Attached files

| file | filename |

|---|---|

| EX-31.2 - CERTIFICATION - Bioflamex Corp | exhibit31-2.htm |

| EX-31.1 - CERTIFICATION - Bioflamex Corp | exhibit31-1.htm |

| EX-31.1 - CERTIFICATION - Bioflamex Corp | exhibit32-1.htm |

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10-K

[X] ANNUAL REPORT UNDER SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934

For the fiscal year ended February 28, 2011

[ ] TRANSITION REPORT UNDER SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT

For the transition period from _________ to ________

Commission file number: 000-53712

BIOFLAMEX CORPORATION

(Exact name of registrant as specified in its charter)

| Nevada | Pending |

| (State or other jurisdiction of incorporation or organization) | (I.R.S. Employer Identification No.) |

| Christiansvej 31, 2920 Charlottenlund, Denmark | ________ |

| (Address of principal executive offices) | (Zip Code) |

Registrant’s telephone number: 646-233-1310

Securities registered under Section 12(b) of the Exchange Act:

| Title of each class | Name of each exchange on which registered |

| None | not applicable |

Securities registered under Section 12(g) of the Exchange Act:

Title of each class

Common Stock, $0.001 par value

Indicate by check mark if the

registrant is a well-known seasoned issuer, as defined in Rule 405 of the

Securities Act.

Yes [ ] No [X]

Indicate by check mark if the

registrant is not required to file reports pursuant to Section 13 or Section 15(d)

of the Act.

Yes [ ] No [X]

Indicate by checkmark whether the

registrant (1) has filed all reports required to be filed by Section 13 or

15(d) of the Securities Exchange Act of 1934 during the proceeding past 12

months (or for such shorter period that the registrant was required to file

such reports), and (2) has been subject to such filing requirements for the

past 90 days.

Yes [ ] No [X]

Indicate by check mark whether

the registrant has submitted electronically and posted on its corporate Web

site, if any, every Interactive Data File required to be submitted and posted

pursuant to Rule 405 of Regulation S-T (§ 232.405 of this chapter) during the

preceeding 12 months (or for such shorter period that the registrant was

required to submit and post such files).

Yes [ ] No [X]

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K (§ 229.405 of this chapter) is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. [ ]

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company. See the definitions of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act.

| Large accelerated filer [ ] | Accelerated filer [ ] |

| Non-accelerated filer [ ] (Do not check if a smaller reporting company) | Smaller reporting company [X] |

Indicate by check mark whether

the registrant is a shell company (as defined in Rule 12b-2 of the Exchange

Act).

Yes [ ] No [X]

State the aggregate market value of the voting and non-voting common equity held by non-affiliates computed by reference to the price at which the common equity was last sold, or the average bid and asked price of such common equity, as of the last business day of the registrant’s most recently completed second fiscal quarter. Unavailable

Indicate the number of shares outstanding of each of the registrant’s classes of common stock, as of the latest practicable date. 92,466,667 as of March 16, 2011.

2

TABLE OF CONTENTS

3

PART I

Item 1. Business

Corporate History

Up to January 25, 2011, we were an exploration stage company engaged in the acquisition and exploration of mineral properties. On March 18, 2008, we entered into a mineral property purchase agreement with Laurence Stephenson to acquire a 100% interest in a mineral claim known as the Emmy Claim located in the Emory Creek area of the New Westminster Mining Division, British Columbia, Canada. This claim expired on January 25, 2010 and was re-staked on February 4, 2010 by Teuton Resources Corp. (“Teuton”). We entered into a Letter and Trust Agreement with Teuton dated February 4, 2010 and paid Teuton Cnd$500 to hold the re-staked Emmy Claim in trust for us.

The Emmy Claim is in good standing until February 4, 2011. As a result of our recent acquisition of certain intellectual property related to the business of fire extinguishing and prevention products, however, we have decided to pursue that new line of business and allow the Emmy Claim to expire in February, 2011.

Business Overview

We are now in the business of developing, producing, and marketing high performance fire extinguishing and prevention products that are based on environment friendly and biological formulations. We have changed our name to Bioflamex Corporation to reflect our new line of business.

We intend to build a leading position within the niche of environmentally friendly fire fighting and prevention solutions in the United States and internationally, both through organic growth and the acquisition of complementary companies and patents. We believe the time is right for our products. The general emphasis on environmental protection and the increased focus on health hazards in chemicals used in conventional fire fighting products paves the way for the substitution of chemical-based fire combatant products with “greener,” non-harmful products.

Fire extinguishers available on the market today mainly use dry chemical powder, chemical foam, CO2 or halon type of gaseous media as bases. These products in general will extinguish fires with a varying efficacy, but most also contain chemical substances that harm the environment or compose a hazard to people. In addition, they can be messy and damage metals (corrosion), increasing the collateral damage. Our products offer water-based clean alternatives which are completely harmless to humans and the environment, and are non-toxic. Combined with their exceptional extinguishing characteristics, we believe these products point to the future of professional and personal fire fighting. In conventional forest fire fighting, the primary media is water which offers good extinguishing power, but has some drawbacks: it must be used in large quantities; it evaporates relatively quickly; and has a short lifespan in hot environments. Chemical AFFF foams and agents are often used to enhance the fire extinguishing or retardant capabilities, but these chemicals affect the environment and leave long-lasting toxic residue. The toxins found in foams accumulate in the food-chain and are detectable in human organs. We believe our products will have no such negative effect upon life.

4

We are in the final stages of testing and development of our proprietary range of products. Our goal is to develop 5-10 unique product formulations and application concepts covering fire fighting and fire prevention. We intend to market our products under the trademarks Bioflamex® and SAFIRE®. Our goal is to penetrate the key United States and international markets with our “clean” fire extinguishing products and fire retardants.

We are currently preparing and submitting United States and international patent applications for our product concepts to ensure the security of our intellectual property rights and enhance the market response to our product propositions. We hope to build a solid portfolio of intellectual property within the industry that can be licensed to third parties. We are currently in the process of applying for patents on our revolutionary products and processes.

We are also preparing the materials necessary to complete the necessary tests, approvals and certifications in the United States and key international markets, that are the prerequisite for sales and marketing. With these approvals and certifications, we hope to gain a solid geographical presence in the United States, key markets in Europe, the Middle East and parts of Asia. We intend to work through distribution partners, agents and/or license holders, and through that presence achieve strong sales with the consumers, professional, business, industrial and government service market segments.

Our Products

We own the flag-ship brands SAFIRE® (a long-lasting fire retardant that can be safely used on any surface) and Bioflamex® (a biodegradable, fast-acting, PFC-free fire extinguishing foam spray). These products can be sold to governments, professional clients, businesses and private users, and can be used in a wide variety of situations from ranging from small stove fires to oil and forest fires.

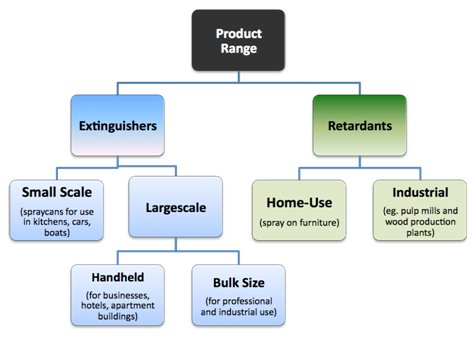

Our products can be divided into two main product types: fire extinguishers (fight fires once they start) and fire retardants (fight fires before they start). Our product range is set forth in the figure below. The scope of business covered by the product range is diverse and targets professional markets, business to business markets and consumer markets across the globe.

5

Of the various industry segments, we intend to focus our business on biological fire fighting. The table below depicts the various industry segments, those industry segments we intend to engage in, and the types of extinguishers and retardants we expect to develop in those segments.

