Attached files

| file | filename |

|---|---|

| EXCEL - IDEA: XBRL DOCUMENT - SOONER HOLDINGS INC /OK/ | Financial_Report.xls |

| EX-31.1 - EXHIBIT 31.1 - SOONER HOLDINGS INC /OK/ | v308912_ex31-1.htm |

| EX-32.2 - EXHIBIT 32.2 - SOONER HOLDINGS INC /OK/ | v308912_ex32-2.htm |

| EX-31.2 - EXHIBIT 31.2 - SOONER HOLDINGS INC /OK/ | v308912_ex31-2.htm |

| EX-32.1 - EXHIBIT 32.1 - SOONER HOLDINGS INC /OK/ | v308912_ex32-1.htm |

U.S. SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10-K

x ANNUAL REPORT UNDER SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934

FOR THE FISCAL YEAR ENDED DECEMBER 31, 2011

OR

¨ TRANSITION UNDER SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934

For the transition period from ________ to ________

Commission File Number 0-18344

FLYING EAGLE PU TECHNICAL CORP.

(Exact name of registrant as specified in its charter)

| Oklahoma | 73-1275261 | |

| (State of Incorporation) | (IRS Employer I.D. Number) |

Long Shan Development Area

Han Jiang Town,

ShiShi City, Fujian, PRC

86-13505080536

(Address and telephone number of registrant's principal

executive offices and principal place of business)

Securities registered under Section 12(b) of the Exchange Act: None

Securities registered under Section 12(g) of the Exchange Act:

Common Stock, $0.001 par value

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes ¨ No x

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Exchange Act. Yes ¨ No x

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding twelve months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes x No ¨

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of the registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K.¨

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company.

| Large accelerated filer ¨ | Accelerated filer ¨ | |

| Non-accelerated filer ¨ | Smaller reporting company x |

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act). Yes ¨ No x

State the aggregate market value of the voting and non-voting common equity held by non-affiliates computed by reference to the price at which the common equity was last sold, or the $2.19 average bid and asked price (adjusted to give effect to 1 for 18.29069125 reverse stock split) of such common equity, as of the last business day of registrant’s most recently completed second fiscal quarter (June 30, 2011): $1,755,906.

As of March 15, 2012, there were 20,000,443 shares of the Registrant's Common Stock, par value $0.001 per share, outstanding after giving effect to 1 for 18.29069125 reverse stock split.

Part I

Item 1. Business

Overview

Through our operating company Shishi Feiying Plastic Co., Ltd. (“SFP”), we manufacture synthetic polyurethane leather (“PU leather”) for the shoe industry in Fujian Province, China. Our primary business is the design, manufacturing and sale of PU leather for the shoe manufacturing industry in China. PU leather design can take two forms; formula design, which can produce PU leather with different physical features like high peel strength, water repellency, or tear strength; and pattern design, which includes different colors, roughness of material and possibly patterns on the material. In addition, we manufacture flip-flops and slippers (footwear) for sale in China and abroad. For the years ended December 31, 2011, and 2010, our sales were $22,324,127 and $27,062,512, respectively, for PU leather and $5,531,291 and $5,999,775, respectively, for footwear.

Our PU leather production facilities are strategically located in Fujian Province, which puts us in close proximity to our target customers. We plan to increase our PU leather production capacity and expand our sales to other industries. Currently, all of our PU leather is used in the manufacture of shoes; however, we believe we can extend our services to other PU leather industries like furniture, footballs, basketballs and other sporting equipment and, clothes and suitcases, to name a few. Towards this goal, our growth strategy includes expansion projects to build a new PU leather factory in the DaTian technology park in Fujian province, China where many of our customers are located.

Mr. Ang Kan Han is our chairman of the board, president and largest shareholder. Mr. Ang is also known as “Hong Jiang Han” which is Mr. Ang’s Mandarin name spelled in English. As discussed, we intend to a build a new PU leather factory. Mr. Ang incorporated Feiying Industrial Co., Ltd. (San Ming) a wholly-foreign owned enterprises (WFOE) in the PRC, to build the PU leather factory in the DaTian technology park in Fujian province. To facilitate the building of the PU leather factory, we have, through our wholly-owned subsidiary SFP, from time to time advanced funds to San Ming. Further, we have entered into a call option agreement with Mr. Ang to allow us to purchase San Ming which owns certain land rights and is building a factory in DaTian technology park for 90% of the net tangible asset value at the time of the exercise. Because Mr. Ang is our president and chairman of the board, we have the power to direct the activities of San Ming. We have also determined that San Ming currently has not been adequately capitalized to carry out its principal operating activities, which is to build a PU leather factory. It is currently the Company’s intention to exercise the call option agreement. The San Ming factory finished testing its production lines and began to sell product in first quarter 2012. We intend to exercise the call option with San Ming by the end of 2012.

From an accounting perspective, we have determined that San Ming is a variable interest entity (VIE) because of its insufficient capital to carry out its principal operating activity (the construction of a PU leather factory), and that we are the primary beneficiary. Accordingly, we have consolidated the financial position of San Ming in our financial statements for the year ended December 31, 2011 and 2010. We will continue to reassess San Ming’s status as a VIE including any potential change in VIE status.

In January, 2012, we changed our name to Flying Eagle PU Technical Corporation and completed a reverse stock split on a 1-for- 18.29069125 shares of common stock. References to the number of shares of common stock discussed in this annual report give effect to the reverse stock split.

History

Flying Eagle PU Technical Corporation

Our company, Flying Eagle PU Technical Corporation (formerly Sooner Holdings, Inc.), an Oklahoma corporation, was formed in 1986 to enter the in-home soda fountain business. We never developed this business into a national market. Subsequently, we evolved into a multi-subsidiary holding company in diverse businesses. From 1993, when we were restructured, until June 1998 we sought acquisitions. In November 1987 we acquired, through our subsidiary Charlie O Business Park Incorporated, a business park from R.C. Cunningham II, our then president and a director. In June 1998 we acquired, through our subsidiary ND Acquisition Corp., the assets and certain liabilities of New Direction Centers of America, LLC and entered the minimum-security correctional business. In May 2000 we purchased the rights to a new, Class 5, hardware and software computer-based platform that resembles the computer-based soft switch. We named it "Cadeum" and organized a wholly owned subsidiary, Sooner Communications, Inc., through which we proposed to market Cadeum to telecommunications carriers.

| 2 |

Until the events described below, we operated the three above-described businesses through three subsidiaries, ND Acquisition Corp., Charlie O Business Park Incorporated and Sooner Communications, Incorporated. These subsidiaries and a brief summary of their businesses are as follow:

| Ÿ | ND Acquisition Corp . ND Acquisition Corp. (NDAC) owned and operated a minimum-security correctional facility for women offenders (Northgate) and a community sentencing facility for men (Eastgate). Both facilities were located in Oklahoma City, Oklahoma. In July 2003 we were notified that the NDAC property was included in an area marked for improvement by the Oklahoma Capital Development Authority. In November 2003 we sold this property to such Authority and exited the correctional facility line of business. Currently, NDAC remains inactive with no assets or liabilities. |

| Ÿ | Charlie O Business Park Incorporated . Charlie O Business Park, Inc. (“CO Park”) operated a multi-unit rental property for business and industrial tenants located in Oklahoma City, Oklahoma. CO Park became an operating subsidiary upon its formation in November 1987 and we owned 100% of the subsidiary. During fiscal year 2002 we were notified by the Oklahoma Department of Transportation (“ODOT”) that the Business Park’s improved real property would be condemned as part of the re-working of Interstate Highway 40. In late July 2003 we settled with ODOT’s appraisers for $4,350,000 for the condemnation of the property. We searched for a replacement property to continue this line of business, but we found none. Currently, CO Park remains inactive with no assets or liabilities. |

| Ÿ | Sooner Communications, Inc . On May 2, 2000 Sooner Communications (“Communications”) subsidiary purchased all the rights to a computer based platform called Cadeum. Cadeum was designed to host computer-based telephony products developed specifically for telecommunication providers. We planned to market these products on a wholesale level to telecommunication carriers. We completed beta testing the answering service section of Cadeum with a large Texas-based regional telecommunication provider. Due to certain interface issues, marketing of the answering service was suspended awaiting a resolution. We resolved these issues in the early second quarter of fiscal 2002, at which time marketing of the answering service was to resume. However, the Texas-based regional telecommunications provider did not resume marketing, due to problems inherent in the telecommunications industry. The Company consider this business to now be defunct with no operations. In preparation of and prior to the closing of the Securities Exchange Agreement, the Company sold all of its shares in Communications to R.C. Cunningham II, our former president and director, for $1.00 for 2011. |

