Attached files

| file | filename |

|---|---|

| EX-31.1 - EX-31.1 - New Enterprise Stone & Lime Co., Inc. | a13-21040_1ex31d1.htm |

| EX-31.2 - EX-31.2 - New Enterprise Stone & Lime Co., Inc. | a13-21040_1ex31d2.htm |

| EX-32.2 - EX-32.2 - New Enterprise Stone & Lime Co., Inc. | a13-21040_1ex32d2.htm |

| EX-32.1 - EX-32.1 - New Enterprise Stone & Lime Co., Inc. | a13-21040_1ex32d1.htm |

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10-K/A

(Amendment No. 3)

(Mark One)

x Annual Report on Form 10-K pursuant to Section 13 or 15(d) of the Securities Exchange Act of 1934,

For the fiscal year ended February 28, 2013

or

o Transition report pursuant to Section 13 or 15(d) of the Securities Exchange Act of 1934,

For the transition period from to

Commission File Number 333-176538

NEW ENTERPRISE STONE & LIME CO., INC.

(Exact name of registrant as specified in its charter)

|

Delaware |

|

23-1374051 |

|

(State or other jurisdiction of incorporation or organization) |

|

(IRS employer identification number) |

|

3912 Brumbaugh Road P.O. Box 77 New Enterprise, PA |

|

16664 |

|

(Address of principal executive offices) |

|

(Zip code) |

Registrant’s telephone number, including area code: (814) 766-2211

Securities registered pursuant to Section 12(b) of the Act: None

Securities registered pursuant to Section 12(g) of the Act: None

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes o No x

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Securities Exchange Act of 1934. Yes o No x

Indicate by check mark whether the registrant: (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes x No o

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes o No x

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K: x

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer or a smaller reporting company. See the definitions of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Securities Exchange Act of 1934. (Check one):

|

Large accelerated filer o |

|

Accelerated filer o |

|

|

|

|

|

Non-accelerated filer x |

|

Smaller reporting company o |

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Securities Exchange Act of 1934). Yes o No x

As of February 28, 2013, there was no established public market for the registrant’s Class A Voting and Class B Non-Voting Common Stock and therefore the aggregate market value of the voting and non-voting common equity held by non-affiliates is not determinable.

As of September 20, 2013, the number of outstanding shares of the registrant’s Class A Voting Common Stock, $1.00 par value was 500 shares and the number of outstanding shares outstanding of the registrant’s Class B Non-Voting Stock, $1.00 par value, was 273,285.

DOCUMENTS INCORPORATED BY REFERENCE

None

Explanatory Note

The sole purpose of this Amendment No. 3 to the Annual Report on Form 10-K/A (the “Form 10-K/A”) of New Enterprise Stone & Lime Co., Inc. (the “Company,” “we,” “us,” or “our”) for the year ended February 28, 2013, originally filed with the SEC on May 29, 2013 and amended on June 11, 2013 (collectively, the “Original Form 10-K”) and September 3, 2013 (the “September 3, 2013 Amended and Restated Form 10-K”), is to revise the “Overview” section of “Item 1 — Business” and the “General” section of “Item 7 — Management’s Discussion and Analysis of Financial Condition and Results of Operations” to clarify the percentage of revenue that the Company derives from governmental and private sector end-use markets based upon fiscal 2013 revenue.

This Form 10-K/A should be read in conjunction with the Company’s periodic filings made with the SEC subsequent to the filing date of the September 3, 2013 Amended and Restated Form 10-K, including any amendments to those filings, as well as any Current Reports filed on Form 8-K subsequent to the date of the September 3, 2013 Amended and Restated Form 10-K. In addition, in accordance with applicable rules and regulations promulgated by the SEC, this Form 10-K/A includes updated certificates from our Chief Executive Officer and Chief Financial Officer as Exhibits 31.1, 31.2, 32.1, and 32.2.

This Form 10-K/A sets forth the September 3, 2013 Amended and Restated Form 10-K in its entirety. It includes both items that have been changed as a result of the amended disclosure discussed above, items that were changed in connection with the September 3, 2013 Amended and Restated Form 10-K, and items that are unchanged from the September 3, 2013 Amended and Restated Form 10-K. Other than the revision of the disclosures as discussed above and as expressly set forth herein and the amended disclosures set forth in the September 3, 2013 Amended and Restated Form 10-K, this Form 10-K/A speaks as of the original filing date of the Original Form 10-K and the September 3, 2013 Amended and Restated Form 10-K and has not been updated to reflect other events occurring subsequent to those filing dates.

CAUTIONARY STATEMENT REGARDING FORWARD-LOOKING STATEMENTS

This Annual Report on Form 10-K for our fiscal year ended February 28, 2013 (“fiscal year 2013”) includes “forward-looking statements” within the meaning of Section 27A of the Securities Act of 1933, as amended (the “Securities Act”) and Section 21E of the Securities Exchange Act of 1934, as amended (the “Exchange Act”), with respect to our financial condition, results of operations and business and our expectations or beliefs concerning future events. Such statements include, in particular, statements about our plans, strategies and prospects under the headings “Management’s Discussion and Analysis of Financial Condition and Results of Operations” and “Business.” You can identify certain forward-looking statements by our use of forward-looking terminology such as, but not limited to, “believes,” “expects,” “anticipates,” “estimates,” “intends,” “plans,” “targets,” “likely,” “will,” “would,” “could” and similar expressions that identify forward-looking statements. All forward-looking statements involve risks and uncertainties. Many risks and uncertainties are inherent in our industry and markets. Others are more specific to our operations. The occurrence of the events described and the achievement of the expected results depend on many events, some or all of which are not predictable or within our control. Actual results may differ materially from the forward-looking statements contained in this Annual Report on Form 10-K. Factors that could cause actual results to differ materially from those expressed or implied by the forward-looking statements include:

· material weaknesses and significant deficiencies in our internal controls over financial reporting;

· risks associated with the cyclical nature of our business and dependence on activity within the construction industry;

· declines in public sector construction and reductions in governmental funding which continue to adversely affect our operations and results;

· our reliance on private investment in infrastructure and a slower than normal recovery which continue to adversely affect our results;

· a decline in the funding of the Pennsylvania Department of Transportation, which we refer to as PennDOT, the Pennsylvania Turnpike Commission, the New York State Thruway Authority or other state agencies;

· difficult and volatile conditions in the credit markets may adversely affect our financial position, results of operations and cash flows;

· the potential for our lender to modify the terms of our asset-based loan facility;

· the risk of default of our existing and future indebtedness, which may result in an acceleration of our indebtedness thereunder;

· the potential to inaccurately estimate the overall risks, requirements or costs when we bid on or negotiate a contract that is ultimately awarded to us;

· the weather and seasonality;

· our operation in a highly competitive industry within our local markets;

· our dependence upon securing and permitting aggregate reserves in strategically located areas;

· risks related to our ability to acquire other businesses in our industry and successfully integrating them with our existing operations;

· risks associated with our capital-intensive business;

· risks related to our ability to meet schedule or performance requirements of our contracts;

· changes to environmental, health and safety laws;

· our dependence on our senior management;

· our ability to recruit additional management and other personnel and our ability to grow our business effectively or successfully implement our growth plans;

· the potential for labor disputes to disrupt operations of our businesses;

· special hazards related to our operations that may cause personal injury or property damage;

· unexpected self-insurance claims and reserve estimates;

· material costs and losses as a result of claims that our products do not meet regulatory requirements or contractual specifications;

· cancellation of significant contracts or our disqualification from bidding for new contracts;

· general business and economic conditions, particularly an economic downturn; and

· the other factors discussed in the section of this Annual Report on Form 10-K/A titled “Item 1A—Risk Factors.”

