Attached files

| file | filename |

|---|---|

| 8-K - FORM 8-K - OLIN Corp | form8kbofaconf12052011.htm |

1

Bank of America

Merrill Lynch

Industrials Conference

December 6, 2011

December 6, 2011

Exhibit 99.1

2

Company Overview

All financial data are for the quarter and year-to-date period ending September 30, 2011 and for the year ending December 31, 2010. Data

are presented in millions of U.S. dollars except for earnings per share on a GAAP basis. 9 month 2011 results include a $181 million gain

associated with the remeasurement of Olin’s SunBelt interest, or $1.30 per share. Additional information is available at www.olin.com.

are presented in millions of U.S. dollars except for earnings per share on a GAAP basis. 9 month 2011 results include a $181 million gain

associated with the remeasurement of Olin’s SunBelt interest, or $1.30 per share. Additional information is available at www.olin.com.

Winchester

Chlor Alkali

Third Largest North American Producer of

Chlorine and Caustic Soda

Chlorine and Caustic Soda

Q3 2011 9Mos 2011 FY 2010

Revenue: $ 386 $ 1,066 $ 1,037

Income: $ 77 $ 195 $ 117

A Leading North American Producer of Small

Caliber Ammunition

Caliber Ammunition

Q3 2011 9Mos 2011 FY 2010

Revenue: $ 164 $ 450 $ 549

Income: $ 13 $ 37 $ 63

Revenue: $ 550 $ 1,515 $ 1,586

EBITDA: $ 103 $ 449 $ 188

Pretax Operating Inc.: $ 69 $ 353 $ 77

EPS (Diluted): $ .58 $ 2.76 $ .81

Q3 2011 9Mos 2011 FY 2010

Olin

3

Investment Rationale

• Leading North American producer of Chlor-Alkali

• Strategically positioned facilities

• Diverse end customer base

• Favorable industry dynamics

• Leading producer of industrial bleach with additional growth

opportunities

opportunities

• Pioneer and SunBelt acquisition synergies improved chlor-alkali

price structure

price structure

• Winchester’s leading industry position

• 340th consecutive quarterly dividend on 12/9/11, yield +4%

4

Chlor Alkali Segment

ECU = Electrochemical Unit; a unit of measure reflecting the chlor alkali process outputs

of 1 ton of chlorine, 1.13 tons of 100% caustic soda and 0.3 tons of hydrogen.

of 1 ton of chlorine, 1.13 tons of 100% caustic soda and 0.3 tons of hydrogen.

North

American

Position

American

Position

Percent

of 2010

Revenue

of 2010

Revenue

#2

#3

#1

Industrial

Industrial

#1

Merchant

Merchant

#1

Burner

Grade

Burner

Grade

42%

10%

4%

11%

32%

1%

Chlor Alkali Manufacturing Process

BRINE + ELECTROLYSIS = OUTPUTS

Caustic Soda - 1.13 Tons

(Sodium Hydroxide)

(Potassium Hydroxide)

Bleach

(Sodium Hypochlorite)

Chlorine - 1 Ton

Potassium Chloride

or

Sodium Chloride

KOH - 1.59 Tons

HCl

(Hydrochloric Acid)

