UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

______________

FORM 8-K

______________

CURRENT REPORT

Pursuant to Section 13 or 15(d) of the Securities Exchange Act of 1934

Date of Report (Date of earliest event reported): February 24, 2011

______________

LEGEND INTERNATIONAL HOLDINGS, INC

(Exact name of registrant as specified in its charter)

______________

|

Delaware

|

000-32551

|

23-3067904

|

|

(State or Other Jurisdiction

|

(Commission

|

(I.R.S. Employer

|

|

of Incorporation)

|

File Number)

|

Identification No.)

|

Level 8, 580 St Kilda Road, Melbourne, Victoria Australia 3004

(Address of Principal Executive Office) (Zip Code)

61-3-8532-2866

(Registrant’s telephone number, including area code)

N/A

(Former name or former address, if changed since last report)

Check the appropriate box below if the Form 8-K filing is intended to simultaneously satisfy the filing obligation of the registrant under any of the following provisions:

o Written communications pursuant to Rule 425 under the Securities Act (17 CFR 230.425)

o Soliciting material pursuant to Rule 14a-12 under the Exchange Act (17 CFR 240.14a-12)

o Pre-commencement communications pursuant to Rule 14d-2(b) under the Exchange Act (17 CFR 240.14d-2(b))

o Pre-commencement communications pursuant to Rule 13e-4(c) under the Exchange Act (17 CFR 240.13e-4(c))

Item 7.01 Regulation FD

In accordance with General Instruction B.2 of Form 8-K, the information in this Item 7.01, shall not be deemed to be “filed” for purposes of Section 18 of the Securities Exchange act of 1934, as amended (the “Exchange Act”), or otherwise subject to the liability of that section, and shall not be incorporated by reference into any registration statement or other document filed under the Securities Act of 1933, as amended, or the Exchange Act, except as shall be expressly set forth by specific reference in such filing.

TECHNICAL REPORT

PARADISE SOUTH RESERVE ESTIMATE

FEBRUARY 24, 2011

For this initial mineral reserve estimate Legend aimed to define reserves for a minimum 30 year mine life to support the base case scenario of producing 600,000 tonnes per year of Diammonium Phosphate (DAP) and Monoammonium Phosphate (MAP) high analysis phosphate fertilizers, for 30 years as covered by Legend’s feasibility study (see press release dated July 24 2010 on the company website www.lgdi.net). The resulting mineral reserve estimate is well above expectations with the following highlights:

|

Ø

|

Proven and probable phosphate rock reserves that will support 59 years of operation for the production of 600,000 tonnes of DAP per year or 29 years at a doubled rate of production.

|

|

Ø

|

‘As-mined’ proven and probable ore reserves of phosphorite of 196.2 million tonnes at 14.6% P2O5.

|

|

Ø

|

Proven and probable mineral reserves of recoverable, commercially useable and internationally marketable phosphate rock concentrate of 55.5 million tonnes at 33% P2O5 (72 BPL).

|

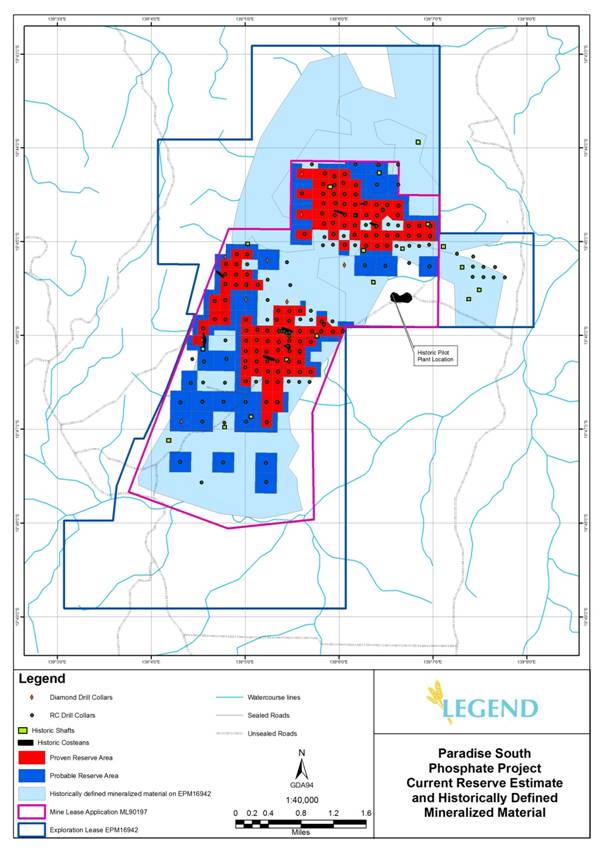

The reserve area targeted by recent drilling within the Paradise South Mining Lease Application (MLA90197 – see Figure 1) equates to only approximately 70% of the area that contains historically defined mineralised material within this lease and only approximately 50% of the area that contains historically defined mineralised material within Legends exploration licence EPM16942 (see Figure 2). The current reserve estimates correlate well to historical (1970’s) estimates. This supports potential further increases in reserve tonnage upon successful future drilling results within areas that have not recently been tested with modern drilling techniques but have reported phosphate intersections in historical drilling information.

Paradise South is one of seven phosphate rock deposits controlled by Legend and is the first to have a current mineral reserve estimate reported. All seven deposits however have historically reported mineralised material of significant tonnage.

Reserves

The reserve estimate is presented below in Table 1 as both “as-mined” ore reserves of phosphorite which will provide feed for the beneficiation plant to be located at Paradise South, and the recoverable commercially useable or marketable phosphate rock concentrate or “product” mineral reserves achievable from the ore reserves. The ore reserves and mineral reserves cannot be aggregated as the mineral reserves represent the recoverable product derived from the ore reserves after beneficiation of the phosphorite. Reserve classifications are as defined in the U.S Securities and Exchange Commission’s Industry Guide No. 7 (see Glossary of Terms below).

2

The “as-mined” proven ore reserves of the Paradise South phosphorite deposit are currently estimated at 98.0 million tonnes of phosphorite at 15.3% P2O5. The Paradise South phosphorite deposit contains additional probable ore reserves estimated at 98.1 million tonnes of phosphorite at 13.9% P2O5. The total proven and probable ore reserves are estimated at 196.1 million tonnes of phosphorite at 14.6% P2O5. These reserves are based on a block model, typical of industry standards, developed from 180 drill holes using reverse circulation drilling technology and 32 cored diamond drill holes.

