Attached files

| file | filename |

|---|---|

| 8-K - 8-K - MARKWEST ENERGY PARTNERS L P | a11-26987_18k.htm |

Exhibit 99.1

|

|

September 27, 2011 Houston, Texas MarkWest Liberty Project Mariner Platts NGLs Forum |

|

|

Forward-Looking Statements This presentation contains forward-looking statements and information. These forward-looking statements, which in many instances can be identified by words like “could,” “may,” “will,” “should,” “expects,” “plans,” “project,” “anticipates,” “believes,” “planned,” “proposed,” “potential,” and other comparable words, regarding future or contemplated results, performance, transactions, or events, are based on MarkWest Energy Partners, L.P. (“MarkWest” and “Partnership”) current information, expectations and beliefs, concerning future developments and their potential effects on MarkWest. Although we believe that the expectations reflected in the forward-looking statements are reasonable, we can give no assurance that such expectations will prove to be correct, and actual results, performance , distributions , events or transactions could vary significantly from those expressed or implied in such statements and are subject to a number of uncertainties and risks. Among the factors that could cause results to differ materially are those risks discussed in the periodic reports we file with the SEC, including our Annual Report on Form 10-K for the year ended December 31, 2010, and our Quarterly Report on Form 10-Q for the quarter ended June 30, 2011. You are urged to carefully review and consider the cautionary statements and other disclosures, including those under the heading “Risk Factors,” made in those documents. If any of the uncertainties or risks develop into actual events or occurrences, or if underlying assumptions prove incorrect, it could cause actual results to vary significantly from those expressed in the presentation, and our business, financial condition, or results of operations could be materially adversely affected. Key uncertainties and risks that may directly affect MarkWest’s performance, future growth, results of operations, and financial condition, include, but are not limited to: Fluctuations and volatility of natural gas, NGL products, and oil prices; A reduction in natural gas or refinery off-gas production which we gather, transport, process, and/or fractionate; A reduction in the demand for the products we produce and sell; Financial credit risks / failure of customers to satisfy payment or other obligations under our contracts; Effects of our debt and other financial obligations, access to capital, or our future financial or operational flexibility or liquidity; Construction, procurement, and regulatory risks in our development projects; Hurricanes, fires, and other natural and accidental events impacting our operations, and adequate insurance coverage; Terrorist attacks directed at our facilities or related facilities; Changes in and impacts of laws and regulations affecting our operations and risk management strategy; and Failure to integrate recent or future acquisitions. 2 |

