Attached files

| file | filename |

|---|---|

| EXCEL - IDEA: XBRL DOCUMENT - SYNTHESIS ENERGY SYSTEMS INC | Financial_Report.xls |

| EX-23.1 - EXHIBIT 23.1 - SYNTHESIS ENERGY SYSTEMS INC | v388046_ex23-1.htm |

| EX-21.1 - EXHIBIT 21.1 - SYNTHESIS ENERGY SYSTEMS INC | v388046_ex21-1.htm |

| EX-32.2 - EXHIBIT 32.2 - SYNTHESIS ENERGY SYSTEMS INC | v388046_ex32-2.htm |

| EX-32.1 - EXHIBIT 32.1 - SYNTHESIS ENERGY SYSTEMS INC | v388046_ex32-1.htm |

| EX-31.1 - EXHIBIT 31.1 - SYNTHESIS ENERGY SYSTEMS INC | v388046_ex31-1.htm |

| EX-31.2 - EXHIBIT 31.2 - SYNTHESIS ENERGY SYSTEMS INC | v388046_ex31-2.htm |

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10-K

| R | ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(D) OF THE SECURITIES EXCHANGE ACT OF 1934 |

| For the fiscal year ended June 30, 2014 | |

| £ | TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(D) OF THE SECURITIES EXCHANGE ACT OF 1934 |

| For the transition period from ______ to ______ | |

Commission file number: 01-33522

SYNTHESIS ENERGY SYSTEMS, INC.

(Exact Name of Registrant as Specified in Its Charter)

| Delaware | 20-2110031 |

| (State or Other Jurisdiction of Incorporation or Organization) | (I.R.S. Employer Identification No.) |

| Three Riverway, Suite 300, Houston, Texas | 77056 |

| (Address of Principal Executive Offices) | (Zip Code) |

Registrant’s telephone number, including area code (713) 579-0600

Securities registered pursuant to Section 12(b) of the Exchange Act:

| Common Stock, $.01 par value | NASDAQ Stock Market |

| (Title of Class) | (Name of Exchange on Which Registered) |

Securities registered pursuant to Section 12(g) of the Exchange Act: None

Indicate by check mark

whether the registrant is a well-known seasoned issuer as defined in Rule 405 of the Securities Act.

Yes £ No R

Indicate by check mark

if the registrant is not required to file reports pursuant to Section 13 of 15(d) of the Exchange Act.

Yes £ No R

Indicate by check mark whether the registrant (1) filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the past 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes R No £

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate website, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes R No £

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K (Section 229.405 of this chapter) is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. £

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company. See the definitions of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act.

| Large accelerated filer £ | Accelerated filer £ | Non-accelerated filer £ | Smaller reporting company R |

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act). Yes £ No R

The aggregate market value of the voting stock held by non-affiliates of the registrant was approximately $30 million on December 31, 2013. The registrant had 73,224,330 shares of common stock outstanding on September 10, 2014.

DOCUMENTS INCORPORATED BY REFERENCE

Certain information required to be disclosed in Part III of this report is incorporated by reference from the registrant’s definitive Proxy Statement for the 2013 Annual Meeting of Stockholders, which will be filed not later than 120 days after the end of the fiscal year covered by this report.

TABLE OF CONTENTS

| 2 |

Forward-Looking Statements

This Annual Report on Form 10-K includes “forward-looking statements” within the meaning of Section 27A of the Securities Act of 1933, as amended, and Section 21E of the Securities Exchange Act of 1934 as amended. All statements other than statements of historical fact are forward-looking statements. Forward-looking statements are subject to certain risks, trends and uncertainties that could cause actual results to differ materially from those projected. Among those risks, trends and uncertainties are: the ability of our ZZ Joint Venture (as defined below under “Description of Business – Current Operations and Projects – Zao Zhuang Joint Venture”) to effectively operate Xuejiao’s methanol plant and produce methanol; the ability of our project with Yima to produce earnings, pay dividends and collect the remaining receivable from the Yima Joint Venture (as defined below under “Description of Business – Current Operations and Projects – Yima Joint Ventures”); our ability to develop and expand business of the TSEC Joint Venture, as defined below, in the joint venture territory; our ability to develop our power business unit and marketing arrangement with GE and our other business verticals, steel and renewables; our ability to successfully develop our licensing business; to reduce operating costs; our limited history, and viability of our technology; commodity prices, and the availability and terms of financing; our ability to obtain the necessary approvals and permits for future projects; our ability to raise additional capital, if any, and our ability to estimate the sufficiency of existing capital resources; the sufficiency of internal controls and procedures; and our results of operations in countries outside of the U.S., where we are continuing to pursue and develop projects. Although we believe that in making such forward-looking statements our expectations are based upon reasonable assumptions, such statements may be influenced by factors that could cause actual outcomes and results to be materially different from those projected. We cannot assure you that the assumptions upon which these statements are based will prove to have been correct.

When used in this Form 10-K, the words “expect,” “anticipate,” “intend,” “plan,” “believe,” “seek,” “estimate” and similar expressions are intended to identify forward-looking statements, although not all forward-looking statements contain these identifying words. Because these forward-looking statements involve risks and uncertainties, actual results could differ materially from those expressed or implied by these forward-looking statements for a number of important reasons, including those discussed under “Risk Factors,” “Management’s Discussion and Analysis of Financial Condition and Results of Operations,” and elsewhere in this Form 10-K.

You should read these statements carefully because they discuss our expectations about our future performance, contain projections of our future operating results or our future financial condition, or state other “forward-looking” information. You should be aware that the occurrence of certain of the events described in this Form 10-K could substantially harm our business, results of operations and financial condition and that upon the occurrence of any of these events, the trading price of our common stock could decline, and you could lose all or part of your investment.

We cannot guarantee any future results, levels of activity, performance or achievements. Except as required by law, we undertake no obligation to update any of the forward-looking statements in this Form 10-K after the date hereof.

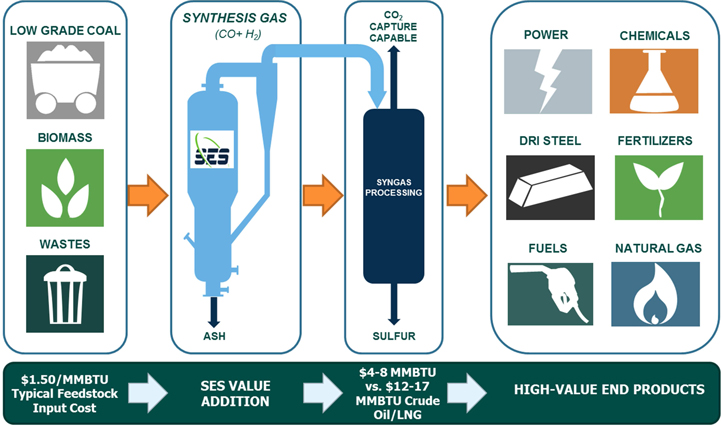

Item 1. Description of Business

We are a global energy and gasification technology company that provides proprietary gasification technology systems and solutions to the energy and chemical industries. Our business strategy is to create value by supplying our technology, equipment and services into global projects where lower cost low quality coals, coal wastes, municipal wastes, agricultural biomass, and other biomass feed stocks can be profitably converted through our proprietary gasification technology into clean synthesis gas, or syngas (a mixture of primarily hydrogen, carbon monoxide, and methane), which is then used to produce a variety of high value energy and chemical products. Our initial operating projects to date convert high ash coal and coal wastes to chemical grade methanol, and we are pursuing a variety of additional global projects under development by customers who may use our technology platform to convert low quality coals such as lignite, coal wastes, municipal wastes and agricultural waste biomass to high value products such as electric power, transportation fuels, substitute natural gas, or SNG, fuel for direct reduction iron, or DRI, steel making and other products. Our technology is originally based on the U-GAS® process developed by the Gas Technology Institute, or GTI, and we have augmented and differentiated the technology through newly developed intellectual property related to design, detailed engineering, constructing, starting up and operating our two commercial joint venture plants in China.

