in which residual impurities are removed from the metal. | |

Reserves | That part of a mineral deposit which could be economically and legally extracted or produced at the time of the reserve determination. | |

Sill | With respect to a mine opening, the base or floor of the excavated area (stope); With respect to intrusive rock, a tabular intrusive unit that is conformable with surrounding rock layers. | |

Stope | A localized area of underground excavation from which ore is extracted. | |

Tailings | The portion of the mined material that remains after the valuable minerals have been extracted. | |

TBRC | A “top-blown rotary converter,” a rotating furnace vessel which processes PGM-rich matte received from the smelter furnace, removing iron from the molten material by injecting a stream of oxygen. This process converts iron sulfides into an iron oxide slag which floats to the surface for separation. | |

CAUTIONARY INFORMATION REGARDING FORWARD-LOOKING STATEMENTS

Some statements contained in this report are forward-looking statements within the meaning of Section 27A of the Securities Act of 1933, as amended (Securities Act), and Section 21E of the Securities Exchange Act of 1934, as amended (Exchange Act), and, therefore, involve uncertainties or risks that could cause actual results to differ materially from management's expectations. These statements may contain words such as “believes,” “anticipates,” “plans,” “expects,” “intends,” “estimates,” “predicts,” “should,” “will,” “may” or similar expressions. Such statements also include, but are not limited to, comments regarding growing profitability; controlling costs; improving the efficiency of our operations; strengthening our financial and operating performance; managing our business through volatile metal prices; estimated 2015 production, cash costs per mined ounce, AISC, general and administrative costs, exploration expense and capital expenditures; and the usefulness of non-GAAP financial measures. The forward-looking statements in this report are based on assumptions and analyses made by the Company in light of its experience and the Company's perception of historical trends, current conditions, expected future developments, and other factors that the Company believes are appropriate under the circumstances. These statements are not guarantees of the Company’s future performance and are subject to risks, uncertainties and other important factors that could cause its actual performance or achievements to differ materially from those expressed or implied by these forward-looking statements. Additional information regarding factors that could cause results to differ materially from management's expectations is described in "Item 1A - Risk Factors" in this Form 10-K.

The Company intends that the forward-looking statements contained herein be subject to the above-mentioned statutory safe harbors. Investors are cautioned that forward-looking statements are not guarantees of future performance and that actual results of performance may be materially different from those expressed or implied in the forward looking statements. Investors should not to rely on forward-looking statements. The forward-looking statements in this report speak as of the filing date of this report. Although the Company may from time to time voluntarily update its prior forward-looking statements, we disclaim any obligation to update forward-looking statements except as required by securities laws.

5

PART I

ITEMS 1 AND 2

BUSINESS AND PROPERTIES

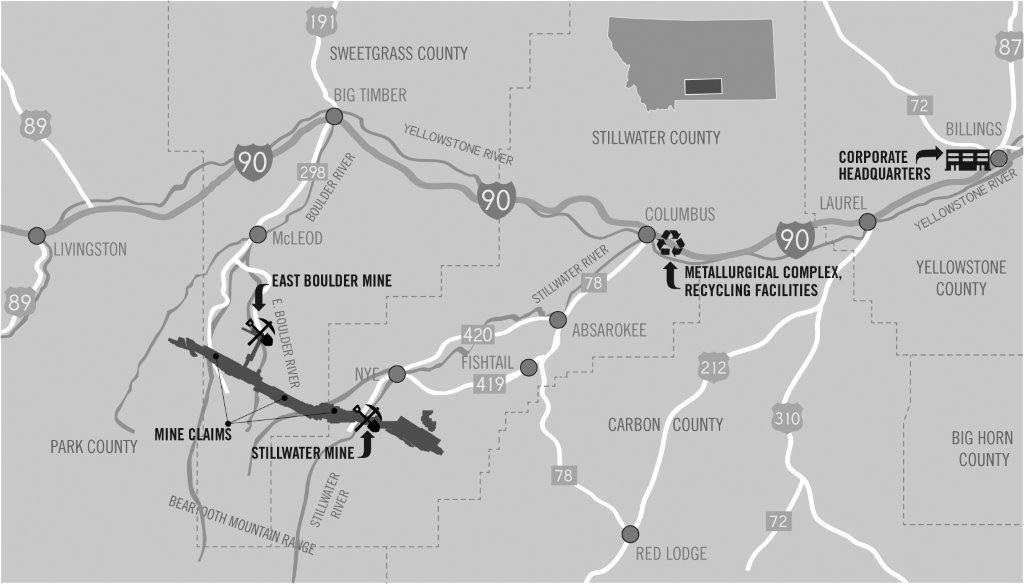

SUMMARY OF THE COMPANY

Stillwater Mining Company (the "Company") is a Delaware corporation, incorporated in 1992 and headquartered in Billings, Montana, and is listed on the New York Stock Exchange under the symbol "SWC." The Company is engaged in the development, extraction, processing, smelting and refining of palladium, platinum and associated metals (platinum group metals or PGMs) produced by mining a geological formation in south-central Montana known as the J-M Reef and recycling spent catalytic converters and other industrial sources. The Company is also engaged in expanding its mining development along the J-M Reef, and holds significant exploration-stage properties at the Marathon PGM copper property adjacent to Lake Superior in northern Ontario, Canada ("Marathon") and at the Altar copper-gold property in San Juan province, Argentina.

The J-M Reef is the only actively mined primary source of PGMs within the United States and one of the more significant resources outside South Africa and the Russian Federation. The J-M Reef is a narrow but extensive mineralized zone containing PGMs, which has been traced over a strike length of approximately 28 miles. In addition to palladium and platinum, the Company's operations produce associated by-product metals including nickel, copper and minor amounts of gold, silver and rhodium.

The Company conducts mining operations at its Stillwater Mine near Nye, Montana and at its East Boulder Mine south of Big Timber, Montana. Ore extraction at both mines takes place within the J-M Reef. A mill at each of the mining operations upgrades the mined production into a concentrated form. The Company operates a smelter and base metal refinery in Columbus, Montana which further upgrades the mined concentrates into a PGM-rich filter cake. The filter cake is then shipped to a third-party refiner for final refining before the PGMs are sold to third-parties. The Company is currently developing the Blitz project, which is situated adjacent to its current operations at the Stillwater Mine.

Along with processing mine concentrates, the Company also recycles spent catalyst material acquired from third-parties in its smelter and base metal refinery facilities to recover the contained PGMs, which consist mainly of palladium, platinum and rhodium. The Company currently has catalyst sourcing arrangements with various suppliers who deliver spent catalysts to the Company for processing. The spent catalysts are commingled with the mine concentrates in the smelter and base metal refinery. The Company purchases recycling materials for its own account and also toll processes recycling materials on behalf of others for a fee.

The Company operates five reportable business segments: Mine Production, PGM Recycling, Canadian Properties, South American Properties and All Other. These segments are managed separately based on fundamental differences in their operations and geographic separation. See "Note 10 - Segment Information" to the Company's 2014 consolidated financial statements for more information.

2014 – YEAR IN REVIEW:

The Company’s liquidity strengthened during the year, as cash and cash equivalents plus short-term investments, after the repayment of $30.0 million of debt, increased by $35.5 million to $531.5 million at December 31, 2014. The Company reported consolidated net income attributable to common stockholders of $70.3 million, or $0.56 per diluted share, for the year ended December 31, 2014, compared to consolidated net loss attributable to common stockholders of $270.2 million, or $2.28 per share, for the year ended December 31, 2013. The improvement in net income in 2014 compared to 2013 was mainly due to charges for the $290.4 million ($226.5 million, after-tax) impairment of the Peregrine property in Argentina and the $171.4 million, ($123.6 million, after-tax) impairment of the Marathon properties that the Company recorded during 2013, combined with better cost performance in the Company's Montana operations. The Company’s revenues for 2014, 2013 and 2012 totaled $943.6 million, $1.04 billion and $800.2 million, respectively. Mine Production segment revenues were $536.0 million, an increase of 11.9% from 2013, as a result of increased PGM prices and sales volume, compared to the $478.9 million in 2013, which included $7.1 million of revenues generated from reprocessed internal furnace brick in the third and fourth quarters.