Hydrogen Gas - 0.3 Tons

KOH

or

Caustic Soda

Chlorine

Hydrogen

1.8 Tons Salt &

.5 Tons Water

2.8 Megawatts Electricity

5

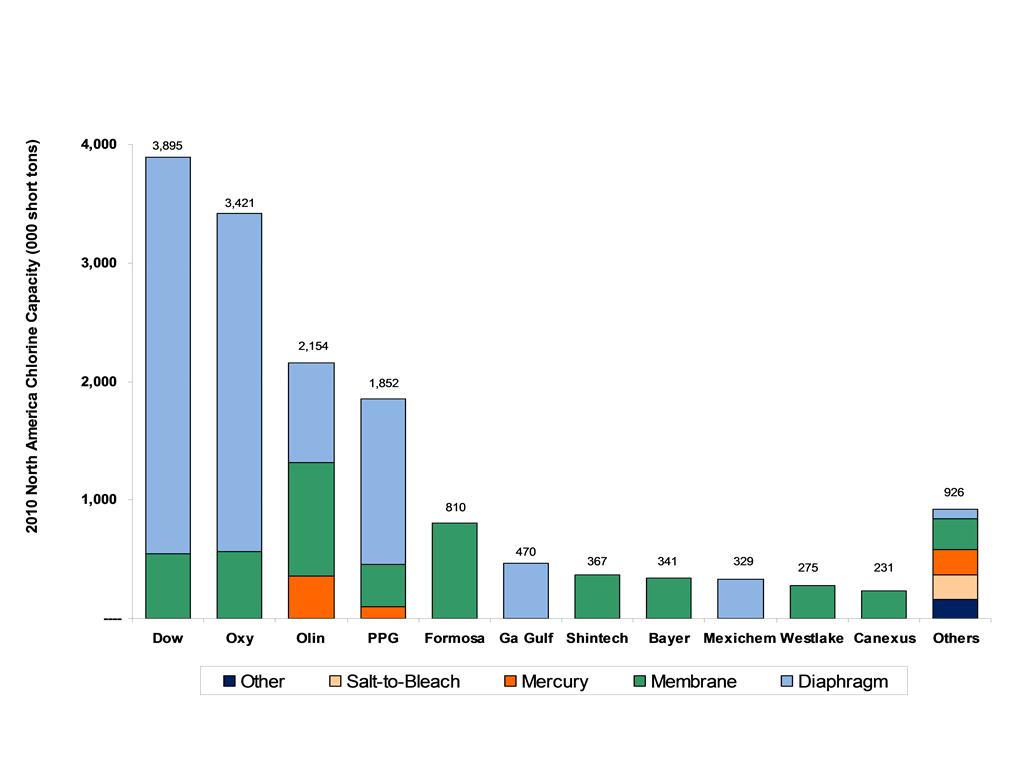

Olin is #3 Chlor-alkali Producer

Source: CMAI/Olin - 2010 year-end figures

Oxy includes OxyVinyls, PPG excludes Equa-Chlor and Olin includes 100% of SunBelt.

6

Mercury Transition Plan

• The North American Chlor Alkali industry has been moving

away from manufacturing chlorine and caustic soda using

mercury cell technology due to customer product de-selection

and threats of potential legislation

away from manufacturing chlorine and caustic soda using

mercury cell technology due to customer product de-selection

and threats of potential legislation

• Olin currently operates 2 mercury cell plants representing

approximately 360,000 ECUs or 17% of our total capacity

approximately 360,000 ECUs or 17% of our total capacity

• By the end of 2012, Olin expects to convert 200,000 ECUs

of mercury cell technology to membrane technology and will

shutdown the remaining 160,000 ECUs

of mercury cell technology to membrane technology and will

shutdown the remaining 160,000 ECUs

• Estimated cost is $160 million over 2 years, aided by $41

million of low-cost Tennessee-sponsored tax-exempt debt

million of low-cost Tennessee-sponsored tax-exempt debt

7

Capacity Rationalization

Favorable Industry Dynamics

Target

Acquisition

Date

Date

Position

2007

2004

• Acquired by Olin

• 725,000 Short Tons ECU Capacity

• 4.7% of North American capacity

• Acquired by OxyChem

• 859,000 Short Tons ECU Capacity

• 5.5% of North American capacity

Source: CMAI.