Given that most current fire fighting- and prevention methods contain toxins and chemicals that can harm humans, animals, and entire ecosystems, there is a real market requirement for more eco-friendly fire fighting methods. In that space, there are small number of independent companies, usually limited in geographic scope and characterized by entrepreneurship and a limited product range. We believe that we are well-positioned to take a significant role in a relatively new “clean” niche of the market. We intend to capture market share by organic growth and from acquisitions to make us the foremost player in this segment.

6

Extinguishers

Small Scale Extinguishers:

Bioflamex aerosol spray is a water-based portable fire extinguishing product that has been designed to put out oil and grease fires. We have dubbed the concept as “the Red Bull of the fire fighting industry.” Bioflamex has been developed as a user friendly, efficient and safe supplement to conventional fire fighting means. Anyone can easily use Bioflamex to quickly and efficiently extinguish dangerous and potentially fatal frying oil or cooking fat kitchen fires.

Bioflamex has been in development for a considerable period of time. Following a series of trials and tests the developers have created the perfect combination of the extinguishing media, the bottle, the nozzle, the propellant and the pressure.

The extinguishing media is based on a biological formula that is composed of a mix of water, natural potassium, salt combinations and plant root extracts in combinations with a concentrated foaming agent. The contents are under pressure in the can and the propellant is carbonic acid.

Bioflamex is characterized by its significant “clean” extinguishing performance, as well as easy and convenient handling. The biological formulation provide some benefits outside the pure extinguishing attributes, namely the benefits of less collateral damage and clean-up after use. It is non-toxic, non-corrosive and bio degradable.

The Bioflamex formula provides 2 significant performance criteria: The biological additive ensures quick knock-down of flames; and the special foam formulation creates a cover that prevents re-ignition of flames, especially relevant when combating oil based fires.

It is expected that Bioflamex will be produced in 2 different sized bottles:

· 650 ml for home and professional use in conjunction with cooking (kitchens, grill)

· 800ml for use in boats, cars, camping etc.

In the smaller bottles for kitchen use, the product contains a heavy PFC-free foam concentration which is developed to tackle Class F/K fire types, i.e. frying oils and fats used in conjunction with cooking.

The larger 800ml bottle is ideal for more all-round emergency/first response extinguishing use. It contains a smaller amount of foam, and is suited for engine fires in cars/boats and Class A/B fire types, i.e. on dry matter such as textiles, wood etc.

Consequently, the Bioflamex products can be targeted towards both the private consumer market as well as small businesses.

7

The product highlights are as follows:

|

|

We believe this product is an ideal and vital product for private households, and boat and car owners for the growing United States market. It is the right product to always have handy in the kitchen, in the boat, in the auto camper or in the car.

Large Scale Extinguishers:

Our large-scale extinguishing products provide a viable and sustainable alternative to conventional products in terms of performance, environment and health. They have been tested extensively by professional institutes, and have proven to be radical improvement over extinguishers available on the market today.

Using the same base formulations of biological additives and foam, BioflamexCorp will also enter the market for conventional fire-sized extinguishers, i.e. the 2, 3 and 6 liter EN-3 types.

The formulation ensures effective extinguishing performance against Class A, B and C fires, providing a broad base of usage in circumstances such as small wildfires and urban residential buildings.

8

Ideal users would be businesses, offices, hotels and public spaces where fire regulations dictate fire extinguishers as part of the general fire safety and emergency plan.

We believe the biological water based extinguisher type will gain market share and revenue on account of substitution for existing chemical foam and chemical powder extinguishers.

Bulk Extinguishers:

The bulk products will be formulated to suit large-scale extinguishing tasks such as fighting fires on professional equipment and tankers, or forest fire fighting.

The solutions can be tailored to fit various needs of professional fire fighting organizations and large business operations, forest fire fighting and prevention, chemical compounds, oil and gas installations and storage facilities.

The extinguisher formulations have proven to be extremely efficient in fighting heavy fuel fires, such as diesel oil, petroleum and jet fuel, especially in combination with systems like IFEX. Since the properties of the product enable the use of less fluids to put out a fire it reduces damage to machines and property.

Through a series of tests, the products demonstrated unparalleled extinguishing power, reducing both the consumption of solution, collateral damage and the burden on the environment. Some examples are as follows:

- A mock-up aircraft-engine fire was extinguished with only 13 liters of foam in under 120 seconds.

- A full blaze car fire was extinguished with only 7 liters of foam in under 2 minutes.

These cases show Bioflamex can provide users dramatic reductions in direct costs of operations, both in terms of manpower and materials.

The biological ingredients are non-toxic and non-corrosive, posing no threat to human beings. In gaseous form they can even act as direct replacement of Halon and other chemical substances.

In various formulations, Bioflamex’s bulk extinguishers can be used for:

9

- Oil and gas industries (class A, B, C, D and K fires)

- Professional systems for Fire brigades

- Wood and forest fires (class A, C)

- Rubber fires

- Trains and busses

- Furniture and textiles

- Natural gas and oil plants

- Telecom facilities

- Industrial machines

- Shipping

Fire Retardants

Industrial retardants:

A fire retardant inhibits fire from being nurtured in textiles, wood, insulation materials etc., and therefore obstructs fires from erupting or spreading. Many different industrial types of fire retardants exist today, but many contain chemicals or compounds that may be harmful to people, the environment or materials - bromides have been banned due to some of these reasons.

Every year over thousands are killed or seriously wounded in fires. Often fires are caused by cigarettes, decorations, open fire or electrical malfunctions. The typical places for fires to start are in kitchens, living rooms, meeting rooms and bedrooms, where furniture or textiles catch fire. The risk of a fire is especially pronounced during Christmas, where the use of candles and dry decorations are a real threat.

|

We will market our industrial retardants under the brand name SAFIRE®. Due to their effectiveness and harmless eco-friendly components, SAFIRE® fire retardants can ensure that a damaging fire becomes a less likely event both at home and in the office. All SAFIRE® products are based on 100% biological components, which contain fire inhibiting capabilities. This makes it possible to treat textiles, wood and insulation materials in a safe and environment friendly way. SAFIRE® not only slows down the spread of fire, but in most instances completely prevents ignition. The active ingredients are mainly composed of salt combinations and extracts. The remaining substance is water, used to ensure that the active ingredients are absorbed in the fibers or mass. We are developing our industrial fire retardants to fit most scales and production circumstances; from furniture in the home, to industrial protection of warehouses filled with textiles, insulation, construction materials, and pulp, paper and wood. |

10

Forest Fire Prevention Retardants:

Forest fires are certain to proliferate in the coming decades, due to climate changes especially in the United States, Spain, Greece, France, and Australia.

The number of wildfires in the United States range from 60,000-75,000 annually costing more than US$1.4 billion in direct damages, but long term effects on ecosystems and personal lives are far beyond that number

In the past few years, California has experienced a number of fires, with increasing intensity and property damage. In 2008 alone, extensive wildfire events led to both civilian casualties and casualties amongst the fire fighting units combating the fires, and led to State of Emergency called by the President. Such events are recurring and have an ever more pronounced effect on the environment and urban planning, as fires draw closer to urbanized/residential areas.

For most government agencies in the United States and globally, the emphasis has now been put on prevention of forest wildlife fires to erupt, and improved preventative measures to reduce risks, especially in “high seasons” of March, July and August.

We will provide an eco friendly and highly effective solution to promote better forest fire prevention. The company is working on several levels to develop new methods to enhance fire protection in the high risk areas, and to improve protection of residential/industrial compounds/facilities.

We hope to develop the following:

- Biological fire retardant that is effective for up to 2-3 months after application to vegetation, acting as passive “fire barriers” that can protect areas of high risk. It is the intention that forest fire services can utilize the product before fire breaks out, for example covering areas around camping sites. The product is also intended to be used to reinforce safe zones and fire breaks as the event unfolds.

- A residential concept where garden facility services companies offer to protect the perimeter of private or business compounds, by spraying the fire retardant onto vegetation around perimeter at relevant intervals.