| 3 |

Our business model is to deploy our technology on a global basis via supplying a technology package, containing license rights to operate a project using our technology, gasification system equipment, and technology related services. As part of our overall strategy we intend to form strategic regional and market-based partnerships or business verticals where our technology offers advantages and through cooperating with these partners grow an installed base of projects. Through collaborative partnering arrangements we believe we will commercialize our technology much faster than entering these markets alone. In addition to regional business units, we are continuing to evaluate and develop our business in markets such as power, steel, fuels, substitute natural gas, chemicals and renewables which can benefit from deploying our technology offering to create these products from low cost coal and renewable feedstocks. We are developing these market-based business vertical opportunities together with strategic partners which have established businesses or interests in these markets with the goal of growing and expanding these businesses by partnering with us and deployment of our technology offering.

We believe our existing operating projects in China have clearly demonstrated that we have several advantages which differentiate our technology over other commercially available gasification technologies, such as entrained flow, fixed bed, and moving bed gasification technologies. The first of these advantages is our ability to use a wide range of feedstocks (including low rank, high ash and high moisture coals, which are significantly cheaper than higher grade coals), coal wastes, municipal wastes, agricultural wastes, and other biomass feedstocks to make clean syngas. Our feedstock advantage opens up many of these global resources for use to manufacture energy and chemical products which otherwise could not be done with other currently available commercial gasification technologies. Secondly, our technology’s advanced fluidized bed design is extremely tolerant to a wide range of changes in feedstock during operation, which allows for flexible fuel purchasing for our customers. Additionally, our technology can use much less water and its simple design leads to more favorable fabrication costs and resulting plant costs being lower compared to other commercially available technologies. We believe that these important cost, feedstock flexibility, and water consumption factors position our technology for future deployment of gasification worldwide because our technology can enable projects to become a lower cost producer of products. Depending on local market needs and fuel sources, our syngas can be used to produce many valuable products including electric power, SNG, chemicals such as methanol, dimethyl ether, or DME, and glycol, ammonia for fertilizer production, reducing gas for DRI processes, and transportation fuels such as gasoline and diesel.

Overview of Our Gasification Process

Our gasification technology uses oxygen, steam and heat to cleanly and economically extract carbon and hydrogen from coal resources, coal wastes and renewable forms of biomass and municipal wastes. This is a partial oxidation process where the carbon and hydrogen molecules are converted to gas in the form of hydrogen (H2), carbon monoxide (CO) and methane (CH4). Other components of syngas include water vapor, carbon dioxide (CO2), inerts such as nitrogen, and traces of compounds derived from other components in the feedstock. This combined gas mixture is called synthesis gas or “syngas”.

Syngas is a valuable and extremely versatile product which can offer lower production costs than using traditional oil and natural gas alternatives. Syngas can be readily converted into a wide range of fundamental energy and chemical products. These products include but are not limited to electric power, natural gas (methane), transportation fuels such as gasoline, diesel and jet fuel, chemicals such as methanol, olefins, glycols and others, ammonia and urea for agricultural fertilizers and feedstocks for steel making.

| 4 |

SES Gasification Technology

Produces Syngas Used for Production of a Variety of Energy and Chemical Products

Our technology is in the family of gasification technologies which have been used successfully in industrial applications for many years. However, our technology is meaningfully differentiated over previous forms of gasification technologies primarily through its ability to produce syngas from most forms of solid-form natural resources including low quality brown coals and lignites, high ash sub-bituminous coals, and including high quality bituminous and anthracite coals, high ash and high moisture coals, and biomass and other renewable waste materials.

Our feedstock advantage opens up new global coal resources to use for manufacturing energy and chemical products which otherwise could not be done with other commercial gasification technologies. Our technology’s advanced fluidized bed design is also extremely tolerant to a wide range of changes in feedstock during operation, which allows for flexible fuel purchasing for our customers. Additionally, our technology can use much less water and its simple design leads to more favorable fabrication costs and resulting plant costs being lower compared to other commercially available technologies. We believe these important cost savings, feedstock flexibility, and water consumption factors position our technology for future deployment of gasification worldwide because our technology can enable projects to become a lower cost producer of products.

Our technology began with U-GAS® gasification technology. We obtained an exclusive worldwide license for the U-GAS® gasification technology, developed by GTI located near Chicago, Illinois, a leading non-profit energy technology research and development organization serving the gas industry. Beginning in 1975, GTI developed a fluidized bed gasification technology trademarked as U-GAS®. Our U-GAS® license grants us the worldwide exclusive right to manufacture, make, use and sell both U-GAS® coal gasification systems and coal and biomass mixture (with coal content exceeding 60% by weight) gasification systems, and a non-exclusive right to manufacture 100% biomass gasification systems and coal and biomass mixtures (with biomass content exceeding 40% by weight) gasification systems. We also have rights to sublicense U-GAS® systems to third parties for coal, coal and biomass mixtures and for 100% biomass projects (subject to the approval of GTI, which approval shall not be unreasonably withheld), with GTI and us to share the revenue from such third party licensing fees based on an agreed percentage split. Our license has an initial term expiring in August 2016, with two additional 10-year extensions exercisable at our option. For more information, see “- GTI Agreement” below.

Since we initially obtained the license in 2004, we have further innovated and developed the U-GAS® process into our technology by developing new intellectual property of our own. We are operating projects and further advancing our gasification technology based on innovations and improvements to the design made during the ZZ Joint Venture plant design and operations and in the design, construction, commissioning, and operation of the Yima Joint Ventures. We will continue to refine and expand our gasification process to further differentiate it from other processes in its ability to reliably, cleanly and efficiently produce valuable products from feedstocks that are of low cost and quality and may even be characterized as wastes.

| 5 |

The primary advantage of our gasification process relative to other leading gasification technologies is its ability to produce syngas from most solid-form natural energy resources, including low quality brown coals and lignite to high quality bituminous and anthracite coals, high ash and high moisture coals, and biomass and other renewable waste materials. Our process is very effective at separating carbon from waste ash, which allows for the efficient processing of lower quality coals and many coal waste products that cannot otherwise be utilized efficiently or economically in gasifiers offered by our competitors. The ability to gasify these lower quality feedstocks unlocks economic advantages by allowing the clean and efficient use of lower cost, abundant, local feedstocks.

Our gasification process uses our advanced fluidized-bed technology for the production of valuable low-to-medium heating value syngas from a wide array of biomass feedstocks and coals using oxygen, oxygen enriched air, or air in the gasification reaction. Our technology was developed for the gasification of most coals as well as coal, biomass and biomass blends.

In our gasification process, the feedstock is prepared and conveyed into the gasifier reactor. Within the fluidized bed inside the gasifier, the feedstock reacts with steam, air and/or oxygen and the temperature is controlled to maintain high carbon conversion and non-slagging conditions for the ash. Our gasification process accomplishes four important functions in a single-stage, fluidized-bed gasifier: it decakes, devolatilizes and gasifies the feedstock, and if necessary, agglomerates and separates ash from the reacting coal. The operating pressure of the gasifier depends on the end use for the syngas and can be designed to range from 0 to 60 bar pressure (14.7 psia to 880 psia) or more. After cleaning, the syngas can be used for many applications such as power, SNG, chemicals such as methanol, DME and glycol, ammonia for fertilizer production, reducing gas for DRI processing, and transportation fuels, such as gasoline and diesels.

