Attached files

| file | filename |

|---|---|

| 8-K - FORM 8-K - Kraton Corp | v313450_8k.htm |

KRATON PERFORMANCE POLYMERS, INC. OPPENHEIMER 7 TH ANNUAL INDUSTRIALS CONFERENCE May 16, 2012

Forward - Looking Statement Disclaimer 2 This presentation may include forward - looking statements that reflect our plans, beliefs, expectations and current views with re spect to, among other things, future events and financial performance. Forward - looking statements are often characterized by the use o f words such as “outlook”, “believes,” “estimates,” “expects,” “projects,” “may,” “intends,” “plans” or “anticipates,” or by di scu ssions of strategy, plans or intentions, including statements regarding our general “outlook”; our ability to obtain raw materials at competitive prices; costs, timing and plans related to our planned joint venture with Formosa Petrochemical Corporation and the related facility; anticipated capital expenditures; anticipated sales volumes or levels of demand for our products; anticipa ted rates of growth, including sales growth and growth in product offerings through innovation; anticipated raw material price movements a nd related expectations regarding customer activities. All forward - looking statements in this presentation are made based on management's current expectations and estimates, which involve known and unknown risks, uncertainties and other important fac tor s that could cause our actual results or industry results to differ materially from historical results or those expressed in forward - looking statements. These risks and uncertainties are more fully described in “Part I. Item 1A. Risk Factors” contained in our Annual Re port on 10 - K, as filed with the Securities and Exchange Commission and as subsequently updated in our Quarterly Reports on Form 10 - Q, an d include the following risk factors: conditions in the global economy and capital markets; our reliance on LyondellBasell Industries for the provision of significant operating and other services; the failure of our raw materials suppliers to perform their obliga tio ns under long - term supply agreements, or our inability to replace or renew these agreements when they expire; limitations in the availabi lity of raw materials we need to produce our products in the amounts or at the prices necessary for us to effectively and profitably ope rate our business; competition in our end - use markets, from other producers of SBCs and from producers of products that can be substi tuted for our products; our ability to produce and commercialize technological innovations; our ability to protect our intellectual pr operty, on which our business is substantially dependent; the possibility that our products infringe on the intellectual property rig hts of others; seasonality in our business, particularly for Paving and Roofing end uses; financial and operating constraints related to ou r p otentially substantial level of indebtedness; the inherently hazardous nature of chemical manufacturing; product liability claims and ot her lawsuits arising from environmental damage, personal injuries or other damage associated with chemical manufacturing or our products; political and economic risks in the various countries in which we operate; health, safety and environmental laws, i ncl uding laws that govern our employees’ exposure to chemicals deemed harmful to humans; regulation of our customers, which could affe ct the demand for our products or result in increased compliance costs; customs, international trade, export control, antitrust, zo ning and occupancy and labor and employment laws that could require us to modify our current business practices and incur increased costs; fluctuations in currency exchange rates; our relationship with our employees; loss of key personnel or our inability to attra ct and retain new qualified personnel; the fact that we typically do not enter into long - term contracts with our customers; a decrease in the fair value of our pension assets, which could require us to materially increase future funding of the pension plan; our planned jo int venture in Asia is subject to risks and uncertainties; Delaware law and some provisions of our organizational documents make a takeov er of our company more difficult; our policy of not paying dividends; our status as a holding company dependent on dividends from our subsidiaries and other risks, factors and uncertainties described in this press release and our other reports and documents; and other factors of which we are currently unaware or deem immaterial. Readers are cautioned not to place undue reliance on forward - look ing statements . Forward - looking statements speak only as of the date they are made, and we assume no obligation to update such information in light of new information or future events. Further information concerning issues that could materially affect fi nancial performance related to forward - looking statements can be found in Kraton’s periodic filings with the Securities and Exchange Commission. KRATON Oppenheimer 7 th Annual Industrials Conference

