Attached files

| file | filename |

|---|---|

| 8-K - FORM 8-K - INTERNATIONAL PAPER CO /NEW/ | d8k.htm |

| EX-99.1 - PRESS RELEASE OF INTERNATIONAL PAPER COMPANY - INTERNATIONAL PAPER CO /NEW/ | dex991.htm |

Second Quarter

2010 Review

July 28, 2010

Second Quarter

2010 Review

July 28, 2010

John V. Faraci

Chairman &

Chief Executive Officer

Tim S. Nicholls

Senior Vice President &

Chief Financial Officer

Exhibit 99.2 |

2

Forward-Looking Statements

Forward-Looking Statements

These slides and statements made during this presentation contain

forward-looking statements. These statements reflect management's

current views and are subject to risks and uncertainties that could cause

actual results to differ materially from those expressed or

implied

in

these

statements.

Factors

which

could

cause

actual

results

to

differ

relate

to:

(i) increases in interest rates; (ii) industry conditions, including but not

limited to changes in the cost or availability of raw materials, energy and

transportation costs, competition we face, cyclicality and changes in

consumer preferences, demand and pricing for our products; (iii) global

economic conditions and political changes, including but not limited to the

impairment of financial institutions, changes in currency exchange rates, credit ratings

issued by recognized credit rating organizations, the amount of our future pension

funding obligation and changes in pension and health care costs; (iv)

unanticipated expenditures related to the cost of compliance with

environmental and other governmental regulations and to actual or potential

litigation; and (v) whether we experience a material disruption at one of

our manufacturing facilities and risks inherent in conducting business through a joint

venture. We undertake no obligation to publicly update any forward-looking

statements, whether as a result of new information, future events or

otherwise. These and other factors that could cause or contribute to actual

results differing materially from such forward looking statements are

discussed in greater detail in the company's Securities and Exchange

Commission filings. |

3

Statements Relating to Non-GAAP

Financial Measures

Statements Relating to Non-GAAP

Financial Measures

During the course of this presentation, certain

non-U.S. GAAP financial information will be

presented.

A reconciliation of those numbers to U.S.

GAAP financial measures is available on the

company’s website at internationalpaper.com

under Investors. |

4

Second Quarter 2010

Headlines

Second Quarter 2010

Headlines

Revenue Growth

Margin Expansion

Strong Free Cash Flow Generation

All businesses posted strong results |

5

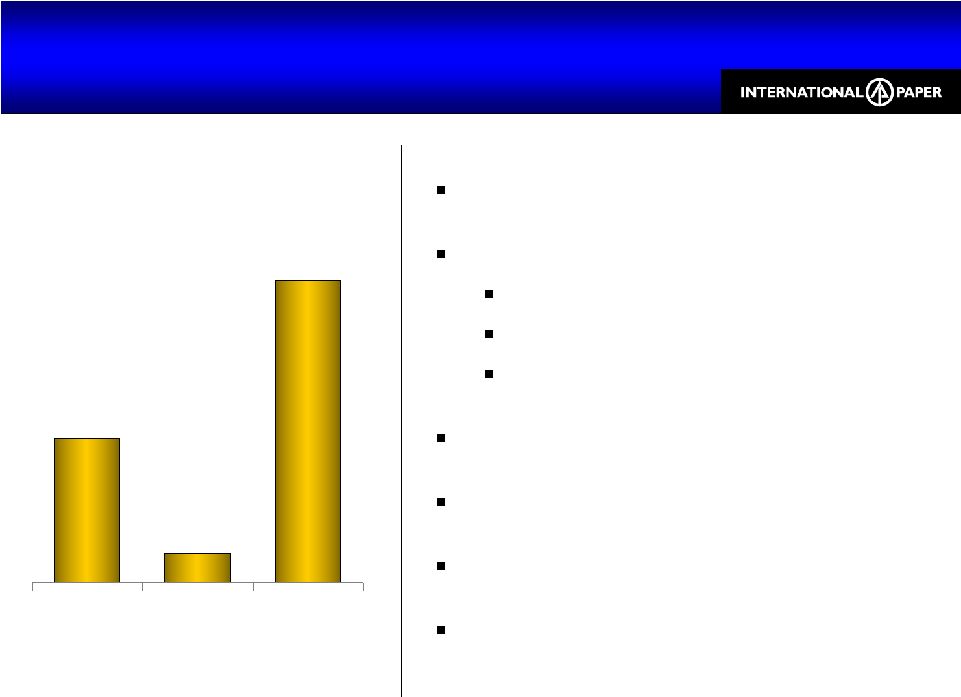

Second Quarter 2010

Significant Earnings Improvement

Second Quarter 2010

Significant Earnings Improvement

Balanced Global Results

Record Earnings

European Paper

European Packaging

Asia

Strong Operations

Continued Cost Reduction

Declining (but Elevated) Fiber Costs

Highest Maintenance Outages of Year

Earnings from continuing operations before

special items

Earnings per Share

$0.20

$0.04

$0.42

2Q09

1Q10

2Q10 |

6

2Q10 Financial Snapshot

2Q10 Financial Snapshot

2Q09

1Q10

2Q10

Sales ($B)

$5.8

$5.8

$6.1

EBITDA

1

($MM)

$723

$560

$782

Free Cash Flow

2

($MM)

$576

$39

$356

Debt ($B)

$10.9

$9.0

$8.9

Cash Balance ($B)

$1.7

$1.7

$1.9

1

Earnings from continuing operations before special items

2

Cash provided by continuing operations less capital expenditures, excluding cash

received from alternative fuel credits of $688 MM in 2Q09 and $132 MM in

2Q10 |

7

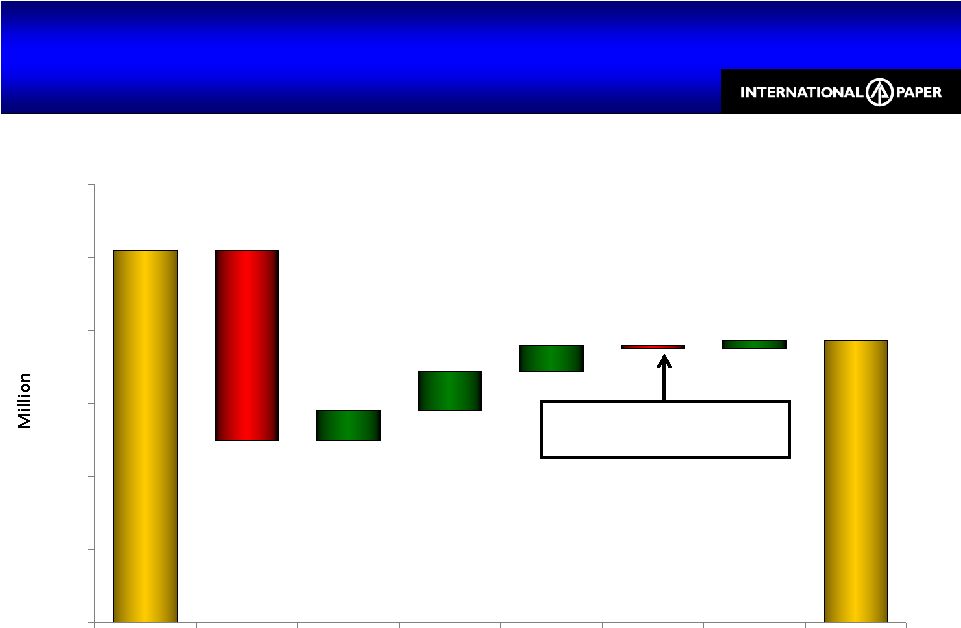

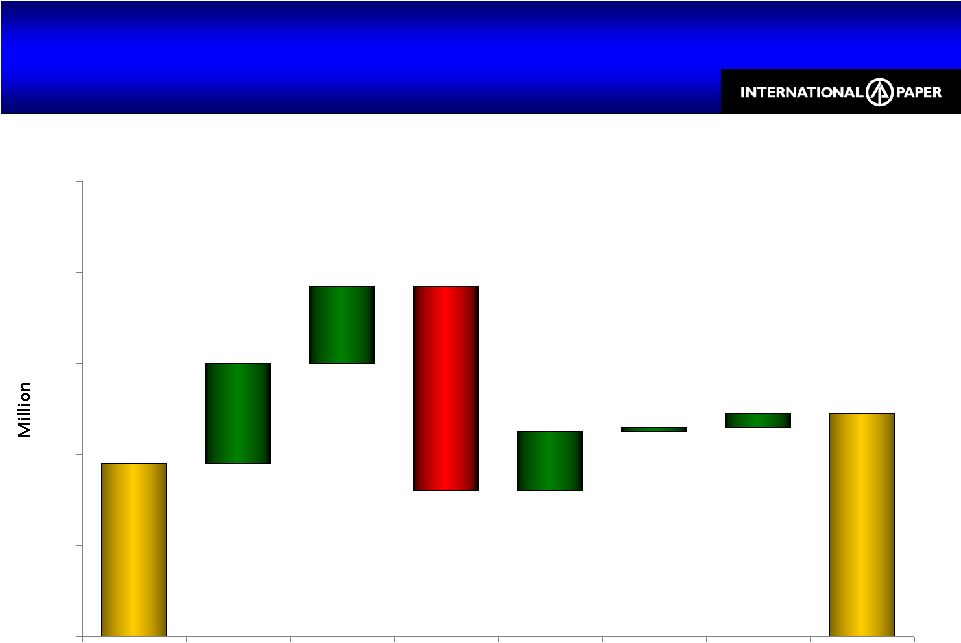

Earnings before special items

2Q10 vs. 1Q10 EPS

Price Realization, Improved Volumes

2Q10 vs. 1Q10 EPS

Price Realization, Improved Volumes

.04

.42

(.03)

(.02)

(.05)

