Attached files

| file | filename |

|---|---|

| 8-K - 8-K - Northern Tier Energy LP | d627199d8k.htm |

| EX-99.1 - EX-99.1 - Northern Tier Energy LP | d627199dex991.htm |

Third Quarter

2013 Earnings Conference Call and Webcast

November 12, 2013

Exhibit 99.2 |

Forward Looking

Statements 1

This presentation includes “forward-looking statements.” The words

“believe,” “expect,” “anticipate,” “plan,” “intend,” “foresee,” “should,” “would,”

“could,” “attempt,” “appears,” “forecast,”

“outlook,” “estimate,” “project,” “potential,” “may,” “will,” “are likely” or other similar expressions are

intended to identify forward-looking statements. These forward-looking

statements are based on management’s current expectations and beliefs concerning

future developments and their potential effect on us. While management believes that these forward-looking statements are reasonable as

and when made, there can be no assurance that future developments affecting us will be those

that we anticipate, and any and all of our forward- looking statements in this

presentation may turn out to be inaccurate. Our forward-looking statements involve significant risks and uncertainties (some

of which are beyond our control) and assumptions that could cause actual results to differ

materially from our historical experience and our present expectations or

projections. Important factors that could cause actual results to differ materially from those in the forward-looking statements include,

but are not limited to, the overall demand for hydrocarbon products, fuels and other refined

products; our ability to produce products and fuels that meet our customers’

unique and precise specifications; the impact of fluctuations and rapid increases or decreases in crude oil, refined products, fuel,

utility services and crack-spread prices, including the impact of these factors on our

liquidity; fluctuations in refinery capacity; accidents or other unscheduled shutdowns

affecting our refineries, machinery, or equipment, or those of our suppliers or customers; changes in the cost or availability of

transportation for feedstocks and refined products; the results of our hedging and other risk

management activities; our ability to comply with covenants contained in our debt

instruments; labor relations; relationships with our partners and franchisees; successful integration and future

performance of acquired assets, businesses or third-party product supply and processing

relationships; our access to capital to fund expansions, acquisitions and our working

capital needs and our ability to obtain debt or equity financing on satisfactory terms; environmental liabilities or events

that are not covered by an indemnity, insurance or existing reserves; dependence on one

principal supplier for our retail merchandise; maintenance of our credit ratings and

ability to receive open credit lines from our suppliers; the effects of competition; continued creditworthiness of, and performance

by, counterparties; the impact of current and future laws, rulings and governmental

regulations, including guidance related to the Dodd-Frank Wall Street Reform and

Consumer Protection Act; shortages or cost increases of power supplies, natural gas, materials or labor; weather interference with

business operations; seasonal trends in the industries in which we operate; fluctuations in

the debt markets; potential product liability claims and other litigation; accidents or

other unscheduled shutdowns or disruptions; and changes in economic conditions, generally, and in the markets we serve,

consumer behavior, and travel and tourism trends. These factors are not necessarily all

of the important factors that could cause actual results to differ materially from

those expressed in any of our forward-looking statements. Other unknown or unpredictable factors could have material adverse effects

on our future results. For additional information regarding known material factors that

could cause our actual results to differ from our projected results, please refer to

our Annual Report on Form 10-K for the year ended December 31, 2012 and other subsequent filings with the SEC.

The presentation also includes non-GAAP measures. We believe that these non-GAAP

financial measures provide useful information about our operating performance and

should not be viewed in isolation or considered as alternatives to comparable GAAP measures. Our non-GAAP financial

measures may also differ from similarly names measures used by other companies. See the

disclosures in the “Management’s Discussion and Analysis of Financial

Condition and Results of Operations” included in our quarterly report on Form 10-Q for the three and nine months ended September 30,

2013 for additional information on the non–GAAP measures used in this presentation and

reconciliations to the most directly comparable GAAP measures.