During operation, the feedstock is gasified rapidly within the fluidized bed and produces a gaseous mixture of hydrogen, carbon monoxide, carbon dioxide, water vapor and methane, in addition to small amounts of hydrogen sulfide and other trace impurities that are derived from the feedstock. Reactant gases, including steam and air or oxygen are introduced into the gasifier to facilitate the chemical reactions, and are also used to fluidize the feedstock inside the reactor. Ash is removed by gravity from the gasifier through a proprietary system for cooling, metering and depressurization. The ash is then typically sold as a raw material for construction and concrete products. The gasifier maintains a low level of carbon in the bottom ash discharge stream, generally achieving overall carbon conversions of over 95%. Cold gas efficiency is a measure of the amount of energy in the feed coal that is converted to syngas and is an important driver of gasification economics. Cold gas efficiencies of up to 83% on high ash coals and carbon conversions of over 99% have been repeatedly demonstrated at commercial scale in the ZZ Joint Venture plant with improved designs by us.

Fines carried over from the fluidized bed are separated from the product syngas prior to heat recovery and syngas cleanup and returned to the gasifier through our proprietary Fines Management System, or FMS, for maximizing carbon conversion. Our FMS which, along with other gasifier improvements, increases conversion of the feedstock which lowers feedstock costs. Using FMS, we achieved over 90-day continuous runs on each single gasifier, which provided very high availability of syngas due to our spare gasifier configuration. With FMS, we believe that we can maximize the utilization of low rank coal in our gasifiers, and as a result, improve the cost advantages derived from using our technology. Our Ash Management System, or AMS, recovers thermal energy from the hot ash generated during gasification and converts it to steam used in the gasification process for export or for generating power. Both our FMS and AMS increase overall efficiency. The product syngas generated from coal is free of tars and oils due to the temperature profile and residence time of the gases in the fluidized bed, simplifying downstream heat recovery and gas cleaning operations.

We believe that our gasification process also minimizes environmental emissions in all forms; air, water, and solid. As described above, due to unique and proprietary features, our gasification process can economically control the carbon content of the feed coal ash remaining after gasification such that the ash is a saleable product in most applications and markets. For wastewater emissions, the combination of dry processes for separation of fine solids from syngas, novel proprietary methods for ash cooling, and high cold gas efficiencies all reduce the water ultimately discharged as wastewater. Process water generated from our gasification units is readily treatable to enable recovery and recycling, such that ultimate wastewater discharge is minimized. Our gasification process and related syngas cleaning also captures the CO2 stream, which can then be used in various applications, such as enhanced oil recovery operations, chemical industry feedstock, and other industrial processes. As regulations that restrict CO2 emissions accelerate, we expect that coal gasification adoption will also accelerate as coal use expands globally.

| 6 |

Competition

We believe that our technology offers an economical and cleaner approach for conversion of coal into energy and chemicals through our ability to economically gasify a wide range of solid-form natural resources including biomass, low quality coals, high quality coals, and coal wastes. We are not aware of commercially available gasifiers with such a wide range of feedstock flexibility. Our gasification technology operates efficiently with high ash and high moisture coals without coal rejection and without the formation of tars and oils. Other technologies, such as the Winkler and High Temperature Winkler fluidized bed gasifiers, British Gas Lurgi fixed bed gasifiers, and others are being marketed in specific regions like China, India, Russia, and North Korea. These technologies have a longer history but generally have inferior performance and economics due to high capital costs, rejection of fine coal, high water usage and production of undesirable by-products such as tars and oils in the syngas which cause additional clean up expense.

The most predominant commercially deployed gasification technology providers are GE, Shell, Siemens and CB&I (formerly Phillips66). These entrained flow slagging gasification technologies operate on more expensive high grade bituminous and some sub-bituminous coals as feedstocks, but lack capability with the more difficult low heating value, high ash and high moisture coals and with biomass or other renewable waste materials. In addition, there are several Chinese companies that utilize entrained flow slagging gasification technologies which are derivatives of the western technologies, and these have been built in commercial scale plants in China. The markets for coal gasification are large with room for competition, however increased competition may impact our future share of the market.

Additionally, several companies, including KBR, are developing gasification technologies targeted for lignite coals which have progressed past the research and development phase but as yet have no commercially operating gasifiers.

SES Gasification Technology Competitive Comparison

| Biomass & Peat | Lignite | Sub Bituminous | Bituminous & Anthracite | Comments | |

| SES Advanced Fluidized Bed |

Good Economics Good Efficiency Low Capex Low water use |

Good Economics Good Efficiency Low Capex Low water use Good for high ash Good for high moisture Includes fine coal

|

Good Economics Good Efficiency Low Capex Low water use Good for high ash Good for high moisture Includes fine coal

|

Best Economics Good Efficiency Low Capex Low water use Good for high ash Good for high moisture Includes fine coal

|

SES Advanced Fluidized gasification maintains its efficiency across all feedstock qualities, and has lower water usage and low Capex and Opex. This leads to attractive economics on most of the world’s solid-form natural resources. |

|

Entrained Flow

|

Excluded due to technology capability or to poor economics |

Reduced Economics Some are Efficient Low to High Capex Med to high water use Not suitable for high ash Not suitable for high moisture Includes fine coal |

Reduced Economics Some are Efficient Low to High Capex Med to high water use Some have moisture or ash limits Includes fine coal

|

Good Economics Efficient Low to High Capex Med to high water use Not suitable for high ash Not suitable for high moisture Includes fine coal |

Entrained flow technologies have been the most widely deployed over the past 4 decades. These technologies tend to perform well and are best suited for highest quality coal resources. They can be large water consumers depending on coal feed type and syngas cooling systems used. Low to high Capex due mainly to variations in gasification heat recovery and integration designs. |

|

Moving Bed

|

Excluded due to technology capability or to poor economics |

Acceptable Economics due to lower coal pricing Good Efficiency High Capex High water use Environmental issues due to tars and oils Lump coal only Excludes fine coal |

Reduced Economics Good Efficiency High Capex High water use Environmental issues due to tars and oils Lump coal only Excludes fine coal |

Reduced Economics Good Efficiency High Capex High water use Environmental issues due to tars and oils Lump coal only Excludes fine coal |

Large installed base in South Africa and China. Prior to SES technology, this was the High Capex alternative for low quality coal where entrained flow technologies were uneconomic. |

|

Emerging Transport Reactor & Other |

Non- Commercial | Non- Commercial | Non- Commercial | Non- Commercial | Emerging technologies have no commercial plants in operation such as the transport reactor which is best suited for low ash lignite coals. Many other emerging technologies attempting to gasify biomass and municipal wastes |

| 7 |

Syngas itself is a competitive alternative to oil, natural gas and conventional coal. Syngas generation technologies such as our technology compete with oil, natural gas and conventional coal combustion technologies. Such competing technologies include reforming of natural gas for chemicals and hydrogen production, oil refining for fuels production and conventional natural gas, fuel oil and coal combustion in power generation equipment and other industrial applications. The competitive landscape and opportunity for all gasification technologies is primarily driven by the price and availability of natural gas and oil. Low natural gas and oil prices can significantly reduce the amount of new syngas capacity additions while high pricing for oil and natural gas or liquefied natural gas (LNG) can increase demand for syngas additions. Additionally, conventional coal combustion technologies such as coal fired boilers for power generation and other conventional coal fired industries compete on an installed cost basis with the much cleaner gasification based coal to syngas technologies. Therefore regulations that restrict pollutants such as sulfur oxides (SOx), nitrous oxides (NOx), particulate matter and heavy metals such as mercury, from conventional coal fired technologies create wider spread adoption of cleaner coal gasification technologies. The lack of regulation on conventional coal based technology conversely delays adoption of coal gasification technologies, especially in the power generation market.

