Attached files

| file | filename |

|---|---|

| EX-23.1 - EXHIBIT 23.1 - Intrepid Potash, Inc. | exhibit2312014.htm |

| EX-10.22 - EXHIBIT 10.22 - Intrepid Potash, Inc. | exhibit1022-ipiseparationa.htm |

| EX-21.1 - EXHIBIT 21.1 - Intrepid Potash, Inc. | exhibit2112014.htm |

| EX-32.2 - EXHIBIT 32.2 - Intrepid Potash, Inc. | ipi12312014exhibit322.htm |

| EX-95.1 - EXHIBIT 95.1 - Intrepid Potash, Inc. | a201410-kxexhibit951.htm |

| EX-23.2 - EXHIBIT 23.2 - Intrepid Potash, Inc. | ipi12312014exhibit232.htm |

| EX-31.2 - EXHIBIT 31.2 - Intrepid Potash, Inc. | ipi12312014exhibit312.htm |

| EX-32.1 - EXHIBIT 32.1 - Intrepid Potash, Inc. | ipi12312014exhibit321.htm |

| EX-31.1 - EXHIBIT 31.1 - Intrepid Potash, Inc. | ipi12312014exhibit311.htm |

| EXCEL - IDEA: XBRL DOCUMENT - Intrepid Potash, Inc. | Financial_Report.xls |

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

_______________________________________________________

FORM 10-K

_______________________________________________________

x | Annual Report Pursuant to Section 13 or 15(d) of the Securities Exchange Act of 1934 |

For the fiscal year ended December 31, 2014 | |

or | |

¨ | Transition Report Pursuant to Section 13 or 15(d) of the Securities Exchange Act of 1934 |

Commission File Number: 001-34025

INTREPID POTASH, INC.

(Exact Name of Registrant as Specified in its Charter)

Delaware | 26-1501877 |

(State or other jurisdiction of incorporation or organization) | (I.R.S. Employer Identification No.) |

707 17th Street, Suite 4200, Denver, Colorado | 80202 |

(Address of principal executive offices) | (Zip Code) |

(303) 296-3006

(Registrant’s telephone number, including area code)

Securities registered pursuant to Section 12(b) of the Act:

Title of each class | Name of each exchange on which registered | |

Common Stock, par value $0.001 per share | New York Stock Exchange | |

Securities registered pursuant to Section 12(g) of the Act: None

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes x No ¨

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or 15(d) of the Act. Yes ¨ No x

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes x No ¨

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§ 232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files.) Yes x No ¨

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of the Form 10-K or any amendment to this Form 10-K. x

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company. See the definitions of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act.

Large accelerated filer x | Accelerated filer ¨ | Non‑accelerated filer ¨ (Do not check if a smaller reporting company) | Smaller reporting company ¨ |

Indicate by check mark whether the registrant is a shell company (as defined by Rule 12b-2 of the Exchange Act). Yes ¨ No x

The aggregate market value of 55,427,763 shares of voting stock held by non-affiliates of the registrant, based upon the closing sale price of the common stock on June 30, 2014, the last business day of the registrant’s most recently completed second fiscal quarter, of $16.76 per share as reported on the New York Stock Exchange was $928,969,308 Shares of common stock held by each director and executive officer and by each person who owns 10% or more of the registrant's outstanding common stock and is believed by the registrant to be in a control position were excluded. The determination of affiliate status for this purpose is not a conclusive determination of affiliate status for any other purposes.

As of January 31, 2015, the registrant had 75,998,708 shares of common stock, par value $0.001, outstanding (including 461,967 restricted shares of common stock).

DOCUMENTS INCORPORATED BY REFERENCE

Certain information required by Items 10, 11, 12, 13 and 14 of Part III is incorporated by reference from portions of the registrant’s definitive proxy statement relating to its 2015 annual meeting of stockholders to be filed within 120 days after December 31, 2014.

INTREPID POTASH, INC.

TABLE OF CONTENTS

Page | ||

PART I

Unless the context otherwise requires, the following definitions apply throughout this Annual Report on Form 10-K:

•"Intrepid," "our," "we," or "us" means Intrepid Potash, Inc. and its consolidated subsidiaries.

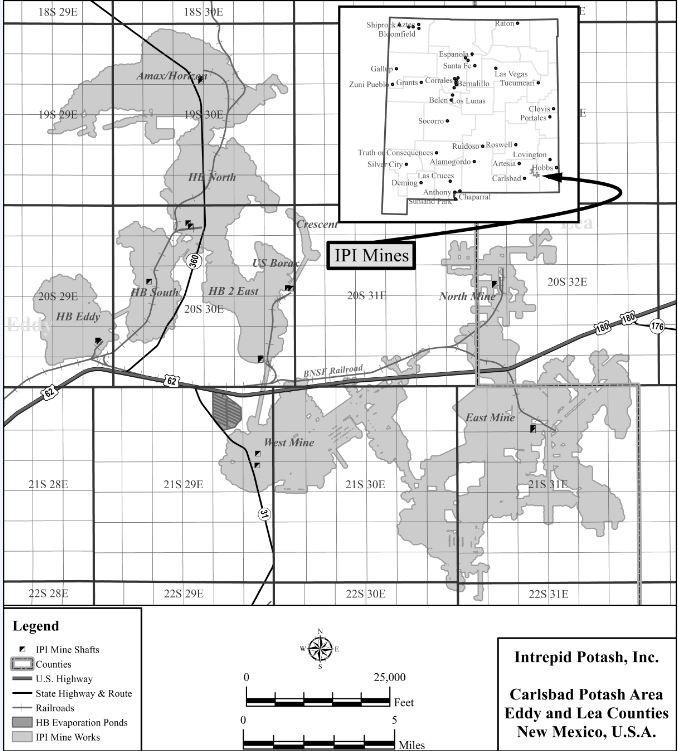

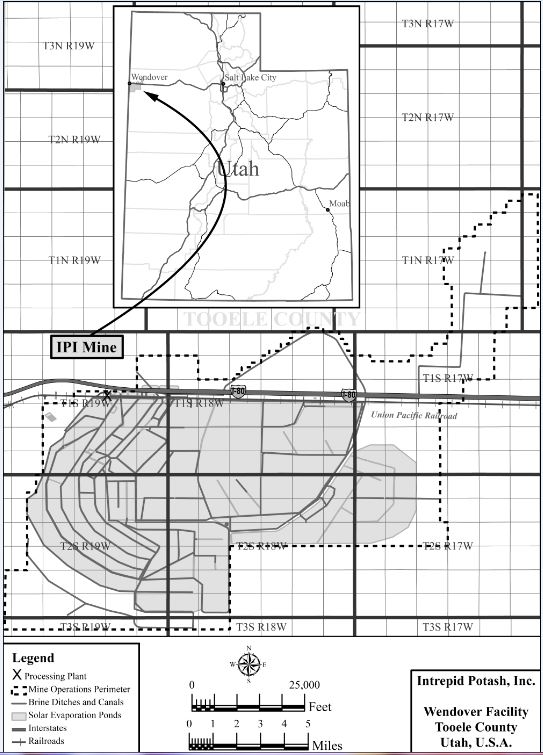

•“West,” “East,” “North,” and “HB” mean our four operating facilities near Carlsbad, New Mexico. "Moab" means our operating facility in Moab, Utah. "Wendover" means our operating facility in Wendover, Utah. You can find more information about our facilities in Item 2 of this Annual Report on Form 10-K.