Prior to entering into the Securities Exchange Agreement, as discussed below, our business plan was to seek, investigate, and, if warranted, acquire one or more properties or businesses, and to pursue other related activities intended to enhance shareholder value.

Shishi Feiying Plastic Co., Ltd.

All of our business operations are conducted through our wholly-foreign owned Chinese subsidiary, Shishi Feiying Plastic Co., Ltd. (“SFP”). SFP was registered in China as a wholly-foreign owned enterprise under Chinese law in December, 2003. During 2004 and 2005 SFP built its factory, purchased and installed factory equipment and tested and modified the production lines, and perfected the formula for PU leather. In January 2006, SFP began its business of manufacturing and selling PU leather when all of its $5,000,000 capital contribution was fully paid as registered capital.

In 2007, SFP acquired substantially all of the assets, excluding land use rights and buildings, of our footwear business from Shishi Changsheng Shoe Industry Co., Ltd., a wholly-foreign owned enterprise under Chinese law (“Shishi Changsheng”) for approximately $359,518, which represents the book value at the time. Shishi Changsheng has been manufacturing footwear since 1998. The entire consideration was paid upon the transfer of the assets and there were no further conditions or agreements as part of the transaction. Shishi Changsheng was owned and operated by Mr. Ang; therefore the assets were transferred at their net book value with no step-up or –down in basis.

| 3 |

Reverse Acquisition of Chinese Weituo

Pursuant to the Securities Exchange Agreement, we acquired 100% of the issued and outstanding capital stock of Chinese Weituo in exchange for 19,200 shares of Series A Preferred Stock which upon conversion will constitute approximately 96.0% of our issued and outstanding common stock after the consummation of the transaction contemplated by the Securities Exchange Agreement In January 2012, we completed a reverse stock split on a 1-for- 18.29069125 basis on our shares of common stock. In addition, upon completion of the reverse stock split, all of the Series A Preferred Stock were converted into approximately 19,200,000 shares of common stock. As a result of the reverse acquisition, we have assumed the business and operations of Chinese Weituo and its subsidiaries.

For accounting purposes, the reverse acquisition with Chinese Weituo was treated as a reverse acquisition, with Chinese Weituo as the acquirer and Sooner Holdings as the acquired party. Unless the context suggest otherwise, when we refer in this report to business and financial information for periods prior to the consummation of the reverse acquisition, we are referring to the business and financial information of Chinese Weituo.

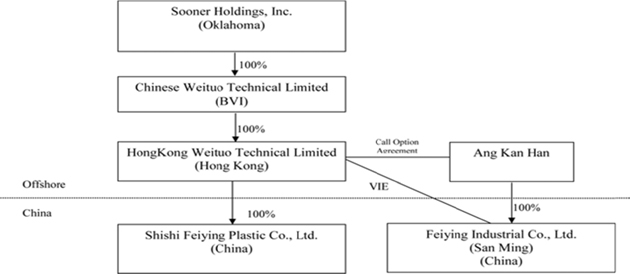

Corporate Structure

All of our operations are conducted through our Chinese subsidiary SFP. In addition, we have entered into call option agreements to procure the manufacturing facilities to be built by San Ming and Fuijian Feiying Plastic Co., Ltd (“FFP”), both of which are independently owned by Mr. Ang, our chairman, president and largest shareholder. Both call option agreements allow our subsidiary Hong Kong Weituo Technical Limited (“HK Weituo”) to purchase the shares of San Ming and/or FFP, respectively, at 90% of the net tangible asset value as of the date of exercise of the call option to be determined by an independent third party appraiser. The total consideration for the San Ming call option agreement was $5,778,005 (RMB 38,082,546) which consisted of $5,694,515 (RMB 37,532,546) in advances made by SFP to Shishi Changsheng, which obligation was subsequently transferred to Mr. Ang and $83,490 (RMB 550,000) in advances made by SFP to San Ming which obligation was subsequently transferred to Mr. Ang. The $5,778,005 (RMB 38,082,546) in obligations due to SFP by Mr. Ang was cancelled upon the execution of the call option and will be applied towards the purchase price of the San Ming if the call option is exercised. The call option agreement for San Ming expires on January 17, 2014.

The consideration for the FFP call option agreement was $152,000 (RMB 1,000,000) which was paid in July 2011. The $152,000 would have been applied towards the purchase price of FFP if the call option was exercised. The call option agreement for FFP expired on January 17, 2012 and was not exercised. Neither call option agreement provides for a refund of the option consideration if such option is not exercised within the prescribed expiration date. The assignment of the San Ming or FFP shares pursuant to the call option agreements do not require government approval, but need to be filed with the relevant local Chinese authorities. It is our intent to exercise the call option to acquire the San Ming, but we did not exercise our call option to acquire the FFP. Accordingly, the $151,800 consideration for the FFP call option was forfeited. In the event that we do not exercise the call option to acquire the shares of San Ming and such option lapses, San Ming will owe us money for funds advanced subsequent to entering into the call option agreement or otherwise due to us. At the time of the lapse of the FFP call option, FFP did not owe us any funds.

We evaluated our call option agreements for the financial accounting and reporting of interests in certain variable interest entities, which are defined as certain business entities that either have equity investors with voting rights disproportionate to their ownership interests, or have equity investors that do not provide sufficient financial resources for the entities to support their activities. The guidance requires consolidation of such entities by any company that is subject to a majority of the risk of loss from the entities’ activities or is entitled to receive a majority of the entities’ residual returns or both, defined as the primary beneficiary of the variable interest entity.

| 4 |

As of December 31, 2011, San Ming has constructed a PU leather manufacturing facility and was testing the production lines in the fourth quarter 2011. As such, we have determined San Ming to be a variable interest entity to which we are deemed to be the primary beneficiary because of (i) their insufficient capital to carry out their principal operating activities, (ii) our ability, through Mr. Ang, to direct and control San Ming’s activities, (iii) San Ming’s reliance on contribution from Mr. Ang and potentially from us to build the manufacturing facility, and (iv) our intention to exercise the call option agreement.

FFP remains inactive as it is still trying to secure land use rights from the Chinese government. Since FFP has no ongoing business operations, we did not consider FFP to be a variable interest entity for 2011.

We have consolidated San Ming’s financial statements with our financial statements for the year ended December 31, 2011 in accordance with U.S. generally accepted accounting principles.

The chart below presents our current corporate structure:

Our principal executive office is located at Han Jiang Town, ShiShi City Fujian, PRC. Our telephone number at our principal executive office is 86-13505080536.

Products

We have two business divisions; our PU leather division and our footwear division. Our primary business is manufacturing PU leather. We maintain our footwear business because of our established distributors and customers, and low cost of manufacturing.