We caution you that the foregoing list of important factors may not contain all of the material factors that are important to you. In addition, in light of these risks and uncertainties, the matters referred to in the forward-looking statements contained in this Annual Report on Form 10-K/A may not in fact occur. We undertake no obligation to publicly update or revise any forward-looking statement as a result of new information, future events or otherwise, except as otherwise required by law.

Overview

We are a leading privately held, vertically integrated construction materials supplier and heavy/highway construction contractor in Pennsylvania and western New York and a national traffic safety services and equipment provider. Founded in 1924, we are one of the top 10 construction aggregates producers based on tonnage of crushed stone produced and one of the top 50 highway contractors based on revenues in the United States, according to industry surveys.

We operate in three segments based upon the nature of our products and services: construction materials, heavy/highway construction and traffic safety services and equipment. Our construction materials operations are comprised of: aggregate production, including crushed stone and construction sand and gravel; hot mix asphalt production; ready mixed concrete production; and the production of concrete products, including precast/prestressed structural concrete components and masonry blocks. Another of our core businesses, heavy/highway construction, includes heavy construction, blacktop paving and other site preparation services. Our heavy/highway construction operations are primarily supplied with construction materials from our construction materials operation. Our third core business, traffic safety services and equipment, consists primarily of sales, leasing and servicing of general and specialty traffic control and work zone safety equipment and devices to industrial construction end-users.

Our core businesses operate primarily in Pennsylvania and western New York, except for our traffic safety services and equipment business, which maintains a national sales network for our traffic safety products and provides traffic maintenance and protection services primarily in the eastern United States.

Our revenue is derived from sales to customers that serve multiple end-use markets. Because of the diversity of construction materials and services that we offer, we are able to meet a wide range of customer requirements on a local scale. We may not always know the end-use for our materials due to the diversity of our product offerings and the fact that our customers serve the various end-use markets, such as public or private sector. However, we believe based upon reasonable assumptions and knowledge of our customers and the possible end-use of particular materials and services, that in fiscal year 2013 approximately 55% to 60% of our revenue was derived from public sector end-use markets and 40% to 45% of our revenue was derived from private sector end-use markets, with approximately three-fourths of our private sector revenue being from non-residential construction.

Through four generations of family management, we have grown both organically and by acquisitions and now operate 52 quarries and sand deposits, 30 hot mix asphalt plants, 19 fixed and portable ready mixed concrete plants, four concrete products production plants, three lime distribution centers and six construction supply centers. Our traffic safety services and equipment business operates five manufacturing facilities and has sales facilities throughout the continental United States. We believe our extensive operating history and industry expertise, combined with strategically located operations and substantial aggregate reserves throughout Pennsylvania and western New York, enable us to be a low-cost supplier, as well as an operator with an established execution track record.

Corporate Information

New Enterprise Stone & Lime Co., Inc. (which we refer to as NESL) is a Delaware corporation initially formed as a partnership in 1924. Our principal executive offices are located at 3912 Brumbaugh Road, P.O. Box 77, New Enterprise, PA 16664, and our telephone number is (814) 766-2211.

Our Markets

Our vertically integrated construction materials and heavy/highway construction businesses operate in competitive regional markets. Many of our contracts are awarded based on a “sealed bid” process, which dictates that the lowest price bidder must be chosen. This dynamic forces us to compete against major, national suppliers and smaller, local operators. We believe that our extensive operational footprint and local market knowledge allow us to bid effectively on jobs, to obtain a unique understanding of our customers’ evolving needs and, most critically, to maintain favorable positions in the markets for our products and services, enabling us to submit lower price bids while maintaining our profitability.

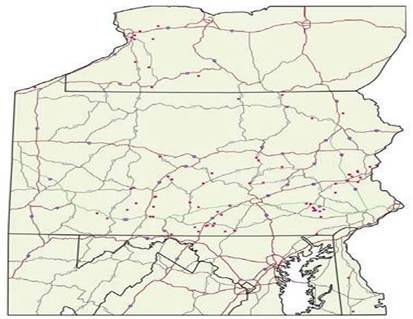

We maintain strategically located construction materials operations across Pennsylvania and western New York. We also provide heavy/highway construction services, primarily in Pennsylvania and, to a lesser degree, into Maryland, West Virginia and Virginia. We operate traffic safety equipment manufacturing facilities and sell these products across the United States and we provide maintenance and traffic protection services primarily in the eastern United States.

Pennsylvania and Western New York

We operate primarily throughout Pennsylvania and western New York. The geography and natural resources of this area contribute to this region being one of the largest consumers of construction aggregates in the United States.

Pennsylvania, which was the third largest producer of construction aggregates and the sixth largest producer of concrete in the United States in 2012, is located between the major consumer markets of the eastern United States and the large agricultural and industrial regions of the Midwestern United States, with an extensive and heavily utilized interstate system connecting the two. In addition, the state has a widely dispersed and dense rural population that requires approximately 120,000 miles of paved roads throughout the state that must be maintained on a regular basis. A high percentage of the state’s roads are built in frost susceptible areas which, when subject to the typical freeze-thaw cycles of Pennsylvania’s climate, create excess pavement stresses, deformation and surface degradation, all requiring road maintenance.

The Appalachian ridge, located in the central part of the state and close to many of our facilities, contains expansive coal strip mining production and Marcellus Shale’s gas well drilling and pipeline expansion, all of which require extensive road networks, and related road maintenance, that provide an additional market for our construction materials and heavy/highway construction. This same area has been the site of recent wind farm expansion. The construction of wind farms and the associated power generation facilities consume substantial amounts of aggregates and ready mixed concrete.

The geography and natural resources of Pennsylvania, western New York and the surrounding states provide a robust market for our product offerings. Geographically, the locations of our quarries allow us to reach a large market area in Pennsylvania and the western part of New York. Our highway construction division can perform work throughout Pennsylvania and is able to respond to this market with aggregates, concrete, blacktop paving and highway construction services. Furthermore, our geographically diverse facilities are situated to maximize the consumption trends in this region. The higher growth areas of eastern Pennsylvania have slowed during the recession. Conversely, our western and central Pennsylvania and New York locations are focused on the less cyclical core highway maintenance and heavy/highway construction, as well as the more stable residential and agricultural needs in these areas.

Public Sector

Public sector construction includes spending by federal, state and local governments for highways, bridges and airports, as well as other infrastructure construction for sewer and waste disposal systems, water supply systems, dams, reservoirs and other public construction projects. Generally, public sector construction spending is more stable than private sector construction. Public sector spending is less sensitive to interest rates and often is supported by multi-year legislation and programs. A significant portion of our revenue is from public highway construction projects. As a result, the funding for public highway construction significantly impacts our market.