PGM Recycling segment revenues decreased by 28.3% during 2014 to $401.7 million from $560.6 million in 2013, the result of a reduction in total volumes processed and sold during 2014. Recycling revenues in the third quarter of 2013 included incremental revenue of $16.4 million from the sale of approximately 12,000 PGM ounces recovered internally from reprocessed furnace brick. See “Management’s Discussion and Analysis of Financial Condition and Results of Operations – Year Ended December 31, 2014 Compared to Year Ended December 31, 2013” and the Company's 2014 consolidated financial statements, each contained in this report, for more information.

6

The following table sets forth the Company's revenues and ounces sold for the years 2014, 2013 and 2012, respectively:

Year ended December 31, (In thousands) | Revenues | Ounces Sold | |||||||||||||||||||||||||||||||||

Palladium | Platinum | Rhodium | Other (1) | Total | Palladium | Platinum | Rhodium | Other (2) | Total | ||||||||||||||||||||||||||

2014 | |||||||||||||||||||||||||||||||||||

Mine Production | $ | 338,526 | $ | 167,892 | $ | 4,650 | $ | 24,942 | $ | 536,010 | 421 | 121 | 4 | 16 | 562 | ||||||||||||||||||||

PGM Recycling | 173,767 | 191,448 | 31,039 | 5,430 | 401,684 | 221 | 134 | 29 | — | 384 | |||||||||||||||||||||||||

Other (1) | 5,517 | — | 5 | 403 | 5,925 | 6 | — | — | — | 6 | |||||||||||||||||||||||||

Total | $ | 517,810 | $ | 359,340 | $ | 35,694 | $ | 30,775 | $ | 943,619 | 648 | 255 | 33 | 16 | 952 | ||||||||||||||||||||

2013 | |||||||||||||||||||||||||||||||||||

Mine Production | $ | 287,167 | $ | 164,666 | $ | 3,402 | $ | 23,683 | $ | 478,918 | 398 | 111 | 3 | 14 | 526 | ||||||||||||||||||||

PGM Recycling | 218,190 | 292,818 | 47,803 | 1,777 | 560,588 | 306 | 192 | 44 | — | 542 | |||||||||||||||||||||||||

Total | $ | 505,357 | $ | 457,484 | $ | 51,205 | $ | 25,460 | $ | 1,039,506 | 704 | 303 | 47 | 14 | 1,068 | ||||||||||||||||||||

2012 | |||||||||||||||||||||||||||||||||||

Mine Production | $ | 247,847 | $ | 176,937 | $ | 4,877 | $ | 25,765 | $ | 455,426 | 386 | 114 | 4 | 15 | 519 | ||||||||||||||||||||

PGM Recycling | 123,876 | 183,719 | 34,817 | 2,406 | 344,818 | 192 | 119 | 25 | — | 336 | |||||||||||||||||||||||||

Total | $ | 371,723 | $ | 360,656 | $ | 39,694 | $ | 28,171 | $ | 800,244 | 578 | 233 | 29 | 15 | 855 | ||||||||||||||||||||

(1) “Revenues - Other” includes gold, silver, nickel and copper by-product revenues from mine production; revenue from processing recycling materials on a toll basis and ounces acquired periodically in the open market and simultaneously resold to third parties.

(2) “Ounces Sold - Other” column includes gold and silver by-product ounces and recycled ounces sold. Not reflected in the “other” ounce column in the table above are approximately 1.5 million pounds, 1.4 million pounds and 1.1 million pounds of nickel sold in 2014, 2013 and 2012, respectively, and approximately 0.9 million pounds, 0.9 million pounds and 0.7 million pounds of copper sold in 2014, 2013 and 2012, respectively.

The Company's mining operations produced a total of 517,700 ounces of palladium and platinum in 2014, a decrease of 1.2% from the 523,900 ounces produced in 2013. Total consolidated cash costs per ounce, net of by-product and recycling credits, (a non-GAAP financial measure of extraction efficiency further defined in Part II, Item 6 of this Form 10-K) averaged $538 in 2014, compared with $496 per ounce in 2013. Higher total consolidated cash costs in 2014 were a result of higher labor costs, general inflation on materials and supplies, a decrease in mine production and lower recycling credits. Total consolidated cash costs per ounce in 2013 benefited from an unusually high recycling credit, reflecting the value of PGM ounces allocated from reprocessing internal furnace brick. Higher labor costs in 2014 were due to increases in contractual wage and benefit rates, offset in part by the effect of manpower reductions.

Approximately 384,400 ounces of PGMs were extracted and sold from recycling materials purchased (at prices reflecting the value of the contained PGMs) for the Company's own account in 2014, a decrease of 29.1% from the 541,800 ounces sold in 2013. The Company’s combined average realization on recycling revenues (which include sales of palladium, platinum and rhodium) was $1,031 per ounce in 2014, unchanged from 2013. In addition to processing spent catalyst material purchased for its own account, the Company processed and returned 72,800 ounces of PGMs treated on a tolling basis in 2014, up from 65,400 toll ounces in 2013. Recycling volumes fed to the smelter totaled 469,400 ounces of PGMs in 2014, down 23.9% from the 616,700 ounces fed in 2013, driven by the greater availability of recycling materials in the market during 2013 and by volumes attributed to the reprocessed internal furnace brick. Working capital associated with recycling activities (in the form of inventories and advances) was $61.5 million, $76.1 million and $87.8 million at December 31, 2014, 2013 and 2012, respectively. Included in these working capital totals were outstanding cash advances to recycling suppliers for material in transit totaling $7.3 million, $6.9 million and $10.2 million at December 31, 2014, 2013 and 2012, respectively.

During the first half of 2014, the Company made all of its sales of mined PGMs either in the spot market or under mutually agreed short-term (one year or less) supply agreements. On July 1, 2014, the Company executed five-year supply and refining agreements with Johnson Matthey, at competitive market prices. See "Note 3 - Sales” to the Company’s 2014 consolidated financial statements for more information.

7

Capital Spend

(In thousands) | December 31, | |||||||

2014 | 2013 | |||||||

Sustaining capital: | ||||||||

Stillwater Mine | $ | 60,131 | $ | 67,413 | ||||

East Boulder Mine | 19,656 | 15,880 | ||||||

Processing and Other | 4,972 | 5,022 | ||||||

Total sustaining capital | $ | 84,759 | $ | 88,315 | ||||

Project capital | ||||||||

Blitz Project * | $ | 23,209 | $ | 21,195 | ||||

Graham Creek Project * | 2,105 | 8,082 | ||||||

Hertzler Tailings Expansion | 9,382 | 247 | ||||||

Other Projects | 10,313 | 6,515 | ||||||

Total project capital | $ | 45,009 | $ | 36,039 | ||||

Total U.S. capital | $ | 129,768 | $ | 124,354 | ||||

Foreign project capital * | 45 | 14,182 | ||||||

Total capital | $ | 129,813 | $ | 138,536 | ||||

Non-cash and accruals at December 31, 2014 | (10,131 | ) | (9,507 | ) | ||||

Cash capital spend for the period | $ | 119,682 | $ | 129,029 | ||||

* Capital spend for Blitz and Graham Creek in 2014 includes approximately $10.3 million of capitalized interest and capitalized depreciation. Total capitalized interest and capitalized depreciation included in capital spend for Blitz, Graham Creek and foreign projects in 2013 was approximately $10.2 million.

The Company spent $2.8 million on exploration during 2014, of which $2.0 million was spent at the Altar property in Argentina and $0.8 million at the Marathon properties in Canada, primarily for updating the project feasibility study. Exploration expenditures during 2013 totaled $11.2 million, of which $8.0 million was spent on drilling and evaluation at Altar and $3.2 million on the Marathon properties. Exploration spending in 2012 totaled approximately $15.0 million, of which $14.2 million was spent on drilling at the Altar property and $0.8 million on the Marathon properties.

