Attached files

| file | filename |

|---|---|

| 8-K - GOLD HILLS MINING, LTD. | v199553_8k.htm |

| EX-99.3 - GOLD HILLS MINING, LTD. | v199553_ex99-3.htm |

| EX-99.1 - GOLD HILLS MINING, LTD. | v199553_ex99-1.htm |

Report

to:

Ardent

Mines Ltd. and Rio São Pedro Mineração Ltda.

WEATHERED

ORES OF THE FAZENDA LAVRAS GOLD

PROPERTY,

PARACATU, MINAS GERAIS, BRAZIL

prepared

by

João

Batista G. Teixeira

Geologist,

PhD, P.Geo.

September,

2010

Summary

|

Purpose

|

2

|

|

Scope

|

2

|

|

Disclaimer

|

3

|

|

Sources

of Information

|

3

|

|

The

Property

|

4

|

|

Regional

Geology

|

7

|

|

Local

Geology

|

8

|

|

Deposit

Type

|

10

|

|

Gold

Mining in Morro do Ouro

|

13

|

|

Early

Mining

|

13

|

|

Operation

of Rio Tinto Zinc

|

13

|

|

Operation

of Kinross Gold Inc.

|

15

|

|

Historical

Estimates (Kinross)

|

17

|

|

Current

Estimates (Kinross)

|

18

|

|

Mineral

Processing (Kinross)

|

18

|

|

Gold

Exploration at Fazenda Lavras

|

20

|

|

Early

Works

|

20

|

|

Exploration

of Weathered Deposits

|

20

|

|

Bulk

Sample and Gold Recovery

|

20

|

|

Recent

Exploration

|

21

|

|

Exploration

of Rio Tinto Zinc

|

24

|

|

Exploration

of Amazon Mining

|

26

|

|

Weathered

Ore Resources

|

26

|

|

Morro

do Ouro

|

26

|

|

Fazenda

Lavras

|

27

|

|

Estimation

of Weathered Ore Resource (Fazenda Lavras)

|

27

|

|

Conclusion

|

29

|

|

Certificate

and Consent

|

30

|

|

List

of Figures

|

|

|

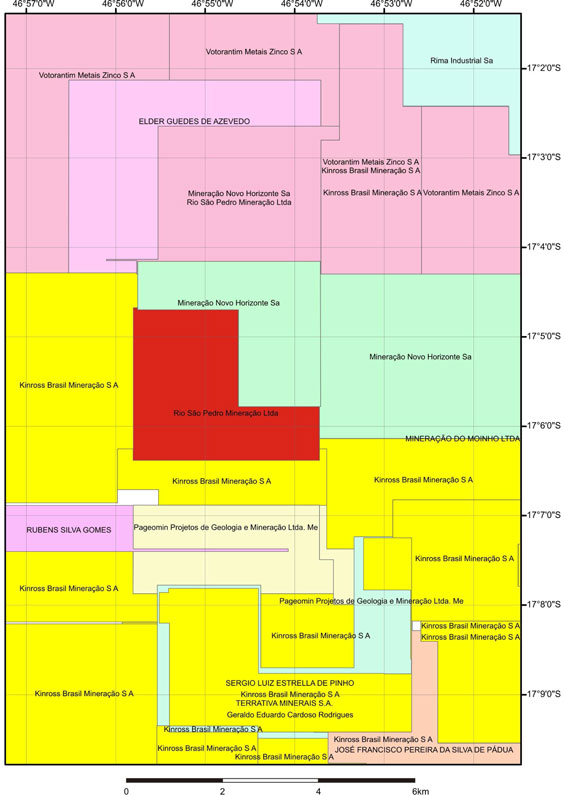

Figure

1 – Location of the Fazenda Lavras gold concession (in red) and adjacent

concessions (Source: DNPM, Sept., 2010)

|

5

|

|

Figure

2 – Mosaic Google Earth image showing locations of the Fazenda Lavras

Property (São Pedro Mineração Ltda.) and of the Morro do Ouro

gold mine (Kinross Brasil Mmineração S.A.)

|

6

|

|

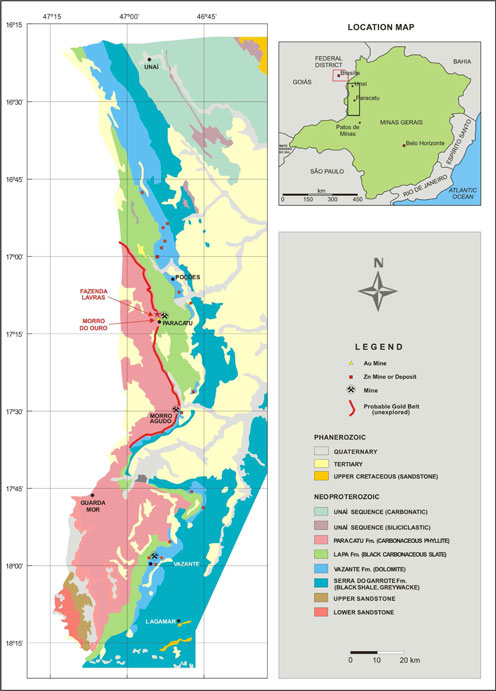

Figure

3 – Regional map of a sector of the Brasília Fold Belt, showing the main

zinc and gold mines and deposits (Source: Misi et al.,

2005).

|

7

|

|

Figure

4 – Satellite image with interpreted traces of regional structures. Barbed

black and red lines mark major east-vergent thrust faults (Source: Coelho

et al., 2008).

|

8

|

|

Figure

5 – Typical sulfide mineralization in boudinage structures of the Morro do

Ouro gold mine (Source: Hanson, 2005).

|

9

|

|

Figure

6 – The same type of mineralized boudinage structures at the Fazenda

Lavras gold deposit (Photo: J.B.G. Teixeira, 2007).

|

9

|

|

Figure

7 – Quartz boudins in the Fazenda Lavras Property (Photo: Y. Munemassa,

2007).

|

10

|

1

|

Figure

8 – Weathered carbonaceous quartz‐sericite

metarhythmite of the Fazenda Lavras Property (Photo: Y. Munemassa,

2007).

|

10

|

|

Figure

9 – Quartz boudins within the carbonaceous metarhythmite (Photo: Y.