The level of state spending on infrastructure varies across the United States and depends on the needs and economies of individual states. However, a large part of any state’s public expenditure on transportation infrastructure is a factor of the amount of federal funds it receives for such purposes. During its fiscal year ended June 30, 2012, PennDOT spent approximately $7.0 billion on transportation projects and administration, which includes its federal funds allocation of approximately $1.5 billion. In addition, the Pennsylvania Turnpike Commission, the roads of which are located near many of our facilities, receives toll revenue less susceptible to variations in state funding which it utilizes for its maintenance and construction operations. The Pennsylvania Turnpike Commission’s Ten-Year Capital Plan for the fiscal year ending May 31, 2013 is $6.8 billion, approximately 90% of which amount is allocated to the cost of resurfacing, replacing or reconstructing the existing turnpike system. The New York Thruway, also in our market area, is a toll road with dedicated funding outside of the New York Department of Transportation.

Private Sector

This market includes both non-residential and residential construction and is more cyclical than public construction.

Private non-residential construction includes a wide array of project types. Overall demand in private non-residential construction is generally driven by job growth, vacancy rates, private infrastructure needs and demographic trends. The growth of the private workforce creates a demand for offices, hotels and restaurants. Likewise, population growth generates demand for stores, shopping centers, warehouses and parking decks as well as hospitals, schools and entertainment facilities. Large industrial projects, such as a new manufacturing facility, can increase the need for other manufacturing plants to supply parts and assemblies, as well as the need for additional residential construction. Construction activity in this end-market is influenced by the ability to finance a project and the cost of such financing.

The majority of residential construction is for single-family houses with the remainder consisting of multi-family construction (i.e., two family houses, apartment buildings and condominiums). Public housing comprises a small portion of housing demand. Construction activity in this end-market is influenced by the cost and availability of mortgage financing. Demand for our products

generally occurs early in the infrastructure phase of subdivision development and residential construction, and later as part of driveways or parking lots.

United States housing starts peaked in 2005 at just over 2.0 million units. From 2007 to 2009, housing starts declined approximately 25% to 40% in each year. Housing starts began to increase modestly in 2010 and 2011, with an approximate 6% and 4%, increase, respectively, and then increased significantly in 2012, with a 25% improvement, according to the National Association of Homebuilders. The housing starts in the Pennsylvania market in which we operate had a similar decline and rebound. We believe lower home prices and attractive mortgage interest rates are positive factors that should continue to impact single-family housing construction in 2013 and beyond.

Consistent with past cycles of private sector construction, private non-residential construction remained strong after residential construction peaked in 2006. However, in late 2008, contract awards for non-residential buildings in the United States peaked. By April 2011, contract awards for non-residential construction had declined approximately 40% from its peak in 2008 and then began to rise modestly at the end of 2011 and into 2012.

Our Competitive Strengths

The following characteristics provide us with competitive advantages relative to others that operate in our markets. While our competitors may possess one or more of these strengths, we believe we are a leader in our markets because of our full complement of these attributes. Our strengths include:

Leading Market Positions

We are one of the top 10 construction aggregates producers based on tonnage of crushed stone produced and one of the top 50 largest highway contractors based on revenues in the United States, according to industry surveys. These leading market positions are driven by our regionally focused operational footprint, which facilitates efficient, low-cost product delivery and responsiveness to customer demands, which are essential to maintaining existing customers and securing new business.

Vertically Integrated Business Model

We generate revenue across a spectrum of related products and services. We are able to mine our quarries to extract aggregates that we use to produce ready mixed concrete and hot mix asphalt materials, which may be utilized by our heavy/highway construction business to service end customers. Our vertically integrated business model enables us to operate as a single source provider of materials and construction capabilities, creating economic, convenience and reliability advantages for our customers, while at the same time creating significant cross-marketing opportunities among our interrelated businesses. Our vertical integration model, combined with the breadth of our construction materials offerings, enhances our position as a construction materials supplier and as a bidder on complex multi-discipline construction projects. In instances where we may not win a local construction contract, for example, we may often serve as a subcontractor or significant supplier to the winning bidder, creating additional revenue opportunities.

Favorable Market Fundamentals

We work extensively for PennDOT and other governmental entities within Pennsylvania which are responsible for the state’s roads and highways. Pennsylvania’s diversified economy is heavily reliant on the state’s approximately 120,000 miles of interstate, state and local roads, and approximately 22,000 state and local bridges. Pennsylvania has the nation’s sixth largest gross state product and the nation’s eleventh largest road network, which serves as a critical highway transportation route connecting Midwestern manufacturing centers and the northeast corridor. The Pennsylvania State Transportation Advisory Committee, in its report dated May 2010, identified over $3.5 billion of annual unmet state and local highway and bridge funding needs in excess of currently available funding levels. In a recent Pennsylvania Senate Transportation Committee Report, approximately 23% of the state owned roads were rated poor and 18% and 34% of the state and local owned bridges, respectively, were rated structurally deficient. In February 2013, Governor Corbett announced a plan to increase annual transportation funding by $1.8 billion. In April 2013, several Pennsylvania state senators, including the Chairman of the Senate Transportation Committee, proposed a senate bill that would add approximately $2.5 billion to be utilized for state and local highway and bridge maintenance and repair. While there is no assurance that such a bill will be enacted, the market for highway and bridge construction in Pennsylvania will be favorably impacted if the state legislature ultimately approves additional highway and bridge funding. We believe our construction materials locations, understanding of various specifications, project management and skilled labor position us to take advantage of these favorable dynamics and enable us to provide competitive bids on most public sector projects in Pennsylvania.

Substantial Reserve Life

We estimate that we currently own or have under lease approximately 2.0 billion tons of permitted proven recoverable and probable recoverable aggregate reserves,

with an average estimated useful life of 115 years at current production levels. These reserves are located across our market area, creating a balanced distribution of reserves to serve customers across our markets. With our long operating experience and local knowledge, we believe we are highly qualified to efficiently identify and develop new quarry opportunities or quarries that become available for acquisition.

High Barriers to Entry

We benefit from barriers to entry that affects both potential new market entrants and existing competitors operating within or near our markets. The high weight-to-value ratio of aggregates and concrete products and the time in which hot mix asphalt and ready mixed concrete begin to set limit the efficient distribution range for these products to roughly a one-hour haul time. Our regionally focused operational footprint allows us to maintain lower transportation costs and compete effectively against large and small players in our local markets.

Quarry and construction operations are inherently asset intensive and require significant investments in land, high-cost equipment and machinery, resulting in significant start-up costs for a new business. We own most of the equipment and machinery used at our facilities, creating an advantage over potential market entrants. The complex regulatory environment and time-consuming permitting process, especially for opening new quarries, add further start-up costs and uncertainty for new market entrants.

Our regional focus and local knowledge, acquired through decades of operating experience, enhance our ability to bid effectively and win profitable contracts. We believe our experience allows us to distinguish ourselves from other competitors in this regard.