.05

.29

.04

.02

.05

.01

.02

$0.00

$0.10

$0.20

$0.30

$0.40

$0.50

1Q10

Volume

Price

Operations

& Costs

Maintenance

Outages

Input

Costs

Mix

Forest

Products

Bad Debt

Tax

Ilim

JV

2Q10 |

8

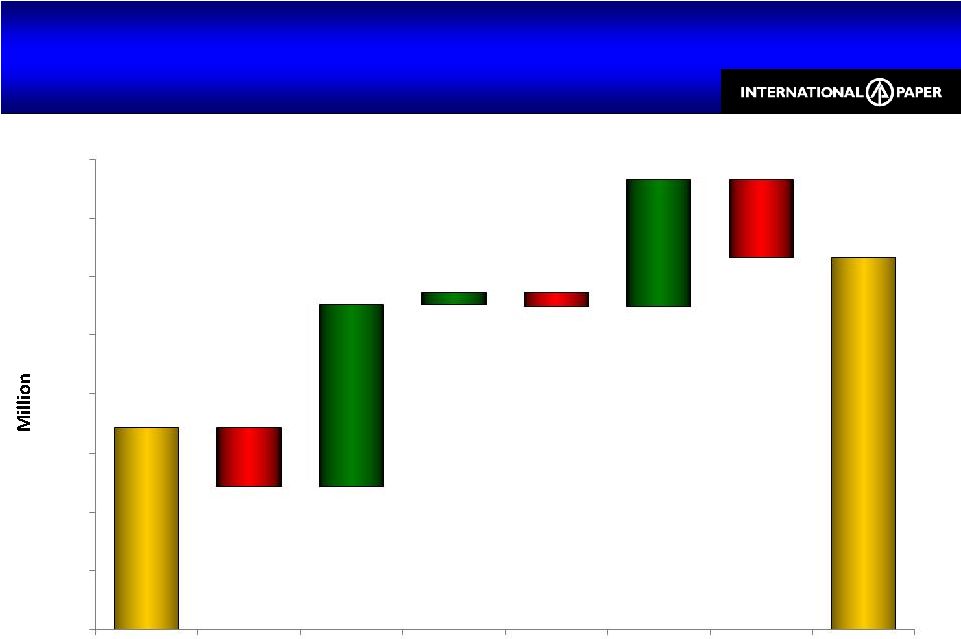

Earnings from continuing operations before special items

1H10 vs. 1H09 EPS

Improved Volumes & Operations, Higher Fiber Costs

1H10 vs. 1H09 EPS

Improved Volumes & Operations, Higher Fiber Costs

.28

.46

(.10)

(.05)

(.45)

(.04)

(.05)

(.04)

.37

.26

.07

.05

.14

.02

$0.00

$0.10

$0.20

$0.30

$0.40

$0.50

$0.60

$0.70

$0.80

$0.90

1H09

Volume

/ LOO

Price

Operations

& Costs

Maintenance

Outages

Input

Costs

Mix

Forest

Products

Bad Debt

Corporate

& Other

Interest

Ilim

JV

Tax

1H10 |

9

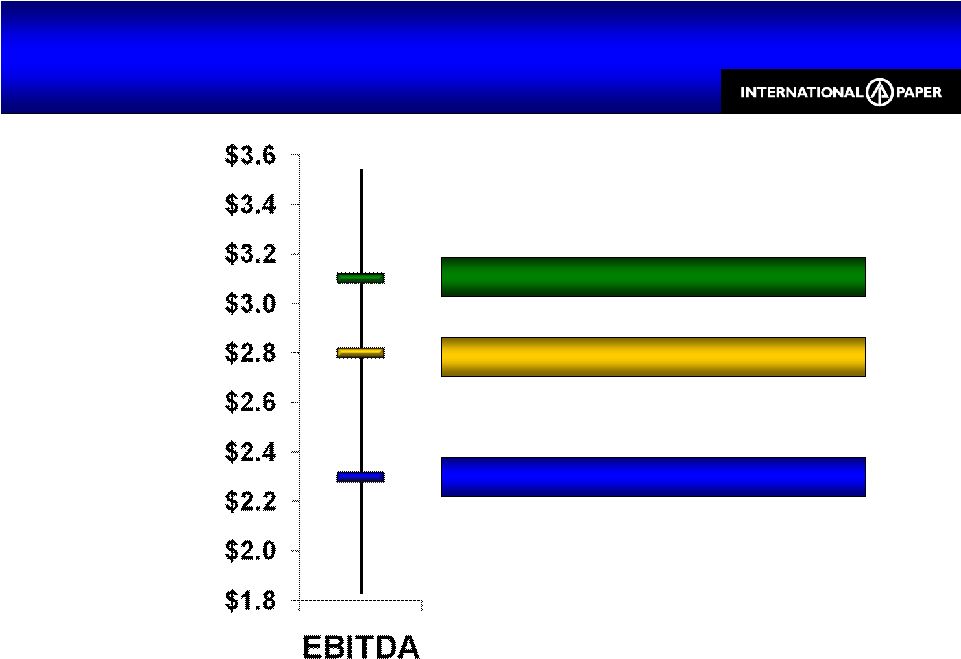

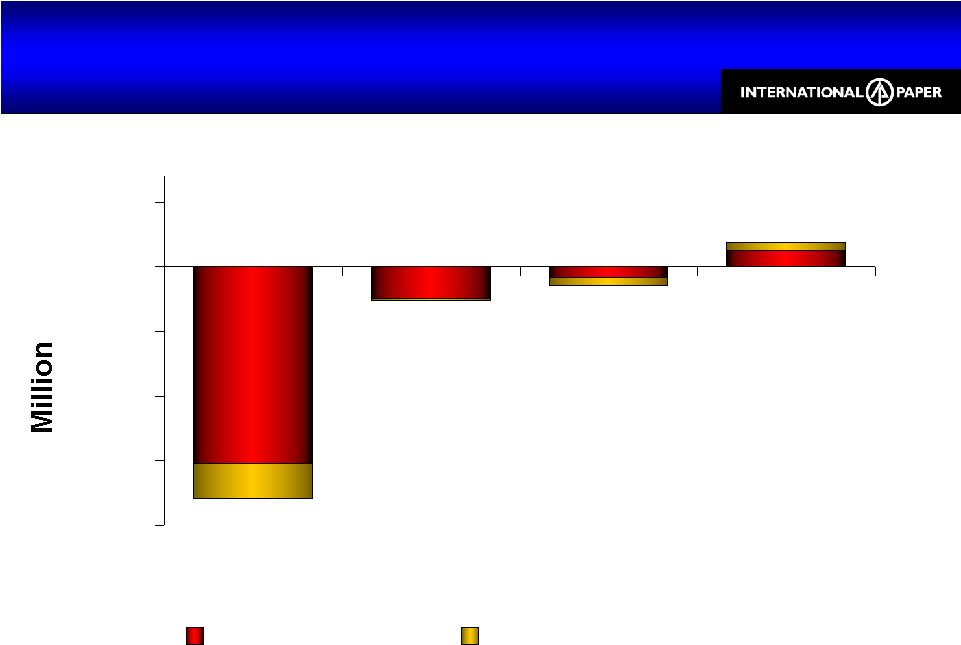

Total IP EBITDA & Margin

Improving EBITDA Annualized Run Rate

Total IP EBITDA & Margin

Improving EBITDA Annualized Run Rate

$ Billion

1Q10 Run Rate (9.5% EBITDA)

2Q10 Run Rate

(13% EBITDA)

2009 Actual

(12% EBITDA) |

10

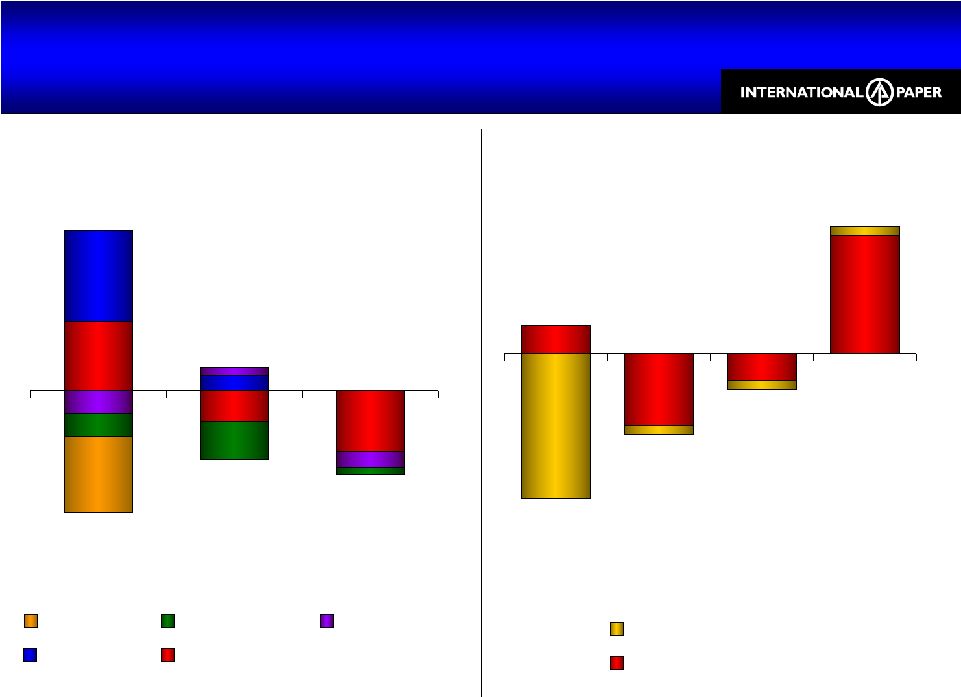

Global Input Costs vs. 1Q10

$12 MM, or $0.02/Share Unfavorable

Global Input Costs vs. 1Q10

$12 MM, or $0.02/Share Unfavorable

By Business

By Input Type

$5

($6)

($11)

Industrial

Packaging

Printing

Papers

Consumer

Packaging

Wood

Energy

Chemicals

Freight

($13)

($9)

($4)