Munemassa, 2007).

|

10

|

|

Figure

10 – Conceptual pre-mining weathering profile in the Morro do Ouro gold

mine (Source: Hanson, 2005).

|

12

|

|

Figure

11 – Early gold mining of the weathered profile at the Fazenda Lavras

Property (Photo: Y. Munemassa, 2007).

|

12

|

|

Figure

12 – Panoramic view of the Morro do Ouro open pit mine (Source: Puhlmann

et al., 2006). The town of Paracatu is in the foreground. In

the left side of the horizon is the Fazenda Lavras

Property.

|

16

|

|

Figure

13 – Drill section 07N Morro do Ouro mine, looking north

(Source: Hanson, 2005).

|

17

|

|

Figure

14 – Drill Section 05N Morro do Ouro mine, looking north (Source: Hanson,

2005).

|

17

|

|

Figure

15 – Gold mined in the Morro do Ouro as of October 31, 2005 (Source:

Hanson, 2007).

|

18

|

|

Figure

16 – Simplified flow sheet existing Morro do Ouro mine process

plant

|

19

|

|

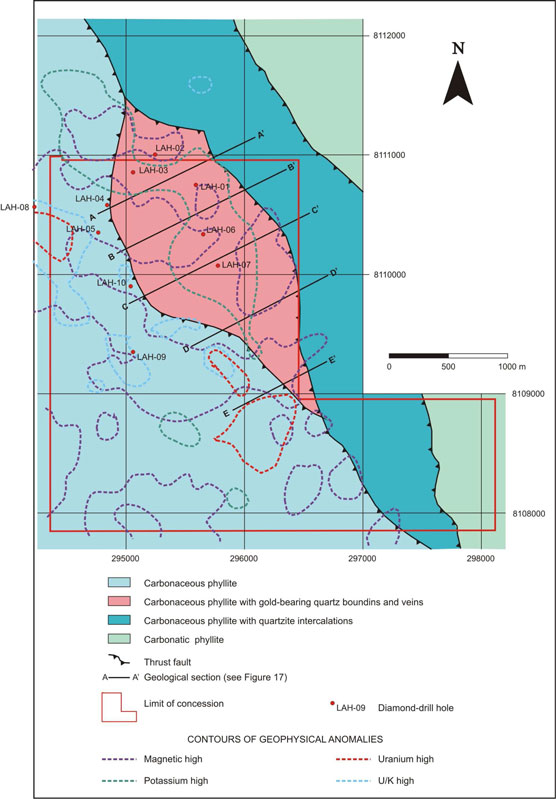

Figure

17 – Simplified geological map of the Fazenda Lavras Property showing RTZ

drill-hole locations and contours of geophysical anomalies from airborne

surveys (Sources: Arantes & Associates, 1997 and Figueira et al.,

2002).

|

22

|

|

Figure

18 – Simplified geological sections of the Fazenda Lavras Property. For

locations see Figure 17 (Source: Arantes & Associates,

1997).

|

23

|

Purpose

To review

exploration potential of the weathered ores of the Fazenda Lavras Gold Property

located near Paracatu, Minas Gerais, Brazil.

Scope

At the

request of Ardent Mines Ltd. and Rio São Pedro Mineração Ltda.,

respectively, Dr. João Batista Guimarães Teixeira,

P.Geo. (the Author) was commissioned in September 2010 to prepare a

Technical Report on the Fazenda Lavras Gold Project. The scope of the inquiries

of the report included the following:

|

|

·

|

A

review of historical exploration, in particular, a detailed review of

early exploration conducted by previous tenement

holders.

|

|

|

·

|

Characterization

of the actual potential for the weathered gold

deposits.

|

2

Disclaimer

The

Author did not conduct a fully review of mineral title and ownership, and status

of claims as outlined in this Report was obtained from the web disclosure site

of DNPM, Departamento Nacional de Produção Mineral, at www.dnpm.gov.br.

Sources

of Information

This

report is based on three field visits to the area (July 4-5, 2007, January 8-10,

2010 and September 9-10, 2010) and on the following:

|

|

·

|

MSc

Dissertation, University of Brasília: “Geochemistry of Carbonaceous

Phyllites of the Morro do Ouro Deposit, Paracatu, State of Minas Gerais”,

by B.S. de Almeida (2009).

|

|

|

·

|

Paper

published in Revista Brasileira de Geociências, vol. 38, p.149-165:

”Estilos estruturais e evolução tectônica da porção mineira da bacia

proterozóica do São Francisco”, by J.C.C. Coelho, M.A. Martins-Neto and M.

S. Marinho (2008).

|

|

|

·

|

Consultancy

report: “Geological evaluation of the Rio São Pedro Mineração Ltda.

Property”, by Y. Munemassa (2007).

|

|

|

·

|

Paper

presented at the 7th International Conference on Acid Rock Drainage

(ICARD), March 26-30, 2006, St. Louis MO. R.I. Barnhisel (ed.) Published

by the American Society of Mining and Reclamation (ASMR), 3134 Montavesta

Road, Lexington, KY 40502: “Development and operation of a water balance

at Rio Paracatu Mineração, Brazil”, by T. Puhlmann, C. Voss, J. Esper and

R. D. Amaral (2006).

|

|

|

·

|

Report

prepared for Kinross Gold Corporation, to comply with Canada’s National

Instrument 43-101: “Paracatu Mining Technical Report, Paracatu, Minas

Gerais State, Brazil”, by R.D.

Henderson (2006).

|

|

|

·

|

Report

prepared for Kinross Gold Corporation, to comply with Canada’s National

Instrument 43-101: “Paracatu Mining Technical Report, Paracatu, Minas

Gerais State, Brazil”, by W. Hanson

(2005).

|

3

|

|

·

|

Paper

published in Ore Geology

Reviews, vol. 26, p. 263-304: “Sediment hosted lead–zinc deposits

of the Neoproterozoic Bambuí Group and correlative sequences, São

Francisco Craton, Brazil: A review and a possible metallogenic evolution

model”, by A. Misi, S.S.S. Iyer, C.E.S. Coelho, C.C. G. Tassinari, W.J.S.

