Attached files

Table of Contents

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D. C. 20549

FORM 10-K

| x | ANNUAL REPORT PURSUANT TO SECTION 13 or 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the fiscal year ended May 31, 2010

OR

| ¨ | TRANSITION REPORT PURSUANT TO SECTION 13 or 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the transition period from to

Commission File Number 1-4887

TEXAS INDUSTRIES, INC.

(Exact name of Registrant as specified in its charter)

| Delaware | 75-0832210 | |

| (State or other jurisdiction of incorporation or organization) |

(I.R.S. Employer Identification No.) |

1341 West Mockingbird Lane, Suite 700W, Dallas, Texas 75247-6913

(Address of principal executive offices, including zip code)

Registrant’s telephone number, including area code: (972) 647-6700

Securities registered pursuant to Section 12(b) of the Act:

| Title of each class | Name of each exchange on which registered | |

| Common Stock, $1.00 Par Value | New York Stock Exchange |

Securities registered pursuant to Section 12(g) of the Act: NONE

Indicate by check mark if the Registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes x No ¨

Indicate by check mark if the Registrant is not required to file reports pursuant to Section 13 or 15(d) of the Act. Yes ¨ No x

Indicate by check mark whether the Registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the Registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes x No ¨

Indicate by check mark whether the Registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§ 232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes ¨ No ¨

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of Registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. x

Indicate by check mark whether the Registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer or a smaller reporting company. See the definitions of “large accelerated filer,” “accelerated filer,” and “smaller reporting company” in Rule 12b-2 of the Exchange Act. (Check one):

Large Accelerated Filer x Accelerated Filer ¨ Non-accelerated Filer ¨ Smaller Reporting Company ¨

Indicate by check mark whether the Registrant is a shell company (as defined in Rule 12b-2 of the Act). Yes ¨ No x

The aggregate market value of the Registrant’s common stock held by non-affiliates of the Registrant was approximately $946,392,222, computed by reference to the price at which the common stock was last sold on the New York Stock Exchange as of November 30, 2009, the last business day of the Registrant’s most recently completed second fiscal quarter.

The number of shares outstanding of the Registrant’s common stock as of June 30, 2010 was 27,796,393.

DOCUMENTS INCORPORATED BY REFERENCE: Portions of the Registrant’s definitive proxy statement for the annual meeting of shareholders to be held October 13, 2010, are incorporated by reference into Part III.

Table of Contents

| Page | ||||

| PART I | ||||

| Item 1. |

1 | |||

| Item 1A. |

10 | |||

| Item 1B. |

16 | |||

| Item 2. |

16 | |||

| Item 3. |

19 | |||

| Item 4. |

19 | |||

| PART II | ||||

| Item 5. |

Market for the Registrant’s Common Equity, Related Stockholder Matters and Issuer Purchases of Equity Securities | 20 | ||

| Item 6. |

22 | |||

| Item 7. |

Management’s Discussion and Analysis of Financial Condition and Results of Operations |

23 | ||

| Item 7A. |

37 | |||

| Item 8. |

37 | |||

| Item 9. |

Changes in and Disagreements with Accountants on Accounting and Financial Disclosure |

69 | ||

| Item 9A. |

69 | |||

| Item 9B. |

71 | |||

| PART III | ||||

| Item 10. |

Directors, Executive Officers and Corporate Governance | 72 | ||

| Item 11. |

72 | |||

| Item 12. |

Security Ownership of Certain Beneficial Owners and Management and Related Stockholder Matters | 72 | ||

| Item 13. |

Certain Relationships and Related Transactions, and Director Independence |

72 | ||

| Item 14. |

72 | |||

| PART IV | ||||

| Item 15. |

73 | |||

| 77 | ||||

Table of Contents

PART I

| ITEM 1. | BUSINESS |

When used in the Report, the terms “Company,” “we,” “us,” or “our” mean Texas Industries, Inc. and subsidiaries unless the context indicates otherwise.

General

We are a leading supplier of heavy construction materials in the United States through our three business segments: cement, aggregates and consumer products. Our cement segment produces gray portland cement and specialty cements. Our cement production and distribution facilities are concentrated primarily in Texas and California, the two largest cement markets in the United States. Based on production capacity, we are the largest producer of cement in Texas with a 24% share in that state. Our aggregates segment produces natural aggregates, including sand, gravel and crushed limestone, and specialty lightweight aggregates. Our consumer products segment produces primarily ready-mix concrete and, to a lesser extent, packaged products. We are a major supplier of natural aggregates and ready-mix concrete in Texas and northern Louisiana and, to a lesser extent, in Oklahoma and Arkansas. For financial information about our business segments, see Note 10 of Notes to Consolidated Financial Statements in Item 8 of this Report.

As of May 31, 2010, we had 85 manufacturing facilities in six states. In fiscal year 2010, our net sales were $621.1 million, of which 40.2% was generated by our cement segment, 23.0% by our aggregates segment, and 36.8% by our consumer products segment. During the year, we shipped 3.2 million tons of finished cement, 11.4 million tons of natural aggregates, 1.0 million cubic yards of lightweight aggregates and 2.1 million cubic yards of ready-mix concrete.

Our revenue is derived from multiple end-use markets, including the public works, residential, commercial, retail, industrial and institutional construction sectors, as well as the oil and gas industry. Our diversified mix of products provides access to this broad range of end-user markets and helps mitigate the exposure to cyclical downturns in any one product or end-user market. No one customer accounted for more than 10% of our total net sales in fiscal year 2010.

During fiscal year 2009 and into fiscal year 2010, the economy in all of our operating regions was in recession. Declining home values, investor losses on mortgage related securities, tight credit conditions, state budget shortfalls, rising unemployment and other factors led to declines in all segments of construction activity in our markets. These conditions impacted all segments of our business. In response, we took numerous steps to manage our production to more closely match market demand, reduce costs and manage our cash position. We significantly reduced both capital and non-capital spending, including delaying construction of the expansion of our Hunter, Texas cement plant. We idled plants where necessary and reduced our employee and contract labor force by approximately 30%. We also significantly reduced overtime pay, implemented a salary freeze for non-union employees and renegotiated a number of supply and service agreements. Our president and chief executive officer voluntarily reduced his salary by 10% and other executive officers similarly reduced their salaries by 5%. We negotiated amendments to our senior secured revolving credit facility to reduce the risk that the market decline would cause our operating results to fall below levels required by financial covenants.

During fiscal year 2010, the national economy began to pull out of the recession, but construction activity has remained at low levels. As a consequence, we have continued with the steps that we began taking in fiscal year 2009 in response to the recession. These steps and others are indicative of our intense focus on cost reduction, management of our cash position and management of production levels, which we believe had a significant positive impact on our operating results in the last two fiscal years.

In October 2007 we commenced construction on a project to expand our Hunter, Texas cement plant. We plan to expand the Hunter plant by approximately 1.4 million tons of advanced dry process annual cement production capacity. The 900,000 tons of existing production will remain in operation. When completed, the Hunter plant will be a modern, low cost facility, similar to our Midlothian and Oro Grande dry process facilities, and we will be well positioned to cost-effectively supply the southern and central Texas market. In May 2009 we

1

Table of Contents

temporarily halted construction on the project because we believed that economic and market conditions made it unlikely that current cement demand levels in Texas would permit the new kiln to operate profitably if the project was completed as originally scheduled. We expect to resume construction by November 2010. We have not entered into a new construction contract to complete the construction, so no schedule for completion has yet been determined. As of May 31, 2010, we had incurred $293.9 million, excluding capitalized interest of $16.3 million, related to the project, of which $289.4 million had been paid. Until we determine the period over which the construction will occur, we cannot accurately estimate the cost of completing the project.