|

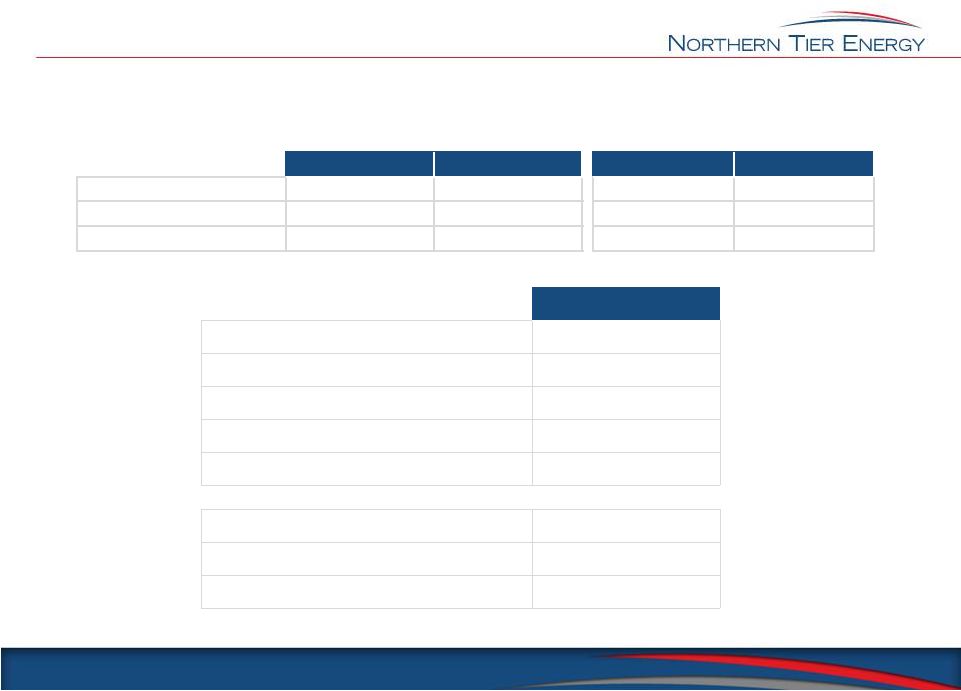

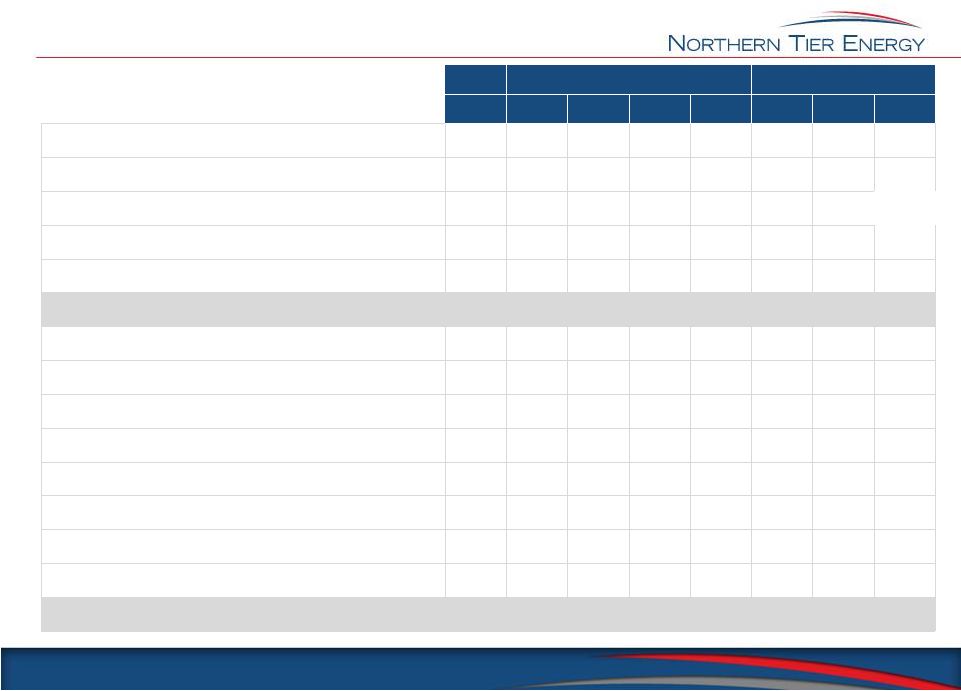

Q3 2013

Financial Results; Select Balance Sheet & Cash Flow Data

2

Consolidated Financial Results

1

See Appendix for reconciliation of Net Income to Adjusted EBITDA.