Barriers to New Competition

Historically gasification technologies have required many years and development costs on the order of hundreds of millions of dollars to reach credible commercial deployment and such development was generally funded by users with strategic interests and deep pockets such as the oil companies or governments such as South Africa during economic sanctions. Most, if not all, gasification technologies have also received significant government subsidies in the early R&D stages. Our technology has been highly developed by both GTI and us over the past 40 years and commercially deployed. We believe that the current range of available technologies leaves little incentive for development of new technologies, and emerging competition for everyone in the industry is likely to be by imitators and adaptors. We believe that we are well positioned as compared to imitators and adaptors due to an operating platform at ZZ that allows rapid development and demonstration of improvements, a rapidly growing intellectual property portfolio, and a technology that requires extensive and deep understanding of a number of complex technical criteria to properly design and operate.

GTI Agreement

On November 5, 2009, we entered into an Amended and Restated License Agreement, or the GTI Agreement, with GTI, replacing the Amended and Restated License Agreement between us and GTI dated August 31, 2006, as amended. Under the GTI Agreement, we maintain our exclusive worldwide right to license the U-GAS® technology for all types of coals and coal/biomass mixtures with coal content exceeding 60%, as well as the non-exclusive right to license the U-GAS® technology for 100% biomass and coal/biomass blends exceeding 40% biomass.

In order to sublicense any U-GAS® system, we are required to comply with certain requirements set forth in the GTI Agreement. In the preliminary stage of developing a potential sublicense, we are required to provide notice and certain information regarding the potential sublicense to GTI and GTI is required to provide notice of approval or non-approval within ten business days of the date of the notice from us, provided that GTI is required to not unreasonably withhold their approval. If GTI does not respond within that ten business day period, they are deemed to have approved of the sublicense. We are required to provide updates on any potential sublicenses once every three months during the term of the GTI Agreement. We are also restricted from offering a competing gasification technology during the term of the GTI Agreement.

For each U-GAS® unit which we license, design, build or operate for ourselves or for a party other than a sub-licensee and which uses coal or a coal and biomass mixture or biomass as the feed stock, we must pay a royalty based upon a calculation using the MMBtu per hour of dry syngas production of a rated design capacity, payable in installments at the beginning and at the completion of the construction of a project, or the Standard Royalty. If we invest, or have the option to invest, in a specified percentage of the equity of a third party, and the royalty payable by such third party for their sublicense exceeds the Standard Royalty, we are required to pay to GTI an agreed percentage split of third party licensing fees, or the Agreed Percentage, of such royalty payable by such third party. However, if the royalty payable by such third party for their sublicense is less than the Standard Royalty, we are required to pay to GTI, in addition to the Agreed Percentage of such royalty payable by such third party, the Agreed Percentage of our dividends and liquidation proceeds from our equity investment in the third party. In addition, if we receive a carried interest in a third party, and the carried interest is less than a specified percentage of the equity of such third party, we are required to pay to GTI, in our sole discretion, either (i) the Standard Royalty or (ii) the Agreed Percentage of the royalty payable to such third party for their sublicense, as well as the Agreed Percentage of the carried interest. We will be required to pay the Standard Royalty to GTI if the percentage of the equity of a third party that we (a) invest in, (b) have an option to invest in, or (c) receive a carried interest in, exceeds the percentage of the third party specified in the preceding sentence.

| 8 |

We are required to make an annual payment to GTI for each year of the term, with such annual payment due by the last day of January of the following year; provided, however, that we are entitled to deduct all royalties paid to GTI in a given year under the GTI Agreement from this amount, and if such royalties exceed the annual payment amount in a given year, we are not required to make the annual payment. We must also provide GTI with a copy of each contract that we enter into relating to a U-GAS® system and report to GTI with our progress on development of the technology every six months.

For a period of ten years, we and GTI are restricted from disclosing any confidential information (as defined in the GTI Agreement) to any person other than employees of affiliates or contractors who are required to deal with such information, and such persons will be bound by the confidentiality provisions of the GTI Agreement. We have further indemnified GTI and its affiliates from any liability or loss resulting from unauthorized disclosure or use of any confidential information that we receive.

The GTI Agreement expires on August 31, 2016, but may be extended for two additional ten-year periods at our option.

Business Strategy

The key elements of our business strategy include:

Generate financial results from our existing joint venture assets in China.

ZZ Joint Venture

Our ZZ JV/MeOH plant produces clean syngas which is blended with coke oven gas, or COG, to produce chemical-grade methanol, or MeOH. This methanol is sold into the local methanol market in Shandong Province, China. The history of the ZZ Joint Venture and the commercially restructured facility is described in more detail under “– Current Operations and Projects – Zao Zhuang Joint Venture. Key elements of our business strategy for the plant are:

a) Operating at the highest possible production rates, based on market conditions, to maximize the financial results from the facility.

b) Maximizing the operation of our gasification systems at the ZZ Joint Venture within local market constraints and continue to demonstrate the robustness and efficient capability of our technology.

c) Secure alternative and increased sources of COG to aid increased production rates and lower production costs.

d) Selective testing of new inventions at the ZZ Joint Venture that will benefit the joint venture and our future gasification projects.

e) Continuously improving and innovating at the ZZ Joint Venture to lower production costs and improve operating margins.

f) Evaluating, advancing and closing new partnering and/or expansion alternatives for improving the financial results which may include additional downstream technologies to produce high value products at the site and further enhance the financial results of the facility.

Yima Joint Venture

The Yima Joint Venture plant generated its first methanol production in December 2012. The Yima Joint Venture plant’s refined methanol section was fully commissioned in December 2013, and has operated at limited capacity since that date. The plant is designed to produce 300,000 tonnes per year of methanol from operating two of its three available gasifiers and has achieved 100% peak syngas production levels and 80% peak methanol production levels. This plant is intended to provide a commercial demonstration of our technology as deployed on a much larger scale than the ZZ Joint Venture plant.

We own 25% of the Yima Joint Ventures and Yima Coal Industry (Group) Co., Ltd., or Yima, owns 75%. Yima controls the construction, startup and operation of the plant. Recently, Yima put in place a new facility management structure, which we believe will significantly improve the operations of the facility. We believe the fundamental value of the Yima Joint Ventures is sound due to (1) the preferential coal pricing Yima can provide to the facility, (2) our technology’s capability to efficiently gasify this low quality coal and (3) the benefits derived from the plant’s large scale. More detail is available under “– Current Operations and Projects – Yima Joint Ventures”. Key elements of our business strategy for the Yima plant are:

| 9 |

a) Achieving formal commercial acceptance of the entire facility including documented acceptance of the performance of our technology at Yima.

b) Achievement of safe, full-design annual methanol production rates and overall profitable operation which can lead to dividend distributions to the shareholders of the joint venture.

c) Increase the scrutiny of results from onsite JV management via cooperation with Yima and Henan Energy and Chemical Industry Group Co., Ltd., parent company of Yima, or HNECGC, senior leadership, maintaining our onsite staff, regular joint venture board meetings and related shareholder meetings.

d) Continually assess long-term approach for us in the Yima Joint Ventures to maximize our financial return through achieving eventual dividends, restructuring alternatives and/or exit strategies.