• | “Tons” mean short tons. One short ton equals 2,000 pounds. Many of our international competitors refer to metric tonnes. One metric tonne equals 1,000 kilograms or 2,205 pounds. |

• | To supplement our consolidated financial statements, which are presented in this Annual Report on Form 10-K and which are prepared and presented in accordance with GAAP, we also use several non-GAAP financial measures to monitor and evaluate our performance. These non-GAAP financial measures include net sales, average net realized sales price, cash operating costs and average potash and Trio® gross margin. These non-GAAP financial measures are described and reconciled to the most comparable GAAP measures in Item 7: Management's Discussion and Analysis of Financial Condition and Results of Operations - Non-GAAP Financial Measures of this Annual Report on Form 10-K. |

We have included technical terms important to understanding our business in the "Glossary of Terms” in Item 1 of this Annual Report on Form 10-K.

CAUTIONARY NOTE REGARDING FORWARD‑LOOKING STATEMENTS

This Annual Report on Form 10-K contains forward‑looking statements within the meaning of the Securities Exchange Act of 1934, as amended (the “Exchange Act”), and the Securities Act of 1933, as amended (the “Securities Act”). These forward‑looking statements are made pursuant to the safe harbor provisions of the Private Securities Litigation Reform Act of 1995. All statements in this Annual Report on Form 10-K other than statements of historical fact are forward‑looking statements. Forward-looking statements include statements about our future results of operations and financial position, our business strategy and plans, and our objectives for future operations, among other things. In some cases, you can identify these statements by forward‑looking words, such as “estimate,” “expect,” “anticipate,” “project,” “plan,” “intend,” “believe,” “forecast,” “foresee,” “likely,” “may,” “should,” “goal,” “target,” “might,” “will,” “could,” “predict,” and “continue.” Forward‑looking statements are only predictions based on our current knowledge, expectations, and projections about future events.

These forward-looking statements are subject to a number of risks, uncertainties, and assumptions, including the following:

• | changes in the price, demand, or supply of potash or Trio®/langbeinite |

• | circumstances that disrupt or limit our production, including operational difficulties or operational variances due to geological or geotechnical variances |

• | interruptions in rail or truck transportation services, or fluctuations in the costs of these services |

• | increased labor costs or difficulties in hiring and retaining qualified employees and contractors, including workers with mining, mineral processing, or construction expertise |

• | the costs of, and our ability to successfully construct, commission, and execute, any of our strategic projects |

• | adverse weather events, including events affecting precipitation and evaporation rates at our solar solution mines |

• | changes in the prices of raw materials, including chemicals, natural gas, and power |

• | the impact of federal, state, or local governmental regulations, including environmental and mining regulations; the enforcement of those regulations; and governmental policy changes |

• | our ability to obtain any necessary governmental permits relating to the construction and operation of assets |

• | changes in our reserve estimates |

• | competition in the fertilizer industry |

• | declines or changes in U.S. or world agricultural production or fertilizer application rates |

• | declines in the use of potash products by oil and gas companies in their drilling operations |

• | changes in economic conditions |

• | our ability to comply with covenants in our debt-related agreements to avoid a default under those agreements, or the total amount available to us under our credit facility is reduced, in whole or in part, because of covenant limitations |

1

• | disruption in the credit markets |

• | our ability to secure additional federal and state potash leases to expand our existing mining operations |

• | the other risks, uncertainties, and assumptions described in Item 1A. Risk Factors and elsewhere in this Annual Report on Form 10-K |

In addition, new risks emerge from time to time. It is not possible for our management to predict all risks that may cause actual results to differ materially from those contained in any forward-looking statements we may make.

In light of these risks, uncertainties, and assumptions, the future events and trends discussed in this Annual Report on Form 10-K may not occur and actual results could differ materially and adversely from those anticipated or implied in these forward-looking statements. As a result, you should not place undue reliance on these forward-looking statements. We undertake no obligation to publicly update any forward-looking statements, except as required by law.

ITEM 1. | BUSINESS |

General

We are the only producer of muriate of potash (“potassium chloride” or “potash”) in the United States and are one of two producers of langbeinite (“sulfate of potash magnesia”). Langbeinite is a low-chloride potassium fertilizer with the additional benefits of sulfate and magnesium. We generally describe this multi-nutrient specialty product as langbeinite when we refer to production and as Trio® when we refer to sales and marketing. Our revenues are generated exclusively from the sale of potash and Trio®. We are a leader in the utilization of solar solution mining to produce potash, which is one of the lowest cost production methods for potash.

Potassium is one of the three primary macronutrients essential to plant formation and growth. Since 2005, we have supplied, on average, approximately 1.5% of annual world potassium consumption and 9.4% of annual U.S. potassium consumption. We also produce salt, magnesium chloride, and metal recovery salts from our potash mining processes, the sales of which are accounted for as by-product credits to our cost of sales.

We own three solution mining facilities and two conventional underground facilities that we utilize for producing potash. Our solution mining production comes from our HB solar solution mine near Carlsbad, New Mexico, a solar solution mine near Moab, Utah and a solar evaporation shallow brine mine in Wendover, Utah. Our conventional production comes from our underground West and East mines near Carlsbad, New Mexico. We also operate the North compaction facility near Carlsbad, New Mexico, which services the West and HB mines. Trio® production comes from underground conventional mining of a mixed ore body that contains both potash and langbeinite, which is mined and processed at the East facility near Carlsbad, New Mexico. We have additional opportunities to develop mineralized deposits of potash in New Mexico as well as to improve recoveries in our processing plants. These opportunities potentially include additional solution mining activities and improved recoveries of langbeinite.

Our principal offices are located at 707 17th Street, Suite 4200, Denver, Colorado 80202, and our telephone number is (303) 296-3006.

We have one operating segment which is the extraction, production and sale of potassium containing products. Our extraction and production operations are conducted entirely in the continental United States. We sell potash primarily into the domestic U.S. market and Trio® into both the domestic and international markets.

Intrepid (through a predecessor entity) was formed in 2000.

Our Products and Markets

Our two primary products are potash and Trio®.

Potash

The majority of our revenues and gross margin are derived from the production and sales of potash. Our potash is marketed for sale into three primary markets. These markets are the agricultural market as a fertilizer input, the industrial market as a component in drilling and fracturing fluids for oil and gas wells and an input to industrial processes, and the animal feed market as a nutrient supplement. The agricultural market is predominately a user of granular-sized potash and Trio®, while the industrial and animal feed markets largely consume standard and fine standard-sized product.

2

We have the flexibility to produce all of our potash in a granular form. This flexibility has allowed us to expand our geographical reach for granular sales and to adjust our production of standard-sized product to more closely align with the specific product demand, thereby decreasing our dependence on sales of any one particular size of potash. In addition, we centrally manage our sales and marketing operations, including our freight and logistics planning, which allows us to evaluate the product needs of our customers and then determine which of our production facilities can be utilized to fill customer orders, all with the design of realizing the highest average gross margin per ton of potash sold by achieving the highest average net realized sales price possible for our potash.

Because many of our sales are geographically concentrated in the central and western United States, our sales can be affected by weather and other conditions in these regions. In addition, our sales into the industrial market tend to correlate with oil and gas pricing, as well as drilling and well completion activity.

Trio®

Trio® is marketed into two primary markets. These markets are the agricultural market as a fertilizer and the animal feed market as a nutrient. We market Trio® internationally through an exclusive marketing agreement with PCS Sales (USA), Inc. (“PCS Sales”) for sales outside the United States and Canada and via a non-exclusive agreement for sales into Mexico.

Industry Overview

Long-term global fertilizer demand has been driven primarily by population growth and global economic conditions with annual demand variations based on planted acreage, agricultural commodity yields and prices, inventories of grains and oilseeds, application rates of fertilizer, weather patterns, and farm sector income. We expect these key variables to continue to have an impact on global fertilizer demand for the foreseeable future. Sustained per capita income growth and agricultural policies in the developing world also affect global demand for fertilizer. Fertilizer demand is affected by other geopolitical factors such as temporary disruptions in fertilizer trade related to government intervention and changes in the buying patterns of key consuming countries. Volatility in agricultural commodity prices also may impact farmer fertilizer buying decisions.