- A business concept where the fire retardant is used in fixed detection and suppression systems, that protect sensitive installations such as mobile antennas located in forest areas, to reduce commercial loss in the event of fires

Internationally, wildfires compose an equally threatening phenomenon. It is believed that in Spain alone, the incidents will increase from about 25,000 fires a year up to about 50,000 in a years to come due to dryer and warmer climate – or if the number of incidents do not escalate, then the intensity is believed to increase with larger burnt area per fire incident. “Desertification” is a real threat to many areas as a result of this, contributing to further climate warming in local and regional areas. The same trend is applicable to Australia, which has experienced an increasing number of uncontrollable wildfires that approach urban areas such as Melbourne and Sydney, causing extensive damage and casualties.

11

Patent Applications

We are in the process of submitting a host of patent applications to enhance our intellectual property rights and marketing opportunities.

In general, we operate within the following categories:

| - Fire fighting category – fire extinguishing products |

| - Fire prevention category – fire retardant products |

Our main products have a base consisting of biological water based solutions, either by itself or in combination with specialized foam types.

We work with a range of key partners for product development and production:

- Solberg Foams in Norway (foam development and sourcing)

- Samson Enviro in Denmark (biological base sourcing)

- Dansoll in Denmark (production of aerosols)

- PL Brandteknik (product development consultancy)

- Prime Solutions in Spain/US (Sentinel fire detection and suppression system)

- Paper Manufacturer TBD (fire protected cardboard boxes)

- Insulation Manufacturer TBD (fire protected wall/roof insulation and panelling)

The outcome of our product development efforts will result in BioflamexCorp taking full or partial intellectual property rights on product concepts and formulations. Below is a summary of the most imminent patent application we would like to submit to ensure protection of those rights. The first two could be submitted as one general application, as the basic formulations are more or less the same, except that foam concentrations vary.

- Bioflamex Extinguishing Foam Spray (Aerosol) for Kitchen Use

The Patent Application Number 1100255.7 registered at the Intellectual Property Office (IPO) at Concept House, Cardiff Road, Newport, South Wales, United Kingdom covers this patent. We are currently in the process of filing a counterpart patent with the United States Patent and Trademark Office (USPTO).

Basically, the kitchen related Bioflamex product consists of 88% biologic water based fire extinguishing solution (appx 40% active ingredients, 60% water) combined with a 10-15% eco-friendly foam concentrate.

This formulation is designed to generate knock-down on even high temperature oil/fats fire and prevent reigniting, as the foam forms a protective layer allowing the liquid to cool down.

12

The packaging itself also contain a special process, utilizing recycled CO2 for the pressurization, a special nozzle for the distribution of extinguishing liquid and foam and a low pressure level, which is designed to avoid exaggerated splashing of the burning liquid.

- Bioflamex Extinguishing Foam Spray (Aerosol) for General Use

As above, but with less foam, higher pressure and a different nozzle for longer range.

- SAFIRE Forest Fire Break Solution

This is a water based biological solution with active ingredients (appx 60% water and 40% salts, citric compunds, natural polymers/binders) designed to protect live vegetation against ignition. Patent application is in the process of filing at IPO/UK and USTPO/USA.

The salts and citric compounds are designed to slow down or prevent ignition of the vegetation. The polymer/binder has the purpose of ensuring that the retardant stays on vegetation for up to 2 months, and thus enabling the product to be used as a preventive measure around facilities in areas prone to fires.

The purpose of the product is to create or enforce fire breaks, which will slow down or hinder spread of forest fire. The application can be by ordinary tenders (tankers with hoses) airplane or other dispersement systems.

- Fire Protected Cardboard Boxes (with Partner)

This product concept is for implementation into the production process of carton and paper materials. Patent application is in process of filing at IPO/UK and USPO/USA.

The water based fire retardant is mixed with the paper pulp (replacing water) and thus creating en end product that is fire protected to be used, for instance, with storage boxes.

We anticipate this concept will be completed in collaboration with a manufacturer of carton and paper products.

- Fire Protected Wall and Ceiling Insulation (with Partner)

As above, the main difference being that the retardant will be mixed with a mix of base materials. Patent application is in process of filing at IPO/UK and USPO/USA.

- Sentinel Fire Detection & Suppression System

We intend to take over the rights for the integrated Sentinel system from Prime Solutions in Spain, with its proprietary system for detection of wildfire in the vicinity of compounds/installations in forests, and the protection of these units by deployment of SAFIRE Frest Fire Break Solution.

13

Approvals and Certifications

We are in the process of filing for UL approvals and Government Dep’t endorsements (USFA, NFPA, CAL FIRE) for the United States, covering the Bioflamex aerosols and also bulk extinguishers. In addition to this, TÜV certification of aerosols covering Europe shall be obtained.

We will be initiating the British Standards approvals process for textile and pulp as soon as R&D work with Solberg Foams is completed.

EN3 certification of standard extinguishers must also be initiated for the EU.

Forest Fire certifications and approvals will be obtained gradually as we target markets; the U.S. (mainly California) and Spain will be the first focus-markets for the approvals.

The following table shows specifically where we are at in the approval and certification process.

| Bioflamex | We are in the process of obtaining UL approval for sales in the United States, which takes 3-6 months. We are contemplating the British Standard as well as TÜV, which is a faster process (2-3 months). NFPA (United States) endorsement is also a key to success. |

| Extinguishing Foam | Must be UL certified in US and EN3 certified for normal extinguishers in EU. Both take 3-6 months. |

| Forest Retardant | Must be tested and approved by United States (CAL FIRE), Greek, Spanish and Russian Forest Fire Authorities for use in forest fire fighting. Will take 3-6 months, depending on timing for initial demonstrations. |

| Retardant | Needs UL and DIN4102/BS5852 approval and certification. Takes 3-6 months. |

In addition to the above, any number of local and/or regional approvals may be necessary for the markets we aim to penetrate, as is the case in states like California, countries like Russia and the individual CIS countries, and even some countries in EU (France for example).

Product Production

We intend to use a number of partners to develop and manufacture our products. These partners include those that follow in this section. In order to successfully reach our objectives, a number of tests, demonstrations, approvals and certifications must be completed successfully during the coming 3-6 months.

We intend to enter into exclusive collaboration and production agreements with SamsonEnviro A/S, Solberg A/S and Dansoll A/S, Denmark for the development of a range of versatile and multipurpose retardant and extinguishing formulations.

14

Samson Enviro A/S

The core biological formula has been developed by SamsonEnviro and shall form the basis for the water based biological additives mixed with water.

This base formula composes the backbone for proprietary washable textile retardants, forest fire protective solutions, non-flammable paper/carton products and the various types of extinguisher products we intend to produce and market. SamsonEnviro delivers the ready produced base formula that we intend to use in our products. All ingredients are supplied by larger and reliable manufacturers.

The collaboration agreement is in verbal form at the present, and covers the direct transfer of rights of base formula to Bioflamex Corp in exchange of common stock. This agreement will be formalized and signed when the Bioflamex Corporation has been duly formed as legal entity.

Dansoll A/S:

Dansoll manufactures over 3,000,000 aerosols per annum, and can easily expand operations in current location and also abroad. The primary suppliers of cannisters and nozzle system have capacity that supercedes any need in the distant future.

The main exclusive collaboration agreement will comprise the manufacturing of Bioflamex products in aerosols both 650ml and 800ml versions. Dansoll will conduct mixing of ingredients, purchase of bottles and nozzle systems, pressurization and packaging, using their proprietary technology for using CO2 as propellant.

This is currently a verbal agreement to be formalized and signed when the Bioflamex Corporation has been properly formed and listed.

Solberg Foams A/S

In addition, we believe the development of specialized non-PFC foams in collaboration with Solberg will lead to a range of unique fire extinguishing products, such as the kitchen spray extinguisher and water based, biological foam solution for hand held extinguishers and use in fire truck tenders. Solberg foams are readily available and we have a large and reliable network of collaboration partners.