At December 31, 2014, the Company reported balance sheet debt and capital lease obligations totaling $296.2 million. This debt is comprised of (i) $291.1 million (face amount of $396.75 million) of highly discounted 1.75% convertible debentures, first redeemable at the option of the holders on October 15, 2019; (ii) $2.2 million of 1.875% convertible debentures, next redeemable at the option of the holders on March 15, 2018; and (iii) various minor secured obligations totaling $2.9 million with maturities over the next three years. Annual cash interest cost on the Company’s debt obligations is expected to be approximately $7.1 million in 2015. In addition to this balance sheet debt, the Company also has outstanding undrawn letters of credit under its revolving line of credit, mostly in support of long-term reclamation obligations, totaling $18.1 million at December 31, 2014. Interest is charged on these letters of credit and on the unused portion of the revolving credit facility at rates determined based on the percent of the total line that is in use in any period. At the rates prevailing on December 31, 2014, the Company would expect to pay cash interest of approximately $1.0 million on its revolving credit facility during 2015.

8

SAFETY

Mining operations at the Stillwater Mine and at the East Boulder Mine are labor intensive, and involve the use of heavy machinery and drilling and blasting techniques specific to a narrow-vein underground working environment. These operations are inherently dangerous and therefore are at the center of the Company’s extensive workplace safety program. In addition, the Company’s metallurgical complex in Columbus, Montana utilizes smelting and refining processes that require careful attention to safety awareness. To partially mitigate worker exposures in these environments, the Company's safety and health management system focuses on accident prevention through managing risk, continually seeking safer methods of mining and processing, and emphasizing employee awareness and training. Specific areas of focus include detailed workplace examinations; regular hazard recognition training; safety audits that focus on continual improvement and industry best practices; consistent adherence to safety standards; accident and incident investigations; near miss reporting and analysis; and use of focus teams drawn from the mining workforce. These proactive focus teams have succeeded in identifying and resolving many safety related challenges. In recent years, the Company has enhanced its successful "G.E.T. (Guide, Educate and Train) Safe" program, incorporating principles from CORESafety, a U.S. mining industry safety initiative endorsed in April 2012 by the National Mining Association's executive Board.

Under the CORESafety system, the Company and its mining industry peers are working together toward a collective five-year goal of eliminating fatal accidents and sharply reducing the frequency and severity of on-the-job injuries within the mining industry. The CORESafety system is based on specific principles and programs, including creating an industry-wide safety forum to share knowledge of safety issues, providing tools to continuously improve safety and health performance, and establishing industry peer groups to share best practices. The CORESafety system is comprised of a series of 20 modules, which can be prioritized to address specific gaps in safety and health performance based on the Company's own "gap analysis." To date, the Company has integrated sixteen of these modules into its existing G.E.T. Safe program and plans to complete the integration effort in 2015. The Company views implementing CORESafety as a significant opportunity to enhance the already successful G.E.T Safe program and continue the pursuit of safety excellence.

For the year ended December 31, 2014, neither of the Company’s mines received any written notices from MSHA of (i) a flagrant violation under section 110(b)(2) of the Mine Act; (ii) a pattern of violations of mandatory health or safety standards that are of such nature as could have significantly and substantially contributed to the cause and effect of other mine health or safety hazards under section 104(e) of the Mine Act; or (iii) the potential to have such a pattern. In addition, the Company's metallurgical complex did not receive any OSHA violations in 2014. The metallurgical complex has been recognized repeatedly by the Montana Department of Labor and by OSHA as a leader in workplace safety.

At year-end 2014 the Company's overall reportable incidence rate of 3.3 (measured as reportable incidents per 200,000 man hours worked) was essentially unchanged from the Company's 2013 incidence rate. The 2014 results do however represent a 73.4% reduction in incidence rates for Company employees and contractors since the inception of the “G.E.T. Safe” Safety and Health Management Systems in 2001.

2015 – LOOKING FORWARD

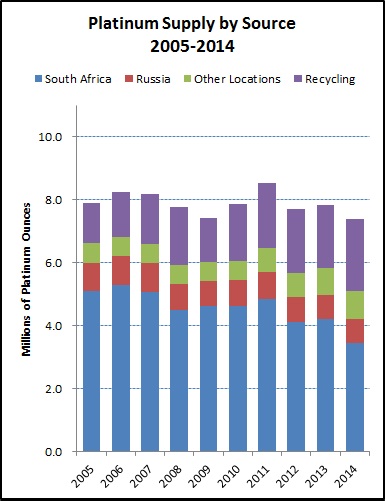

Pricing Background and Outlook

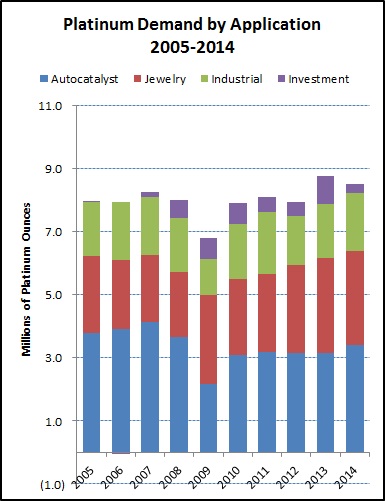

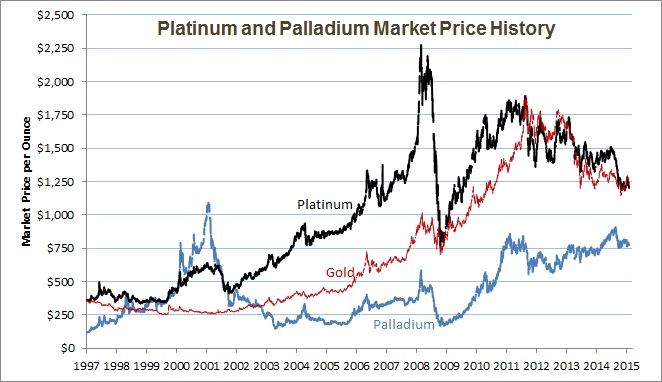

Since the beginning of 2013, the price of platinum has closely tracked the price of gold, generally trending downward in response to a strengthening U.S. dollar and the end of bond purchases under the Federal Reserve's quantitative easing program. After declining during the first half of 2013, platinum prices did strengthen modestly in mid to late 2013 and during the first half of 2014, the Company believes as a result of the effect of labor disruptions at the major South African PGM mines. Following resolution of these labor issues, however, the platinum price declined sharply in the second half of 2014 and ended the year quoted in the London market at $1,210 per ounce, an 11.1% decline from previous year-end, a price level last previously seen in mid-2009.

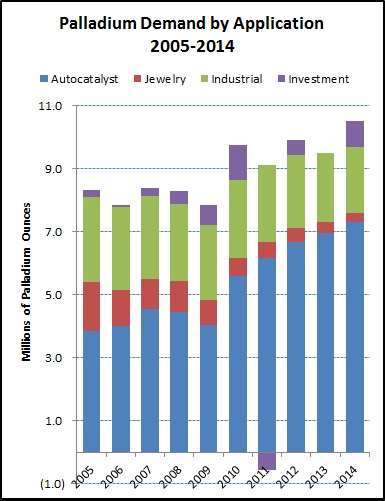

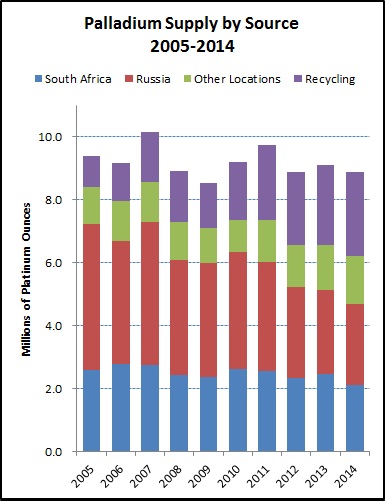

The price of palladium, while not immune to currency movements, held up relatively well during 2013 and 2014. Palladium appears not to be linked as closely with gold as is platinum, which may be explained by the key role industrial demand plays in the palladium market. The large and growing production deficit relative to total industrial and automotive demand for palladium is generally met out of above-ground inventories, and this has tended to keep upward pressure on the palladium price. Uncertainty among investors as to the implications of economic sanctions against Russia may also have benefited the palladium price, as Russia is the largest producer of the metal. The palladium price did decline, along with platinum and gold, as the U.S. dollar began to strengthen in September of 2014, but palladium ended 2014 quoted in the London market at $798 per ounce, up 12.2% for the year.

