Attached files

| file | filename |

|---|---|

| 8-K - 8-K - PBF Energy Inc. | d654465d8k.htm |

PBF

Energy Inc. January 2014

PBF Energy Inc.

January 2014

Exhibit 99.1 |

2

Legal Notice / Forward-Looking Statements

Legal Notice / Forward-Looking Statements

This presentation contains forward-looking statements made by PBF Energy Inc. (the

“Company” or “PBF”) and its management. Such statements are based on

current expectations, forecasts and projections, including, but not limited to, anticipated

financial and operating results, plans, objectives, expectations and intentions that are not historical in

nature. Forward-looking statements should not be read as a guarantee of future performance or

results, and may not necessarily be accurate indications of the times at, or by which, such

performance or results will be achieved. Forward-looking statements are based on

information available at the time, and are subject to various risks and uncertainties that

could cause the Company’s actual performance or results to differ materially from those expressed

in such statements. Factors that could impact such differences include, but are not limited to,

changes in general economic conditions; volatility of crude oil and other feedstock prices;

fluctuations in the prices of refined products; the impact of disruptions to crude or feedstock

supply to any of our refineries, including disruptions due to problems with third party

logistics infrastructure; effects of litigation and government investigations; the timing and announcement of

any potential acquisitions and subsequent impact of any future acquisitions on our capital structure,

financial condition or results of operations; changes or proposed changes in laws or

regulations or differing interpretations or enforcement thereof affecting our business or

industry, including any lifting by the federal government of the restrictions on exporting U.S.

crude oil; actions taken or non-performance by third parties, including suppliers,

contractors, operators, transporters and customers; adequacy, availability and cost of capital; work

stoppages or other labor interruptions; operating hazards, natural disasters,

weather-related delays, casualty losses and other matters beyond our control; inability to

complete capital expenditures, or construction projects that exceed anticipated or budgeted

amounts; inability to successfully integrate acquired refineries or other acquired businesses or operations;

effects of existing and future laws and governmental regulations, including environmental, health and

safety regulations; and, various other factors.

Forward-looking statements reflect information, facts and circumstances only as of the date they

are made. The Company assumes no responsibility or obligation to update forward-looking

statements to reflect actual results, changes in assumptions or changes in other factors

affecting forward-looking information after such date. |

3

U.S. Refining Industry Strengths

U.S. Refining Industry Strengths

Inexpensive

Natural Gas

Growth in supply driving decline in U.S. natural gas pricing

U.S. natural gas currently priced more than 60% below Europe

~$0.10 / bbl benefit to domestic refiners for every $1 / MMBtu

difference in natural gas price

North American

Crude

Oil Production

Secular growth in North American crude oil production

Favorable price dislocations between North American crude

and rest of world

Complex

Refineries

U.S. average refinery Nelson Complexity of 10.8 versus Western

European average refinery Nelson Complexity of 7.8

Product

Exports

Cost and technological advantages have spurred export

opportunities

East Coast to Europe, West Africa, and Latin America

Why will the U.S. refining industry prosper for the next 5 years?

|

4

PBF owns three oil refineries located in Ohio,

Delaware and New Jersey

Aggregate throughput capacity of

approximately 540,000 barrels per day

Weighted average Nelson Complexity of 11.3

Fifth largest U.S. independent refiner

East Coast rail infrastructure results in the

entire system having access to WTI-based,

cost-advantaged crude supply

Summary Company Profile

Region

Throughput

Capacity (bpd)

Date

Acquired

Nelson

Complexity

Replacement

Cost

Benchmark

Crack Spread

Mid-Continent

170,000

3/1/2011

9.2

$2.4 billion

WTI (Chicago) 4-3-1

East Coast

370,000

2010

12.2

$5.8 billion

Dated Brent (NYH) 2-1-1

Total

540,000

11.3

(1)