TSEC Joint Venture

The purpose of the TSEC Joint Venture is to establish our gasification technology as the leading gasification technology in the TSEC Joint Venture territory (which is China, Indonesia, the Philippines, Vietnam, Mongolia and Malaysia) by becoming a leading provider of proprietary equipment for the technology. The scope of the TSEC Joint Venture is to market and license our gasification technology via project sublicenses; procurement and sale of proprietary equipment and services; coal testing; and engineering, procurement and research and development related to the technology. In addition, we believe our TSEC Joint Venture will also help build new partnerships within market segments such as DRI steel, power, transportation fuels and for longer term value creation, larger scale SNG projects utilizing low rank coal resources and biomass where our technology brings, and accelerate the commercialization of our technology on a global basis enabling us to reduce the capital requirements to achieve this acceleration. We own a 35% interest in the TSEC Joint Venture. More detail is available under “– Current Operations and Projects – TSEC Joint Venture”. Key elements of our business strategy for TSEC are:

a) Achieve initial orders for new project license and equipment supply.

b) Secure first customers for our higher pressure 40bar gasification platform, with a focus on brown field projects which could move quickly to install and operate the 40 bar system.

c) Expand the scope of supply of the TSEC joint venture to grow from licenses and proprietary equipment supply into supply of non-proprietary process equipment into TSEC projects.

d) Expand the TSEC engineering and construction capability together with ZCM to provide fully constructed fixed priced gasification systems in the territory.

e) Endeavor to form collaborations and partnerships in market segments with known leaders in those markets to help advance our technology, such as our exclusive marketing agreement with the TSEC Joint Venture and Midrex Technologies for coal gasification-based DRI.

f) Build implementation capability with TSEC to supply high quality, low cost equipment into our global projects outside the territory.

Partnering with proven project development companies.

We believe that partnering to enable the development of gasification projects, which can benefit from our technology’s capability regarding low cost feedstock flexibility, lower capital cost and reduce water usage footprint, can provide value through creating a channel for us to secure new orders and the ability to share in project development fees and/or achieve carried interests in projects. We believe that we have the greatest competitive advantage by using our gasification technology in situations where there is a ready source of low quality coal, coal waste or biomass to utilize as a feedstock. In many cases such low cost resources are not a viable energy source without our technology’s capability to convert the resource into syngas and resulting energy and chemical products.

Increase our organizational and financial capability to deliver our technology, equipment and services.

As our business verticals and other business initiatives develop and we secure new technology orders, we believe we may need to add significant implementation capability to follow through with fulfillment and implementation and increase our ability to provide the necessary financial and performance guarantees required by project customers and equity and debt financiers. We intend to seek new and impactful partnering opportunities to provide this needed capability in similar fashion to our TSEC Joint Venture in China.

| 10 |

Continue to develop and improve our technology.

We are continually seeking to advance and improve our gasification technology. We are continuing to work with our prospective customers to determine the suitability of their low rank coals for our technology through proprietary coal characterization testing and bench scale gasification tests. We are advancing our higher pressure 40bar to 60bar gasification system designs which can further enhance our capital and operating expenses effectiveness and allow our system to achieve much higher syngas output from a smaller sized gasifier. Additionally, we are growing our technology base through (i) continued development of know-how with our engineering and technical staff, (ii) growing and protecting our trade secrets as a result of patenting improvements tested at our ZZ and Yima Joint Venture plants, (iii) developing improvements resulting from integration of our technology with downstream processes, and (iv) developing improvements resulting from scaling up the design of our technology in pressure and capacity. Examples of our technology development include our High Pressure Gasifier, Fines Management System and Ash Management System which increase overall efficiency. We have several patent applications pending relating to these technology improvements in addition to a number of other improvements to increase the gasifier availability and to lower the costs of the gasifier installation and subsequent operations. For more information, see-“Patents” below.

Relationships with Strategic Partners and Business Verticals

As part of our overall strategy we intend to continue to form new strategic market-based partnerships or business verticals and grow our existing partner relationships where our technology offers advantages and through cooperating with these partners grow an installed base of projects. Through collaborative partnering arrangements we believe we will commercialize our technology much faster than entering these markets alone. In addition to regional business units, we are continuing to evaluate and develop our business in markets such as power, steel, fuels, substitute natural gas, chemicals and renewables which can benefit from deploying our technology offering to create these products from low cost coal and renewable feedstocks. We are developing these market-based business vertical opportunities together with strategic partners which have established businesses or interests in these markets with the goal of growing and expanding these businesses by partnering with us and deployment of our technology offering.

Our collaboration with GE Packaged Power, Inc., a subsidiary of GE, which began in early 2013 to jointly evaluate and market a small scale power generation unit combining our gasification technology with GE’s aeroderivative gas turbines, is an ongoing example of our market-based business vertical developments underway. This marketing arrangement will focus on regions of the world where conversion of non-conventional feedstock sources such as lignite and coal wastes into synthesis gas fuel via our technology may be highly price advantaged over conventional gas turbine fuel sources such as natural gas and fuel oil. Together with GE, we have completed a preliminary evaluation of this application of our combined technologies. Under the terms of this agreement, the two businesses on a non-exclusive basis will complete the market evaluation and seek initial customers for this small scale power product. We, along with our distributed power collaborators, GE, ISTROENERGO GROUP, Inc. and TUTEN Ltd, have signed our first LOI with K-Electric, formerly known as Karachi Electric Supply Company. K-Electric is a large electric utility company in Karachi, Pakistan with over 2.3 GW of installed electric generating capacity. The exclusive LOI calls for an engineering and financial feasibility evaluation of a coal gasification power generation project with a capacity between 90 and 200 MW to be constructed near Karachi. The completed feasibility study can serve as the basis for further discussions and negotiations for a syngas power plant contract. We believe the distributed power segment offers opportunity over time to provide meaningful sales opportunities for our gasification technology and equipment systems. We intend to focus on the continued development of this business vertical.

We are also advancing developments via technology integration studies with potential partners for business verticals in DRI steel and “green” chemicals derived from municipal wastes, including through an exclusive agreement with TSEC and Midrex Technologies, Inc., or Midrex, a subsidiary of Kobe Steel Limited, for the joint marketing of coal gasification-based DRI facilities in China. These facilities will combine our gasification technology with the Direct Reduction Process of Midrex to create syngas from low quality coals in order to convert iron ore into high-purity DRI. As part of the agreement, we are working on developing a marketing package with which to address the potential China DRI market and are actively engaged in discussions with potential customers. The TSEC Joint Venture is participating in this marketing effort, as they will be integral to any projects that arise in that region. We are planning to begin a more detailed engineering study of our integrated solution in order to assist our marketing efforts with more robust technical solution data. We, Midrex and TSEC are having meetings with potential customers in China and the initial feedback from potential customers on the integrated process is generally positive.

