Attached files

Table of Contents

UNITED STATES SECURITIES AND EXCHANGE COMMISSION

WASHINGTON, D.C. 20549

FORM 10-K

(Mark One)

[ x ] ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE

SECURITIES EXCHANGE ACT OF 1934

For the fiscal year ended August 31, 2010

or

[ ] TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d)

OF THE SECURITIES EXCHANGE ACT OF 1934.

For the transition period from to

Commission File Number 0-22496

SCHNITZER STEEL INDUSTRIES, INC.

(Exact name of registrant as specified in its charter)

| OREGON | 93-0341923 | |

| (State of Incorporation) | (I.R.S. Employer Identification No.) |

| 3200 NW Yeon Ave., Portland, OR |

97210 | |

| (Address of principal executive offices) | (Zip Code) |

Registrant’s telephone number, including area code: (503) 224-9900

Securities registered pursuant to Section 12(b) of the Act:

| Class A Common Stock, $1 par value | The NASDAQ Global Select Market | |

| (Title of Each Class) | (Name of each Exchange on which registered) |

Securities registered pursuant to Section 12(g) of the Act:

None

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act.

Yes [ x ] No [ ]

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act.

Yes [ ] No [ x ]

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes [ x ] No [ ]

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Website, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files) Yes [ ] No [ ]

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. [ ]

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer or a smaller reporting company. See definitions of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act. (check one)

| Large Accelerated Filer [ x ] | Accelerated Filer [ ] | |

| Non-Accelerated Filer [ ] | Smaller Reporting company [ ] |

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act).

Yes [ ] No [ x ]

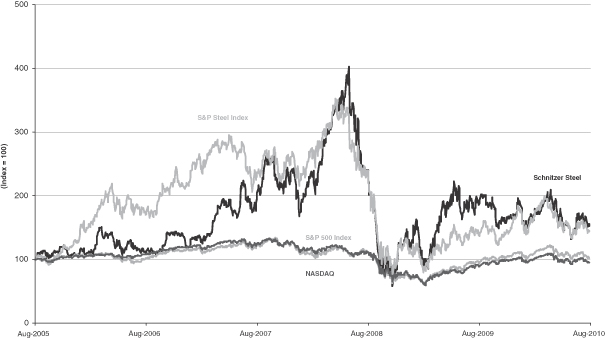

The aggregate market value of the registrant’s voting common stock outstanding held by non-affiliates on February 28, 2010 was $1,012,089,697.

The Registrant had 22,699,657 shares of Class A common stock, par value of $1.00 per share, and 4,720,760 shares of Class B common stock, par value of $1.00 per share, outstanding as of October 12, 2010.

DOCUMENTS INCORPORATED BY REFERENCE

Portions of the registrant’s definitive Proxy Statement for the January 2011 Annual Meeting of Shareholders are incorporated herein by reference in Part III.

Table of Contents

SCHNITZER STEEL INDUSTRIES, INC.

FORM 10-K

| PAGE | ||||

| 1 | ||||

| Item 1 |

Business | 2 | ||

| Item 1A |

Risk Factors | 14 | ||

| Item 1B |

Unresolved Staff Comments | 19 | ||

| Item 2 |

Properties | 20 | ||

| Item 3 |

Legal Proceedings | 20 | ||

| Item 4 |

Reserved | 20 | ||

| Item 5 |

21 | |||

| Item 6 |

Selected Financial Data | 23 | ||

| Item 7 |

Management’s Discussion and Analysis of Financial Condition and Results of Operations | 24 | ||

| Item 7A |

Quantitative and Qualitative Disclosures About Market Risk | 43 | ||

| Item 8 |

Financial Statements and Supplementary Data | 44 | ||

| Item 9 |

Changes in and Disagreements with Accountants on Accounting and Financial Disclosure | 84 | ||

| Item 9A |

Controls and Procedures | 84 | ||

| Item 9B |

Other Information | 84 | ||

| Item 10 |

Directors, Executive Officers and Corporate Governance | 85 | ||

| Item 11 |

Executive Compensation | 86 | ||

| Item 12 |

Security Ownership of Certain Beneficial Owners and Management and Related Stockholder Matters |

86 | ||

| Item 13 |

Certain Relationships and Related Transactions, and Director Independence | 86 | ||

| Item 14 |

Principal Accounting Fees and Services | 86 | ||

| Item 15 |

Exhibits and Financial Statement Schedules | 87 | ||

| 90 | ||||

Table of Contents

Statements and information included in this Annual Report on Form 10-K by Schnitzer Steel Industries, Inc. (the “Company”) that are not purely historical are forward-looking statements within the meaning of Section 21E of the Securities Exchange Act of 1934 and are made pursuant to the “safe harbor” provisions of the Private Securities Litigation Reform Act of 1995. All references to “we,” “our,” “us” and “SSI” refer to the Company.

Forward-looking statements in this Annual Report on Form 10-K include statements regarding our expectations, intentions, beliefs and strategies regarding the future, including statements regarding trends, cyclicality and changes in the markets we sell into; strategic direction; changes to manufacturing processes; the cost of compliance with environmental and other laws; expected tax rates and deductions; the realization of deferred tax assets; planned capital expenditures; liquidity positions; ability to generate cash from continuing operations; the potential impact of adopting new accounting pronouncements; expected results, including pricing, sales volumes and profitability; obligations under our retirement plans; savings or additional costs from business realignment and cost containment programs; and the adequacy of accruals.

When used in this report, the words “believes,” “expects,” “anticipates,” “intends,” “assumes,” “estimates,” “evaluates,” “may,” “could,” “opinions,” “forecasts,” “future,” “forward,” “potential,” “probable,” and similar expressions are intended to identify forward-looking statements.

We may make other forward-looking statements from time to time, including in press releases and public conference calls. All forward-looking statements we make are based on information available to us at the time the statements are made, and we assume no obligation to update any forward-looking statements, except as may be required by law. Our business is subject to a number of risks and uncertainties that could cause actual results to differ materially from those included in, or implied by, such forward-looking statements. Some of these risks and uncertainties are discussed in Item 1A. Risk Factors of Part I of this Form 10-K. Other examples include volatile supply and demand conditions affecting prices and volumes in the markets for both our products and raw materials we purchase; world economic conditions; world political conditions; our ability to match raw material intake and finished product output with demand; changes in federal and state income tax laws; government regulations and environmental matters; the impact of pending or new laws and regulations regarding imports into and exports from the United States and other countries; foreign currency fluctuations; competition; seasonality, including weather; energy supplies; freight rates and availability of transportation; loss of key personnel; the inability to obtain sufficient quantities of scrap metal to support current orders; purchase price estimates made during acquisitions; business integration issues relating to acquisitions of businesses; creditworthiness of and availability of credit to suppliers and customers; new accounting pronouncements; availability of capital resources; business disruptions resulting from installation or replacement of major capital assets; and the adverse impact of climate change, including as a result of treaties, legislation or regulations.

Schnitzer Steel Industries, Inc. Form 10-K 2010 / 1

Table of Contents

General

Founded in 1906, Schnitzer Steel Industries, Inc., an Oregon corporation, is one of the nation’s largest recyclers of ferrous and nonferrous scrap metal, a leading recycler of used and salvaged vehicles and a manufacturer of finished steel products. Our founding business practice is a commitment to sustainability – recycling metal to generate additional value while achieving profitable growth. The worldwide demand for scrap metal is driven by continued demand for new steel products, electric arc furnace steel mill technology which relies on scrap metal as its primary feedstock and, to a certain extent, the use by blast furnaces of scrap metal because it reduces energy costs, virgin materials use, water use and mining wastes.