$8.2 billion

(1) Represents weighted average Nelson Complexity for PBF’s three

refineries Cushing

Toledo

Paulsboro

Delaware City |

5

Increasing East Coast access to currently cost-advantaged

North American crude oil

Increasing East Coast access to currently cost-advantaged

North American crude oil

PBF’s onsite rail-infrastructure at Delaware City provides the

opportunity to save approximately $3/bbl on delivered Bakken

barrels

versus

using

3

party

facilities

rd |

North

American Crude Production North American Crude Production

U.S. crude production is estimated

to grow by 55% (3 million bpd)

from 2010 through 2014

Pushes barrels South (via

water, pipeline and rail), East

and West (primarily by rail)

Ultimately displaces USGC

imports

Canadian crude production is

expected to grow by 32%

(900 kbpd) from 2010 through

2014

Bitumen by rail advantaged

versus pipeline transportation

of diluted crudes

6 |

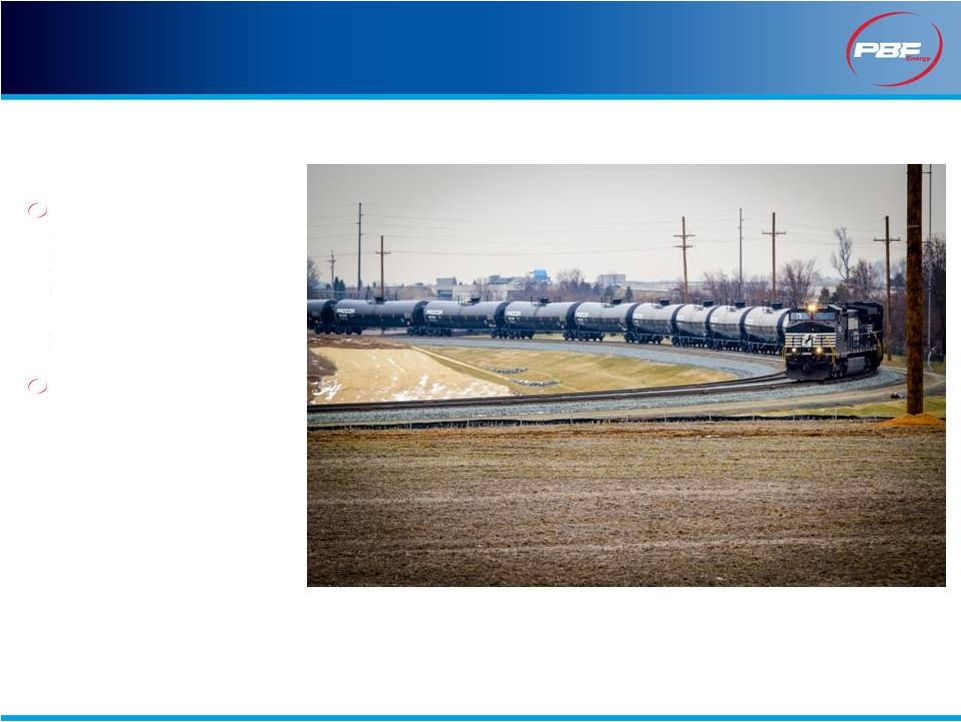

PBF

Rail Deliveries of Light Crude to East Coast PBF Rail Deliveries of Light Crude

to East Coast Light crude discharge

capacity is over 100,000

bpd with a project to

increase capacity to

120,000 –

130,000 bpd

by Q3-2014

PBF is able to deliver

Bakken barrels to

Delaware City at a cost of

approximately $12 per

barrel

7 |

PBF

Rail Deliveries of Canadian Heavy Crude to East Coast PBF Rail Deliveries of

Canadian Heavy Crude to East Coast PBF’s heavy crude unloading capacity

is expected to double from approximately

40,000 bpd to approximately 80,000 bpd

by Q3-2014 as PBF completes its ongoing

rail expansion project and infrastructure

projects are completed in Canada

Deliveries of Canadian heavy crude are

dependent on access to coiled and

insulated railcars as well as rail

transloading facilities in Canada

Transportation costs for Canadian-heavy

are expected to decline from above $20

per barrel to below $17 per barrel as PBF-

controlled railcar fleet expands and the

benefits of unit-train economics are

realized

8 |

9

Crude-by-Rail Pipeline

Planned Leased or Owned Railcars

Note: Schedule is subject to change based on current company plans and on current