The recoverable, proven mineral reserves of the Paradise South phosphorite deposit are currently estimated at 28.9 million tonnes of phosphate rock concentrate at 33.1% P2O5 (72.4 BPL). The Paradise South phosphorite deposit contains additional probable mineral reserves estimated at 26.6 million tonnes of phosphate rock concentrates at 32.9% P2O5 (71.8 BPL). The total proven and probable mineral reserves are estimated at 55.5 million tonnes of phosphate rock concentrates at 33.0% P2O5 (72.1 BPL). These reserves are based on a block model, typical of industry standards, developed from 180 drill holes using reverse circulation drilling technology, 32 cored diamond drill holes and a beneficiation process developed specifically for Legend’s phosphorite ore types.

The production scenario of producing 600,000 tonnes per year of DAP fertilizer requires approximately 0.95 million tonnes per annum of phosphate rock concentrate at 33.0% P2O5 to feed Legend’s proposed Mt Isa Fertilizer Complex. The above proven and probable phosphate rock concentrate reserves of 55.5 million tonnes therefore provide a total project life estimated at 59 years. This mine life calculation is based on recovering 93% of the P2O5 from the rock concentrate during the acidulation process and 95% of the P2O5 during the DAP/MAP granulation process. It is also based on producing only DAP containing 46% P2O5. A doubled production scenario would provide an estimated total project mine life of 29 years. Producing both MAP and DAP at a 2:1 production ratio would reduce the total mine life to 54 years due to the higher P2O5 content of MAP (52% P2O5).

Proven reserves are based on an area of influence for each drill hole not to exceed 20 acres (8 hectares). Probable reserves are based on an area of influence for each drill hole not to exceed 40 acres (16 hectares).

It is reasonable to expect that additional fill-in drilling to reduce the drill hole area of influence will result in the reclassification of probable reserves into the proven category. Legend may endeavour to expand the Paradise South proven and probable reserves in future drilling seasons.

3

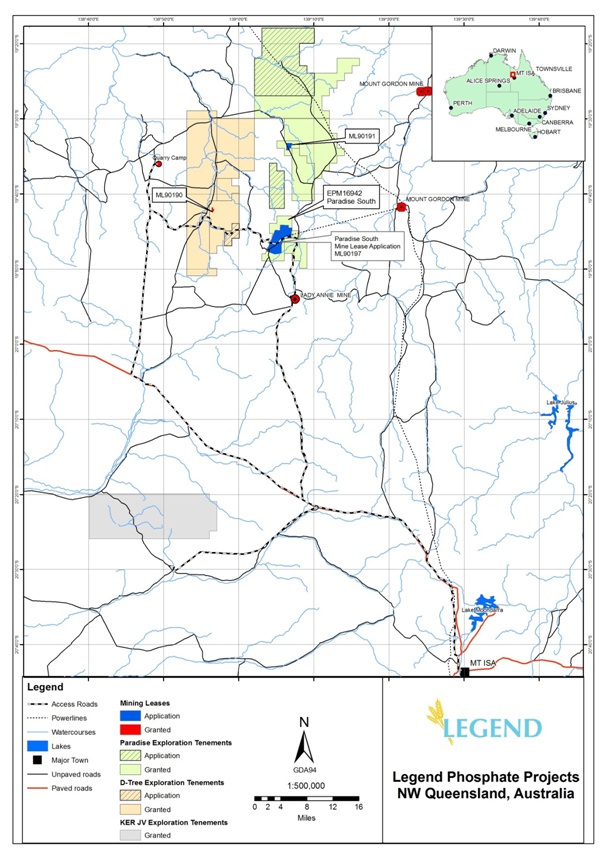

Figure 1 - Location and access to Paradise South.

4

Figure 2 – Paradise South Reserve Blocks

5

Table 1. Ore & Mineral Reserves for the Paradise South Phosphate Rock Deposit.

|

(1) (2) ORE RESERVES - "As-Mined” Phosphorite (Pre Processing)

|

|||||||

|

Tonnes (Millions)

|

%P2O5

|

Average BPL

|

%Fe2O3

|

%Al2O3

|

%MgO

|

%CaO

|

|

|

Proven

|

98.0

|

15.3

|

33.4

|

6.5

|

2.6

|

0.4

|

21.3

|

|

Probable

|

98.1

|

13.9

|

30.4

|

6.1

|

2.4

|

0.4

|

19.3

|

|

Total

|

196.1

|

14.6

|

31.9

|

6.3

|

2.5

|

0.4

|

20.3

|

|

Acres

|

Hectares

|

(3)Overburden

|

(3)Ore

|

(3)Interburden

|

|||

|

Proven

|

1,277

|

517

|

10.1

|

10.5

|

2.3

|

||

|

Probable

|

1,315

|

532

|

13.4

|

10.2

|

3.2

|

||

|

Total

|

2,592

|

1,049

|

11.8

|

10.4

|

2.8

|

||

|

(4) (2) MINERAL RESERVES - Recoverable Phosphate Rock Concentrate (Post Processing)

|

|||||||

|

Tonnes (Millions)

|

%P2O5

|

Average BPL

|

%Fe2O3

|

%Al2O3

|

%MgO

|

%CaO

|

|

|

Proven

|

28.9

|

33.1

|

72.4

|

(5)3.0

|

0.8

|

0.2

|

47.0

|

|

Probable

|

26.6

|

32.9

|

71.9

|

(5)2.9

|

0.8

|

0.2

|

46.6

|

|

Total

|

55.5

|

33.0

|

72.1

|

(5)2.9

|

0.8

|

0.2

|

46.8

|

|

(1)

|

Ore reserves are defined here as the phosphorite ore material for the beneficiation plant. It is “as-mined” material and is before screening and processing in the proposed flotation beneficiation plant to be located at Paradise South. All ore reserves are in areas that are fully accessible for mining; free of surface or subsurface encumbrance, legal setbacks, environmental reserves and other legal restrictions that preclude permittable access for mining; believed by us to be permittable within a reasonable timeframe; and meet specified minimum physical, economic and chemical criteria related to current mining and production practices of the industry.