To this effect, we have entered into an exclusive collaboration with Solberg Foam for the development of special PFC-free foams for our Bioflamex foam extinguishers. The agreement provides that all rights for the developed foam types shall be transferred to us in return for shares of our common stock. This is currently a verbal agreement to be formalized and signed when the Bioflamex Corporation has been properly formed and listed.

In addition to the development of foams, we have entered R&D collaboration with Solberg speclialists to enhance the base formula in terms of extinguishing capabilities, especially to improve the fire “knock-down” effect of the formula. We hope this work will translate into the completion of the new formulations for Bioflamex aerosol extinguishers and the completion of patent application, as well as the certification for EN3 extinguishers.

15

In addition, this collaboration should enhance the product attributes on forest fire protection, especially the active duration after application to vegetation, and will be essential for designing paper pulp and biological insulation materials.

This additional R&D work is based on same terms as the work on foams. According to plan, it should translate into completion of the product line for industrial use as well as forest fire fighting, and shall form the basis of 2-3 patent applications.

Partnerships for Industrial Development:

We are working with two insulation manufacturers and one paper/carton manufacturer to complete trials of industrial-level fire retardants. This work will take 3-6 months to complete after the work with Solberg has been completed, and should result in 1-2 patent applications.

In addition, development of a washable fire retardant for textiles (especially beddings) should open up for collaboration with industrial linen service companies, as the likes of Berendsen and gain access to hospitals, hotels and prisons to mention a few institutional clients.

National Fire Departments: Upon completion of formula work, critical testing will be conducted in collaboration with fire departments in the United States (California, Chicago and New York initially and with other states/cities to be added later), Denmark, Spain and Greece.

Distribution

The company will use a number of distribution channels and distribution partners, depending on the type of product, market segment and region. In some cases, we have already secured verbal agreements with distributors and end user outlets, which we expect to be formalized in the near future.

Distribution in the United States will be determined by the certifications/approvals obtained, but we are in dialogue with networks that have been developed over the years that we believe will open the distributions channels to government and retail targets.

The main focus will be on establishing contracts with strong local, regional or multinational companies, such as UPC (KIdde, Chubb) or Tyco (Tyco, Ansul, ADT) with a commanding relationship to government departments, fire fighting purchasing departments, large distributing channels and/or businesses.

In some instances we will enter collaboration on all products with one partner for a country or region, and in others multiple distributors will operate individual sectors, depending on the nature of the market and the positioning of partner companies.

We intend to have our sales personnel primarily servicing the distribution partner as key account managers; however some key multinational companies will be approached and handled directly by management.

16

At the present, we have discussed preliminary Exclusive Distributor/Agent agreements ready for execution with companies covering United States and regions such as India, UAE, Kuwait, Egypt, Saudia Arabia. Partners for certain sectors and/or regions in EU and Asia have also been identified and soft negotiations initiated.

Consumer / Retail

The main product for the Retail/Consumer segment is the Bioflamex extinguisher, which we believe holds a global potential (“The Red Bull of fire fighting”).

The key to the distribution strategy is to gain access to consumer outlet networks as well as semi-professional / specialty outlets. The distribution and marketing will initially be conducted through the networks’ own marketing programmes/media towards potential end users.

As an example, the Automobile Owners’ Associations in the United States counts more than 50,000,000 members and publishes web content and magazines directed at its members. In EU the same applies, counting more than 40,000,000 members and publishing magazines that have circulations of more than 7,000,000 copies monthly or quarterly depending on the country/region. This composes a strong promotion vehicle for the All-purpose Bioflamex for car/boat owners.

The push for distribution in the United States will be focused around a number of key distribution partners and 5 key states with a high population/business density, high media saturation and high level of distribution outlets. These states include: New York, California, Illinois, Texas and Florida.

We have identified these states as being highly relevant for penetration into the retail/private consumption sphere as well as the public institutions and businesses.

In addition to this, the states selected individually have some characteristics that support focused efforts into certain business areas. Examples of this include:

- The high proportion of Oil & Gas industry in Texas supports the distribution and sales of bulk extinguishers and retardants to professional clients;

- The high level of forest fire threats in California, makes it an ideal market to introduce the forest fire solutions to local Government departments and fire fighting departments; and

- The high number of elderly people in Florida supports the introduction of Bioflamex kitchen extinguisher and textile retardants to Government Departments and institutions as well as key retail partners.

We also intend to focus on a number of countries in Europe with high population/business density, high media saturation and high level of distribution outlets. These countries include: the Nordic Countries, Germany, France, Benelux, England, and Spain.

It is our goal to achieve a 10% penetration into the market through professional, business to business and retail distribution/sales partners, over the course of a 3 year period.

17

Business to Business / Professional

The distribution of product for the business to business and professional market will mainly be conducted either through large multinational corporations with a strong sales and distribution networks in key markets or through local/regional partners with strong association and sales record to the primary clients.

Large multinational distribution partners may include: TYCO, UTC, ISS (50+ countries), G4S (70+ countries), and Würth (40+ countries). Local/regional distribution partners may include:

Delma Group (Middle East/India), Blue Dome Company (Middle East), and Falck (Nordic),

Industrial

The industrial segment will primarily be targeted by our staff directly with potential clients, as significant consultancy and development of applications is involved in this. Main clients are manufacturers of paper product, insulation material for construction, timber and wood manufacturers and textile/furniture producers.

Employees

Staff Development

Our ability to generate revenue will require 2-3 offices and a consistent increase in staff count over the first 1-4 years, as reflected in the personnel chart below:

However, we do not have an ambition to become a high headcount operation; but rather have a tight and highly skilled group of people employed within the technical, sales and marketing Divisions.

Mainly, the distribution sales and marketing efforts will require support and key account capacity, and we will be looking to hire individuals with strong skills within regional or global sales, and also recruit from the professional fire services environment to ensure deep understanding of the technical aspects within the sales/marketing force and to leverage industry insight and professional connections.

In addition to this, we aim to recruit technical staff with fire fighting, biochemistry and/or logistics skills who can ensure strong coordination with manufacturing partners, counseling of distributors and key clients (for the professional / industrial segments), and drive the product development within the company.

18

Advisory Board

We intend to develop an advisory board in the near future that will consist of a collection of individuals who bring unique knowledge and skills which complement the knowledge and skills of our board members in order to more effectively govern the organization. We expect that our advisory board will be staffed in the next six months.

Item 1A. Risk Factors.

A smaller reporting company is not required to provide the information required by this Item.

Item 1B. Unresolved Staff Comments

A smaller reporting company is not required to provide the information required by this Item.

Item 2. Properties

Our corporate headquarters are located at Christiansvej 31, 2920 Charlottenlund, Denmark. This location is provided by our Chief Executive Officer and Director without cost. We intend to move into another facility as soon as capital permits.

Item 3. Legal Proceedings

We are not a party to any pending legal proceeding. We are not aware of any pending legal proceeding to which any of our officers, directors, or any beneficial holders of 5% or more of our voting securities are adverse to us or have a material interest adverse to us.

Item 4. (Removed and Reserved)

PART II

Item 5. Market for Registrant’s Common Equity and Related Stockholder Matters and Issuer Purchases of Equity Securities

Market Information Our common stock is currently quoted on the OTC Bulletin Board (“OTCBB”), which is sponsored by FINRA. The OTCBB is a network of security dealers who buy and sell stock. The dealers are connected by a computer network that provides information on current "bids" and "asks", as well as volume information. Our shares are quoted on the OTCBB under the symbol “DBAY.”The following table sets forth the range of high and low bid quotations for our common stock for each of the periods indicated as reported by the OTCBB. These quotations reflect inter-dealer prices, without retail mark-up, mark-down or commission and may not necessarily represent actual transactions.