As the global population grows, more food is required from decreasing arable land per capita. A balanced approach to nutrient application will allow farmers to maximize yield and aid in feeding this growing population. As incomes grow in the developing world, people tend to change their diet and consume more animal protein, which requires larger amounts of grain for feed. In addition, the focus on increasing renewable energy has led to regulatory policies supportive of ethanol and bio-diesel production, which currently rely on agricultural products as feedstock.

Fertilizer serves a fundamental role in global agriculture by providing essential crop nutrients that help sustain both the yield and the quality of crops. The three primary nutrients required for plant growth are nitrogen, phosphate, and potassium, and there are no known substitutes for these nutrients. A proper balance of each of the three nutrients is necessary to maximize their effectiveness. Potassium helps regulate plants’ physiological functions and improves plant durability, providing crops with protection from drought, disease, parasites, and cold weather. Unlike nitrogen and phosphate, the potassium contained in naturally occurring potash does not require additional chemical conversion to be used as a plant nutrient.

While industry experts continue to expect that potash consumption rates will increase as world population grows, significant additional capacity has been brought on line over the last two years by existing potash producers. There are a number of brownfield expansions that have been commissioned or that are under construction by the larger potash producers. The estimated worldwide annual capacity is now in excess of recent annual demand. We expect that this supply surplus will exist for several years. As it is difficult to operate at full capacity for sustained periods of time, the larger, well-established producers are operating at less than full capacity, and have a history of managing production levels to more closely meet worldwide demand.

Potash is mined from conventional underground mines, such as at our West and East mines near Carlsbad, as well as through solution mining sub-surface structures and brine recovery from surface resources, as is done at our Moab, Wendover and HB facilities. In conventional underground mines, shafts are sunk to the ore body and mining machines cut out the ore, which is lifted to the surface for processing. In solution mining, the potash is dissolved in brine and pumped to the surface for evaporation and processing.

Virtually all of the world’s potash is currently extracted from approximately 19 commercial deposits. According to the International Fertilizer Industry Association and data published by potash mining companies, six countries accounted for approximately 85% of the world’s aggregate potash production during 2013. During this time period, the top nine potash producers supplied approximately 94% of world production. The three major Canadian producers participate in the Canpotex marketing group that supplied approximately 35% of the global potash production in 2013, one producer in Russia supplied

3

approximately 18% of global production and one producer in Belarus supplied approximately 12% of global potash production during 2012.

There are substantial challenges to adding new potash production as economically recoverable potash deposits are scarce, deep in the earth and geographically concentrated. In addition, a considerable amount of capital is required to produce potash. In addition to typical mining and processing infrastructure, product storage, product load out, and rail access to ship the product are required. A further challenge is that the majority of unexploited mineralized deposits of potash existing outside the Canadian province of Saskatchewan are located in remote and/or politically unstable regions such as the Congo, Thailand, Ethiopia, Argentina, and Kazakhstan.

Energy prices and consumption affect the potash industry in several ways. Energy policies in the U.S. have supported the development of biofuels, which currently rely upon agricultural products as feedstock. As demand and prices for these agricultural products increase or decrease, the use of fertilizer becomes more or less economically attractive. In addition, energy prices affect the global levels of oil and gas drilling, and potash is used as a fluid additive as a means to reduce the risk of swelling in clays in the formation. The level of drilling activity in the United States impacts demand for standard-sized potash.

Competition and Competitive Strategy

We sell into commodity markets and compete based on delivered price of potash and Trio®, reliability and timeliness of supply, and product quality. Products must be durable, and maintain particle size and potassium oxide (“K2O”) content benchmarks in order to compete effectively.

We compete primarily with much larger potash producers, principally Canadian producers and, to a lesser extent, producers located in Russia, Belarus, Chile, Germany, and Israel.

Our competitive strategy is focused on the following:

• | Maximizing margin. We focus on marketing our products into markets that provide the greatest margins relative to our production capacity. By fully participating in these markets at competitive prices, we aim to operate our plants at maximum capacity, which in turn, maximizes production and reduces per ton operating costs. We have the advantage of being located close to the markets we serve and the North American market is much larger than our production capacity. Over the long term, we have achieved a higher average net realized sales price for our potash products compared to our North American competitors because of our freight advantage to key geographies, our diverse customer and market base and our flexible marketing approach. We continue to look for additional opportunities to control our fixed and variable operating expenses and plan to pursue various initiatives to increase the sustainability and reliability of our facilities. |

• | Expanding potash production. We are focused on expanding our potash production through the optimization of our current facilities and through additional solar solution production. The capital that we have invested in recent years has been focused on additional solution mining opportunities from our existing reserves and on increasing our recoveries at our West facility, which is expected to increase production and decrease our costs per ton. |

• | Expanding langbeinite production. We believe the demand for Trio® significantly exceeds the amount of supply. We are focused on increasing our Trio® production by developing our significant langbeinite reserves, optimizing our recovery techniques and maximizing the amount of premium-sized product we manufacture. |

Competitive Strengths

• | U.S. based potash-only producer. We are one of three publicly traded potash-only companies, and the only U.S. producer of potash. We are dedicated to the production and marketing of potash and Trio®. We are located in the heart of a market that consumes significantly more potash than we can produce on an annual basis. Our geographic location also provides us with a transportation advantage shipping our product to our customers. |

As a U.S. producer, we enjoy a significantly lower total production tax and royalty burden than our principal competitors, which operate primarily in Saskatchewan, Canada. The Saskatchewan tax system for potash producers includes a capital tax and several potash mineral taxes, none of which are imposed on us as a U.S. producer. We currently pay an average royalty rate of approximately 4% of our net sales, which compares favorably to that of our competitors in Canada. The relative tax and royalty advantage for U.S. producers becomes more pronounced when profits per ton increase due primarily to the profit tax component of the Saskatchewan potash mineral tax.

4

• | Solar evaporation operations. The HB mine, located in the New Mexico desert, the Moab mine and the Wendover facility, both located in the Utah desert, utilize solar evaporation to crystallize potash from brines. Solar evaporation is a cost efficient production method because it significantly reduces our labor and energy consumption, which are two of the largest costs of production. Our understanding and application of low cost solution mining, combined with the fact that our reserves are located where a favorable climate for evaporation exists, make solar solution mining difficult for other producers to replicate. We also have significant reserves for future expansion of our solar solution mining operations. |

• | Assets located near our primary customer base. We believe that our locations allow us to obtain higher average net realized sales prices than our competitors, who must ship their products across longer distances to consuming markets, which are often export markets. Our location allows us to target sales to the markets in which we have the greatest transportation advantage, maximizing our average net realized sales price. Our access to strategic rail destination points and our location along major agricultural trucking routes support this advantage. |

• | Diversity of markets. We sell to three different markets for potash—the agricultural, industrial and feed markets. During 2014, these markets represented approximately 76%, 19%, and 5% of our potash sales, respectively. |

• | Marketing flexibility. We have the ability to convert all of our standard-sized product into granular-sized product as market conditions warrant. This also provides us with increased marketing flexibility as well as decreased dependence on any one particular market. |

• | Participation in specialty markets. Given the greater scarcity of langbeinite relative to potash and its agronomic suitability for certain soils and crops, there is demand for our langbeinite product, known as Trio®, outside of our core potash markets. There continues to be a growing awareness of the agronomic value of this specialty product. |

• | Significant reserve life and water rights. Our potash and langbeinite reserves each have substantial years of reserve life, with remaining reserve life ranging from 28 to 163 years, based on proven and probable reserve estimates. In addition to our reserves, we have valuable water rights and access to significant mineralized areas of potash for potential future exploitation. |

• | Existing facilities and infrastructure. Constructing a new potash production facility requires substantial time and extensive capital investment in mining, milling, and infrastructure to process, store and ship product. Our operating facilities already have significant facilities and infrastructure in place. We also have the ability to expand our business using existing installed infrastructure, in less time and with lower expenditures than would be required to construct entirely new mines. |

International Sales and Distribution

During 2014, approximately 9% of our Trio® tons were sold internationally, representing approximately 2% of our total net sales. During the years ended December 31, 2014, 2013, and 2012, approximately 96% of our net sales were in the United States, with the remaining sales into countries and regions such as Ghana, Canada, Mexico and other countries in Latin America.

