Attached files

| file | filename |

|---|---|

| 8-K - CPS PRESENTS AT SIDOTI CONFERENCE - CPS TECHNOLOGIES CORP/DE/ | k8conf01132014.htm |

reliability with smart composite products CPS Technologies Corporation Overview January 13, 2014

reliability with smart composite products Forward - L ooking Statements Statements made in this presentation that are not historical facts or which apply prospectively, are forward - looking statements that involve risks and uncertainties. Investors should not rely on forward looking statements because they are subject to a variety of risks and uncertainties and other factors that could cause actual results to differ materially from the Company's expectation . Additional information concerning risk factors is contained from time to time in the Company's SEC filings, including its Annual Report on Form 10 - K and other periodic reports filed with the SEC. Forward - looking statements contained in this press release speak only as of the date of this release. Subsequent events or circumstances occurring after such date may render these statements incomplete or out of date. The Company expressly disclaims any obligation to update the information contained in this presentation. 2

reliability with smart composite products Why Invest? • Markets - Large & growing (high speed rail, HEV/EV, aerospace/defense, oil and gas) • Technology – Strong, proprietary process technology for combining metals and ceramics • Products – Components which improve performance and reliability (providing thermal expansion matching, light weight, strength and stiffness) • Customers - Major electronics OEMs ; 2/3 of revenue from Europe and Asia • Competition – Primarily Japanese (competitors use different process technologies) • Financial – Profitable, cash - flow positive, no debt • Management – Experienced and capable • Facilities – Lean manufacturing in USA, can double in size in existing facilities 3

reliability with smart composite products What do we do? Using proprietary process technology, we develop and manufacture advanced materials solutions and products particularly combinations of metals and ceramics to improve the performance and reliability of applications in a variety of end markets. Our primary advanced materials today are metal matrix composites (MMCs), particularly AlSiC. 4

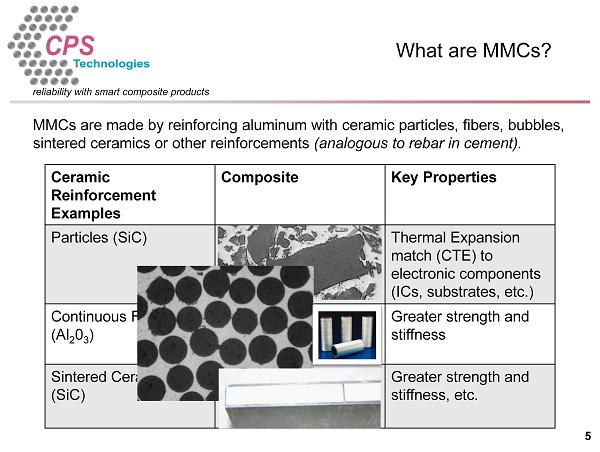

reliability with smart composite products What are MMCs? Ceramic Reinforcement Examples Composite Key Properties Particles (SiC) Thermal Expansion match (CTE) to electronic components (ICs, substrates, etc.) Continuous Fiber (Al 2 0 3 ) Greater strength and stiffness Sintered Ceramics (SiC) Greater strength and stiffness, etc. MMCs are made by reinforcing aluminum with ceramic particles, fibers, bubbles, sintered ceramics or other reinforcements (analogous to rebar in cement). 5

reliability with smart composite products Our History – and Where Are We Today? Founded in 1984 as MIT spin - off, IPO in 1987, Symbol CPSH. Research 1984 - 1993 Development 1994 - 1997 Manufacturing 1998 forward 2013 ~$21 M in revenues, solidly profitable, 160 employees Located in Massachusetts; 2/3 of revenues from export to Europe and Asia ISO 9001:2008 certified, fully - qualified manufacturer at multi - national electronics systems houses 6

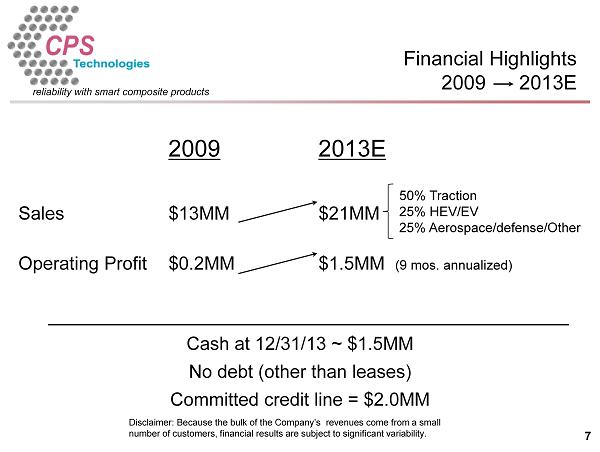

reliability with smart composite products Financial Highlights 2009 2013E 2009 2013E Sales $13MM $21MM Operating Profit $0.2MM $1.5MM (9 mos. annualized) ________________________________________ Cash at 12/31/13 ~ $1.5MM No debt (other than leases) Committed credit line = $2.0MM 50% Traction 25% HEV/EV 25% Aerospace/defense/Other 7 Disclaimer: Because the bulk of the Company’s revenues come from a small number of customers, financial results are subject to significant variability.