|

|

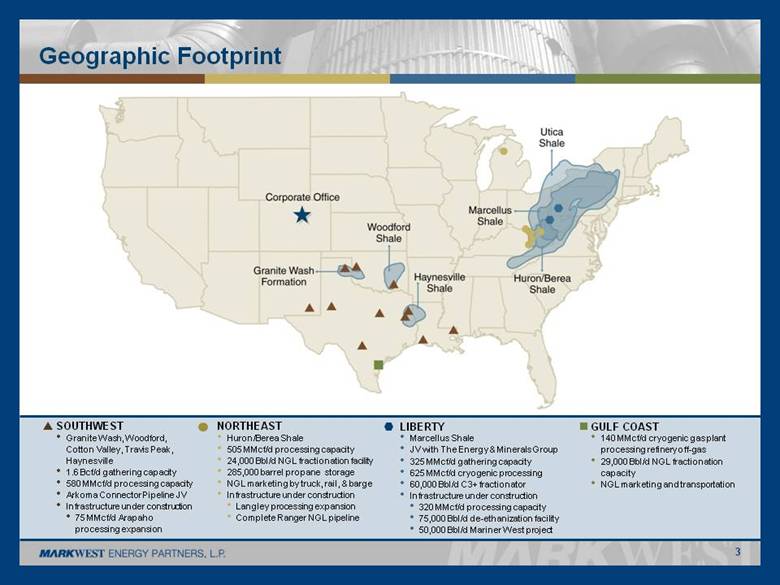

Geographic Footprint SOUTHWEST Granite Wash, Woodford, Cotton Valley, Travis Peak, Haynesville 1.6 Bcf/d gathering capacity 580 MMcf/d processing capacity Arkoma Connector Pipeline JV Infrastructure under construction 75 MMcf/d Arapaho processing expansion NORTHEAST Huron/Berea Shale 505 MMcf/d processing capacity 24,000 Bbl/d NGL fractionation facility 285,000 barrel propane storage NGL marketing by truck, rail, & barge Infrastructure under construction Langley processing expansion Complete Ranger NGL pipeline LIBERTY Marcellus Shale JV with The Energy & Minerals Group 325 MMcf/d gathering capacity 625 MMcf/d cryogenic processing 60,000 Bbl/d C3+ fractionator Infrastructure under construction 320 MMcf/d processing capacity 75,000 Bbl/d de-ethanization facility 50,000 Bbl/d Mariner West project GULF COAST 140 MMcf/d cryogenic gas plant processing refinery off-gas 29,000 Bbl/d NGL fractionation capacity NGL marketing and transportation 3 |

|

|

Growth Driven by Customer Satisfaction 4 Since 2006, MarkWest has Ranked #1 or #2 in Natural Gas Midstream Services Customer Satisfaction EnergyPoint Research, Inc. Customer Satisfaction Survey |

|

|

MarkWest Liberty Overview Joint Venture with The Energy & Minerals Group Partners one of the best midstream companies with a strong financial partner that shares a common view towards the value of the Marcellus Competitive advantages Significant first mover advantage in the prolific Marcellus Shale with key producer production commitments and acreage dedications in excess of 400,000 liquids-rich acres Critical gathering, processing, transportation, fractionation, storage, and marketing infrastructure On-site NGL storage capacity of approximately 52,000 barrels with access to more than 1MM barrels of additional dedicated storage Extensive NGL marketing experience in the Northeast Market Access Interconnected to Columbia Gas Transmission (CGT), National Fuel, TETCO, and TEPPCO Products Pipeline 50,000 Bbl/d Mariner West Project to deliver Marcellus ethane to Sarnia, Ontario markets under construction Gas gathering capacity 325 MMcf/d gathering capacity More than 200 miles of pipe and 72,000 hp of compression Cryogenic gas processing capacity 625 MMcf/d current 945 MMcf/d by mid-2012 NGL fractionation capacity 60,000 Bbl/d C3+ fractionation capacity 75,000 Bbl/d de-ethanization facility under construction 5 |

|

|

MarkWest Liberty’s Processing Complex Supports Ethane Recovery Since 2008, MarkWest Liberty has developed 625 MMcf/d of gas processing capacity in the Marcellus By mid-2012, MarkWest Liberty expects to add up to 320 MMcf/d for a total of 945 MMcf/d of gas processing capacity Today, MarkWest Liberty has 35 miles of Y-grade pipeline with 48,000 Bbl/d of capacity. By the end of 2012, this will increase by 65 miles to a total of 100 miles In August 2011, the Houston fractionator began operations with an initial capacity of 60,000 Bbl/d of C3+ With the addition of de-ethanization at the Houston and Majorsville processing complexes, MarkWest Liberty will be able to recover sufficient ethane to meet pipeline specifications with the ability to expand to allow for additional ethane recovery 6 |

|

|

Liberty Marcellus Project Schedule 7 Mobley Processing Complex Under Construction Mobley I (2Q12) 120 MMcf/d NGL Pipeline to Majorsville (2Q12) Majorsville Processing Complex Majorsville I and II 270 MMcf/d NGL Pipeline to Houston Houston Processing Complex Houston I, II, and III 355 MMcf/d C3+ fractionation 60,000 Bbl/day C3 pipeline TEPPCO deliveries NGL Storage 1.3MM bbls Truck loading 8 bays Under Construction Rail Loading (4Q11) 200 Rail Cars De-ethanization (3Q13) 75,000 Bbl/day Mariner West ethane pipeline (3Q13) 50,000 Bbl/day MarkWest Liberty is developing integrated and scalable gathering, processing, fractionation, and marketing infrastructure to support production in excess of 1 Bcf/d Sherwood Processing Complex Under Construction Sherwood I (3Q12) 200 MMcf/d NGL Pipeline to Mobley (3Q12) TEPPCO PRODUCTS PIPELINE Majorsville I,II Houston I,II,III Mobley I Sherwood I MARINER WEST |