$14

Fiber

Freight

Chemicals

Energy

Outside North America

North America

OCC |

11

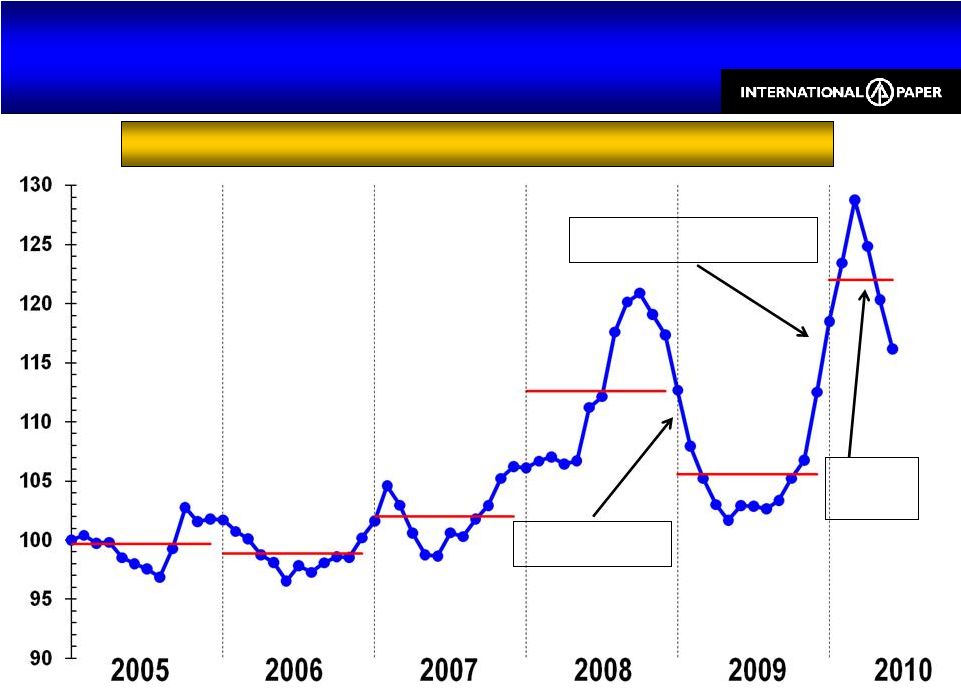

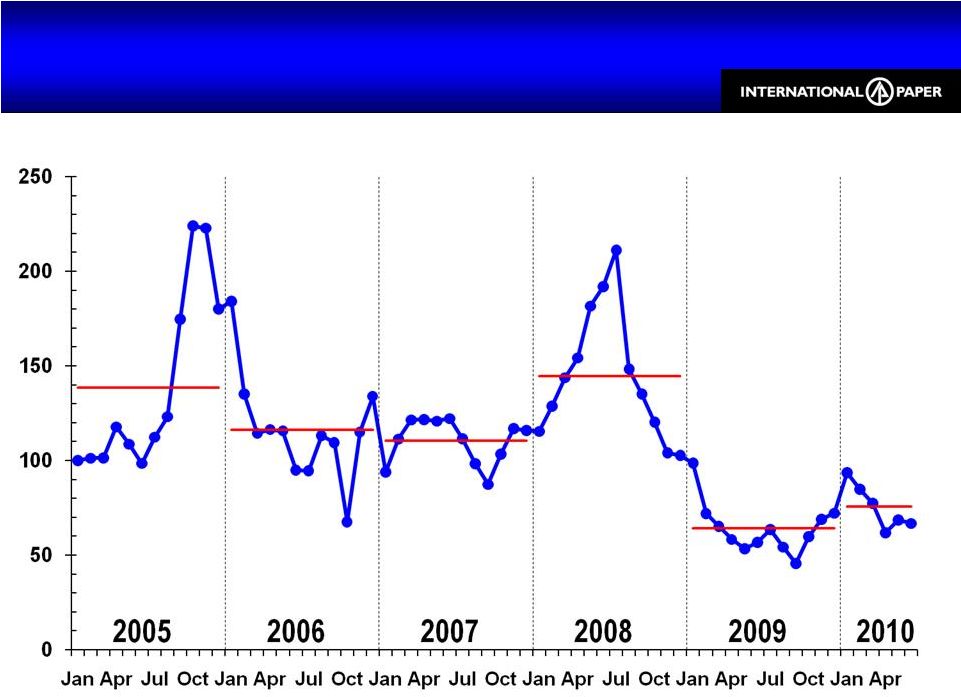

Index

U.S. Mill Wood Delivered Cost Trends

3% Decrease vs. 1Q10 Average Cost

U.S. Mill Wood Delivered Cost Trends

3% Decrease vs. 1Q10 Average Cost

Wood Costs Declining, But Still Elevated

Declining Wood

Demand

Poor Harvesting Conditions

& Higher Wood Demand

Normal

Harvesting

Conditions |

12

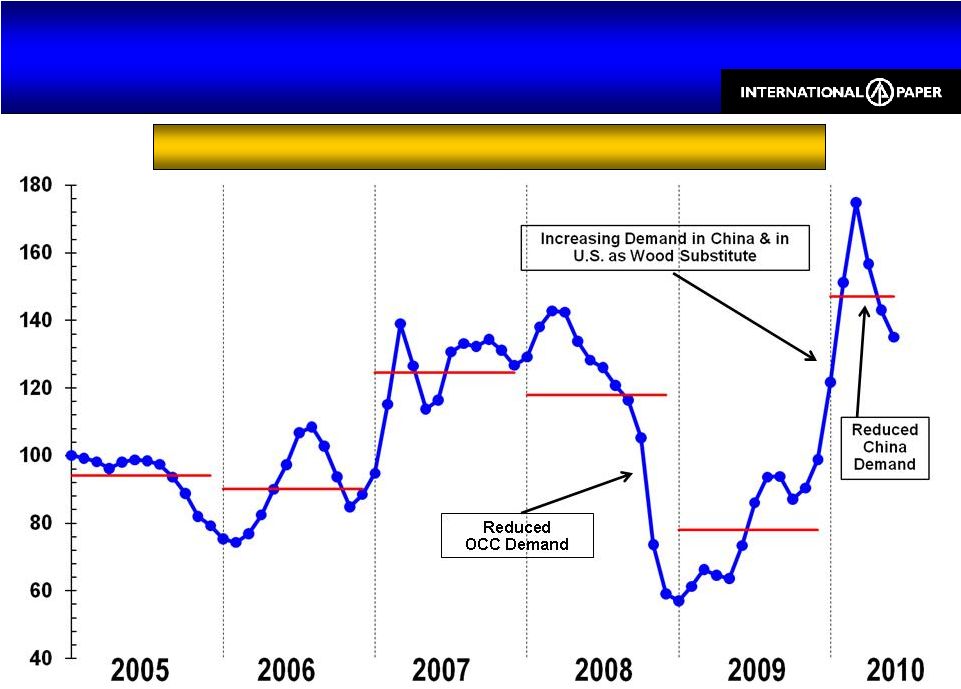

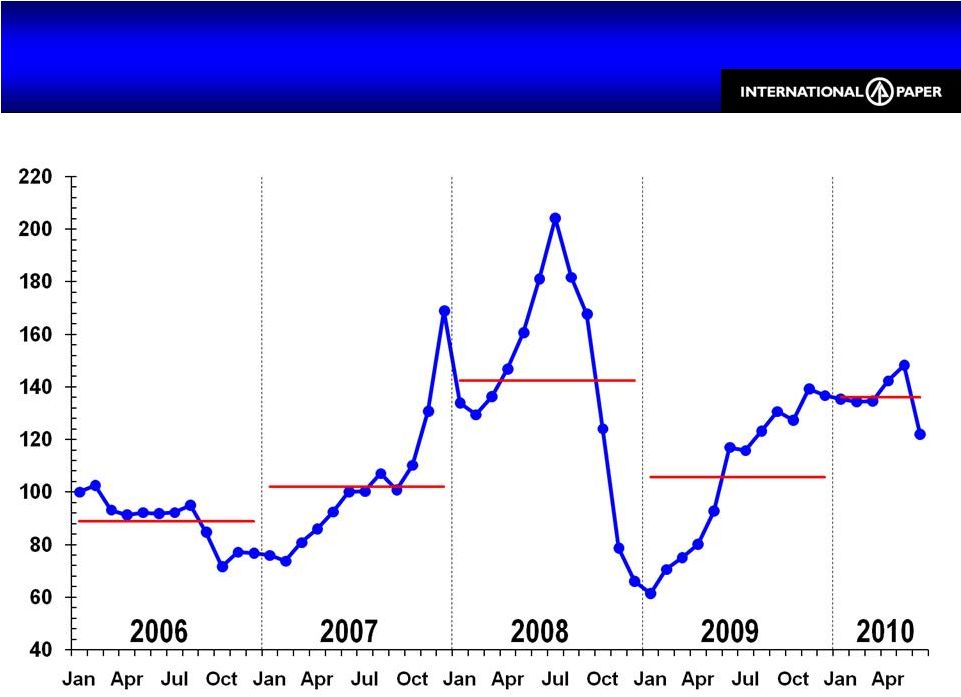

U.S. OCC Delivered Cost Trends

3% Decrease vs. 1Q10 Average Cost

U.S. OCC Delivered Cost Trends

3% Decrease vs. 1Q10 Average Cost

Index

2005-2007 represents WY PKG delivered costs; 2008-2010 represents delivered

costs to the integrated system OCC Costs Declining, But Still Elevated

|

13

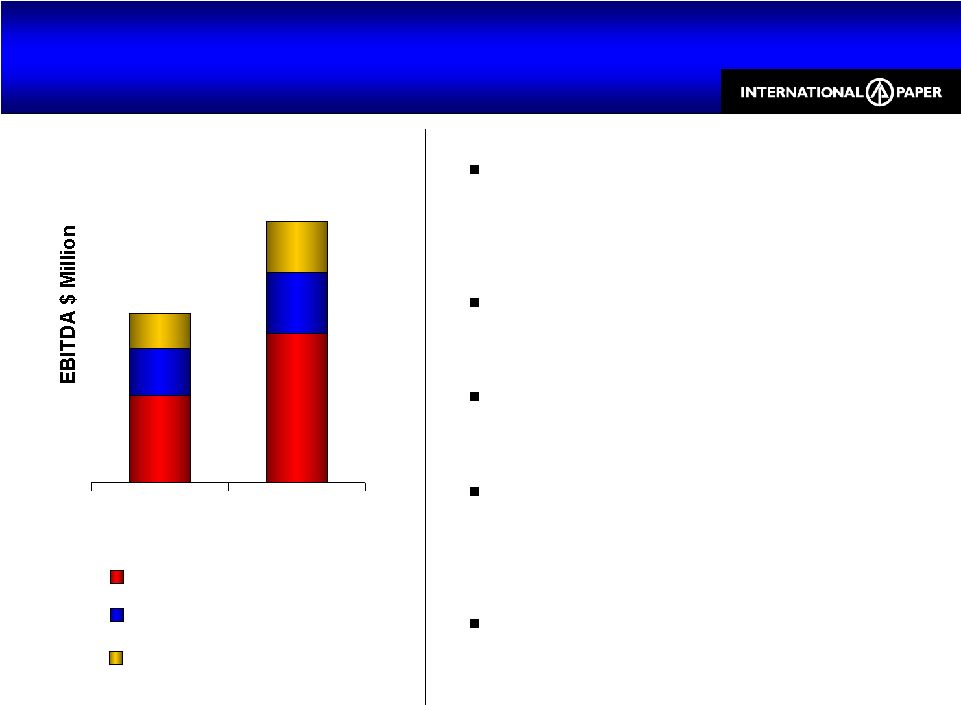

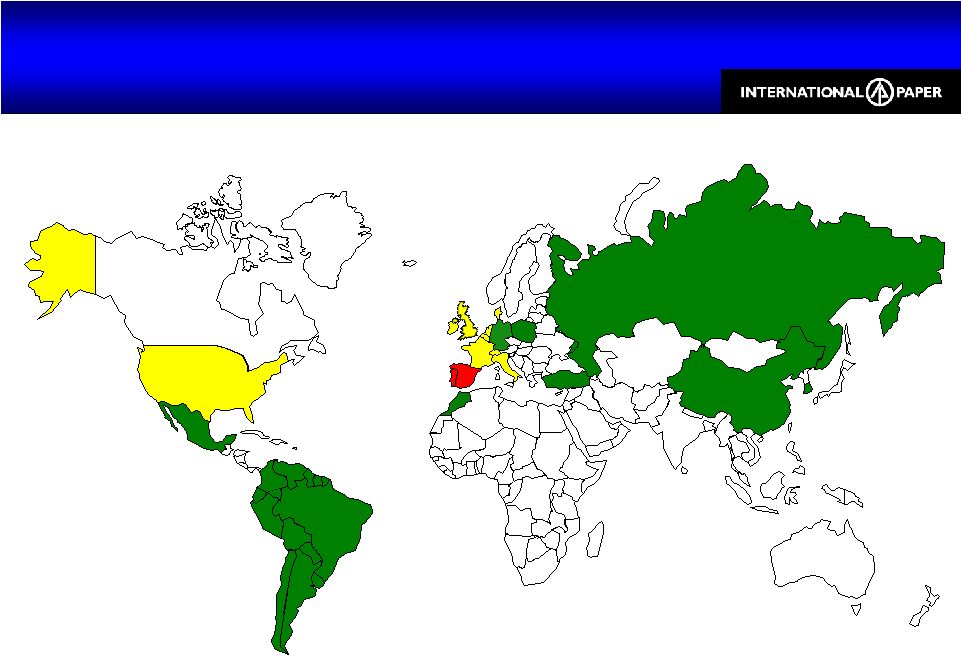

IP Europe, Middle East & Africa

1H10: 11% of IP Sales & 18% of IP EBITDA

IP Europe, Middle East & Africa

1H10: 11% of IP Sales & 18% of IP EBITDA

EBITDA margins increased

from 12% to 19%

Record Paper Earnings

Record Container Earnings

Cost-of-Capital Returns in

Paper & Packaging

Inverurie

& Etienne mill