reliability with smart composite products Who Buys from CPS? Major electronics and automotive OEMs worldwide. Today 2/3 of revenues are from Europe and Asia 8

reliability with smart composite products Current Market Segments CPS is the worldwide leader in MMCs in these growth electronics m arkets: • Traction Market: We make components for motor control modules used in high - speed and regular railways, subway cars, and electricity - generating wind turbines. • Hybrid and Electric Vehicle Market (HEV/EV): We make components for motor control modules used in HEV/EVs. • Aerospace/Defense: We make components used as heat spreaders and housings for high performance ICs and hybrid circuits used in aerospace/defense applications. 9

reliability with smart composite products What Pain Do We Solve at our Customers? The pain is heat - thermal management – Many electronic applications are limited in reliability and/or performance because of Mismatch in the thermal expansion of components and the inability to remove heat from the assembly. The pain is increasing in many, many applications! 10

reliability with smart composite products Motor Control Module for Traction Applications 1.2 - 6.5 KV operation 600 - 3600 Amps 30 year reliability IGBT Module (Insulated Gate Bipolar Transistor) 11

reliability with smart composite products Coefficient of Thermal Expansion (CTE) AlSiC Baseplate Substrate Thermal expansion differences between electronics, substrates and baseplates result in increased mechanical stresses that decrease reliability. IGBT IC and Diodes 12

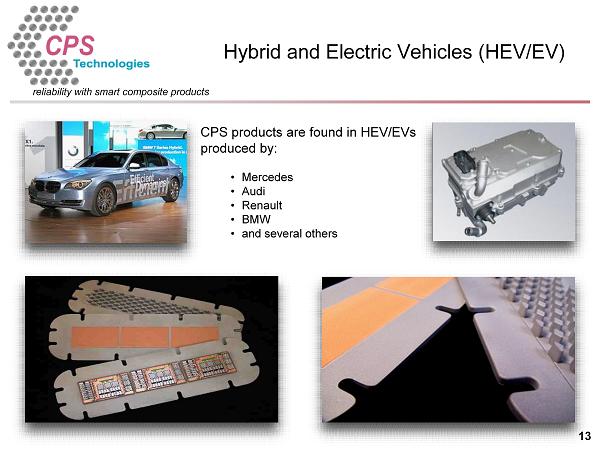

reliability with smart composite products Hybrid and Electric Vehicles (HEV/EV) CPS products are found in HEV/EVs produced by: • Mercedes • Audi • Renault • BMW • and several others 13

reliability with smart composite products Current Markets are Growth Markets Traction Market (High - Speed Trains) • China is driving growth. 50% of world - wide high - speed rail “in service” + “under construction” is in China • China high - speed locomotives in use are projected to double 2011 - 2015 • China high - speed rail track expected to increase 4x (CAGR=15%) between 2010 - 2020 • (Source: Morgan Stanley) HEV/EV Market • World - wide market projected to increase 5x (CAGR=17%) from $69 billion in 2013 to $334 billion in 2023 (Source: ID Tech Ex, Dec. 2013) 14

reliability with smart composite products Other Electronics Markets with Similar Needs 15

reliability with smart composite products New Market Segments CPS is developing and introducing products for new structural markets: Armor and Blast Protection: The US Army has provided funding for development of lightweight MMC armor for vehicle applications Oil and Gas: We are developing components used in oil & gas exploration, including fracking 16

reliability with smart composite products Structural MMCs 17

reliability with smart composite products Senior Management / Directors 18 CEO / Pres./ Director Grant Bennett M.S. Sloan/MIT; 25+ yrs at CPS. CFO Ralph Norwood CPA/M.B.A Darden School/ UVa ; 2 yrs at CPS. (Former Controller / VP Treasurer of Polaroid Corp.) CTO / Sr. V.P Rich Adams M.S. MIT/Materials Science; 25+ yrs at CPS VP Marketing Mark Occhionero Ph.D. Case Western/ M’tls Science; 25+ yrs at CPS VP Sales Cheryl Oliveira 8 yrs at CPS; 25+ years in related sales VP Operations Charles DaRosa 3 yrs at CPS; 25+ yrs in lean operations management Independent Director Frank Hughes Pres. American Research & Development (M.B.A - HBS) Independent Director Dan Snow Professor Brigham Young (Ph.D. Berkeley)

reliability with smart composite products Why Invest? This is Why! • Markets - Large & growing (high speed rail, HEV/EV, aerospace/defense, oil and gas) • Technology – Strong, proprietary process technology for combining metals and ceramics • Products – Components which improve performance and reliability (providing thermal expansion matching, light weight, strength and stiffness) • Customers - Major electronics OEMs ; 2/3 of revenue from Europe and Asia • Competition – Primarily Japanese (competitors use different process technologies) • Financial – Profitable, cash - flow positive, no debt • Management – Experienced and capable • Facilities – Lean manufacturing in USA, can double in size in existing facilities 19