($ in millions)

Q3 2013

Cash and Cash Equivalents

$126.7

Total Debt (including capital leases)

$282.3

Equity

$408.1

Adjusted EBITDA (last twelve months)

$456.2

Debt to LTM Adjusted EBITDA

0.6x

Cash Flow from Operations

$98.5

Cash Available for Distribution

$28.3

Distribution per Unit

$0.31

Balance Sheet & Cash Flows

Q3 2013

Q3 2012

Q3 YTD 2013

Q3 YTD 2012

Net Income

$27.2

$61.1

$210.5

$113.1

Operating Income

27.3

199.4

206.8

426.8

Adjusted EBITDA

1

51.3

249.5

293.8

577.3 |

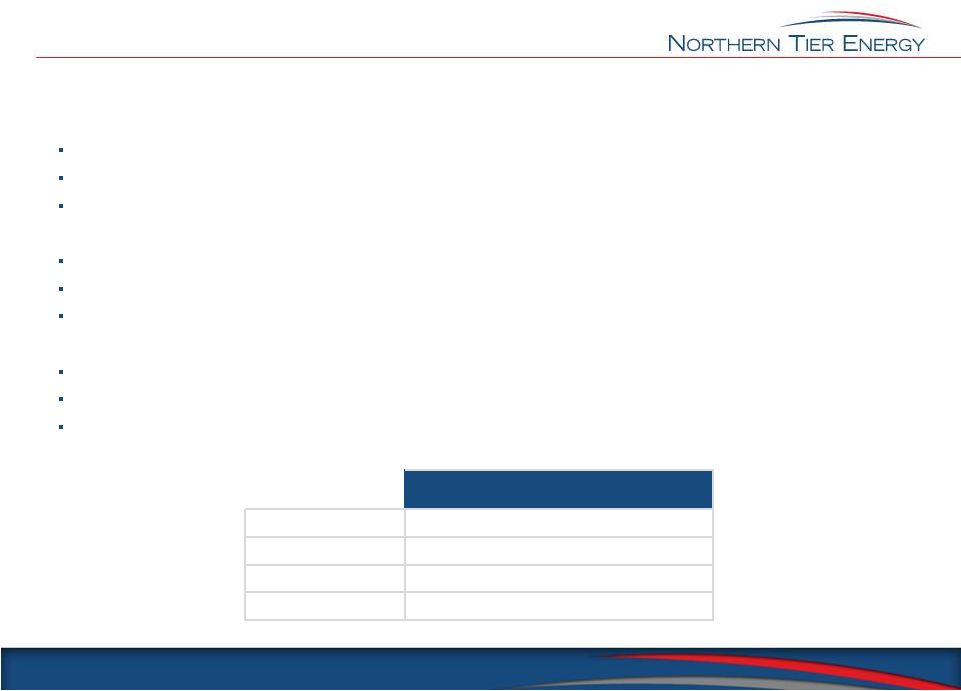

Refinery

Expansion Projects NTI has successfully completed the two previously announced

discretionary projects at the Saint Paul Park Refinery, with the third one to be

completed in Q1 2014: 1.Sweet crude tower expansion

project: Completed in Q2 13

Increased throughput on the #2 crude tower (sweet tower) by 8kbpd

Total cost was $40 million

2.Wet gas compressor project:

Completed in Q4 13

Decreases output of black oil by approximately 2kbpd and converts to gasoline, distillate and

LPGs Total cost was $5 million

3.Slurry stripper project:

To be completed in Q1 14

Allows Fuel Oil to be saleable by itself, unblended

Total cost is $4 million

Net Yield Change:

3

1

Prior to the Saint Paul Park discretionary projects, which were initiated in Q2 of 2013.

2014

Delta

to

Historic

1

Yields

(% of Input)