shutdowns completed

$158

$245

1H09

1H10

Coated Paperboard

Container

Papers |

14

46

193

(2)

(6)

21

99

5

30

$0

$25

$50

$75

$100

$125

$150

$175

$200

$225

1Q10

Volume

Price

& Mix

Input

Costs

Operations

& Costs

Maintenance

Outages

Other

2Q10

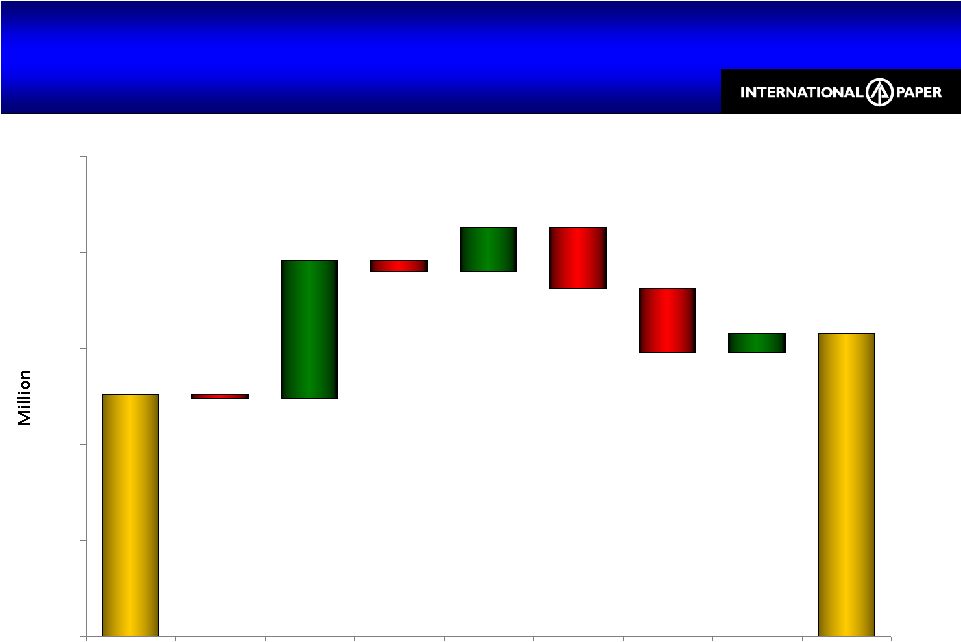

Industrial Packaging Earnings

2Q10 vs. 1Q10

Industrial Packaging Earnings

2Q10 vs. 1Q10

Earnings before special items

Operations

LIFO, Other Costs (33)

31 |

15

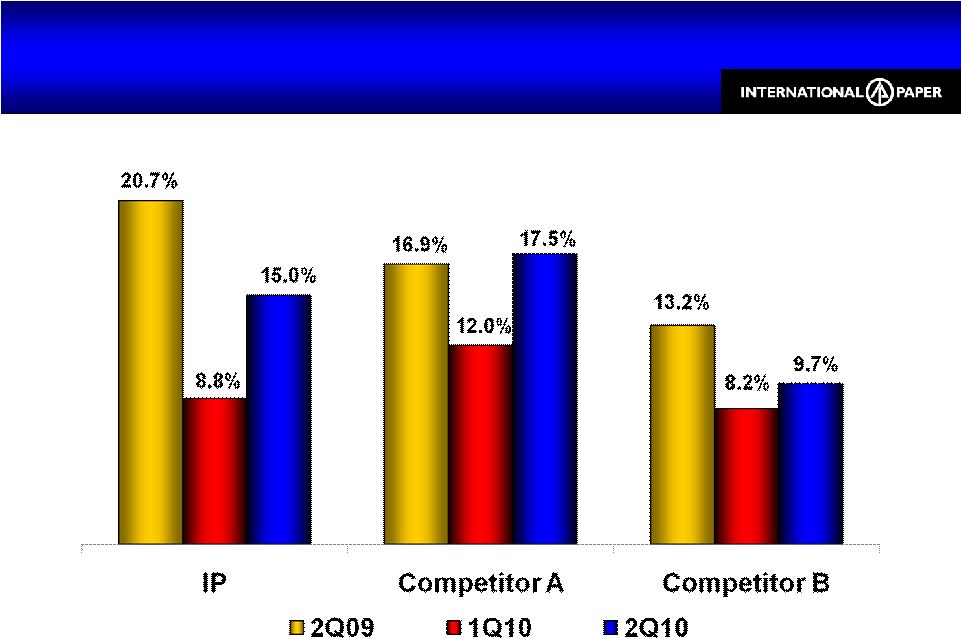

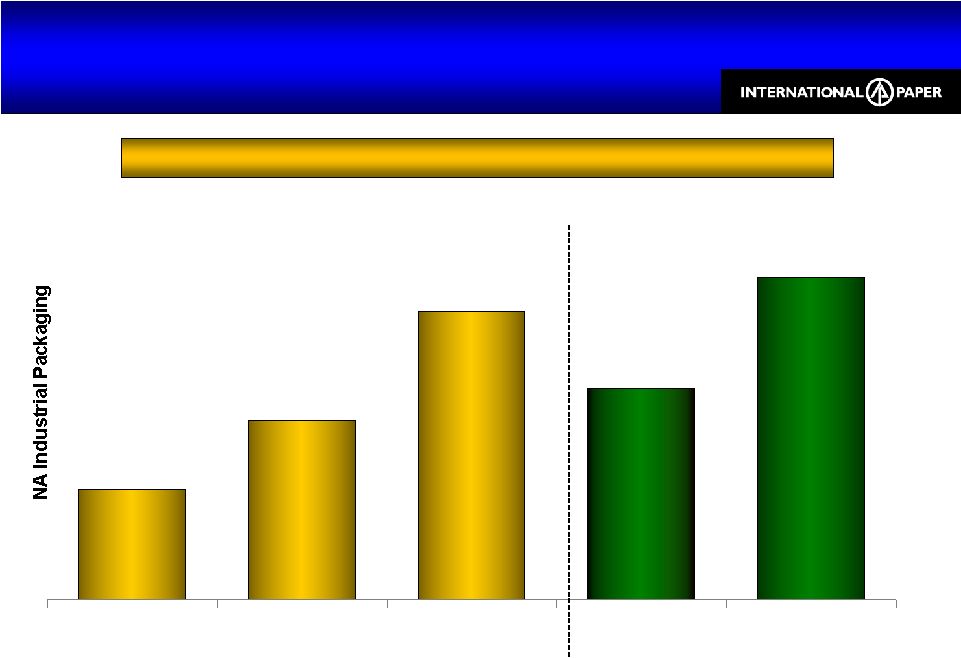

N.A. Industrial Packaging Relative EBITDA Margins

N.A. Industrial Packaging Relative EBITDA Margins

IP EBITDA margins based on North American Industrial Packaging operating profit

before special items Competitor EBITDA margin estimates obtained from public

filings and IP analysis |

16

$0.5

$0.8

$1.3

$1.0

$1.5

2007

2008

2009

1H10

Run Rate

June 2010

Run Rate

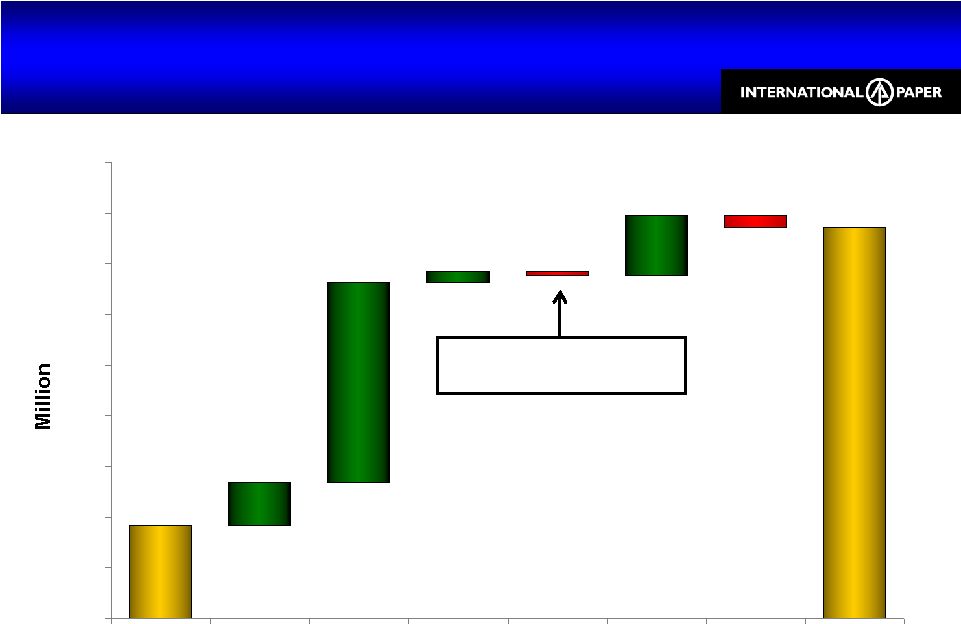

Progress on Industrial Packaging Integration

Approaching Cost-of-Capital Returns

Progress on Industrial Packaging Integration

Approaching Cost-of-Capital Returns

June Run Rate of $1.5 Billion EBITDA and 8% ROI

Earnings before special items |

17

Printing Papers Earnings

2Q10 vs.