Pioneer

Vulcan

Industry Consolidation

1.4 mm MT

net capacity

net capacity

reduction; or

9% of 2000

capacity

mmMT

14.2

15.6

2010

2000

2010

• Acquired by Cydsa/Iquisa

• 45,000 Short Tons ECU Capacity

Mexichem

2011

• Olin acquired SunBelt interest

• 176,000 Short Tons ECU Capacity

PolyOne

Olin announced capacity reductions expected to be in place by 12/31/2012

2011

• Acquired by PPG

• 70,000 Short Tons ECU Capacity

Equa-Chlor

8

• On February 28, 2011, Olin purchased PolyOne’s 50%

interest in SunBelt for $132.3 million in cash plus the

assumption of a PolyOne guarantee related to the SunBelt

Partnership debt

interest in SunBelt for $132.3 million in cash plus the

assumption of a PolyOne guarantee related to the SunBelt

Partnership debt

• Olin and PolyOne agreed to a three-year earn out based on

the performance of SunBelt

the performance of SunBelt

• The SunBelt 352,000 ton membrane plant located within

Olin’s McIntosh, AL facility, which has been operated by

Olin since 1997, is now 100% owned by Olin

Olin’s McIntosh, AL facility, which has been operated by

Olin since 1997, is now 100% owned by Olin

• Olin recorded a pretax gain of approximately $181 million

and a deferred tax expense of $76 million as a result of an

accounting remeasurement associated with the value of its

original 50% interest in the SunBelt Partnership

and a deferred tax expense of $76 million as a result of an

accounting remeasurement associated with the value of its

original 50% interest in the SunBelt Partnership

Acquisition of PolyOne’s

Interest in SunBelt

Interest in SunBelt

9

SunBelt Acquisition Benefits

• Olin expects the acquisition to be accretive to both

EBITDA and earnings in 2011

EBITDA and earnings in 2011

• SunBelt currently has the lowest cash manufacturing

costs in the Olin system

costs in the Olin system

• SunBelt has a long-term contract for 250,000 tons of

chlorine per year

chlorine per year

• During Q3 2011, SunBelt contributed approximately

$12 million of incremental Chlor Alkali segment

earnings

$12 million of incremental Chlor Alkali segment

earnings

• Expected annual synergies of $5-10 million associated

with increased use of low cost capacity and increased

sales of membrane grade caustic soda

with increased use of low cost capacity and increased

sales of membrane grade caustic soda

10

Diverse Customer Base

Chlorine

Caustic Soda

North American Industry

Olin Corporation

Source: CMAI and Olin 2010 demand. Includes sales of SunBelt.

Chlorine: “Organics” includes: Propylene oxide, epichlorohydrin, MDI, TDI, polycarbonates. “Inorganics” includes: Titanium dioxide and bromine.

Caustic Soda: “Organics” includes: MDI, TDI, polycarbonates, synthetic glycerin, sodium formate, monosodium glutamate. “Inorganics” includes: titanium dioxide, sodium silicates, sodium cyanide.

11

Bleach Plants

39

Tacoma, WA

Tracy, CA

Santa Fe Springs, CA

Henderson, NV

St. Gabriel, LA

Augusta, GA

Charleston, TN

Niagara Falls, NY

Becancour,

Quebec

Olin’s Geographic Advantage

|

Location

|

Chlorine Capacity

(000s Short Tons)

|

|

McIntosh, AL

|

426 Diaphragm

|

|

McIntosh, AL - SunBelt

|

352 Membrane

|

|

Becancour, Quebec

|

252 Diaphragm

65 Membrane

|

|

Niagara Falls, NY

|

300 Membrane

|

|

Charleston, TN(1)

|

260 Mercury

|

|

St. Gabriel, LA

|

246 Membrane

|

|

Henderson, NV

|

153 Diaphragm

|

|

Augusta, GA(1)

|

100 Mercury

|

|

Total

|

2,154

|

• Access to regional customers including bleach and water treatment

• Access to alternative energy sources

– Coal, hydroelectric, nuclear, natural gas

(1) Announced the conversion of 200,000 tons of mercury cell technology to membrane cell technology at the Charleston, TN facility

and the closure of the mercury cell facility in Augusta, GA, both are expected to be completed by 12/31/12.