LPGs

0.9 %

Gasoline

0.5 %

Distillates

3.7 %

Black Oil

(4.9) % |

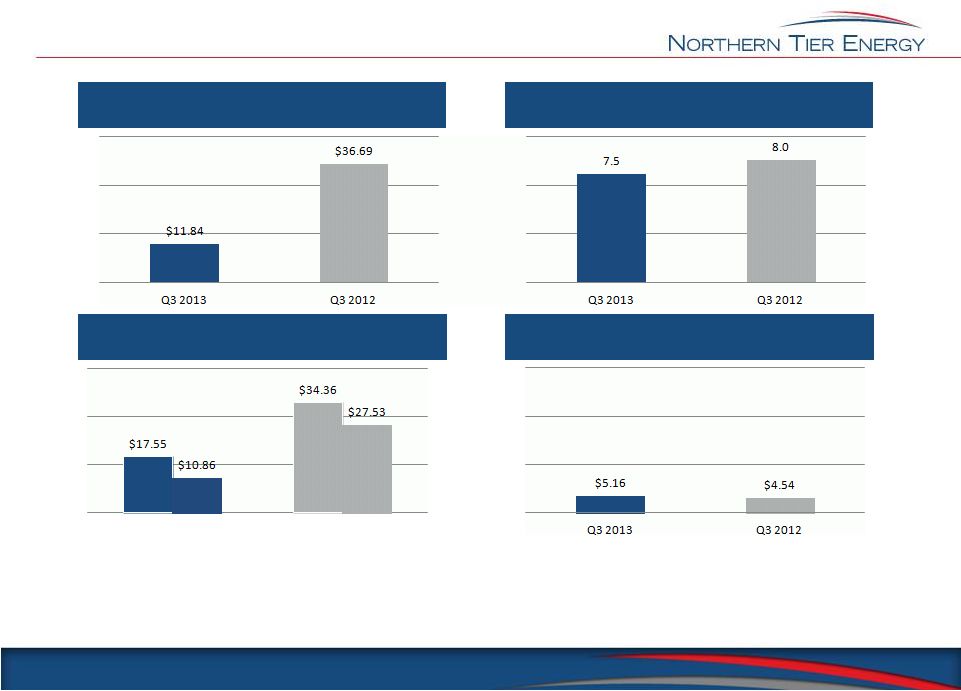

Key Refining

Performance Metrics 4

Gross Margin

1

($ per throughput barrel)

Group 3 Benchmark Crack Spread

2

Direct Operating Expenses

3

($ per throughput barrel)

Throughput

(millions of barrels)

3-2-1

3-2-1

6-3-2-1

6-3-2-1

Q2 2013

Q2 2012

1

See Appendix for each of the components used in this calculation (revenue and cost of

sales). 2

Typically, 80% of our products are comparable to a 3-2-1 crack spread, while 95% of

our products are comparable to a 6-3-2-1 crack spread. 3

Direct operating expenses per barrel is calculated by dividing direct operating expenses by

the total barrels of throughput for the respective periods presented.

|

Cash Available

for Distribution Reconciliation For the 3 months ending

9/30/13

Net income

$27.2

Adjustments:

Interest expense

6.3

Income tax provision

1.4

Depreciation and amortization

9.8

EBITDA subtotal

$44.7

Minnesota Pipe Line proportionate EBITDA

0.7

Turnaround and related expenses

12.2

Equity-based compensation impacts

0.7

Unrealized gains on derivative activities

(6.8)

Formation and offering costs

0.6

Realized gains on derivative activities

(0.8)

Adjusted EBITDA

$51.3

Cash interest expense

(5.7)

Current tax position

(1.4)

Minnesota Pipe Line proportionate EBITDA

(0.7)

Realized gains on derivative activities

0.8

Capital expenditures¹

(5.4)

Formation and offering costs

(0.6)

Cash reserve for turnaround and related expenses

(5.0)

Cash reserve for discretionary capital expenditures

(5.0)

Cash Available for Distribution

$28.3

($ in millions)

5

1

Capital expenditures include maintenance, replacement, and regulatory capital projects.