third party railcar manufacturer delivery schedules Longer-term focus on

logistics Rail services agreements with Norfolk Southern and BNSF

Increased ability to load unit trains

Transloading agreement with Savage in Trenton, ND

Advantageous commercial arrangements with crude producers

Supply agreement with Continental Resources for Bakken

Ensuring delivery

Agreement with Trinity for delivery of rail cars

PBF’s fleet of new railcars meet the highest DOT-111A standards

Increased availability of “delivered”

deals

1,808

1,966

2,023

2,625

3,100

3,800

4,516

4,600

1,283

1,300

1,300

1,300

1,300

1,300

1,300

1,300

-

1,000

2,000

3,000

4,000

5,000

6,000

1Q14

2Q14

3Q14

4Q14

1Q15

2Q15

3Q15

4Q15

Coiled & Insulated

General Purpose |

10

Widening Crude Differentials

Widening Crude Differentials

Crude differentials widened out during the fourth quarter of 2013 and PBF

expects to realize the benefits of the wider differentials as crude

purchased during the fourth quarter is processed at our refineries in the

latter part of Q4-13 and the beginning of Q1-14

$/bbl

Q1 –

Q3-2103

Average

Q4-2013

Average

WCS-Brent

(32.67)

(43.15)

Bakken-Brent

(13.05)

(22.72)

ASCI-Brent

(4.30)

(13.53)

Syncrude-WTI

2.26

(9.35)