We expect our capital expenditures in fiscal year 2011 to be approximately $15 million to $25 million, excluding those related to the construction of the Hunter cement plant expansion.

Our Competitive Strengths and Strategies

We believe the following competitive strengths and strategies are key to our ability to grow and compete successfully:

Leading Market Positions. We strive to be a major supplier in markets that have attractive characteristics, such as large market size, above average long-term projected population growth, strong economic activity and a year-round building season. Based on production capacity, we are the largest producer of cement in Texas (with a 24% share of total production capacity), and the second largest producer of cement in southern California. We believe we are also the largest supplier of expanded shale and clay specialty aggregate products west of the Mississippi River, the second largest supplier of stone, sand and gravel natural aggregate products in North Texas, one of the largest suppliers of ready-mix concrete in North Texas and one of the largest suppliers of sand and gravel aggregate products and ready-mix concrete in northern Louisiana. We believe our leadership in these markets enhances our competitive position.

Low Cost Supplier. We strive to be a low cost supplier in our markets. We believe we have some of the lowest operating costs in the cement and aggregate industries. We focus on optimizing the use of our equipment, enhancing our productivity and exploring new technologies to further improve our unit cost of production at each of our facilities. Our low operating costs are primarily a result of our efficient plant designs, high productivity rate and innovative manufacturing processes.

Strategic Locations and Markets. The strategic locations of our facilities near our customer base and sources of raw materials allow us to access the largest cement consuming markets in the United States. Our cement manufacturing facilities are located in Texas and California, the two largest U.S. cement markets. During calendar year 2009, Texas and California accounted for approximately 10.8 million and 7.4 million tons, respectively, of cement consumption or approximately 14% and 10%, respectively, of total U.S. cement consumption. California and Texas have also been the largest beneficiaries of federal transportation funding during the last several years. Funds distributed under multi-year federal highway legislation historically have comprised a majority of California and Texas’ public works spending.

Diversified Product Mix and Broad Range of End-User Markets. Our revenue streams are derived from multiple end-user markets, including the public works, residential, commercial, retail, industrial and institutional construction sectors, as well as the oil and gas industry. Accordingly, we have a broad and diverse customer base. Our diversified mix of products provides access to this broad range of end-user markets and helps mitigate the exposure to cyclical downturns in any one product or end-user market. No one customer accounted for more than 10% of our net sales in fiscal year 2010.

Long-Standing Customer Relationships. We have established a solid base of long-standing customer relationships. For example, our ten largest customers during fiscal year 2010 have done business with us for an average of over 15 years. We strive to achieve customer loyalty by delivering superior customer service and maintaining an experienced sales force with in-depth market knowledge. We believe our long-standing relationships and our leading market positions help to provide additional stability to our operating performance and make us a preferred supplier.

Experienced Management Team. Mel Brekhus, our chief executive officer, Ken Allen, our chief financial officer, and the vice presidents responsible for the cement, aggregates and consumer products segments have an

2

Table of Contents

average of 28 years of industry experience. Our management team has led our company through several industry cycles and has demonstrated the ability to successfully complete and operate major expansion projects.

Products

Cement Segment

Our cement segment produces gray portland cement as its principal product. We also produce specialty cements such as masonry and oil well cements.

Our cement production facilities are located at three sites in Texas and California: Midlothian, Texas, south of Dallas/ Fort Worth, the largest cement plant in Texas; Hunter, Texas, south of Austin; and Oro Grande, California, near Los Angeles. The limestone reserves used as the primary raw material are located on property we own adjacent to each of the plants. Additional information about our cement production facilities and associated limestone reserves is provided in Item 2, Properties, of this Report.

Due to the recession that gripped our nation throughout fiscal year 2009 and into fiscal year 2010, we modified our operating processes in order to reduce costs and more closely match cement production to demand in our markets. We temporarily idle each of our dry process gray cement kilns from time to time in order to control inventories. We idled the four wet kilns at our Midlothian, Texas plant which are less efficient than the large dry kiln at that plant. Finally, the white cement production facility and the gray cement grinding facility at our Crestmore plant near Riverside, California remain idled. We continue to operate a cement terminal and packaging facility at the Crestmore plant.

In July 2010 we decided to surrender the operating permits for the four wet kilns at our Midlothian plant, which had a rated annual production capacity of 600,000 tons of clinker. We plan to replace the production capacity of the wet kilns by increasing the much more efficient capacity of the large modern dry process kiln at the plant. Closing the four wet kilns is expected to allow us to obtain the permits needed to enhance and optimize the dry kiln. We do not know how long it will take to obtain the permits needed to make the enhancements to the dry kiln. As a consequence, we cannot yet estimate the cost or schedule for the enhancements. We do not expect that the closure of the wet kilns will have a material impact on our consolidated financial statements.

The primary fuel source for all of our facilities is coal. At our Hunter, Texas plant we also use alternative fuels. Our facilities also consume large amounts of electricity. We believe that adequate supplies of both fuel and electricity are available.

We produced approximately 3.2 million tons of finished cement during fiscal year 2010. We shipped approximately 3.2 million tons during the year, of which 2.7 million tons were shipped to outside trade customers. At May 31, 2010, our backlog was approximately 509,000 tons, approximately 194,000 tons of which we do not expect to fill in fiscal year 2011. At May 31, 2009, our backlog was approximately 682,000 tons.

We market our cement products in the southwestern United States. Our principal marketing area includes the states of Texas, Louisiana, Oklahoma, California, Nevada and Arizona. Sales offices are maintained throughout the marketing area and sales are made primarily to numerous customers in the construction industry, no one of which would be considered material to our business.

Cement is distributed by rail or truck to 8 distribution terminals located throughout the marketing area.

Aggregates Segment

Natural Aggregates. Our natural aggregate operations produce sand, gravel and crushed limestone. These operations are conducted from facilities primarily serving the Dallas/Fort Worth, Austin and Houston areas in Texas; the southern Oklahoma area; and the Alexandria and Monroe areas in Louisiana. Additional information about our natural aggregates production facilities and associated reserves is provided in Item 2, Properties, of this Report.

We produced approximately 11.8 million tons of natural aggregate during fiscal year 2010. We shipped approximately 11.4 million tons of natural aggregate during fiscal year 2010, of which 9.1 million tons were

3

Table of Contents

shipped to outside trade customers. At May 31, 2010, our backlog was approximately 1.5 million tons, the majority of which will be shipped in 2011. At May 31, 2009, our backlog was approximately 1.8 million tons.

The cost of transportation limits the marketing of aggregate products to the areas within approximately 100 miles of the plant sites. Sales are therefore related to the level of construction activity near the plants. The products are marketed by our sales organization located in the areas served by the plants and are sold to numerous customers, no one of which would be considered material to our business.

Products are distributed to trade customers principally by contract or customer-owned haulers or through rail distribution facilities. To enhance our efficiency and competitiveness, particularly in sales of crushed stone, we strive to establish direct rail links between production facilities and our key markets, reducing the cost of transportation. We have installed rail loops at our crushed stone plants and rail terminals close to major markets, which allow rapid loading and unloading of product. In local areas surrounding our rail terminals, we believe we have a transportation cost advantage over some competing suppliers who rely to a greater extent on truck transportation.

Lightweight Aggregates. Expanded shale and clay, a specialty lightweight aggregate product, is manufactured from facilities serving the Dallas/Fort Worth, Austin and Houston areas in Texas; the Oakland/San Francisco and Los Angeles areas in California; and the Denver area in Colorado. Additional information about our lightweight aggregates production facilities and associated reserves is provided in Item 2, Properties, of this Report.