19

| Fiscal Year Ending February 28, 2011 | |||||

| Quarter Ended | High $ | Low $ | |||

| February 28, 2011 | 0 | 0 | |||

| November 30, 2010 | 0 | 0 | |||

| August 31, 2010 | 0 | 0 | |||

| May 31, 2010 | 0 | 0 | |||

| Fiscal Year Ending February 28, 2010 | |||||

| Quarter Ended | High $ | Low $ | |||

| February 28, 2011 | 0 | 0 | |||

| November 30, 2010 | 0 | 0 | |||

| August 31, 2010 | 0 | 0 | |||

| May 31, 2010 | 0 | 0 | |||

Penny Stock

The SEC has adopted rules that regulate broker-dealer practices in connection with transactions in penny stocks. Penny stocks are generally equity securities with a market price of less than $5.00, other than securities registered on certain national securities exchanges or quoted on the NASDAQ system, provided that current price and volume information with respect to transactions in such securities is provided by the exchange or system. The penny stock rules require a broker-dealer, prior to a transaction in a penny stock, to deliver a standardized risk disclosure document prepared by the SEC, that: (a) contains a description of the nature and level of risk in the market for penny stocks in both public offerings and secondary trading; (b) contains a description of the broker's or dealer's duties to the customer and of the rights and remedies available to the customer with respect to a violation of such duties or other requirements of the securities laws; (c) contains a brief, clear, narrative description of a dealer market, including bid and ask prices for penny stocks and the significance of the spread between the bid and ask price; (d) contains a toll-free telephone number for inquiries on disciplinary actions; (e) defines significant terms in the disclosure document or in the conduct of trading in penny stocks; and (f) contains such other information and is in such form, including language, type size and format, as the SEC shall require by rule or regulation.

The broker-dealer also must provide, prior to effecting any transaction in a penny stock, the customer with (a) bid and offer quotations for the penny stock; (b) the compensation of the broker-dealer and its salesperson in the transaction; (c) the number of shares to which such bid and ask prices apply, or other comparable information relating to the depth and liquidity of the market for such stock; and (d) a monthly account statement showing the market value of each penny stock held in the customer's account.

In addition, the penny stock rules require that prior to a transaction in a penny stock not otherwise exempt from those rules, the broker-dealer must make a special written determination that the penny stock is a suitable investment for the purchaser and receive the purchaser's written acknowledgment of the receipt of a risk disclosure statement, a written agreement as to transactions involving penny stocks, and a signed and dated copy of a written suitability statement.

20

These disclosure requirements may have the effect of reducing the trading activity for our common stock. Therefore, stockholders may have difficulty selling our securities.

Holders of Our Common Stock

We are authorized to issue 200,000,000 shares of common stock with a par value of $0.0001 per share. As of March 16, 2011 we had 92,466,667 shares of common stock outstanding. Our shares are held by approximately 37 shareholders of record.Dividends

There are no restrictions in our articles of incorporation or bylaws that prevent us from declaring dividends. The Nevada Revised Statutes, however, do prohibit us from declaring dividends where after giving effect to the distribution of the dividend:

| 1. | we would not be able to pay our debts as they become due in the usual course of business, or; |

| 2. | our total assets would be less than the sum of our total liabilities plus the amount that would be needed to satisfy the rights of shareholders who have preferential rights superior to those receiving the distribution. |

We have not declared any dividends and we do not plan to declare any dividends in the foreseeable future.

Recent Sales of Unregistered Securities

The information set forth below relates to our issuances of securities without registration under the Securities Act of 1933 during the reporting period which were not previously included in a Quarterly Report on Form 10-Q or Current Report on Form 8-K.

On April 26, 2011, we issued 333,333 in a private transaction for $0.15 per share for total proceeds of $50,000.

On January 25, 2011, we entered into an Asset Purchase Agreement with Kristian Schiørring and Henrik Dahlerup to acquire certain intellectual property related to line of fire extinguishing and prevention products that are based on environment friendly and biological formulations. In consideration for the newly acquired assets, we issued 19,000,000 shares of our common stock to each of Messrs. Schiørring and Dahlerup.

The above issuances were made pursuant to Regulation S of the 1933 Act. Each purchaser represented to us that the purchaser was a Non-US Person as defined in Regulation S. We did not engage in a distribution of this offering in the United States. Each purchaser represented their intention to acquire the securities for investment only and not with a view toward distribution. All purchasers were given adequate access to sufficient information about us to make an informed investment decision. None of the securities were sold through an underwriter and accordingly, there were no underwriting discounts or commissions involved. The selling stockholders named in this prospectus include all of the purchasers who purchased shares pursuant to this Regulation S offering.

21

Securities Authorized for Issuance under Equity Compensation Plans

We do not have any equity compensation plans.

Item 6. Selected Financial Data

A smaller reporting company is not required to provide the information required by this Item.

Item 7. Management’s Discussion and Analysis of Financial Condition and Results of Operations

Forward-Looking Statements

Certain statements, other than purely historical information, including estimates, projections, statements relating to our business plans, objectives, and expected operating results, and the assumptions upon which those statements are based, are “forward-looking statements” within the meaning of the Private Securities Litigation Reform Act of 1995, Section 27A of the Securities Act of 1933 and Section 21E of the Securities Exchange Act of 1934. These forward-looking statements generally are identified by the words “believes,” “project,” “expects,” “anticipates,” “estimates,” “intends,” “strategy,” “plan,” “may,” “will,” “would,” “will be,” “will continue,” “will likely result,” and similar expressions. We intend such forward-looking statements to be covered by the safe-harbor provisions for forward-looking statements contained in the Private Securities Litigation Reform Act of 1995, and are including this statement for purposes of complying with those safe-harbor provisions. Forward-looking statements are based on current expectations and assumptions that are subject to risks and uncertainties which may cause actual results to differ materially from the forward-looking statements. Our ability to predict results or the actual effect of future plans or strategies is inherently uncertain. Factors which could have a material adverse affect on our operations and future prospects on a consolidated basis include, but are not limited to: changes in economic conditions, legislative/regulatory changes, availability of capital, interest rates, competition, and generally accepted accounting principles. These risks and uncertainties should also be considered in evaluating forward-looking statements and undue reliance should not be placed on such statements. We undertake no obligation to update or revise publicly any forward-looking statements, whether as a result of new information, future events or otherwise. Further information concerning our business, including additional factors that could materially affect our financial results, is included herein and in our other filings with the SEC.

22

Results of Operations for the Years Ended February 28, 2011 and 2010

We generated no revenue for the period from August 25, 2004 (Date of Inception) until February 28, 2011. Our Operating Expenses were $45,377 for the year ended February 28, 2011, as compared with $12,441 for the same period ended 2010. The increase was the result of professional fees of $37,682 for the year ended February 28, 2011, as compared with only $10,500 for the same period 2010. Our operating expenses were $134,581 for the period from August 25, 2004 (Date of Inception) until February 28, 2011.

We recorded a net loss of $45,377 for the year ended February 28, 2011, as compared with $12,441 for the same period ended 2010, and $134,581 for the period from August 25, 2004 (Date of Inception) until February 28, 2011.

Liquidity and Capital Resources

As of February 28, 2010, we had current assets of $10,059, represented by $59 in cash and $10,000 in prepaid expenses. We had total assets of $1,201,059 as of February 28, 2011. We had current liabilities of $8,340 and total liabilities of $68,840 as of February 28, 2011. We had working capital of only $1,719 as of February 28, 2011.

Operating activities used $49,537 in cash for the year ended February 28, 2011. Our net loss of $45,377 and prepaid expenses of $10,000 were the contributing factors to our negative operating cash flow, offset mainly by an increase in accounts payable and accrued liabilities of $5,340. Investing activities used $500 for mineral property costs for the year ended February 28, 2011. Financing activities for the year ended February 28, 2011 generated $50,000as a result of convertible loan proceeds of $60,500 and officer loans of $8,169, offset by the repayment of officer loans in the amount of $18,669.