Expansion capital projects are not included. |

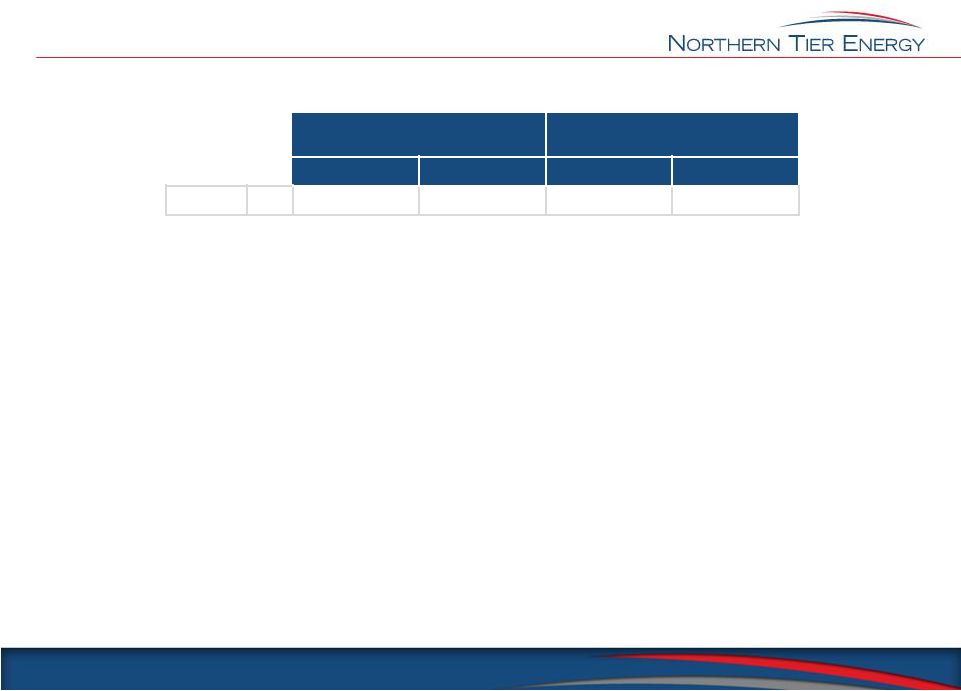

Hedge

Positions 6

1

30,000 barrels of gasoline per quarter and 15,000 barrels of diesel per quarter are

hedged at cracks against WCS, while the remaining barrels are hedged at cracks against WTI.

Volume Hedged

(000

barrels)

NTI Strike Price

Gasoline

Diesel

Gasoline

Distillate

2013

1

Q4

504

761

16.08

21.40 |

Q4 ‘13

Operating and Capex Guidance 7

1

Includes gasoline bought on the open market to satisfy SuperAmerica and other contractual

obligations during our planned FCC turnaround. We do not expect to earn a

meaningful margin on these purchases. `

Q4 2013

Low

High

Refinery Statistics:

Total throughput (bpd)

80,000

85,000

Total refined

products sold (bpd)

1

82,500

87,500

Direct opex ex. Turnaround ($/throughput bbl)

$5.25 -

$5.75

Retail Statistics

:

Forecasted gallons (mm)

79

Retail fuel margin ($/gallon)

$0.16

Merchandise

sales ($ in mm)

$91

Merchandise gross

margin (%)

26.0%

Direct operating

expense ($ in mm)

$30

Other Guidance ($ in mm):

Reserve for turnaround

and related expenses

$5 -

$10

Cash reserve for discretionary capital expenditures

$5 -

$10

SG&A

$22

Depreciation & amortization

$10

Cash interest expense

$6

Current tax expense

$1

Capital Program:

Maintenance

and replacement capital

$8

Waste Water Treatment

(non recurring regulatory capital)

$8

Discretionary

capital

$4

Total Planned

Capital Expenditures

($

in

mm)

$20 |

APPENDIX

|

Adjusted

EBITDA Reconciliation 9

2011

2012

2013

4Q

1Q

2Q

3Q

4Q

1Q

2Q

3Q

Net Income (Loss)

$292.7

$(193.6)

$245.6

$61.1

$84.5

$119.4

$63.9

$27.2

Adjustments:

Interest Expense

11.5

10.4

10.7

15.6

5.5

6.4

6.3

6.3

Income Tax Provision

-

-

0.1

7.7

2.0

(0.1)

3.0

1.4

Depreciation and Amortization

7.2

8.5

7.8

8.3

8.6

8.6

9.4

9.8

EBITDA Subtotal

$311.4

(174.7)

$265.2

$92.7

$100.6

$134.3

$82.6

$44.7

Minnesota Pipe Line Proportionate EBITDA

0.1

0.7

0.7

0.7

0.7

0.7

0.7

0.7

Turnaround and Related Expenses

0.1

3.5

11.5

2.1

9.0

9.7

27.3

12.2

Equity-based Compensation Impacts

0.5

0.4

0.5

0.5

(0.5)

5.3

0.4

0.7

Unrealized (Gains) / Losses on Derivative Activities

(292.6)

88.4

(191.3)

70.3

(35.4)

(11.2)

(28.7)

(6.8)

Contingent Consideration (Income) / Loss

(18.2)

65.7

0.1

38.5

-

-

-

-

Formation and Offering Costs

1.3

-

1.0

-

0.4

0.4

0.5

0.6

Loss on Early Extinguishment of Derivatives/Debt

-

44.6

92.2

-

50.0

-

-

-

Realized (Gains) Losses on Derivative Activities

63.9

52.9

67.4

44.7

37.6

17.4

3.1

(0.8)