Franca-Rocha, I.A. Cunha, A.S.R. Gomes, T.F. Oliveira, J.B.G.Teixeira and

V.M.Conceição Filho (2005).

|

|

|

·

|

Geophysical

report: Interpretação aerogeofísica do prospecto aurífero da Faz. Lavras,

Paracatu – MG. Ralatório Final, by E. P. Figueira, M.Vieira, E. Henrique

and R. Cordani (2002).

|

|

|

·

|

Consultancy

report: “Avaliação Geo-econômica do Prospecto Aurífero da Fazenda Lavras,

Paracatu, Minas Gerais”, by F.F. Silva, R. Moura, E. Lloyd, F.

Gomes, A. Borges, D. Arantes and A.C. Coelho

(2000).

|

|

|

·

|

Consultancy

report: “ Relatório da Fase I – Diagnóstico Técnico e Econômico do Projeto

Fazenda Lavras – Volume I: Texto e Anexos – Volume II: Mapa geológico;

Mapa de trincheiras e furos de sonda; Mapa de cubagem; Boletins de

análises químicas e logs de furos de sondagem; Perfís de cubagem”, by

Arantes & Associates (1997).

|

|

|

·

|

Consultancy

report: “Relatório Final de Pesquisa, Referência DNPM 831.810/86, Alvará

2432/93; Local: Fazenda Lavras; Substância: Ouro; Município: Paracatu;

Estado: Minas Gerais – Volumes I and II”, by A. N. de Figueiredo

(1996).

|

The

Property

The

Fazenda Lavras Property consists of one mineral concession covering an area of

859.5 hectares, which holds the mining permit granted to Rio São Pedro Mineração

Ltda.

The

Property is centered at latitude 17°05’30” South and longitude 46°55’00” West,

which is 10km northwest of the open pit of the Morro do Ouro mine, owned by

Kinross Gold Corporation (Figures 1and 2). The nearest large city is Brasília,

about 230km to the northwest.

4

Figure 1

– Location of the Fazenda Lavras gold concession (in red) and adjacent

concessions

(Source:

DNPM, Sept., 2010)

5

Figure 2

– Mosaic Google Earth image showing locations of the Fazenda Lavras Property

(São

Pedro

Mineração Ltda.) and of the Morro do Ouro gold mine (Kinross Brasil

Mmineração

S.A.)

6

Regional

Geology

The

mineralization is hosted by a thick sequence of phyllites belonging to the basal

part of the Neoproterozoic Paracatu Formation and known locally as the Morro do

Ouro Sequence (Figure 3).

Figure 3

– Regional map of a sector of the Brasília Fold Belt, showing the main zinc and

gold

mines and

deposits (Source: Misi et al., 2005).

7

The

sequence outcrops in a northerly trend in the eastern Brasilia Fold Belt, which,

in turn, forms the western edge of the São Francisco Craton.

The

Brasilia Fold Belt predominantly consists of clastic sediments, which have

undergone lower greenschist grade metamorphism along with significant nappe and

thrust deformation. A series of east-northeast trending thrust faults are

extensively developed along the belt. Metamorphic grade increases towards the

west as the thickness of the fold belt increases.

The

timing of deformation is estimated at between 800-600 Ma during the Brasiliano

orogenic cycle and the mineralization is believed to originate syngenetically

with this period of deformation.

The

geotectonic evolution and the geological characteristics of the region allow one

to believe that the gold mineralizations of the Morro do Ouro mine and of the

Fazenda Lavras deposit belong to the same near N-S thrust related gold belt

located at the base of the Paracatu Formation (Figure 4). Until now this very

interesting gold belt is largely unexplored.

Figure 4

– Satellite image with interpreted traces of regional structures. Barbed black

and red lines mark major east-vergent thrust faults (Source: Coelho et al.,

2008).

Local

Geology

The

phyllites exhibit extensive deformation and feature well developed quartz

boudins and associated sulfide mineralization (Figures 5, 6 and 7). Sericite is

common, likely as a result of extensive metamorphism of the host

rocks.

Primary

sedimentary features and bedding planes are easily recognizable but are

intensively deformed with development of thrusting, bedding plane thrusting,

sygmoidal and boudinage structures (Figures 8 and 9).

Mineralization

is closely related to a period of ductile deformation, associated shearing and

thrust faulting. Overall, the Morro do Ouro sequence has been thrust to the

northeast. Intense, low angle isoclinal folds are commonly

observed.

The

mineralization plunges to the west-southwest at low angles (5 to 20°), and there

is secondary folding with axial planes striking to the northwest resulting in

kink bands and egg box fold pattern in some areas.

8

Figure 5

– Typical sulfide mineralization in boudinage structures of the Morro do Ouro

gold mine (Source: Hanson, 2005).

Figure 6

– The same type of mineralized boudinage structures at the Fazenda Lavras gold

deposit (Photo: J.B.G. Teixeira, 2007).

9

Figure 7

– Quartz boudins in the Fazenda Lavras Property (Photo: Y. Munemassa,

2007).

Figure 8

– Weathered carbonaceous quartz‐sericite

metarhythmite of the Fazenda Lavras Property (Photo: Y. Munemassa,

2007).

Figure 9

– Quartz boudins within the carbonaceous metarhythmite (Photo: Y. Munemassa,

2007).

Deposit

Type

The Morro do Ouro mine is the lowest

grade gold operation in the world (0.41g Au/t), notwithstanding, from 2009 it

became the largest gold producer in Brazil. In 2006, Kinross began an

expansion of the mill facilities, with an expected throughput to 61 million

tonnes per annum. Production of gold from the expansion plant began in September

2008. The expansion is expected to extend the life of the mining operation to

2040 (Kinross Gold Inc., Sept. 2010).

10

The Morro

do Ouro orebody is hosted by a shallow southwest dipping structural zone, within

which the Morro do Ouro metasedimentary rocks host abundant

quartz-carbonate-sulfide boudins.

Boudin

occurrence is higher in the central part of the deposit (5%) than on the margins

(2%). The boudins contain a sulfide assemblage dominated by pyrite and

arsenopyrite, with minor sphalerite, galena, pyrrhotite and

chalcopyrite.