|

|

(2)

|

Proven and Probable Reserves have been estimated by Henry J. Lamb (a member of the American Institute of Professional Geologists and Licensed Professional Geologist Registered in the states of Florida and North Carolina), who has more than 30 years experience in the exploration, development, valuation and operation of phosphorite deposits throughout the world including the United States, Peru, Egypt, Iraq, Uganda, Australia, Jordan, and Kazakhstan. Mr. Lamb is an independent consultant contracted to Legend. During this project, Mr. Lamb had opportunities to observe portions of the drilling and sampling activity, reviewed analytical and metallurgical laboratory procedures, reviewed the geologic database, converted the phosphorite ore information to phosphate rock concentrate (product); reviewed the operating cost model, and independently estimated the proven and probable reserves based on phosphate industry accepted procedures and standards. In preparing this proven and probable phosphate rock concentrate reserve estimate, Mr. Lamb relied upon his independent examination of geologic, metallurgical, and cost estimate data provided by Legend. Throughout the exploration and development program, Mr. Lamb has been an independent Technical Advisor to the Legend staff and project management regarding the exploration and development of the Paradise South Phosphorite Deposit.

|

|

(3)

|

Overburden, ore and interburden are reported here as average thicknesses in vertical metres.

|

|

(4)

|

Mineral reserves are defined here as the recoverable rock concentrate post screening and processing of the ore through the proposed flotation beneficiation plant to be located at Paradise South. This material is therefore a subset of the ore reserves and cannot be summed with the ore reserves. These reserves are in areas that are fully accessible for mining; free of surface or subsurface encumbrance, legal setbacks, environmental reserves and other legal restrictions that preclude permittable access for mining; believed by us to be permittable within a reasonable timeframe; and meet specified minimum physical, economic and chemical criteria related to current mining and production practices of the industry.

|

6

|

(5)

|

Please see comments below in the section on Metallurgy titled “Investigative studies on the Fe2O3 content” which details testwork that shows less than 50% of the iron contained in the rock concentrate leaches into the phosphoric acid due to the iron species being less amenable to acidulation than other known iron species.

|

Commodity Pricing

Legend currently intends to use its Paradise South phosphate rock concentrate mineral reserves in its own Mt Isa Fertilizer Complex proposed for construction at the development site in Mt Isa, Queensland, Australia, to produce the high analysis phosphate fertilizers MAP and DAP. Profit will be attributable to the Fertilizer Complex rather than the phosphate rock mine. Legend has therefore optimized the Paradise South reserve estimates with the aim of achieving average mining and processing costs across the life of mine to be consistent with similar new phosphate developments around the world, and within an acceptable range of costs estimated in Legend’s 2010 feasibility study to achieve similar profit margins as estimated in the study.

The feasibility study assumed a long term average DAP selling price equivalent to US$445 per tonne sold FOB Tampa (US$531 FOB Townsville) which reported cash margins of US$210 per tonne of DAP produced. The DAP price FOB Tampa used is within 2% of CRU Group’s(1) long term 10 year average forecast from 2010 to 2019. It is worth noting that current spot prices for DAP are over US$610(2) per tonne FOB Tampa ($696 fob Townsville) as of 24 February 2011. All Australian dollar costs were converted to USD at a rate of 1.00 AUD = 0.85 USD.

|

(1)

|

CRU Group are commodity research analysts who currently publish fertilizer prices in the weekly industry recognised publication FERTILIZER WEEK.

|

|

(2)

|

Sourced from recognised fertilizer industry weekly price publications.

|

Project Description

Legend is focused on the development of mining, beneficiation and processing of its phosphate mineral reserves near Mount Isa in northwest Queensland, Australia. Legend has a phased implementation plan to become one of the world's leading suppliers of the phosphate fertilizers DAP and MAP and the valuable by-product Aluminum Fluoride (AlF3).

The Paradise South project involves development of a beneficiation plant at Paradise South to upgrade the phosphorite ore into a phosphate rock concentrate suitable for phosphate-based fertilizer manufacture. The phosphate rock concentrate will be transported to Mount Isa for treatment in a purpose built DAP/MAP fertilizer manufacturing facility in Mount Isa. The DAP, MAP and AlF3 will be transported from Mount Isa to the Port of Townsville via rail for local and international markets. A feasibility study conducted in 2010 outlined that the project was technically and economically viable (see press release dated July 24 2010) for the base case scenario as described below:

|

Ø

|

Transport approximately 1 million tonnes of upgraded ore by road from Paradise South to the proposed Mt Isa Fertilizer Complex.

|

|

Ø

|

Direct acidulation in Legend’s proposed phosphoric acid plant of upgraded ore to produce approximately 300ktpa phosphoric acid using approximately 800ktpa of sulfuric acid (200ktpa sourced from local smelters and 600ktpa produced in Legend’s sulfuric acid plant, using imported sulfur).

|

|

Ø

|

Import of approximately 100ktpa of liquid ammonia (NH3) to combine with phosphoric acid in the ammonium phosphate plant to enable granulation of MAP and DAP in a ratio dependent on market conditions but currently assumed at 400ktpa MAP and 200ktpa DAP.

|

|

Ø

|

Production of 15ktpa of aluminium fluoride (AlF3) through Wengfu’s proprietary technology for their self-developed dry process. This marketable chemical product is used in the aluminium industry which currently has a strong demand both locally in Australia and in overseas markets.

|

7

|

Ø

|

Water for the phosphoric acid plant will be sourced from the Lake Julius water allocation. Water will be transferred from Lake Julius to Lake Moondarra via the existing transfer pipeline. An existing pumping station and new pipeline from Lake Moondarra will service the phosphoric acid plant.

|

|

Ø

|

Power for phosphoric acid plant will come from the Ergon Energy eastern transmission line near Mica Creek Power Station.

|

|

Ø

|

Transport 600ktpa of MAP/DAP and 15ktpa aluminium fluoride in containers on flat bed rail wagons from Mt Isa to the Port of Townsville using 2 train sets for sale on the local and international markets.

|

Project Expansion Study

An expanded study has also been underway to examine the feasibility of doubling production to produce 1.2 million tonnes of DAP/MAP and 30,000 tonnes of AlF3 per year. Indications are positive in that the project economics improve with increased scale and that the proposed scale is technically and economically feasible. The above reported mineral reserve estimate also warrants an expanded production scenario with no further drilling required at this stage. Completion and reporting of results of this study are now estimated to occur before the end of this current quarter (Q1 2011).