Experienced and Dedicated Management Team

Our senior management team includes certain third and fourth generation members of our founding family, the Detwiler family, who have spent a significant portion of their professional careers in the aggregate and heavy construction businesses and are complemented and supported by highly trained and experienced senior managers who came to us through various acquisitions and internal advancement. Our Chairman, Paul Detwiler, Jr., and our Vice Chairman, Donald Detwiler, have spent their entire careers working at NESL (54 and 47 years, respectively), with Paul’s expertise centered on the operation of the plants and quarries and Donald’s focused on the heavy/highway construction business. Two of Paul, Jr.’s sons, Paul Detwiler, III and Steven Detwiler hold senior management positions and serve on our Board of Directors and Executive Committee. Our Chief Executive Officer and President, Paul Detwiler, III, joined us in 1981. Steven Detwiler joined us in 1990 and currently serves as Senior Vice President-Construction Materials and President of our Buffalo Crushed Stone Division. Albert Stone became our Chief Financial Officer on March 22, 2013. Mr. Stone has been in the aggregates and heavy/highway construction business since 1986. G. Dennis Wiseman joined us in 1984 and currently serves as our Chief Accounting Officer and Assistant Secretary. The senior management team is complemented and supported by a large number of talented, highly trained and experienced senior managers with an average of approximately 34 years of experience. Our senior management team makes joint decisions on all major operating issues including capital deployments, acquisitions and expansions. Other corporate responsibilities are divided among the senior management group to ensure adequate contingency planning and leadership across all of our segments and divisions. We continue to focus on succession planning and focus on growing our company management from our internal ranks. Accordingly, we believe our management team has served and will continue to serve a critical role in our growth and profitability. Management remains dedicated to continuing to develop our operations and executing our business strategy as we continue to grow the business. We have management and leadership training programs in place and have trained hundreds of employees over the years so that we are not dependent on the outside market place to fill open positions. Members of the Detwiler family, who control all of the voting equity of NESL, have demonstrated a commitment to continued reinvestment in NESL. With the exception of certain tax-related dividends, we have not issued a dividend to any of our equity holders in 20 years.

Our Business Strategy

We are focused on growing our sales, profitability and cash flow and strengthening our balance sheet by capitalizing on our competitive strengths and reinvesting in our core businesses. Key elements of our business strategy include:

Leverage Our Vertically Integrated Business Model

We generate revenue across a spectrum of related products and services, many of which comprise a vertically integrated business that provides both raw materials and construction services. By maintaining production and cost control over this vertically integrated supply chain, we believe we are better able to serve our customers and be a low-cost supplier. We intend to leverage this vertical integration to continue to minimize our costs, improve our customer service and win profitable new business.

Maintain a Competitive Position in Our Markets

We are competitive in the areas we serve due to our extensive network of quarries and related operations that facilitate efficient distribution throughout our geographical market area. We believe that our vertically integrated model, including our network of operational facilities, as well as our tightly managed costs, project management, safety and educational training, technological improvements and value engineering focus all further drive our low-cost position. We continuously work to exploit new technologies, such as implementing improved global positioning systems to monitor truck delivery activity and increase precision in construction projects. These technological improvements, coupled with our comprehensive employee training program and health and safety training programs and policies, allow us to make optimal use of our employees and equipment, operate safely and lower our insurance claims. Our extensive operating experience allows us to identify value engineering opportunities on certain projects, allowing us to propose enhancements to project specifications which we believe save our customers money and enhance our profitability. The mechanics of the “sealed bid” process that govern many of our contract awards require that we submit a bid that is low enough to win the business, but also includes a margin sufficient to maintain profitability. We will continue to manage our business aggressively to minimize costs to ensure that we are positioned to continue to win competitive, profitable new business in our markets.

Capitalize on Our Strategically Located Operations to Expand Market Share

We believe our existing operational footprint places us in proximity to some of the strongest market opportunities in the mid-Atlantic and western New York regions. Our proximity to areas of high construction activity, including the extensive Pennsylvania and western New York road networks and the Pennsylvania coal and gas industries, creates attractive revenue opportunities for which we are particularly well positioned relative to both major, national and smaller, local competitors. We believe our strategically situated construction materials locations create an inherent competitive advantage for us in our markets. We intend to continue to capitalize on these advantages to increase revenues and drive profitability. In those instances where our construction materials locations do not create an inherent competitive advantage, we remain competitive through our local knowledge of required specifications and industry expertise.

Drive Profitable Growth Through Reinvestment

Through over 86 years of operations, we have developed significant experience and expertise in identifying and executing new growth opportunities. We expect to continue to enhance our overall competitive position and customer base by reinvesting in our business. We also anticipate that we will leverage our experience to develop more greenfield quarry locations within or adjacent to our current markets.

Our Industry

Our core construction materials, heavy/highway construction and traffic safety services and equipment businesses are organized to deliver customers products and services from six interrelated industry sectors:

· aggregates;

· hot mix asphalt;

· ready mixed concrete;

· concrete products;

· heavy/highway construction; and

· traffic safety services and equipment.

Competitors in these industries range from small, privately held firms that produce a single product, to multinational corporations that offer a comprehensive suite of construction materials and services, including design, engineering, construction and installation. However, day-to-day execution for construction materials for all competitors remains local or regional in nature based upon typical value-to-weight ratios which limit the distance construction materials can be transported in a cost effective manner.

Transportation infrastructure projects represent a substantial portion of the overall U.S. infrastructure market. These projects are driven by both state and federal funding programs. During 2012, the U.S. Congress passed a two year funding bill, Moving Ahead for Progress, or MAP-21, which provides relatively flat infrastructure funding for Pennsylvania as compared to the previous federal

allocation. With approximately 120,000 miles of interstate, state and local roads and approximately 22,000 state and local bridges,

Pennsylvania currently has the fifth largest allocation of the Federal Highway Trust Fund budget, receiving approximately $1.5 billion annually.

In addition to federal funding, highway construction and maintenance funding is also available through state agencies. In Pennsylvania, new highway and bridge construction and maintenance is coordinated by PennDOT. During its fiscal year ended June 30, 2012, PennDOT spent approximately $7.0 billion on transportation projects and administration, which includes its federal funds allocation. Typically the federal government funds a portion of PennDOT’s annual budget, while Pennsylvania funds the balance through the Motor License Fund, which we refer to as MLF. MLF funds are mandated per the state constitution to fund expenditures on highways and bridges and may not be reallocated to other state funding needs in the annual budgeting process. The Pennsylvania Turnpike Commission has a budget that is currently separate from PennDOT. The Pennsylvania Turnpike Commission’s Ten-Year Capital Plan for the fiscal year ending May 31, 2013 was $6.8 billion, approximately 90% of which amount is allocated to the cost of resurfacing, replacing or reconstructing the existing turnpike system.

PennDOT and the Pennsylvania Turnpike Commission have historically provided consistent demand for construction materials and projects in our markets. In addition, we also bid on purchase order contracts for hot mix asphalt and aggregates supplied directly to PennDOT maintenance districts and municipalities.

Construction Materials

Aggregates

The aggregates industry generated over $17.7 billion in sales through the production and shipment of 2.0 billion metric tons in 2012 in the United States, according to the United States Geological Survey, which we refer to as USGS. Aggregates include materials such as gravel, crushed stone, limestone and sand, which are primarily incorporated into construction materials, such as hot mix asphalt, cement and ready mixed concrete. Aggregates are also used for various applications and products, such as railroad ballast, filtration, roofing granules and in solutions for snow and ice control. The U.S. aggregate industry is highly fragmented with numerous participants operating in localized markets. The USGS reported that a total of 1,550 companies operating 4,000 quarries and 91 underground mines produced or sold crushed stone valued at $11.0 billion in 2012 in the United States.