Major Customers

Within the agricultural market, we supply a diversified customer base of distributors, cooperatives, retailers, and dealers, which in turn supply farmers producing a wide range of crops in different geographies. Servicing the industrial and feed markets provides us with a customer base that is unrelated to agricultural markets.

In 2014, no customer accounted for more than 10% of our sales. In 2013 and 2012, one of our distributor customers accounted for approximately 11% and 22%, respectively, of our sales. Because of the size of our company compared to the overall size of the North American market and the regional demands for our products, we do not believe that a decline in a specific customer's purchases would have a material adverse long-term effect upon our financial results.

Environmental, Safety, and Health Matters

We are subject to an evolving set of federal, state, and local environmental, safety, and health (“ESH”) laws that regulate, or propose to regulate (1) soil, air and water quality standards for our facilities; (2) disposal, storage, and management

5

of hazardous and solid wastes; (3) post-mining land reclamation and closure; (4) conditions of mining and production operations; (5) employee and contractor safety and occupational health; and (6) product content and labeling.

We employ, both within and outside Intrepid, environmental professionals to review our operations, assist with environmental compliance, and obtain new and maintain established permits and licenses to operate. These environmental professionals identify and address compliance issues regarding hydrocarbon management, solid and hazardous waste management, protection of water and air quality, asbestos abatement, potable water standards, reclamation and closure, radiation control, animal and plant life, and other ESH issues.

We have spent, and anticipate that we will continue to spend, financial and managerial resources to comply with ESH standards. In 2014, we had approximately $5.8 million of capital investments, and $0.3 million in other expenses, relating to environmental compliance, environmental studies and remediation efforts. We expect to have a similar level of expenditures in 2015. If potential negative effects to the environment are discovered, or if the potential negative effects are of a greater magnitude than currently estimated, material expenditures could be required in the future to remediate the identified effects at these or at other current or former sites.

We cannot predict the potential effects of new or changed laws, regulations, or permit requirements, including the matters discussed below, or changes in the ways that such laws, regulations, or permit requirements are enforced, interpreted, or administered. ESH laws and regulations are complex, are subject to change and have become more stringent over time. It is possible that greater than anticipated ESH capital expenditures or reclamation and closure expenditures will be required in 2015 or in the future. We expect continued government and public emphasis on environmental issues will result in increased future investments for environmental controls at our operations.

Product Registration Requirements

We are required to register fertilizer products with each U.S. state and foreign country where products are sold. Each brand and grade of commercial fertilizer must be registered with the appropriate state agency before being offered for sale, sold, or distributed in that state. Registration requires a completed application, guaranteed analysis, product labels, and registration fee. Sold products must have specified information printed on the bag, on tags affixed to the end of the package, or, if in bulk shipments, written or printed on the invoice, bill of lading, or shipping papers.

State registrations are for one to two-year periods, depending on each state’s requirements. In addition, each state requires tonnage reporting for products sold into that state either monthly, quarterly, semi-annually, or annually, depending on the state’s requirements. Some states require the same registration and reporting process for feed grade products; industrial-grade products do not require registration or tonnage reporting.

Operating Requirements and Government Regulations

Permits. We are subject to numerous environmental laws and regulations, including laws and regulations regarding land use and reclamation; release of emissions to the atmosphere or water; plant and animal life; and the generation, treatment, storage, disposal, and handling of hazardous substances and wastes. These laws include the Clean Air Act; the Clean Water Act; the Resource Conservation and Recovery Act; the Comprehensive Environmental Response, Compensation, and Liability Act (“CERCLA”); the Toxic Substances Control Act; and various other federal, state, and local laws and regulations. Violations can result in substantial penalties, court orders to install pollution‑control equipment, civil and criminal sanctions, permit revocations and facility shutdowns. In addition, environmental laws and regulations may impose joint and several liability, without regard to fault, for cleanup costs on potentially responsible parties who have released, disposed of or arranged for release or disposal of hazardous substances in the environment.

We hold numerous environmental, mining and other permits or approvals authorizing operations at each of our facilities. Our operations are subject to permits for, among other things, extraction of salt and brine, discharges of process materials and waste to air and surface water, and injection of brine. Some of our proposed activities may require waste storage permits. A decision by a government agency to deny or delay issuing a new or renewed permit or approval, or to revoke or substantially modify an existing permit or approval, could limit or prevent us from mining at these properties. In addition, changes to environmental and mining regulations or permit requirements could limit our ability to continue operations at the affected facility. Expansion of our operations also is predicated upon securing the necessary environmental or other permits or approvals. In certain cases, as a condition to procuring the necessary permits and approvals, we are required to comply with financial assurance regulatory requirements. The purpose of these requirements is to assure the government that sufficient company funds will be available for the ultimate reclamation, closure, and post-closure care at our facilities. We obtain bonds as financial assurance for these obligations. These bonds require annual payment and renewal.

We believe we are in compliance with existing regulatory programs, permits, and approvals where non-compliance could have a material adverse effect on our operating results or financial condition. From time to time, we have received

6

notices from governmental agencies that we are not in compliance with certain environmental laws, regulations, permits, or approvals. For example, although designated as zero discharge facilities under the applicable water quality laws and regulations, our East facility, North facility, and Moab facility at times may experience some water discharges during periods of significant rainfall. We have implemented several initiatives to address discharge issues, including the reconstruction or modification of certain impoundments, increasing evaporation, and reducing process water usage and discharges. State and federal officials are aware of these issues and have visited the sites to review our corrective efforts and action plans.

Air Emissions. With respect to air emissions, we anticipate that additional actions and expenditures may be required in the future to meet increasingly stringent U.S. federal and state regulatory and permit requirements, including existing and anticipated regulations under the federal Clean Air Act. We will continue to monitor developments and assess their potential impacts on our operations.

From time to time, in the ordinary course of our business, we receive notices from the New Mexico Environment Department of alleged air quality control violations. Upon receipt of such notices, we promptly evaluate the matter and take any required corrective actions. In these circumstances, we may be required to pay certain civil penalties for any such notices of violation. The malfunction or failure of pollution control equipment and/or production equipment, the failure to follow operating procedures, more stringent air quality regulations, or a change in interpretation and enforcement of applicable air quality laws and regulations could result in future enforcement actions.

Safety and Health Regulation and Programs. Our New Mexico and Utah facilities are subject to the Federal Mine Safety and Health Act of 1977, the Occupational Safety and Health Act, related state statutes and regulations, or a combination of these laws.

The Mine Safety and Health Administration ("MSHA") is the governing agency for our conventional New Mexico facilities. As required by MSHA for underground mines and attendant surface facilities, our New Mexico facilities are inspected by MSHA personnel regularly. Item 4 and Exhibit 95 to this Annual Report on Form 10-K provide information concerning mine safety violations and other regulatory matters required by Section 1503(a) of the Dodd-Frank Wall Street Reform and Consumer Protection Act and Item 104 of Regulation S-K.