Through our North American metals recycling business, we collect and recycle autobodies, rail cars, home appliances, industrial machinery, manufacturing scrap and construction demolition from bridges, buildings and other obsolete structures. With 43 operating facilities located in 14 states and Puerto Rico, we are uniquely positioned to efficiently collect scrap metal throughout North America and export product to where demand is greatest. Utilizing our seven deep water ports, we have the capability to export to customers around the world.

Our metals recycling business also benefits from synergies with our auto parts business. Our auto parts business, which has 45 retail locations, buys end-of-life vehicles, sells parts to retail customers and sells scrap metal to our metals recycling business depending upon location. In addition, our metals recycling business benefits from synergies with our steel manufacturing business by selling scrap metal to our steel mini-mill that produces finished steel products such as rebar, wire rod, coiled rebar, merchant bar and other specialty products using nearly 100% recycled metal.

We report the operations of these three businesses in three segments: the Metals Recycling Business (“MRB”), the Auto Parts Business (“APB”) and the Steel Manufacturing Business (“SMB”). See Note 20 – Segment Information in the notes to the consolidated financial statements in Part II, Item 8 of this report.

Metals Recycling Business

Business

MRB buys, collects, processes, recycles, sells and brokers ferrous scrap metal (containing iron) to foreign and domestic steel producers, including SMB, and nonferrous scrap metal (not containing iron) to both foreign and domestic markets. MRB processes mixed and large pieces of scrap metal into smaller pieces by sorting, shearing, shredding and torching, resulting in scrap metal pieces of a size, density and purity required by customers to meet their production needs. The manufacturing process includes physical separation of materials through manual and sophisticated mechanical processes into ferrous and nonferrous sub-classifications, each of which has a value and metal content of importance to different customers for their end product.

One of the most efficient ways to process and sort recycled scrap metal is through the use of shredding systems. Currently, each of MRB’s facilities in Everett, Massachusetts; Portland, Oregon; Oakland, California; and Tacoma, Washington has a mega-shredder capable of processing over 2,500 tons of scrap metal per day. MRB’s Johnston, Rhode Island facility operates a large shredder capable of processing up to 1,500 tons of scrap metal per day, MRB’s Salinas, Puerto Rico facility operates a shredder that can process up to 500 tons of scrap metal per day and the Kapolei, Hawaii; Anchorage, Alaska; and Concord, New Hampshire facilities each operate smaller shredders. Mega-shredders are designed to provide a denser product and, in conjunction with new separation equipment, a more refined and preferable form of ferrous scrap metal which can be more efficiently used by steel mills. The larger shredders are also able to accept more types of material, resulting in more efficient processing. Shredders can reduce autobodies, home appliances and other scrap metal into fist-size pieces of shredded recycled scrap metal. The shredded material is then carried by conveyor under magnetized drums that attract the recycled ferrous scrap metal and separate it from the nonferrous scrap metal and other residue found in the shredded material, resulting in a consistent and high quality shredded ferrous product. The remaining nonferrous scrap metal and residue then pass through a series of

2 / Schnitzer Steel Industries, Inc. Form 10-K 2010

Table of Contents

additional mechanical and manual sorting systems designed to separate the nonferrous metal from the residue. The remaining nonferrous metal is then hand-sorted and graded before being sold or sold as a mixed product. MRB continues to invest in nonferrous metal separation technologies in order to maximize the recoverability of valuable nonferrous metal. MRB also purchases nonferrous metal directly from industrial vendors and other suppliers and bundles this metal to sell to customers.

Products

MRB sells both ferrous and nonferrous scrap metal. The primary product produced is ferrous scrap metal, which is a key feedstock used in the production of finished steel products. Ferrous scrap metal is categorized into plate and structural, or “bonus,” heavy melting steel (“HMS”) and shredded scrap. Our nonferrous products include aluminum, copper, stainless steel, nickel, brass, titanium, lead, high temperature alloys and joint products such as zorba (primarily mixed nonferrous material) and zurik (predominantly stainless steel).

Customers

MRB sells its products to steel mills and smelters located in the United States (“US”) and around the world and provides substantially all of the ferrous scrap metal required by SMB.

Presented below are MRB revenues by continent for the last three years ended August 31 (dollars in thousands):

| 2010 | % of Revenue |

2009 | % of Revenue |

2008 | % of Revenue |

||||||||||||||||

| Asia |

$ | 1,228,022 | 67 | % | $ | 981,127 | 70 | % | $ | 1,437,850 | 53 | % | |||||||||

| North America |

503,651 | 28 | % | 301,093 | 22 | % | 917,485 | 34 | % | ||||||||||||

| Europe |

162,284 | 9 | % | 176,754 | 13 | % | 446,012 | 16 | % | ||||||||||||

| Africa |

85,813 | 5 | % | 48,681 | 3 | % | 261,503 | 9 | % | ||||||||||||

| Sales to SMB |

(155,310 | ) | (9 | %) | (109,985 | ) | (8 | %) | (328,412 | ) | (12 | %) | |||||||||

| Total revenues (net of |

$ | 1,824,460 | 100 | % | $ | 1,397,670 | 100 | % | $ | 2,734,438 | 100 | % | |||||||||

In fiscal 2010, MRB generated revenues of $10 million or more from customers in 12 countries, including the United States, China, South Korea, Taiwan, Malaysia, Thailand, India, Turkey, Egypt, Greece, Indonesia and Japan. MRB generated revenues of $10 million or more from customers in 12 countries in fiscal 2009 and 14 countries in fiscal 2008. MRB had no external customers that accounted for 10% or more of consolidated revenues in fiscal 2010, 2009 or 2008.

MRB’s five largest external ferrous scrap metal customers accounted for 35%, 35% and 37% of recycled ferrous metal revenues in fiscal 2010, 2009 and 2008, respectively. Customer purchase volumes of ferrous scrap metal vary from year to year due to demand, competition, economic growth, infrastructure spending, relative currency values, availability of credit and other factors. Ferrous metal sales are generally denominated in US dollars, and almost all of the largest shipments of ferrous scrap metal to foreign customers are supported by letters of credit.

The table below sets forth, on a revenue and volume basis, the amount of recycled ferrous scrap metal sold by MRB to foreign and domestic customers during the last three fiscal years ended August 31:

| 2010 | 2009 | 2008 | |||||||||||||

| Revenues(1) | Volume(2) | Revenues(1) | Volume(2) | Revenues(1) | Volume(2) | ||||||||||

| Foreign |

$ | 1,188,490 | 3,122 | $ | 1,032,571 | 3,436 | $ | 1,935,084 | 3,655 | ||||||

| SMB |

155,310 | 458 | 109,985 | 335 | 328,412 | 737 | |||||||||

| Other domestic |

214,864 | 651 | 106,752 | 418 | 327,300 | 805 | |||||||||

| Total |

$ | 1,558,664 | 4,231 | $ | 1,249,308 | 4,189 | $ | 2,590,796 | 5,197 | ||||||

| (1) | Revenues stated in thousands of dollars. |

| (2) | Volume stated in thousands of long tons (one long ton = 2,240 pounds). |

Schnitzer Steel Industries, Inc. Form 10-K 2010 / 3

Table of Contents

MRB also sells nonferrous scrap metal to foreign and domestic customers. MRB continues to grow its nonferrous volumes available for sale by extracting higher amounts of nonferrous products due to improvements in the extraction processes used to recover nonferrous metal from the shredding process and by expanding its nonferrous collection facilities.