PU Leather

Development of PU Leather

As natural leather has excellent natural characteristics, it is widely used in the production of commodities and industrial products. With the world's population growth, demand for leather has increased, and the production of natural leather cannot satisfy such demand. To replace the use of natural leather, scientists began to study and develop artificial leather and synthetic leather as early as five decades ago.

Polyvinyl chloride (“PVC”) leather or vinyl was one of the earlier forms of artificial leather. Although PVC has advantages including, acid alkali resistance, resistance to water, and bright luster, PVC leather has poor air permeability, feels stiff in cold environment and has worse touch feel than PU leather. Another weakness of PVC is that it can damage the environment. Because it is hard to degrade, the discarded PVC leather pollutes the environment. In the production process of PVC leather, plasticizer, stabilizer and other addictives are added. Stabilizers in PVC leather contain lead, cadmium and other heavy metals, which are prohibited by developed countries including the EU, Japan and the USA. As PVC leather is lower in price, it is mainly used in low-grade bags, sofas, and decorations.

| 5 |

Polyurethane synthetic leather (PU leather) is the second generation artificial leather. In 1937, polyurethane was successfully developed, laying a foundation for the development of PU leather and the progress of artificial leather industry. In 1953, polyurethane was used for shoe soles and synthetic leather and in 1964, PU leather was used for production of shoe upper. (Source: www.polyurethanes.org)

PU leather has certain advantages such as mild burnish, soft feeling, and similar feeling to genuine leather, fine low temperature resistance, fine air permeability, and washability. In addition, PU leather has excellent adhering function to base material, is abrasion resistant, resists flexure, and has excellent mechanical properties of aging resistance. Compared to natural leather, PU leather processing is simpler at a lower cost. As a result, PU leather had become an ideal substitute for natural leather products, and it has been widely used for clothing, furniture, and luxury shoes.

Superfine fiber PU leather is the third generation artificial leather. It adopts bunchy superfine fiber that is similar to bunchy collagenous fiber in natural leather in terms of structure and performance, which is processed into three-dimensional network structured high-density nonwovens, and filled with optimal form microporous-structured polyurethane. The superfine fiber PU leather comes out after a special post-processing. Superfine fiber PU leather has better function and performance than genuine leather including: tear resistance, high pulling tension, wear-resistance, low temperature resistance, acid and alkali resistance, fade resistance, hydrolysis resistance, light quality, soft and fine air permeability, smooth feel and even thickness. In terms of chemical resistance, quality uniformity and production processing adaptability, waterproof, mildew-proof, superfine fiber PU exceeds natural leather. Superfine fiber PU leather is suitable for fabrics for high-grade sport clothes, shoes, bags and furniture.

The PU leather industry is developing in terms of product quality, varieties and output, and it is undergoing a transition from ordinary PU synthetic leather to high-quality PU synthetic leather through technology and more salient physical performance.

Our Industry

Artificial synthetic leather is mainly composed of base cloth and coating resin. In industrial practice, the artificial leather with PVC resin as coating is generally called PVC artificial leather; the artificial leather with PU resin as coating is called PU leather; the synthetic leather with superfine fiber nonwoven cloth as base cloth and PU resin as coating is called superfine fiber genuine leather (also called superfine fiber synthetic leather). In industrial statistics, superfine fiber genuine leather is listed as the category of synthetic leather. Source Taiwan Synthetic Leather Industry Published at April 2009. http://www.ibuyplastic.com/tech_center/tech_paper/tech_detailcontent.phtml?id=559&IBP_SID=f31d1238f6b8415ef933a717a331c130

PU leather is similar to genuine leather in terms of structure and performance. With a three-dimensional appearance, PU synthetic leather has superior durability, resilience, softness, tensile strength and solvent resistance. It can be cut, ground and processed like genuine leather to be air permeable and moisture permeable.

PU leather is used in a wide variety of industries including clothing, shoes, furniture, and athletic equipment. Different uses require different types and quality of PU leather. Traditionally, Japanese companies were known for their technology in creating synthetic leather while Italian companies were known for creating fashionable synthetic leather for higher-end products. Taiwanese and Korean companies also grew to produce high-tech synthetic leather. Lately, Chinese companies have emerged as producers of high-quantity PU leather. According to Taiwan Industrial Technology Research Institute, China National Bureau of Statistics, China’s output of synthetic leather makes up 70% of the world’s total output, becoming the top manufacturer and consumer of synthetic leather. The synthetic leather products are raw materials for shoes, bags, garments, and furniture products.

| 6 |

Increasing Demand for Artificial and Synthetic Leather

According to China Plastics Processing Industry Association (Source: The situation and tendency of synthetic leather industry in China, Published at Sept. 2010, www.cn-plastics.net/docc/reports/detail.asp?news_id=853 ), by 2013 the quantity demanded for the domestic artificial leather and synthetic leather will reach 3.24 billion m2 (square meters). According to the National Bureau of Statistics, in 2009 the production of artificial leather in China was 1.07 billion m2 representing a year-on-year increase of 6.6% while the production of synthetic leather is 1.28 billion m2 representing a year-on-year increase of 13.2%. The gross output value of industry is 58.67 billion RMB with a year-on-year increase of 11.24 %.

In addition, it is anticipated that PU synthetic leather, which is the second generation of artificial leather and synthetic leather, will increase as customers look for alternatives to the PVC artificial leather. In terms of performance, PU synthetic leather is considered by many to be better than PVC artificial leather in terms of feel and likeness to real leather. In addition, at present, the European Union has limited the production and sale of PVC artificial leather and Japan has already banned the use of PVC artificial leather as car decoration material. With the tightening of international environmental policy, it is anticipated that the demand for PU synthetic will grow.

According to Statistics on synthetic leather factories and their production lines in domestic China in 2008 by Chinapu.com (Source: Research report on China PU leather industry 2008, Shanghai; http://www.chinatimes.cc/site1/hxsb/html/2010-01/09/content 28698.htm) which is specialized in PU market research, in 2008 there were approximately 364 synthetic leather enterprises in Mainland China, which had 1,343 production lines. Among them there are 694 dry process production lines and 649 wet process production lines. These enterprises are mainly concentrated in provinces including Zhejiang, Fujian, Guangdong and Jiangsu. Manufacturers in Fujian Province, China represented approximately 13% of all of the manufacturers included in the statistical report. In addition, according to China National Bureau of Statistics, Guangdong, Fujian and Zhejiang are three major leather shoe production bases in China, producing 83% of the country’s total output. These three provinces are main areas with demand for synthetic leather in China and 80% of domestic production lines of synthetic leather are distributed in the three provinces.