Location and Access

The Paradise South Phosphate deposit is located approximately 130 kilometres to the North West of Mt Isa in north-western Queensland. Access from Mt Isa is via the main Barkly Highway, which connects Mt Isa to Tennant Creek in the Northern Territory, for 67km, then via the McNamara Highway, which is a well maintained haul road used by the Lady Annie Copper Mine, for about 50km, then via farm access roads for a further 10 kilometres (see Figure 1). The farm access roads have been maintained by Legend sub-contractors for the duration of drilling and exploration activities.

Paradise South is part of the EPM16942 lease, which is one of 12 exploration tenements covering 7 phosphate deposits granted to Legend or its joint venture partner King Eagle Resources Ltd, located in Queensland, Australia.

Mining Title

Legend currently has a Mining Lease Application (MLA) being processed by the Queensland Government for MLA 90197, Paradise South (See Figure 1) and a granted exploration permit EPM16942 which encompasses the entire mineral reserve as reported above. The MLA process involves approval through the Environmental Protection (EP) Act, Native Title Act (NTA) and Mineral Resources Act (MRA).

Due to the scale of the proposed Paradise South production, Legend has voluntarily submitted an application to undertake an Environmental Impact Statement (EIS) under the EP Act for the Paradise South mine lease (MLA 90197), beneficiation plant and associated infrastructure. Legend agreed to the Terms of Reference (TOR) for the EIS with the Queensland Government’s Department of Environment & Resource Management (DERM) on June 30, 2010, and these were advertised in a public notice on July 3, 2010. Post wet-season environmental surveys were undertaken in 2010 and all data required for the environmental studies of the EIS is now available. Legend was granted a ‘Right to Negotiate’ under the NTA for the Paradise South mine lease as advertised in a public notice on May 5, 2010. Legend continues to negotiate access and compensation agreements as required by the NTA and MRA for the Paradise South mine lease with the local indigenous group, pastoralists and mining companies – some of which are parties who have already provided consent in respect of the Paradise North mine lease application (MLA90191).

8

Legend has reasonable expectations that MLA90197 for Paradise South will be granted within approximately 12 months although exact timeframes will not be known until closer to the time of grant. This is well within the current projected timelines for the project development which is currently forecasting mining production to begin in 2017 at this location. Legend has already successfully been granted a Mining Lease (ML90190) over a portion of the D-Tree deposit (see press release dated 13 August 2010 and Figure 1) which demonstrates Legends ability to work within the Queensland Government’s procedures to successfully secure mining tenure. Legend has also submitted a Mining Lease Application for Paradise North (MLA90191) which is anticipated to be granted within the next few months and is the proposed location of initial mining for the project beginning in 2013. Reserves for Paradise North are currently being estimated and will be reported later this year.

Project History

The Paradise South Mineral Reserve estimate forms part of the historical phosphate deposit known as Lady Annie which was discovered in 1967 by Broken Hill South Ltd (BH South). BH South reported historical tonnages of mineralised material in 1972 using 54,499 metres of rotary percussion drilling, 33 shafts and 10 deep trenches which provided feed to a pilot plant which was constructed on site and operated for 1 year processing 64,000 tonnes of material. The phosphate rock concentrate produced from the pilot plant achieved grades between 32% P2O5 and 36% P2O5 and was used to produce DAP and MAP in full scale plant testing by international fertilizer manufacturers (Rogers, J.K. and Keevers, R.E., 1976).

Feasibility studies were carried out by BH South with a view to the development of the Lady Annie deposit and included investigation of mining and beneficiation, transportation, port location, power and water supply and townships. Results of these studies were positive however subsequent market events caused development to be postponed.

In 1980 Western Mining Corporation (WMC) and Conzinc Rio Tinto of Australia (CRA) made a successful bid for BH South and in 1990 acquired all the remaining shares in Queensland Phosphates Ltd which was the holding company of the phosphate assets in Queensland.

In 2005 WMC was taken over by BHP Billiton Ltd who then sold its Queensland Phosphate assets to Incitec Pivot Ltd in 2006. Legend successfully applied for and was granted the exploration permit in 2007.

Legend commenced drilling at Paradise South in 2009, operated a pilot beneficiation plant in late 2009 and completed a feasibility study in 2010 which has culminated in this initial reserve estimate to support the project defined in the 2010 feasibility study.

Geology

Regional Geology

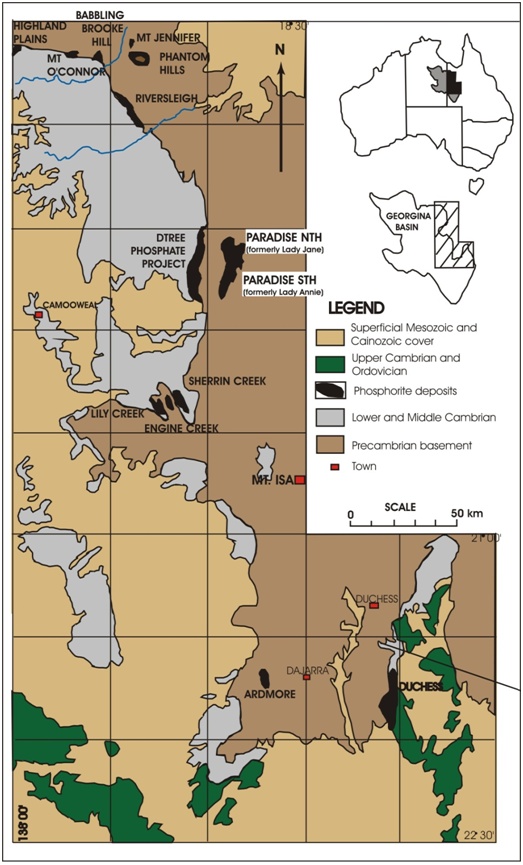

The majority of Australia’s sedimentary phosphorite (phosphate rock ore) reserves lie within early Middle Cambrian successions of the Georgina Basin in northwest Queensland and northeast Northern Territory (see Figure 3). Some eighteen named, discrete phosphorite deposits occur within the lower Middle Cambrian Beetle Creek Formation, or its stratigraphic equivalent the Border Waterhole Formation, that are basal in the stratigraphy of the Georgina Basin.