Mineralization

in the Morro do Ouro mine is subdivided into four horizons defined by the degree

of oxidation and surface weathering and the associated sulfide mineralization.

These units are, from surface, the “C”, “T”, “B1” and “B2” horizons (Figure

10).

Type “C”

mineralization occurs at surface and extends to 20-40 meters from surface. Type

“C” mineralization is completely altered with no remaining sulfides. It also

features localized laterite development (Figure 11).

The “T”

horizon is generally only a couple of meters thick. It is multicolored and is

essentially marks the transition from the “C” horizon to the “B1”

horizon.

The “B1”

horizon is dark in colour and carbonaceous with less oxidation than the “C”

horizon. Sulfides have been completely oxidized but some fresh sulfide material

is visible in the quartz boudins.

“B2”

mineralization was originally described as unweathered or fresh mineralization

with primary sulfides. The contact between un-mineralized host rock (Type “A”)

and the various mineralized horizons is gradational, occurring over a 10 m wide

zone that is characterized by arsenic values of 200-500 ppm and up to 0.2 g

Au/t.

The Morro

do Ouro deposit is a metamorphic gold system with finely disseminated gold

mineralization hosted within an original bedded sedimentary host (phyllite).

Very fine, evenly distributed gold (associated with sulfides) is finely

disseminated throughout a thinly bedded phyllite (metamorphosed argillaceous

sedimentary rock) of Neoproterozoic age.

Whole

rock geochemistry, x-ray diffractrometry and counts of boudin volumes were used

to investigate geochemical variations within and around the orebody and their

relationship to boudins. Unmineralized carbonaceous phyllites in the footwall of

the orebody are composed of chlorite, muscovite and quartz, with rare quartz

boudins and weak deformation indicators. These rocks have higher values of

SiO2, Zr, V, Cr and Al than the mineralized phyllites..In contrast, mineralized

carbonaceous phyllites are dominated by quartz and muscovite (no chlorite), have

much higher boudin volumes (quartz, siderite and sulfides), have much more

intense deformation and are also enriched in Au, Ag, As, Pb, Zn, C and S

(Almeida, 2009).

11

Figure 10

– Conceptual pre-mining weathering profile in the Morro do Ouro gold mine

(Source: Hanson, 2005).

Figure 11

– Early gold mining of the weathered profile at the Fazenda Lavras Property

(Photo: Y. Munemassa, 2007).

The

phyllites at Morro do Ouro are highly deformed as a result of tectonic

processes. Gold mineralization was introduced syntectonically, the result of

metamorphic alteration during thrusting of the Morro do Ouro sequence over top

of the rocks of the younger Vazante Formation. Metamorphic grade increases from

east to the west.

12

Structural

interpretation suggests that mineralization was precipitated within a high

strain zone where silica and carbonate were scavenged out of the host phyllites

resulting in an increase in graphite content that may have acted as a chemical

trap, precipitating out gold and sulfide mineralization remobilized during

metamorphic alteration of the Morro do Ouro Sequence.

Gold

Mining in Morro do Ouro

Early

Mining

The

mining history of the Paracatu region is closely associated with the activities

of the “bandeirantes”, who prospected for gold in Brazil’s interior, arriving in

the Paracatu region in 1722 after the discovery of gold alluvial

placers.

Alluvial

mining peaked during the second half of the 18th century. The alluvial mining

was not limited to the placer deposits along Riacho Rico (creek), they also

exploited the oxidized ore outcrop on the top of Morro do Ouro hill or the “Hill

of Gold”.

Gold

production declined sharply in the region during the first decade of the 19th

century. From this point forward, production was limited to “garimpeiros”,

subsistence level mining practiced by local inhabitants. Various prospectors

explored the region but economically viable operations were limited as a result

of the low-grade nature of the deposits.

Operation

of Rio Tinto Zinc

Beginning

in 1970, Paracatu attracted some attention from mineral exploration companies

looking for lead and zinc deposits in the area. The interest in the gold of

Morro do Ouro was secondary as the majority of the companies were not attracted

by the gold grade, considered to be too low to be economically

extracted.

13

In 1980,

Rio Tinto Zinc (RTZ), operating in Brazil under the name of Riofinex do Brasil,

joined with Billiton in a partnership to explore land in Brazil. Billiton owned

the Morro do Ouro area but had no interest in investing in the

area.

In 1984

Billiton sold the balance of its shares in the Morro do Ouro area to Riofinex.

Riofinex embarked on a surface exploration program that focused on the oxidized

and weathered horizons of the Moro do Ouro area. At the end of 1984, based on

the data from hundreds of test pits (up to 25 m deep) and further supported by a

total of 44 drill holes, a reserve of 97.5Mt at 0.587g Au/t was

estimated at what is currently known as the Paracatu Mine.

RTZ was

the first company to apply modern exploration methods at Paracatu. Northeast of

Riacho Rico, the deposit had been drilled on a nominal 100×100 meter drill

spacing.

This

estimate only included the superficial oxidized ore, then categorized as type

“C” or “T” ore. Despite the low gold grade, Riofinex’s geologists believed that

profitable extraction of the ore could be realized. In 1985 this was confirmed

by a feasibility study. Total investment up to that period was $7.3 million

including ground acquisition costs, exploration costs, and the cost of the

feasibility study.

Approval

was granted by Rio Tinto to construct a mining project at a capital cost of

approximately US$ 65 million, on the condition that a Brazilian partner could be

secured for the venture. At the end of 1985, RTZ Mineracão, successor to

Riofinex, struck a joint venture agreement with Autram Mineração e Participações

(Autram) to joint venture the project through a new company, Rio Paracatu

Mineração (RPM), with Rio Tinto holding a 51% operating interest and Autram the

remaining 49%.

Autram’s

interest was ceded to TVX Participações who later became TVX Gold Inc. (TVX).

TVX entered into an agreement with Newmont that resulted in Newmont and TVX

holding a 24.5% interest in Paracatu.