We produced approximately 1.1 million cubic yards of lightweight aggregate during fiscal year 2010. We shipped approximately 1.0 million cubic yards of lightweight aggregate during fiscal year 2010, of which approximately 0.9 million cubic yards were shipped to outside trade customers. At May 31, 2010, our backlog was approximately 125,000 cubic yards, the majority of which will be shipped in 2011.

The cost of transportation limits the marketing of most lightweight aggregate products to the areas within approximately 200 miles of the plant or terminal sites. Sales are therefore related to the level of construction activity near the plants and terminals. The products are marketed by our sales organization located in the areas served by the plants and terminals and are sold to numerous customers, no one of which would be considered material to our business. Products are distributed to trade customers principally by contract or customer-owned haulers and, to a lesser extent, by rail. Certain specialty products we have developed from our expanded shale and clay, such as DiamondPro® baseball infield conditioner, have developed a geographically dispersed customer base and are shipped to a significant portion of the continental United States.

Consumer Products Segment

Ready-mix Concrete. Our ready-mix concrete operations are situated in three areas in Texas (Dallas/Fort Worth/Denton, Houston and east Texas), in north and central Louisiana, and at one location in southern Arkansas. Additional information about our ready-mix concrete production facilities and associated equipment is provided in Item 2, Properties, of this Report.

We shipped approximately 2.1 million cubic yards of ready-mix concrete during fiscal year 2010. At May 31, 2010, our backlog was approximately 1.4 million cubic yards, the majority of which will be shipped in 2011. At May 31, 2009, our backlog was approximately 1.5 million cubic yards.

We manufacture and supply a substantial amount of the cement and aggregates used by the ready-mix plants. The remainder is purchased from outside suppliers. Ready-mix concrete is sold to various contractors in the construction industry, no one of which would be considered material to our business. We believe that we are a significant participant in the Texas and Louisiana concrete products markets in which we operate. The principal methods of competition in concrete products markets are quality and service at competitive prices. Because we are a producer of cement and aggregates, the primary components of concrete, we believe that our customers view us as a reliable supplier of quality concrete, particularly during times that the supply of raw material is tight.

Other Products. We manufacture and market packaged concrete mix, mortar, sand and related products from plant or distribution sites we own in the Dallas/Fort Worth, Austin and Houston areas in Texas. We also

4

Table of Contents

market our Maximizer packaged concrete mix in southern California. The products are marketed by our sales force in each of these locations, and are delivered primarily by contract haulers direct to retailers. Since the cost of delivery is significant to the overall cost of most of these products, the market area is generally restricted to within approximately 100 miles of the plant locations. These products are sold by the retailers to contractors, distributors and property owners.

Competition

All of the product segments and markets in which we participate are highly competitive. These markets are also generally regional because transportation costs are high relative to the value of the product. Ready-mix concrete also competes in relatively small geographic areas due to delivery time constraints associated with pre-mixed concrete after the addition of water. As a result, in our aggregates and consumer products markets, there is little competition from imported products. However, our cement segment does compete with imported cement because of the higher value of the product.

The nature of our competition varies among our product lines due to the widely differing amounts of capital necessary to build production facilities. Construction of cement production facilities is highly capital intensive and requires long lead times to complete engineering design, obtain regulatory permits, acquire equipment and construct a plant. Most domestic producers of cement are owned by large foreign companies operating in multiple international markets. Many of these producers maintain the capability to import cement from foreign production facilities.

Sand and gravel production by dredging, or crushed stone production from stone quarries, is moderately capital intensive. Our major competitors in the aggregates markets are typically large vertically integrated companies.

Ready-mix concrete production requires relatively small amounts of capital to build a concrete batching plant and acquire delivery trucks. As a result, in each local market we face competition from numerous small producers as well as large vertically integrated companies with facilities in many markets.

Due to the lack of product differentiation, competition for all of our products is based largely on price and, to a lesser extent, quality of product and service. As a result, the prices that we charge our customers are not likely to be materially different from the prices charged by other producers in the same markets. Accordingly, our profitability is generally dependent on the level of demand for cement, aggregates and concrete products in the local markets we serve, and on our ability to control operating costs.

Employees

At May 31, 2010, we had approximately 1,930 employees. Approximately 108 employees at our Oro Grande, California cement plant are covered by a collective bargaining agreement that expires in June 2012. Approximately 13 employees at our Crestmore plant near Riverside, California are covered by a collective bargaining agreement that expires in 2013.

We believe our relationship with our employees is good.

Legal Proceedings

In March 2008, the South Coast Air Quality Management District, or SCAQMD, informed one of our subsidiaries, Riverside Cement Company (Riverside), that it believed that operations at the Crestmore cement plant in Riverside, California caused the level of hexavalent chromium, or chrome 6, in the air in the vicinity of the plant to be elevated above ambient air levels. Chrome 6 has been identified by the State of California as a carcinogen. Riverside immediately began taking steps, in addition to its normal dust control procedures, to reduce dust from plant operations and eliminate the use of open clinker stockpiles. In February 2008, the SCAQMD placed an air monitoring station at the downwind property line closest to the open clinker stockpiles. In the SCAQMD’s first public report of the results of its monitoring, over the period of February 12 to April 9, 2008, the average level of chrome 6 was 2.43 nanograms per cubic meter, or ng/m³. Since that time, the average

5

Table of Contents

level has decreased. The average levels of chrome 6 reported by the SCAQMD at all of the air monitoring stations in areas around the plant, including the station at the property line, are below 1.0 ng/m³ over the entire period of time it has operated the stations. The SCAQMD compared the level of exposure at the air monitor on our property line with the following employee exposure standards established by regulatory agencies:

| Occupational Safety and Health Administration |

5,000 ng/m³ | |

| National Institute for Occupational Safety and Health |

1,000 ng/m³ | |

| California Environmental Protection Agency |

200 ng/m³ |

In public meetings conducted by the SCAQMD, it stated that the risk of long term exposure immediately adjacent to the plant is similar to living close to a busy freeway or rail yard, and it estimated an increased risk of 250 to 500 cancers per one million people, assuming continuous exposure for 70 years. Riverside has not determined how this particular risk number was calculated by SCAQMD. However, the Riverside Press Enterprise reported in a May 30, 2008 story that “John Morgan, a public health and epidemiology professor at Loma Linda University, said he looked at cancer cases reported from 1996 to 2005 in the … census [tract] nearest the [plant] and found no excess cases. That includes lung cancer, which is associated with exposure to hexavalent chromium.”

In late April 2008, a lawsuit was filed in Riverside County Superior Court of the State of California styled Virginia Shellman, et al. v. Riverside Cement Holdings Company, et al. The lawsuit against three of our subsidiaries purports to be a class action complaint for medical monitoring for a putative class defined as individuals who were allegedly exposed to chrome 6 emissions from our Crestmore cement plant. The complaint alleges an increased risk of future illness due to the exposure to chrome 6 and other toxic chemicals. The suit requests, among other things, establishment and funding of a medical testing and monitoring program for the class until their exposure to chrome 6 is no longer a threat to their health, as well as punitive and exemplary damages.

Since the Shellman lawsuit was filed, five additional putative class action lawsuits have been filed in the same court. The putative class in each of these cases is the same as or a subset of the putative class in the Shellman case, and the allegations and requests for relief are similar to those in the Shellman case. As a consequence, the court has stayed four of these lawsuits until the Shellman lawsuit is finally determined.