9

The outlook for PGM pricing in 2015 is mixed, reflecting disparate economic forces at work in the world. Worldwide automotive demand looks fairly encouraging, with recovery in the European auto markets apparently continuing (although off a very low base by historical standards) and demand in both North America and China still growing. As automotive demand is the largest use for palladium, the Company expects that demand for palladium will be healthy in 2015. On the supply side, given major labor disruptions in South Africa and barring any expansion of Russian economic sanctions affecting the PGM markets, 2015 could be a relatively quiet year in comparison to 2014. The other uncertainty, as always, is the direction of the world economy as 2015 progresses - if world economic conditions deteriorate, demand for PGMs could falter. See “Risk Factors - Volatility in the price of the metals sold by the Company, and changes in the supply and demand of these metals could reduce profitability" for more information.

The Company's financial performance is closely linked to the price of palladium and, to a lesser extent, platinum. The Company's earnings and cash flows are sensitive to changes in PGM prices - based on 2014 revenues and costs, a 1% (or approximately $9 per ounce) change in the Company's average combined realized price for palladium and platinum would result in approximately a 5.6% change to before-tax net income and a 2.6% change to cash flow from operations of approximately $5 million.

While changes in the PGM market prices directly affect the Company's profitability, another important competitive consideration for the Company is the relative level of and relationship between the price of palladium and platinum. The Company’s mines generally produce approximately 3.4 times as much saleable palladium as platinum, while its South African competitors in many cases produce nearly twice as much platinum as palladium. Consequently, the Company benefits competitively relative to these producers whenever the spread between the palladium price and the platinum price narrows. From 2003 through to the first half of 2010, the price of palladium averaged 20% - 25% of the price of platinum. However, the gap has narrowed to approximately 60%, a shift that has benefited the Company significantly. It is difficult to predict how this relationship might evolve during 2015, but the sharp decline in oil prices in early 2015 could benefit automotive demand for PGMs, both because lower oil prices may make larger vehicles (with higher PGM loadings per vehicle) more attractive, and because consumers may have more discretionary income available for major purchases.

One other key element of PGM markets in 2015 will be the relationship between various key currencies. Virtually all PGM sales transactions worldwide (with the possible exception of retail sales of platinum jewelry) are denominated in U.S. dollars. However, mining costs typically are incurred mostly in the local currencies of the country in which the mine is located. Weakening of the South African rand and Russian rouble relative to the U.S. dollar has served to increase the competitiveness of the South African and Russian PGM producers, as their costs in U.S. dollar terms have declined (or their revenues in local currency terms have increased, depending on the perspective).

Operational and Development Outlook

Capital spending in 2015 anticipates customary spending for equipment replacement and mine development, plus ongoing development spending (including capitalized interest and capitalized depreciation) for the Blitz development area adjacent to the Stillwater Mine. The Company expects to undertake a limited exploration program at Marathon and will maintain baseline environmental monitoring activities at Marathon and Altar. However, that work will be expensed as incurred and is included in capital spending.

As noted, the Company is continuing its development of the Blitz mine expansion infrastructure. Blitz is adjacent to the existing Stillwater Mine operations and it will ultimately extend new underground development approximately 23,000 feet to the east of the current mine works on two levels. A new portal and decline from surface is expected to be permitted and installed approximately four miles to the east of the existing Stillwater Mine surface facilities, intersecting the two new drifts and providing ventilation and emergency egress for the Blitz area. As now contemplated, Blitz is estimated to cost approximately $200 million (of which approximately $62 million has been incurred through the end of 2014), with the basic infrastructure expected to be completed in late 2018.

The Company completed development work and the installation of basic infrastructure for its Graham Creek project, located adjacent to and west of the East Boulder Mine, during 2014. A continuing program of definitional drilling during 2015 will better define attractive mining areas along the 8,800 feet of new development.

10

ORE RESERVES DETERMINATION METHODOLOGY

The Company utilizes statistical methodologies to calculate ore reserves based on interpolation between and projection beyond sample points. Interpolation and projection are limited by certain modifying factors including geologic boundaries, economic considerations and constraints imposed by safe mining practices. Sample points consist of variably spaced drill core intervals through the J-M Reef obtained from drill sites located on the surface and in underground development workings. Results from all sample points within the ore reserve area are evaluated and applied in determining the ore reserve.

For proven ore reserves, distances between samples range from 25 to 100 feet but are typically spaced at 50 foot intervals both horizontally and vertically. The sample data for proven ore reserves consists of survey data, lithologic data and assay results. Quality Assurance / Quality Control (QA / QC) protocols are in place at both mine sites to test the sampling and analysis procedures. To test assay accuracy and reproducibility, pulps from core samples are resubmitted and compared. To test for sample label errors or cross-contamination, blank core (waste core) samples are submitted with the mineralized sample lots and compared. The QA / QC protocols are practiced on both resource delineation and development and production samples. The resulting data is entered into a 3-dimensional modeling software package and is analyzed to produce a 3-dimensional solid block model of the resource. The assay values are further analyzed by a geostatistical modeling technique (kriging) to establish a grade distribution within the 3-dimensional block model. Dilution is then applied to the model and a diluted tonnage and grade are calculated for each block. Ore and waste tons, contained ounces and grade are then calculated and summed for all blocks.

Two types of cut-off grades are recognized for the J-M Reef, a geologic cut-off grade and an economic cut-off grade. The geologic cut-off grade for both the Stillwater and East Boulder mines falls in the range of 0.2 to 0.3 troy ounces of palladium plus platinum (Pd+Pt) per ton. The economic cut-off grade is lower than the geologic cut-off and can vary between the mines based on cost and efficiency factors. The determination of the economic cut-off grade is completed on a round by round basis and is driven primarily by available mill capacity, geologic character encountered at the mining face and incremental costs of processing the broken rock. See “Business and Properties – Proven and Probable Ore Reserves – Discussion” for discussion of reserve sensitivity to changes in PGM pricing.

Probable ore reserves estimations are based on longer projections than proven reserves, and projections up to a maximum radius of 1,000 feet beyond the limit of existing drill hole sample intercepts of the J-M Reef are acceptable. Statistical modeling and the established continuity of the J-M Reef, as determined from results of 28 years of mining activity to date, support the Company’s technical confidence in estimates of tonnage and grade over this projection distance. Where appropriate, projections for the probable ore reserve determination are constrained by any known or anticipated restrictive geologic features.

The Company reviews its methodology for calculating ore reserves on an annual basis. Conversion, an indicator of the success in upgrading probable ore reserves to proven ore reserves, is evaluated annually as part of the reserve estimation process. The annual review examines the effect of new geologic information, changes implemented or planned in mining practices and mine economics on the measures used for the estimation of probable ore reserves. The review includes an evaluation of the Company’s rate of conversion of probable reserves to proven reserves.

The proven and probable ore reserves are then modeled as a long-term mine plan and additional factors including mining methods, process recoveries, metal prices, mine operating productivities and costs and capital estimates are applied to determine the overall economics of the ore reserves. The Company has made available on its website (www.stillwatermining.com) in the Investor Relations section a report entitled “Technical Report for the Mining Operations at Stillwater Mining Company”, dated as of March 2011 and furnished to the United States Securities and Exchange Commission (SEC) on Form 8-K on June 23, 2011, that discusses the Company’s ore reserve methodology in greater detail. The information contained on the Company's website or connected to its website is not incorporated by reference into this Annual Report on Form 10-K and should not be considered part of this report.

SEC ORE RESERVE GUIDELINES

The SEC has established guidelines contained in Industry Guide No. 7 to assist registered companies as they estimate ore reserves. These guidelines set forth technical, legal, and economic criteria for determining whether the Company’s ore reserves can be classified as proven and probable.

The SEC’s economic guidelines historically have not constrained the Company’s ore reserves, and did not constrain the Company's ore reserves at December 31, 2014. Under these guidelines, ore may be classified as proven or probable if extraction and sale will result in positive cumulative undiscounted cash flow. The Company utilizes the historical trailing twelve-quarter average combined PGM market price in ascertaining these cumulative undiscounted cash flows.