In early

2003, TVX acquired Newmont’s 24.5% interest resulting in TVX having a 49%

interest in Paracatu. Almost immediately, Kinross acquired TVX’s interest as

part of the Kinross, TVX, Echo Bay Mines Ltd (EBM), merger

agreement.

Production

at Paracatu commenced in October 1987 treating oxidized and highly weathered ore

from the “C” and “T” ore horizons described above. The first gold bar was poured

in December 1987. The following year, the mine throughput reached the design

capacity of 6.1Mtpa.

14

After

start up, the throughput rate was progressively increased to 13 Mtpa, as a

result of a number of improvement programs. In 1993, an $18.3M Optimization

Project was commissioned providing extra water and flotation capacity for the

circuit.

Throughput

at Paracatu was increased again to 16 Mtpa in 1997 after completion of Expansion

Project I with a capital cost expenditure of $47.3 M.

Expansion

Project II (1999) increased the mill throughput to 20Mtpa after a capital

investment of $6.2M. Due to an increase in ore hardness, throughput has now

fallen to the 17.0Mtpa level.

Total

capital investment to December 31, 2004 totalled $249.4M dollars. This includes

the initial purchase costs of the land, all engineering, the initial

construction costs, later optimization and expansion capital costs, the purchase

of the mining fleet and other smaller capital investments to optimize the

existing project.

In

December 2004, Kinross purchased Rio Tinto’s 51% interest in the RPM mine giving

Kinross a 100% interest in RPM and the Paracatu mine.

Operation

of Kinross Gold Inc.

The Morro

do Ouro mine is operated by Kinross Brasil Mineração S.A., a wholly owned

subsidiary of Kinross Gold Corporation.

The mine

includes an open cast mine, process plant, tailings impoundment area and related

surface infrastructure and support buildings. The planned open pit operation

will developed over an area of 5000 by 2500 meters. Current plant throughput

averages 18Mtpa.

Currently,

mining does not require any waste removal (stripping) and just a limited amount

of explosive is necessary to blast the harder ores prior to excavation (Figure

12).

15

Figure 12

– Panoramic view of the Morro do Ouro open pit mine (Source: Puhlmann et al.,

2006). The town of Paracatu is in the foreground. In the left side of

the horizon is the Fazenda Lavras Property.

The

mineral resource model for Morro do Ouro is developed from a series of oriented

drill sections on which all exploration results have been plotted. Observation

of the drill core is used to define the “C”, “T”, “B1” and “B2” contacts, which

are interpreted on individual sections (Figures 13 and

14).

16

Figure 13

– Drill section 07N Morro do Ouro mine, looking north (Source:

Hanson, 2005).

Figure 14

– Drill Section 05N Morro do Ouro mine, looking north (Source: Hanson,

2005).

Historical

Estimates (Kinross)

The

history at Morro do Ouro indicates continuous growth of the reserve base

reflecting increased geological knowledge and improved process efficiencies.

Figure 15 is a graph showing the changes in contained ounces from the

start of commercial production.

17

Figure 15

– Gold mined in the Morro do Ouro as of October 31, 2005 (Source: Hanson,

2007).

Current

Estimates (Kinross)

The

proven and probable mineral reserve estimate for the Morro do Ouro mine is

summarized in Table 1. The mean specific gravity for mineralized drill cores was

2.77 and the cut off grade used to report mineral reserves was 0.21g

Au/t.

Table 1 -

Gold Reserves for the Morro do Ouro gold mine. (Source: Kinross Gold Inc., Sept.

2010)

|

Tonnes

|

Grade

|

Ounces

|

|||||||

|

Gold

|

(kt)

|

(g/t)

|

(koz)

|

||||||

|

Proven

& Probable Reserves

|

1,320,886

|

0.41

|

17,472

|

Mineral

Processing (Kinross)

Run-of-mine

ore is crushed and sent to blending bins, which feed the grinding circuit of

single stage ball mills. Ball mills are in closed circuit with hydrocyclones. A

portion of the circulating load passes through jigs for gravimetric recovery of

gold (Figure 16).

18

Flotation

is conducted in three stages: flash, scavenger and cleaner for Au and sulfide

recovery. The flotation tails are thickened and then sent to the main tailings

pond.

The

sulfidic flotation concentrates are sent to the hydrometallurgy plant and

average about 20g Au/t. The coarser fraction of this concentrate, about 10 %, is

treated gravimetrically in a Knelson concentrator recovering approximately 20%

of the Au. Concentrate from the Knelson is sent to shaking tables and then on to

the smelting furnace. The finer sulfide concentrate is reground, thickened and

sent to the carbon-in-leach (CIL) circuit. The Au is recovered by electrowinning

and then sent to the smelting furnace.

The

products from CIL and from the shaking tables are calcined and smelted in an

induction furnace resulting in bullion containing 75 to 80% Au and 20 to 25%

Ag.

Figure 16

– Simplified flow sheet existing Morro do Ouro mine process plant

(Source:

Hanson, 2005).

19

Gold

Exploration at Fazenda Lavras

Early

Works

Gold was

first recovered from the local streams in 1733. When settlers arrived during the

18th century they worked the alluvial deposits and later the soft bedrock of the

Morro do Ouro and surrounding areas. Old workings, excavations and washed

gravels are still visible on the ground of Fazenda Lavras.

Exploration

of Weathered Deposits

The

Fazenda Lavras deposit was first worked by Mineração Serra do Encanto Ltda. The

final exploration report was presented to the DNPM on August 1996 (Relatório

Final de Pesquisa. Reference: DNPM 831810/86. Alvará: 2432/93).

The

following reserves were calculated:

|

|

·

|

Proven:

16,464,350t @ 0.791g Au/t.

|

|

|

·

|

Indicated:

8,349,464t @ 0.618g Au/t.

|

|

|

·

|

Inferred:

7,326,131t @ 0.618g Au/t.

|

The

reserves were calculated using the analytical results of 11 diamond drill holes.

The maximum depth was observed on hole F5-08 (46 meters). The average Au values

obtained on 135 core samples from 15 diamond drill holes was 0.67g Au/t. The

assays were carried out at METAGO laboratory (currently FUNMINERAL), in Goiânia,

Goiás.