PU Applications

PU leather is used in the following application fields: shoe leather, furniture leather, leather for luggage and case, leather for garment, leather for balls, and leather for inner decoration of cars. Sports shoes are an important application area of synthetic leather. China’s annual output of sneakers stands at about 3 billion pairs, which are mainly produced in Fujian and Guangdong. Jinjiang of Fujian province is the largest production base of sports shoes. There are more than 3,000 shoe-making manufacturers in Jinjiang, with a total annual output of 1.2 billion pairs of sports shoes and sneakers, accounting for 40% of China’s output, or 20% of the world's total output. (Source Fujian government, published at April 2009, http://www.fujian.gov.cn/wsbs/jg/jjdt/200904/t20090414 120083.htm)

In addition, there are many shoe-manufacturers who engaged in production with leather shoe upper, mainly distributed in Guangdong and Zhejiang. Huidong of Guangdong is “China’s Production Base of Ladies Shoes,” with more than 3,000 shoe-making enterprises, of which more than 95% produced ladies shoes of synthetic leather; these enterprises produced a total of 300 to 400 million pairs of ladies shoes a year. Wenling of Zhejiang mainly produces shoes of synthetic leather, and this city has more than 6,000 shoe-making enterprises, with a total annual output of 400 million pairs. (Source : Wenling Statistion Intranet, published Dec. 2010, http://www.wltj.org/listnew.php?new_id=124&d=003)

| 7 |

Market

We believe we are one of the leading manufacturers of PU leather for the shoe manufacturing industry in Fujian Province, China. We are located in the area of Jinjiang County of Quanzhou, which is China’s largest production base of sports shoes. (Source: Sports Shoe’s Capital of China –Jinjiang , China Daily, January 22, 2009) There are over 4,000 shoe manufacturers in this area including well-known companies, such as “Anta,” “Peak,” “361°,” “Voit,” “Xtep,” “Erke” and “Deerway.” The annual production of sport shoes and sneakers in Jinjiang is above 1 billion pairs. (Source: Fujian government, published April 2009, http://www.fujian.gov.cn/wsbs/jg/jjdt/200904/t20090414_120083.htm) Our major customers are shoe factories which are concentrated in the area of Jinjiang County of Quanzhou. As the production base is close to the sales market, our sales and transportation costs are greatly reduced. Meanwhile because the production base is close to the market, we can quickly access the customers’ information which becomes a significant advantageous position in terms of R&D and market response.

Manufacturing

PU synthetic leather refers to a type of artificial leather with PU resin coatings applied and dried over the release paper and then transferred to the base cloth or wet-process substrate layer (BASE). PU synthetic leather is similar to genuine leather in terms of structure and performance. With a three-dimensional appearance, PU synthetic leather has superior durability, resilience, softness, tensile strength and solvent resistance. It can be cut, ground and processed like genuine leather to be air permeable and moisture permeable. PU synthetic leather can be further categorized by intended use as follows: ball leather, footwear leather, upholstery leather, garment leather, bag leather, car interior leather, fancy leather, industrial accessory / packaging leather etc.

High-performance PU leather refers to PU synthetic leather using high-density nonwoven fabric as base cloth and featuring superior hydrolysis resistance, peel strength, tear strength, durability, air permeability and moisture permeability. The mid-grade high-performance PU leather we are currently manufacturing is mainly used to make high-grade athletic shoes.

We manufacture a variety of mid-grade PU leather products including the conventional and high-performance series. These products are basically intended for footwear applications.

We have a 66,700 square meter factory for the production of five lines of PU leather. Our five production lines consist of three wet-process production lines to produce semi-finished PU leather and two dry-process production lines, which produce the finished product. Altogether, we can produce over 12 million meters of PU leather per year.

We also have another 5 production lines in San Ming factory, which include 3 wet and 2dry for doubling our output. As of March 31, 2012, San Ming has finished construction and testing of their equipment and begun to sell.

A brief overview of the wet-process and dry process is described below.

Wet-Process Production – Semi-finished PU leather

| 8 |

Dry-Process Production – Finished PU leather

1-hour agitation at 70°C

RDMF is added for dilution.

RDMF and MEK are added repeatedly to obtain the desired viscosity and solid content.

Various additives are added as required and adequately agitated for 1 hour.

Terminator is added to end the reaction.

In addition to our manufacturing process for the PU leather, we also produce roughly 14,400 tons of resins a year that we use for our manufacturing process as well as to sell to other manufacturers. This allows us to be less dependent on suppliers and market conditions of raw materials. We also developed a proprietary process to recover and reuse our production remains as part of our manufacturing process. This reduces waste in our manufacturing process. As discussed in growth strategy, subject to availability of funds we intend to expand our manufacturing capacity by acquiring one or two production plants.

Raw Materials and Suppliers

Resin pastes and base cloths are the key raw materials used in the production of PU synthetic leather and therefore constitute a major part of approximately 80% of the production cost, specifically, resin pastes 60% and base cloths 20%. We have established a resin paste plant in the SFP factory to support our production needs. Through San Ming, we intend to establish a cloth production plant so we will be able to manufacture the resin pastes and base cloths required for production of PU leather and mitigate the potential adverse impact of the rise in raw material price on the profit margin of PU leather products. The key raw materials of PU resins are coal-based DMF, petroleum-based AA and MDI and other chemical products. DMF, AA and MDI stand at approximately 70% of the total cost of PU resins. We purchase our raw materials, including the base cloth, from a number of suppliers and are not dependent on any single supplier. In addition, the suppliers for our base cloth include the raw materials for base cloth is all located in Fujian Province. We do not have a formal long term contract with any of our suppliers. During the fiscal years ended December 31, 2011 and 2010, we had one supplier that account for 12.8% and 16.1% respectively.

| 9 |

Design

There are two parts to the design aspect of PU leather. One is formulas design, which we can produce PU leather with different physical features like high peel strength, water repellency, and/or tear strength. For formulas design, we will tailor the formulas with different proportion of ingredients to satisfy client’s requirements. The other is pattern design, which we establish colors, roughness of materials, and different patterns on the materials. We monitor and review trends to keep our products current with fashion trends and styles.

Marketing, Sales and Distribution

We sell PU leather mostly to shoe factories in China. 90% of our sales are to distributors, and the remaining through direct sales to customers. For year ended December 31, 2011, Jinjiang Yuanfeng Shoes Trading Co., Ltd.(“Yuanfeng”), our largest PU leather distributor, accounted for 5.03% of our total sales. In general, Yuanfeng purchases our products pursuant to a standard purchase order. However, on January 10, 2011, we memorialized a cooperation agreement with Yuanfeng that extended to them up to $5.27 million in credit on the purchase of our products that occurred in 2010. In consideration for extending credit, Yuanfeng will pay us interest on the outstanding balance at a rate equal to a 15% discount of the one-year bank interest rate. See “Management's Discussion and Analysis Of Financial Condition and Results of Operations - Liquidity and Capital Resources”. We currently do not actively market any of our PU leather to foreign markets (outside of China). However, since many of our distributors are currently supplying PU leather to other Asian countries, we believe we can expand our sales, primarily throughout Asia based on our relationships with our distributors. We intend to expand our sales to foreign markets by increasing our production capacity through the construction of the San Ming manufacturing plant, the first phase is ready for trial production. The first phase consists of a production center and the purchase and installation of three wet process production lines and two dry process production lines. See the discussion “ New Manufacturing Facilities” below .

In connection with our sales, we provide consistent and reliable customer services from product development, communication in production to after-sales support and maintenance. At the point of product development, the sales representative will introduce the market trends to the customer and provide market research and product-specific consultation services upon the customer’s request. During the product process, we strive to be highly responsive to the changes in terms of specifications such as physical properties, and since we have our own resin plant we are able to accommodate changes quickly with accurate adjustment to the resin formulas in response to customer needs. During the after-sales stage, we provide training, on-site instruction and call center services. We give information to our customers about how to preserve PU leather products, especially high-performance PU leather, for a longer period of time, so as to prevent product returns or disputes due to improper storage.

Seasonality

We experience some seasonal trends in the sale of our products. Sales in our PU leather division are often stronger in our second, third and fourth quarter and often weaker in first quarter. Historically, the net result of seasonal trends has not been material relative to our overall results of operations, but many of the factors that create and affect seasonal trends are beyond our control.