Transportation cost is a major variable in determining aggregate pricing and marketing radius. The cost of transporting aggregate products from the plant to the market often equates to or exceeds the sale price of the product at the plant. As a result of the high transportation costs and the large quantities of bulk material that have to be shipped, finished products are typically marketed locally. High transportation costs are responsible for the wide dispersion of production sites. Where possible, construction material producers maintain operations adjacent to highly populated areas to reduce transportation costs and enhance margins.

The demand for aggregates is a function of several factors, including transportation infrastructure spending and changes in population density. In the past few years, the recession in the United States has led to a decrease in overall private construction activity. Despite the increase in federal stimulus spending, public construction activity has also suffered a decline over this period. Crushed stone production was approximately 1.24 billion tons in 2012, a 7% increase compared with that of 2011. Apparent consumption also increased to approximately 1.28 billion tons. Demand for crushed stone was slightly higher in 2012 because of the apparent end of the slowdown in activity that some of the principal construction markets have experienced during the last 6 years. Long-term increases in construction aggregates demand will be influenced by activity in the public and private construction sectors, as well as by construction work related to security measures being implemented around the nation. The underlying factors that would support a rise in prices of crushed stone are expected to be present in 2013, especially in and near metropolitan areas. With U.S. economic activity slowly improving, construction sand and gravel output for 2012 increased about 5% compared with that of 2011. The total number of employees in the U.S. construction sand and gravel industry increased by 6% in 2012 compared with that of 2011. Growth in housing starts in 2012 is increasing demand for construction sand and gravel in many states. Growth was also seen in some nonresidential construction, especially within the sectors of communications, power generation, and non-highway transportation.

We believe that the long-term growth of the market for aggregates is largely driven by growth in population, jobs and households. While short-term and medium-term demand for aggregates fluctuates with economic cycles, the declines have historically been followed by strong recovery, with each peak establishing a new historical high.

A significant portion of our aggregates is utilized in heavy/highway construction projects. Highways located in our markets are particularly vulnerable to freeze-thaw conditions that lead to excessive pavement stress and surface degradation conditions. The highway pavement deterioration in our markets is accelerated by the large volume of intrastate and interstate trucking in Pennsylvania given its location between the eastern United States consumer markets and other agricultural and industrial regions of the United States. Surface maintenance repairs, as well as general highway construction and repair, occur in the warmer months. Heavy/highway construction in our target markets tends to be similarly seasonal. As a result, our aggregate business is seasonal in nature as the

majority of production and sales occur in the eight months between April and November.

Hot Mix Asphalt

Hot mix asphalt is the most commonly utilized pavement surface. Hot mix asphalt is produced by mixing asphalt cement and aggregate. The asphalt cement is heated to increase its viscosity and the aggregate is dried to remove moisture from it prior to mixing. Paving and compaction must be performed while the asphalt is sufficiently hot, typically within a one-hour haul from the production facility. In many parts of the country, including the market in which we operate, paving is generally not performed in the winter months because of cold temperatures.

Asphalt pavement is one of the building blocks of the United States. The United States has more than two million miles of paved roads and highways, 94% of which are surfaced with asphalt.

The United States has approximately 4,000 asphalt plants. Each year, these plants produce 500 million tons of asphalt pavement material worth in excess of $30 billion. Asphalt pavement material is a precisely engineered product composed of approximately 95% stone, sand and gravel by weight, and approximately 5% asphalt cement, a petroleum product. Asphalt cement acts as the glue to hold the pavement together.

Asphalt is the United States’ most recycled material. Reclaimed asphalt pavement is reusable as an aggregate mixture. In addition, the asphalt cement in the reclaimed pavement when reheated is reactivated to become an integral part of the new pavement. The recycled asphalt pavement replaces part of the new liquid asphalt cement required for the mixture, thereby reducing costs for asphalt mixtures.

Ready Mixed Concrete

Demand for ready mixed concrete is driven by its highly versatile end use applications. The ready mixed concrete industry generated approximately $30 billion in sales in 2012, according to the National Ready Mixed Concrete Association. Ready mixed concrete is created through the combination of coarse and fine aggregates with water, various chemical admixtures and cement. Given the high weight-to-value ratio, delivery of ready mixed concrete is typically limited to a one-hour haul from a production plant location and is further limited by a 90 - minute window in which newly mixed concrete must be poured to maintain quality and desired performance characteristics. Most industry participants produce ready mixed concrete in batch plants and use concrete mixer trucks to deliver the concrete to customers’ job sites. Ready mixed concrete, which is poured in place at a construction site, can compete with other precast concrete products and concrete masonry block products.

According to the National Ready Mixed Concrete Association, it is estimated that that there are approximately 5,500 ready mixed concrete plants in the United States. The North American ready mixed concrete industry is highly fragmented. Given that the concrete industry has historically consumed approximately 75% of all cement produced annually in the United States, many cement companies choose to be vertically integrated. Additionally, we face competition from precast concrete manufacturers.

Concrete Products

Precast and prestressed concrete products are utilized in highway construction to build bridges and decks and in non-residential construction to build a broad range of large structures such as parking garages, prison cells and sports stadium risers. Precast and prestressed concrete products offer many building advantages, including flexibility in design, speed to completion and low maintenance.

Masonry blocks are widely used in the construction of buildings, such as foundations, arches and retaining walls, due to their durability and relative low cost. Most of the companies that produce masonry blocks, such as ours, also produce other concrete-related products, including architectural block, pavers and franchised building systems such as Anchor ® Segmental Retaining Walls, which can be manufactured centrally and shipped to the point of installation.

Heavy/Highway Construction

Heavy/highway construction businesses provide a broad range of transportation and site preparation construction services, including grading and drainage, building bridge structures and concrete and blacktop paving services. While we provide services for a range of projects from driveway construction to the construction of new interstate highways, our business is primarily focused on structures, road construction and maintenance and blacktop/concrete paving. In general, the highway construction industry’s growth rate is directly related to federal and state transportation agencies’ funding of road, highway and bridge maintenance and construction. While public sector spending for highway construction has increased over the past two years, primarily as a result of federal stimulus money released under the American Recovery and Reinvestment Act, the simultaneous decrease in private sector spending has resulted in a contraction of the overall market. In Pennsylvania, public spending on third-party highway construction in 2012 was approximately $2.0 billion due to reallocation of funds by the state that shifted funds from certain other existing projects. Public spending on third-party highway construction for 2013 is budgeted at approximately $1.7 billion.

We stand to benefit from the additional federal investments in our core Pennsylvania and western New York markets as municipal, state, and federal agencies represent our largest customer base. We believe we will also benefit from the renewed emphasis on investments in Pennsylvania’s transportation and highway systems at the state level. Along with the rest of the country, Pennsylvania has decreased its highway construction, but it has not kept pace with its growing investment needs.

The Pennsylvania Transportation Advisory Committee finalized a Transportation Funding Study in May 2010 which concluded that Pennsylvania needs to invest an additional $3.5 billion annually from federal, state and local sources, which investment must grow with inflation, if Pennsylvania is going to upgrade its infrastructure and maintain it in a state of good repair. The recommended funding needs for highways and bridge construction and maintenance in the study for 2010 were $2.6 billion in additional funds for state-owned facilities and $432 million for local government projects. To address these needs, the Governor appointed the Transportation Funding Advisory Committee, or TFAC, in 2011. TFAC provided a final recommendation in its report dated August 2011 that is a partial solution to the $3.5 billion annual shortfall by developing additions to the existing revenue stream equal to $2.7 billion annually. The majority of the income comes by incrementally increasing the cap on the state’s Oil Company Franchise Tax.