Since August 2008, 25 additional lawsuits have been filed in the same court against us or one or more of our subsidiaries containing allegations of personal injury and wrongful death by over 2,700 individual plaintiffs who were allegedly exposed to chrome 6 and other toxic or harmful substances in the air, water and soil caused by emissions from the Crestmore plant. The plaintiffs allege causes of action that vary somewhat from suit to suit, but typically include, among other things, negligence, intentional and negligent infliction of emotional distress, trespass, public and private nuisance, strict liability, willful misconduct, fraudulent concealment, wrongful death and loss of consortium. The plaintiffs generally request, among other things, general and punitive damages, medical expenses, loss of earnings, property damages and medical monitoring costs. Some of the suits include additional defendants, such as the owner of another cement plant located approximately four miles from the Crestmore plant.

Since January 2009, seven lawsuits have been filed against us or one or more of our subsidiaries in the same court involving similar allegations, causes of action and requests for relief, but with respect to our Oro Grande, California cement plant instead of the Crestmore plant. The suits involve approximately 300 individual plaintiffs. Prior to the filing of the lawsuits, the air quality management district in whose jurisdiction the plant lies conducted air sampling from locations around the plant. None of the samples contained chrome 6 levels above 1.0 ng/m³.

At the date of this report, none of the plaintiffs in these cases has alleged any specific amount or range of damages. We will vigorously defend all of these suits but we cannot predict what liability, if any, could arise from them. We also cannot predict whether any other suits may be filed against us alleging damages due to injuries to persons or property caused by claimed exposure to chrome 6.

We are defendants in other lawsuits that arose in the ordinary course of business. In our judgment the ultimate liability, if any, from such legal proceedings will not have a material effect on our consolidated financial position or results of operations.

6

Table of Contents

Environmental

We are subject to various federal, state and local environmental, health and safety laws and regulations. These laws and regulations govern, among other things:

| • | air emissions, |

| • | wastewater discharges, |

| • | generation, use, handling, storage, transportation and disposal of hazardous substances and wastes, |

| • | investigation and remediation of contamination existing at current and former properties, and at third-party waste disposal sites, |

| • | exposure limits of our employees and others to dust, silica and other substances, and |

| • | safety standards for operating our quarries and plant equipment. |

Sources of air emissions and wastewater discharges at our facilities are regulated by a combination of permit limitations and emission standards of national and statewide application. The laws and regulations requiring permits and establishing emission standards have tended to become increasingly stringent over time. In addition, permits are subject to modification, renewal and revocation requirements, which allow issuing agencies to tighten the permit limitations.

One area in which changes in laws and regulations are likely to have a significant impact on us and our industry is climate change. Many scientists believe that carbon dioxide, a product of combustion of fuel in cement kilns and a natural byproduct of the cement manufacturing process, is a greenhouse gas that contributes to global warming.

In 2006, California adopted the “California Global Warming Solutions Act of 2006”, which requires the California Air Resources Board (CARB) to achieve a statewide reduction in emissions of greenhouse gases in California to 1990 levels by 2020. A significant portion of our cement production capacity is in California, but CARB has not yet adopted regulations fully defining how the new law may apply to us.

The U.S. Supreme Court decision in Massachusetts v. EPA relating to regulation of carbon dioxide emissions from automobiles has spurred the EPA to issue in December 2009 a finding that greenhouse gases contribute to air pollution that may endanger public health or welfare. Numerous parties, including certain states, industry associations and other private parties, have filed court petitions challenging the validity of the finding. We cannot predict the ultimate outcome of those challenges.

The endangerment finding does not include any proposed regulations. Although both the Obama administration and the Administrator of the EPA have indicated their preference for comprehensive federal legislation to address this issue, in May 2010 the EPA issued a final rule under which it will begin implementing greenhouse gas emission limitations in permits for stationary sources such as cement plants in January 2011. The rule would require us to incorporate best available control technology in a new cement plant or an existing plant that we propose to modify in a manner that would increase carbon dioxide emissions by more than 75,000 tons per year. No technologies or methods of operation for reducing or capturing carbon dioxide have been proven successful in large scale applications other than improvements in fuel efficiency. In addition, the rule appears to require us to incorporate greenhouse gas related provisions in the operating permits for our cement plants. We do not currently know what the EPA will require as best available control technology or what conditions it will require to be added to operating permits. Therefore, at this time, it is impossible to predict what the cost or effect of the rule will be on our business.

Although no federal laws currently limit greenhouse gas emissions, in June 2009, the U.S. House of Representatives passed the American Clean Energy and Security Act of 2009, a bill introduced by Rep. Henry Waxman and Rep. Edward Markey and popularly known as the Waxman Markey bill. The bill would regulate greenhouse gas emissions by instituting a cap-and-trade-system in which an economy-wide cap on U.S. greenhouse gas emissions would be established starting in 2012 with a cap 3% below the baseline 2005 level.

7

Table of Contents

The cap would steeply decline over time until in 2050 it reaches 83% below the baseline level. Emissions allowances, which are rights to emit greenhouse gases, would be both allocated for free and auctioned. Trade vulnerable industries would be allocated for free up to 15% of the total allowances in 2014. This percentage would be gradually reduced over time until it is phased out in 2025. We expect that the cement industry would qualify as a trade vulnerable industry under the bill.

In May 2010, Senators John Kerry and Joe Lieberman released a proposed Senate bill that contains cap-and-trade provisions with emission caps similar to the Waxman Markey bill. It also contains similar provisions for trade vulnerable industries. The prospects for passage of the Kerry Lieberman bill by the U.S. Senate are uncertain. As a consequence, at this time it is impossible to predict whether any federal climate change legislation will be enacted, and if enacted, what the cost or effect on our business will be.

Various states have banded together in three initiatives to develop regional strategies to address climate change. Six western states, including California, and four Canadian provinces have formed the Western Climate Initiative, six Midwestern states and one Canadian province are members of the Midwestern Greenhouse Gas Reduction Accord, and ten northeastern and mid-Atlantic states have joined the Regional Greenhouse Gas Initiative. These initiatives call for establishing goals for reduction of greenhouse gas emissions in the member states and designing market-based mechanisms to help achieve these reduction goals. Other states may join these initiatives.

In April 2009, the EPA issued a proposed rule amendment that would dramatically reduce the permitted levels of emissions of mercury, total hydrocarbons, particulate matter and hydrochloric acid from cement plants. The amendments, if adopted as proposed, would take full effect no earlier than 2013, and would likely be subject to court challenges. Our cement plants do not currently meet all of the proposed standards, and we believe that it is unlikely that any cement plant in the U.S. meets all of these standards. We can not predict whether the amendments will be adopted as proposed. If they are, since it is unknown how effective currently existing control technology will be in meeting the proposed standards, we cannot predict the cost or effect on our business of the proposed amendments.

Many of the raw materials, products and by-products associated with the operation of any industrial facility, including those for the production of cement or concrete products, contain chemical elements or compounds that can be designated as hazardous. Some examples are the metals present in cement kiln dust, or CKD, and the ignitability of the waste derived fuels that we use as a primary or supplementary fuel substitute for nonrenewable fuels such as coal and natural gas to fire certain of our cement kilns. Currently, CKD is exempt from hazardous waste management standards under the Resource Conservation and Recovery Act, or RCRA, if certain tests are satisfied. We have demonstrated that the CKD we generate satisfies these tests, but there can be no guarantee that the tests will not be changed in the future.