The Georgina Basin is a broad intracratonic basin covering some 325,000 km2 of western Queensland and east-central Northern Territory (Shergold and Druce, 1980). The basin is bound by Proterozoic basement of the Mount Isa Block and South Nicholson Basin to the east and north; and by the Tennant Creek Block and the Arunta Complex to the west and south.

9

Sediments within the Georgina Basin consist mainly of Cambrian to Middle Ordovician marine sedimentary rocks. The Cambrian and Early Ordovician sediments are dominated by marine carbonate rocks with minor sandstone and siltstone, while the Middle Ordovician rocks are comprised primarily of siltstone and sandstone. Silurian to Devonian freshwater sandstone and Permian boulder beds overlie the early Palaeozoic Georgina Basin succession and are thought to represent younger successions laid down in later basins. Throughout the basin, sediments have been deformed by minor to moderate folding and faulting, with moderate to strong folding, faulting and overthrusting along the southern margin.

10

Figure 3 - Location of major phosphorite deposits of the Georgina Basin, northwest Queensland (after Rogers and Keevers, 1976).

11

Local Geology

Due to considerable exploration efforts in the 1960’s and 70’s the local geology of the Paradise South area has been well-described in several publications, namely Rogers and Keevers (1976), Thomson and Russell (1971) and Thomson and Rogers (1974). The results of the current drilling program concur with the findings of the historic drilling results and geological interpretation. The geology description herein is derived from both historic and recent observation and results.

The Paradise South phosphorite deposit, discovered in the late 1960’s and formerly known as the Lady Annie phosphorite deposit, is located in an outlier of the Georgina Basin, separated from the D-Tree deposit to the west by outcropping Precambrian sediments (Figure 2). It is confined to an area of low relief, approximately 25 km long and 5 km wide, trending north-south between ridges and hills of Precambrian shales, quartzites, siltstones and dolomite. The sedimentary phosphate rock was deposited in an embayment of the inland sea that covered the Georgina Basin during the early Middle Cambrian.

Stratigraphy of the embayment hosting the Paradise South phosphorite is comprised of sediments of Cambrian and Mesozoic age, with some thin overlying Tertiary and Recent deposits. The phosphatic unit that comprises the reserves defined herein is the Beetle Creek Formation. The most prominent units of the Paradise South project area are as follows:

|

●

|

Tertiary laterite and silcrete up to 5m thick.

|

|

●

|

Mesozoic quartz sandstones, micaceous mudstone and coarse conglomerate beds. These sediments are mostly confined to the western boundary of the Paradise South project area, adjacent to the Western Fault and can be up to 40m thick.

|

|

●

|

The Inca Formation of Middle Cambrian age consists of well-laminated fissile shale with some interbeds of siltstone and minor chert. This unit has a recorded maximum thickness of 24m in the project area.

|

|

●

|

The Beetle Creek Formation of Lower Middle Cambrian age consists of beds of phosphorite, siltstone, shale and chert. Phosphorite lithologies include friable pelletal phosphorite and soft clayey phosphatic mudstone. This unit attains a maximum thickness of 46.5m in the Paradise South project area.

|

|

●

|

The Thorntonia Limestone underlies the Beetle Creek Formation on the eastern margin of the Paradise South project area. In contrast to the Beetle Creek Formation this unit is characterised by dolomitic limestone containing abundant chert nodules. The thickness of this unit is highly variable and reaches a maximum of 16m.

|

|

●

|

The Mt Hendry Formation forms the basal unit of the Cambrian stratigraphy and is typically a 2m thick conglomerate with lesser sandstone.

|

Drilling, Sampling and Metallurgical Testing

Legend has completed 180 reverse circulation (RC) drill holes within the MLA area of the Paradise South Phosphorite Deposit and an additional 32 core diamond drill holes have been completed with 23 of those diamond drill holes being twins to the reverse circulation drill holes.

The RC drill holes were 120mm in diameter and extended to variable depths each of which was sufficient to intersect the anticipated and full thickness of the phosphate rock bearing horizon. RC sampling was conducted using a commercially available rig-mounted static cone splitter. The sampling procedures were developed by the Legend Geology team and required several steps:

|

●

|

The RC samples were composites, collected for each 1 metre interval.

|

|

●

|

A cone splitter was used to collect a 1 to 3 kilogram subsample for ore interval assaying. A second field duplicate was collected at the same time for future reference.

|

12

|

●

|

All sample reject through the cone splitter was collected, labelled and stored in a temporary storage area at Paradise South and are available for future testing.

|

|

●

|

A combined sample weight was measured using on site scales and logged into the database.

|

|

●

|

Each sample was tested in the field using the modified Shapiro test for estimating phosphate content. A sample returning a positive field test result was submitted to the analytical laboratory for final analysis.

|

|

●

|

For each hole two field duplicates were submitted for analytical testing.

|

|

●

|

A set of matrix matched reference standards were inserted into the lab submission for QA/QC purposes. Standards were submitted to the lab at a rate of 1 in 25 samples. A coarse blank sample was also inserted for submission at a rate of 1 in 25 samples.

|

The cored diamond drill holes were 83mm in diameter and also intersected the full thickness of the phosphate rock horizon. Diamond core samples were generally collected in 1.5m core runs, except where ground conditions dictated shorter run lengths. To ensure diamond core sample integrity was maintained, each run of diamond drill core was transferred from the inner tube to a PVC split placed inside the core tray to hold the core in place. This was particularly effective in maintaining the sample integrity of highly oxidised, friable core samples.

For the metallurgical testwork conducted on the Paradise South phosphorite in 2010, 39 samples were composited from the phosphorite horizon/s from 22 diamond holes and 4 RC holes. Diamond drill cores were sampled for bulk density analysis as whole core samples. Where core samples have been submitted for assay, quarter core samples were taken using a manual diamond blade core saw. Before cutting, diamond cores were metre-marked and assessed to make sure all of the pieces of core were positioned to conform to the original orientation, i.e. all core breaks were aligned. Core samples were then crushed at the laboratory prior to being riffle split into sub-samples and prepared for analysis by the same method used for RC samples.