We intend to focus on developing new opportunities for our proprietary technology whereby we may (i) integrate our technology package with downstream technologies to provide a fully integrated offering, (ii) partner with engineering, equipment and technology companies to provide our technology package into an integrated modular product offering, (iii) provide technology to enable coal resources to be integrated together with our technology where the coal resources may be of little commercial value without our conversion technology, or (iv) partner with owners of these coal resources to create more value and opportunity for us through the integration of our technology with the coal resource. We understand the need to partner in certain markets, and plan to do so with companies that we believe can help us accelerate our business. For example, we have entered into an agreement with Simon India Ltd, a subsidiary of Adventz, to exclusively market our technology in India where we believe the market for coal gasification plants is now developing due to large infrastructure growth demands and an increasing need for a variety of basic chemical and energy products. Additionally, Simon India Ltd is our exclusive engineering partner to assist us in completing our process design package (PDP) for the SES Gasification Technology for projects in India that utilize our technology. This relationship with Simon gives us a large and well-established network within India from which to develop and participate in projects using our technology. Our partnering approach in some cases is country specific and in other cases is industry or market segment specific. Additionally, where strategic relationships and capital and/or financing is available, we may acquire operating assets with potential to generate near term earnings and provide us with advantages in deploying our technology. We are also actively pursuing business verticals in the diversified segments of transportation fuels, steel and fertilizers where our technology is specifically well suited and developing new downstream coal-to-chemicals and coal-to-energy projects which may expand our initial focus to include facilities producing SNG, MTG, glycol, and power and reducing gas for the steel industry

| 11 |

Target Markets

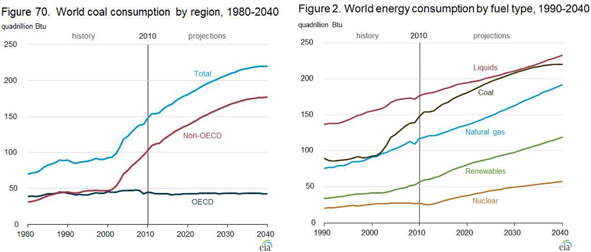

The energy and chemicals landscape has evolved rapidly over the past five to ten years with upward pressure on demand and increasing pressure to deliver outstanding environmental performance while simultaneously delivering economics that will attract investment capital. World energy consumption is expected to increase significantly over the next two decades. Demand is heavily driven by non-OECD nations where those developing economies require ever increasing access to more energy products to establish healthy economies that improve the living conditions of those populations. Energy and chemical products are needed for basic health, food and agricultural products, housing needs and infrastructure for safety and mobility. A 2013 EIA report projects that total worldwide energy consumption will exceed 800 quadrillion British thermal units, or BTU, by 2040 with non-OECD nations making up close to 75% of that consumption.

Growth in energy in non-OECD nations is expected to be led by growth in Asia. The same EIA reports projects Asia to make up close to 66% of that projected 2040 consumption. We believe we are well positioned in Asia where we have two operating projects using five of our gasification systems. In addition, the TSEC Joint Venture provides us with a strong Chinese partner already specialized in the manufacturing and design of processing industry equipment and projects. The TSEC Joint Venture territory initially covers China, Vietnam, Indonesia, Philippines, Malaysia and Mongolia.

Coal is required as a major source of energy for decades to come. Growth in coal usage is also expected to be led by the Non-OECD nations. Coal based energy in combination with other energy producing technologies is required to help alleviate energy poverty around the world. In 2011, approximately 1.3 billion people lived without access to electricity and significant investment is required to alleviate this energy poverty by 2030. This need for energy access is in addition to continued energy demand required by GDP growth in both OECD and Non-OECD nations. All combined coal is expected to continue to be a large scale source of affordable energy.

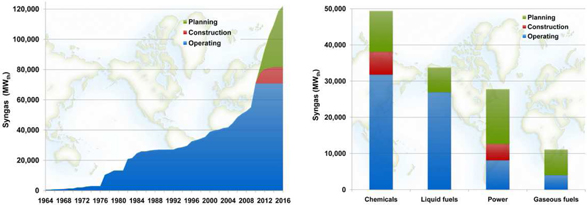

Transforming coal into clean energy and chemical products. Against the backdrop of significant growth in global energy needs and the requirement for coal to supply a large portion of this energy emerges the need to transform coal into energy products in a clean and sustainable manner. Commercially proven gasification technologies such as our technology are able to cleanly extract the important carbon and hydrogen components from coal in the form of a clean syngas product. This syngas product is then readily converted into a variety of energy and chemical products. Transforming coal into clean energy and chemical products is a growing opportunity as can be seen from the charts below. Global syngas growth is expected to accelerate rapidly. In fact, we believe the versatility and capability of syngas to make such a variety of products has just begun to be tapped and the quantity of syngas capacity in operation today on a global basis is only a fraction of what is required to meet the growing global energy demand.

| 12 |

Total Worldwide Gasification Capacity and Planned Growth and Planned Gasification Growth – by Product

NETL 2010 Worldwide Gasification Database

We believe that our technology is well positioned to be an important solution that addresses the market needs of the changing global energy landscape. Our gasification technology is unique in its ability to provide an economic, efficient and environmentally responsible alternative to many energy and chemical products normally derived from natural gas, LNG, crude oil, and oil derivatives.

Our target markets focus primarily on lower quality coals, biomass and municipal waste and our gasification technology allows energy in the widest range of feedstocks to be unlocked and converted into flexible and valuable syngas. We offer a compelling advantage because of our ability to use such wide range of solid fuel natural resources. Without our technology, regions where lignite coal, high moisture coal, high ash coal and/or high fines coals exist may face technology barriers that trap those resources. Our technology can transform most of these natural resources into a valuable and flexible syngas product. This clean syngas product can then be used in place of natural gas and oil for making most energy and chemical products.

Because of these market dynamics, we believe our gasification technology has broad strategic importance to:

| 1) | Countries and regions with developing economies which have their own low cost domestic coal resources or easy access to imported low cost coal. Such countries and regions need access to low cost clean energy and chemical products to grow and in some cases to provide basic necessities that improve the health and well-being of their populations. These regions have limited access to affordable alternate energy sources like natural gas and oil, and can benefit from economic growth by using the lowest cost energy resources such as low cost domestic or imported coal for the production of vital products. Many Asian countries expect to see a surge in imported coal in addition to increased use of domestic coal to meet their energy product demand increase. |

| 2) | Developed nations in the west such as Australia, Europe and the US which possess significant low cost coal resources and which have a strategic need and desire to produce clean and affordable energy and chemicals from their own domestic resources. |

| 3) | Existing operating companies which deploy their own technologies for energy and/or chemicals production. These technologies have been well established for use with oil and natural gas resources but are constrained from growing in parts of the world where the oil and natural gas feedstocks are either not readily available due to missing infrastructure and/or very expensive such as LNG in much of Asia. Integrating those establish technologies with our technology opens these technologies to a new low cost natural resource in low quality coals thereby transforming the economic opportunity. Such is the case for example in producing power, methanol, DRI steel product, ammonia and urea for fertilizers and many transportation fuels such as gasoline, diesel and jet fuel. |

| 13 |

China Market

The development of the modern coal chemical industry in China depended mainly on the country’s resource possession status, i.e. coal-rich, oil-lean and gas-lacking, and has also been driven by the vast and increasing demand for energy and chemical products. Coal has been and is predicted to continue to be the most vastly used natural resource for energy production in China.

Other contributors to the growth of China’s industrial sector include the government’s ambition for economic development, unlimited access to coal resources including low cost coal, better profitability for utilizing these lowest cost and highly available resources, abundant capital flow, demand for the development of clean energy products to mitigate the severe air pollution problem, as well as China’s historic experience and application of coal chemical processes.

The Chinese government puts particular emphasis on the “Introduction, Digestion & Absorption” of imported advanced technologies. The Chinese equipment industry and locally developed coal chemical processes have matured in recent years.

Gasification is the leading technology for coal chemical processes development in China. The development and improvement of gasification technology over the past decade in China is expected to contribute to the growth of the Chinese coal chemical industry. In comparison to fixed bed gasification processes, which have already been widely deployed in China, fluidized bed gasification is capable of using finer coal (with smaller coal particles), which greatly broadens the raw coal supply availability for projects based on SES Gasification Technology.

As China’s energy demand is expected to nearly double over the next 25 years, the production of electricity, steel, chemicals and transportation fuels from Chinese coal and other imported coals will continue to grow and we believe will require the widespread use of coal gasification. The pressure that the Chinese government is under to improve the environmental quality, especially around the large metropolis areas, has put conventional coal utilization technologies under pressure.