Our New Mexico facilities participate in MSHA’s Region 8 “Partnership Program.” There is a formally signed document and plan, pursuant to which each party commits to specific actions and behaviors. Examples of principles include working for an open, cooperative environment; agreeing to citation and conflict processes; and improving training. Our New Mexico facilities are serviced by a trained mine rescue team, which is ready to respond to on-site incidents. The team practices and participates at state and federal events and competitions.

The Occupational Safety and Health Administration ("OSHA") is the governing agency relating to the safety standards at our Utah facilities, as well as our HB solar solution mine and plant. Regular meetings are held covering various safety topics. Training and other certifications is provided to employees as needed based upon their work duties.

Remediation at Intrepid Facilities. Many of our current facilities have been in operation for a number of years. Operations by us and our predecessors have involved the historical use and handling of potash, salt, related potash and salt by-products, process tailings, hydrocarbons and other regulated substances. Some of these operations resulted, or may have resulted, in soil, surface water or groundwater contamination. At some locations, there are areas where process waste, building materials (including asbestos‑containing transite), and ordinary trash may have been disposed or buried, and have since been closed and covered with soil and other materials.

At many of these facilities, spills or other releases of regulated substances may have occurred previously and potentially could occur at any of our facilities in the future, possibly requiring us to undertake or fund cleanup efforts under CERCLA or state laws governing cleanup or disposal of hazardous and solid waste substances.

We work closely with governmental authorities to obtain the appropriate permits to address identified site conditions. For example, buildings located at our facilities in both Utah and New Mexico have a type of siding that contains asbestos. We have adopted programs to encapsulate and stabilize portions of the siding through use of an adhesive spray and to remove the siding, replacing it with an asbestos-free material. Also, we have trained asbestos abatement crews that handle and dispose of the asbestos‑containing siding and related materials. We have a permitted asbestos landfill in Utah. We have worked closely with Utah officials to address asbestos‑related issues at our Moab mine.

7

Reclamation Obligations

Mining and processing of potash generates residual materials that must be managed both during the operation of the facility and upon facility reclamation and closure. Potash tailings, consisting primarily of salt and fine sediments, are stored in surface disposal sites. Some of these tailing materials may also include other contaminants, such as lead, that were introduced as reagents during historic processing methods that may require additional management and could cause additional disposal and reclamation requirements to be imposed. For example, at least one of our New Mexico mining facilities may have legacy issues regarding lead in the tailings pile resulting from production methods utilized prior to our acquisition of these assets. During the life of the tailings management areas, we have incurred and will continue to incur significant costs to manage potash residual materials in accordance with environmental laws and regulations and with permit requirements. Additional legal and permit requirements will take effect when these facilities are closed.

Our surface permits require us to reclaim property disturbed by operations at our facilities. Our operations in Utah and New Mexico have specific obligations related to reclamation of the land after mining and processing operations are concluded. The discounted present value of our estimated reclamation costs for our mines as of December 31, 2014, is approximately $22.0 million, which is reflected in our financial statements. Various permits and authorization documents negotiated with or issued by the appropriate governmental authorities include these estimated reclamation costs on an undiscounted basis. The undiscounted amount of our estimated reclamation costs for our mines as of December 31, 2014, is approximately $57.6 million.

It is difficult to estimate and predict the potential actual costs and liabilities associated with remediation and reclamation, and there is no guarantee that we will not be identified in the future as potentially responsible for additional remediation and reclamation costs, either as a result of changes in existing laws and regulations or as a result of the identification of additional matters subject to remediation and/or reclamation obligations or liabilities.

Royalties

The potash, langbeinite, and by-products we produce and sell from mineral leases are subject to royalty payments. We produce and sell from leased land owned by the U.S. Federal government, the states of New Mexico and Utah, and private landowners. The terms of the royalty payments are determined at the time of the issuance or renewal of the leases. Some royalties are determined as a fixed percentage of revenue and others are on a sliding scale that varies with the ore grade. Additionally, some of our leases are subject to overriding royalty interest payments paid to various owners. In 2014, we paid $14.0 million, or an average of 4% of net sales, in royalties and other taxes. The royalty rates on our state and federal leases in New Mexico are currently set at various rates from 2.0% to 5.0%. The royalty rates for the private leaseholds are between 5.0% and 7.5%. The royalty rates on our state and federal leases in Utah are currently set at rates from 2.5% to 5.0%.

Seasonality

The sales patterns of our agricultural products are generally seasonal. Using averages of the monthly sales data over the last three years, our sales volumes are highest from March through October, which coincides with the spring and fall application seasons in the United States. Likewise, during the colder, winter months, our sales tend to be lower. The month-to-month seasonality of our sales is somewhat moderated due to the variety of crops, industries, distribution strategies and geographies that we serve. We generally build inventories during the low demand periods of the year in order to ensure timely product availability during the peak sales seasons. The seasonality of fertilizer demand results in our sales volumes and net sales being the highest during the spring and our working capital requirements being the highest just before the start of the spring season. We have seen that the fertilizer dealers in North America have instituted practices that are designed to reduce their risk of changes in the price of fertilizer products through consignment type programs. These programs tend to make the timing of the spring and fall seasonal demand profile less predictable within the season.

Our quarterly financial results can vary from one year to the next due to weather‑related shifts in planting schedules and purchasing patterns.

Employees

As of December 31, 2014, we had 928 employees, the majority of which were full-time employees.

We have a collective bargaining agreement with a labor organization representing our hourly employees in Wendover, Utah, which expires on May 31, 2017. This is the sixth agreement negotiated between us and the United Steel, Paper and Forestry, Rubber, Manufacturing, Energy, Allied Industrial and Service Workers International Union 00867. We consider our relationships with our employees to be good.

8

Available Information

We file or furnish with the SEC reports, including our annual reports on Form 10-K, quarterly reports on Form 10-Q, currents reports on Form 8-K, proxy statements, and any amendments to these reports. These reports are available free of charge on our website at www.intrepidpotash.com as soon as reasonably practicable after they are electronically filed with or furnished to the SEC. These reports also can be obtained at www.sec.gov, or by visiting the Public Reference Room of the SEC at 100 F Street, N.E., Washington, D.C. 20549, or by calling the SEC at 1-800-SEC-0330.

We routinely post important information about us and our business, including information about upcoming investor presentations, on our website under the Investor Relations tab. We encourage investors and other interested parties to enroll on our website to receive automatic email alerts or Really Simple Syndication (RSS) feeds regarding new postings. The information found on, or that can be accessed through, our website is not part of this or any other report we file with, or furnish to, the SEC.

Glossary of Terms

Conventional Underground Mine: A mine that uses a mechanical method of extracting economically attractive mineralization from deeper deposits. Underground mining generally consists of multiple shafts and/or entry points and a network of tunnels to provide access to minerals and haulage and conveyance systems to transport materials to the surface. Underground mining machines are used to remove the ore and a series of pillars are left behind to provide the appropriate level of ground support to ensure safe access and mining.

Designated Potash Area: A 497,000 acre location in southeastern New Mexico established by order of the U.S. Secretary of the Department of the Interior and administered by the BLM encompassing the United States' strategic potash reserve.

Langbeinite: A low-chloride potassium fertilizer that also contains sulfate and magnesium. We generally describe this specialty nutrient as langbeinite when we refer to production and as Trio® when we refer to sales and marketing. It is also sometimes referred to as sulfate of potash magnesia.

Magnesium Chloride: A by-product brine containing approximately 30% magnesium chloride that is typically used as a de-icing and de-dusting agent.

Metal Recovery Salt: Potash combined with salt in various ratios that chemically enhances the recovery of aluminum in aluminum recycling processing facilities.