1Q10

Printing Papers Earnings

2Q10 vs.

1Q10

Earnings before special items

126

158

(2)

(6)

(32)

(33)

72

23

10

$0

$50

$100

$150

$200

$250

1Q10

Volume

Price

& Mix

Input

Costs

Operations

& Costs

Maintenance

Outages

Bad Debt

Other

2Q10 |

18

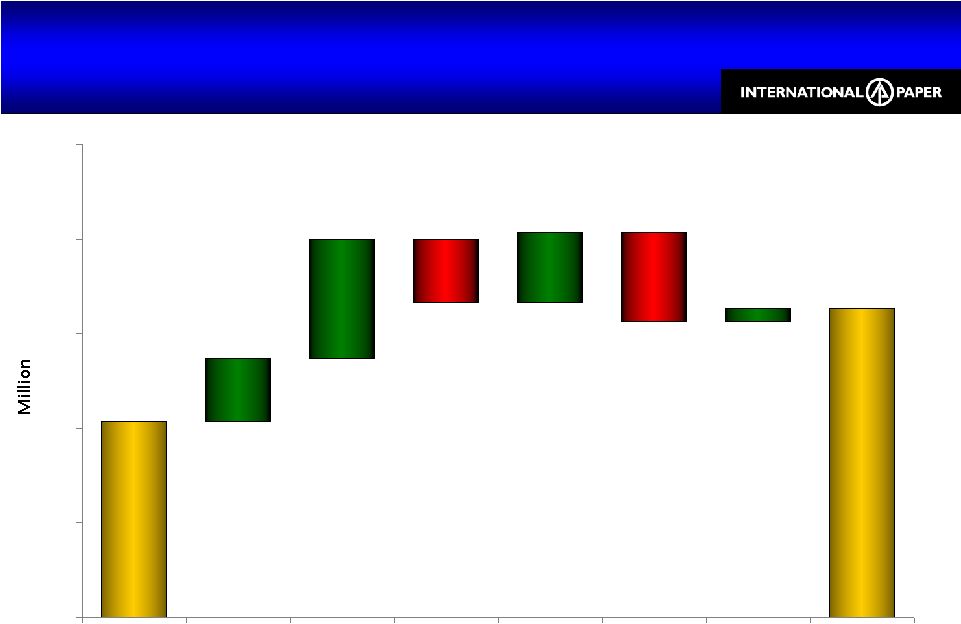

Consumer Packaging Earnings

2Q10 vs.

1Q10

Consumer Packaging Earnings

2Q10 vs.

1Q10

Earnings before special items

31

49

(10)

(14)

10

19

11

2

$0

$15

$30

$45

$60

$75

1Q10

Volume

Price

& Mix

Input

Costs

Operations

& Costs

Maintenance

Outages

Other

2Q10 |

19

Progress on Fixed Cost Reductions

All Fixed Cost Reductions Achieved by 2Q

Progress on Fixed Cost Reductions

All Fixed Cost Reductions Achieved by 2Q

$ Million

Mill

2

nd

-Quarter Annualized

Run-Rate Fixed Cost

Savings

Industrial Packaging

Albany,

Pineville

$60

Printing & Communications Papers

Franklin

$90

Coated Paperboard

Franklin

$20

In

addition,

the

closure

of

the

Inverurie

&

Etienne

mills

have

been

completed,

and

the

associated

operating

losses

have

been

eliminated. |

20

$ Million

2Q09

1Q10

2Q10

Sales

$1,595

$1,580

$1,630

Earnings

$10

$21

$26

xpedx

Improvement from 1Q10

xpedx

Improvement from 1Q10

Revenues up 3%

from 1Q10

Strong year-over-year earnings growth driven

by aggressive operating cost management

* Facility supplies daily sales change reflects the loss of a large national

account; daily sales rate up 9.1% excluding this impact Daily Sales

Change vs. 1Q10

Printing

1.6%

Packaging

2.6%

Facility Supplies*

(2.1%) |

21

Forest Products

Mineral Rights Sale; Land Sale Agreement

Forest Products

Mineral Rights Sale; Land Sale Agreement

Mineral rights sale to Natural Resource Partners in June

$43 MM revenue

$39 MM operating profit

Agreement to sell 163,000 acres to Rock Creek Capital

$200 MM sales price plus ongoing profits interest

Expect $50 MM in 3Q operating profit

Expected to close in 3Q10

Completion of land sales program |

22

Sun Joint Venture

Record EBIT in 2Q10

Sun Joint Venture

Record EBIT in 2Q10

2009: 4 MM tons of coated paperboard demand in China

Projected 2010 –

2013 Demand CAGR: 8% -

9%

3 existing board machines

915,000 tons of capacity

Sold out since March 2009

New 4

th

board machine approved by Sun & IP boards

550,000-ton annual capacity

~$300 MM investment ($55 MM of IP cash)

Yanzhou, China

Start up in 1Q12

5

th

board machine in planning stage |

23

$ Million

2Q09

1Q10

2Q10

Sales (100%)

$290

$395

$435

Earnings (IP Share)

($30)

($3)

$5

Ilim’s

results are reported on a one-quarter lag

IP’s shares of Ilim’s

2Q09 & 1Q10 earnings includes an after-tax foreign exchange loss of $22 MM

and $2 MM, respectively. The foreign exchange impact in 2Q10 was

minimal. Ilim

Joint Venture

Ilim

Joint Venture

2Q10 vs. 1Q10

2Q10 vs. 2Q09

Business

Volume

Price /

Ton

Volume

Price /

Ton

Pulp

4%

$56

14%

$202

Containerboard

1%

$22

15%

$54 |

24

Ilim Joint Venture Update

Ilim Joint Venture Update

Stabilized Russian Economy

Improved Results after Russian Crisis

Siberian pulp business continues to improve

Koryazhma mill improving with domestic market

Ilim JV Paid Cash Dividends of $330 Million

IP received $152 million, or ~ 25% of capital invested

Resuming Capital Projects to Strengthen Ilim

Focus on value-added paper products for Ilim West

Leverage competitive advantage of Siberian pulp mills

|

25

Ilim Joint Venture

Resuming Capital Investment Plan

Ilim Joint Venture

Resuming Capital Investment Plan

1.

Expand Siberian pulp business

790,000-ton NBSK pulp line at Bratsk

550,00-ton net increase in capacity

$700 MM in capital

Recovery boiler start-up in 3Q11

Pulp line start-up in 2Q12

2.