In February 2013, Pennsylvania Governor Corbett unveiled a plan to raise $1.8 billion annually for transportation needs. The increased spending would occur incrementally over a 5-year period. More recently, in April 2013, Senate Transportation Committee Chairman John Rafferty announced his plan which would raise $2.5 billion annually over a 3-year period. Both plans rely on the Pennsylvania Oil Company Franchise Tax limit being lifted over time. The senator’s plan also includes increasing fees and fines. There can be no assurance that either these plans will be enacted or, if enacted, the extent of the funding provided by such legislation.

Traffic Safety Services and Equipment

The traffic safety services and equipment industry comprises companies that produce, sell and set up traffic safety equipment in the United States. Traffic safety products generally consist of portable products such as message boards, arrow boards and speed awareness monitors, as well as traffic cones, barrels and signs. Demand for traffic safety services and equipment is particularly sensitive to changes in activity in the highway construction end-market. While significant challenges to the traffic safety equipment industry remain due to the recent economic downturn, we believe that the long-term growth prospects for the industry are favorable, given increasingly stringent highway and workplace safety regulations and standards, in addition to an anticipated cyclical recovery in highway spending.

Our Operations

We operate our construction materials, heavy/highway construction and traffic safety services and equipment businesses through local operations and marketing teams, which work closely with our end customers in the local markets where we operate. We believe that this strong local presence gives us a competitive advantage by keeping our costs low and allows us to obtain a unique understanding for the evolving needs of our customers.

We have construction material operations across Pennsylvania and western New York. We provide heavy/highway construction services in these markets and, to a lesser degree, Maryland, West Virginia and Virginia. We operate traffic safety equipment manufacturing facilities and sell these products across the United States. Additionally, we provide maintenance and traffic protection services primarily in the eastern United States.

Construction Materials

We are a leading provider of construction materials in Pennsylvania and western New York. Our construction materials operations are comprised of aggregate production, including crushed stone and construction sand and gravel; hot mix asphalt production; ready mixed concrete production; and the production of concrete products, including precast/prestressed structural concrete components and masonry blocks. We also operate transportation facilities complete with deep water port facilities for bulk cargo storage, railroad transportation and other transportation and distribution at the Port of Buffalo.

Our largest construction materials customer is our heavy/highway construction operations which are almost wholly supplied with our construction materials. Additionally, our largest external customer is PennDOT.

Our Aggregate Operations

Aggregate Products

We mine limestone, sandstone, dolomite, clay, gravel, white quartzite and other natural resources from 52 quarries and sand

deposits throughout Pennsylvania and western New York. Aggregates are produced mainly from blasting hard rock from quarries and then crushing and screening it to various sizes to meet our customers’ needs. The production of aggregates also involves the extraction of sand and gravel, which requires less crushing, but still requires screening for different sizes. Aggregate production utilizes capital intensive heavy equipment which includes the use of loaders, large haul trucks, crushers, screens and other heavy equipment at quarries. According to the USGS, we were the tenth largest crushed stone producer in the United States in 2011.

Once extracted, the minerals are processed and/or crushed on site into crushed stone, concrete and masonry sand, specialized sand, pulverized lime or agricultural lime. The minerals are processed to meet customer specifications or to meet industry standard sizes. Crushed stone is used in ready mixed concrete, hot mix asphalt, the construction of road base for highways, ditch and pipe bedding, drainage channels, retaining walls and backfill. Our sand products are used in the production of masonry grout, ready mixed concrete and hot mix asphalt as well as sand traps on golf courses, baseball fields and landfill cover. Pulverized limestone is primarily used as an absorbent for sulfur dioxide gases in power generation. Farmers use agricultural lime to reduce the acidity level in soil and enhance crop growth.

Transportation cost is a major variable in determining aggregate pricing and marketing radius. The cost of transporting aggregate products from the plant to the market often equates to or exceeds the sale price of the products at the plant. As a result of high transportation costs and the large quantities of bulk material that have to be shipped, finished products are typically marketed locally. High transportation costs are responsible for the wide dispersion of production sites. Where possible, construction material producers maintain operations adjacent to highly populated areas to reduce transportation costs and enhance margins. Our operations near Allentown, Pennsylvania are located in a strategic position of the densely populated eastern Pennsylvania corridor and our Buffalo, New York operations are also in an area of high population density.

However, more recently, rising land values combined with local environmental concerns are forcing production sites to move further away from the end-use locations. Our extensive network of quarries, plants and facilities, located throughout Pennsylvania, New York and Delaware ensures that we have a nearby operation to meet the needs of customers in Pennsylvania, New York, Delaware, Maryland, West Virginia, Virginia and New Jersey.

Aggregate Markets

The shipping distance from each quarry and the proximity to competitors are key factors that determine the geographic market area for each quarry. Each quarry location is unique in that demand for each product, proximity to competition and truck availability are different. Accordingly, our aggregate customers are generally located within Pennsylvania, Delaware, northern Maryland and western New York.

Aggregate Reserves

Through acquisitions of raw land and existing quarries, we have assembled significant operating reserves throughout our geographic market area. We estimate that we currently own or have under lease approximately 2.0 billion tons of permitted proven recoverable and probable recoverable aggregate reserves, with an average estimated useful life of 115 years at current production levels. See “Item 2 — Properties.”

Aggregate Sales and Marketing

Each of our aggregate operations is responsible for the sale and marketing of its aggregate products. The method that each entity employs to sell aggregates is similar and varies by customer type. Standard price lists are developed for each construction season. This list is used to establish a list price and is typically discounted for contractors or special customers. Large orders are quoted to each contractor in a bidding process and pricing is established based on plant and haul costs, plus appropriate margins.

Most bids to non-governmental agencies are either accepted or negotiated with the end result being a purchase order at a fixed price for a specified amount during a given period of time. Bids submitted directly to a governmental agency generally utilize the low bid process. The low bidder is responsible for providing the material within specifications at a specific location for the bid price. We will also negotiate long-term (greater than one year) supply contract agreements at predetermined prices.

Aggregate Competition

The U.S. aggregate industry is highly fragmented with numerous participants operating in localized markets. The USGS reported that a total of 1,550 companies operating 4,000 quarries and 91 underground mines produced or sold crushed stone in 2012 in the United States. This fragmentation is a result of the cost of transporting aggregates, which limits producers to a market area within 100 miles of their production facilities.

Lehigh Hanson Building Materials America, PLC (a unit of Heidelberg Cement Group), Oldcastle, Inc. and Lafarge Corporation are our largest aggregate producer competitors across all of our market areas.

Our Hot Mix Asphalt Operations

Hot Mix Asphalt Products

Our hot mix asphalt products are produced by heating asphalt cement to increase its viscosity and drying the aggregate to remove moisture from it prior to mixing. Hot mix asphalt consists of approximately 95% stone, sand and gravel by weight, and approximately 5% of asphalt cement that serves as a binder. The aggregates used for our production of these products are generally supplied from internal sources through our construction materials division and through purchases of bitumen from third party suppliers. Since bitumen is a by-product of petroleum refining, the price of this material is aligned with the price of oil. The asphalt and aggregates mixture is heated to a temperature of approximately 300 degrees Fahrenheit. While still hot, the paving mixture is transported by truck to a mechanical spreader where it is placed in a smooth layer and compacted by rollers.