Mill Feed Grade: A measurement of the amount of mineral contained in an ore as a percentage of the total weight of the ore. For potash it is often represented as percent of potassium oxide (K2O) or percent potassium chloride (KCl).

Potash: A generic term for potassium salts (primarily potassium chloride, but also potassium nitrate, potassium sulfate and sulfate of potash magnesia, or langbeinite) used predominantly and widely as a fertilizer in agricultural markets worldwide. Potash also has numerous industrial uses, including oil and gas drilling and stimulation fluids. The chloride containing potash salt is commonly called sylvite in the mineral form or muriate of potash in the product form. Unless otherwise indicated, references to “potash” refer to muriate of potash. Muriate of potash is either red or white in appearance, depending on how it is processed.

Probable (Indicated) Reserves: Reserves for which quantity and grade and/or quality are computed from information similar to that used for proven (measured) reserves, but the sites for inspection, sampling and measurement are farther apart or are otherwise less adequately spaced. The degree of assurance of probable (indicated) reserves, although lower than that for proven (measured) reserves, is high enough to assume geological continuity between points of observation. The classification of minerals as probable reserves requires that Intrepid believe with reasonable certainty that access to the reserves can be obtained, even though currently‑issued permits are not required.

Productive Capacity: The estimated amount of potash production that will likely be achieved based on the amount and quality of ore that we estimate can currently be mined, milled, and/or processed, assuming an estimated average reserve grade, no modifications to the systems, a normal amount of scheduled down time, average or typical mine development efforts and operation of all of our mines and facilities at or near full capacity.

Proven (Measured) Reserves: Reserves for which (a) quantity is computed from dimensions revealed in outcrops, trenches, workings or drill holes; grade and/or quality are computed from the results of detailed sampling, and (b) the sites for inspection, sampling and measurement are spaced so closely and the geologic character is so well-defined that the size, shape, depth and mineral content of the reserves are well-established.

9

Recovery: The percentage of valuable material in the ore that is beneficiated prior to further treatment to develop a saleable product.

Reserve: That part of a mineral deposit, which could be economically and legally extracted or produced at the time of the reserve determination.

Solar Evaporation: A mineral concentration process by which brines containing salt, potash and magnesium chloride are collected into ponds, and solar energy is used to evaporate water thus crystallizing out the salt and potash contained in the brine. The resulting evaporate is then processed to separate the potash from the salt and subsequently prepared for sale.

Solution Mining: For potash, a mining process by which potash is extracted from mineralized beds by injecting a salt-saturated brine into a potash ore body and recovering a brine that is saturated in salt and also close to saturated in potash. The double mineral heavy brine is rich in potash that is brought to the surface for mineral recovery. Solution mining does not require employees or machines to be underground.

Tailings: Salt and insoluble minerals that remain after potash is removed from ore during processing, typically disposed of in a tailings pile.

Ton: A short ton, or a measurement of mass equal to 2,000 pounds. Unless expressly stated otherwise or the context otherwise requires, references to “tons” in this report refers to short tons.

Trio®: The product Intrepid markets for sale that is recovered from langbeinite ore and which serves as a low-chloride potassium, magnesium and sulfur‑bearing fertilizer primarily for use in citrus, vegetable, sugarcane and palm applications and as an animal feed supplement. This product is a double sulfate of potash magnesia concentrate containing approximately 95% langbeinite and 5% salt or other minerals.

Executive Officers

The following section includes biographical information for our executive officers.

Name | Age | Position | ||

Robert P. Jornayvaz III | 56 | Executive Chairman of the Board | ||

James N. Whyte | 56 | Executive Vice President of Human Resources and Risk Management | ||

Kelvin G. Feist | 47 | Senior Vice President of Sales and Marketing | ||

John G. Mansanti | 59 | Senior Vice President of Strategic Initiatives and Technical Services | ||

Brian D. Frantz | 52 | Interim Chief Financial Officer | ||

Margaret E. McCandless | 42 | Vice President, General Counsel, and Secretary | ||

Robert P. Jornayvaz III has served as our Executive Chairman of the Board since May 2010 and as our President and Chief Executive Officer since August 2014. Mr. Jornayvaz served as our Chairman of the Board and Chief Executive Officer from our formation in November 2007 until May 2010. Mr. Jornayvaz served, directly or indirectly, as a manager of our predecessor, Intrepid Mining LLC, from 2000 until its dissolution at the time of our IPO in 2008. Mr. Jornayvaz is the sole owner of Intrepid Production Corporation, which owns approximately 14% of our common stock. Mr. Jornayvaz has over 30 years of experience in the oil and gas industry and over 15 years of experience in the potash industry.

James N. Whyte has served as our Executive Vice President of Human Resources and Risk Management since December 2007. Mr. Whyte joined Intrepid Mining LLC as Vice President of Human Resources and Risk Management in 2004. Prior to joining Intrepid, Mr. Whyte spent 17 years in the property and casualty insurance industry including roles with Marsh and McLennan, Incorporated, American Re-Insurance, and a private insurance brokerage firm he founded. Mr. Whyte is a director of American Eagle Energy Corporation.

Kelvin G. Feist has served as our Senior Vice President of Sales and Marketing since November 2011. Mr. Feist also served as our Vice President of Sales and Marketing from February 2011 to November 2011. From 1994 to January 2011, Mr. Feist held various positions with Agrium Inc., a provider of fertilizer products and services, and its subsidiaries, most recently as Director of Potash Marketing from July 2010 to January 2011 and National Account Manager from July 2007 to July 2010. While at Agrium, Mr. Feist was responsible for all marketing and sales programs related to Agrium’s potash portfolio, including matters relating to production and logistics.

10

John G. Mansanti has served as our Senior Vice President of Strategic Initiatives and Technical Services since January 2015. Mr. Mansanti served as our Senior Vice President of Operations from November 2011 to January 2015, and as our Vice President of Operations from 2009 to November 2011. From 2006 to 2009, Mr. Mansanti worked for Barrick Gold Corporation, a gold production company. While at Barrick, Mr. Mansanti’s roles included General Manager of Goldstrike Mines in Nevada, where he was responsible for managing Barrick’s largest gold producer at approximately 1.7 million ounces a year, and General Manager at the Cortez Gold Mine in Nevada, where he was responsible for managing all aspects of operations and managing the engineering, underground development, and permitting associated with the Cortez Hills project. From 2003 to 2006, Mr. Mansanti served as General Manager at the Turquoise Ridge Joint Venture (a joint venture between Placer Dome Inc. and Newmont Mining Corporation).

Brian D. Frantz has served as our Interim Chief Financial Officer since August 2014. He served as our Vice President-Finance from February 2012 to August 2014 and our Controller and Chief Accounting Officer from July 2010 to August 2014. From October 2008 to July 2010, Mr. Frantz served as Chief Financial Officer of Honnen Equipment Company, a private company specializing in selling and leasing construction equipment. In 2008, Mr. Frantz served as Chief Financial Officer of DWF Wholesale Florists Company, a national wholesale florist. From 1998 to 2007, Mr. Frantz held various positions at RE/MAX International, Inc., a private company engaged in the franchising of real estate brokerage businesses, most recently as Senior Vice President and Chief Financial Officer. From 1986 to 1998, Mr. Frantz was with Arthur Andersen LLP in Denver, most recently as a senior manager, serving public and private companies primarily in the cable television, manufacturing, mining, and real estate industries.

Margaret E. McCandless has served as our Vice President, General Counsel, and Secretary since January 2015. Ms. McCandless served as our Assistant General Counsel and Assistant Secretary from January 2012 to January 2015. Before joining Intrepid, Ms. McCandless served as Associate General Counsel-Securities, Disclosure and Corporate Governance for Qwest Communications International Inc. and then CenturyLink, Inc., which acquired Qwest in April 2011. Prior to joining Qwest in 2004, Ms. McCandless was an associate at the law firms of Hogan Lovells LLP and Cooley LLP.