Backlog

At December 31, 2011 and 2010, we had no backlog. We do not believe that backlog is a meaningful indicator of sales that can be expected for any period, and there can be no assurance that the backlog at any point in time will translate into sales in any subsequent period, particularly in light of our policy of allowing customers to cancel or reschedule orders without penalty prior to commencement of manufacturing. We have not recorded any provision for sales returns and have no provisions for the years ended December 31, 2011 and 2010.

| 10 |

Inventory Levels

We produce according to actual sale orders, and forecasted sale projections that we receive from our distributors. This strategy gives us the ability to operate with reduced levels of raw materials and finished goods inventories; however there is generally a build-up of work in process inventory in anticipation of future orders. Work in process inventory is generally inventory that has gone through the wet process. We commonly call this semi-finished inventory. Semi-finished inventory can be sold and is generally the product that is sold internationally. Most of the design aspects take place in the dry-process, so we can build-up semi-finished inventory in anticipation of future needs. Fluctuations in market demand may nevertheless result in excess inventory. However, since most of our non-committed inventory is either raw materials or semi-finished we considerably reduce the risk of declining inventory values and obsolescence.

Growth Strategy

We currently produce mid-grade PU leather products with both normal performance and high-performance features. We intend to focus on mid- to high-grade PU leather products in the next few years while (i) entering other regional markets in China, such as Hunan and Jiangxi Provinces that are located near our manufacturing facility in Fujian, (ii) increasing our sales in Asian countries outside of China, specifically Japan and Korea, and (iii) increase our sales in overseas markets such as Europe and America. We intend to achieve growth by pursuing the following strategies:

| Ÿ | Focus on key markets . China continues to present strong growth opportunities especially in the Fujian Province, with increasing demand for our mid-grade high-performance PU leather. We plan to expand into other regional markets by opening sales centers in other provinces. We have already opened a sales center in Hebei Province and have begun to market to shoe manufactures in Hebei Province, but we have not had any significant sales in that province. We are also planning to work closely with our distributors to explore direct sales opportunities to customers outside of China. Our distributors have a great deal of experience in the selling of PU leather outside of China to other Asian countries. We intend to leverage their experience and contacts to try to procure contracts for the sale of our PU leather. These efforts are generally based on our relationships with our distributors and our based on our ability to provide a higher-quality product at a competitive price. During March 2011, we shipped some small orders to shoe factories in Japan and Korea. |

| Ÿ | Focus on shoe industry . We will continue to focus our sales to the shoe industry which demand high quality PU leather such as ours. We will continue to improve the quality of our products, develop proprietary technology and formulas, and upgrade aesthetic designs to differentiate our products from our competitors. |

| Ÿ | Expand our sales to other industries . We seek to expand our sales to other industries such as furniture, balls, clothes and suitcases that focus on higher quality of PU leather. We plan to expand into other industries once we are able to increase our capacity as a result of the new manufacturing facilities. We intend to leverage our brand and reputation, and utilize our distributors to explore sales of our PU leather in the other industries. Presently, our focus for our PU leather is in the shoes industry, but in the near future, when the new San Ming manufacturing facilities is up and running, we intend to sell to other PU industries, like furniture, balls, clothes and suitcase. We believe that we can easily extend our sales to other PU leather industries because we have a good reputation with our distributors and we have strong control over our quality and our operations. |

| Ÿ | Research and Development . We will continue to commit resources for research and development in order to improve our manufacturing process and develop new formulas to improve the quality of our PU leather. In particular, our efforts will focus on (1) developing more advanced technologies to increase our productivity and efficiency in the manufacturing process and reduce cost of production; (2) developing and refining our proprietary manufacturing process for the resins used in our manufacturing process as well as methods of recycling our used manufacturing remains to cut costs and preserve the environment; and (3) enhancing our product quality to satisfy stringent manufacturing requirements and to keep abreast of rapidly changing industry standards and evolving market trends. |

| Ÿ | Upgrade on technology . We will continue to upgrade and refurbish our machinery so that we can stay ahead of the technology curve with the most efficient use of capital investment. |

| Ÿ | New manufacturing facilities . We intend to increase our production to meet current and future demand by building a new manufacturing facility in DaTian city, Fujian Province. On January 17, 2011, we entered into a call option agreement with Mr. Ang granting us the right to purchase Mr. Ang’s shares in San Ming which is building a facility in DaTian city. |

| 11 |

New Manufacturing Facilities

We intend to increase our production capacity by building new manufacturing facilities. We had plans to construct two facilities, the FFP facility in Yong’an city and the San Ming facility in DaTian city, Fujian. The development of the manufacturing facility in Yong’an city was on hold due to issues securing the land use rights, and as discussed below, we did not exercise our right to acquire the FFP facility. Construction on the San Ming facility in DaTian city began in June 2010. There are three phases for the new PU leather factory. Phase 1 has been finished and consists of construction of the actual facilities that will house the production center and the purchases and installation of three wet process production lines, two dry process production lines and installation of recycling equipment to recapture and recycle chemicals used in the production process. Two wet process production lines are assembling and are ready to be placed into trial production. Phase 1 has an estimated total cost of $20.0 to $21.0 million. Phase 1 has been finished. The San Ming has been testing its machine and equipment for the past 5 months, except for a one month break during spring holiday. San Ming is currently in production and had sales in the first quarter 2012. Phase 2 has not started yet. timing for phase 2 is somewhat dependent on PU leather demand and the availability of capital resources. Phase 2 will consist of the expansion from 3 wet processing lines to 9 wet processing lines, from 2 dry process lines to 7 dry processing lines, and the addition of a resin plant and 5 base-cloth production lines. Phase 2 has not started yet due to the softness in demand for the PU leather market. We intend to fund phase 2 from the sale of equity instruments and bank financing. After the construction of Phase 2, San Ming will decide how it wishes to proceed on Phase 3. Phase 3 consists of installing new wet and dry processing lines to manufacture super-fiber PU leather, and the ability to produce PU leather for other industries at high capacity.

Competitive Strengths

We believe that the following competitive strengths enable us to compete effectively in, and to capitalize on the growth of, the PU leather market:

| Ÿ | Strong Cost Control. We produce our own raw materials for the production of PU leather. In addition, we recover and reuse our waste manufacturing materials. |

| Ÿ | Strong Relationships. We enjoy long-term relationships with our suppliers. |

| Ÿ | Loyalty . We cultivate strong employee loyalty to the company. |

| Ÿ | Differentiation . We have unique formulations for certain PU leather products. |

| Ÿ | Strong Trademarks . Our WINTOP, WINTOP plus graphic, and NIVIANI plus graphic trademarks are well-known in China. |

| Ÿ | Strong Research and Development Capabilities . We place a strong emphasis on research and development, particularly focusing on improving the quality and uniqueness of our products. Our strong research and development commitment have enabled us to develop special formulas to differentiate our products from our competitors. We have in-house engineers who calculate the best formula for each batch of raw materials based on their experience. |

| Ÿ | Recognized Quality Products . We strive to manufacture quality products. We have the facilities for experimenting, inspecting and testing as well as a sophisticated production process. Our products receive accreditation from famous footwear manufacturers such as Erke and Xtep. As a leading supplier of PU leather, our products are used in both domestic athletic shoe brands and internationally recognized brands. |

| Ÿ | Eco-Friendly Production. We are committed to a long-term strategy of green, eco-friendly and sustainable development. We have maintained a sophisticated recycling and post-treatment process. The new facility at San Ming will replace the conventional HTF heating solution with a steam recovery and zero heat emission system. |

| Ÿ | Low-cost manufacturing model . We conduct all of our manufacturing activities in Fujian Province, China. Our access to China's abundant supply of skilled and low-cost labor, as well as our ability to source raw materials, equipment, land and manufacturing facilities locally and economically, has considerably lowered our operating cost and expenses as a percentage of revenues. |

| Ÿ | Location . We are located near our customers. This reduces cost of transportation and allows us to better serve our customers. |

| Ÿ | Brand Awareness and Customer Loyalty . We have established a good long-term cooperative relationship with our distributors. Our ability to adjust, accommodate and update our products in time and develop new products to adapt to the needs of our end consumers have resulted in a group of long-term loyal customers. In addition, our relationships with our distributors allow us to gather important market information and potentially enter new markets. |

| 12 |

Competitors

The competition in our industry is intense and there is a high concentration of competitors in our geographical area. Our products are positioned to be medium and high-end PU synthetic leather and our major competitors are domestic competitors which we have identified to include Jinjiang Lanfeng Leather Manufacturing Co., Ltd., Kunshan Xiefu Group, and Jinjiang Tianshou Artificial Leather Co., Ltd. In general, our direct competitors have overseas sales capacity. However, they lack our low-cost advantage, focused concentration on research and development, close proximity to customers, high quality, and centralized product offerings.