12

Why Industrial Bleach?

• Olin is the leading North American bleach producer with 18% market

share and current installed capacity to service 25% of the market with

low-cost expansion opportunities

share and current installed capacity to service 25% of the market with

low-cost expansion opportunities

• Bleach utilizes both chlorine and caustic soda in an ECU ratio

• Bleach commands a premium price over an ECU

• Demand is not materially impacted by economic cycles

• Regional nature of the bleach business benefits Olin’s geographic

diversity, further enhanced by Olin’s proprietary railcar technology to

reach distant customers

diversity, further enhanced by Olin’s proprietary railcar technology to

reach distant customers

• Low salt, high strength bleach investments will lower freight costs

• Bleach volumes accounted for almost 10% of total 2010 ECUs

produced; these volumes are expected to grow to 15% to 20%

produced; these volumes are expected to grow to 15% to 20%

13

Chlor-Alkali Outlook

• Q3 2011 ECU netbacks(1) of $590 are up sequentially for the eighth

consecutive quarter and $40 higher than the prior quarter

consecutive quarter and $40 higher than the prior quarter

• Positive price momentum from 2010 has continued in 2011:

Chlorine Caustic Soda

2010 Increases $ 50 $ 300

Q1 2011 $ 60 $ 100

April 2011 $ 50

June 2011 $ 25 (TVA)

August 2011 $ 65

November 2011 $ 80

• Q3 2011 operating rates remained at 85% despite several planned and

unplanned outages during the quarter

unplanned outages during the quarter

• Q4 2011 pricing and operating rates are expected to decrease as normal

seasonal weakness in the industry occurs

seasonal weakness in the industry occurs

(1) ECU netback = Price of 1 ton of Chlorine + 1.1 x price of 1 ton of Caustic Soda - Freight cost