The table below sets forth, on a revenue and volume basis, the amount of recycled nonferrous scrap metal sold by MRB to foreign and domestic customers during the last three fiscal years ended August 31:

| 2010 | 2009 | 2008 | |||||||||||||

| Revenues(1) | Volume(2) | Revenues(1) | Volume(2) | Revenues(1) | Volume(2) | ||||||||||

| Foreign |

$ | 288,472 | 351,821 | $ | 174,756 | 294,016 | $ | 239,765 | 260,798 | ||||||

| Domestic |

124,455 | 126,665 | 76,752 | 103,040 | 220,874 | 178,672 | |||||||||

| Total |

$ | 412,927 | 478,486 | $ | 251,508 | 397,056 | $ | 460,639 | 439,470 | ||||||

| (1) | Revenues stated in thousands of dollars. |

| (2) | Volume stated in thousands of pounds. |

Pricing

Domestic and foreign prices for ferrous scrap metal are generally based on prevailing market rates, which can differ by region and are subject to market cycles that are influenced by worldwide demand from steel and other metal producers and by the availability of materials that can be processed into saleable scrap metal, among other factors. Export recycled ferrous metal sales contracts generally provide for shipment within 30 to 90 days after the price is agreed to which, in most cases, includes freight. MRB responds to changing price levels by adjusting scrap metal purchase prices at its recycling facilities in order to manage the impact on its operating income. The spread between selling prices and the cost of purchased material is subject to a number of factors, including differences in the market conditions in the domestic regions where recycled metal is acquired and the areas in the world where the processed materials are sold, market volatility from the time the selling price is agreed with the customer until the time the raw material is purchased, and changes in the assumed costs of transportation to the buyer’s facility. We believe MRB generally benefits from rising recycled metal selling prices, which allow it to better maintain or expand both operating income and unprocessed metal flow into its facilities, and suffers when recycled metal selling prices decline, which tend to compress its operating margins.

Markets

In recent years, worldwide demand for finished steel products has been growing at a faster rate than the available supply of recycled ferrous metal, which is one of the primary raw materials used in manufacturing steel. During this time, the demand for finished steel has been growing most rapidly in developing countries in Asia and the Mediterranean, which currently do not possess an adequate supply of raw materials to produce steel. As a result of this demand, MRB’s ferrous exports have made up 74%, 82% and 70% of its total ferrous sales volume in fiscal 2010, 2009 and 2008, respectively. The Asian developing countries have also been the primary recipients of MRB’s nonferrous products with nonferrous exports making up 74%, 74% and 59% of its total nonferrous sales volumes in fiscal 2010, 2009 and 2008, respectively. Unlike the ferrous export market, China has been the largest destination for MRB’s nonferrous export sales.

Consolidation in the Scrap Metal Industry

The metals recycling industry has been consolidating over the last several years, primarily due to a high degree of fragmentation and the ability of large, well-capitalized processors to achieve competitive advantages by investing in capital improvements to improve efficiencies and lower processing costs. We believe that we are in a position to make reasonably priced acquisitions in the metals recycling industry as a result of our low levels of debt, historical ability to generate cash from operations and available borrowing capacity.

4 / Schnitzer Steel Industries, Inc. Form 10-K 2010

Table of Contents

Distribution

MRB delivers recycled ferrous and nonferrous scrap metal to foreign customers by ship and to domestic customers by barge, rail and over the road transportation networks. Cost efficiencies are achieved by operating deep water terminal facilities at Everett, Massachusetts; Portland, Oregon; Oakland, California; Tacoma, Washington; and Providence, Rhode Island, all of which are owned except for the Providence, Rhode Island facility, which is operated under a long-term lease. We also have access to deep water terminal facilities at Kapolei, Hawaii and Salinas, Puerto Rico through public docks. These seven deep water terminals enable us to load large vessels capable of trans-oceanic shipments. Additionally, because we own most of the terminal facilities in which MRB operates, MRB is not normally subject to the same berthing delays often experienced by users of unaffiliated terminals. We believe that MRB’s loading costs are lower than they would be if it utilized third party terminal facilities. From time to time MRB may enter into contracts of affreightment, which guarantee the availability of ocean going vessels, in order to manage the risks associated with ship availability and freight costs.

Sources of Unprocessed Metal

The most common forms of purchased raw metal are obsolete machinery and equipment, such as automobiles, railroad cars, railroad tracks, home appliances and other consumer goods, waste metal from manufacturing operations and demolition metal from buildings and other obsolete structures. This metal is acquired from suppliers who unload at MRB’s facilities, from drop boxes at a diverse base of suppliers’ industrial sites and through negotiated purchases from other large suppliers, including railroads, industrial manufacturers, automobile salvage facilities, metal dealers, various government entities and individuals. The majority of MRB’s scrap metal collection and processing facilities receive raw metal via major railroad routes, waterways or major highways. Metal recycling facilities situated near unprocessed metal sellers and major transportation routes have the competitive advantage of reduced freight costs because of the significant cost of freight relative to the cost of metal. The locations of MRB’s West Coast facilities allow it to competitively purchase raw metal from the Northern California region, northwards up the West Coast to Western Canada and Alaska and to the east, including Idaho, Montana, Utah, Colorado and Nevada. The locations of the East Coast facilities provide access to sources of unprocessed metal in New York, Connecticut, Maine, Massachusetts, New Hampshire, Rhode Island, Vermont, Eastern Canada and, from time to time, the Midwest. In the Southeastern US, approximately half of MRB’s ferrous and nonferrous unprocessed metal volume is purchased from industrial companies, including domestic and international auto manufacturers, with the remaining volume being purchased from smaller dealers and individuals. These industrial companies provide MRB with metals that are by-products of their manufacturing processes. The supply of scrap metal from these manufacturers can fluctuate with the level of automotive and other manufacturing production in the region.

Backlog

As of October 13, 2010, MRB had a backlog of orders to sell $221 million of export ferrous metal compared to $73 million as of October 13, 2009. Additionally, as of September 30, 2010, MRB had a backlog of orders to sell $20 million of export nonferrous metal compared to $18 million as of September 30, 2009.

Competition

MRB faces stiff competition for both the purchase and sale of scrap metal. MRB competes domestically for the purchase of scrap metal with large, well-financed recyclers of scrap metal, steel mills that own scrap yards and smaller metal facilities and dealers. In general, the competitive factors impacting the purchase of scrap metal are the price offered by the purchaser and the proximity of the purchaser to the scrap metal source. MRB also competes with brokers who buy scrap metal on behalf of domestic and foreign steel mills.

MRB competes globally for the sale of processed recycled metal to finished steel producers. The predominant competitive factors that impact recycled metal sales are price (including shipping cost), reliability of service, product quality and availability of scrap metal and scrap metal substitutes.

Schnitzer Steel Industries, Inc. Form 10-K 2010 / 5

Table of Contents

We believe MRB’s ability to process substantial volumes of scrap metal products, state of the art equipment, number of locations, access to a variety of different modes of transportation, geographic dispersion and cross-divisional synergies provide its business with competitive advantages.

Auto Parts Business

Business and Products

APB procures used and salvaged vehicles and sells serviceable used auto parts from these vehicles through its 45 self-service auto parts stores which are located across the US and Western Canada. The remaining portions of the vehicles, primarily autobodies, cores (which include engines, transmissions, alternators and catalytic converters) and nonferrous materials, are sold to metal recyclers, including MRB where geographically feasible. APB completed the sale of its full-service used auto parts operation to LKQ Corporation in October 2009.

Customers

Self-service stores generally serve customers who are looking to obtain serviceable used auto parts at a competitive price. These customers remove the used auto parts from vehicles in inventory without the assistance of store employees. In addition, APB sells the cores to a variety of wholesale buyers and the scrap metal from end-of-life vehicles to MRB and third party recycling yards throughout the US and Western Canada.

We believe that APB has an enhanced competitive advantage through its various information technology systems, which are used to centrally manage and operate the geographically diverse network of stores; by applying a consistent approach to offering customers a large selection of vehicles from which to obtain parts; and by its efficient processing of autobodies. APB had no external customers that accounted for 10% or more of consolidated revenues in fiscal 2010, 2009 or 2008.