We will require a cash injection of $2,000,000 to: begin operations, launch a full marketing and branding campaign, manufacture and deliver products and to begin and increase revenues from its products. Subsequent to the reporting period, we raised $50,000 in a private placement to an accredited investor. Notwithstanding, as of February 28, 2010, we have insufficient cash to operate our business at the current level for the next twelve months and insufficient cash to achieve our business goals. The success of our business plan beyond the next 12 months is contingent upon us obtaining additional financing. We intend to fund operations through debt and/or equity financing arrangements, which may be insufficient to fund our capital expenditures, working capital, or other cash requirements. We do not have any formal commitments or arrangements for the sales of stock or the advancement or loan of funds at this time. There can be no assurance that such additional financing will be available to us on acceptable terms, or at all.

Off Balance Sheet Arrangements

As of February 28, 2011, there were no off balance sheet arrangements.

23

Going Concern

The accompanying financial statements have been prepared on a going concern basis which assumes we will be able to realize our assets and discharge our liabilities in the normal course of business for the foreseeable future. We have incurred losses since inception resulting in an accumulated deficit of $134,581 as at February 28, 2011 and have working capital of $1,719 as at February 28, 2011. Further losses are anticipated in the development of our business raising substantial doubt about our ability to continue as a going concern. The ability to continue as a going concern is dependent upon our generating profitable operations in the future and/or to obtain the necessary financing to meet our obligations and repay our liabilities arising from normal business operations when they come due.

Critical Accounting Policies

In December 2001, the SEC requested that all registrants list their most “critical accounting polices” in the Management Discussion and Analysis. The SEC indicated that a “critical accounting policy” is one which is both important to the portrayal of a company’s financial condition and results, and requires management’s most difficult, subjective or complex judgments, often as a result of the need to make estimates about the effect of matters that are inherently uncertain.

Our accounting policies are set forth in Note 2 to the financial statements. Management does not believe that our accounting policies are critical enough to mention in the body of this annual report on Form 10-K.

Recently Issued Accounting Pronouncements

We do not expect the adoption of recently issued accounting pronouncements to have a significant impact on our results of operation, financial position or cash flow.

Item 7A. Quantitative and Qualitative Disclosures About Market Risk

A smaller reporting company is not required to provide the information required by this Item.

Item 8. Financial Statements and Supplementary Data

Index to Financial Statements Required by Article 8 of Regulation S-X:

| Audited Financial Statements: | |

| F-1 | Report of Independent Registered Public Accounting Firm |

| F-2 | Consolidated Balance Sheets as of February 28, 2011 and 2010; |

| F-3 | Statements of Operations for the years ended February 28, 2011 and 2010, and the period from inception to February 28, 2011; |

| F-4 | Statement of Stockholders’ Equity for period from inception to February 28, 2011; |

| F-5 | Statements of Cash Flows for the years ended February 28, 2011 and 2010, and the period from inception to February 28, 2011; |

| F-6 | Notes to Financial Statements |

24

REPORT OF INDEPENDENT REGISTERED PUBLIC ACCOUNTING FIRM

To the Board of Directors and

Stockholders of Bioflamex Corporation

(formerly, Deer Bay Resources, Inc.)

(A Development Stage Company)

Charlottenlund, Denmark

We have audited the accompanying balance sheets of Bioflamex Corporation, (formerly, Deer Bay Resources, Inc.), (A Development Stage Company) as of February 28, 2011 and 2010, and the related statements of income, stockholders’ equity and comprehensive income, and cash flows for each of the years in the two-year period ended February 28, 2011 and the period from August 25, 2004 (inception) to February 28, 2011. Bioflamex Corporation’s management is responsible for these financial statements. Our responsibility is to express an opinion on these financial statements based on our audits.

We conducted our audits in accordance with the standards of the Public Company Accounting Oversight Board (United States). Those standards require that we plan and perform the audit to obtain reasonable assurance about whether the financial statements are free of material misstatement. An audit includes examining, on a test basis, evidence supporting the amounts and disclosures in the financial statements. An audit also includes assessing the accounting principles used and significant estimates made by management, as well as evaluating the overall financial statement presentation. We believe that our audits provide a reasonable basis for our opinion.

In our opinion, the financial statements referred to above present fairly, in all material respects, the financial position of Bioflamex Corporation as of February 28, 2011 and 2010, and the results of its operations and its cash flows for each of the years in the two-year period ended February 28, 2011 and the period from August 25, 2004 (inception) to February 28, 2011 in conformity with accounting principles generally accepted in the United States of America.

The accompanying financial statements have been prepared assuming that the Company will continue as a going concern. As discussed in note 1 to the financial statements, the Company has suffered recurring losses and had negative cash flows from operations that raise substantial doubt about the Company’s ability to continue as a going concern. Management’s plans in regard to these matters are also described in Note 1. The financial statements do not include any adjustments that might result from the outcome of this uncertainty.

| /s/ Weaver, Martin & Samyn, LLC | |

| Kansas City, Missouri | |

| May 18, 2011 |

F-1

Bioflamex

Corporation (formerly known as Deer Bay Resources Inc.)

(A Development Stage Company)

Balance

Sheets

| February 28, 2011 | February 28, 2010 | |||||

| $ | $ | |||||

| Assets | ||||||

| Current Assets | ||||||

| Cash | 59 | 96 | ||||

| Prepaid expenses | 10,000 | - | ||||

| Total Current Assets | 10,059 | 96 | ||||

| Intangible Assets (Note 4) | 1,191,000 | - | ||||

| Total Assets | 1,201,059 | 96 | ||||

| Liabilities and Stockholders’ Equity (Deficit) | ||||||

| Current Liabilities | ||||||

| Accounts payable | 8,340 | 3,000 | ||||

| Related party loans (Note 5) | - | 10,500 | ||||

| Total Current Liabilities | 8,340 | 13,500 | ||||

| Convertible Debt (Note 6) | 60,500 | - | ||||

| Total Liabilities | 68,840 | 13,500 | ||||

| Nature of Operations and Continuance of Business (Note 1) | ||||||

| Subsequent Events (Note 9) | ||||||

| Stockholders’ Equity (Deficit) | ||||||

| Capital Stock (Note 7) | ||||||

| Authorized: | ||||||

| 200,000,000 common shares with a par value of $0.0001 | ||||||

| Issued and outstanding: | ||||||

| 92,466,667 and 130,110,000 common shares issued and outstanding, respectively | 9,247 | 13,011 | ||||

| Additional Paid-in-Capital | 1,257,553 | 62,789 | ||||

| Deficit Accumulated During the Development Stage | (134,581 | ) | (89,204 | ) | ||

| Total Stockholders’ Equity (deficit) | 1,132,219 | (13,404 | ) | |||

| Total Liabilities and Stockholders’ Equity (Deficit) | 1,201,059 | 96 |

(See Accompanying Notes)

F-2

Bioflamex

Corporation (formerly known as Deer Bay Resources Inc.)

(A Development Stage Company)

Statements

of Operations

| Cumulative from August 25, 2004 (Inception) to February 28, 2011 | Year Ended February 28, 2011 | Year Ended February 28, 2010 | |||||||

| $ | $ | $ | |||||||

| Revenue | - | - | - | ||||||

| Expenses | |||||||||

| Bank charges | 803 | 135 | 115 | ||||||

| Mineral property costs | 16,500 | 500 | 500 | ||||||

| Office expenses | 1,856 | 131 | 80 | ||||||

| Professional fees | 93,262 | 37,682 | 10,500 | ||||||

| Transfer agent and filing fees | 22,160 | 6,929 | 1,246 | ||||||

| Net Loss | (134,581 | ) | (45,377 | ) | (12,441 | ) | |||

| Net Loss per Share – Basic and Diluted | - | - | |||||||

| Weighted Average Number of Common Shares Outstanding | 126,604,000 | 130,110,000 |

(See Accompanying Notes)

F-3

Bioflamex

Corporation (formerly known as Deer Bay Resources Inc.)