14

Winchester Segment

Winchester Strategy

• Leverage existing strengths

– Seek new opportunities

to leverage the

legendary Winchester®

brand name

to leverage the

legendary Winchester®

brand name

– Investments that

maintain Winchester as

the retail brand of

choice, and lower costs

maintain Winchester as

the retail brand of

choice, and lower costs

• Focus on product line

growth

growth

– Continue to develop

new product offerings

new product offerings

• Provide returns in excess of

cost of capital

cost of capital

|

|

Hunters & Recreational Shooters

|

|

|

|

||

|

Products

|

Retail

|

Distributors

|

Mass

Merchants |

Law

Enforcement |

Military

|

Industrial

|

|

Rifle

|

ü

|

ü

|

ü

|

ü

|

ü

|

N/A

|

|

Handgun

|

ü

|

ü

|

ü

|

ü

|

ü

|

N/A

|

|

Rimfire

|

ü

|

ü

|

ü

|

ü

|

ü

|

ü

|

|

Shotshell

|

ü

|

ü

|

ü

|

ü

|

ü

|

ü

|

|

Components

|

ü

|

ü

|

ü

|

ü

|

ü

|

ü

|

Brands

15

Favorable Industry Dynamics

Commercial

• Economic environment leading to personal security concerns

• Fears of increased gun/ammunition control due to change in administration

• New gun and ammunition products

• Strong hunting activity in weak economy, driven by cost/benefit of hunting

for food and increased discretionary time

for food and increased discretionary time

Law

Enforcement

Enforcement

• Significant new federal agency contracts and solid federal law enforcement

funding

funding

• Higher numbers of law enforcement officers and increase in federal agency

hiring

hiring

• Increased firearms training requirements among state and local law

enforcement agencies

enforcement agencies

Military

• Sustained high demand for small caliber ammunition due to wars in Iraq and

Afghanistan

Afghanistan

• Awarded 5 year contract to supply the US Army 5.56mm, 7.62mm and 50

caliber ammunition; expected to generate $300 million in revenues over the

contract term

caliber ammunition; expected to generate $300 million in revenues over the

contract term

16

Winchester

• Q3 2011 segment earnings of $13.1 million include restructuring

charges associated with the move of centerfire operations to Oxford, MS

and higher commodity costs versus Q3 2010

charges associated with the move of centerfire operations to Oxford, MS

and higher commodity costs versus Q3 2010

• In response to higher metals costs, Olin and two other North American

producers announced price increases that became effective in June or

July

producers announced price increases that became effective in June or

July

• The U.S. Army awarded Winchester a 5 year contract to produce .50

caliber, 5.56mm and 7.62mm ammunition beginning Q1 2012 providing

expected revenues of approximately $300 million

caliber, 5.56mm and 7.62mm ammunition beginning Q1 2012 providing

expected revenues of approximately $300 million

• As a result of the continued stronger than expected demand, we see no

indication that the normal 20% to 30% reduction in demand that

typically follows a surge will occur following this buying surge

indication that the normal 20% to 30% reduction in demand that

typically follows a surge will occur following this buying surge

• Last quarter, a 5.5 year labor agreement was reached with the East

Alton, IL unions that will facilitate a smooth transition to Oxford

Alton, IL unions that will facilitate a smooth transition to Oxford

17

Centerfire Relocation

• The decision to relocate Winchester’s centerfire operations,

including 1,000 jobs, was made on November 3, 2010

including 1,000 jobs, was made on November 3, 2010

• The controlled relocation process is expected to take up to 5

years to complete assuring high quality product is available

for our customers.

years to complete assuring high quality product is available

for our customers.

• Successful equipment relocation began in Q3 2011

• In 2011, we expect a $4 to $5 million negative pretax impact

on earnings associated with the relocation project

on earnings associated with the relocation project

• Annual operating costs are forecast to be reduced by $30

million once the move is complete

million once the move is complete

• The net project cost is estimated to be $80 million, of which

approximately $50 million is related to capital expenditures

approximately $50 million is related to capital expenditures

• $42 million of low-cost Mississippi-sponsored tax-exempt

debt has been made available to the company

debt has been made available to the company

18

Financial Highlights

• Strong Balance Sheet

– The Q3 2011 cash balance of $390 million reflects the use of

$132 million to acquire PolyOne’s 50% interest in SunBelt

and approximately $71 million for working capital

$132 million to acquire PolyOne’s 50% interest in SunBelt

and approximately $71 million for working capital

– Pension plans remain fully funded with no contributions

expected until at least 2013

expected until at least 2013

– 2011 CAPEX is forecast to be $255 million, approximately

65% relates to the mercury conversion and Oxford relocation

65% relates to the mercury conversion and Oxford relocation

• Profit Outlook

– ECU pricing trends are positive driven by caustic increases

– Higher margin bleach business is growing

– Acquisition of PolyOne’s interest in SunBelt is expected to

be significantly accretive to EBITDA and earnings in 2011

be significantly accretive to EBITDA and earnings in 2011

19

Forward-Looking Statements

This presentation contains estimates of future

performance, which are forward-looking

statements and actual results could differ

materially from those anticipated in the forward-

looking statements. Some of the factors that could

cause actual results to differ are described in the

business and outlook sections of Olin’s Form 10-K

for the year ended December 31, 2010 and in

Olin’s Third Quarter 2011 Form 10-Q. These

reports are filed with the U.S. Securities and

Exchange Commission.

performance, which are forward-looking

statements and actual results could differ

materially from those anticipated in the forward-

looking statements. Some of the factors that could

cause actual results to differ are described in the

business and outlook sections of Olin’s Form 10-K

for the year ended December 31, 2010 and in

Olin’s Third Quarter 2011 Form 10-Q. These

reports are filed with the U.S. Securities and

Exchange Commission.