Like others in our business, we expend substantial amounts to comply with these environmental, health and safety laws, regulations and permit limitations, including amounts for pollution control equipment required to monitor and regulate air emissions and wastewater discharges. Since many of these requirements are subjective and therefore not quantifiable, or are presently not determinable, or are likely to be affected by future legislation or rule making by government agencies, it is not possible to accurately predict the aggregate future costs of compliance and their affect on our future results of operations or financial condition.

For additional information about the environmental, health and safety risks inherent in our operations, see “Legal Proceedings” above and Item 1A, Risk Factors, in this Report.

Intellectual Property

We own trademarks such as TXI® and Maximizer® and certain process patents. While we believe that none of our active trademarks or patents are essential to our business as a whole, brand recognition can play a role in sales of specialty products and packaged products. We believe our packaged product brands are perceived as premium quality in the local markets we serve, such as the Maximizer® brand of patented lightweight concrete in Texas and southern California.

8

Table of Contents

Real Estate

We own significant amounts of land, acquired for our business purposes such as mining limestone, sand, gravel and clay. When mining is completed or land becomes surplus for other reasons, we sell it for development or, in some instances, develop it ourselves. We are involved in the sale of land in a high quality industrial and multi-use park that we developed in the metropolitan area of Dallas/Fort Worth, Texas.

Research and Development

We incurred no research and development cost for any of the past three fiscal years. All of our innovations are developed through the production process.

Executive Officers of the Registrant

Following is information as of June 30, 2010 about our executive officers:

Mel G. Brekhus, age 61, has been President and Chief Executive Officer since June 1, 2004. From 1998 through May 2004, he was Executive Vice President, Cement, Aggregate and Concrete. He joined us in 1989 as Vice President, Cement Production and within a short period became Vice President, Cement. His career in the cement industry began in 1972 when he joined Lehigh Portland Cement Company (1972-1983). While at Lehigh, he held various positions throughout the United States as Chemist, Production Manager and Plant Manager. He was Technical Manager and Plant Manager for Missouri Portland Cement Company (1984-1989) in their Midwest operations. His professional affiliations include the Portland Cement Association, where he is Past Chairman and presently a Director.

Kenneth R. Allen, age 52, has been Vice President, Finance and Chief Financial Officer since August 1, 2008. Mr. Allen joined us in 1985 and became Treasurer in 1991 and Vice President and Treasurer in 1999. Mr. Allen is a director of The Empire District Electric Company.

Frederick G. Anderson, age 59, has been Vice President, General Counsel and Secretary since November 2004. He has been a practicing attorney for 29 years. From March 2003 until November 2004 he engaged in the private practice of law, including as of counsel to Davis Munck P.C., a Dallas, Texas based law firm. From August 1997 through March 2003, he was Senior Vice President, General Counsel and Secretary of WebLink Wireless, Inc., a wireless telecommunications company. Mr. Anderson maintains membership in the State Bar of Texas and Dallas Bar Association. He is Chairman of the Legal Counsels Committee of the Portland Cement Association.

Barry M. Bone, age 52, has been Vice President-Real Estate since 1995 and President of Brookhollow Corporation, our real estate subsidiary, since 1991. He joined us in 1982 and has served in various real estate positions since then.

Michael P. Collar, age 57, has been Vice President-Human Resources of the Company since June 1, 2010. From June 2002 until June 2010, he was Director, Human Resources of the Company. Prior to joining the Company in 2002, Mr. Collar had over 20 years of human resources experience with companies such as Ford Motor Company and Atlantic Richfield Company. Mr. Collar is a member of the Executive Committee of the Cement Employers Association.

J. Lynn Davis, age 61, has been Vice President-Cement since August 2002. From 1996 until August 2002 he was Vice President-Cement Production. He joined us in 1971 and has served in various positions in our cement, aggregates and concrete operations since then.

Stephen D. Mayfield, age 50, has been Vice President-Aggregates since September 2000. He joined us in 1984 and has held various positions in our cement, aggregates and concrete operations since then. He is a director and a member of the executive committee of the National Stone, Sand and Gravel Association and a director of the Texas Aggregate and Concrete Association.

Ronnie Pruitt, age 39, has been Vice President-Cement & Aggregates Marketing and Sales since August 2002. He joined us in 1995 and has held various positions in our cement, aggregates and concrete operations since then.

9

Table of Contents

James B. Rogers, age 43, has been Vice President-Consumer Products since August 2002. He joined us in 1996 and has held various positions in our cement, aggregates and concrete operations since then. He is a director of the National Ready-Mix Concrete Association and the Texas Aggregates and Concrete Association. Mr. Rogers is the son of Robert D. Rogers, our Chairman of the Board.

Executive officers are elected annually by the board of directors and serve at the pleasure of the board.

Available Information

Our company was incorporated in Delaware in 1951. Our internet address is www.txi.com. We file annual, quarterly and current reports, proxy statements and other information with the Securities and Exchange Commission, or SEC. You may read and copy any reports, statements and other information filed by us at the SEC’s Public Reference Room at 100 F Street, N.E., Washington, D.C. 20549. Please call (800) SEC-0330 for further information on the Public Reference Room. The SEC maintains an internet web site that contains our reports, proxy and information statements and other information about us that is filed electronically with the SEC, which may be accessed at http://www.sec.gov.

We make available, free of charge, through our investor relations website at http://investorrelations.txi.com/our reports on Forms 10-K, 10-Q and 8-K, and amendments to those reports, as soon as reasonably practicable after they are filed with the SEC. Our annual report to shareholders and Code of Ethics for the CEO and Senior Financial Officers are also available at this website. We intend to disclose amendments and waivers of such Code of Ethics on this website.

| ITEM 1A. | RISK FACTORS |

In addition to the risks discussed elsewhere in this annual report, you should carefully consider the risks described below before making an investment decision. If any such risks materialize, our business and results of operations could be materially and adversely affected, which in turn could materially and adversely affect our cash flow and financial condition. In such an instance, the trading price of our securities could decline, and you might lose all or part of your investment.

Our business is sensitive to economic cycles within the public, residential and non-residential construction segments as well as seasonality and inclement weather conditions. Some of our competitors may cope better than we can with adverse economic and market conditions.

The cement, aggregate and concrete markets are generally regional because transportation costs are high relative to the value of the product. Demand for our products is derived primarily from public (infrastructure), residential and non-residential construction activity in our specific regional markets. Construction activity in each of these markets is cyclical and is influenced by prevailing economic conditions in these markets. During fiscal year 2009 and into fiscal year 2010, the economy in all of our operating regions was in recession. Declining home values, investor losses on mortgage related securities, tight credit conditions, state budget shortfalls and significant levels of unemployment have led to declines in all segments of construction activity in our markets. Demand for our products has fallen, and our results of operations have been negatively impacted. If these conditions continue or worsen, we could incur significant losses, which could materially and adversely affect our business and financial condition.

Economic factors may fluctuate more widely in regional markets than in the United States as a whole. As a result, even though we sell in more than one region, our operating results are subject to significant fluctuation from region to region. Because we sell most of our cement in Texas and southern California, and because cement sales have historically contributed more to our profitability than any other product line, a significant further decline in cement demand or prices in Texas or southern California could materially and negatively impact our profitability.

Our product prices are subject to material changes in response to relatively minor fluctuations in supply and demand, which can be affected by economic and other market conditions beyond our control. In the last year we

10

Table of Contents

have experienced both volume and price declines in the Texas and California cement markets and the Texas aggregates and ready mix markets. We may face more price or volume declines in the future. Due to the high fixed cost nature of our business, our operating results may be significantly affected by relatively small changes in production volumes. Moreover, our industry is characterized by low backlogs, which means that our results of operations may be promptly affected by short term economic fluctuations.