11

The Company believes that it is appropriate to use a long-term average price for measuring ore reserves; as such a price better matches the period over which the reserves will ultimately be mined. However, should metal prices decline substantially from their present level for an extended period, the twelve-quarter trailing average price might also decline and could result in a reduction of the Company’s reported ore reserves.

The Company’s Technical and Ore Reserve Committee, a committee of the Board, met four times during 2014 with management and third-party independent outside experts to review ore reserve methodology, to identify best practices in the industry and to receive reports on the progress and results of the Company’s mine development efforts. The Committee has reviewed the Company’s ore reserves as reported at December 31, 2014, and has met with management and with the Company’s independent consultant on ore reserves to discuss the conclusions of this review.

RESULTS

The December 31, 2014, ore reserves for the Montana operations were reviewed by Behre Dolbear & Company, Inc. (Behre Dolbear), third-party independent consultants, who are experts in mining, geology and ore reserve determination. The Company has utilized Behre Dolbear to carry out independent reviews and inventories of the Company’s ore reserves since 1990. Behre Dolbear has consented to be a named expert herein. See “Risk Factors – Ore reserve estimates are inherently imprecise and may require adjustment in the future; changes in ore grades, mining practices and economic factors could materially affect the Company’s production and reported results.”

PROVEN AND PROBABLE ORE RESERVES

The Company’s proven ore reserves are generally expected to be extracted utilizing existing mine infrastructure. However, additional infrastructure development will be required to extract the Company’s probable ore reserves. Based on the 2015 mining plans at each mine, the year-end 2014 proven ore reserves of 3.4 million tons at the Stillwater Mine and 2.8 million tons at the East Boulder Mine represent an adequate level of proven ore reserves to support planned mining activities.

The grade of the Company’s J-M Reef ore reserves, measured in combined palladium and platinum ounces per ton, is a composite average of samples in all reserve areas. As is common in underground mines, the grade mined and the recovery rate achieved varies depending on the area being mined. In particular, mill head grade varies significantly between the Stillwater and East Boulder mines, as well as within different areas of each mine. The average mill head grade for each of the years 2014 and 2013 for all tons processed from the Stillwater Mine was 0.50 PGM ounces per ton of ore and for 2012 the average mill head grade was 0.58 PGM ounces per ton of ore. During 2014 the average mill head grade for all tons processed from the East Boulder Mine was approximately 0.38 PGM ounces per ton of ore compared to an average mill head grade of 0.37 PGM and 0.35 PGM ounces per ton of ore in 2013 and 2012, respectively. Concentrator feeds at both mines typically include, along with the ore, some PGM-bearing material that is below the cut-off grade for reserves (reef waste) but that is economic to process so long as there is available capacity in the concentrator. See “Risk Factors – An extended period of low PGM prices could result in a reduction of ore reserves and potential asset impairment charge."

At December 31, 2014, 2013 and 2012 the Company’s proven and probable ore reserves in the J-M Reef were as follows:

TOTAL MONTANA MINES | ||||||||||||

ORE TONS (000’s) | AVERAGE GRADE (OZ/TON) | CONTAINED OUNCES (000’S) | SALEABLE OUNCES (2) (000’S) | |||||||||

At December 31, 2014 | ||||||||||||

Proven Reserves | 6,166 | 0.51 | 3,140 | 2,634 | ||||||||

Probable Reserves | 42,732 | 0.45 | 19,086 | 16,206 | ||||||||

Total Proven and Probable Reserves (1) | 48,898 | 0.45 | 22,226 | 18,840 | ||||||||

At December 31, 2013 | ||||||||||||

Proven Reserves | 6,098 | 0.50 | 3,037 | 2,547 | ||||||||

Probable Reserves | 42,411 | 0.45 | 19,027 | 16,030 | ||||||||

Total Proven and Probable Reserves (1) | 48,509 | 0.45 | 22,064 | 18,577 | ||||||||

At December 31, 2012 | ||||||||||||

Proven Reserves | 6,023 | 0.51 | 3,078 | 2,590 | ||||||||

Probable Reserves | 40,119 | 0.46 | 18,377 | 15,491 | ||||||||

Total Proven and Probable Reserves (1) | 46,142 | 0.46 | 21,455 | 18,081 | ||||||||

12

STILLWATER MINE | ||||||||||||

ORE TONS (000’s) | AVERAGE GRADE (OZ/TON) | CONTAINED OUNCES (000’S) | SALEABLE OUNCES (2) (000’S) | |||||||||

At December 31, 2014 | ||||||||||||

Proven Reserves | 3,351 | 0.57 | 1,984 | 1,635 | ||||||||

Palladium | 0.46 | 1,551 | 1,270 | |||||||||

Platinum | 0.13 | 433 | 365 | |||||||||

Probable Reserves | 12,619 | 0.56 | 7,120 | 5,868 | ||||||||

Palladium | 0.44 | 5,564 | 4,559 | |||||||||

Platinum | 0.12 | 1,556 | 1,309 | |||||||||

Total Proven and Probable Reserves (1) | 15,970 | 0.57 | 9,104 | 7,503 | ||||||||

Palladium | 0.45 | 7,115 | 5,829 | |||||||||

Platinum | 0.12 | 1,989 | 1,674 | |||||||||

At December 31, 2013 | ||||||||||||

Proven Reserves | 3,246 | 0.57 | 1,856 | 1,545 | ||||||||

Palladium | 0.45 | 1,449 | 1,199 | |||||||||

Platinum | 0.12 | 407 | 346 | |||||||||

Probable Reserves | 12,314 | 0.57 | 6,989 | 5,818 | ||||||||

Palladium | 0.44 | 5,457 | 4,516 | |||||||||

Platinum | 0.13 | 1,532 | 1,302 | |||||||||

Total Proven and Probable Reserves (1) | 15,560 | 0.57 | 8,845 | 7,363 | ||||||||

Palladium | 0.44 | 6,906 | 5,715 | |||||||||

Platinum | 0.13 | 1,939 | 1,648 | |||||||||

At December 31, 2012 | ||||||||||||

Proven Reserves | 3,333 | 0.59 | 1,952 | 1,639 | ||||||||

Palladium | 0.46 | 1,524 | 1,272 | |||||||||

Platinum | 0.13 | 428 | 367 | |||||||||

Probable Reserves | 12,149 | 0.59 | 7,189 | 6,035 | ||||||||

Palladium | 0.46 | 5,612 | 4,684 | |||||||||

Platinum | 0.13 | 1,577 | 1,351 | |||||||||

Total Proven and Probable Reserves (1) | 15,482 | 0.59 | 9,141 | 7,674 | ||||||||

Palladium | 0.46 | 7,136 | 5,956 | |||||||||

Platinum | 0.13 | 2,005 | 1,718 | |||||||||

13

EAST BOULDER MINE | ||||||||||||

ORE TONS (000’s) | AVERAGE GRADE (OZ/TON) | CONTAINED OUNCES (000’S) | SALEABLE OUNCES (2) (000’S) | |||||||||

At December 31, 2014 | ||||||||||||

Proven Reserves | 2,815 | 0.41 | 1,156 | 999 | ||||||||

Palladium | 0.32 | 905 | 776 | |||||||||

Platinum | 0.09 | 251 | 223 | |||||||||

Probable Reserves | 30,113 | 0.40 | 11,966 | 10,338 | ||||||||

Palladium | 0.31 | 9,365 | 8,035 | |||||||||

Platinum | 0.09 | 2,601 | 2,303 | |||||||||

Total Proven and Probable Reserves (1) | 32,928 | 0.40 | 13,122 | 11,337 | ||||||||