APB is dedicated to supplying low-cost used auto parts to its customers. In general, we believe that the sale prices of auto parts at APB’s self-service stores are significantly lower than those offered at full-service auto dismantlers, retail car parts stores and car dealerships. Each self-service store offers an extensive selection of vehicles (including domestic and foreign cars, vans and light trucks) from which consumers can remove parts. APB regularly rotates its vehicle inventory to provide its customers greater access to a continually changing parts inventory.

The table below sets forth APB revenues from domestic and foreign customers for the last three fiscal years ended August 31 (in thousands):

| 2010 | 2009 | 2008 | ||||||||||

| Domestic |

$ | 225,403 | $ | 144,346 | $ | 213,643 | ||||||

| Foreign |

15,830 | 8,861 | 14,439 | |||||||||

| Sales to MRB |

(49,538 | ) | (26,916 | ) | (48,759 | ) | ||||||

| Total revenues (net of intercompany) |

$ | 191,695 | $ | 126,291 | $ | 179,323 | ||||||

Fragmentation of the Auto Parts Industry

The auto parts industry is characterized by diverse and fragmented competition and is comprised of a large number of aftermarket and used auto parts suppliers of all sizes. These companies range from large, multinational corporations, which serve both original equipment manufacturers and the aftermarket on a worldwide basis, to small, local producers which supply only a few parts for a particular car model.

Distribution

APB sells used auto parts from each of its self-service retail stores. Upon arriving at a self-service store, a customer typically pays an admission charge and signs a liability waiver before entering the car lot. When a customer finds a desired part on a vehicle, the customer removes it and pays a pre-established price for the part.

The wholesale component of APB’s business consists of core and scrapped vehicle sales. Once the vehicle is removed from the customer area, cores are removed from the vehicle and consolidated at central facilities in California, Florida,

6 / Schnitzer Steel Industries, Inc. Form 10-K 2010

Table of Contents

Texas and Calgary, Canada. From these facilities, the cores are sold to a variety of wholesale buyers through a competitive bidding process. Due to the larger quantities generated by this consolidation process, APB is able to obtain higher prices by focusing on larger wholesale customers that purchase in volume. After the core removal process is complete, the remaining autobody is crushed and sold as scrap metal in the wholesale market. The autobodies are sold on a price per ton basis, which is subject to fluctuations in the recycled ferrous metal markets. During fiscal 2010, 2009 and 2008, APB generated revenues of $50 million, $27 million and $49 million, respectively, from sales to MRB, making MRB the single largest customer of APB.

Marketing

APB has customized marketing initiatives that are unique to its self-service brand. The brand marketing plan focuses on the acquisition of private party vehicles and attracting auto parts customers into the stores. The marketing plan targets the local markets surrounding the stores and incorporates various strategies including the use of radio advertising to promote vehicle purchasing, regularly scheduled in-store promotions and other forms of product promotion. Each store has a customized marketing calendar designed for its market and the community it serves.

APB typically seeks to locate its facilities with convenient access to major streets and in major population centers. By operating at locations that are convenient and visible to the target customer, the stores seek to become the customer’s first stop in acquiring used auto parts.

Sources of Vehicles

APB obtains vehicles from five primary sources: private parties, tow companies, charities, auto auctions and city contracts. APB has a program to purchase vehicles from private parties called “Cash for Junk Cars,” which is advertised in local markets. Private parties call a toll-free number and receive a quote for their vehicle. The private party can either deliver the vehicle to one of APB’s retail locations or arrange for the vehicle to be picked up. APB also employs car buyers who travel to vendors and bid on vehicles. In fiscal 2010, APB’s ability to obtain additional and higher quality vehicles was temporarily enhanced through the government’s Cash-For-Clunkers stimulus program.

Competition

APB competes for the purchase of vehicles with other auto dismantlers, used car dealers, auto auctions and metal recyclers. APB competes for the sale of used auto parts with other self-service and full-service auto dismantlers as well as larger well-financed retail auto parts businesses.

Steel Manufacturing Business

Business

SMB operates a steel mini-mill in McMinnville, Oregon that produces a wide range of finished steel products using recycled metal and other raw materials. SMB purchases substantially all of its recycled metal from MRB at rates that approximate export market prices for shipments from the West Coast of the US.

Manufacturing

SMB’s melt shop includes an electric arc furnace (“EAF”), a ladle refining furnace, a five-strand continuous billet caster and has enhanced steel chemistry refining capabilities, permitting the mill to produce special alloy grades of steel not currently produced by other mills on the US West Coast. The melt shop produced 494 thousand, 401 thousand and 802 thousand tons of steel in the form of billets during fiscal 2010, 2009 and 2008, respectively. SMB continues to reinvest in its melt shop to improve efficiencies in the melting process.

SMB also operates two computerized rolling mills that allow for synchronized operations of the rolling mills and related equipment. Billets produced in SMB’s melt shop are reheated in two natural gas-fueled furnaces and are then hot-rolled through one of the two rolling mills to produce finished products. SMB has completed a number of improvement projects to both mills designed to increase both their operating efficiency and the types of products that can be competitively produced. SMB continues to monitor the market for new products and, through discussions with customers, identify additional opportunities to expand its product lines and sales.

Schnitzer Steel Industries, Inc. Form 10-K 2010 / 7

Table of Contents

SMB’s effective annual finished goods production capacity is approximately 800 thousand tons under current conditions.

Products

SMB produces semi-finished goods (billets) and finished goods consisting of rebar, coiled rebar, wire rod, merchant bar and other specialty products. Semi-finished goods are predominantly used for SMB’s finished products, but also have been produced for sale to other steel mills. Rebar is produced in either straight length steel bars or coils and used to increase the tensile strength of poured concrete. Coiled rebar is preferred by some manufacturers because it reduces the waste generated by cutting individual lengths to meet customer specifications and, therefore, improves yield. Wire rod is steel rod, delivered in coiled form, used by manufacturers to produce a variety of products such as chain link fencing, nails, wire and stucco netting. Merchant bar consists of round, flat, angle and square steel bars used by manufacturers to produce a wide variety of products, including gratings, steel floor and roof joists, safety walkways, ornamental furniture, stair railings and farm equipment. SMB is also certified to produce high quality rebar to support nuclear power plant construction.

The table below sets forth, on a revenue and volume basis, the sales of these products during the last three fiscal years ended August 31:

| 2010 | 2009 | 2008 | |||||||||||||

| Revenues(1) | Volume(2) | Revenues(1) | Volume(2) | Revenues(1) | Volume(2) | ||||||||||

| Rebar |

$ | 122,879 | 217,302 | $ | 129,750 | 226,796 | $ | 352,087 | 470,111 | ||||||

| Wire rod |

102,690 | 157,677 | 67,800 | 88,512 | 133,815 | 178,508 | |||||||||

| Coiled rebar |

25,762 | 43,005 | 25,404 | 38,618 | 51,020 | 67,598 | |||||||||

| Merchant bar |

19,381 | 25,432 | 22,221 | 27,181 | 49,324 | 59,565 | |||||||||

| Other products(3) |

14,373 | 40,199 | 18,094 | 32,664 | 16,943 | 32,048 | |||||||||

| Total |

$ | 285,085 | 483,615 | $ | 263,269 | 413,771 | $ | 603,189 | 807,830 | ||||||

| (1) | Revenues stated in thousands of dollars. |

| (2) | Volume stated in short tons (one short ton = 2,000 pounds). |

| (3) | Includes primarily sales of billets (semi-finished goods). |

Customers

SMB’s customers are principally steel service centers, construction industry subcontractors, steel fabricators, wire drawers and major farm and wood products suppliers. During fiscal 2010, SMB sold its finished steel products to customers located primarily in the Western US and Canada and its billets to customers in Asia. Customers in California accounted for 34% of SMB’s revenue in fiscal 2010. SMB’s ten largest customers accounted for 54%, 47% and 36% of its revenues during fiscal 2010, 2009 and 2008, respectively. SMB had no external customers that accounted for 10% or more of consolidated revenues in fiscal 2010, 2009 or 2008.