|

|

In the Heart of the Shale Opportunities 8 Siloam Langley Kenova Cobb Kermit Boldman Majorsville Houston Mobley Marcellus Shale Huron Shale Utica Shale Sherwood |

|

|

MarkWest Liberty Propane Supply and Distribution 9 MarkWest Liberty has invested significant capital to develop a world-class NGL fractionation, storage, and marketing complex with pipeline, rail, and truck facilities Northeast markets can support significant propane sales from the Marcellus MarkWest Liberty will continue to develop additional pipeline, rail, and truck markets to further optimize NGL sales in the Northeast markets |

|

|

Marcellus Ethane 10 In September 2011, MarkWest Liberty announced the development of three large de-ethanizers at its Houston and Majorsville processing complexes The first phase will have capacity of ~75,000 Bbl/d and will commence operation in mid-2013 to coincide with the start-up of Mariner West The second phase will increase the capacity to more than 115,000 Bbl/d of ethane MarkWest will also construct an ethane pipeline to transport ethane from Majorsville to Houston MarkWest Liberty has the ability to recover ethane at all of its processing plants and to transport the ethane to de-ethanization facilities via its extensive NGL gathering system MarkWest Liberty provides Marcellus producers with optimal NGL infrastructure to maximize ethane economics Marcellus Ethane Production Versus MarkWest Liberty Ethane Fractionation Capacity MW Liberty Planned Ethane Fractionation Capacity MW Liberty Future Ethane Fractionation Capacity |

|

|

Mariner West Ethane Pipeline 11 Houston Fractionator Mariner West New MarkWest Liberty Pipeline Existing Sunoco Pipeline Sarnia Pittsburgh Philadelphia In September, Sunoco Logistics announced the successful open season for Mariner West and the execution of definitive transportation agreements MarkWest Liberty will install de-ethanization at the Houston fractionation complex and will construct a 40-mile liquid ethane pipeline to connect to the Sunoco pipeline system Sunoco Logistics will utilize its existing pipeline network to deliver purity ethane to petrochem markets in Sarnia, Ontario, Canada Mariner West will have initial capacity of up to 50,000 Bbl/day and will be operational by mid-2013 A purity-ethane project to petrochem markets in Sarnia, Ontario, Canada |

|

|

Mariner East Ethane Pipeline 12 Houston Fractionator Mariner East Mariner West New MarkWest Liberty Pipeline Existing Sunoco Pipeline Existing Sunoco Pipeline Sarnia Pittsburgh Philadelphia A purity-ethane project to premium Gulf Coast / International markets MarkWest Liberty would construct a 45-mile liquid ethane pipeline to connect to the Sunoco pipeline system Sunoco Logistics would convert its existing 250-mile, 8-inch refined products pipeline to liquid ethane service, would construct refrigerated ethane storage facilities, and would load the ethane onto refrigerated LPG carriers for transport Mariner East would have initial capacity of up to 50,000 Bbl/day and would be operational in mid-2013 |

|

|

Project Mariner: A Comprehensive Ethane Solution MarkWest Liberty and Sunoco Logistics are developing efficient and scalable ethane projects that meet the producers’ ethane production schedule and provide access to attractive NGL markets in North America and Europe Project Mariner requires minimal pipeline construction – a combined total of 85 miles of new pipe is required to deliver ethane to Sarnia, Gulf Coast, and European markets Mariner would have access to ethane storage at Sarnia, Philadelphia, and the Gulf Coast near Nederland, Texas Timely start up of Mariner West in July 2013 for transportation to Sarnia with potential future ethane deliveries to favorable European and Gulf Coast markets via Mariner East The capacity of Sunoco Logistics’ 8-inch pipeline to Philadelphia can be increased to meet increased demand 13 Sarnia Pittsburgh Gulf Coast Philadelphia |

|

|

MarkWest Liberty Project Mariner Platts NGLs Forum |