Palladium | 0.31 | 10,270 | 8,811 | |||||||||

Platinum | 0.09 | 2,852 | 2,526 | |||||||||

At December 31, 2013 | ||||||||||||

Proven Reserves | 2,852 | 0.41 | 1,181 | 1,002 | ||||||||

Palladium | 0.32 | 924 | 779 | |||||||||

Platinum | 0.09 | 257 | 223 | |||||||||

Probable Reserves | 30,097 | 0.40 | 12,038 | 10,212 | ||||||||

Palladium | 0.31 | 9,422 | 7,937 | |||||||||

Platinum | 0.09 | 2,616 | 2,275 | |||||||||

Total Proven and Probable Reserves (1) | 32,949 | 0.40 | 13,219 | 11,214 | ||||||||

Palladium | 0.31 | 10,346 | 8,716 | |||||||||

Platinum | 0.09 | 2,873 | 2,498 | |||||||||

At December 31, 2012 | ||||||||||||

Proven Reserves | 2,690 | 0.42 | 1,126 | 951 | ||||||||

Palladium | 0.33 | 881 | 739 | |||||||||

Platinum | 0.09 | 245 | 212 | |||||||||

Probable Reserves | 27,970 | 0.40 | 11,188 | 9,456 | ||||||||

Palladium | 0.31 | 8,756 | 7,349 | |||||||||

Platinum | 0.09 | 2,432 | 2,107 | |||||||||

Total Proven and Probable Reserves (1) | 30,660 | 0.40 | 12,314 | 10,407 | ||||||||

Palladium | 0.31 | 9,638 | 8,088 | |||||||||

Platinum | 0.09 | 2,676 | 2,319 | |||||||||

(1) Reserves are defined as that part of a mineral deposit that could be economically and legally extracted or produced at the time of the reserve determination. Proven ore reserves are defined as ore reserves for which (a) quantity is computed from dimensions revealed in outcrops, trenches, workings or drill holes; grade and / or quality are computed from the results of detailed sampling and (b) the sites for inspection, sampling and measurement are spaced so closely and the geologic character is so well defined that size, shape, depth and mineral content of ore reserves are well-established. Probable ore reserves are defined as ore reserves for which quantity and grade and / or quality are computed from information similar to that used for proven ore reserves, but the sites for inspection, sampling, and measurement are farther apart or are otherwise less adequately spaced. The degree of assurance, although lower than that for proven ore reserves, is high enough to assume continuity between points of observation. The proven and probable ore reserves reflect variations in the PGM content and structural impacts on the J-M Reef. These variations are the result of localized depositional and structural influences on the distributions of economic PGM mineralization. Geologic domains within the reserve boundaries of the two mines include areas where as little as 0% and up to 100% of the J-M Reef is economically mineable. The ore reserve estimate gives effect to these assumptions. Using the Company’s combined twelve-quarter trailing weighted average price for palladium and platinum at December 31, 2014, of approximately $891 per ounce ($724/oz. for palladium and $1,474/oz. for platinum), the Company’s ore reserves at each mine are projected to generate (undiscounted) positive cash flow over the life of the reserve. See “Risk Factors” and “Cautionary Information Regarding Forward-Looking Statements.”

(2) Contained ounces net of estimated mining and processing losses.

14

DISCUSSION

The Company’s mine development efforts over the past several years have focused on converting probable reserves to proven reserves. At December 31, 2014, the Company’s total proven palladium and platinum ore reserves in the J-M Reef were 6.2 million tons at an average grade of 0.51 ounces per ton, containing an estimated 3.1 million ounces of palladium and platinum. This represented a net increase of 3.4% in proven contained ounces compared to the proven ore reserves reported at December 31, 2013. The Company’s total probable palladium and platinum ore reserves at December 31, 2014, were 42.7 million tons at an average grade of 0.45 ounces per ton, containing approximately 19.1 million ounces of palladium and platinum. This represented a net increase of 0.3% in probable contained ounces compared to the probable reserves reported at December 31, 2013. Combined, the Company’s total proven and probable palladium and platinum ore reserves at December 31, 2014, were 48.9 million tons at an average grade of 0.45 ounces per ton, containing an estimated 22.2 million ounces of palladium plus platinum – a net increase of approximately 0.7% in total proven and probable contained ounces from the 22.1 million ounces reported at December 31, 2013.

In 2014, proven and probable ore tons increased 0.8% and contained ounces reflected an increase of 0.7% from the respective amounts reported at December 31, 2013. In 2013 proven and probable ore tons increased 5.1% while contained ounces increased by 2.8% from those reported at December 31, 2012. The Company’s total proven and probable ore reserve tonnage in the J-M Reef at December 31, 2014, has increased by approximately 6.0% or 2.8 million tons over the past two years. However, total contained ounces in proven and probable reserves have increased by approximately 3.6% from those reported December 31, 2012.

The Stillwater Mine proven and probable ore reserves at year-end 2014 increased by 2.6% in terms of ore tons from the respective proven and probable amounts reported at year-end 2013. The East Boulder Mine proven and probable ore reserves at year-end 2014 decreased by 0.1% in ore tons from those reported at year-end 2013. Overall, the Company’s estimated proven and probable ore reserves based on ore tons increased by 0.8% in 2014. The Company’s ore reserve determination for 2014, calculated at December 31, 2014, was limited by geologic certainty and not by economic constraints.

The following table compares 2014 and 2013 year-on-year proven and probable ore reserves for the Montana operations:

At December 31, 2014 | At December 31, 2013 | Tonnage | Ounce | |||||||||||||||||

Tons | Grade | Ounce | Tons | Grade | Ounce | Change | Change | |||||||||||||

Stillwater Mine | ||||||||||||||||||||

Proven | 3,351 | 0.57 | 1,984 | 3,246 | 0.57 | 1,856 | 3.2 | % | 6.9 | % | ||||||||||

Probable | 12,619 | 0.56 | 7,120 | 12,314 | 0.57 | 6,989 | 2.5 | % | 1.9 | % | ||||||||||

Sub-Total | 15,970 | 0.57 | 9,104 | 15,560 | 0.57 | 8,845 | 2.6 | % | 2.9 | % | ||||||||||

East Boulder Mine | ||||||||||||||||||||

Proven | 2,815 | 0.41 | 1,156 | 2,852 | 0.41 | 1,181 | -1.3 | % | -2.1 | % | ||||||||||

Probable | 30,113 | 0.40 | 11,966 | 30,097 | 0.40 | 12,038 | 0.1 | % | -0.6 | % | ||||||||||

Sub-Total | 32,928 | 0.40 | 13,122 | 32,949 | 0.40 | 13,219 | -0.1 | % | -0.7 | % | ||||||||||

Total | ||||||||||||||||||||

Proven | 6,166 | 0.51 | 3,140 | 6,098 | 0.50 | 3,037 | 1.1 | % | 3.4 | % | ||||||||||

Probable | 42,732 | 0.45 | 19,086 | 42,411 | 0.45 | 19,027 | 0.8 | % | 0.3 | % | ||||||||||

Total | 48,898 | 0.45 | 22,226 | 48,509 | 0.45 | 22,064 | 0.8 | % | 0.7 | % | ||||||||||

Changes in proven and probable ore reserves are due to the net effect of the following:

• | Additions to proven ore reserves from new definition drilling, |

• | Deletions as proven reserves are mined, (See Item 6 - Selected Financial Data for prior year production data and concentrator recoveries), |

• | Deletions from probable ore reserves as areas are converted by new drilling from probable to proven ore reserves, |

• | Additions from development activity to convert mineralized inventory to probable ore reserves, and |

• | Additions and deletions from adjustments to ore reserve estimation factors and mine planning criteria. The cut-off grade used in mine planning ranges from 0.2 to 0.3 troy ounces of palladium and platinum per ton for the Stillwater Mine and is 0.2 troy ounces of palladium and platinum per ton for the East Boulder Mine. The economic value of this cut-off grade varies with palladium and platinum prices and with the cost and efficiency of the different mining methods employed. |

15

CURRENT OPERATIONS

Montana Properties and Facilities - February 2015

MINING OPERATIONS

Mine production of palladium and platinum totaled 517,700 ounces for the year ended December 31, 2014, a decrease of 1.2% from the 523,900 ounces produced from the mines in 2013. Changes in mining conditions and the array of stopes available for mining in any period generally account for any slight variability in total mined ounces produced.