The table below sets forth SMB revenues from domestic and foreign customers for the last three fiscal years ended August 31 (in thousands):

| 2010 | 2009 | 2008 | |||||||

| Domestic |

$ | 206,943 | $ | 226,675 | $ | 515,629 | |||

| Foreign(1) |

78,142 | 36,594 | 87,560 | ||||||

| Total |

$ | 285,085 | $ | 263,269 | $ | 603,189 | |||

| (1) | Includes sales to Canada of $56 million, $27 million and $52 million in fiscal 2010, 2009 and 2008, respectively. |

8 / Schnitzer Steel Industries, Inc. Form 10-K 2010

Table of Contents

Consolidation in the Steel Industry

While the pace of consolidation in the global steel industry has slowed due to the impact of the global economic crisis, we continue to see consolidation of smaller steel producers or fabricators. In addition, cross-border consolidation remains attractive due to the potential for achieving greater efficiency and economies of scale, particularly in response to the consolidation undertaken by raw material suppliers and consumers of steel products.

Distribution

SMB sells directly from its mini-mill in McMinnville, Oregon, its owned distribution center in El Monte, California (Los Angeles area) and a third party distribution center in Lathrop, California (Central California). Products are shipped from the mini-mill to the distribution centers primarily by rail. The distribution centers facilitate sales by maintaining an inventory of products close to major customers for just-in-time delivery. SMB communicates regularly with major customers to determine their anticipated needs and plans its rolling mill production schedule accordingly. Shipments to customers are made by common carrier, primarily truck or rail.

Recycled Metal Supply

We believe SMB operates the only mini-mill in the Western US that obtains substantially all of its recycled metal requirements from affiliated metal recycling operations. MRB is able to deliver a mix of recycled metal grades to achieve optimum efficiency in SMB’s melting operations. As the steel mill and various MRB facilities are located on railway routes, SMB benefits from the ability to ship by either rail or truck.

Energy Supply

SMB needs a significant amount of electricity to run its operations, primarily its EAF. SMB purchases electricity under a long-term contract with McMinnville Water & Light that expires in September 2011, which in turn relies on the Bonneville Power Administration. Electricity represented 4%, 3% and 3% of SMB’s cost of goods sold in fiscal 2010, 2009 and 2008, respectively.

SMB also needs a significant amount of natural gas to run its reheat furnaces, which are used to reheat billets prior to running them through the rolling mills. SMB meets this demand through a take-or-pay natural gas contract that expires on May 31, 2011 and obligates it to purchase minimum quantities of natural gas per day through October 2010, whether or not the amount is utilized. Natural gas represented 3%, 2% and 2% of SMB’s cost of goods sold in fiscal 2010, 2009 and 2008, respectively. See Note 14 – Derivative Financial Instruments and Fair Value Measurements in the notes to the consolidated financial statements in Part II, Item 8 of this report for further detail.

Backlog

SMB generally ships products within days after the receipt of purchase orders. As of September 30, 2010 SMB had a backlog of orders of $24 million, compared to $6 million as of September 30, 2009.

Competition

SMB’s primary domestic competitors for the sale of finished steel products include Nucor Corporation’s manufacturing facilities in Arizona, Utah and Washington, TAMCO Steel’s facility in California and Commercial Metals Company’s manufacturing facility in Arizona. In addition to domestic competition, SMB has historically competed with foreign steel producers, principally located in Asia, Canada, Mexico and Central and South America, primarily in shorter length rebar and certain wire rod grades. The principal competitive factors in SMB’s market are price, product availability, quality and service. In addition, demand and the resulting level of steel imports are impacted by general economic conditions and the value of the US dollar.

In 2002, the US Government imposed anti-dumping and countervailing duties against wire rod products from eight foreign countries. These duties remain in effect today, are periodically reviewed and do not have a set expiration date. In 2007, the International Trade Commission extended existing rebar anti-dumping duties of up to 233% on imports from seven nations through 2012.

Schnitzer Steel Industries, Inc. Form 10-K 2010 / 9

Table of Contents

Strategic Focus

Use of our Seven Deep Water Ports to Access Global Demand

We maintain deep water terminal facilities adjacent to our operating facilities in Everett, Massachusetts; Portland, Oregon; Oakland, California; Tacoma, Washington; and Providence, Rhode Island and also have access to deep water terminal facilities at Kapolei, Hawaii and Salinas, Puerto Rico through public docks. These seven deep water terminals enable us to load large vessels capable of trans-oceanic shipments, which allows us to ship product globally to wherever demand is highest. Cost efficiencies are achieved because we own the majority of these terminal facilities, as we are not normally subject to the same berthing delays often experienced by users of unaffiliated terminals.

Acquisitions and Divestitures

We continue to focus on growth through value-creating acquisitions and will pursue acquisition opportunities we believe will create shareholder value and generate long-term returns in excess of our cost of capital. With our historically strong balance sheet, cash flows from operations and available borrowing capacity, we believe we are in a position to continue to complete reasonably priced acquisitions fitting our long-term strategic plans.

During fiscal 2010, we spent $41 million to acquire six self-service used auto parts stores and a metals recycler. These acquisitions were as follows:

| • | In October 2009, we acquired four self-service used auto parts stores located near our MRB export facility in Portland, Oregon. This acquisition represented our first used auto parts operations in the Pacific Northwest. |

| • | In January 2010, we acquired two self-service used auto parts stores, which increased to four the number of used auto parts facilities that we operate in the Dallas-Fort Worth Metroplex. |

| • | In April 2010, we acquired a metals recycler in Montana to provide an additional source of scrap metal for our Tacoma, Washington export facility. |

In October 2009, we sold our full-service used auto parts operation, which had operated as part of the APB reporting segment, to LKQ Corporation. The full-service used auto parts operation is not included in APB’s results of operations in fiscal 2010, 2009 or 2008 because the results of this discontinued operation have been reclassified for all periods presented.

In fiscal 2009, we acquired the following:

| • | In December 2008, we acquired a metals recycler in Washington to provide an additional source of scrap metal to MRB’s Tacoma, Washington export facility. |

| • | In February 2009, we acquired the leading metals recycler in Puerto Rico. This acquisition expanded our presence into a new region, increased our processing capability and provided new sources of scrap metal and access to international export facilities. |

| • | In February 2009, we acquired an additional 16.66% equity interest in an auto parts business located in California, and in April 2009, we acquired the remaining 8.34% minority equity interest in this business, thus increasing our equity ownership in this business to 100%. The acquired equity was previously consolidated into our financial statements because we maintained operating control over the entity. |

| • | In February 2009, we acquired a self-service used auto parts business with two locations in California, strengthening our presence in Northern California. |

| • | In March 2009, we acquired a metals recycler in Nevada, providing an additional source of scrap metal for MRB’s Oakland, California export facility. |

In fiscal 2008, we acquired the following:

| • | In September 2007, we acquired a mobile metals recycling business that provides additional sources of scrap metal to MRB’s Everett, Massachusetts facility. |

| • | In November 2007, we acquired two metals recycling businesses and in February 2008 we acquired one metals recycling business that expanded our presence in the Southeastern US. |

10 / Schnitzer Steel Industries, Inc. Form 10-K 2010

Table of Contents

| • | In February 2008, we acquired the remaining 50% equity interest in an auto parts business located in Nevada in exchange for our 50% interest in the land and buildings owned by the business. The acquired business was previously consolidated into our financial statements because we maintained operating control over the entity. |

| • | In August 2008, we acquired a self-service used auto parts business with three locations in the Southern US. |

Processing and Manufacturing Technology Improvements

We aim to be an efficient and competitive producer of both recycled metal and finished steel products in order to maximize the operating income for both operations. To meet this objective, we have historically focused on, and will continue to emphasize, the cost-effective purchasing and efficient processing of scrap metal.