GAAP Disclaimer This presentation includes the use of both GAAP (generally accepted accounting principles) and non - GAAP financial measures. The non - GAAP financial measures are EBITDA and Adjusted EBITDA. In each case the most directly comparable GAAP financial measure is net income. A table included in this earnings release reconciles these non - GAAP financial measures with the most directly comparable GAAP financial measure. We consider EBITDA and Adjusted EBITDA important supplemental measures of our performance and believe they are frequently used by investors, securities analysts and other interested parties in the evaluation of our performance and companies in our industry. Further, management uses these measures to evaluate operating performance; our executive compensation plan bases incentive compensation payments on our EBITDA performance; and our long - term debt agreements use EBITDA (with additional adjustments) to measure our compliance with certain financial covenants such as leverage and interest coverage. EBITDA and Adjusted EBITDA have limitations as analytical tools, and you should not consider them in isolation, or as a substitute for analysis of our results under GAAP in the United States. Some of these limitations include: EBITDA does not reflect our cash expenditures, or future requirements for capital expenditures or contractual commitments; EBITDA does not reflect changes in, or cash requirements for, our working capital needs; EBITDA does not reflect the significant interest expense, or the cash requirements necessary to service interest or principal payments, on our debt; although depreciation and amortization are non - cash charges, the assets being depreciated and amortized will often have to be replaced in the future, and EBITDA does not reflect any cash requirements for such replacements; and other companies in our industry may calculate EBITDA differently than we do, limiting its usefulness as a comparative measure. In addition, we prepare Adjusted EBITDA by adjusting EBITDA to eliminate the impact of a number of items we do not consider indicative of our ongoing performance, and you should be aware that in the future we may incur expenses similar to the adjustments in this presentation. Our presentation of Adjusted EBITDA should not be construed as an inference that our future results will be unaffected by unusual or non - recurring items. Because of these and other limitations, EBITDA and Adjusted EBITDA should not be considered as a measure of discretionary cash available to us to invest in the growth of our business. 3 KRATON Oppenheimer 7 th Annual Industrials Conference

41% 19% 40% 35% 30% 28% 7% Kraton Overview Global SBC Market Leader ▪ We invented and commercialized Styrenic Block Copolymer (SBC) technology nearly 50 years ago ▪ We hold leading market share positions in each of our end - use markets providing industrial, consumer and geographical diversification that is second to none ▪ We design and manufacture customized SBC polymer and compound solutions to meet our leading customers’ specific innovation needs ▪ We produce the following: ▪ Unhydrogenated Styrenic Block Copolymers (USBCs ) ▪ Hydrogenated Styrenic Block Copolymers (HSBCs ) ▪ Isoprene Rubber and Isoprene Rubber Latex ▪ We currently offer approximately 800 products to more than 800 customers, in over 60 countries ▪ We employ approximately 920 people in 9 locations in all major regions of the world ▪ 2011 revenue of $ 1,437 million and Adjusted EBITDA (1) of $ 194 million 4 Paving and Roofing Adhesives , Sealants and Coatings Cariflex TM Advanced Materials 2011 Revenue by End - Use 2011 Revenue by Geography North and South America Asia Pacific Europe, Middle East & Africa (1) Adjusted EBITDA is GAAP EBITDA excluding restructuring and related charges, non - cash compensation expense and the gain (loss) on extinguishment of debt. KRATON Oppenheimer 7 th Annual Industrials Conference

SBC’s Are Engineered to Meet Customer Needs 5 KRATON Overview Primary Raw Materials Products Customer Value End - Use Applications Styrene Un - Hydrogenated SBCs Hydrogenated SBCs Isoprene Rubber and Latex Compounds Butadiene Isoprene Paving Roofing Personal Care Tapes Formulators Labels & Printing Compounds Packaging Auto Lubricants Medical Stretch Soft - Touch Adhesion Strength Durability Thickening Compatibility Clarity Recyclability Kraton is the only provider of these value components across all products touching a wide array of applications

Before Kraton After Kraton Kraton Makes Products Better 6 ▪ Phthalate plasticizers are used to make PVC soft but they can leach from finished products and create health concerns ▪ Limited recyclability ▪ PVCs are unsafe when burned or incinerated improperly ▪ Environmentally friendly – 100% recyclable ▪ Kraton imparts softness, toughness and clarity ▪ Plasticizer & chlorine free Kraton material as % of finished product cost: <5% Kraton as an Alternative for Soft PVC KRATON Oppenheimer 7 th Annual Industrials Conference ▪ Cracking ▪ Rutting ▪ Frequent resurfacing ▪ Superior rutting and crack resistance ▪ Reduced maintenance costs ▪ Improved workability at lower temperatures ▪ 30% to 40% reduction in thickness ( HiMA ) delivers upfront cost savings Performance Pavement