Our customers are engaged in a substantial amount of construction in which government funding is a component and, as a result, can be subject to government budget constraints and political shifts resulting in funding reallocation. In February 2009, President Obama signed into law an economic stimulus plan, which provides billions of dollars in new funding for infrastructure construction projects. We expect these funds will have a positive impact on demand for our products for a period of time, but the length and depth of that demand cannot be predicted. The current multi-year federal highway funding legislation expired on September 30, 2009, but was extended by an authorization bill through the end of calendar year 2010. Funding provided by this legislation has historically comprised a majority of California and Texas’ public works spending. Failure to pass new long-term federal highway funding legislation upon expiration of the current extension period, or a significant decrease in public works spending in either state for any reason, including the recent budget crisis in the state of California, could have a material and adverse effect on our operating results.

The regional nature of our business also makes us vulnerable to changes in regional weather and its impact on the regional construction industry. Our operating profit is generally lower in our fiscal quarter ending on the last day of February than it is in our other three fiscal quarters because of the impact of winter weather on construction activity. Although southern California and Texas are regions characterized by longer periods of favorable weather, extended periods of inclement weather can reduce construction activity at any time of the year.

Some of our competitors are larger and have greater financial resources or less financial leverage than we do. As a result, these competitors may cope better than we can with adverse economic or market conditions and any downward pressure on prices or volumes.

The availability and pricing of energy could materially and adversely affect our results of operations.

We are dependent upon energy sources, including electricity and fossil fuels. Prices for energy are subject to market forces largely beyond our control. We have generally not entered into any long-term contracts to satisfy our fuel and electricity needs, with the exception of coal which we purchase from specific mines pursuant to contracts that expire on December 31, 2011 and May 31, 2014. Despite our long-term coal contracts, we expect our coal supplies could be interrupted in the event of rail service disruptions or mine failures. If we are unable to meet our requirements for fuel and electricity, we may experience interruptions in our production.

Price increases that we are unable to pass through in the form of price increases for our products, or disruption of the uninterrupted supply of fuel and electricity, could adversely affect our results of operations.

The enforcement of environmental, health and safety laws and regulations may result in liability for civil or criminal fines or penalties or curtailment or suspension of our operations. We may become liable for environmental injury to persons or property. We may incur substantial expenditures to comply with changes in such laws and regulations.

We are subject to various federal, state and local environmental, health and safety laws, regulations and permits as described more fully under the caption “Environmental Matters” in Item 1, Business. The U.S. Environmental Protection Agency, the Occupational Safety and Health Administration, the Mining Safety and Health Administration and various state agencies are charged with enforcing these laws, regulations and permits. These agencies can impose substantial civil and criminal fines and penalties, as well as curtail or suspend our operations, for violations and non-compliance. Moreover, private parties may bring civil actions against us for injuries to persons and damages to property allegedly caused by our operations. We intend to comply with these laws, regulations and permits. However, from time to time we receive claims from federal and state regulatory agencies asserting that we are or may be in violation of certain of these laws, regulations and permits, or from private parties alleging that our operations have injured them or their property. See “Legal Proceedings” in

11

Table of Contents

Item 1, Business, for a description of certain claims. If violations of law, injury to persons, damage to property or contamination of the environment has been or is caused by the conduct of our business or hazardous substances or wastes used, generated or disposed of by us, we may be liable for such violations, injuries and damages and be required to pay the cost of investigation and remediation of such contamination. The amount of such liability could materially and adversely affect our results of operations.

Changes in federal or state laws, regulations or permits or discovery of currently unknown conditions could increase our cost of compliance, require additional capital expenditures, reduce or shut down production or hinder our ability to expand or build new production facilities. See “Environmental” in Item 1, Business, for a description of certain existing or proposed laws and regulations affecting our industry. Although we cannot yet predict the final nature of these laws and regulations, each one could have a significant impact on the cement manufacturing industry and a material adverse effect on our results of operations.

Our construction project to expand our Hunter, Texas cement plant has been delayed. We expect to resume construction by November 2010. The capital expenditures that we have already incurred for construction of the Hunter plant, and future capital expenditures for expansion of our business may not strengthen our competitive position.

In order to strengthen our competitive position, in recent years we have made significant capital expenditures to expand our facilities. In October 2007 we commenced construction on a project to expand our Hunter, Texas cement plant by approximately 1.4 million tons of advanced dry process annual cement production capacity. In May 2009 we temporarily halted construction on the project because we believed that economic and market conditions made it unlikely that current cement demand levels in Texas would permit the new kiln to operate profitably if the project was completed as originally scheduled. We expect to resume construction by November 2010. We have not entered into a new construction contract to complete the construction, so no schedule for completion has yet been determined. As of May 31, 2010, we had incurred $293.9 million, excluding capitalized interest of $16.3 million related to the project, of which $289.4 million had been expended. Until we determine the period over which the construction will occur, we cannot accurately estimate the cost of completing the project.

Our Hunter plant expansion, when construction resumes, and future expansion projects could experience construction delays or cost overruns for many reasons, including inclement weather, unavailability of materials or equipment, unanticipated site conditions and unanticipated problems in obtaining required permits during construction, startup and commissioning. We currently have all material environmental authorizations necessary for the Hunter plant expansion. We cannot assure you that market conditions will be favorable, that the actual cost of the plant expansion will not exceed our cost projections or that additional financing, if required, will be available on acceptable terms. We cannot assure you that our expanded Hunter plant or any new plant, when completed, will operate in accordance with its design specifications. If it does not, we could incur additional costs or production delays while problems are corrected. As we do not have control over the cost or the outcome of these factors, we cannot assure you that any planned expansion will occur on schedule or within budget.

As a result of these or other unanticipated factors, the Hunter project or any other future expansionary capital expenditures may not improve our competitive position and business prospects as anticipated. If certain of the events described above occur, it could materially and adversely affect our results of operations.

Future litigation could affect our profitability.

The nature of our business exposes us to various litigation matters. These matters may include claims by private parties or governmental entities seeking compensatory and punitive damages, environmental clean up costs, penalties, injunctive relief or other types of recovery. The types of claims to which we may be subject include:

| • | Product liability claims that our products have caused buildings, roadways, oil wells, or other structures to fail or not comply with specifications. |

12

Table of Contents

| • | Contract claims that we have breached a legally enforceable agreement in a manner that has damaged one or more other parties. |

| • | Employment claims that we violated anti-discrimination, wage and hour, fair labor standards or other employment related laws, regulations or contracts. |

| • | Claims by regulatory or administrative bodies that we have violated specified laws, regulations or permit conditions. |

| • | Environmental claims that we have exposed individuals to or contaminated property with toxic or hazardous substances. |

| • | Other tort claims that our actions or omissions caused damage to persons or property. |

See “Legal Proceedings” in Item 1, Business, for a description of certain legal proceedings. We contest these matters vigorously and make insurance claims where appropriate. However, litigation is inherently costly and unpredictable, making it difficult to accurately estimate the outcome of existing or future litigation. Although we make accruals as we believe warranted and in accordance with generally accepted accounting principles, the amounts that we accrue could vary significantly from any amounts we actually pay due to the inherent uncertainties and shortcomings in the estimation process. Future litigation costs, settlements or judgments could materially and adversely affect our results of operations.

Unexpected equipment failures, catastrophic events and scheduled maintenance may lead to production curtailments or shutdowns.