Adjusted EBITDA

$66.5

$81.5

$246.3

$249.5

$162.4

$156.6

$85.9

$51.3

($ in millions) |

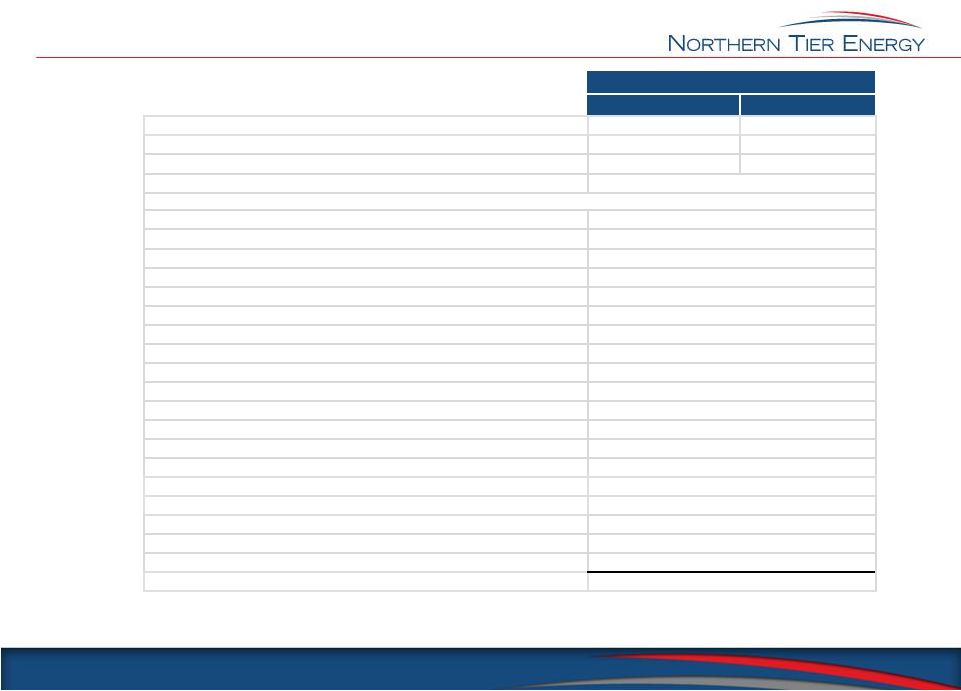

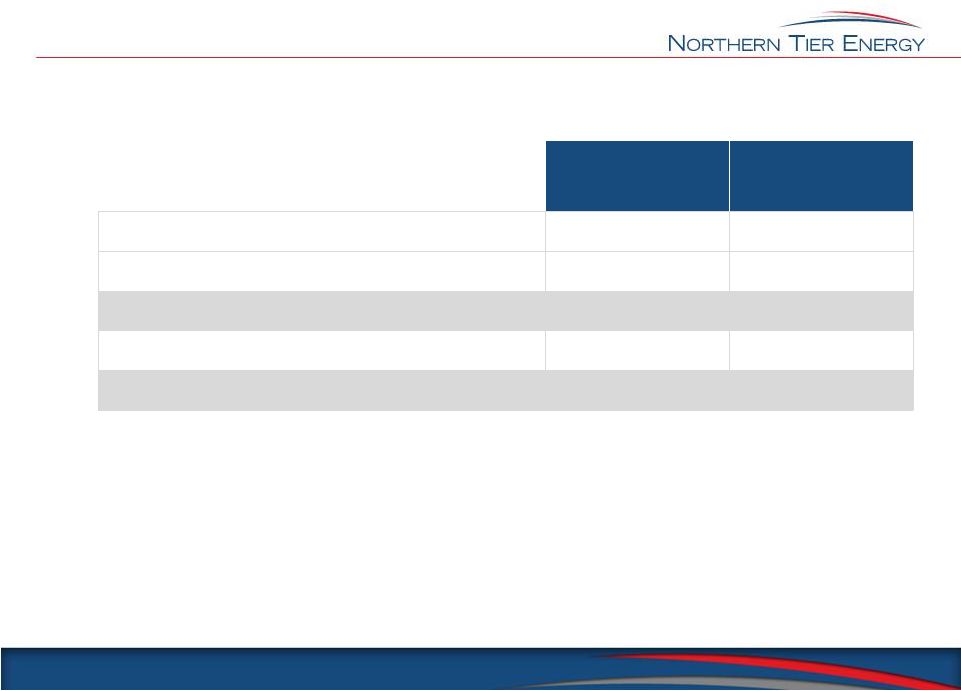

Refining Gross

Product Margin Per Barrel of Throughput Reconciliation

10

Q3 2013

Q3 2012

Refinery Revenue

$1,321.7

$1,151.1

Refinery Costs of Sales

1,233.3

855.8

Refinery Gross Product Margin

$88.4

$295.3

Total Refinery Throughput

7.5

8.0

Refinery Gross Product Margin Per Barrel of Throughput

$11.84

$36.69

($ in millions, unless otherwise indicated) |