Increasing North American production, North American crude oil

distribution logistics, seasonality and other events will continue to impact

differentials and PBF expects differentials to remain volatile but favorable

for US refiners |

11

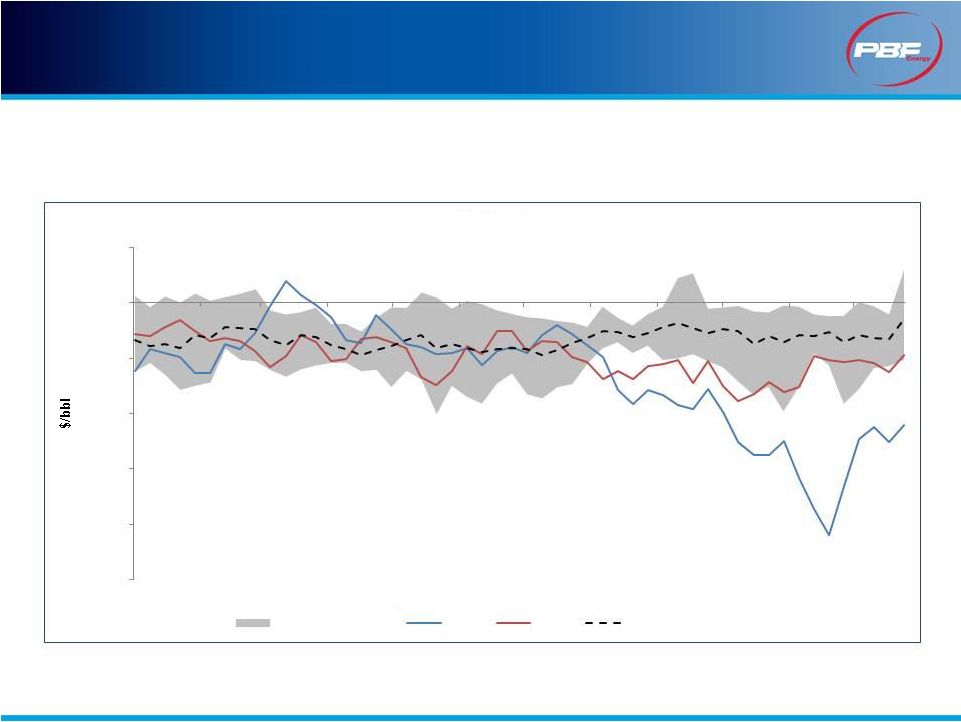

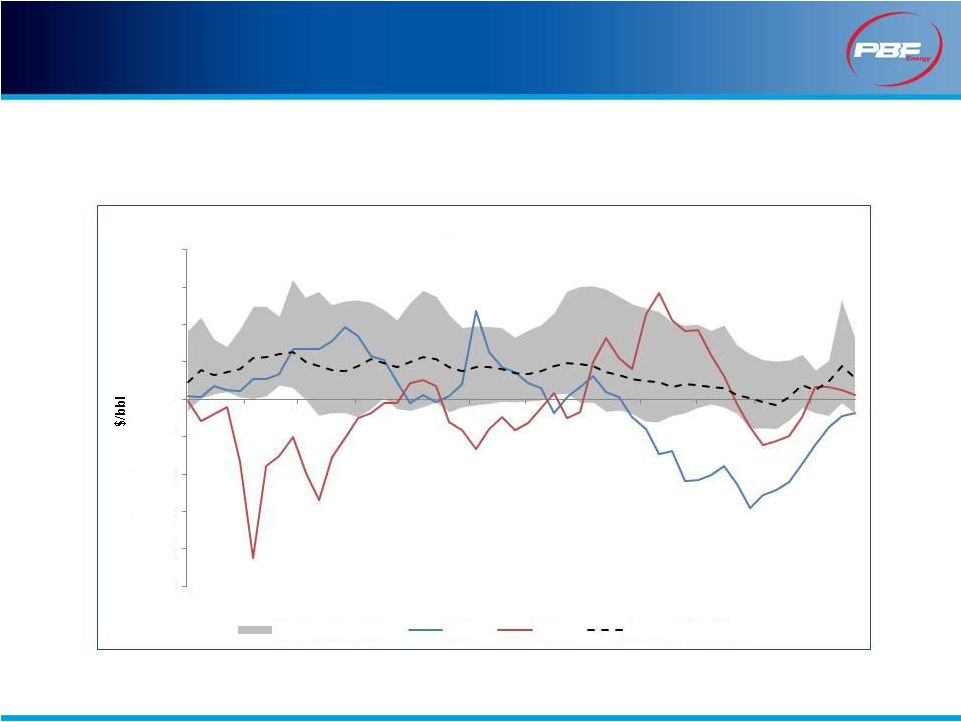

Brent versus WTI

Brent versus WTI

Widening Brent –

WTI differential positively impacts cost-advantage of

North American produced crude oils

(35.00)

(30.00)

(25.00)

(20.00)

(15.00)

(10.00)

(5.00)

-

5.00

10.00

Jan

Feb

Mar

Apr

May

Jun

Jul

Aug

Sep

Oct

Nov

Dec

WTI -

Brent

Min Max (07 to 11)

2013

2012

Average (07 to 11)