Due to the high fixed cost nature of our business, interruptions in our production capabilities may cause our productivity and results of operations to decline significantly during the affected period. Our manufacturing processes are dependent upon critical pieces of equipment, such as our kilns and finishing mills. This equipment, on occasion, may be out of service as a result of unanticipated failures or damage during accidents. In addition to equipment failures, our facilities are also subject to the risk of catastrophic loss due to unanticipated events such as fires, explosions or violent weather conditions. In addition, our operations in California are susceptible to damage from earthquakes, for which we maintain only a limited amount of earthquake insurance and, therefore, we are not fully insured against earthquake risk. We also have one to two-week scheduled outages at least once a year to refurbish our cement production facilities. Any significant interruption in production capability may require us to make significant capital expenditures to remedy problems or damage as well as cause us to lose revenue due to lost production time, which could have a material adverse effect on our results of operations.

We rely heavily on third-party truck and rail transportation, which is subject to delays and rate fluctuations.

We rely heavily on third-party truck and rail transportation to ship our products to customers and coal, our primary fuel, to our plants. Rail and trucking operations are subject to capacity constraints, high fuel costs and various hazards, including extreme weather conditions and slowdowns due to labor strikes and other work stoppages. If there are material changes in the availability or cost of rail or trucking services, we may not be able to arrange alternative and timely means to ship our products or coal at a reasonable cost, which could lead to interruptions or slowdowns in our businesses or increases in our costs, either of which could materially and adversely affect our results of operations.

Implementation of our growth strategy has certain risks.

As part of our growth strategy, we may expand existing facilities, build additional plants, acquire other reserves or operations, enter into joint ventures or form strategic alliances that we believe will expand or complement our existing business. If any of these transactions occur, they will likely involve some or all of the following risks:

| • | the potential disruption of our ongoing business; |

| • | the diversion of resources and management’s time and attention; |

13

Table of Contents

| • | the inability of management to maintain uniform standards, controls, procedures and policies; |

| • | the difficulty of managing the operations of a larger company; |

| • | the risk of becoming involved in labor, commercial or regulatory disputes or litigation related to the new enterprise; |

| • | the risk of contractual or operational liability to joint venture participants or to third parties as a result of our participation; |

| • | the difficulty of competing for acquisitions and other growth opportunities with companies having greater financial resources than we have; and |

| • | the difficulty of integrating the acquired operations and personnel into our existing business. |

Pursuing our growth strategy may be required for us to remain competitive, but we may not be able to complete any such transactions or obtain financing, if necessary, for such transactions on favorable terms or at all. Future transactions may not improve the competitive position and business prospects as anticipated, and could reduce sales or profit margins, and, therefore, our results of operations if they are not successful.

Our business could suffer if cement imports from other countries significantly increase or are sold in the U.S. in violation of U.S. fair trade laws.

The cement industry has in the past obtained antidumping orders imposing duties on imports of cement and clinker from other countries that violated U.S. fair trade laws. Currently, an antidumping order against cement and clinker from Japan is expected to remain in effect until at least 2011. As has always been the case, cement operators with import facilities can purchase cement from other countries, such as those in Latin America and Asia, which could compete with domestic producers. In addition, if currently proposed environmental regulations increase the costs of domestic producers compared to foreign producers that are not subject to similar regulations, imported cement could achieve a significant cost advantage over domestically produced cement. An influx of cement or clinker products from countries not subject to antidumping orders, or sales of imported cement or clinker in violation of U.S. fair trade laws, could materially and adversely affect our results of operations.

Additionally, fluctuations in the value of the dollar could affect our business. A strong U.S. dollar makes imported cement less expensive, resulting in more imports into the United States by foreign competitors, while a weak U.S. dollar has the opposite effect. If the dollar strengthens appreciably against other world currencies, it will encourage additional imports of cement, which could negatively affect our results of operations.

We have a substantial amount of debt which will require a significant amount of cash to service and which could have important consequences for us. Our ability to generate cash from operations or borrowing depends on many factors beyond our control.

Our debt could have important consequences for us. For example, it could:

| • | make it more difficult for us to satisfy our other obligations; |

| • | increase our vulnerability to general adverse economic and industry conditions; |

| • | require us to dedicate a substantial portion of our cash flow from operations to service our debt, thereby reducing the availability of our cash flow to fund working capital, capital expenditures, investments and other general corporate purposes; |

| • | limit our flexibility in planning for, or reacting to, changes in our business, the cement, aggregate and concrete industry or the markets in which we operate; |

| • | place us at a competitive disadvantage compared to our competitors that have less debt or debt with less restrictive terms; and |

| • | limit, among other things, our ability to borrow additional funds, even when necessary to maintain adequate liquidity. |

14

Table of Contents

Our ability to make payments on, or repay or refinance, our debt and to fund planned capital expenditures will depend largely upon the availability of financing and our future operating performance. In fiscal year 2010 we had a net loss of $38.9 million. Our future operating performance, to a certain extent, is subject to general economic, financial, competitive, legislative, regulatory and other factors that are beyond our control. In addition, our ability to borrow funds in the future if needed to make payments on our debt will depend on our satisfaction of the covenants in our senior secured credit facility and our other current and future debt agreements. We cannot assure you that our business will generate sufficient cash flow from operations or that future borrowings will be available to us under our senior secured credit facility or from other sources in an amount sufficient to pay our debt or to fund our other liquidity needs. If we are unable to generate sufficient cash flow to meet our debt service requirements, we may have to renegotiate the terms of our debt or obtain additional financing. We cannot assure you that we will be able to refinance any of our debt or obtain additional financing on commercially reasonable terms or at all. If we were unable to meet our debt service requirements or obtain new financing under these circumstances, we would have to consider other options, such as:

| • | sales of certain assets to meet our debt service obligations; |

| • | sales of equity; and |

| • | negotiations with our lenders to restructure the applicable debt. |

Our debt agreements may restrict, or market or business conditions may limit, our ability to do any of these things.

The financing agreements governing our debt contain various covenants that limit our discretion in the operation of our business and could lead to acceleration of debt and foreclosure on collateral.

Our financing agreements impose operating and financial restrictions on our activities. Restrictions contained in these financing agreements also limit or prohibit our ability and certain of our subsidiaries ability to, among other things:

| • | pay dividends to our stockholders; |

| • | make certain investments and capital expenditures; |

| • | incur additional debt or sell preferred stock; |

| • | create liens; |

| • | restrict dividend payments or other payments from subsidiaries to us; |

| • | engage in consolidations and mergers or sell or transfer assets; |

| • | engage in transactions with our affiliates; and |

| • | sell stock in our subsidiaries. |

We are not required to maintain any financial ratios or covenants unless an event of default occurs or the unused portion of our borrowing base under our senior secured credit facility is less than $40 million, in which case we must comply with a fixed charge coverage ratio of 1.1 to 1.0.

At May 31, 2010 we were in compliance with our loan covenants. Various risks and events beyond our control could in the future affect our ability to comply with these covenants and maintain financial tests and ratios. If we cannot comply with the fixed charge coverage ratio in our senior secured credit facility and the unused portion of our borrowing base falls below $40 million, we may not be able to borrow under this facility. At May 31, 2010, our fixed charge coverage ratio was .7 to 1.0. Given this ratio, we may use only $117.7 million of the borrowing base as of such date. Because $28.5 million of the borrowing base was used to support letters of credit, the maximum amount we could borrow as of May 31, 2010 was $89.2 million. In addition, failure to comply with any of the covenants in our existing or future financing agreements could result in a default under those agreements and under other agreements containing cross-default provisions. A default would permit

15

Table of Contents

lenders to accelerate the maturity of the debt under these agreements, terminate any commitments they made to supply us with further funds and foreclose on collateral. Under these circumstances, we might not have sufficient funds or other resources to satisfy all of our obligations. In addition, the limitations imposed by our financing agreements on our ability to incur additional debt and to take other actions might significantly impair our ability to obtain other financing. We cannot assure you that we will be able to obtain waivers or amendments of our financing agreements, if necessary, on acceptable terms or at all.

| ITEM 1B. | UNRESOLVED STAFF COMMENTS |

None.

| ITEM 2. | PROPERTIES |

General

As of May 31, 2010, we:

| • | manufactured cement at three facilities in Texas and California using limestone from adjacent quarries, |

| • | produced natural aggregates (sand, gravel and crushed limestone) from 12 quarries in Texas, Louisiana and Oklahoma, |

| • | manufactured lightweight aggregates from three facilities in Texas, Colorado and California using shale and clay from adjacent quarries, and |

| • | manufactured ready mix concrete at 59 plants in Texas, Louisiana and Arkansas. |

In addition, we operated 8 cement distribution terminals, 5 aggregate distribution terminals, and 5 cement and aggregate packaging facilities.