Integrate Koryazhma pulp into domestic market

Install paper machine at Koryazhma

165,000 tons of UFS; 55,000 tons of coating base

$270 MM in capital

Shift from export pulp to uncoated freesheet

Evaluating 75,000-ton off-line coater

Paper machine start-up in 2012 |

26

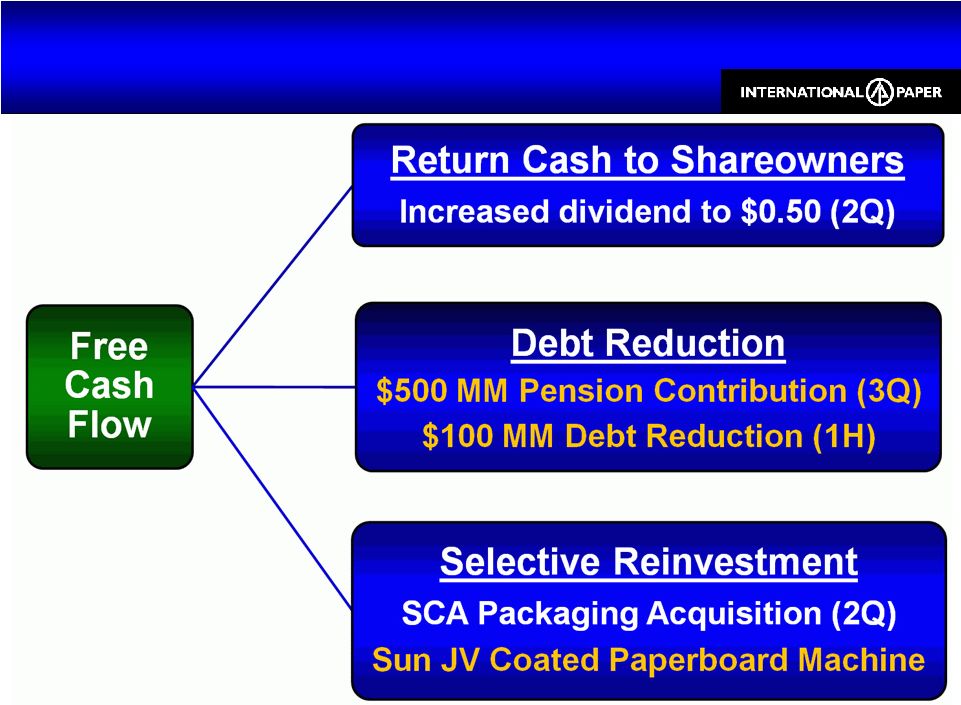

Balanced Capital Allocation

to Increase Shareowner Value

Balanced Capital Allocation

to Increase Shareowner Value |

27

Current Macroeconomic Conditions

Current Macroeconomic Conditions |

28

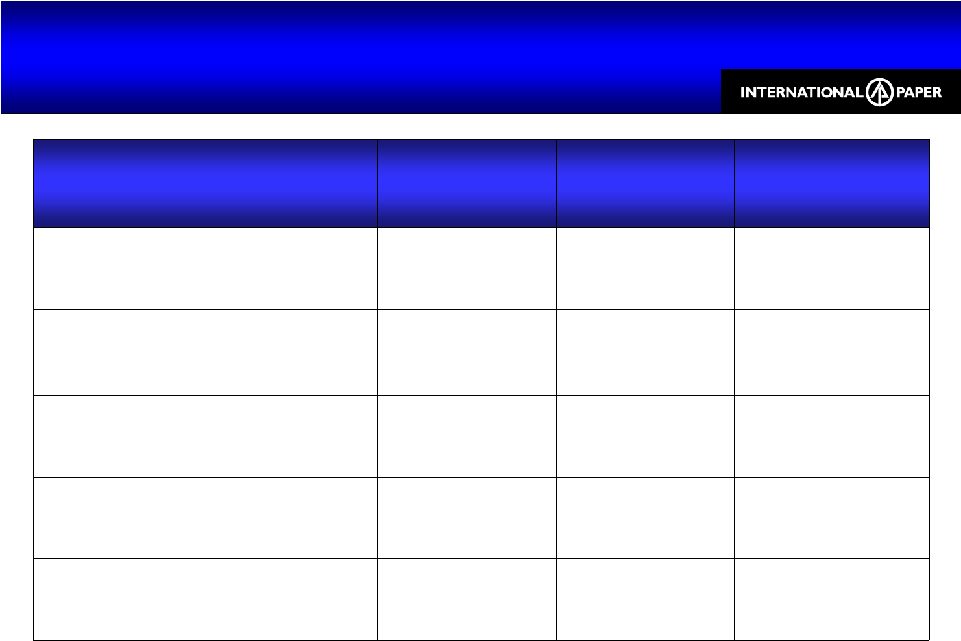

Third Quarter Outlook

Changes from 2Q10

Third Quarter Outlook

Changes from 2Q10

North America

Europe

Brazil

Asia

Volume

Paper

Growth at

Slower Rate

Stable

Stable

Packaging

Growth at

Slower Rate

Seasonal

Decrease

Stable

Pricing

Paper

Continued

Realization

Stable

Increasing

Packaging

Significant

Increase

Stable

CPB Decreasing,

Box Stable

Maintenance Outages

~$77 MM

Decrease

~$4 MM

Increase

Stable

Input & Freight Costs

Moderating

Linerboard

Increasing

Stable

Pulp Decreasing,

Linerboard

Increasing

xpedx

Slight

Decrease

Ilim

Increase

Other Costs

Significant

Increase |

29

Summary

Significant Earnings & Cash Flow

Summary

Significant Earnings & Cash Flow

2Q10 Summary

Volume recovery

Significant price increase

realization

Strong operations

Declining fiber costs

3Q10 Outlook

N.A. demand growing at

slower rate

Further realization of

announced price increases

Moderating wood costs

Uncertain OCC costs

Significant reduction in

maintenance outages |

30

Appendix

Investor Relations Contacts

Thomas A. Cleves

901-419-7566

Emily Nix

901-419-4987

Media Contact

Patty Neuhoff

901-419-4052 |

31

$ Million

2008

2009

2010

Estimate

Capital Spending

$1,002

$534

$800

Depreciation &

Amortization

$1,347

$1,472

$1,450

Net Interest Expense

$492

$669

$600 -

$625

Corporate Items

$103

$181

$200 -

$225

Effective Tax Rate

31.5%

30%

30-32%

Before special items and excluding Ilim

Key Financial Statistics

Key Financial Statistics |

32

Free Cash Flow

Free Cash Flow

$ Million

2Q09

1Q10

2Q10

Cash from Operations

$707

$159

$509

Cash Received from Alternative Fuel

Mixture Tax Credits (AFMTC)

$688

$0

$132

Cash Provided by Continuing

Operations

$1,395

$159

$641

Less Capital Investment

($131)

($120)

($153)

Free Cash Flow

$1,264

$39

$488

Free Cash Flow Excluding AFMTC

$576

$39

$356 |

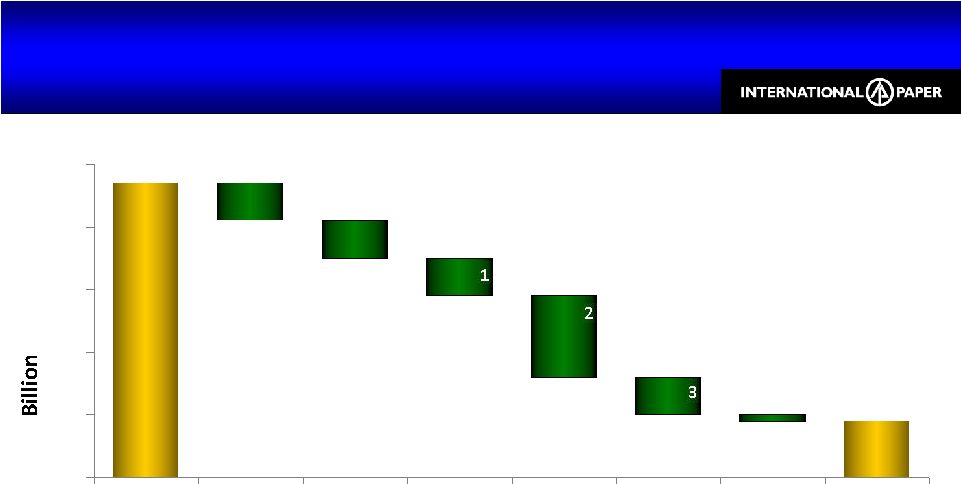

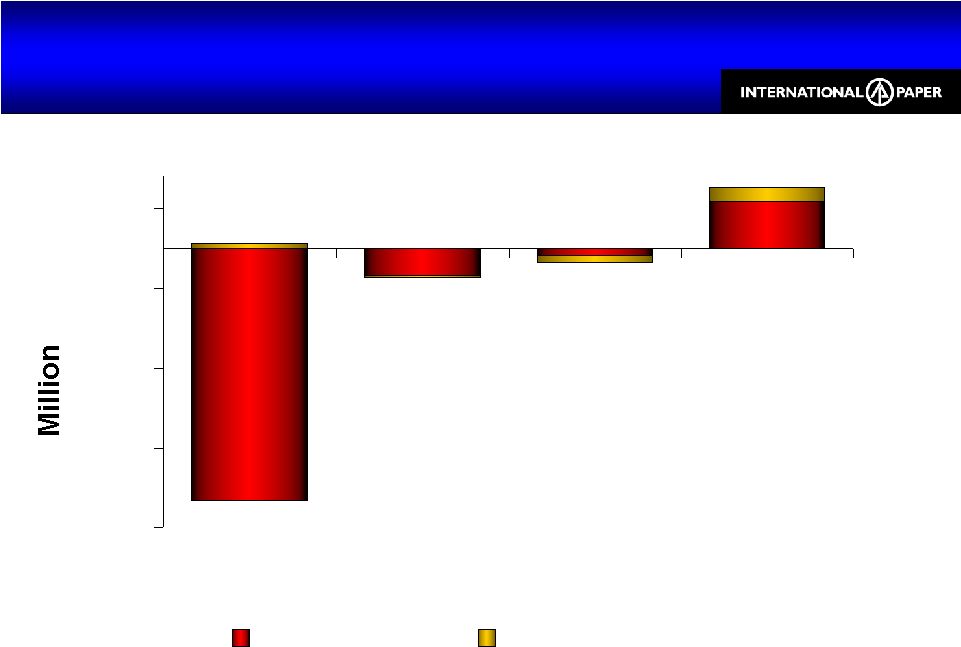

33

Debt Reduction Progress

$3.8 Billion Reduction since Acquisition

Debt Reduction Progress

$3.8 Billion Reduction since Acquisition

1

Excludes the debt repayment of $1 B from the proceeds of our May bond issuance: $1

B 9.375% notes due 2019 2

Excludes the debt repayment of $1 B from the proceeds of our August bond issuance:

$1 B 7.5% notes due 2021 3

Excludes the debt repayment of $750 MM from the proceeds of our November bond

issuance: $750 MM 7.3% notes due 2039 $12.7

$8.9

$0.6

$0.6

$0.6

$1.3

$0.6

$0.1

$8

$9

$10

$11

$12

$13

August

2008 Pro

Forma with

Acquisition

2H08

1Q09

2Q09

3Q09

4Q09

1H10

2Q Balance |

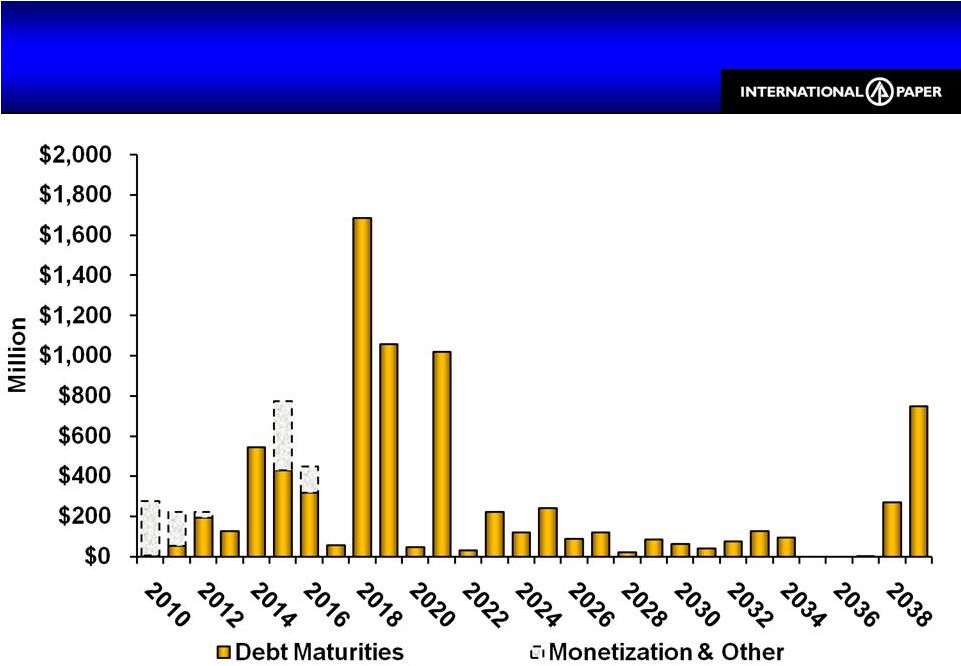

34

Monetization & Other: Intend to rollover or refinance timber monetization debt,

Sun JV debt and other foreign subsidiary debt Debt Maturity Profile

Maturities as of Quarter-End

Debt Maturity Profile

Maturities as of Quarter-End |

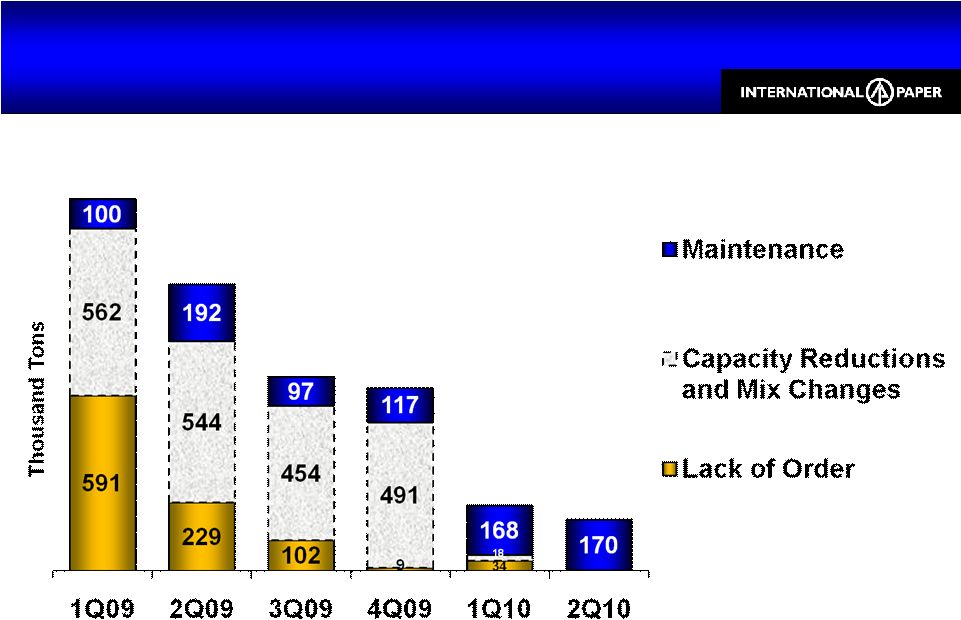

35

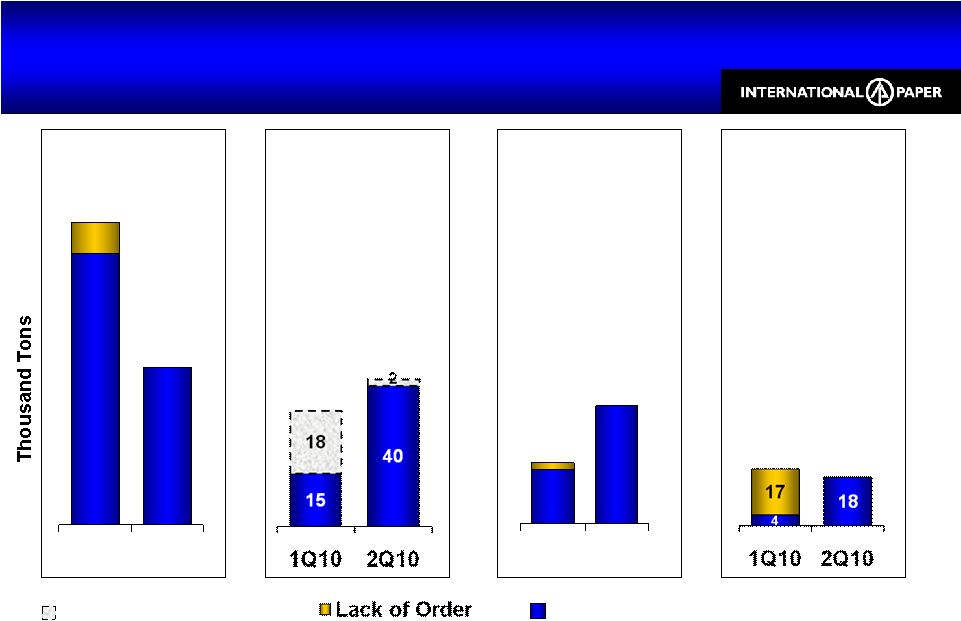

North American Downtime

5% of Capacity in 2Q

North American Downtime

5% of Capacity in 2Q

•

Lack-of-order & maintenance downtime for North American Containerboard,

Uncoated Papers, Market Pulp, & Coated

Paperboard. See the following slide for detail by business.

Lack of order downtime excludes capacity from mills or machines that have been

permanently shutdown 1,253

965

653

617

220

172 |

36

133

77

15

1Q10

2Q10

Capacity Reductions

and Mix Changes

North American Downtime

North American Downtime

•

Lack of order downtime excludes capacity from mills or machines that have been

permanently shutdown 16

35

2

1Q10

2Q10

Maintenance

Containerboard

Uncoated Papers

Market Pulp

Coated

Paperboard

148

42

33

21

18 |

37

$ Million

1Q10

2Q10

3Q10E

4Q10E

2010E

Industrial Packaging

$70

$41

$4

$24

$139

North America

$27

$45

$24

$21

$117

Europe

0

10

14

16

$40

Brazil

0

5

5

0

$10

Printing Papers Total

$27

$60

$43

$37

$167

Consumer Packaging

$6

$19

$0

$17

$42

Total Impact

$103

$120

$47

$78

$348

Dollar impact of planned maintenance outages are estimates and subject to

change Maintenance Outages Expenses

Maintenance Outages Expenses |

38

Rock Creek Capital Agreement

Rock Creek Capital Agreement

$ Millions

Acres

Cash Value

Potential Value of

Partnership

Interest

Total Value

Original 2009 Sale

Agreement

143,000

$220

$55

$275

Rock Creek Capital

Agreement

163,000

$200

$35

$235

•

10,000

acres

of

the

land

in

the

Original

2009

Sale

Agreement

was

subsequently

sold

for

$25 MM

•

30,000 acres worth $36 MM were added to the Rock Creek Capital Agreement

•

Lower total value of the Rock Creek Capital Agreement reflects the different land mix

and the change in market value driven by a later and slower recovery in real

estate •

Competitive bidding process indicated that land value had declined by ~15% over the

last 12 –

18 months

After the Rock Creek transaction, IP will have ~24,000 acres of land worth up to

$15 million |

39

2Q10 vs. 1Q10

2Q10 vs. 2Q09

Business

Volume

Price /

Ton

Volume

Price /

Ton

N.A. Container

8%

$43

3%

($6)

European Container*

1%

€26

9%

(€3)

Industrial Packaging

Industrial Packaging

N.A. Price Improvement per Ton

vs. December 2009 Price

June 2010

Price

Corrugated Boxes

$70

* European Container volumes reflect box shipments only, including the shipments by

the non-consolidated joint venture in Turkey

|

40

Average

IP

price

realization

(includes

the

impact

of

mix

across

all

grades)

2Q10 vs. 1Q10

2Q10 vs. 2Q09

Business

Volume

Price / Ton

Volume

Price / Ton

N.A. Paper

(5%)

$39

(4%)

$27

N.A. Pulp

(13%)

$106

(18%)

$228

European Paper

1%

€28

(7%)

€0

Printing Papers

Printing Papers |

41

Average IP price realization (includes the impact of mix across all grades)

2Q10 vs. 1Q10

2Q10 vs. 2Q09

Volume

Price/Ton

Volume

Price/Ton

U.S. Coated Paperboard

4%

$28

12%

($7)

Revenue

Price

Revenue

Price

Converting Businesses

4%

NA

(6%)

NA

Consumer Packaging

Consumer Packaging |

42

Special Items Pre-Tax

from Continuing Operations

Special Items Pre-Tax

from Continuing Operations

Special Items Pre-Tax ($Million)

2Q09

1Q10

2Q10

Industrial

Packaging

Alternative Fuel Mixture Credits

$208

Facility & Machine Closure Costs

($18)

($5)

($1)

Integration Costs

($63)

Printing

Papers

Alternative Fuel Mixture Credits

$197

Facility Closure Costs

($4)

($204)

($111)

Consumer

Packaging

Alternative Fuel Mixture Credits

$77

Reorganization

($1)

($3)

($1)

Corporate

Restructuring & Other Charges

($59)

($3)

($31)

Total Special Items Pre-Tax

$337

($215)

($144) |

43

Special Items Net of Taxes

from Continuing Operations

Special Items Net of Taxes

from Continuing Operations

2Q10

$ Million

EPS

Earnings Before Special Items

$181

$0.42

Special Items Net of Taxes:

Franklin Mill Shutdown

($68)

Debt Extinguishment

($11)

Tax Adjustment

($7)

Other

($2)

Total Special Items Net of Taxes

($88)

($0.21)

Net Earnings

$93

$0.21 |

44

2Q10 EBITDA

before Special Items

2Q10 EBITDA

before Special Items

Operating

Profit

$ Million

D & A

$ Million

Tons

Thousand

EBITDA

per Ton

EBITDA

Margin

Industrial Packaging

North America

1

$171

$143

2,608

$120

15.8%

Europe

$19

$7

259

$100

11.2%

Printing Papers

North America

2

$46

$51

688

$141

14.3%

Western Europe

3

$7

$5

70

$171

16.2%

Eastern Europe & Russia

3

$39

$13

240

$217

26.3%

Brazil

$39

$34

282

$259

26.6%

U.S. Market Pulp

$18

$13

215

$144

19.5%

Consumer Packaging

U.S. Coated Paperboard

$14

$35

354

$138

12.5%

1

Excludes Recycling & Bag businesses; includes Saturating Kraft business

2

Includes Bleached Kraft business

3

Excludes Market Pulp |

45

Operating Profits by Industry Segment

Operating Profits by Industry Segment

$ Million

2Q09

1Q10

2Q10

Industrial Packaging

$255

$46

$193

Printing Papers

$86

$126

$158

Consumer Packaging

$38

$31

$49

Distribution

$10

$21

$26

Forest Products

$3

$8

$40

Operating Profit

$392

$232

$466

Net Interest Expense

($173)

($149)

($157)

Noncontrolling Interest / Equity Earnings Adjustment

$8

$8

$7

Corporate Items

($44)

($51)

($54)

Special Items

$337

($215)

($144)

Earnings (Loss) from continuing operations before

income taxes, equity earnings & noncontrolling interest

$520

($175)

$118

Equity Earnings (Loss), net of taxes -

Ilim

($30)

($3)

$5 |

46

Geographic Business Segment Operating Results

Before Special Items

Geographic Business Segment Operating Results

Before Special Items

$ Million

Sales

Operating Profit

2Q09

1Q10

2Q10

2Q09

1Q10

2Q10

Industrial Packaging

North American

$1,955

$1,890

$2,120

$241

$23

$172

European

$240

$245

$235

$14

$24

$19

Asian

$75

$85

$85

$0

($1)

$2

Printing Papers

North American

$685

$685

$675

$61

$70

$46

European

$315

$315

$320

$16

$48

$55

Brazilian

$215

$225

$275

$23

$11

$39

U.S. Market Pulp

$135

$155

$160

($14)

($3)