ITEM 1A. | RISK FACTORS |

Our future performance is subject to a variety of risks and uncertainties that could materially and adversely affect our business, financial condition, and results of operations, and the trading price of our common stock.

Risks Related to Our Business

Our potash sales are subject to price and demand volatility resulting from periodic imbalances of supply and demand, which could negatively affect our results of operations.

Historically, the market for potash has been cyclical, and the prices and demand for potash have fluctuated. Periods of high demand, increasing profits, and high-capacity utilization tend to lead to new plant investment and increased production. This growth continues until the market is over-saturated, leading to decreased prices and lower-capacity utilization until the cycle repeats. Also, individual potash producers have, at times, independently suspended production in response to market outlook. As a result of these various factors, the prices and demand for potash can be volatile. This volatility could reduce profit margins and negatively affect our results of operations. We sell the majority of our potash into the spot market in the U.S. In addition, there is no active hedge market for potash as compared to many other commodities. As a result, we do not have protection from this price and demand volatility.

Changes in fertilizer application rates could exacerbate the cyclical nature of the prices and demand for our products.

Farmers attempt to apply the optimum amounts of fertilizer to maximize their economic returns. A farmer’s decision about the application rate for each fertilizer, or the decision to forgo the application of a fertilizer, particularly potash and Trio®, varies from year to year depending on a number of factors. These factors include crop prices, weather patterns, fertilizer and other crop input costs, and the level of crop nutrients remaining in the soil following the previous harvest. Farmers are more likely to increase application rates of fertilizers when crop prices are relatively high, fertilizer and other crop input costs are relatively low, or the level of crop nutrients remaining in the soil is relatively low. Conversely, farmers are likely to reduce application of fertilizers when farm economics are weak or declining or the level of crop nutrients remaining in the soil is relatively high. This variability in application rates can impact the cyclical nature of the prices and demand for our products. In addition, farmers may buy and apply potash or Trio® in excess of current crop needs, which results in a build-up of potassium in the soil that can be used by crops in subsequent crop years. If this occurs, demand for our products could be delayed to future periods.

11

Aggressive pricing or operating strategies by other potash producers could adversely affect our sales and results of operations.

The potash industry is concentrated, with a relatively small number of producers accounting for the majority of global production. Many of these producers have significantly larger operations and more resources than we do and mine potash from reserves that are thicker, higher-grade, and less geologically complex than our reserves. These larger producers may have greater leverage in pricing negotiations with customers and transportation providers. They may also be able to mine their potash at a lower cost due to economies of scale or other competitive advantages. In addition, they may decide to pursue aggressive or new pricing or operating strategies that disrupt the global and U.S. potash markets. These disruptions could cause lower prices or demand for our product, which would adversely affect our sales and results of operations.

Adverse conditions in the global economy and disruptions in the financial markets could negatively affect our results of operations and financial condition.

Global economic volatility and uncertainty can create uncertainty for farmers and customers in the geographic areas where we sell our products. If farmers reduce, delay, or forgo their potash and Trio® purchases due to this uncertainty, our results of operations would be adversely affected. Moreover, volatility and disruptions in the financial markets could limit our customers’ ability to obtain adequate financing or credit to purchase and pay for our products, which would decrease our sales volume. Changes in governmental banking, monetary, and fiscal policies to restore liquidity and increase credit availability may not be effective. It is difficult to determine the extent of economic and financial market problems and the many ways in which they could negatively affect our customers and business. In addition, if we are required to raise additional capital or obtain additional credit during an economic downturn, we could be unable to do so on favorable terms or at all.

If we are required to write down the value of our inventories, our financial condition and results of operations would be adversely affected.

We carry our inventories at the lower of cost or market. In periods when the market prices for our products fall below our cost to produce them and the lower prices are not expected to be temporary, we are required to write down the value of our inventories. Any write-down would adversely affect our financial condition and results of operations, possibly materially.

Mining is a complex process that frequently experiences production disruptions. Because of the nature of our operations, we could be more vulnerable to these disruptions than our competitors, which could adversely affect our results of operations.

The process of mining is complex. Production delays can occur due to equipment failures, unusual or unexpected geological conditions, environmental hazards, acts of nature, and other unexpected events or problems. In addition, we must transport mined ore for long distances to remove it from the mines for processing, which creates a higher probability of incidents. Many of our facilities have had long service lives and may require more maintenance or be more likely to fail than newer facilities or equipment. For example, the shafts at our West mine were constructed in 1931, are located in an area of known subsidence, and require frequent maintenance due to water inflow, wooden structures, and salt build-up. Additionally, at our East mine, the mining of langbeinite ore, which is harder and more abrasive than sylvite ore, has caused greater wear on our equipment, thereby increasing the expense and frequency of maintenance and repairs. Operational difficulties can also arise from our milling processes. For example, the mill at our East mine experiences build-ups of complex salts, an undesirable by-product of langbeinite production that we must remove. In addition, the mixed ore body, which contains sulfates, can cause changes in brine chemistry that may impact potash production. Furthermore, production at our facilities is dependent upon the maintenance and geotechnical structural integrity of our tailings and storage ponds. The amounts that we are required to spend on maintenance and repairs may be significant. Production delays and stoppages, and higher-than-expected maintenance and repair expense, could have an adverse effect on our results of operations.

Mining is a hazardous process, and accidents occurring in the course of our operating activities could result in significant costs or production delays.

The process of mining is hazardous and involves various risks and hazards that can result in serious accidents. If unforeseen accidents or events occur, or if our safety procedures are not effective, we could be subject to liabilities arising out of personal injuries or death, our operations could be interrupted, or we could be required to shut down or abandon affected facilities. Accidents could cause us to expend significant amounts to remediate safety issues or repair damaged facilities.

Existing or expanded oil and gas development near our mines could result in methane gas leaking from an oil and gas well into our mines. We test our mines daily for methane gas. However, unlike coal mines, our mines are not constructed or equipped to deal with methane gas. Any intrusion of methane gas into our mines could cause an explosion resulting in loss of life or significant property damage or could require the suspension of all mining operations until the completion of extensive modifications and re-equipping of the mine. The costs of modifying our mines and equipment could make it uneconomical to

12

reopen our mines. You can find more information about the co-development of potash and oil and gas resources in the Designated Potash Area under the risk factor below entitled “Existing and further oil and gas development in the Designated Potash Area could impair our potash reserves, which could adversely affect our financial condition or results of operations."

The grade of ore that we mine could vary from our projections due to the complex geology and mineralogy of potash reserves, which could adversely affect our potash production and our results of operations.

Potash ore bodies have complex geology. Our potash production is affected by the potassium content and other mineralogy of the ore. Our projections of ore grade may not be accurate. There are numerous uncertainties inherent in estimating ore grade, including many factors beyond our control. An unexpected reduction in the grade of our ore reserves would decrease our potash production because we would need to process more ore to produce the same amount of saleable-grade product. As a result, our results of operations would be adversely affected.

If the assumptions underlying our reserve estimates are inaccurate, the quantities and value of our reserves, and in turn our financial condition and results of operations, could be adversely affected.