As part of our vertically integrated structure, we operate 30 hot mix asphalt plants and seven blacktop paving divisions.

Hot Mix Asphalt Markets

Our hot mix asphalt businesses operate independent paving crews that service various markets. Our Pennsylvania hot mix asphalt plants generate the majority of their revenue through sales to our heavy/highway construction division, which then places the material under contract with the owner, typically a governmental agency such as PennDOT or the Pennsylvania Turnpike Commission. Our New York operation does not operate any paving crews, but does sell hot mix asphalt to paving contractors.

Each hot mix asphalt plant is unique in that demand for hot mix asphalt, proximity to competition; transportation costs and supply of aggregates are different. Most of our hot mix asphalt operations use a combination of company- owned and hired haulers to deliver materials. Hauling costs can range from 5% to 20% of the total cost of the materials. To optimize crew demand and costs, each hot mix asphalt operation has a fleet manager and plant dispatchers. Our New York operations contract for delivery and do not have their own delivery trucks.

Aggregates are another major factor in the cost of producing hot mix asphalt. In an effort to reduce cost, we have located the majority of our hot mix asphalt plants in our aggregate quarries. This is the most efficient production method because costs associated with transporting the raw materials are minimized. However, we do operate facilities that are not at quarries. These facilities are situated to meet market demand due to the constraint that the hot mix asphalt material can only be in a truck for one hour before it cools too much to compact correctly on the job site.

The preparation and placement of the hot mix asphalt is also a major cost. Most of our hot mix asphalt operations operate paving crews. The management of these crews is regionalized and is typically located near a plant. We operate seven blacktop paving divisions throughout Pennsylvania, Maryland and West Virginia. In addition to paving crews, each hot mix asphalt operation also operates a number of grading/preparation crews. Depending on project size, we will hire subcontractors or, in certain cases, will utilize our heavy/highway construction division to prepare a site for paving.

We also generate revenue by selling material freight on board plant or quarry. On many Pennsylvania highway projects, we will quote hot mix asphalt freight on board, or in place to the competition, as well as bid a project directly as the prime contractor.

Hot Mix Asphalt Sales and Marketing

Hot mix asphalt customers include our own heavy/highway construction, other heavy/highway contractors and state and federal agencies, building contractors and homeowners. One of our largest hot mix asphalt customers is PennDOT. Each individual hot mix asphalt operation estimates, markets and performs its own work. The sales and marketing process is divided into two categories: PennDOT and other government projects and private projects. Our hot mix asphalt operations will bid on state, township, county or other governmental entities’ projects under the “sealed” bid system. Each project is estimated and quoted to the requesting municipality. This is most often the case for hot mix asphalt put in place, however, some municipalities and department of transportation maintenance districts have their own paving crews and in those instances, the project is bid freight on board plant or delivered to PennDOT crews.

Sales to private entities are typically submitted to the owner as a quoted price. Key factors for obtaining sales from private entities are the relationship with the owner or contractor and price. Our sales and estimating staff are responsible for maintaining and enhancing customer relationships and prospecting new customers and projects.

Our New York hot mix asphalt business is based predominantly on its relationships with paving contractors and pricing projects competitively. It also provides material quotes directly to those government agencies that have their own paving crews.

There are approximately 4,000 asphalt plants in the United States, and in each year these plants collectively product approximately 500 to 550 million tons of asphalt pavement material.

Our Ready Mixed Concrete Operations

Ready Mixed Concrete Products

We are one of the leading suppliers of ready mixed concrete in Pennsylvania and western New York according to the most recent industry surveys. We produce ready mixed concrete by blending aggregates, cement, chemical admixtures in various ratios and water at our concrete production plants and placing the resulting product in ready mixed concrete trucks where it is then delivered to our customers. Our construction aggregates region serves as the primary source of the raw materials for our concrete production, functioning essentially as a supplier to our ready mixed concrete operations. Aggregates are a major component in ready mixed concrete, comprising approximately 60%-75% of ready mixed concrete by volume. Our wide variety of mixes, which are certified for use by PennDOT, the New York Department of Transportation and other state and federal agencies, are used in activities ranging from building construction to highway paving.

We operate 19 fixed and portable ready mixed concrete plants for highway paving and bridge construction.

Each plant’s capacity is determined, to a large degree, by the local plants production capacity and the number of ready mixed concrete trucks dispatched out of each location. However, trucks can be re-routed to accommodate demand fluctuations at a given plant. Currently, we operate a fleet of approximately 178 ready mixed concrete trucks.

Ready Mixed Concrete Markets

Due to the finite time before concrete hardens, our market area is limited to an approximate one-hour hauling radius around a plant. Portable ready mixed concrete plants allow for an extended marketing area, but are only cost effective for larger projects in excess of 5,000 cubic yards. Our ready mixed concrete customers are generally located within Pennsylvania, northern Maryland and western New York. One of our largest ready mixed concrete customers is our precast concrete products division, which employs ready mixed concrete for the production of structural precast concrete structures such as bridge beams, double tee beams, modular prison cells and stadium risers.

Ready Mixed Concrete Sales and Marketing

Each of our ready mixed concrete operations is responsible for the sale and marketing of its ready mixed concrete products. The method that each operation employs to sell ready mixed concrete is similar and varies by customer type. Standard price lists are developed for each construction season. This list is used to establish a list price and is typically discounted for contractors or special customers. The majority of direct bids are either accepted or negotiated with the end result being a purchase order at a fixed price for a specified amount during a given period of time. Larger projects with multi-year construction phases have price increases built into the bids.

Our Concrete Products Operations

Our Precast/Prestressed Products Operations

We produce precast/prestressed concrete components for highway bridges and various commercial structures, including I-beams, box beams, double tee beams, stadium risers, prison cells and wall panels. Each of these products is manufactured pursuant to unique specifications for each particular job. Prestressed concrete units can then be used in the construction of bridges, modular correctional facilities, parking structures and sports facilities. Our ready mixed concrete operations supply the high strength mixes used in the precast/prestressed beams, stadium risers, prison cells and wall panels we produce. Our sales staff work with our engineers and production staff to maximize value and reduce overall construction time. Our precast/prestressed manufacturing and sales facility is located in Roaring Spring, Pennsylvania with an additional sales office in Center Valley, Pennsylvania. Our manufacturing facility produces prestressed concrete bridge beams and a number of commercial structural building components.

Precast/Prestressed Concrete Products Markets

The two primary factors that influence market size for bridge and commercial products are the distance from our facilities to the project and the proximity of the competition to the project. Our non-residential market area encompasses Pennsylvania, northern Maryland, western New York and New Jersey. Our bridge beam market encompasses Pennsylvania, New York and Maryland. The hauling cost of these products can be quite expensive, in some cases requiring 13 axle tractor-trailers.

Precast/Prestressed Concrete Products Sales and Marketing

The sale of bridge beams to contractors is typically based on price and delivery schedule. Most beams are sold to a bridge contractor and integrated into their bridge construction quote. Generally, if we are the low bidder at the time of bid and are able to accommodate the contractor’s schedule, the sale will be made.