Samples were routinely assayed by an ICP acid digest method that conforms to the internationally accepted analytical method of the Association of Fertiliser and Phosphate Chemists (AFPC). The specific method is ICP Method 3D-2. The samples are dried at 105°C, pulverised and an aliquot taken for acid digest in two parts nitric acid, two parts water and 1 part hydrochloric acid. The acid digest is then analysed using the multi-element inductively coupled plasma atomic emission spectrometer (ICP-AES). The standard assay suite for the ICP analytical technique is:

|

●

|

P2O5, Al2O3, Fe2O3, MgO, and CaO

|

Metallurgy

Beneficiation Process Testing

Legend processed 32 out of the 39 composited Paradise South drill core and reverse circulation samples through their beneficiation flow sheet to model the relationships between ore and concentrate analyses for P2O5 and the main impurity species Fe2O3, Al2O3, MgO and CaO. Each selected metallurgical diamond and RC drill core was individually dry tumbled and screened at 25mm to remove silica in the +25mm fraction. The -25mm fractions were wet milled to a minimum P80 150 microns and then filtered to at least 75% solids. This slurry was then systematically conditioned with flotation reagents including a collector and an iron depressant at 75% solids before being diluted to approximately 20% solids with water and transferred to the pilot scale flotation cell. Rougher, scavenger and cleaner flotation was completed on each sample, followed by filtering, drying, and weighing of the products. Each product was assayed for P2O5, Fe2O3, Al2O3 and CaO by ICP and MgO and SiO2 by XRF.

13

The results of this work allowed Legend to calculate the mineral reserve tonnes in terms of phosphate rock concentrate product. These samples provided a full range of phosphorite samples and variations of the primary chemical components (P2O5, Fe2O3, Al2O3, MgO and CaO) in the ore and the resulting primary chemical components after the initial crushing and sizing, in the flotation feed, and in the phosphate rock concentrate. From these metallurgical tests it was possible to develop high-quality, strongly correlated regression formulas to convert the ore assays to reliable estimates of the concentrate chemistry and the amount of recoverable product.

Investigative Studies of the Fe2O3 Content

Many phosphorite deposits in the Georgina Basin have a higher than normal Fe2O3 content when compared to the typical world phosphorite deposits. This results in a higher than normal MER (Minor Element Ratio) defined as the metallic contents of Fe2O3 + Al2O3 + MgO divided by the P2O5. In the case of the Paradise South Deposit, the MER ratio for the phosphate rock concentrates is 0.12 compared to the more common ratio of 0.10.

Legend commissioned definitive chemical and mineralogical studies to define the behaviour of the Fe2O3 in the Paradise South phosphate rock concentrates. Phosphoric acid testing at an independent laboratory (Crescent Technologies in New Orleans, Louisiana) and at the company laboratories of IFFCO (Indian Farmers Fertilizer Cooperative (India) and Wengfu (China) confirmed that approximately 50% of the iron content was not reporting to the phosphoric acid; therefore, the phosphoric acid MER was acceptable for manufacturing ammoniated granular phosphate-base fertilizers (DAP). Further testing of several phosphate rock concentrate samples with varying Fe2O3 contents were acidulated with the phosphate rock concentrate, the acidulation residue, and the phosphoric acid being assayed and the residue mineralogy being defined by QEM-SCAN (Quantitative Evaluation of Minerals by SCANning electron microscopy). The electron microscopy work clearly indicated than much of the residual solids from the phosphoric acid test was goethite, an iron mineral, which resisted acidulation. Further, the goethite particles contained apatite inclusions and voids that appeared to be similar to the apatite inclusions but indicated that some of the apatite inclusions had been acidulated.

Table 3 below shows some results from these tests and indicates only 29.2%, 11.6% and 21% of the Fe2O3 in these phosphate rock concentrate leaches into the resulting phosphoric acid. Mineralogical examination concluded that the Fe2O3 in Paradise South phosphorite is present as the refractory mineral goethite and does not leach as readily as other Fe2O3 minerals. These three samples were selected for testing due to their higher than typical Fe2O3 contents. Approximately 82 grams were used for the iron leach tests which were split from a 0.5kg sample of concentrate derived from individual composited drill core samples.

Additional tests with samples representing higher Fe2O3 contents are being planned. The results of those tests may result in an increase in the Paradise South reserve tonnage estimate as higher levels of Fe2O3 could potentially be processed.

Table 3- Iron solubilities in phosphoric acid.

|

Sample

|

Rock

Concentrate Units Fe2O3 |

Phosphoric

Acid Units Fe2O3 |

Fe2O3

Extraction % to acid |

|

JC14

|

2.12

|

0.62

|

29.2

|

|

JC19

|

3.20

|

0.37

|

11.6

|

|

JC20

|

6.92

|

1.45

|

21.0

|

Bulk Density Testing

Bulk density and associated tonnage calculations have been determined from a series of diamond holes distributed across the Paradise South phosphorite deposit. A bulk density sampling program was carried out on diamond core samples from 17 locations with a total of 281 samples. In each drill core, samples were taken from each identified lithology, which in most cases involved taking samples at intervals ranging from 0.5 - 2m.

14

Whole drill core samples, typically of minimum 100mm length and up to 350mm in length, were submitted to the laboratory for bulk density analysis using a standard Archimedes method. Dried core samples were coated in paraffin wax and then weighed in air and again in a liquid of known density, i.e. water, and the bulk density calculated from the difference in weights. The dry bulk densities were determined from samples from the mineralized horizon and for host rock and waste rock lithologies.

A review of the bulk density data relative to lithology and assay grades showed that a range of bulk density values were recorded in the ore zone. The bulk density of the ore zone is generally fairly high (1.9), and the range in bulk density values may be attributed to the different lithologies that comprise the ore zone. For example, mudstone phosphorite, also known as microsphorite, tends to show lower bulk density than peloidal and replacement phosphorite. Differences in clay content and varying states of oxidation and porosity of the ore zone throughout the deposit, may also contribute to the range in bulk density.