In the power generation market, many provinces are not permitting new plants to utilize coal-fired boilers for small scale power generation due to the poor environmental performance of these boilers. For transportation fuels development, the National Development and Reform Commission of China has begun work on providing guidance to industrial companies for the generation of diesel and gasoline with stricter emissions regulations. The government is requiring industrial companies to become more conscious of water consumption and pollution, coal utilization with regards to using more efficient technologies, and tighter emissions controls in order to improve the current air quality situation.

While the Chinese government is encouraging improvement in environmental performance industry wide, the demand for energy products is continuing to increase at a remarkable pace. The intersection of these two driving forces, need for improved environment and need for more energy products based on China’s most abundant natural resource, drives all major industry sectors in China towards the only clean use of coal – gasification.

ASIACHEM, the Coal Chemical Consultancy, summarized that the continued development of a Chinese macro economy and the tremendous demand for energy and chemical products in China creates a large market for clean coal conversion. Liquid fuels, substitute natural gas, chemicals including olefins, ethylene glycol, and aromatics, steel products and other insufficiently supplied products in China will be the greatest developing sectors in the modern coal chemical industry.

India

We believe that India is poised for coal-based gasification growth, and is turning the corner to be capable to realize that growth. Although India has substantial low rank coal resources, many of which are not able to be used in conventional coal technologies without significant upgrading, there has historically been limited coal gasification in India due to the cost of competing alternatives derived from oil and natural gas and due to the challenging nature of the high ash Indian coals to be gasified. India continues to put a fixed tariff on its natural resources with multiple price points for different types of end users (i.e. by industry, residential, commercial).

For the last several years, our business development activities in India were slow due to the fallout from allegations of government corruption in India related to energy and resource distribution. One of the more highly publicized allegations is the so-called “coal-gate” scandal which alleged widespread government corruption in the awards and non-awards of Indian coal allocations to various companies. Many of coal mine allocations were left undeveloped for a variety of reasons, including the Indian government’s price controls, strict environmental and land use regulations and other government policies. India’s growing population and standards of living demand a wide variety of infrastructure projects such as for power, steel and fertilizer, all of which could be aided by coal development. Many of our prospective customers were among these affected by the inability to get access to local Indian coal, and in these cases the customers’ projects have experienced significant delays.

| 14 |

This year India held elections and brought in a new government with the goal of cleaning up corruption, and opening the pathways for companies to develop clean energy projects for the benefit of India. We have begun to see an increase in interest in our technology from potential customers in India, and we are working with our Indian partner Simon India Ltd to meet the near-term needs of these potential customers.

Once the availability of coal is resolved, the market for coal gasification based plants is poised for growth due to reduced availability and increasing prices of oil and natural gas, large infrastructure growth demands, rapid economic growth, and an increasing need for a variety of basic chemical and energy products, which may be derived from coal gasification to fuel this growing market. We are actively pursuing significant opportunities in India and we believe that we have competitive advantages in this market due to India’s high ash coals for which other commercialized technologies are not as suitable. India also offers a base for high quality engineering and other technical resources at low cost.

Current Operations and Projects

Zao Zhuang Joint Venture

On July 6, 2006, we entered into a cooperative joint venture contract with Shandong Hai Hua Coal & Chemical Company Ltd., or Hai Hua, which established Synthesis Energy Systems (Zao Zhuang) New Gas Company Ltd., or the ZZ Joint Venture, a joint venture company that has the primary purposes of (i) developing, constructing and operating a syngas production plant utilizing the U-GAS® technology in Zao Zhuang City, Shandong Province, China and (ii) producing and selling syngas and the various byproducts of the plant. In August 2012, Hai Hua’s name was changed to Shandong Weijiao Group Xuecheng Energy Company Ltd., or Xuecheng Energy, after a change in control transaction. We own 97.6% of the ZZ Joint Venture and Xuecheng Energy owns the remaining 2.4%. We consolidate the results of the ZZ Joint Venture in our consolidated financial statements.

On July 24, 2013, the ZZ Joint Venture entered into a cooperation agreement (the “ZZ Cooperation Agreement”) with Xuecheng Energy and its parent company, Shandong Xuejiao Chemical Co., Ltd. (collectively referred to as “Xuejiao”), which serves to supersede the existing syngas purchase and sale agreement among the parties dated October 22, 2006 and supplemented previously in 2008. The ZZ Cooperation Agreement, which became effective on October 31, 2013, represents the basis for an integrated syngas to methanol operation and resolution of the nonpayment of the contractual capacity fees by Xuejiao. Under the terms of the ZZ Cooperation Agreement, Xuejiao will (i) provide the ZZ Joint Venture with use of their methanol plant for ten years at no cost to the ZZ Joint Venture, (ii) provide a bank loan guarantee of approximately $3.3 million for a majority of the financing necessary for the ZZ Joint Venture for the retrofit and related costs of the ZZ Joint Venture plant, (iii) waive certain advances previously made to the ZZ Joint Venture and (iv) supply discounted coke oven gas produced by its existing coke ovens to be used in combination with synthesis gas to produce refined methanol from the new ZZ Joint Venture integrated syngas methanol operation. The new integrated operation will be managed by the ZZ Joint Venture.

Effective October 31, 2013, the ZZ Joint Venture terminated and waived its claims to past due capacity fees owed by Xuejiao under the prior syngas purchase and sale agreement. Pursuant to the ZZ Cooperation Agreement, prior payments of approximately $1.8 million were applied to settling the prior payments due under the syngas purchase and sale agreement.

The ZZ Joint Venture began producing and selling methanol in November 2013 and sold 35,682 tonnes of methanol during the year ended June 30, 2014. We assumed operational control of the integrated methanol production facility in October 2013 under a restructured commercial arrangement. The ZZ Joint Venture has worked to complete the plant retrofits and equipment upgrades to enable increased methanol production from integrated syngas and coke oven gas feedstock. The ZZ Joint Venture is now operating an integrated plant which has two operating modes where it (i) converts coke oven gas directly to methanol and (ii) converts coal to syngas, then blends the syngas and coke oven gas at a specific ratio to produce additional quantities of methanol. The ZZ Joint Venture began producing and selling methanol in November 2013 from coke oven gas. The ZZ Joint Venture restarted its syngas plant for approximately two weeks during December 2013. In January 2014, the ZZ Joint Venture produced methanol only from coke oven gas due to lower coke oven gas supplies during the cold weather. The ZZ Joint Venture intends to manage syngas production in order to optimize results. The syngas facility will generally operate when adequate coke oven gas supplies are available to achieve the correct syngas to coke oven gas blend ratio. The ZZ Joint Venture also recently executed agreements to secure an additional minimum 4,000 normal cubic meters per hour of coke oven gas from a local supplier, with a target of 5,000 normal cubic meters per hour, in order to increase methanol production and reduce supply risks. This additional coke oven gas represents approximately a 30% increase in feedstock supply for the ZZ Joint Venture Plant. In addition, we are focused on lowering our operating costs, as well as reducing forced outages at the facility.

| 15 |

Additionally, we are also evaluating alternative products and partnership structures for a possible expansion of the ZZ Joint Venture plant. In 2010, the ZZ Joint Venture received the necessary government approval for an expansion into monoethylene glycol production. This expansion project remains under evaluation by us. We are also evaluating certain new downstream technologies to produce high value products.