In an effort to influence project designs to be compatible with our manufacturing standards and specifications, commercial products are marketed directly to architects and engineers. Once a private project has been designed and bid, the purchase decision/negotiations can extend for months until an owner or general contractor makes a decision and awards the contract. For publicly owned projects, the low bidder is typically awarded the project.

Precast/Prestressed Concrete Products and Purchasers

Bridge products include prestressed concrete I-beams, box beams and precast box culverts. The largest purchasers of bridge beams are state departments of transportation, which we refer to as DOTs, through a general contractor or erector. The second largest purchasers are port authorities for airport runways, shipping ports and bridges. Commercial products include parking garages, prison cells and sports stadium risers. Parking garage owners vary from private developers to parking authorities to governmental agencies. Stadiums and prisons are typically owned by a state, county, city or the federal government. We generally sell these products, erected, to a general contractor, but will also contract directly with the owner.

Our Masonry Block Operations

We operate our masonry block operation from three facilities located in Pennsylvania. We sell directly to customers within an approximately 60-mile radius of each production facility and indirectly through broker/dealers within an approximately 100-mile radius.

Masonry Block Markets

The market for a block plant is dependent upon transportation costs and product mix. The product mix for masonry block has changed considerably over the past 20 years, expanding from a predominantly gray block offering to a range of architectural blocks for buildings and landscaping blocks for retaining walls. Architectural blocks are generally colored with a textured outer surface. Many blocks are also produced with a waterproofing feature or an interlocking feature to allow retaining wall construction. New products offer expanded market potential until competition develops a similar product. Although we can produce masonry products in any color, we have a number of standard colors, allowing us to deliver quickly, minimize inventory and reduce wasted customized blocks. This has reduced product lead time and contractor costs, since the contractor can now return any unused blocks.

Masonry Block Sales and Marketing

We market directly to architects and designers in an attempt to influence plans to incorporate our product offerings. This marketing strategy provides us with a competitive edge in the sales process because the customer has less flexibility to choose alternative products once our products have been incorporated into the design. In an effort to add greater value to the block package, our Construction Supply Centers will quote a package to the contractors for most of their building supply needs on a project.

Our Heavy/Highway Construction Operations

Heavy/Highway Construction

Our heavy/highway operations are separated into two basic categories: (i) large heavy/highway projects, which are typically complex roadway and bridge rehabilitation or new construction projects that incorporate all or most of our construction operation disciplines, including grading, drainage, paving, structure work and civil engineering and project management, and (ii) private and non-residential blacktop paving projects or small- and mid-size maintenance projects, which are typically less complex roadway and bridge rehabilitation projects and involve minor bridgework, roadway patching and blacktop paving. In addition, we also provide gas and fiber optic line installation and repair services. These combined operations made us one of the top 50 largest highway contractors in the United States, according to a survey of contractors and design firms published by the Engineering News Record in May 2012.

Heavy/highway projects are managed by our contract division located at our New Enterprise, Pennsylvania headquarters. This division manages projects across the state ranging in size up to $90.0 million. This division typically manages 15 to 25 projects at any given time. Our seasoned contract division management team is comprised of project managers, estimators, production supervisors and field superintendents and foremen. These projects may or may not be located near our construction material locations. The construction teams operate competitively both with our construction materials as well as with materials purchased from third parties when the projects are not within the economic reach of our construction materials production facilities.

Our blacktop paving and maintenance projects are located within the economic shipping radius of our hot mix asphalt plants and quarries as they are generally very highly construction materials-dependent projects. These projects include driveways, parking lots, race tracks and roadways and are typically one construction season in duration, although some of the larger projects may span two seasons. Our blacktop paving and maintenance projects are all bid and managed across our markets through our regional offices. These operations manage projects in their localities, ranging in size from tens of thousands of dollars to upwards of several million dollars. The largest and most construction materials-intense projects can exceed $10.0 million. Collectively, there are hundreds of projects per year ranging from driveways to large maintenance projects that we perform. The number of these projects for governmental agencies typically ranges from 50 to 100 per year. Management teams for these projects generally consist of salesmen, production supervisors, estimators and field foremen.

The bulk of our contracted jobs are public projects, which have replaced some of the private spending shortfall. The procedures and bid documents governing the contracts with our public sector customers typically allow the customers to terminate the project at their discretion. Cancellation of a few of our very large contracts could have a materially adverse impact on our revenues and results of operations. See “Item 1A—Risk Factors—The Cancellation Of Significant Contracts Or Our Disqualification from Bidding for New Contracts Could Reduce Revenues and Have a Material Adverse Effect On Our Results Of Operations.”

Heavy/Highway Construction Markets

Our largest heavy/highway construction customer is PennDOT. We also work with municipalities, state and national parks, the Army Corps of Engineers, industrial facilities, other contractors and private customers. Along with the local county and municipal governments, PennDOT controls and maintains its approximately 40,000 mile system, with the remaining approximately 80,000 miles maintained by local county and municipal governments. Our extensive network of quarries, hot mix asphalt plants, paving crews and traffic safety services and equipment sales, in combination with our unlimited prequalification bid capacity for PennDOT projects, ensures a broad marketing area. Our core heavy construction market extends throughout Pennsylvania. Our core blacktop paving and maintenance and highway construction market is located within an approximately 50 mile radius from each hot mix asphalt plant, which covers a large portion of Pennsylvania.

For our heavy construction market we operate with a non-union workforce that will travel to each project. This enables construction project staffing with a predictable stable workforce. It also allows predictable production rates when market forces require us to look for work beyond our core market. The hot mix asphalt and maintenance markets also operate with non-union workforces throughout our market area, as well as a small union operation in the heavily unionized Delaware Valley market. These projects are generally local crews, so overnight stays are unnecessary.

We act as the prime contractor on the majority of our projects, with 15% to 20% of a project performed by subcontractors. We will subcontract larger pieces of a project if necessary to manage labor and equipment costs. Subcontractors typically perform specialized services such as line stripping, guide rail installation, clearing, signing, lighting and providing traffic protection services.

For our blacktop paving and maintenance operations we will serve either as the prime contractor when we are the low bidder or as a subcontractor for another general contractor when we are either not the low bidder or we chose not to bid on the project.

Heavy/Highway Construction Sales and Marketing

All public work is awarded in a “sealed bid.” Estimators and engineers review the work to be performed and estimate the cost to complete the project. On heavy/highway construction projects, teams of three to six people under the direction of a chief estimator, develop the estimate. The majority of our estimators are also project managers, which allows for greater accuracy in estimating crew sizes and production capabilities. Typically, each project has approximately four to eight bidders.

With respect to blacktop paving and maintenance work, the sales effort varies significantly depending on the project scope. All projects are staffed with an estimating or sales person or team, depending on the size, and generally reviewed by a manager. For private and subcontracted public work, salesmen will negotiate both the project scope and price. For low bid public work, the estimating team will submit a sealed bid.

Heavy/Highway Construction Competition

The competition for our heavy/highway work is complex. On the heavy side, competition varies by the work discipline on the project, the amount of each discipline on the project and the location. Our competition for blacktop paving and maintenance work is much more localized, since these projects are typically material-intensive and the competition is generally vertically integrated construction materials suppliers and local contractors that specialize in roadway rehabilitation, site development or paving.

Our Traffic Safety Services and Equipment Operations