16

Table of Contents

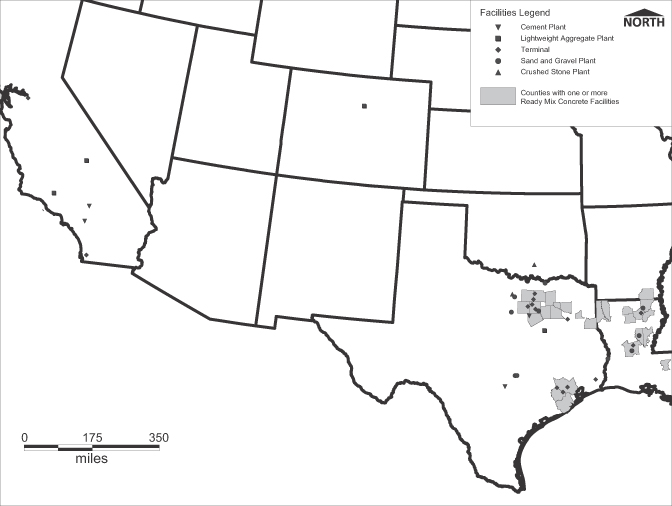

The following map shows the locations of our cement, aggregate and ready mix manufacturing and distribution facilities at May 31, 2010, all of which are in the U. S.

Reserves are estimated by our geological and mine services group based upon drilling and testing data sufficient to elevate reserves to probable status. The estimates of reserves are of recoverable stone, sand, gravel, shale and clay of suitable quality for economic extraction, recognizing reasonable economic and operating constraints as to excavation, maximum depth of overburden, permit or zoning restrictions and lease terms on any leased property. Aggregate resource holdings are generally not reported as reserves until a recovery plan has been developed. The average estimated minimum reserves in years shown below are based on normalized annual rates of production. Certain individual locations may be subject to more limited reserves.

17

Table of Contents

Cement

Our cement production facilities are located at three sites in Texas and California: Midlothian, Texas, south of Dallas/ Fort Worth, the largest cement plant in Texas; Hunter, Texas, south of Austin; and Oro Grande, California, near Los Angeles. The following table summarizes certain information about our cement manufacturing facilities at May 31, 2010:

| Plant |

Rated Annual Productive Capacity— Tons of Clinker |

Manufacturing Process |

Service Date |

Internally Estimated Minimum Reserves—Years | ||||

| Midlothian, TX |

2,200,000 | Dry | 2001 | 46 | ||||

| Hunter, TX |

850,000 | Dry | 1979 | 100 | ||||

| Oro Grande, CA |

2,200,000 | Dry | 2008 | 48 | ||||

| Total |

5,250,000 | |||||||

Reserves identified with the facilities shown above are contained on approximately 5,579 acres of land we own. At May 31, 2010, we estimate our total proven and probable limestone reserves to be approximately 908 million tons.

Our cement manufacturing facilities include kilns, crushers, pre-heaters/calciners, coolers, finish mills and other equipment used to process limestone and other raw materials into cement, as well as equipment used to extract and transport the limestone from the adjacent quarries. The cement manufacturing facilities are served by rail and truck. We believe the facilities are generally in good condition and suitable for the purposes for which they are used.

Natural Aggregates

Our natural aggregate operations are conducted from facilities primarily serving the Dallas/Fort Worth, Austin and Houston areas in Texas; the southern Oklahoma area; and the Alexandria and Monroe areas in Louisiana. The following table summarizes certain information about our natural aggregate production facilities at May 31, 2010.

| Type of Facility and General Location |

Number of Plants |

Rated Annual Productive Capacity |

Internally Estimated Minimum Reserves—Years | |||

| Crushed Limestone: |

||||||

| North Central Texas |

1 | 9.0 million tons | 30 | |||

| Oklahoma |

1 | 6.0 million tons | 90 | |||

| Sand & Gravel: |

||||||

| North Central Texas |

4 | 4.3 million tons | 10 | |||

| Central Texas |

2 | 3.5 million tons | 6 | |||

| Louisiana |

4 | 1.5 million tons | 10 |

Reserves identified with the facilities shown above and additional reserves available to support future plant sites are contained on approximately 25,000 acres of land, of which we own approximately 17,475 acres and lease the remainder. We typically acquire an option on a property prior to lease or purchase. At May 31, 2010, we estimate our total proven and probable aggregate reserves to be approximately 810 million tons, of which 78% are owned and 22% are leased.

Our crushed limestone production facilities include primary and secondary crushers used to process limestone extracted from quarries we own adjacent to each plant, as well as equipment to produce manufactured sand at each site. The stone facilities are served by rail and truck. Our sand and gravel production facilities include excavating or dredging equipment used to extract sand and gravel from open pits owned or leased near each plant. The sand and gravel facilities are served by truck. We use mining contractors to provide blasting services at our stone quarries and to extract limestone to fulfill certain sales contracts for larger specialty products such as rip rap used in erosion control. We believe the facilities are generally in good condition and suitable for the purposes for which they are used.

18

Table of Contents

Lightweight Aggregates

Our lightweight aggregate manufacturing facilities serve primarily the Dallas/Fort Worth, Austin and Houston areas in Texas; the Oakland/San Francisco and Los Angeles areas in California; and the Denver area in Colorado. The following table summarizes certain information about our lightweight aggregate production facilities at May 31, 2010.

| Location |

Number of Plants |

Rated Annual Productive Capacity |

Internally Estimated Minimum Reserves—Years | |||

| North Central Texas |

1 | .8 million cu. yds. | 100 | |||

| California |

1 | .3 million cu. yds. | 100 | |||

| Colorado |

1 | .5 million cu. yds. | 25 |

Reserves identified with the facilities shown above are contained on approximately 4,062 acres of land, of which we own approximately 1,291 acres and lease the remainder. At May 31, 2010, we estimate our total proven and probable shale and clay reserves to be approximately 147 million tons.

Our lightweight aggregate manufacturing facilities include kilns, crushers, coolers and other equipment used to process shale and clay into lightweight aggregate, as well as equipment used to extract and transport the shale and clay from the adjacent quarries. The lightweight aggregate facilities are served by rail and truck. We believe the facilities are generally in good condition and suitable for the purposes for which they are used.

Ready-Mix Concrete

Our ready-mix concrete operations are situated in three areas in Texas (Dallas/Fort Worth/Denton, Houston and east Texas), in north and central Louisiana, and at one location in southern Arkansas. The following table summarizes certain information about our ready mix concrete facilities at May 31, 2010.

| Location |

Number of Plants | Number of Trucks | ||

| Texas |

45 | 371 | ||

| Louisiana |

13 | 75 | ||