The overburden bulk density is generally quite similar to the phosphate zone, likely reflecting an indistinct boundary and contrast between phosphate and waste lithologies.

Table 4 below gives a statistical summary of the bulk density data from within the ore and waste zones.

For the reserve estimate, a conservative bulk density of 1.8 tonnes per cubic meter was used to convert measured phosphorite volumes to phosphorite tonnes.

Table 4: Statistical summary of bulk density data taken from Paradise South core samples and coded according to the resource model domain for ore composite intervals and waste.

|

Ore

|

Waste

|

|

|

Mean

|

1.89

|

2.04

|

|

Standard Error

|

0.02

|

0.05

|

|

Standard Deviation

|

0.24

|

0.29

|

|

Sample Variance

|

0.06

|

0.09

|

|

Confidence Level (95.0%)

|

0.04

|

0.09

|

Note that bulk density data are given in units of tonnes per cubic metre.

15

References:

Association of Fertilizer and Phosphate Chemists. 2010. AFPC Analytical Methods Manual, 10th Edition.

Rogers, J.K. and Keevers, R.E. 1976. Lady Annie-Lady Jane Phosphate Deposits, Georgina Basin, Queensland. In: Economic Geology of Australia and Papua New Guinea, Vol. 4. Industrial Minerals and Rocks (Ed C.L. Knight), pp. 251-265. Australasia Institute of Mining and Metallurgy, Monograph 8.

Shergold, J.H. and Druce, E.C. 1980. Upper Proterozoic and Lower Palaeozoic rocks of the Georgina Basin. In: The Geology and Geophysics of North-Eastern Australia (Eds R.A. Henderson and P.J. Stephenson), pp. 149 - 174. Geological Society of Australia, Queensland Division, Brisbane.

Thomson, L.D. and Rogers, J.K. 1974. The Discovery and Development of Queensland Phosphates by BH South Limited. Paper presented to the Regional Meeting of the Australasian Institute of Mining and Metallurgy (North-west Queensland Branch) on August 27th, 1974, Mt Isa, 26 pp.

Thomson, L.D. and Russell, R.T. 1971. Discovery, Exploration, and Investigations of Phosphate Deposits in Queensland. Proceedings of the Australian Institute of Mining and Metallurgy, 240: 1-14.

Freeman, M.J., Shergold, J.H., Morris, D.G. and Walter, M.R. 1990. Late Proterozoic and Palaeozoic basins of Central and Northern Australia - regional geology and mineralisation. In: Geology of the Mineral Deposits of Australia and Papua New Guinea (Ed F.E. Hughes), pp. 1125-1133. The Australasian Institute of Mining and Metallurgy, Melbourne.

Howard, P.F. 1972. Exploration for phosphorite in Australia - a case history. Economic Geology, 67: 1180 - 1192.

Rogers, J.K. 1986. Report on area relinquished – April 1985, Authority to prospect 903M, Northwest Queensland, Queensland Phosphate Ltd, CR15132. 64p.

Rogers, J.K. and Keevers, R.E. 1976. Lady Annie-Lady Jane Phosphate Deposits, Georgina Basin, Queensland. In: Economic Geology of Australia and Papua New Guinea, Vol. 4. Industrial Minerals and Rocks (Ed C.L. Knight), pp. 251-265. Australasia Institute of Mining and Metallurgy, Monograph 8.

Shergold, J.H. and Druce, E.C. 1980. Upper Proterozoic and Lower Palaeozoic rocks of the Georgina Basin. In: The Geology and Geophysics of North-Eastern Australia (Eds R.A. Henderson and P.J. Stephenson), pp. 149 - 174. Geological Society of Australia, Queensland Division, Brisbane.

Thomson, L.D. and Russell, R.T. 1971. Discovery, Exploration, and Investigations of Phosphate Deposits in Queensland. Proceedings of the Australian Institute of Mining and Metallurgy, 240: 1-14.

16

Glossary of Technical Terms:

Aluminum Fluoride – AlF3 an inorganic compound produced by reacting Aluminium Hydroxide Al(OH)3 with Fluorosilicic Acid H2SiF6. It is an important additive for the production of aluminium by electrolysis.

Apatite - a pale green to purple mineral, found in sedimentary rocks, igneous rocks and metamorphosed limestones. It is used in the manufacture of phosphorus, phosphates, and fertilizers. Composition: calcium fluorophosphate or calcium chlorophosphate. General formula: Ca5(PO4,CO3)3(F,OH,Cl). Crystal structure: hexagonal

Assaying - Qualitative or quantitative analysis of a metal or ore to determine its chemical components.

Beneficiation – any process that, from an ore feedstock, liberates valuable minerals, in this case phosphates, from most other waste materials.

BPL – the traditional measure known as the Bone Phosphate of Lime, by weight percentage, of calcium phosphate contained in phosphate rock which converts to % P2O5 by dividing by 2.185.

Bulk density - is a property of powders, granules and other "divided" solids, especially used in reference to mineral components. It is defined as the mass of many particles of the material divided by the total volume they occupy. The total volume includes particle volume, inter-particle void volume and internal pore volume.

Cambrian - The Cambrian is the first geological period of the Paleozoic Era, lasting from 542 ± 0.3 million years ago to 488.3 ± 1.7 million years ago.

Cone splitter – Sample splitting device attached to the bottom of the cyclone on a RC (reverse circulation) drill rig. Cuttings are gravity fed over a stainless steel cone and multiple outlets capture the divided sample. This splitting method is considered “best practice” within the industry as it eliminates a grainsize bias between samples.

Confidence Level – statistical likelihood (probability) that a random variable lies within the confidence interval of an estimate.

DAP/MAP – Diammonium Phosphate (DAP) and Monoammonium Phosphate (MAP) are phosphate salts produced by reacting phosphoric acid with ammonia. They are both used as fertiliser.

Devonian - The fourth geological period of the Paleozoic Era, spanning 408 to 360 million years ago.

Diamond drill – A method of extracting core samples from the earth. A series of rods/ tubes with a diamond encrusted drill bit on the end are rotated under pressure to cut a drill hole into the earth. The internal core sample is then recovered for testing and study.