During fiscal 2010, 2009 and 2008, we spent $64 million, $59 million and $84 million, respectively on capital improvements. These capital expenditures primarily reflect our significant investments in modern equipment to improve the efficiency and capabilities of our businesses and to further maximize our economies of scale. Our capital expenditures in fiscal 2010 included further investments in technology to improve the recovery of nonferrous materials from the shredding process and investments to further improve efficiency and increase capacity, increase worker safety and enhance environmental systems, including investments in storm water systems and in equipment to ensure ongoing compliance with air quality and other environmental regulations.

Capital projects in fiscal 2011 are expected to include continued investments in technology to improve the recovery of nonferrous materials from the shredding process, material handling and processing equipment, enhancements to our information technology infrastructure, improvements to our facilities’ environmental and safety infrastructure and normal equipment replacement and maintenance. We believe these investments will create or protect value for our shareholders.

Continued Improvements in Productivity and Focus on Cost Containment

We have continuous improvement programs that focus on increasing production from shredders, improving existing scrap metal recovery processes and ongoing performance initiatives throughout our operations. The objective of these programs is to identify areas in existing processes that may be inefficient or where current performance could be improved, and to recommend and implement solutions that may increase revenues or reduce costs by increasing output or recovery.

Environmental Matters

Impact of Legislation and Regulation

Compliance with environmental laws and regulations is a significant factor in our operations. Our businesses are subject to extensive local, state and federal environmental protection, health, safety and transportation laws and regulations relating to, among others:

| • | The US Environmental Protection Agency (“EPA”); |

| • | Remediation under the Comprehensive Environmental Response, Compensation and Liability Act (“CERCLA”); |

| • | The discharge of materials and emissions into the air; |

| • | The prevention and remediation of soil and groundwater contamination; |

| • | The management and treatment of wastewater and storm water; |

| • | Global climate change; |

| • | The treatment, handling and/or disposal of solid waste and hazardous waste; and |

| • | The protection of our employees’ health and safety. |

These environmental laws regulate, among other things, the release and discharge of hazardous materials into the air, water and ground; exposure to hazardous materials; and the identification, storage, treatment, handling and disposal of hazardous materials. Environmental legislation and regulations have changed rapidly in recent years, and it is likely that we will be subject to even more stringent environmental standards in the future.

Schnitzer Steel Industries, Inc. Form 10-K 2010 / 11

Table of Contents

Concern over climate change, including the impact of global warming, has led to significant US and international regulatory and legislative initiatives to limit greenhouse gas (“GHG”) emissions. In 2007 the US Supreme Court ruled that the EPA was authorized to regulate carbon dioxide under the US Clean Air Act. As a consequence, the EPA initiated a series of regulatory efforts aimed at addressing greenhouse gases as pollutants, including finding that GHG emissions endanger public health, implementing mandatory GHG emission reporting requirements, setting carbon emission standards for light-duty vehicles and promulgating a New Source Review/Title V “tailoring rule” setting emissions thresholds beyond which stationary sources will require permits. Legislation has also been proposed in the US Congress to address GHG emissions and global climate change, including “cap and trade” programs, and some form of federal climate change legislation or additional federal regulation is possible. In addition, we are required to annually report our GHG emissions to the State of Oregon Department of Environmental Quality, effective March 2010, and to the US EPA effective March 2011. A number of other states, including states in which we have operations and facilities, have considered, are considering or have already enacted legislation to develop information or address climate change and GHG emissions as well.

We have, in the past, been found not to be in compliance with certain environmental laws and regulations and have incurred liabilities, expenditures, fines and penalties associated with such violations. Our objective is to maintain compliance with applicable environmental regulations, and we believe that we are materially in compliance with currently applicable environmental regulations (see Note 12 – Commitments and Contingencies in the notes to the consolidated financial statements in Part II, Item 8 of this report). In fiscal 2010, capital expenditures related to ongoing environmental compliance were $13 million, and we expect to spend approximately $18 million on capital expenditures for ongoing environmental compliance in fiscal 2011.

Indirect Consequences of Future Legislation and Regulation

Increased regulation regarding climate change and GHG emissions could impose significant costs on our business and our customers and suppliers, including increased energy, capital equipment, environmental monitoring and reporting and other costs in order to comply with regulations concerning and limitations imposed on climate change and GHG emissions. The potential costs of allowances, offsets or credits that may be part of “cap and trade” programs or similar future regulatory measures are still uncertain. Any adopted future climate change and GHG regulations could negatively impact our ability (and that of our customers and suppliers) to compete with companies situated in areas not subject to such limitations. Furthermore, even without such regulation, increased awareness and any adverse publicity in the global marketplace about the GHGs emitted by companies in the metal recycling and steel manufacturing industries could harm our reputation and reduce customer demand for our products.

GHG legislation and regulation is also expected to have an effect on the price of electricity, especially when generated using carbon-based fuels. As such, demand for SMB’s steel products could increase as its costs of production become more competitive, since they are manufactured using an EAF, which uses less energy than the blast furnaces of some of our competitors. Since the electricity supply for SMB includes a significant element of hydro-generated production, SMB’s energy costs are less likely to be impacted than those of our competitors using electricity generated by carbon-based fuels. In addition, demand for scrap metal may increase as a result of mills with blast furnaces seeking to maximize the scrap metal component of raw material infeed, as melting scrap metal involves less energy than is required for melting iron ore.

Since the use of recycled iron and steel instead of iron ore to make new steel results in savings in the consumption of energy, virgin materials and water and reduces mining wastes, we believe our recycled metal products position us to be more competitive in the future for business from companies wishing to reduce their carbon footprint and impact on the environment. In addition, our electric arc furnaces generate fewer greenhouse gas emissions than the traditional blast furnaces.

Physical Impacts of Climate Change on Our Costs and Operations

There has been public discussion that climate change may be associated with extreme weather conditions such as rising sea levels and more intense hurricanes, thunderstorms, tornados and snow or ice storms. Extreme weather conditions

12 / Schnitzer Steel Industries, Inc. Form 10-K 2010

Table of Contents

may increase our costs or cause damage to our facilities, and any damage resulting from extreme weather may not be fully insured. As many of our recycling facilities are located near deep water ports, significantly rising sea levels may disrupt our ability to receive scrap metal, process the scrap metal through our mega-shredders and ship product to our customers. Our MRB and APB operations can also be impacted by severe weather conditions. Periods of extended adverse weather conditions may inhibit our supply of scrap metal which could cause us to fail to meet our sales commitments. In addition, if temperature levels in the summer were to significantly increase for a sustained period in areas where our APB operations are located, this could result in less customer traffic, thus resulting in reduced admissions and parts sales.

Employees

As of September 30, 2010, we had 3,237 full-time employees, consisting of 1,491 employees at MRB, 1,178 employees at APB, 413 employees at SMB and 155 corporate administrative employees. Of these employees, 832 were covered by collective bargaining agreements. The SMB contract with the United Steelworkers of America, which covers 297 of these employees, was ratified in June 2008 and will expire on March 31, 2012. We believe that in general our labor relations are good.