Footwear

There is a tremendous continuing demand for PVC flip-flops and slippers all over the world, and particularly in countries with hot climates such as those in Africa, the Middle East, Southeast Asia and South America.

Manufacturing

Our PVC foam slippers are made of PVC resins which are transformed into lightweight and soft sheets through high-pressure foaming and then stamped and cut into soles with reserved holes. Non-foam PVC materials are used to make the Y-shaped strap through injection molding which is then fastened to the sole to form a thong flipper. PVC foam slippers are mainly made of PVC, DOP, DDP and AS. We have a 5,000 square meter factory that manufacturers PVC flip-flops and slippers. We use a semi-automated processes to boil, mix, vulcanize, mold, drill, and press raw PVC and chemicals into innovative fashionable flip-flops and slippers. We can currently produce more than 40 million flip-flops and slippers per year. We believe that we are one of the leading PVC slipper manufacturers in China, with state-of-the-art production process and equipment. From 1998 to 2005, we were one of the key suppliers of White Dove, an internationally recognized slipper brand. Since 2006, we focused on building our own brand WINTOP which is well received in Africa, Middle East, Southeast Asia, and South America for its premium quality, stylish design, attractive patterns and competitive price.

Raw Materials and Suppliers

The key raw materials of PVC foam slippers are PVC (Polyvinyl chloride) resins, DOP (Dibutyl phthalate), and DDP. We purchase our raw materials from a number of suppliers and are not dependent upon any raw material supplier for PVC slipper production. We do not have a formal long term contract of any of our suppliers. During the fiscal year ended December 31, 2011 and 2010, we had one supplier that accounted for 12.8% and 16.1% of our purchases of raw materials.

Sales and Distribution

We sell our footwear in China, Middle East and Africa. The bulk of our sales occur in Africa and the Middle East through our sole distributor, Ransford Limited. Ransford accounted for 18.07% and 13.82% respectively of our gross sale at year ended December 31, 2011 and 2010. Ransford purchases our products pursuant to a standard purchase order. In general, a standard Ransford purchase order covers basic terms including type of product to be sold, quantity of product to be sold, specifications, if any, of the product to be sold, purchase price, payment terms, time of shipment, loading port and destination, and insurance. Once the products have been delivered and we have been paid, there are no further obligations by the parties under the purchase order. In China, we sell our footwear to one customer which accounted for 2% and 2% of our gross sales at year ended December 31, 2011 and 2010. For the years ended December 31, 2011 and 2010, our percentage of revenues for the footwear business were 82%, 8% and 10%, and 84%, 10% and 6%, in China, Middle East and Africa, respectively. Sales in our footwear division are often stronger in our second, third and fourth quarter, and often weaker in first quarter.

| 13 |

Competitors

We have been in this business since 1998 and our WINTOP brand is well known by our customers and end users. However, the PVC flip-flop and slipper business is highly competitive and fragmented where manufactures around the world competes by pricing. As such, we will competitive in the market place as long as we can maintain our low cost of production.

PRC Government Regulations.

Business License

Any company that conducts business in the PRC must have a business license that covers a particular type of work. We obtained a business license from the Quanzhou Administration for Industry and Commerce on November 24, 2010, which identifies our business scope as “Production of plastic.” Prior to expanding our business beyond that of our business licenses, we may be required to apply and receive approval from the relevant PRC government authorities and we cannot assure you that we will be able to obtain the necessary government approval for any change or expansion of our business.

Environmental Regulations

Major regulations applicable to us include the PRC Environmental Protections Law, the PRC Law on Prevention and Control of Water Pollution and its associated Implementation Rules. In compliance with these regulations, we have obtained a Pollution Emission License and an Environmental Protection Opinion from the Shishi Municipal Environmental Protection Bureau.

Taxation

On March 16, 2007, the National People’s Congress of China passed a new Enterprise Income Tax Law, or EIT Law, and on November 28, 2007, the State Council of China passed its implementing rules, which took effect on January 1, 2008. Before the implementation of the EIT Law, foreign invested enterprises, or FIEs, established in the PRC, unless granted preferential tax treatments by the PRC government, were generally subject to an earned income tax, or EIT, rate of 33.0%, which included a 30.0% state income tax and a 3.0% local income tax. The EIT Law and its implementing rules impose a unified EIT of 25.0% on all domestic-invested enterprises and FIEs, unless they qualify under certain limited exceptions. Despite these changes, the EIT Law gives FIEs established before March 16, 2007, or Old FIEs, a five-year grandfather period during which they can continue to enjoy their existing preferential tax treatments. During this five-year grandfather period, the Old FIEs which enjoyed tax rates lower than 25% under the original EIT law will be subject to gradually increased EIT rates over a 5-year period until their tax rate reaches 25%. In addition, the Old FIEs that are eligible for other preferential tax treatments by the PRC government under the original EIT law are allowed to continue enjoying their preference until these preferential treatment periods expire. The discontinuation of any such special or preferential tax treatment or other incentives would have an adverse effect on any organization's business, fiscal condition and current operations in China.

In addition to the changes to the current tax structure, under the EIT Law, an enterprise established outside of China with “de facto management bodies” within China is considered a resident enterprise and will normally be subject to an EIT of 25% on its global income. The implementing rules define the term “de facto management bodies” as “an establishment that exercises, in substance, overall management and control over the production, business, personnel, accounting, etc., of a Chinese enterprise.” If the PRC tax authorities subsequently determine that we should be classified as a resident enterprise, then our organization's global income will be subject to PRC income tax of 25%. For detailed discussion of PRC tax issues related to resident enterprise status, see “Risk Factors – Risks Related to Our Business – Under the Enterprise Income Tax Law, we may be classified as a ‘resident enterprise' of China. Such classification will likely result in unfavorable tax consequences to us and our non-PRC shareholders.”

In addition, the EIT Law and its implementing rules generally provide that a 10% withholding tax applies to China-sourced income derived by non-resident enterprises for PRC enterprise income tax purposes unless the jurisdiction of incorporation of such enterprises’ shareholder has a tax treaty with China that provides for a different withholding arrangement. SFP is considered FIEs and are directly held by our subsidiary in Hong Kong. According to a 2006 tax treaty between the Mainland and Hong Kong, dividends payable by an FIE in China to the company in Hong Kong who directly holds at least 25% of the equity interests in the FIE will be subject to a no more than 5% withholding tax. We expect that such 5% withholding tax will apply to dividends paid to HK Weituo by SFP, but this treatment will depend on our status as a non-resident enterprise.

| 14 |

Pursuant to the Provisional Regulation of China on Value Added Tax and its implementing rules, all entities and individuals that are engaged in the sale of goods, the provision of repairs and replacement services and the importation of goods in China are generally required to pay value added tax, or VAT, at a rate of 17.0% of the gross sales proceeds received, less any deductible VAT already paid or borne by the taxpayer. Further, when exporting goods, the exporter is entitled to some or all of the refund of VAT that it has already paid or borne.