Direct acidulation – reaction of phosphate rock or beneficiated phosphate concentrates with sulfuric acid to produce phosphoric acid feedstocks.

Fe2O3 – Iron Oxide

FOB – acronym meaning “free on board” used in conjunction with a port of reference. It is a shipping term outlining which party pays for transportation costs to port, as well as loading costs.

Goethite – FeO(OH) is an iron hydroxide mineral often formed through the weathering of other iron compounds. As a result, it is usually unreactive to acid attack.

17

ICP acid digest – Is a technique used for assaying phosphate rock. Commercial laboratories digest the sample in acid and then analyse it using a multi-element inductively coupled plasma atomic emission spectrometer (ICP-AES).

Intracratonic basin – A depression in the Earths surface caused by subsidence, notable for its lack of significant surrounding highland areas and is usually subsequently filled with sediments..

Laterite - Weathered material composed principally of the oxides of iron, aluminum, titanium, and manganese; laterite ranges from soft, earthy, porous soil to hard, dense rock.

Lithology – A set of characteristics particular to a rock formation.

Mean - The average value of a set of numbers.

Mesozoic - The era of geologic time from about 245 to 65 million years ago.

Micaceous – Mica’s are a group of platy silicate minerals. A rock described as micaceous is either consisting of or pertaining to mica, or has characteristics resembling a mica, either in lustre or in having the property of being easily split into thin sheets.

Microns – a unit of measurement equal to the micrometer, or one-millionth of a meter (1x10-6m).

Ordovician - The second period of the Paleozoic Era, from about 505 to 438 million years ago.

Ore – a mineral that contains a metal, or in this case phosphate, that is economic enough to be mined.

Outlier - an outcrop of rocks that is entirely surrounded by older rocks.

Overthrusting - a reverse fault in which the rocks on the upper surface of a fault plane have moved over the rocks on the lower surface.

P2O5, - phosphorus pentoxide

P80 – a measurement of grinding ability, where 80% of the ground ore will pass through mesh of a pre-determined screen. In this case, a P80 of 150 microns is required.

Palaeozoic - The era of geologic time from about 540 to 245 million years ago.

Pelletal phosphorite– These particulate rocks vary from pale grey-white to yellowish-brown, are highly porous, with a sandy texture and are friable. Pelletal phosphorites are almost completely comprised of collophane (carbonate fluorapatite) occurring as phosphatic fossil fragments and ovulitic peloids. Grainsize is typically around 0.2 - 1.0 mm with a loose cement of collophane mud.

Permian - The seventh and last period of the Paleozoic Era, from about 286 to 245 million years ago.

Phosphorite – a sedimentary rock that contains at least 20 per cent of phosphate minerals.

Probable Reserves - Probable (Indicated) Reserves refers to reserves for which quantity and grade and/or quality are computed from information similar to that used for proven (measured) reserves, but the sites for inspection, sampling, and measurement are farther apart or are otherwise less adequately spaced. The degree of assurance, although lower than that for proven reserves, is high enough to assume continuity between points of observation.

Proterozoic - The later of the two divisions of the Precambrian Eon, from about 2.5 billion to 540 million years ago.

18

Proven Reserves - Proven (Measured) Reserves refers to reserves for which (a) quantity is computed from dimensions revealed in outcrops, trenches, workings, drillholes; grade and/or quality are computed from the results of detailed sampling and (b) the sites of inspection, sampling and measurement are spaced so closely and geologic character is so well defined that size, shape, depth and mineral content of reserves are well-established.

QA/QC – Quality Assurance and Quality Control – refers to the procedures and measures put in place and taken during the drilling and assaying process of the deposit that ensure only repeatable and high quality data is obtained.

Replacement phosphorite - BH South geologists recognised a more indurated, porcellanous form of phosphorite which they termed ‘replacement’ phosphorite. Petrographic studies suggested this material originated from the replacement of limestone or dolomite in the sub-stratum by phosphate (Rogers and Keevers, 1976). Replacement phosphorite is white to tan in colour and consists of structureless collophane containing minor silt, chert and clay. Replacement phosphorite is typically of high-grade.

Reverse Circulation – The method of drilling that was used to obtain the majority of data that has been used in this resource estimation process. Pressurised air is forced down the outside of a string of drill rods that contain an inner-tube. The air drives a hammer and drill bit that breaks and pulverises the rock, once broken down the reverse air pressure forces the resulting material back up the inner-tube to be sampled at the top of the hole.

Sample Variance – A measurement of how spread out a set of numbers/results are from each other.

Shapiro test – A chemical visual colorimetric test developed in the 1960’s that was used in the field by LIH geologists to allow a quantitive estimate of phosphate content of material at the time of sampling.

Silcrete – A hard surface deposit composed of sand and gravel cemented by chert and quartz, it is formed by chemical weathering and water evaporation in semi-arid environments.

Silurian - The third period of the Paleozoic Era, from about 438 to 408 million years ago.

Standard Deviation - A statistic used as a measure of the dispersion or variation in a distribution, equal to the square root of the arithmetic mean of the squares of the deviations from the arithmetic mean.

Standard Error - The standard deviations of the sample in a frequency distribution, obtained by dividing the standard deviation by the total number of cases in the frequency distribution.

Stratigraphy – that aspect of the geology of an area that pertains to the character of its stratified rock.

Tenement - An area of land leased by a mining company from the government upon which they carry out exploration activities.

Terms of Reference - Terms of reference describe the purpose and structure of a project, committee, meeting, negotiation, or any similar collection of people who have agreed to work together to accomplish a shared goal. The terms of reference of a project are often referred to as the project charter.

Tertiary - The first period of the Cenozoic Era, from about 65 to 2 million years ago.

XRF – X-Ray Fluorescence Spectroscopy is a means of identifying elements in a compound by bombarding that compound with x-rays and measuring the unique elemental signature produced.

19

SIGNATURES

Pursuant to the requirements of the Securities Exchange Act of 1934, the Registrant has duly caused this report to be signed on its behalf by the undersigned, hereunto duly authorized.

|

|

LEGEND INTERNATIONAL HOLDINGS, INC.

|

|

|

|

||

|

By:

|

|

|

|

Peter Lee

Secretary

|

||

Date: February 28, 2011