(A Development Stage Company)

Statements

of Cash Flows

| Cumulative from August 25, 2004 (Inception) to February 28, 2011 | Year Ended February 28, 2011 | Year Ended February 28, 2010 | |||||||

| $ | $ | $ | |||||||

| Cash Flows from Operating Activities | |||||||||

| Net Loss | (134,581 | ) | (45,377 | ) | (12,441 | ) | |||

| Adjustment to Reconcile Net Loss to Net Cash: | |||||||||

| Write-off of mineral properties | 16,500 | 500 | 500 | ||||||

| Changes in Operating Assets and Liabilities: | |||||||||

| (Increase) in prepaid expenses | (10,000 | ) | (10,000 | ) | - | ||||

| Increase in accounts payable and accrued liabilities | 8,340 | 5,340 | 3,000 | ||||||

| Net Cash used in Operating Activities | (119,741 | ) | (49,537 | ) | (8,941 | ) | |||

| Cash Flows to Investing Activities | |||||||||

| Mineral property costs | (16,500 | ) | (500 | ) | (500 | ) | |||

| Net Cash used in Investing Activities | (16,500 | ) | (500 | ) | (500 | ) | |||

| Cash Flows from Financing Activities | |||||||||

| Proceeds from officer’s loan | 18,669 | 8,169 | 9,500 | ||||||

| Repayment of officer’s loan | (18,669 | ) | (18,669 | ) | - | ||||

| Convertible loan proceeds | 60,500 | 60,500 | - | ||||||

| Common shares issued for cash | 75,800 | - | - | ||||||

| Net Cash Provided by Financing Activities | 136,300 | 50,000 | 9,500 | ||||||

| Net Increase (Decrease) in Cash | 59 | (37 | ) | 59 | |||||

| Cash - Beginning of Period | - | 96 | 37 | ||||||

| Cash - End of Period | 59 | 59 | 96 | ||||||

| Non-cash Investing and Financing Activities: | |||||||||

| Common shares issued for intellectual property | 1,191,000 | 1,191,000 | - | ||||||

| Supplemental Cash Flow Information: | |||||||||

| Cash paid for: | |||||||||

| Interest | - | - | - | ||||||

| Taxes | - | - | - |

(See Accompanying Notes)

F-4

Bioflamex

Corporation (formerly known as Deer Bay Resources Inc.)

(A Development Stage Company)

Statement

of Stockholders’ Equity (Deficit)

From

August 25, 2004 (Inception) to February 28, 2011

| Number of Common Shares | Par Value | Additional Paid-in- Capital | Deficit Accumulated During the Development Stage | Total | |||||||||||

| $ | $ | $ | $ | ||||||||||||

| August 25, 2004 | - | - | - | - | - | ||||||||||

| October 11, 2004 - Issued for cash at $0.001 | 6,300,000 | 630 | 5,670 | - | 6,300 | ||||||||||

| October 25, 2004 - Issued for cash at $0.01 | 1,050,000 | 105 | 10,395 | - | 10,500 | ||||||||||

| January 5, 2005 - Issued for cash at $0.05 | 260,000 | 26 | 12,974 | - | 13,000 | ||||||||||

| Net loss | - | - | - | (3,729 | ) | (3,729 | ) | ||||||||

| Balance, February 28, 2005 | 7,610,000 | 761 | 29,039 | (3,729 | ) | 26,071 | |||||||||

| Net loss | - | - | - | (11,824 | ) | (11,824 | ) | ||||||||

| Balance, February 28, 2006 | 7,610,000 | 761 | 29,039 | (15,553 | ) | 14,247 | |||||||||

| Net loss | - | - | - | (2,598 | ) | (2,598 | ) | ||||||||

| Balance, February 28, 2007 | 7,610,000 | 761 | 29,039 | (18,151 | ) | 11,649 | |||||||||

| Net loss | - | - | - | (11,925 | ) | (11,925 | ) | ||||||||

| Balance, February 29, 2008 | 7,610,000 | 761 | 29,039 | (30,076 | ) | (276 | ) | ||||||||

| June 24, 2008 - Issued for cash at $0.001 | 32,500,000 | 3,250 | 29,250 | - | 32,500 | ||||||||||

| June 24, 2008 - Issued for cash at $0.0001 | 85,000,000 | 8,500 | - | - | 8,500 | ||||||||||

| October 24, 2008 - Issued for cash at $0.001 | 5,000,000 | 500 | 4,500 | 5,000 | |||||||||||

| Net loss | - | - | - | (46,687 | ) | (46,687 | ) | ||||||||

| Balance, February 28, 2009 | 130,110,000 | 13,011 | 62,789 | (76,763 | ) | (963 | ) | ||||||||

| Net loss | - | - | - | (12,441 | ) | (12,441 | ) | ||||||||

| Balance, February 28, 2010 | 130,110,000 | 13,011 | 62,789 | (89,204 | ) | (13,404 | ) | ||||||||

| January 25, 2011 - Issued for assets at $0.0313 per share | 38,000,000 | 3,800 | 1,187,200 | - | 1,191,000 | ||||||||||

| January 25, 2011 – Returned to treasury and canceled | (75,643,333 | ) | (7,564 | ) | 7,564 | - | - | ||||||||

| Net loss | - | - | - | (45,377 | ) | (45,377 | ) | ||||||||

| Balance, February 28, 2011 | 92,466,667 | 9,247 | 1,257,553 | (134,581 | ) | 1,132,219 |

(See Accompanying Notes )

F-5

Bioflamex Corp. (formerly known as Deer Bay Resources Inc.)

(A Development Stage Company)

Notes to The Financial Statements

For the Years Ended February 28, 2011 and 2010

| 1. | Nature of Operations and Continuance of Business |

| The Company was incorporated as Deer Bay Resources Inc. (“the Company”) under the laws of State of Nevada, U.S. on August 25, 2004. The Company’s principal business up to January 25, 2011 was the acquisition and exploration of mineral resources. On January 25, 2011, the Company entered into an Asset Purchase Agreement to acquire certain intellectual property related to line of fire extinguishing and prevention products that are based on environment friendly and biological formulations. In consideration for the newly acquired assets, the Company issued 38,000,000 shares at $0.013 per share. We have not produced any revenues from the Company’s newly acquired assets or commenced significant business operations and are considered a development stage company as defined by SEC Guide 7 with reference to Financial Accounting Standards Board (FASB) issued Accounting Standards Codification (ASC) topic 915. |

| These financial statements have been prepared on a going concern basis which assumes the Company will be able to realize its assets and discharge its liabilities in the normal course of business for the foreseeable future. The Company has incurred losses since inception resulting in an accumulated deficit of $134,581 as at February 28, 2011 and has working capital of $1,719 as at February 28, 2011. Further losses are anticipated in the development of its business raising substantial doubt about the Company’s ability to continue as a going concern. The ability to continue as a going concern is dependent upon the Company generating profitable operations in the future and/or to obtain the necessary financing to meet its obligations and repay its liabilities arising from normal business operations when they come due. |

| The Company will require a cash injection of $2,000,000 to: begin operations, launch a full marketing and branding campaign, manufacture and deliver products and to begin and increase revenues from its products. Management hopes to raise capital to meet these goals. The Company does not have any formal commitments or arrangements for the sales of stock or the advancement or loan of funds at this time. There can be no assurance that such additional financing will be available to us on acceptable terms, or at all. |

| 2. | Summary of Significant Accounting Policies |

| Use of Estimates |

| The preparation of financial statements in accordance with United States generally accepted accounting principles requires management to make estimates and assumptions that affect the reported amounts of assets and liabilities at the date of the financial statements and the reported amounts of revenue and expenses in the reporting period. The Company regularly evaluates estimates and assumptions related to donated services and expenses, and deferred income tax asset valuation allowances. The Company bases its estimates and assumptions on current facts, historical experience and various other factors that it believes to be reasonable under the circumstances, the results of which form the basis for making judgments about the carrying values of assets and liabilities and the accrual of costs and expenses that are not readily apparent from other sources. The actual results experienced by the Company may differ materially and adversely from the Company’s estimates. To the extent there are material differences between the estimates and the actual results, future results of operations will be affected. |

| Mineral Claim Payments and Exploration Expenditures |

| The Company is primarily engaged in the acquisition and exploration of mining properties. Mineral property exploration costs are expensed as incurred. Mineral property acquisition costs are initially capitalized when incurred. We assess the carrying cost for impairment under the FASB ASC topic 360 at each fiscal quarter end. When it has been determined that a mineral property can be economically developed as a result of establishing proven and probable reserves, the costs subsequently incurred to develop such property are capitalized. Such costs will be amortized using the units-of-production method over the established life of the proven and probable reserves. If mineral properties are subsequently abandoned or impaired, any capitalized costs will be charged to operations. |

| Long-lived Assets |

| The Company tests long-lived assets or asset groups for recoverability when events or changes in circumstances indicate that their carrying amount may not be recoverable. Circumstances which could trigger a review include, but are not limited to: significant decreases in the market price of the asset; significant adverse changes in the business climate or legal factors; accumulation of costs significantly in excess of the amount originally expected for the acquisition or construction of the asset; current period cash flow or operating losses combined with a history of losses or a forecast of continuing losses associated with the use of the asset; and current expectation that the asset will more likely than not be sold or disposed significantly before the end of its estimated useful life. |