Available Information

Our internet address is www.schnitzersteel.com. The content of our website is not incorporated by reference into this Annual Report on Form 10-K. We make all filings with the Securities and Exchange Commission (“SEC”) available on our website, free of charge, under the caption “Investors – SEC Filings.” Included in these filings are our annual reports on Form 10-K, quarterly reports on Form 10-Q, current reports on Form 8-K, and any amendments to those reports, which are available as soon as reasonably practicable after electronically filing with or furnishing such materials to the SEC pursuant to Sections 13(a) or 15(d) of the Securities Exchange Act of 1934.

The public may read and copy any materials that are filed with the SEC at the SEC’s Public Reference Room located at 100 F Street NE, Washington, DC 20549. The public may obtain information on the operation of the Public Reference Room by calling the SEC at 1-800-SEC-0330. The SEC also maintains electronic versions of reports on its website, www.sec.gov.

Schnitzer Steel Industries, Inc. Form 10-K 2010 / 13

Table of Contents

Described below are risks, which are categorized as “Risk Factors Relating to Our Business,” “Risk Factors Relating to the Regulatory Environment” and “Risk Factors Relating to Our Employees,” that could have a material adverse effect on our results of operations and financial condition or could cause actual results to differ materially from the results contemplated by the forward-looking statements contained in this Annual Report. See “Forward-Looking Statements” that precedes Part I of this report. Additional risks and uncertainties that we are unaware of or that we currently deem immaterial may in the future have a material adverse effect on our results of operations and financial condition.

Risk Factors Relating to Our Business

Potential costs related to the environmental cleanup of Portland Harbor may be material to our financial position and liquidity

We have been notified by the EPA under the CERCLA that we are a potentially responsible party (“PRP”) that owns or operates or formerly owned or operated sites adjacent to the Portland Harbor Superfund site (the “Site”). The precise nature and extent of any cleanup of the Site, the parties to be involved, the process to be followed for any cleanup and the allocation of the costs for any cleanup among responsible parties have not yet been determined. A group of PRPs is currently conducting a remedial investigation and feasibility study (“RI/FS”) to identify and characterize the contamination at the Site and develop alternative approaches to remediation of the contamination. A separate process to allocate the costs of the RI/FS and the ultimate remedy is also currently underway. The EPA has indicated that it expects to issue a record of decision that will discuss remedial alternatives for the Site sometime in 2012. Separately, the natural resource damages trustees for the Site are conducting a process to determine the amount of natural resource damages at the Site and identify the persons liable for such damages. It is currently unclear to what extent we will be liable for environmental costs or damages associated with the Site or for natural resource damage claims or third party contribution or damage claims with respect to the Site; however, given the size of the Site, the costs to date of the RI/FS and the nature of the conditions identified to date, the total cost of the investigations, remediation and natural resource damages claims are likely to be substantial. Significant cash outflows in the future related to the Site could reduce the amount of our borrowing capacity that could otherwise be used for investment in capital expenditures and acquisitions. Because there has not been a determination of the total investigation costs, the remediation that will be required, the amount of natural resource damages or how the costs of the ongoing investigations and any remedy and natural resource damages will be allocated among the PRPs, it is not presently possible to estimate the costs which we are likely to incur in connection with the Site, although such costs could be significant and material to our financial position, results of operations and cash flows. See Contingencies – Environmental in Note 12 – Commitments and Contingencies in the notes to the consolidated financial statements in Part II, Item 8 of this report.

Consolidation in the steel industry may reduce demand for our products

There has been a significant amount of consolidation in the steel industry in recent years that has included steel mills acquiring steel fabricators. This activity has been accelerated by the recent economic downturn where steel mills have acquired these customers to ensure demand for their products. If any of our significant customers were to be acquired by competing steel mills, this could reduce the demand for our products and force us to lower our prices, reducing our revenues, or to reduce production, which could increase our unit costs and have a material adverse effect on our financial condition and results of operations.

Significant decreases in scrap metal prices may adversely impact our operating results

The timing and magnitude of the cycles in the industries in which we operate are difficult to predict and are influenced by different economic conditions in domestic (where we typically acquire our raw materials) and foreign (where we typically sell a significant portion of our products) markets. Purchase prices for autobodies and scrap metal and selling prices for scrap and recycled metal are volatile and beyond our control. While we attempt to respond to changing recycled metal selling prices through adjustments to our metal purchase prices, our ability to do so is limited

14 / Schnitzer Steel Industries, Inc. Form 10-K 2010

Table of Contents

by competitive and other market factors. A significant reduction in selling prices for recycled metal may adversely impact both our operating income and our ability to recover purchase costs from end customers.

Changes in the availability or price of raw materials could restrict our ability to meet our sales commitments

Our businesses require certain materials that are sourced from third party suppliers. Although our cross-divisional synergies allow us to be our own source for some raw materials, particularly with respect to scrap metal for SMB, we rely on other suppliers as well as industry supply conditions generally, which involves risks, including the possibility of shortages of raw materials, increases in raw material costs and reduced control over delivery schedules. Failure to obtain a steady supply of scrap material could both adversely impact our ability to meet sales commitments and reduce our operating margins. Failure to obtain an adequate supply of end-of-life vehicles could adversely impact our ability to attract customers and charge admission fees and reduce our parts sales. Failure to obtain raw materials such as alloys used in the steel-making process could adversely impact our ability to make steel to the specifications of our customers.

Uncertain economic conditions may cause customers to be unable to fulfill their contractual obligations

We enter into export ferrous sales contracts preceded by negotiations that include fixing price, quantity, shipping terms and other contractual elements. Upon finalization of these terms and satisfactory completion of other contractual contingencies, the customer typically opens a letter of credit to satisfy its obligation under the contract prior to our shipment of the cargo. Although not considered normal course of business, during uncertain economic conditions, we are at risk on consummating the transaction until successful completion of the letter of credit. As a result, customers may not be able to fulfill their contractual obligations in times of illiquid market conditions. As of August 31, 2010 and 2009, 43% and 49%, respectively, of our trade accounts receivable balance was covered by letters of credit.

Fluctuations in the value of the US dollar relative to other currencies may reduce the demand for our products

A significant portion of MRB’s revenues and operating income earned is generated from sales to foreign customers, including customers located in Asia, Africa and Europe. A strong US dollar would make our products more expensive for non-US customers, which could negatively impact export sales. A strong US dollar would also make imported metal products less expensive, resulting in an increase in imports of scrap metal, scrap substitutes and steel products into the US. As a result, our products, which are made in the US, may become more expensive relative to imported raw metal and steel products, which could have a material adverse effect on our financial condition and results of operations.

Increases in imports of foreign steel into the US may reduce domestic demand for our products

Economic expansion in China and other foreign countries has affected the availability and increased the price volatility of recycled metal and steel products. Expansions and contractions in these economies can significantly affect the price of commodities used and sold by our business, as well as the price of finished steel products. Additionally, in a number of foreign countries, such as China, steel producers are generally government-owned and may therefore make production decisions based on political or other factors that do not reflect market conditions. Disruptions in foreign markets from excess steel production may encourage importers to target the US with excess capacity at aggressive prices, and existing trade laws and regulations may be inadequate to prevent unfair trade practices, which could have a material adverse effect on our financial condition and results of operations. If foreign steel production significantly exceeds consumption in those countries, imports of steel products into the US could increase, resulting in lower volumes and selling prices for SMB’s steel products.

Reliance on third party shipping companies may restrict our ability to ship our products

MRB and SMB generally rely on third parties to handle and transport their raw materials to their production facilities and finished products to end users. Due to factors beyond our control, including changes in fuel prices, political events, governmental regulation of transportation, changes in market rates, carrier availability and disruptions in transportation infrastructure, our suppliers may be forced to increase their charges for transportation services or

Schnitzer Steel Industries, Inc. Form 10-K 2010 / 15

Table of Contents

otherwise reduce the availability of their vehicles or ships, and thus we may not be able to transport our products in a timely and cost-effective manner, which could have a material adverse effect on our financial condition and results of operations and may harm our reputation.