$18

Asian

$10

$25

$15

$0

$0

$0

Consumer Packaging

North American

$565

$550

$580

$17

($1)

$17

European

$80

$85

$80

$14

$20

$19

Asian

$125

$170

$185

$7

$12

$13

Distribution

$1,595

$1,580

$1,630

$10

$21

$26

Excludes Forest Products |

47

1

Assuming dilution

2

A

reconciliation

to

GAAP

EPS

is

available

at

www.internationalpaper.com

under

the

Investors

tab

at

Webcasts

and

Presentations

Pre-Tax

$MM

Tax

$MM

Non-

controlling

Interest

$MM

Equity

Earnings

Net

Income

$MM

Estimated

Tax Rate

Average

Shares

MM

Diluted

EPS

Before Special Items

1Q10

$40

($13)

($9)

($2)

$16

32%

429

$0.04

2Q10

$262

($81)

($7)

$7

$181

31%

433

$0.42

Special Items

1Q10

($215)

$37

$0

$0

($178)

17%

429

($0.42)

2Q10

($144)

$56

$0

$0

($88)

39%

434

($0.21)

Earnings

1Q10

($175)

$24

($9)

($2)

($162)

14%

429

($0.38)

2Q10

$118

($25)

($7)

$7

$93

21%

433

$0.21

2010 Earnings from Continuing Operations

2010 Earnings from Continuing Operations

2

1 |

48

Earnings from continuing operations before special items

2Q10 vs. 2Q09 EPS

2Q10 vs. 2Q09 EPS

.20

.42

(.31)

(.05)

.13

.19

.09

.01

.06

.01

.08

.01

$0.00

$0.10

$0.20

$0.30

$0.40

$0.50

$0.60

$0.70

2Q09

Volume

/ LOO

Price

Operations

& Costs

Input

Costs

Mix

Forest

Products

Bad Debt

Corporate

& Other

Ilim

JV

Tax

2Q10 |

49

255

193

(130)

(2)

20

27

18

5

$0

$50

$100

$150

$200

$250

$300

2Q09

Input

Costs

Volume

LOO

Price

& Mix

Operations

& Costs

Maintenance

Outages

2Q10

Industrial Packaging Earnings

2Q10 vs. 2Q09

Industrial Packaging Earnings

2Q10 vs. 2Q09

Earnings before special items

Operations

32 LIFO, Other Costs (34) |

50

Printing Papers Earnings

2Q10 vs. 2Q09

Printing Papers Earnings

2Q10 vs. 2Q09

Earnings before special items

86

158

(25)

(6)

(33)

77

5

54

$0

$25

$50

$75

$100

$125

$150

$175

$200

2Q09

Input

Costs

Price

& Mix

Volume

Maintenance

Outages

Operations

& Costs

Bad Debt

2Q10 |

51

$ Million

2Q09

1Q10

2Q10

Sales

$215

$225

$275

Earnings

$23

$11

$39

EBITDA Margin

24%

20%

27%

IP Brazil results are reported in the Printing Papers segment

IP Brazil

IP Brazil

2Q10 vs. 1Q10

2Q10 vs. 2Q09

Business

Volume

Price /

Ton

Volume

Price /

Ton

Uncoated Freesheet

14%

$43

20%

($9)

Domestic

3%

$54

(7%)

($37)

Export

21%

$36

44%

$6 |

52

Consumer Packaging Earnings

2Q10 vs. 2Q09

Consumer Packaging Earnings

2Q10 vs. 2Q09

Earnings before special items

38

49

(45)

22

17

13

1

3

$0

$20

$40

$60

$80

$100

2Q09

Price

& Mix

Volume

/ LOO

Input

Costs

Operations

& Costs

Maintenance

Outages

Other

2Q10 |

53

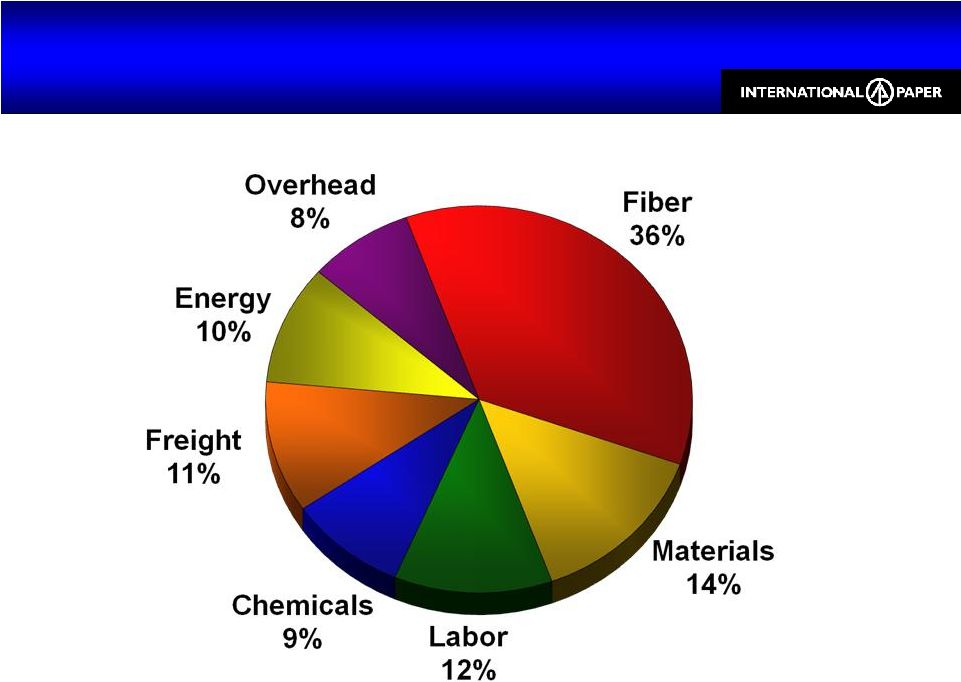

Total Cash Cost Components

2Q10 YTD

Total Cash Cost Components

2Q10 YTD

North American Mills Only |

54

Global Input & Freight Costs vs. 1H09

$287 MM, or $0.45/Share Unfavorable

Global Input & Freight Costs vs. 1H09

$287 MM, or $0.45/Share Unfavorable

Input costs for continuing businesses

76

(17)

(36)

(310)

($350)

($250)

($150)

($50)

$50

Fiber

Freight

Energy

Chemicals

Outside North America

North America |

55

Global Input & Freight Costs vs. 2Q09

$200 MM, or $0.32/Share Unfavorable

Global Input & Freight Costs vs. 2Q09

$200 MM, or $0.32/Share Unfavorable

Input costs for continuing businesses

(179)

(26)

(14)

19

($200)

($150)

($100)

($50)

$0

$50

Fiber

Freight

Energy

Chemicals

North America

Outside North America |

56

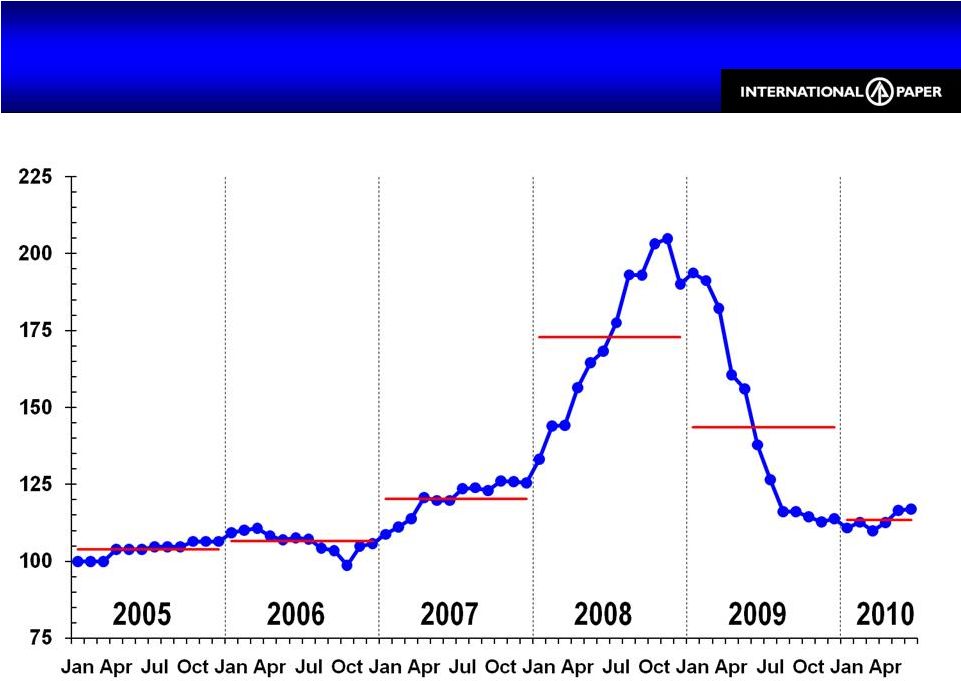

NYMEX Natural Gas closing prices

Index: Jan 2005 Natural Gas Costs = 100

Natural Gas Costs

23% Decrease vs. 1Q10 Average Cost

Natural Gas Costs

23% Decrease vs. 1Q10 Average Cost |

57

U.S. Fuel Oil

2% Increase vs. 1Q10 Average Cost

U.S. Fuel Oil

2% Increase vs. 1Q10 Average Cost

Index: Jan 2006 Fuel Oil Costs = 100

WTI Crude prices |

58

U.S. Chemical Composite Index

4% Increase vs. 1Q10 Average Cost

U.S. Chemical Composite Index

4% Increase vs. 1Q10 Average Cost

Delivered cost to U.S. facilities; includes Caustic Soda, Sodium

Chlorate, Starch and Sulfuric Acid

2005 -

2008 excludes WY PKG

Index: 1Q05 Chemical Composite= 100 |

59

2010 Global Consumption

Annual Purchase Estimates for Key Inputs

2010 Global Consumption

Annual Purchase Estimates for Key Inputs

Does not include Asian or Ilim consumption

Estimates are based on normal operations and may be impacted by downtime

Commodity

U. S.

Non –

U. S.

Energy

Natural Gas (MM BTUs)

42,000,000

13,000,000

Fuel Oil (Barrels)

1,500,000

500,000

Coal (Tons)

860,000

260,000

Fiber

Wood (Tons)

44,200,000

8,800,000

Old Corrugated Containers (Tons)

3,000,000

310,000

Chemicals

Caustic Soda (Tons)

250,000

70,000

Starch (Tons)

394,000

96,000

Sodium Chlorate (Tons)

180,000

40,000

LD Polyethylene (Tons)

39,000

-

Latex (Tons)

22,000

4,000 |