Bulk

Sample and Gold Recovery

During

the 1990’s a small plant was set up to bulk sample the Fazenda Lavras Property

bedrock. The first pass in 1993 processed 22 thousand tonnes of ore and

recovered 14.78kg of gold, for an approximate average grade of 0.67g Au/t.

During 1995 the same plant processed 30 thousand tonnes of ore, but the total

gold recovered has not been reported.

20

Results,

however, were encouraging enough that in 1997 a feasibility study was initiated

to investigate the technical and economic aspects of the Fazenda Lavras

deposit.

Recent

Exploration

A summary

of the modern sequential exploration done at the Fazenda Lavras Property is

presented below:

|

|

·

|

Geological

mapping, pitting, trenching and shallow drilling (average depth of 15

meters), described by Figueiredo

(1996).

|

|

|

·

|

Geological

mapping and detailed investigation of the gold mineralization, described

by Arantes & Associates (1997).

|

|

|

·

|

Geological

mapping, drilling (10 diamond-drill holes) and geophysical survey

(airborne and ground magnetometry), described by Silva et al.

(2000).

|

|

|

·

|

Arantes

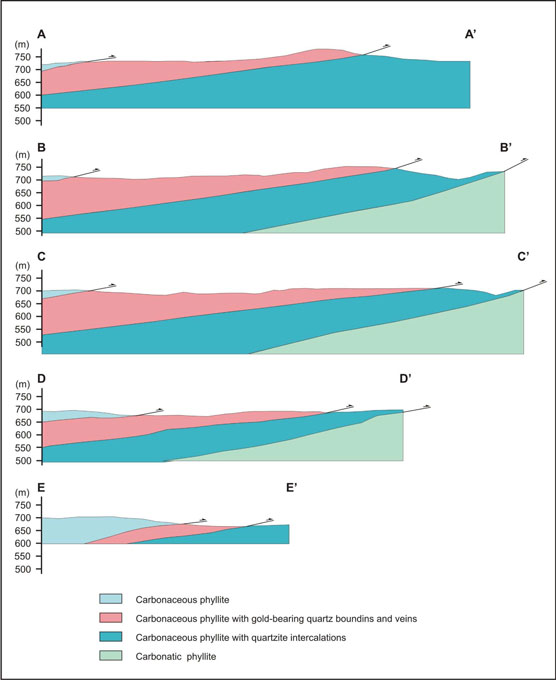

& Associates (1997) presented a geological map (Figure 17) and a

series of interpreted cross sections of the Fazenda Lavras Property

(Figure 18).

|

Based on

the previous work commented above and on his own field observations, the present

Author concluded that the geological units, structures and gold mineralization

of the Fazenda Lavras deposit are quite similar to those of the Morro do Ouro

gold mine.

The

low-grade gold mineralization is hosted by a thick sequence of carbonaceous

phyllites belonging to the basal part of the Neoproterozoic Paracatu Formation

(Morro do Ouro Sequence).

21

Figure 17

– Simplified geological map of the Fazenda Lavras Property showing RTZ

drill-hole

locations and contours of geophysical anomalies from airborne surveys

(Sources:

Arantes & Associates, 1997 and Figueira et al., 2002).

22

Figure 18

– Simplified geological sections of the Fazenda Lavras Property. For

locations

see Figure 17 (Source: Arantes & Associates, 1997).

23

Exploration

of Rio Tinto Zinc

Subsequently,

the Fazenda Lavras deposit was explored by RTDM a Brazilian exploration branch

of Rio Tinto Zinc (RTZ) in 2000 (Silva et al., 2000).

A diamond

core drilling program (1,613.57 m) was distributed in ten holes (Figure 17 and

Table 2).

A total

of 1,565 core samples were sent to the Bondar Clegg lab (now ALS Chemex) for

gold assays by FA/AA (50 grams). Standard controls samples were inserted on the

batches sent to the lab (total of 30 samples). The assays of the core samples

yielded very low Au values (Table 3) and no resource estimation was carried out

by RTZ.

Table 2 –

List of RTDM diamond drill holes in the Fazenda Lavras Property (Source: Silva

et al, 2000)

|

DDH

|

UTM

|

Altitude

of

collar

(m)

|

Inclination

|

Final

depth

(m)

|

Number

of

samples

|

Number

of

analyses

|

||||||||||||

|

LAH-01

|

295849.166

8110558.337

|

781.062

|

90º | 50.80 | 51 | 51 | ||||||||||||

|

LAH-02

|

2955512.173

8110809.173

|

790.792

|

90º | 67.50 | 67 | 67 | ||||||||||||

|

LAH-03

|

295329.529

8110662.340

|

765.918

|

90º | 135.10 | 135 | 135 | ||||||||||||

|

LAH-04

|

295113.692

8110391.714

|

758.444

|

90º | 169.05 | 169 | 157 | ||||||||||||

|

LAH-05

|

295040.550

8110163.771

|

749.759

|

90º | 166.68 | 167 | 153 | ||||||||||||

|

LAH-06

|

295910.469

8110149.908

|

749.415

|

90º | 159.75 | 160 | 149 | ||||||||||||

|

LAH-07

|

296031.999

8109888.920

|

734.245

|

90º | 151.50 | 151 | 151 | ||||||||||||

|

LAH-08

|

294512.047

8110376.374

|

768.792

|

90º | 229.50 | 229 | 229 | ||||||||||||

|

LAH-09

|

295330.468

8109174.377

|

746.194

|

90º | 248.54 | 248 | 248 | ||||||||||||

|

LAH-10

|

295308.711

8109717.768

|

|

742.862

|

70º/140º | 235.15 | 235 | 225 | |||||||||||

|

TOTAL

|

1,613.57 | 1,612 | 1,565 | |||||||||||||||

24

Table 3 –

Gold results of RTDM diamond drill holes in the Fazenda Lavras Property (Source:

Silva et al, 2000)

|

DDH

(LAH)

|

SAMPLE

(LAT)

|

Depth

(m)

|

Interval

(m)

|

Au

(ppm)

|

Best

sample

in

interval

|

|||||

|

01

|

12

– 17

|

11.00

– 17.00

|

6

|

0.329

|

LAT-15

1m @ 1.036 ppm

|

|||||

|

01

|

01

|

0.00

– 1.00

|

1

|

0.136

|

||||||

|

01

|

07

|

6.00

– 7.00

|

1

|

0.141

|

||||||

|

01

|

46

|

45.00

– 46.00

|

1

|

0.134

|

||||||

|

01

|

48

– 49

|

47.00

– 49.00

|

2

|

0.109

|

LAT-48

1m @ 0.122 ppm

|

|||||

|

02

|

65

– 68

|

13.00

– 17.00

|

4

|

0.245

|

LAT-65

1m @ 0.520 ppm

|

|||||

|

02

|

54

|

2.00

– 3.00

|

1

|

0.143

|

||||||

|

02

|

83

|

31.00

– 32.00

|

1

|

0.128

|

||||||

|

03

|

149

– 150

|

30.00

– 32.00

|

2

|

0.253

|

LAT-150

1m @ 0.356 ppm

|

|||||

|

04

|

256

– 259

|

2.00

– 6.00

|

4

|

0.130

|

LAT-259

1m @ 0.173 ppm

|

|||||

|

04

|

262

– 264

|

8.00

– 11.00

|

3

|

0.112

|

LAT-263

1m @ 0.136 ppm

|

|||||

|

04

|

266

|

12.00

– 13.00

|

1

|

0.111

|

||||||

|

04

|

276

– 280

|

22.00

– 27.00

|

5

|

0.681

|

LAT-279

1m @ 1.004 ppm

|

|||||

|

04

|

282

– 289

|

28.00

– 36.00

|

8

|

0.250

|

LAT-283

1m @ 0.436 ppm

|

|||||

|

04

|

331

|

77.00

– 78.00

|

1

|

0.218

|

||||||

|

04

|

350

|

96.00

– 97.00

|

1

|

0.610

|

||||||

|

05

|

417

– 418

|

6.00

– 8.00

|

2

|

0.135

|

LAT-418

1m @ 0.138 ppm

|

|||||

|

05

|

438

|

27.00

– 28.00

|

1

|

0.112

|

||||||

|

05

|

454

|

43.00

– 44.00

|

1

|

0.566

|

||||||

|

05

|

465

– 470

|

54.00

– 60.00

|

6

|

0.188

|

LAT-469

1m @ 0.592 ppm

|

|||||

|

06

|

573

|

9.00

– 10.00

|

1

|

0.298

|

||||||

|

06

|

583

|

19.00

– 20.00

|

1

|

0.162

|

||||||

|

06

|

586

|

22.00

– 23.00

|

1

|

0.398

|

||||||

|

06

|

592

|

28.00

– 29.00

|

1

|

0.171

|

||||||

|

06

|

599

|

35.00

– 36.00

|

1

|

0.255

|

||||||

|

06

|

609

|

45.00

– 46.00

|

1

|

0.112

|

||||||

|

06

|

623

|

59.00

– 60.00

|

1

|

0.262

|

||||||

|

06

|

626

|

62.00

– 63.00

|

1

|

0.144

|

||||||

|

07

|

713

|

0.00

– 1.00

|

1

|

0.162

|

||||||

|

07

|

718

|

5.00

– 6.00

|

1

|

0.283

|

||||||

|

07

|

730

– 733

|

17.00

– 21.00

|

4

|

0.120

|

LAT-730

1m @ 0.152 ppm

|

|||||

|

07

|

743

|

30.00

– 31.00

|

1

|

0.145

|

||||||

|

07

|

775

|

62.00

– 63.00

|

1

|

0.186

|

||||||

|

08

|

973

|

109.00

– 110.00

|

1

|

0.289

|

||||||

|

08

|

983

|

119.00

– 120.00

|

1

|

0.372

|

||||||

|

08

|

987

– 990

|

123.00

– 127.00

|

4

|

0.120

|

LAT-988

1m @ 0.229 ppm

|

|||||

|

08

|

992

– 993

|

128.00

– 130.00

|

2

|

0.112

|

LAT-992

1m @ 0.112 ppm

|

|||||

|

08

|

998

|

134.00

– 135.00

|

1

|

0.145

|

||||||

|

08

|

999

– 1005

|

135.00

– 142.00

|

7

|

0.365

|

||||||

|

08

|

1009

|

145.00

– 146.00

|

1

|

0.241

|

||||||

|

09

|

1230

|

137.00

– 138.00

|

1

|

0.152

|

||||||

|

09

|

1239

|

146.00

– 147.00

|

1

|

0.124

|

||||||

|

09

|

1246

|

153.00

– 154.00

|

1

|

0.180

|

||||||

|

09

|

1299

|

206.00

– 207.00

|

1

|

0.158

|

||||||

|

09

|

1302

|

209.00

– 210.00

|

1

|

0.117

|

||||||

|

09

|

1304

|

211.00

– 212.00

|

1

|

0.123

|

||||||

|

10

|

1412

|

71.00

– 72.00

|

1

|

0.124

|

||||||

|

10

|

1419

|

78.00

– 79.00

|

1

|

0.434

|

||||||

|

10

|

1423

|

82.00

– 83.00

|

1

|

0.208

|

||||||

|

10

|

1452

|

111.00

– 112.00

|

1

|

0.839

|

||||||

|

10

|

1456

|

115.00

– 116.00

|

1

|

0.350

|

||||||

|

10

|

1493

|

152.00

– 153.00

|

1

|

0.103

|

||||||

|

10

|

1522

|

181.00

– 182.00

|

1

|

0.119

|

25

Exploration

of Amazon Mining

In July

2007, an agreement with São Pedro Mineração Ltda. was signed in which Amazon

Mining Holding Plc. – AMZ (a UK public company with shares listed on the TSX

Venture Exchange) acquired a 100% interest in the Fazenda Lavras Gold Project.

In January 2008 AMZ announced that it would start drilling on the Lavras

Project.

Probably

affected by the financial crisis that developed worldwide in the Summer and Fall

of 2008, AMZ never committed resources to conduct a compliant drilling program.

In July of 2008 AMZ notified the owners of São Pedro Mineração Ltda of their

financial limitations and inability to conduct the promised drilling program or

effect payments as contemplated in their contract, which became

ineffective.