Clear Leader in Attractive Markets Market Position 2011 Revenue (1) #1 ~64% Adhesives, Sealants, and Coatings Advanced Materials #1 ~69% Paving and Roofing #1 ~64% Cariflex TM #1 100% 35% 28% 30 % 7% Source: Management estimates. (1) Based on 2011 sales of $ 1,437 million . #1 Market Position in Each End Use Top 4 Market Share 7 ▪ Tapes and labels ▪ Non - woven and industrial adhesives ▪ Industrial and consumer weather sealants ▪ White elastomeric roof coatings ▪ Soft touch for consumer products ▪ Elastic films (diapers) ▪ Skin care and lotions ▪ Food packaging ▪ Automotive ▪ Medical packaging ▪ Wire and cable ( PVC alternatives) Examples of End Use Applications ▪ Asphalt modification for performance roadways, bridges and airports ▪ Asphalt modification for roofing felts and shingles ▪ Surgical gloves ▪ Condoms ▪ Medical components KRATON Oppenheimer 7 th Annual Industrials Conference

Asia HSBC Project 8 KRATON Oppenheimer 7 th Annual Industrials Conference Project ▪ 30 kT HSBC plant ▪ To be owned and operated by a 50/50 joint venture to be formed with Formosa Petrochemical Corporation ▪ Located at Formosa site in Mailiao, Taiwan Project Specifics ▪ Cost of +$200 Mln plus working capital ▪ Startup in second half 2014 ▪ Anticipate financing at JV level ▪ Kraton to retain 100% marketing rights for offtake Status Update ▪ Framework Agreement signed ▪ Currently negotiating definitive documents ▪ Project approved by local FTC ▪ Permits pending ▪ Detailed engineering complete ▪ Expect $45 mln spend in 2012

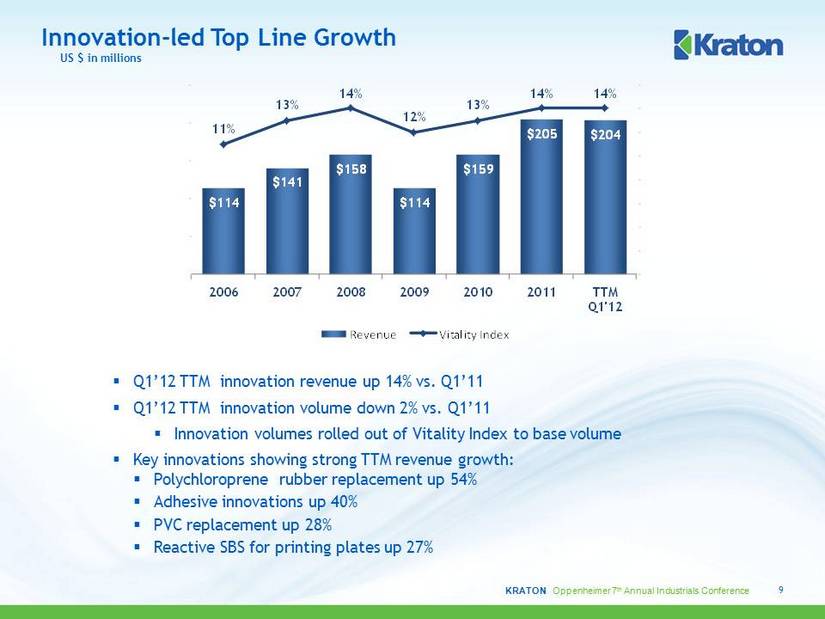

Innovation - led Top Line Growth ▪ Q1’12 TTM innovation revenue up 14% vs. Q1’11 ▪ Q1’12 TTM innovation volume down 2% vs. Q1’11 ▪ Innovation volumes rolled out of Vitality Index to base volume ▪ Key innovations showing strong TTM revenue growth: ▪ Polychloroprene rubber replacement up 54% ▪ Adhesive innovations up 40% ▪ PVC replacement up 28% ▪ Reactive SBS for printing plates up 27% 9 US $ in millions $114 $141 $158 $114 $159 $205 $204 11% 13% 14% 12% 13% 14% 14% 0% 2% 4% 6% 8% 10% 12% 14% 16% 0 50 100 150 200 250 2006 2007 2008 2009 2010 2011 TTM Q1'12 Revenue Vitality Index KRATON Oppenheimer 7 th Annual Industrials Conference