The Chinese State Administration of Taxation, or SAT, released a circular on December 15, 2009 that addresses the transfer of shares by nonresident companies, generally referred to as Circular 698. Circular 698 may have a significant impact on many companies that use offshore holding companies to invest in China. Circular 698, which provides parties with a short period of time to comply with its requirements, indirectly taxes foreign companies on gains derived from the indirect sale of a Chinese company. Where a foreign investor indirectly transfers equity interests in a Chinese resident enterprise by selling the shares in an offshore holding company, and the latter is located in a country or jurisdiction where the effective tax burden is less than 12.5% or where the offshore income of his, her, or its residents is not taxable, the foreign investor is required to provide the tax authority in charge of that Chinese resident enterprise with the relevant information within 30 days of the transfer.

Employment Laws

We are subject to laws and regulations governing our relationship with our employees, including: wage and hour requirements, working and safety conditions, and social insurance, housing funds and other welfare. The term social insurance refers to five basic social security insurances under PRC law including basic pension, basic medical insurance, work-related injury insurance, unemployment insurance and maternity insurance. These laws and regulations include local labor laws and regulations, which may require substantial resources for compliance.

China’s National Labor Law, which became effective on January 1, 1995, and China’s National Labor Contract Law, which became effective on January 1, 2008, permits workers in both state and private enterprises in China to bargain collectively. The National Labor Law and the National Labor Contract Law provide for collective contracts to be developed through collaboration between the labor union (or worker representatives in the absence of a union) and management that specify such matters as working conditions, wage scales, and hours of work. The laws also permit workers and employers in all types of enterprises to sign individual contracts, which are to be drawn up in accordance with the collective contract. The National Labor Contract Law has enhanced rights for the nation’s workers. The legislation requires employers to provide written contracts to their workers, restricts the use of temporary labor and makes it harder for employers to lay off employees. It also requires that employees with fixed-term contracts be entitled to an indefinite-term contract after a fixed-term contract is renewed twice or the employee has worked for the employer for a consecutive ten-year period.

Foreign Currency Exchange

Under the PRC foreign currency exchange regulations applicable to us, the Renminbi is convertible for current account items, including the distribution of dividends, interest payments, trade and service-related foreign exchange transactions. Conversion of Renminbi for capital account items, such as direct investment, loan, security investment and repatriation of investment, however, is still subject to the approval of the PRC State Administration of Foreign Exchange, or SAFE. FIEs established in the PRC may only buy, sell and remit foreign currencies at those banks authorized to conduct foreign exchange business after providing valid commercial documents and, in the case of capital account item transactions, obtaining approval from the SAFE. Capital investments by FIEs outside of China are also subject to limitations, which include approvals by the Ministry of Commerce, the SAFE and the State Reform and Development Commission. We currently do not hedge our exposure to fluctuations in currency exchange rates.

| 15 |

Dividend Distributions

Under applicable PRC regulations, FIEs in China may pay dividends only out of their accumulated profits, if any, determined in accordance with PRC accounting standards and regulations. In addition, a FIE in China is required to set aside at least 10% of its after-tax profit based on PRC accounting standards each year to its general reserves until the accumulative amount of such reserves reach 50% of its registered capital. These reserves are not distributable as cash dividends. The board of directors of a FIE has the discretion to allocate a portion of its after-tax profits to staff welfare and bonus funds, which may not be distributed to equity owners except in the event of liquidation.

Offshore Special Purpose Companies

Under applicable PRC regulations, PRC residents are required to register with the local SAFE branch before establishing or acquiring control over an offshore special purpose company, or SPV, for the purpose of engaging in an equity financing outside of China on the strength of domestic PRC assets originally held by those residents. Failure to comply with the relevant PRC regulations may result in fines and other penalties under PRC laws for evasion of applicable foreign exchange restrictions. Any such failure could also result in the SPV’s affiliates being impeded or prevented from distributing their profits and the proceeds from any reduction in capital, share transfer or liquidation to the SPV, or from engaging in other transfers of funds into or out of China.

See also, “Risk Factors - RISKS RELATED TO DOING BUSINESS IN CHINA”

Research and Development

Our research and development efforts are supported by our consultant from South Korea who has been studying and manufacturing PU leather products for nearly two decades. We also have many technical experts with years of experience. We have developed a variety of proprietary PU leather products with high-performance and proven performance. In addition we continue to develop technology upgrades to stay competitive, i.e. constantly improving resin formulas and production processes for PU leather to achieve premium performance while reducing the amount of resin used in the coating process, which results in the greater value of equipment and effective cost reduction.

We have focused most of our research and development attention on the further development of our PU leather products: high-density PU leather and Nano PU leather.

We intend to continue to grow and maintain our competitive advantage by focus on the development and use of our new materials, expand our formularies, production process and new product development.

Intellectual Property

Many elements of our resin formula and production process for our PU leather involve proprietary technologies, processes, know-how or data that are non-patentable. Other methods and formulations may be patentable, but we have determined that our business interests are better served by trying to protect them as trade secrets or confidential information. We rely heavily on trade secret protection and confidentiality agreements rather than patent laws to protect our rights in these proprietary technologies, processes, know-how and data. We have taken security measures to protect its trade secret rights in this regard. For example, we have signed a confidentiality agreement with its employees and signed the Commercial and Technical Non-disclosure Agreement with our key employee to ensure that our intellectual property and intangible assets are properly protected. The core technology used in our PU leather production process is proprietary and only known by key employees, all of whom have signed the above-mentioned confidentiality agreement to prevent the leakage of core technology.

We have an exclusive right to use the trademark “WINTOP” pursuant to a trademark license contract with Shishi Changsheng. The trademark fee is $3,036 (RMB 20,000) annually ending on January 1, 2012. There are four trademarks with registered numbers; 3646701, 5342599, 3646699, 3646700 (Wintop; Pattern; Wintop with pattern and NIVIANI). Shishi Changsheng owns the trademarks.

Employees

We currently employ approximately 516 full time employees and no part-time employees.

| 16 |

Item 1A. Risk Factors

An investment in our common stock involves a high degree of risk. You should carefully consider the risks described below, together with all of the other information included in this report, before making an investment decision. If any of the following risks actually occurs, our business, financial condition or results of operations could suffer. In that case, the trading price of our common stock could decline, and you may lose all or part of your investment. You should read the section entitled “Special Note Regarding Forward Looking Statements” above for a discussion of what types of statements are forward-looking statements, as well as the significance of such statements in the context of this report.

RISKS RELATED TO OUR OVERALL BUSINESS OPERATIONS

We lack liquidity.

As of December 31, 2011, our current liabilities of $26,062,142 exceed our current assets of $15,691,895, the majority of which consists of inventory in the amount of $12,611,763. In the event that our creditors demand immediate payment in the near term, we would not be able to pay off such amounts in a timely manner. Further, because the majority of our current assets consists of inventory, it may take more time liquidate these assets in order to pay off our creditors.

Our Independent Accountants have issued a going concern opinion

As previously disclosed, our current liabilities exceed our current assets. Further, as discussed below, we are in violation of certain financial covenants on one of our loans and have experienced a decline in revenues. Although our consolidated financial statements have been prepared on a going concern basis, because of our lack of liquidity, violation of certain covenants on one of our loans and declining revenues, our independent accountants have raise substantial doubt about our ability to continue as a going concern. We may seek additional financing to provide us capital to address some of these issues. However, no assurance can be given that we will be successful in raising capital.

We are in violation of certain financial covenants on one of our loans.