Weathered

Ore Resources

Morro

do Ouro

The Morro

do Ouro mine is located within a regional gold belt, which is structuraly

controlled at the basal part of the Neoproterozoic Paracatu

Formation.

Mineralization in this belt occurs

within a sequence of phyllites that have been thrust from SW to NE producing

extensive deformation. Gold grades increase along with the frequency of boudins,

intensity of shearing and arsenopyrite content.

The

timing of gold and sulfide mineralization was syn-deformational. Gold and

sulfides were scavenged from the Morro do Ouro sedimentary sequence during

deformation and localized within the high strain zone(s) that acted as chemical

traps due to dissolution of silica and carbonate and resulting increase in

graphite.

Subsequent

surface weathering produced four, discrete, weathering horizons, known as the

“C”, “T”, “B1” and “B2”, which are defined by the degree of oxidation and

surface weathering and the associated sulfide mineralization.

The

weathered ore contained in the “C” and “T” horizons of Morro do Ouro has been

entirely mined by Rio Tinto Zinc (RTZ), during a continuous operation that

lasted 17 years (1987-2004).

26

Exploitation

of the primary ore at Morro do Ouro (“B1” and “B2” horizons) is currently under

way, and was made possible because of a large amount of time and money invested

by Kinross on the optimization technology of resource evaluation and low-grade

gold recovery (0.4g Au/t), allied to the highly favorable gold price (for

details, see Henderson. 2006).

The Morro

do Ouro gold mine is now comprised of a large open pit, a mineral processing

plant, tailings storage facilities and related surface infrastructure, currently

operating at approximately 18 million tonnes per year.

Fazenda

Lavras

Based on

its geological characteristics and close proximity, the Fazenda Lavras deposit

appears to be the northward continuation of the gold mineralization found in the

Morro do Ouro mine.

Exploration

for the “B1” and B2” horizons, conducted by Rio Tinto Zinc and later by Amazon

Mining Holding Plc. failed to get any economic resource from the primary

ores.This could be interpreted in two ways: (i) both companies have employed

accurate exploration techniques, but primary mineralization in Fazenda Lavras is

discontinuous and prevents identification of an ore reserve amenable to open pit

mining, or (ii) exploration techniques were not adequate in regard of this

unique, very low-grade and unevenly distributed gold

mineralization.

In the

decade of 1990 a small sector of the “C” horizon of Fazenda Lavras was explored

by Mineração Serra do Encanto Ltda., which attained an approximate resource of

33Mt of ore @ 0.67g Au/t. Recent exploration efforts, however, paid little

attention to the potential for low-grade deposits hosted by the “C” and “T”

weathered horizons of the Fazenda Lavras Property.

Estimation

of Weathered Ore Resource (Fazenda Lavras)

The following estimate is based on

information from previous mining operations developed by Mineração Serra do

Encanto Ltda and also on additional investigation carried out by the

Author.

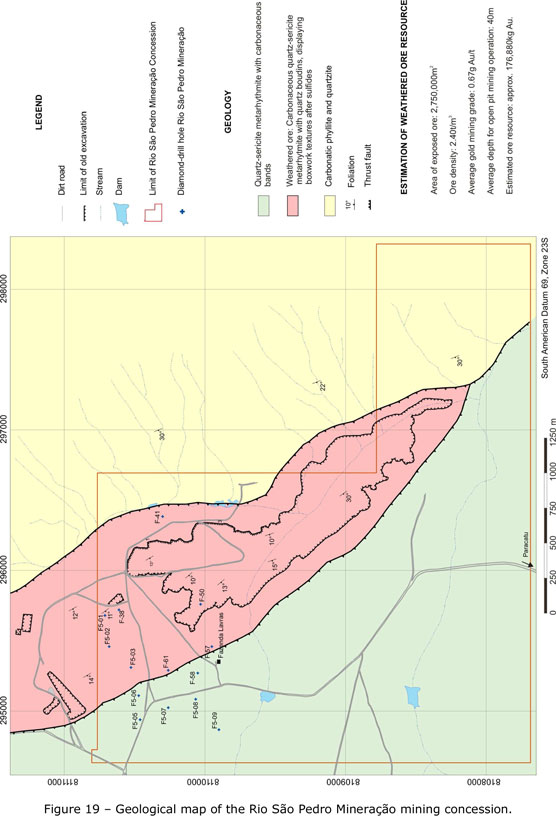

The total area of weathered ore outcrop

can be seen in Figure 19.

27

28

The

estimated (noncompliant) mineral resource for the Fazenda Lavras Property is

summarized in Table 4. The mean specific gravity for mineralized drill cores was

2.40 and the average grade was 0.67g Au/t. The average depth of mining operation

is 40 meters, and no cut off grade was used to report mineral

resources.

Table 4 –

Weathered Ore Resources for the Fazenda Lavras Gold Property

|

Resource

|

Grade

|

Gold

|

Ounces

|

|||||||||

|

(t)

|

(g/t)

|

(kg)

|

(oz)

|

|||||||||

|

Estimated

Resources

|

264,000,000

|

0.67

|

176,880

|

5,700,000

|

The

estimated mineral resources lie below the current water table and virtually

there is no overburden.

The

estimated metal content does not include any consideration of mining, mineral

processing, or metallurgical recoveries.

The most

likely cut-off grade for this deposit is not known at this time and must be

confirmed by the appropriate economic studies.

Conclusion

|

|

·

|

Recent

exploration, including 14 core holes, followed by a bulk sampling

prodecure, has identified potentially economic mineralization below the

depth reached by past garimpeiro mining inside the Fazenda Lavras gold

property.

|

|

|

·

|

A

mineral (noncompliant) resource estimation yielded approximately 5,700Moz

gold up to an average depth of 40

meters.

|

|

|

·

|

The

Fazenda Lavras Project justifies an exploration program and budget, of

which the greater part should be invested in detailed geological mapping,

trenching, pitting and shallow

drilling.

|

|

|

·

|

The

objective of this program is to calculate the actual ore reserves and

elaborate the mining planning for the weathered gold

mineralization.

|