F-6

Bioflamex Corp. (formerly known as Deer Bay Resources Inc.)

(A Development Stage Company)

Notes to The Financial Statements

For the Years Ended February 28, 2011 and 2010

| Recoverability is assessed based on the carrying amount of the asset and its fair value which is generally determined based on the sum of the undiscounted cash flows expected to result from the use and the eventual disposal of the asset, as well as specific appraisal in certain instances. An impairment loss is recognized when the carrying amount is not recoverable and exceeds fair value. |

| Financial Instruments |

| The fair values of financial instruments, which include cash, note payable and due to related party were estimated to approximate their carrying values due to the immediate or short-term maturity of these financial instruments. Foreign currency transactions are primarily undertaken in Canadian dollars. The financial risk is the risk to the Company’s operations that arise from fluctuations in foreign exchange rates and the degree of volatility of these rates. Currently, the Company does not use derivative instruments to reduce its exposure to foreign currency risk. |

| Foreign Currency Translation |

| The Company’s functional and reporting currency is the United States dollar. Monetary assets and liabilities denominated in foreign currencies are translated in accordance with ASC 820, using the exchange rate prevailing at the balance sheet date. Gains and losses arising on settlement of foreign currency denominated transactions or balances are included in the determination of income. Foreign currency transactions are primarily undertaken in Canadian dollars. The Company has not, to the date of these financials statements, entered into derivative instruments to offset the impact of foreign currency fluctuations. |

| New Accounting Standards Adopted During the Year Ended February 28, 2011 |

| In June 2009, the FASB issued ASC topic 860-20 for changes to the accounting for transfers of financial assets. These changes remove the concept of a qualifying special-purpose entity and remove the exception from the application of variable interest accounting to variable interest entities that are qualifying special-purpose entities; limits the circumstances in which a transferor derecognizes a portion or component of a financial asset; defines a participating interest; requires a transferor to recognize and initially measure at fair value all assets obtained and liabilities incurred as a result of a transfer accounted for as a sale; and requires enhanced disclosure; among others. These changes become effective for the Company on March 1, 2010. The adoption of these changes did not have an impact on the Company’s financial statements. |

| In June 2009, the FASB issued changes to the accounting for variable interest entities. These changes require an enterprise to perform an analysis to determine whether the enterprise’s variable interest or interests give it a controlling financial interest in a variable interest entity; to require ongoing reassessments of whether an enterprise is the primary beneficiary of a variable interest entity; to eliminate the quantitative approach previously required for determining the primary beneficiary of a variable interest entity; to add an additional reconsideration event for determining whether an entity is a variable interest entity when any changes in facts and circumstances occur such that holders of the equity investment at risk, as a group, lose the power from voting rights or similar rights of those investments to direct the activities of the entity that most significantly impact the entity’s economic performance; and to require enhanced disclosures that will provide users of financial statements with more transparent information about an enterprise’s involvement in a variable interest entity. This Statement became effective for the Company on March 1, 2010. Earlier application was prohibited. The adoption of these changes did not have an impact on the Company’s financial statements. |

| In October 2009, the FASB issued ASU 2009-13 for changes to multiple-deliverable revenue arrangements a consensus of the FASB emerging issues task force, which amends ASC topic 605, Revenue Recognition, to require companies to allocate revenue in multiple-element arrangements based on an element’s estimated selling price if vendor-specific or other third-party evidence of value is not available. ASU 2009-13 is effective for us on November 1, 2010. Earlier application is permitted. The adoption of these changes did not have an impact on the Company’s financial statements. |

| 3. | Mineral Interests |

| On March 18, 2008, the Company entered into a mineral property purchase agreement to acquire a 100% interest in the Emmy Claim located in the New Westminster Mining Division, BC for total consideration of $8,000. This mining interest was held in trust for the Company by the vendor of the property. On January 25, 2010 this mineral claim had lapsed and was re-staked by a third party. On February 4, 2010 the Company entered into a Letter and Trust Agreement with this third party to acquire the Emmy Claim. The Company paid $500 as consideration. The Emmy Claim expired February 4, 2011. The Company is no longer exploring for mineral properties. |

| 4. | Intangible Assets |

F-7

Bioflamex Corp. (formerly known as Deer Bay Resources Inc.)

(A Development Stage Company)

Notes to The Financial Statements

For the Years Ended February 28, 2011 and 2010

| On January 25, 2011, the Company entered into an Asset Purchase Agreement to acquire certain intellectual property related to line of fire extinguishing and prevention products that are based on environment friendly and biological formulations. In consideration for the newly acquired assets, the Company issued 38,000,000 shares at $0.0313 per share, totaling $1,191,000, to two individuals who became the entire Board of Directors and the two senior officers of the Company. The Company followed SAB Topic 5 G in determining value as the transaction was considered a non-monetary related party transaction. Value was determined based on historical costs associated with testing, patenting and trademarking the intellectual property and also supported by an independent valuation of the intellectual property. The entire purchase price was allocated to the intangible asset category of Patents and Trademarks. |

| 5. | Related Party Loans/Transactions |

| The President of the Company loaned a further $2,939 during the year ended February 28, 2011 for a total loan outstanding of $5,439. This loan was repaid in full on December 22, 2010. |

| A shareholder of the Company loaned a further $5,250 during the year ended February 28, 2011 for a total loan outstanding of $13,250. This loan was non-interest bearing and was repaid in full on December 21, 2010. |

| See Intangible Assets, Note 4 and Common Stock, Note 7 for other related party transactions. |

| 6. | Convertible Debt |

| The Company received $60,500 pursuant to a convertible debenture subscription agreement. The loan is convertible into 6,050,000 common shares of the Company at a rate of $0.01 of debt for each share issued. The maturity date of this convertible debenture is December 13, 2012. The debenture does not carry any rate of interest and is unsecured. |

| 7. | Common Stock |

| On January 25, 2011, the Company entered into an Asset Purchase Agreement to acquire certain intellectual property related to line of fire extinguishing and prevention products that are based on environment friendly and biological formulations. In consideration for the newly acquired assets, the Company issued 19,000,000 common shares to each of two individuals at $0.0313 per share. The vendors became the sole directors and officers of the Company and acquired 12,856,667 common shares from the former director and Chief Executive Officer. Also on January 25, 2011 the former director and Chief Executive Officer returned to treasury for cancellation at total of 75,643,333 common shares. |

| At February 28, 2011, there were no outstanding stock options or warrants. |

| 8. | Income Taxes |

| Potential benefits of income tax losses are not recognized in the accounts until realization is more likely than not. The Company has net operating losses of $89,000 which commence expiring in 2025. The Company is required to compute tax asset benefits for net operating losses carried forward. Potential benefits of net operating losses have not been recognized in these financial statements because the Company cannot be assured it is more likely than not it will utilize the net operating losses carried forward in future years. |