Combined total cash costs per mined ounce, net of by-product and recycling credits, (a non-GAAP financial measure) averaged $538 per ounce for the year ended December 31, 2014. See "Item 6 - Selected Financial Data - Reconciliation of Non-GAAP Financial Measures to Consolidated Costs of Revenues." Note that, for historical reasons, the Company’s measurement of total cash costs per mined ounce customarily has been reported net of credits for sales of by-products from mining and also net of PGM Recycling segment margins. The table below illustrates the effect of by-product and recycling credits on the average cash costs per mined ounce net of credits for the combined Montana mining operations.

Cash Costs Per Mined Ounce - Combined Montana Mining Operations | Full Year 2014 | Full Year 2013 | ||||||

Reported Total Cash Costs per Mined Ounce net of Credits* | $ | 538 | $ | 496 | ||||

Add Back By-Product Revenue Credit | 57 | 52 | ||||||

Add Back PGM Recycling Income Credit | 23 | 68 | ||||||

Total Cash Costs per Mined Ounce before Credits* | $ | 618 | $ | 616 | ||||

* These are non-GAAP financial measures. For a reconciliation of non-GAAP financial measures to GAAP accounting measures, see "Reconciliation of Non-GAAP Financial Measures to Consolidated Costs of Revenues" in Part II, Item 6 of this report.

16

STILLWATER MINE

The underground Stillwater Mine facility near Nye, Montana accesses, extracts and processes PGM ores from the eastern portion of the J-M Reef using mine openings located in the Stillwater River Valley. The mine began operating 29 years ago in 1986. All surface structures and tailings management facilities are located within the 2,613 acre Stillwater Mine Operating Permit area which is administered collectively by the Montana Department of Environmental Quality (DEQ) and the United States Forest Service (USFS). Ore reserves developed at the Stillwater Mine are controlled by patented mining claims either leased or owned outright by the Company. The mine is located approximately 85 miles southwest of Billings, Montana and is accessed by a paved road. The mine has adequate water and power from established sources to conduct its current operations. See “Risk Factors – Certain of the Company's properties are subject to title risk, particularly related to the validity of unpatented mining claims.”

The Stillwater Mine accesses and has developed a 5.9 mile-long underground segment of the J-M Reef, on various levels between 1,900 and 7,500 feet above sea level. Access to the ore at the Stillwater Mine is accomplished by means of a 1,950 foot vertical shaft from the valley floor and by a system of horizontal adits and drifts driven parallel to the strike of the J-M Reef at vertical intervals of between 150 feet and 300 feet. Seven main adits have been driven from surface portals on the west and east slopes of the Stillwater Valley at various elevations between 5,000 and 5,900 feet above sea level. Additional principal levels have been developed below the 5000 level, accessed from the vertical shaft and associated ramp systems. Extensive underground rail haulage has been installed on the 5000 and 3500 levels to the west of the shaft, with future rail planned on the 2000 level. Ore from this region of the mine is hauled by truck and / or rail to the shaft, where it is crushed and hoisted out of the mine. The Company is continuing to develop a decline system and additional principal mining levels to access and develop deeper areas in the central part of the mine. At the end of 2014 this decline system extended down to the 1900 level.

The headframe for the shaft at the Stillwater Mine is situated in the Stillwater Valley adjacent to the concentrator, at 5,000 feet above sea level. Ore and any waste rock to be transported to the surface from the off-shaft and deeper areas of the mine are crushed prior to being hoisted up the shaft. The production shaft and underground crushing station reduce haulage times and costs, facilitate the handling of ore and waste, and improve the grinding capabilities of the concentrator. Ore produced from above the 5,000 foot elevation on the west side of the mine is hauled to the surface by rail. Waste material not used for backfilling in underground excavations is transported to the surface and placed in permitted waste rock disposal sites.

During 2007 the Company began construction of a major dedicated decline ramp for electric truck haulage of material mined from below the 3500 rail level. The Kiruna electric trucks haul material up to the 3500 level of the shaft, where it can then be hoisted to the surface. This ramp currently services down to the 2500 level of the mine, but it is planned to extend down ultimately to approximately the 1,400 foot elevation. The first-phase installation of the Kiruna electric trucks at Stillwater Mine was completed and the first two trucks were placed into operation during the first quarter of 2011. A third Kiruna electric truck was received and placed in service during 2013. In the future, the Company expects the horizontal rail haulage system on the 2000 level will transport ore and waste material from the deeper mining faces to the electric truck ramps. By the end of 2014 the Kiruna ramp had been developed down to the 1900 level, although it is not yet electrified to that depth.

Since 1994, the Company has used two mechanized mining methods: ramp-and-fill and sub-level stoping. Ramp-and-fill is a mining method in which a series of horizontal cuts are extracted from the ore body using mobile equipment. Access to the ore body is from ramps driven within or adjacent to the ore body, allowing the use of hydraulic drills and load-haul-dump equipment. Sub-level stoping is a mining method in which blocks of the reef approximately 50 feet high and up to 75 feet in length are extracted in 30 foot intervals utilizing mobile long-hole drills and remote-control rubber tired load-haul-dump equipment. The reef is mined in a retreat sequence and mined out areas are filled with development waste or sand backfill as appropriate. Traditionally, captive cut-and-fill has been viewed as being more selective in nature than either ramp-and-fill or sub-level stoping, but it also requires miners with specialized skills and is generally less productive. Other factors considered in determining the most appropriate mining method for each area include the amount of ancillary development required, as well as the ore grade and ground conditions expected. The Company determines the appropriate mining method to be used on a stope-by-stope basis utilizing engineering and economic analysis.

The Company processes ore from the Stillwater Mine through a surface concentrator facility (mill) adjacent to the Stillwater Mine shaft. The mill has a design capacity of 3,000 tons per day. Crushed mine ore is fed into the concentrator, mixed with water and ground to slurry in the concentrator’s mill circuits to liberate the PGM-bearing sulfide minerals from the rock matrix. Various reagents are added to the slurry, which then is agitated in a froth flotation circuit to separate the valuable sulfides from the waste rock. In this circuit, the sulfide minerals are successively floated, recycled, reground and refloated to produce a concentrate suitable for further processing. The final flotation concentrate, which represents approximately 2.0% of the original ore weight, is filtered, placed in large bins and then transported by truck to the Company’s metallurgical complex in Columbus, Montana.

17

In 2014 approximately 57.8% of the tailings material from the mill was returned to the mine and used as underground fill material to provide support for additional mining activities. The balance was placed in permitted tailings containment areas on the surface. Tailings are disposed of into the impoundment areas pursuant to the Company’s operating permits. In 1998 the Company received an amendment to its existing operating permit providing for the construction of a lined surface tailings impoundment that would serve the Stillwater Mine for approximately the next 30 years. This facility, located approximately eight miles from the mine and generally referred to as the Hertzler impoundment, was placed into operation in late 2000. See “Business and Properties - Regulatory and Environmental Matters – Permitting and Reclamation.”

During 2014, ore and reef waste production at the Stillwater Mine averaged 2,051 tons, a decrease from the 2,194 tons produced in 2013. Historically, mill recovery of the PGMs contained in the ore have been approximately 92%. The Stillwater Mine produced 340,800 ounces of palladium and platinum, a decrease of 6.9% from the 366,100 ounces produced in 2013. The Stillwater Mine’s total cash costs, net of by-product and recycling credits, (a non-GAAP financial measure) averaged $533 per ounce in 2014 compared to $484 per ounce in 2013. Total cash costs per ounce in 2013 benefited from an exceptionally high recycling credit, reflecting PGM ounces extracted and sold from reprocessing internal furnace brick from the smelter. Before taking the benefit of recycling and by-product sales credits, the Stillwater Mine’s total cash costs averaged $606 per ounce in 2014 and $595 per ounce in 2013. The 1.8% increase in average total cash costs (before credits) was attributable to the lower total mine production in 2014 which was 6.5% lower than 2013.