There are numerous uncertainties inherent in estimating our potash and langbeinite reserves. As a result, our reserve estimates necessarily depend upon a number of assumptions, including the following:

• | geologic and mining conditions, which may not be fully identified by available exploration data and may differ from our experiences in areas where we currently mine or operate |

• | future potash prices, operating costs, capital expenditures, royalties, severance and excise taxes, and development and reclamation costs |

• | future mining technology improvements |

• | the effects of governmental regulation |

• | variations in mineralogy |

In addition, because reserves are only estimates built on various assumptions, they cannot be audited for the purpose of verifying exactness. It is only after extraction that reserve estimates can be compared to actual values to adjust estimates of the remaining reserves. If any of the assumptions that we make in connection with our reserve estimates are incorrect, the amounts of potash and langbeinite that we are able to economically recover from our mines could be significantly lower than our reserve estimates. In turn, our financial condition and results of operations could be adversely affected.

The seasonal demand for our products, and the resulting variations in our cash flows from quarter to quarter, could have an adverse effect on our results of operations and working capital requirements.

The fertilizer business is seasonal. We typically experience increased sales during the North American spring and fall application seasons. The degree of seasonality can change significantly from one year to the next due to weather-related shifts in planting schedules and purchasing patterns. We and our customers generally build inventories during low-demand periods of the year to ensure timely product availability during high-demand periods, resulting in increased working capital requirements just before the start of these seasons. If we are unable to accurately predict the timing of demand for our products due to variations in seasonality from year to year, our results of operations and working capital requirements could be adversely affected.

Changes in laws and regulations affecting our business, or changes in enforcement practices, could have an adverse effect on our financial condition or results of operations.

We are subject to numerous federal and state laws and regulations covering a wide variety of subject matters. Changes in these laws or regulations could require us to modify our operations, objectives, or reporting practices in ways that adversely impact our financial condition or results of operations. In addition, new laws and regulations, or new interpretations of or enforcement practices with respect to existing laws and regulations, could similarly impact our business.

For example, we are subject to significant regulation under MSHA and OSHA. High-profile mining accidents could prompt governmental authorities to enact new laws and regulations that apply to our operations or to more strictly enforce existing laws and regulations.

Physical effects of climate change, and climate change legislation, could have a negative effect on our operations and results of operations.

The potential physical effects of climate change could have an adverse effect on us and our customers. These effects could include changes in weather patterns (including drought and rainfall levels), water availability, storm patterns and intensities, and temperature levels. These changes could have an adverse effect on our costs, production, or sales. These changes could also have an adverse effect on our customers, which in turn could reduce the demand or price for our products.

13

In addition, federal and state legislators and regulators regularly consider ways to reduce greenhouse gas emissions in an effort to mitigate climate change. Any new rules could have a significant impact on our operations and products and could result in substantial additional costs for us.

Our business depends on skilled and experienced workers, and our inability to find and retain quality workers could have an adverse effect on our development and results of operations.

The success of our business depends on our ability to attract and retain skilled managers, engineers, and other workers. At times, we may not be able to find or retain qualified workers. In particular, the labor market around Carlsbad, New Mexico, is very competitive and employee turnover is generally high. In that market, we compete for experienced workers with several other employers, including natural resource facilities, oil fields, and other potash facilities. In addition, there is high demand globally for technical mining talent. If we are not able to attract and retain quality workers, the development of our business could suffer or we could be required to raise wages to keep our employees, hire less qualified workers, or incur higher training costs. The occurrence of any of these events could have an adverse effect on our results of operations.

Changes in the prices of energy and other important materials used in our business, or disruptions to their supply, could adversely impact our sales, results of operations, or financial condition.

Natural gas, electricity, steel, water, chemicals, diesel, and gasoline are key materials that we purchase and use in the production of our products. The prices of these commodities are volatile.

Our sales and profitability are impacted by the price and availability of these materials. A significant increase in the price of these materials that is not recovered through an increase in the price of our products, or an extended interruption in the supply of these materials to our production facilities, could adversely affect our results of operations or financial condition. In addition, high natural gas or other fuel costs could increase crop input costs for farmers, which could cause our sales to decline.

Any decline in U.S. agricultural production or any limitations on the use of our products for agricultural purposes could adversely affect the markets for our products and our results of operations.

The U.S. agricultural industry can be affected by a number of factors, including weather patterns, field conditions, current and projected grain inventories and prices, the domestic and international demand for U.S. agricultural products, and U.S. and foreign policies regarding trade in agricultural products. State and federal governmental policies, including farm and ethanol subsidies and commodity support programs, may also influence the number of acres planted, the mix of crops planted, and the use of fertilizers. In addition, there are various city, county, and state initiatives to regulate the use and application of fertilizers due to various environmental concerns. If U.S. agricultural production or fertilizer use decreased significantly due to one or more of these factors, our results of operations could be adversely affected.

A decline in oil and gas drilling or a reduction in the use of potash in drilling fluids could increase our operating costs and decrease our average net realized sales price of potash.

A significant portion of our revenue comes from the sale of potassium chloride for use in oil and gas drilling fluids. A decline in oil and gas drilling could reduce our sales into this industrial market. In addition, alternative products that have some of the same clay-inhibiting properties as potash are commercially available. These alternative products could temporarily or permanently replace some of our sales into the industrial market. If a significant amount of our sales into the industrial market shifted to the agricultural market due to any of these factors, our average net realized sales price of potash could decline.

Increased costs could affect our per-ton profitability.

A substantial portion of our operating costs is comprised of fixed costs that do not vary based on production levels. These fixed costs include labor and benefits, base energy usage, property taxes, insurance, maintenance expenditures, and depreciation. Any increase in fixed costs or decrease in production generally increases our per-ton costs and correspondingly decreases our per-ton operating margin. As a result, a significant increase in costs at any of our facilities could have an adverse effect on our profitability and cash flows, particularly during periods of decreasing potash prices.

A shortage of railcars or trucks for transporting our products, increased transit times, or interruptions in railcar or truck transportation could result in customer dissatisfaction, loss of sales, higher transportation or equipment costs, or disruptions in production.

We rely heavily upon truck and rail transportation to deliver our products to our customers. In addition, the cost of transportation is an important component of the price of our products. A shortage of trucks or railcars for carrying product or increased transit times due to accidents, highway or railway disruptions, congestion, high demand, labor disputes, adverse weather, natural disasters, changes to transportation systems, or other events could prevent us from making timely delivery to our customers or lead to higher transportation costs. As a result, we could experience customer dissatisfaction or a loss of sales.

14

Similarly, disruption within the transportation systems could negatively affect our ability to obtain the supplies and equipment necessary to produce our products. We may also have difficulty obtaining access to ships to deliver our products to overseas customers.

We rely on our management personnel for the development and execution of our business strategy, and the loss of one or more members of our management team could harm our business.

Our management personnel have significant relevant industry and company-specific experience. Our senior management team has developed and implemented first-of-their-kind processes and other innovative ideas that are largely responsible for the success of our business. If we are unable to retain these individuals, our operations could be disrupted and we may be unable to achieve our business strategies and grow effectively. We do not currently maintain “key person” life insurance on any of our management personnel.

Weakening of the Canadian dollar and Russian ruble against the U.S. dollar could lead to lower domestic potash prices, which would adversely affect our results of operations. Fluctuations in these currencies could cause our results of operations to fluctuate.

The U.S. imports the majority of its potash from Canada and Russia. If the Canadian dollar and the Russian ruble strengthen in comparison to the U.S. dollar, foreign suppliers realize a smaller margin in their local currencies unless they increase their nominal U.S. dollar prices. Strengthening of the Canadian dollar and Russian ruble therefore tends to support higher U.S. potash prices as Canadian and Russian potash producers attempt to maintain their margins. However, if the Canadian dollar and Russian ruble weaken in comparison to the U.S. dollar, foreign competitors may choose to lower prices proportionally to increase sales volumes while again maintaining a margin in their local currency. These activities could cause our sales prices and results of operations to decrease or fluctuate significantly.

Existing and further oil and gas development in the Designated Potash Area could impair our potash reserves, which could adversely affect our financial condition or results of operations.