Source: Platts |

12

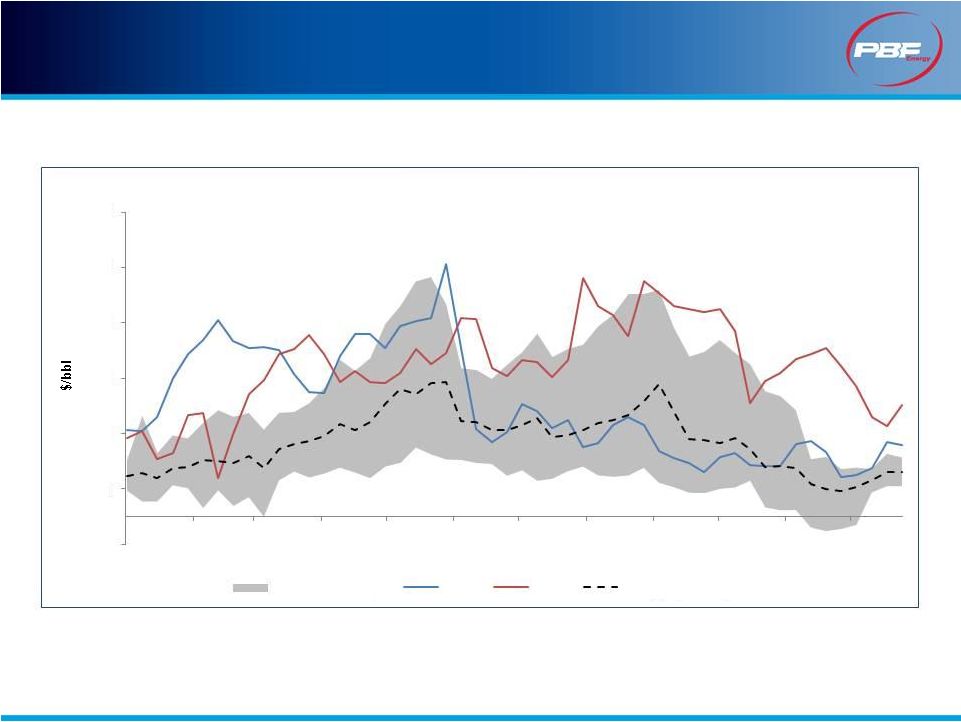

WCS versus Brent

WCS versus Brent

Expanding differentials positively impact rail economics for Canadian

Heavy crude oil processed at PBF’s East Coast refineries

(70.00)

(60.00)

(50.00)

(40.00)

(30.00)

(20.00)

(10.00)

-

10.00

Jan

Feb

Mar

Apr

May

Jun

Jul

Aug

Sep

Oct

Nov

Dec

WCS -

Brent

Min Max (07 to 11)

2013

2012

Average (07 to 11)

Source: Platts |

Bakken versus Brent

Bakken versus Brent

13

Note: Prior to May 2010 Bakken pricing is unavailable

Expanding differentials positively impact rail economics for Mid-continent

light-sweet crude oil processed at PBF’s East Coast

refineries (50.00)

(45.00)

(40.00)

(35.00)

(25.00)

(20.00)

(15.00)

(10.00)

(5.00)

-

Jan

Feb

Mar

Apr

May

Jun

Jul

Aug

Sep

Oct

Nov

Dec

Bakken -

Brent

Min Max (10 to 12)

2013

Average (10 to 12)

Source: Platts

(30.00) |

14

ASCI Differential versus Brent

ASCI Differential versus Brent

ASCI is an indicator for medium-sour barrels processed

at PBF’s East Coast facilities

(25.00)

(20.00)

(15.00)

(10.00)

(5.00)

-

5.00

Jan

Feb

Mar

Apr

May

Jun

Jul

Aug

Sep

Oct

Nov

Dec

ASCI -

Brent

Min Max (07 to 11)

2013

2012

Average (07 to 11)

Source: Platts, Argus |

15

PBF’s Key Mid-continent differential versus WTI

PBF’s Key Mid-continent differential versus WTI

Toledo processes approximately 35% to 40% Syncrude

(25.00)

(20.00)

(15.00)

(10.00)

(5.00)

-

5.00

10.00

15.00

20.00

Jan

Feb

Mar

Apr

May

Jun

Jul

Aug

Sep

Oct

Nov

Dec

Syncrude -

WTI

Min Max (07 to 11)

2013

2012

Average (07 to 11)

Source: Platts |

PBF’s East Coast Benchmark Crack

PBF’s East Coast Benchmark Crack

16

NYH 2:1:1 = ((–2*Dated Brent) + (1*NY RBOB) + (1*NO.2 Heating Oil))/2

-

5.00

10.00

15.00

20.00

25.00

30.00

Jan

Feb

Mar

Apr

May

Jun

Jul

Aug

Sep

Oct

Nov

Dec

NYH 2:1:1

Min Max (07 to 11)