Cash Costs Per Mined Ounce - Stillwater Mine | Full Year 2014 | Full Year 2013 | ||||||

Reported Total Cash Costs per Mined Ounce net of Credits* | $ | 533 | $ | 484 | ||||

Add Back By-Product Revenue Credit | 50 | 44 | ||||||

Add Back PGM Recycling Income Credit | 23 | 67 | ||||||

Total Cash Costs per Mined Ounce before Credits* | $ | 606 | $ | 595 | ||||

* These are non-GAAP financial measures. For a reconciliation of non-GAAP financial measures to GAAP accounting measures, see "Reconciliation of Non-GAAP Financial Measures to Consolidated Costs of Revenues" in Part II, Item 6 of this report.

EAST BOULDER MINE

The East Boulder Mine is located in Sweet Grass County, Montana, approximately 32 miles south of the town of Big Timber and is accessed by a public road. The East Boulder Mine is fully permitted independently of the Stillwater Mine and comprises a second distinct mining operation accessing the western portion of the J-M Reef. The mine was commissioned in 2002 and is actively mining approximately 2.5 horizontal miles underground along the J-M Reef. The mine consists of underground mine development and surface support facilities, including a concentrator, shop and warehouse, changing facilities, storage facilities, office and tailings management facility. All mine facilities are wholly-owned and operated by the Company. Surface facilities for the East Boulder Mine are situated on unpatented mill site claims maintained on federal lands located within the Gallatin National Forest and administered by the USFS and the Montana DEQ. All surface facilities, including the tailings management complex, are located within a 986 acre operating permit area. Proven and probable ore reserves for the mine are controlled by patented mining claims owned by the Company. Development of the East Boulder Mine began in 1998, and the mine commenced commercial production effective January 1, 2002.

From the surface facilities at the East Boulder Mine, the J-M Reef is accessed by two 18,500 foot long, 15 foot diameter horizontal rail adits driven into the mountain. These two parallel tunnels intersect the ore body deep within the mountain at an elevation 6,450 feet above sea level. Within the mine, the ore body currently is accessed from seven levels of horizontal footwall lateral drifts driven parallel to the J-M Reef totaling approximately 37,500 feet in length, and from four primary ramps totaling approximately 16,815 feet of development. The ore body is accessed vertically by ramp systems tying together the footwall laterals and driven approximately every 2,500 feet along the length of the deposit. The mined ore is transported horizontally out of the East Boulder Mine by rail haulage to the mine portal, where it is processed through the East Boulder Mine concentrator facility. The East Boulder Mine concentrator has a permitted throughput capacity of 2,000 tons per day.

18

In 2014, approximately 49.0% of the East Boulder Mine tailings material was returned to the mine and used for backfill in mined out voids to provide a foundation upon which additional mining activities can occur. The balance was placed in surface tailings containment areas. Tailings placed into the impoundment areas are disposed of pursuant to requirements in the Company’s operating permits. The remaining permitted impoundment area has an estimated staged life of approximately 16 years at the original planned production and processing rate of 2,000 tons per day. During 2014, ore and reef waste production at the East Boulder Mine averaged 1,434 tons per day, compared to 1,299 tons per day during 2013. Mill recovery of the PGMs contained in the ore was approximately 90% for the years ended December 31, 2014, 2013 and 2012, respectively. The East Boulder Mine produced 176,900 ounces of PGMs in 2014, an increase of 12.1% compared to the 157,800 ounces of PGMs produced in 2013, reflecting some initial 2014 production from a stope block in the Graham Creek area. The East Boulder Mine’s total cash costs net of by-product and recycling credits, (a non-GAAP financial measure) were $547 per ounce in 2014 compared to $525 per ounce in 2013. As at the Stillwater Mine, East Boulder Mine's 2013 total cash costs benefited from an unusually high recycling credit attributable to recycling PGM ounces in internal furnace brick. Excluding the benefit of recycling and by-product credits, total cash costs before credits were $641 per ounce in 2014 and $664 per ounce in 2013.

Cash Costs Per Mined Ounce - East Boulder Mine | Full Year 2014 | Full Year 2013 | ||||||

Reported Total Cash Costs per Mined Ounce net of Credits* | $ | 547 | $ | 525 | ||||

Add Back By-Product Revenue Credit | 71 | 69 | ||||||

Add Back PGM Recycling Income Credit | 23 | 70 | ||||||

Total Cash Costs per Mined Ounce before Credits* | $ | 641 | $ | 664 | ||||

* These are non-GAAP financial measures. For a reconciliation of non-GAAP financial measures to GAAP accounting measures, see "Reconciliation of Non-GAAP Financial Measures to Consolidated Costs of Revenues" in Part II, Item 6 of this report.

METALLURGICAL COMPLEX

SMELTER

The Company owns and operates a smelter facility situated along Interstate 90 in Columbus, Montana. The smelter facility consists of two electric furnaces, two top blown rotary converters (TBRCs), a matte granulator, and gas handling and solution regeneration systems. During 2009 the Company completed construction of a new primary 150 ton-per-day smelter furnace at the Columbus facility. This second, larger furnace allows room for growth in future processing volumes, partially mitigates potential operational risk by providing some redundancy (virtually all of the Company’s metal production is dependent on the availability of the smelter facility), and provides capacity for the Company to continue processing during periodic scheduled maintenance shutdowns. After stripping out the old refractory material from the original furnace during 2010, the furnace structure was re-bricked during 2011 and reconfigured during 2012 as a “slag cleaning” furnace. In this configuration, slag tapped from the primary furnace is transferred into the original furnace, providing additional residence time for PGM matte to separate from the slag material, with the intent of increasing metal recoveries. Reconfigured as such, the slag cleaning furnace also serves as a backup for the primary furnace if needed.

Concentrates from the mine sites are transported by truck to the smelter, dried, and fed into the electric furnace. In the furnace, the concentrates are commingled with spent catalyst materials collected by the Company’s recycling business segment. The combined feed is melted in the furnace, where the lighter silica-rich slag separates out into a distinct layer that floats on top of the heavier nickel-copper PGM-rich matte. The matte is tapped from the furnace periodically and granulated. This granulated furnace matte is then re-melted and processed in a TBRC, which extracts iron from the converter matte. The converter matte is poured from the TBRC, granulated and transferred to the base metal refinery for further processing. The granulated converter matte, approximately 6% of the original smelter feed by weight, consists principally of copper and nickel sulfides containing approximately 1.5% to 2.5% PGMs. Any residual slag from the slag cleaning furnace is periodically tapped from the furnace, cooled and returned to the Stillwater Mine concentrator for reprocessing.

The gases released from the smelting operations are routed through a gas / liquid scrubbing system, which removes approximately 99.8% of the contained sulfur dioxide. Spent scrubbing solution is treated in a process that converts the sulfur dioxide into gypsum, or calcium sulfate, and regenerates clean scrubbing solution. The gypsum is used by farmers as a soil amendment and as a water treatment additive by the coal bed methane industry.

19

BASE METAL REFINERY

The Company’s base metal refinery is located on property the Company owns adjacent to the smelter in Columbus, Montana.

The base metal refinery utilizes the patented Sherritt Process, whereby a sulfuric acid solution dissolves out the nickel, copper, cobalt and any residual iron from the PGM-bearing converter matte. The copper and nickel ultimately are marketed as by-products. A nickel crystallizer circuit produces a crystalline nickel sulfate by-product containing minor amounts of cobalt, which is marketed under sales contracts with various companies. A copper electrowinning circuit removes copper from solution as cathode copper that is marketed to copper refiners for upgrading to commercial grade material. The removal of these metals upgrades the PGM fraction of the converter matte product from approximately 2% PGMs to approximately 40% PGMs.

The base metal refinery produces a palladium, platinum and rhodium-rich filter cake, which also contains minor amounts of gold and silver. This filter cake is shipped to a third-party precious metal refinery in New Jersey under a toll-processing agreement that provides the Company with returns of finished metal. The palladium and platinum metals are returned to the Company’s account as 99.95% purity palladium and platinum sponge; and refined rhodium, gold and silver are also separately returned to the Company’s account. Refined metals from the Company's mine production are sold to Johnson Matthey and Tiffany & Co.; refined metals from the Company's recycling segment are normally delivered to the Company’s counterparties. The Company pays its refiner a per-ounce refining charge for toll processing of the refined filter cake, and the refiner also retains a small percentage of the contained metals.

PGM RECYCLING