Some of our banks required us to meet certain financial covenants during the term of a loan. For one of our loans in the amount of $785,583 (RMB 5 million), we did not meet the bank’s financial covenants. Although the bank has not declared a default on the loan, in the event the bank does not agree to waive these covenants or otherwise revise the terms of the loan, they can declare a default on our loan and seek immediate repayment which would have an adverse financial effect on us and our operations.

We are dependent on our short term loans with financial institutions and substantially all of our short term loans are secured by our real estate.

We have short term loans and notes payable with financial institutions. The short term loans are due within one year and the notes payable are due in less than a year. The short term loans are secured by our real estate. Although the notes payable are not secured, the financial institutions require that we have a cash reserve of 20% to 100% of the total outstanding balance. As of December 31, 2011 and December 31, 2010, we had $15,499,552 and $11,586,254, respectively, amounts outstanding in short term loans and notes payable. Although we are current in our obligations under the short term loans and notes payable, a default in these loans, could require all amounts to be due immediately and result in the loss of our real property.

Current economic conditions may adversely affect consumer spending and the overall general health of our customers, which, in turn, may adversely affect our financial condition, results of operations and cash resources.

Uncertainty about the current and future global economic conditions may cause our customers to defer purchases or cancel purchase orders for our products in response to tighter credit, decreased cash availability and weakened consumer confidence. Our financial success is sensitive to changes in general economic conditions, both globally and nationally. Recessionary economic cycles, higher interest borrowing rates, higher fuel and other energy costs, inflation, increases in commodity prices, higher levels of unemployment, higher consumer debt levels, higher tax rates and other changes in tax laws or other economic factors that may affect consumer spending or buying habits could continue to adversely affect the demand for our products. In addition, a number of our customers may be impacted by the significant decrease in available credit that has resulted from the current financial crisis. If credit pressures or other financial difficulties result in insolvency for our customers it could adversely impact our financial results.

| 17 |

We may be unable to successfully execute our long-term growth strategy or maintain our current revenue levels.

Although we exhibited significant growth from our inception through 2010, the company did not exhibit growth in 2011 due to financial crises of PU industry and downstream market. No assurance can be given that our revenues will continue to grow. Our ability to maintain our revenue levels or to grow in the future depends upon, among other things, the continued success of our efforts to maintain our brand image and bring new products to market and our ability to expand within our current distribution channels and other distributors.

Our sales are dependent on the sales of our customer’s products.

Because our PU leather products are part of our customers’ products, our sales and success is dependent on the success of our customers’ products. If our customers’ products are no longer popular, and our customers reduce the purchase for our products, this will have an adverse effect on our revenues.

If we do not accurately forecast consumer demand, we may have excess inventory to liquidate or have greater difficulty filling our customers' orders, either of which could adversely affect our business.

The shoe manufacturing industry is subject to cyclical variations, consolidation, contraction, and closings, as well as fashion trends, rapid changes in consumer preferences, the effects of weather, general economic conditions, and other factors affecting demand. These factors make it difficult to forecast our product demand and, if we overestimate demand for our products, we may be forced to liquidate excess inventories at a discount to customers, resulting in markdowns and lower gross margins. Conversely, if we underestimate customer demand, we could have inventory shortages, which can result in lost potential sales, delays in shipments to customers, strains on our relationships with customers and diminished brand loyalty. Moreover, because our product line is limited, we may be disproportionately affected by cyclical downturns in the shoe manufacturing industry, changes in consumer preferences, and other factors affecting demand, which may make it more difficult for us to accurately forecast our production needs, exacerbating these risks. A decline in demand for our products, or any failure on our part to satisfy increased demand for our products, could adversely affect our business and results of operations.

We are dependent on sales of a small number of products, and the absence of continued market demand for these products would have a significant adverse effect on our operating results.

We generated approximately 80.14% and 81.85% of our revenues for the years ended December 31, 2011 and 2010 from sales of PU leather products. Because we are dependent on a line of footwear models that have substantial similarities, factors such as changes in consumer preferences and general market conditions in the shoe manufacturing industry may have a disproportionately greater impact on us than on our competitors. In addition, other footwear companies have introduced products that are substantially similar to our footwear models, which may reduce sales of our footwear products. In the event that consumer preferences evolve away from our footwear models or from casual lifestyle footwear in general, or if our retail customers purchase similar products sold by our competitors, the resulting loss of sales, increase in inventories and discounting of our products are likely to be significant, which could have a material and adverse impact on our business and operations.

Our accounting staff and Board of Directors have limited knowledge of US GAAP.

All of our operations are located in the PRC, and we keep our books and records in accordance with PRC GAAP, which are then converted into financial statements prepared in accordance with US GAAP. Although we have hired a senior manager to assist in the preparation of our financial statements in accordance US GAAP, we do not have a large staff that has knowledge of or experience with US GAAP. In addition, at this time, our Board of Directors serve as the audit committee and our members are not experienced with and have limited knowledge of US GAAP. As a result, there is a risk that in light of our staff and Board of Directors with limited US GAAP knowledge and experience, that our financial statements may not be in compliance with US GAAP.

| 18 |

We cannot evaluate the effectiveness of our Internal Control over Financial Reporting.

In accordance with Sarbanes Oxley, we are required, on an annual basis, to measure the effectiveness of our Internal Control over Financial Reporting. Due to limited personnel and funds, we have not develop a framework from which to determine whether our internal controls over financial reporting are effective. As a result, we cannot conclude whether our internal controls over financial reporting are effective or ineffective for the year ended December 31, 2011.

Our operating results are dependent on a number of factors which may cause our operating results to fluctuate from time to time .

Our operating results may fluctuate from period to period and will depend on numerous factors, including customer demand and market acceptance of our products, new product introductions, product obsolescence, raw material price fluctuations, varying product mix, foreign currency exchange rates, foreign currency, income tax rates, timely payment and other factors. Our business is sensitive to the spending patterns of our end customers, which in turn are subject to prevailing economic conditions and other factors beyond the our control. If demand does not meet our expectations in any given period, the sales shortfall may result in an increased effect on operating results if we unable to adjust operating expenditures quickly enough to compensate for such a shortfall, which will affect our operating results.

Since we are dependent on a key customer, the loss of this customer would cause a significant decline in our revenues while a delay or failure to collect on trade receivables from our key customer will adversely affect our results of operations.

A large percentage of our accounts receivable is concentrated with one customer.

One distributor accounted for 20.9% of our accounts receivables as of December 31, 2011. The failure by this distributor to pay its accounts receivable would adversely affect our cash flow. In addition, we do not require collateral or security to support this distributor’s accounts receivable. Accordingly, if we are unable to receive payment from this distributor, our cash flow will be adversely affected.

We only have one customer and one distributor for our footwear business.

Our footwear segment which accounted for 19.86% and 18.15% of our gross revenues as of December 31, 2011 and 2010, respectively, is dependent on one distributor for Africa and the Middle East, and one customer for China. The loss of this distributor and/or customer will adversely affect our revenues and profitability.

We are guarantors to loans of unrelated third parties pursuant to a cross guarantee arrangement, and in the event of a default of the loans by the third party we will assume the liabilities of the third parties, which will adversely affect our operating results and business.

We have entered into arrangements with unrelated third parties pursuant to which we have agreed to guarantee their loans with financial institutions and exchange for a guarantee by the third parties for our loans with financial institutions. Although cross guarantee arrangements with unrelated parties in different industries are common in China, our business and results of operations will be adversely affected in the event the third parties default on their loans. As of December 31, 2011, the third parties were current with their obligations to the financial institution; however, if the third parties are unable to satisfy the terms of the loans, we will be obligated to assume the liabilities of the third parties.

| 19 |

Our limited operating history may not serve as an adequate basis to judge our future prospects and results of operations.