2013

2012

Average (07 to 11)

Source: Platts |

PBF’s Mid-continent Benchmark Crack

PBF’s Mid-continent Benchmark Crack

Chicago 4:3:1 = ((–4*WTI) + (3*Chic CBOB pipe) + (0.5*Chic ULSD Pipe) +

(0.5*USGC Jet Kero 54))/4 17

Note: Prior to September 2009 Rul87 Chicago Pipe is used for substitution of CBOB

Chicago Pipe, which is unavailable prior to this period

(5.00)

5.00

15.00

25.00

35.00

45.00

55.00

Jan

Feb

Mar

Apr

May

Jun

Jul

Aug

Sep

Oct

Nov

Dec

Chicago 4:3:1

Min Max (07 to 11)

2013

2012

Average (07 to 11)

Source: Platts |

18

PBF MLP

PBF MLP

Submitted confidential registration statement in August 2013

PBF

has

identified

a

pool

of

assets

that

could

be

contributed

to

a

logistics-focused Master Limited Partnership (MLP)

Possible MLP assets include but are not limited to:

Rail terminals and railcars

Refinery truck terminals

Pipeline assets

Tank storage facilities |

No

near-term debt maturities $675.5 million 8.25% Senior Secured Notes due

2020 Net Debt/Net Cap was approximately 29% as of September 30, 2013

Liquidity

$1.575 billion Asset-based Facility (with an accordion up to $1.8

billion) Approximately $600 million of liquidity as of September 30,

2013 19

PBF’s Strong Financial Position

PBF’s Strong Financial Position

PBF

Financial

Snapshot

–

September

30,

2013

($MM, Unless

Otherwise

Noted)

Capitalization Table

Actual

Cash and Cash Equivalents

$57.4

Debt

Long-Term Debt

722.6

Total Debt

738.6

Net Debt

681.2

Total Equity

1,648.8

Net Capitalization

2,330.0 |

20

PBF’s Fourth Quarter 2013 Cash Highlights

PBF’s Fourth Quarter 2013 Cash Highlights

PBF’s Q4-2013 Cash Highlights

($MM, Unless

Otherwise

Noted)

Est. Cash and Cash Equivalents as of December 31, 2013

$75

Est. Total Debt outstanding as of December 31, 2013

$745 –

$755

Est. Net Debt at December 31, 2013

$670 –

$680

Est. Uses of cash in Q4-2013

Est. Decrease in Net Debt from September 30, 2013

$0 –

$10

Est. Q4 Capital Expenditures

$85 –

$100

Dividend Payments

$30

Est. Cash Interest Expense

$10

Est. Cash generated from Operations/Working Capital

$125 –

$150

All

figures

displayed

below

are

estimates,

unaudited,

subject

to

change,

are

provided

for information purposes only and are not indicative of the actual earnings of the

company for the period

In Q4-13, PBF generated an estimated $125-$150 million of cash from

operations and working capital |

21

2014 Full Year Guidance

2014 Full Year Guidance

Guidance provided constitutes forward-looking information and is based on current PBF

Energy operating plans, company assumptions and company configuration. All figures are

subject to change based on market and macroeconomic factors, as well as company strategic

decision-making and overall company performance Throughput, based on current plans, is expected to be 315,000 to 335,000 barrels per day for the East Coast including the impact of

turnarounds

140,000 to 150,000 barrels per day for the Mid-continent including the impact of

turnarounds

Operating expenses are expected to be $4.50 – $4.75 per barrel across all three refineries

SG&A expense is expected to be approximately $75 – $85 million D&A expense is expected to be approximately $140 – $150 million Interest expense is expected to be approximately $100 – $110 million Capital

expenditures, including projects and turnarounds, are expected to be approximately $250

million |

|