Equipment upgrades and equipment failures may lead to production curtailments or shutdowns

Our recycling and manufacturing processes depend upon critical pieces of equipment, including shredders and furnaces, which may be out of service occasionally for scheduled upgrades or maintenance. Our equipment is also subject to failure and the risk of catastrophic loss due to unanticipated events such as fires, accidents or violent weather conditions. As a result, we may experience interruptions in our processing and production capabilities, which could inhibit our ability to meet our sales commitments and thus have a material adverse effect on our financial condition and results of operations.

The cost and availability of electricity and natural gas are subject to volatile market conditions and may restrict our ability to manufacture our products

We rely on third parties for our supply of energy resources that are consumed in the manufacturing of our products. The prices for and availability of electricity, natural gas and other energy resources are subject to volatile market conditions which can be affected by weather conditions and political and economic factors that are beyond our control. Disruptions in the supply of energy resources could impair our ability to process and manufacture our products for our customers or result in increases in our energy costs, which could have a material adverse effect on our financial condition and results of operations.

Goodwill impairment charges may adversely affect our operating results

We test our goodwill balances for impairment on an annual basis and if events occur or circumstances change that would reduce the fair value of the reporting segment below the reporting segment’s carrying amount. In determining fair value, we use an income approach based on the present value of expected future cash flows utilizing a market-based weighted average cost of capital. Given that market prices of our reporting segments are not readily available, we make various estimates and assumptions in determining the estimated fair values of the reporting segments, including forecasts of future sales and operating costs, prices, capital expenditures, working capital requirements, discount rates, growth rates and general market conditions. Fair value determinations require considerable judgment and are sensitive to inherent uncertainties and changes in the factors described above. However, in light of current economic conditions, impairments to one or more of our reporting segments could occur in interim periods, whether or not connected to the annual goodwill impairment analysis. A sustained decline in the quoted market prices of our stock could denote a triggering event indicating that the fair value of goodwill may be impaired. At that time, additional testing would be performed to evaluate the recoverability of goodwill and assess the need for an impairment charge, which could have an adverse effect on our financial condition and results of operations.

Inability to integrate future acquisitions may adversely impact our operating results

We have completed a number of recent acquisitions and expect to continue making acquisitions of, and strategic alliances with, complementary businesses to enable us to enhance our customer base and grow our revenues. Execution of this strategy involves a number of risks, including:

| • | Inaccurate assessment of or undisclosed liabilities; |

| • | Difficulty integrating the acquired businesses’ personnel and operations; |

| • | Potential loss of key employees or customers of the acquired business; |

| • | Difficulties in realizing anticipated cost savings, efficiencies and synergies; |

| • | Competition for such acquisitions and alliances; |

| • | Inability to maintain uniform standards, controls and procedures; and |

| • | Managing the growth of a larger company. |

Failure to successfully integrate acquisitions could have a material adverse effect on our financial condition and results of operations.

16 / Schnitzer Steel Industries, Inc. Form 10-K 2010

Table of Contents

Potential limitations on our ability to access credit facilities may restrict our ability to operate

Although we believe we have adequate access to contractually committed borrowings, we could be adversely affected if our banks refused to honor their contract commitments or ceased lending. While we believe the lending institutions participating in our credit arrangements are financially capable, recent events in the global credit markets, including the failure, takeover or rescue by various government entities of major financial institutions, have created uncertainty of credit availability to an extent not experienced in recent decades. Failure to access our credit facilities could restrict our ability to fund operations or make strategic acquisitions.

Product liability claims may adversely impact our operating results

We could inadvertently acquire radioactive scrap metal that could potentially end up in mixed scrap metal shipped to consumers worldwide. Although we have invested in radiation detection equipment in certain of our locations to address this risk, failure to detect radioactive scrap metal remains a possibility. Even though we maintain insurance to address the risk of this failure in detection, there can be no assurance that the insurance coverage would be adequate or will continue to be available on acceptable terms. In addition, if we fail to meet contractual requirements for a product we may be subject to product warranty costs and claims. These costs are generally not insured and could both have a material adverse effect on our financial condition and results of operations and harm our reputation.

Increases in consumer fuel costs and decreases in the miles they drive may decrease demand for our auto parts

In times of rapid increases in crude oil and gasoline prices, motorists may reduce the amount of travel by automobile. As the economy slows, consumer confidence weakens and fuel costs become a more significant factor in buying decisions and discretionary driving. Over time, significantly reduced driving leads to fewer accidents and lower demand for replacement parts, which may impact APB’s parts sales.

Risk Factors Relating to the Regulatory Environment

Environmental regulations may cause us to incur significant compliance costs

Compliance with environmental laws and regulations is a significant factor in our business. We are subject to local, state and federal environmental laws and regulations in the US and other countries relating to, among other matters:

| • | Waste disposal; |

| • | Air emissions; |

| • | Waste water and storm water management and treatment; |

| • | Soil and groundwater contamination remediation; |

| • | Global climate change; |

| • | The discharge, storage, handling and disposal of hazardous materials; and |

| • | Employee health and safety. |

We are also required to obtain environmental permits from governmental authorities for certain operations. Violation of or failure to obtain permits or comply with these laws or regulations could result in our business being fined or otherwise sanctioned by regulators or becoming subject to litigation by private parties. Our operations use and generate hazardous substances. In addition, previous operations by others at facilities that we currently or formerly owned, operated or otherwise used may have caused contamination from hazardous substances. As a result, we are exposed to possible claims under environmental laws and regulations, especially for the remediation of waterways and soil or groundwater contamination. These laws can impose liability for the cleanup of hazardous substances even if the owner or operator was neither aware of nor responsible for the release of the hazardous substances. We have, in the past, been found not to be in compliance with certain of these laws and regulations, and have incurred liabilities, expenditures, fines and penalties associated with such violations. Although we believe that we are currently in material compliance with all applicable environmental laws and regulations, future environmental compliance costs may increase because of new laws and regulations and changing interpretations by regulatory authorities, uncertainty regarding adequate pollution control levels, the future costs of pollution control technology and issues related to global climate change. Environmental compliance costs and potential environmental liabilities could have a material adverse effect on our financial condition and results of operations.

Schnitzer Steel Industries, Inc. Form 10-K 2010 / 17

Table of Contents

Climate change may adversely impact our facilities and our ongoing operations

The potential physical impacts of climate change on our operations are highly uncertain, and will be particular to the geographic circumstances. These may include significant rising sea levels at our deep water port facilities, changing storm patterns and intensities, and changing temperature levels. As many of our recycling facilities are located near deep water ports, rising sea levels may disrupt our ability to receive scrap metal, process the scrap metal through our mega-shredders and to ship product to our customers. Our MRB and APB operations are also dependent upon weather conditions. Periods of extended adverse weather conditions may inhibit our supply of scrap metal which could cause us to fail to meet our sales commitments. In addition, if temperature levels in the summer were to significantly increase for a sustained period in areas where our APB operations are located, this could result in less customer traffic, thus resulting in reduced admissions and parts sales.

Our effective tax rate could increase if our earnings from operations in Puerto Rico are taxed at higher rates

We currently calculate the taxes on our earnings in Puerto Rico to include benefits from industrial tax exemptions available to companies doing business there. Should it be determined by Puerto Rican taxing authorities that we are not entitled to all or a portion of these exemptions, the taxes on our earnings from operations in Puerto Rico and our consolidated effective tax rate could increase, which would adversely impact our results of operations and financial position.

Compliance with existing and new greenhouse gas emission regulations may adversely impact our operating results