Current ZZ Operating Description and Capability

As described above, we assumed operational control of the integrated methanol production facility in October 2013 under a restructured commercial arrangement pursuant to the ZZ Cooperation Agreement. The ZZ Joint Venture completed plant retrofits and equipment upgrades to enable increased methanol production from integrated syngas and COG feedstock. The ZZ Joint Venture began producing and selling methanol in November 2013 and sold 35,682 tonnes of methanol during the year ended June 30, 2014 generating approximately $13.3 million of revenue. The ZZ Joint Venture restarted its syngas plant for approximately two weeks during December 2013. In January 2014, the facility produced methanol from coke oven gas only due to coke oven gas supplies disruptions during the cold weather when COG was diverted to the city gas loop for residential heating needs. We expect such diversions of COG into residential heating during the winter months to be reduced or eliminated in the future due to local town gas system being upgraded to use pipeline natural gas.

Between January and August 2014, methanol prices in China and at our ZZ facility have been near historic lows. Under these conditions the facility has operated primarily in the COG only mode. We believe methanol prices have been at these recent low levels primarily related to the general economic conditions in China as demonstrated by China’s current low PMI. We are aware of new facilities soon to startup in local Shandong province area which will increase local demand for methanol to be used for olefins production, which we believe will be reflected in improving methanol prices over time.

Other non-market based factors affect economic expectations at the ZZ Joint Venture facility such as but not limited to unscheduled maintenance, forced outages, catalyst degradation and performance in both the COG reformer and methanol synthesis loop and third party coke oven outages which can curtail available COG feedstock. The ZZ facility is limited to approximately 24 hours of COG storage.

Although we intend for the ZZ Joint Venture to sustain itself through its own earnings, we may need to make additional contributions to the ZZ Joint Venture in order for it to meet its obligations. In September 2014, we made a capital contribution of $1.5 million to the ZZ Joint Venture. This capital contribution was used to pay a portion of the ZZ Short-term Loan, which was due on September 9, 2014. We are currently in discussions with Zao Zhuang Bank Co., Ltd to replace the ZZ Short-term Loan with another similar loan and line of credit.

During meetings with the local government at Xuecheng in June, 2014 and separate meetings with Xuejiao, the ZZ Joint Venture has been advised that the existing Xuejiao coke oven facility may be permanently shutdown in the future. A definitive timeline has not been established for this shutdown and the ZZ Joint Venture was informed that it may occur in the next 3 to 4 years. Xuejiao has constructed and new coking coal facility about 20KM away for the current facility and this new facility is intended to eventually replaced the current facility which has come under scrutiny for pollution from its old generation coking coal technology used. Because of this the ZZ Joint Venture intends to develop its alternatives for continued production of methanol and other products from the facility. The ZZ Joint Venture is expected to qualify as a clean industrial producer of chemicals such as methanol which can be expanded into a clean industrial park once the existing coke ovens are removed. We are evaluating alternative products and partnership structures for partnering and/or expansion of the ZZ Joint Venture plant. In 2010, the ZZ Joint Venture received the necessary government approval for an expansion into mono-ethylene glycol production. This expansion project remains under evaluation by us. We are also evaluating new downstream technologies to produce high value products at the site.

Yima Joint Ventures

In August 2009, we entered into amended joint venture contracts with Yima, replacing the prior joint venture contracts entered into in October 2008 and April 2009. The joint ventures were formed for each of the gasification, methanol/methanol protein production, and utility island components of the plant, or collectively, the Yima Joint Ventures. The amended joint venture contracts provide that: (i) we and Yima contribute equity of 25% and 75%, respectively, to the Yima Joint Ventures; (ii) Yima will guarantee the repayment of loans from third party lenders for 50% of the project’s cost and, if debt financing is not available, Yima is obligated to provide debt financing via shareholder loans to the project until the project is able to secure third-party debt financing; and (iii) Yima will supply coal to the project from a mine located in close proximity to the project at a preferential price subject to a definitive agreement to be subsequently negotiated. In connection with entering into the amended contracts, we and Yima contributed remaining cash equity contributions of $29.3 million and $90.8 million, respectively, to the Yima Joint Ventures during the three months ended September 30, 2009. We are responsible for our share of any cost overruns on the project.

| 16 |

In exchange for such capital contributions, we own a 25% interest in each joint venture and Yima owns a 75% interest. Notwithstanding this, in connection with an expansion of the project, we have the option to contribute a greater percentage of capital for the expansion, such that as a result, we would have up to a 49% ownership interest in the Yima Joint Ventures.

The remaining capital for the project has been funded with project debt obtained by the Yima Joint Ventures. Yima agreed to guarantee the project debt in order to secure debt financing from domestic Chinese banking sources. We have agreed to pledge to Yima our ownership interests in the joint ventures as security for our obligations under any project guarantee. In the event that the necessary additional debt financing is not obtained, Yima has agreed to provide a loan to the joint ventures to satisfy the remaining capital needs of the project with terms comparable to current market rates at the time of the loan.

Under the terms of the joint venture agreements, the Yima Joint Ventures are to be governed by a board of directors consisting of eight directors, two of whom were appointed by us and six of whom were appointed by Yima. The joint ventures also have officers that are nominated by us, Yima and/or the board of directors pursuant to the terms of the joint venture contracts. We and Yima shall share the profits, and bear the risks and losses, of the joint ventures in proportion to our respective ownership interests. The term of the joint venture shall commence upon each joint venture company obtaining its business operating license and shall end 30 years after commercial operation of the plant.

The Yima Joint Venture plant generated its first methanol production in December 2012. The Yima Joint Venture plant’s refined methanol section was fully commissioned in December 2013, and has operated at limited capacity since that date. The plant is designed to produce 300,000 tonnes per year of methanol from operating two of its three available gasifiers and has achieved 100% peak syngas production levels and 80% peak methanol production levels. This plant is intended to provide a commercial demonstration of our technology as deployed on a much larger scale than the ZZ Joint Venture plant.

The Yima Joint Venture initiated an outage in March that was intended to allow the plant to make broad and miscellaneous improvements to many areas of the entire methanol producing facility which had not been completed or properly installed. Many of these improvements were punch-list items left over from construction, along with improvements which have been learned from the past year’s operation at the plant. Additionally, it was identified during this time that the Yima Joint Venture has not installed all the required units related to removal of sulfur compounds from syngas. A portion of these repairs were completed and the facility was restarted in late June, 2014. After three weeks of operation the plant was shut down again due to improper repair techniques on its Heat Recovery System Generator.

We believe there is a consistent pattern of the Yima Joint Venture management not demonstrating an understanding of the methanol facility operations and not sourcing available expertise in China to improve the overall operations. We have witnessed operation of its gasifier systems at Yima with design and operating parameter deviations from our existing technology recommendations. We have previously experienced limited ability to influence the Yima Joint Ventures’ operating performance. Our conclusion regarding our lack of significant influence is based on our interactions with the Yima Joint Ventures related to the start-up and operations and due to various other circumstances including limited participation in operating and financial policymaking processes and our limited ability to influence technological decisions.

As a result of these issues, HNECGC restructured the management of the Yima Joint Ventures under the direction of the Henan Coal Gasification Company or Henan, which is an affiliated company reporting directly to HNEGC. The ownership of the Yima Joint Ventures is unchanged. Henan currently has full authority of day to day operational and personnel decisions at the Yima Joint Venture. The goal of the management restructuring is to provide for a more experienced and efficient operations management system. The management team at Henan is experienced at running and optimizing coal gasification facilities, and they currently operate other coal gasification facilities. We currently plan to rely upon and assist Henan's management to achieve optimized operations and will continue to attempt to improve our influence on the Yima Joint Ventures. Despite this, we believe the fundamental value of the Yima Joint Ventures remains sound due to (1) the preferential coal pricing Yima can provide to the facility, (2) our technology’s capability to efficiently gasify this low quality coal and (3) the benefits derived from the plant’s large scale.

| 17 |

TSEC Joint Venture