Cari flex TM Isoprene Rubber and Isoprene Rubber Latex 10 Natural Rubber Cari flex TM IR Ziegler - Natta IR Features & Benefits ▪ Anionic polymerization ▪ No proteins ▪ Low residual metals ▪ Low gel content (~0 %) ▪ No odour ▪ Excellent transparency due to high purity Cariflex IR applications ▪ Medical stoppers ▪ Septum for IV bags ▪ Needle shields ▪ Medical shields Cari flex IR Latex applications ▪ Surgical gloves ▪ Condoms ▪ Catheter balloons ▪ Cold seal adhesives ▪ Self - sticking medical bandages KRATON Oppenheimer 7 th Annual Industrials Conference

PVC Alternatives Cost effect PVC Alternatives for medical and wire & cable applications . Features & Benefits ▪ Halogen free ▪ Phthalate plasticizer free ▪ Soft, flexible ▪ Easy processability ▪ Recyclability ▪ Compatible with PP ▪ Clean, colorless, odorless ▪ Sterilization ▪ Strong USP VI & FDA Position Markets & Application ▪ Medical ▪ IV bags ▪ Medical tubing ▪ Wire & Cable ▪ Consumer electronics power cord components (UL, VDE, PSE) 11 KRATON Oppenheimer 7 th Annual Industrials Conference

Nexar TM Polymers 12 Features & Benefits ▪ High water flux and transport rates ▪ Mechanical strength & ion selectivity ▪ Chlorine resistance and low electrical resistance ▪ Mechanical strength both wet and dry; good dimensional stability in wet and dry conditions ▪ Stable under ambient conditions - no special packaging required ▪ Can be applied using current commercial coating and laminating lines Applications ▪ Sports and outdoor apparel and gear, military and industrial uniforms and medical and geotextile applications ▪ Energy recovery ventilation (ERV) systems ▪ Water filtration ▪ Water management systems ▪ Electro dialysis and electro dialysis reversal KRATON Oppenheimer 7 th Annual Industrials Conference

Highly - Modified Asphalt ( HiMA ) Definition ▪ ~7.5% modification vs. 3% typical ▪ Superior rutting and cracking resistance ▪ 20 – 40% reduction in pavement thickness ▪ Low viscosity polymer modified binder Applications ▪ Base and binder courses ▪ Thin lift wearing course ▪ Micro surfacing ▪ Chip seals ▪ Bridge decking Recent Successes ▪ I - 40 Project in Oklahoma Geographic Opportunities ▪ Russia ▪ South America ▪ Canada 13 KRATON Oppenheimer 7 th Annual Industrials Conference

Kraton TM Polymers in Oilfield Applications Viscosity Modification of Drilling Fluids ▪ Shear thinning behavior (low shear rheology) ▪ High temperature stability ▪ Inherent compatibility with base oils High Temperature/Pressure Fluid Loss Additive ▪ High temperature stability ▪ Low API fluid loss Modification of Cement ▪ Flexibility, reduction of modulus ▪ Swelling in the presence of hydrocarbon Water Treatment ▪ Purification of produced water ▪ Purification of flowback water 14 KRATON Oppenheimer 7 th Annual Industrials Conference

$12 $39 $78 $93 $36 $67 $46 $89 $233 $0 $50 $100 $150 $200 $250 Cash US $ in millions 15 Balance Sheet 49.7% 47.0% 40.0% 39.1% 42.2% 37.2% 37.9% 37.0% 32.1% 0% 10% 20% 30% 40% 50% 60% $0 $50 $100 $150 $200 $250 $300 $350 $400 Net Debt to Cap Net Debt Net Debt (1) and Net Debt to Capitalization (1) Net debt is equal to total debt, less c ash and cash equivalents. KRATON Oppenheimer 7 th Annual Industrials Conference

KRATON PERFORMANCE POLYMERS, INC. OPPENHEIMER 7 TH ANNUAL INDUSTRIALS CONFERENCE May 16, 2012