Attached files

UNITED STATES SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

Form 10-K

|

x

|

ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934

|

|

For the fiscal year ended March 31, 2010

|

|

|

or

|

|

|

o

|

TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934

|

|

For the transition period from to

|

Commission file number: 000-51323

Micrus Endovascular Corporation

(Exact name of registrant as specified in its charter)

|

Delaware

|

23-2853441

|

|

(State or other jurisdiction of

incorporation or organization)

|

(I.R.S. Employer

Identification No.)

|

|

821 Fox Lane

|

95131

|

|

San Jose, California

(Address of principal executive offices)

|

(Zip Code)

|

(408) 433-1400

(Registrant’s telephone number, including area code)

Securities registered pursuant to Section 12(b) of the Act:

|

Title of each class

|

Name of each exchange on which registered

|

|

Common Stock, $0.01 par value per share

|

The NASDAQ Stock Market, LLC

|

Securities registered pursuant to Section 12(g) of the Act:

None

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes o No x

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Exchange Act. Yes o No x

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes x No o

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§ 232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes o No o

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K (§ 229.405 of this chapter) is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. o

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company. See the definitions of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act. (Check one):

|

Large accelerated filer o

|

Accelerated filer x

|

Non-accelerated filer o

|

Smaller reporting company o

|

|

(Do not check if a smaller reporting company)

|

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act). Yes o No x

As of September 30, 2009, the aggregate market value of the registrant’s common stock held by non-affiliates of the registrant was $126.1 million based on the closing sale price of such stock as reported on the NASDAQ Global Market. Shares of common stock held by each officer and director as of that date and by each person who owned 5% or more of the registrant’s outstanding common stock as of September 30, 2009 have been excluded in that such persons may be deemed to be affiliates. This determination of affiliate status is not necessarily a conclusive determination for other purposes.

As of May 28, 2010 registrant had outstanding 16,571,131 shares of common stock, $0.01 par value per share.

DOCUMENTS INCORPORATED BY REFERENCE

The Registrant has incorporated by reference portions of its Proxy Statement for its 2010 Annual Meeting of Stockholders to be filed with the Securities and Exchange Commission within 120 days after the close of the fiscal year covered by this annual report.

MICRUS ENDOVASCULAR CORPORATION

|

Page

|

|||||

|

3

|

|||||

|

23

|

|||||

|

36

|

|||||

|

36

|

|||||

|

37

|

|||||

|

37

|

|||||

|

37

|

|||||

|

40

|

|||||

|

41

|

|||||

|

54

|

|||||

|

55

|

|||||

|

86

|

|||||

|

86

|

|||||

|

86

|

|||||

|

87

|

|||||

|

87

|

|||||

|

87

|

|||||

|

87

|

|||||

|

87

|

|||||

|

87

|

|||||

|

|

88

|

||||

2

FORWARD-LOOKING STATEMENTS

Certain information contained in or incorporated by reference in this Report contains forward-looking statements that involve risks and uncertainties. The statements contained in this Report that are not purely historical are forward-looking statements within the meaning of Section 27A of the Securities Act of 1933, as amended (the “Securities Act”), and Section 21E of the Securities Exchange Act of 1934, as amended (the “Exchange Act”), including statements regarding our expectations, beliefs, intentions or strategies regarding the future. All forward-looking statements included in this Report are based on information available to us on the date hereof, and we assume no obligation to update any such forward-looking statements. Our actual results could differ materially from those discussed herein. Factors that could cause or contribute to such differences include, but are not limited to, those discussed in Item 1A, Risk Factors, and elsewhere in this Report. References herein to “Micrus,” “the Company,” “we,” “our,” “us” and similar words or phrases are references to Micrus Endovascular Corporation and its subsidiaries, unless the context otherwise requires. Unless otherwise provided in this Report, trademarks identified by ® and ™ are registered trademarks or trademarks, respectively, of Micrus Endovascular Corporation or its subsidiaries. All other trademarks are the properties of their respective owners.

The Company

We develop, manufacture and market implantable and disposable medical devices used in the treatment of cerebral vascular diseases. Our products are used by interventional neuroradiologists, interventional neurologists and endovascularly trained neurosurgeons to treat both cerebral aneurysms responsible for hemorrhagic stroke and intracranial atherosclerosis which may lead to ischemic stroke. Hemorrhagic and ischemic stroke are both significant causes of death and disability worldwide.

Our product lines consist of endovascular systems that enable a physician to gain access to the brain in a minimally invasive manner through the vessels of the arterial system. We believe that our products provide a safe and reliable alternative to more invasive neurosurgical procedures for treating aneurysms. Our proprietary family of embolic coils anatomically conforms to a wide diversity of aneurysm shapes and sizes and rapidly deploys. We also supply products such as guide catheters, microcatheters, occlusion balloon catheters, guidewires and stents for the treatment of both hemorrhagic and ischemic stroke. In addition, our Cerecyte® microcoil product line incorporates bioactive filaments of an absorbable material called polyglycolic acid (“PGA”), which reside within the central lumen of our microcoils. We believe, based on interim data from the Cerecyte Coil Trial (“CCT”) and single center peer review journal publications, that Micrus platinum and Cerecyte coils result in superior clinical outcomes when compared to data from the International Subarachnoid Aneurysm Trial (“ISAT”).

We continue to expand our product line beyond microcoils and access systems. In January 2006, we entered into a license, development and distribution agreement with Biotronik AG (“Biotronik”) which provides us with exclusive access to certain stent technologies for neurovascular applications. In February 2006, Biotronik received CE Mark authorization for the PHAROS® stent for both the treatment of cerebral aneurysms and the treatment of ischemic disease (atherosclerosis). In March 2006, we launched our PHAROS® stent in certain countries that recognize the CE Mark, providing us with our first commercial product for the treatment of ischemic disease. The PHAROS® Vitesse® is our second generation balloon-expandable stent for intracranial ischemic stenosis and the treatment of wide-neck aneurysms. In June 2008, we launched the PHAROS® Vitesse® intracranial stent for commercial distribution in the European Union and all other countries that recognize the CE Mark. In August 2009, we received U.S. Food and Drug Administration (“FDA”) approval of our investigational device exemption for the PHAROS® Vitesse® Intracranial Stent Study for Ischemic Therapy (“VISSIT”). The VISSIT study is the first industry-sponsored, randomized, prospective clinical trial designed to compare the clinical outcomes between patients who are stented for intracranial ischemic stenosis versus treated with medical therapy. We are currently enrolling patients in our VISSIT Investigational Device Exemption (“IDE”) trial in the United States, Europe and China.

On November 30, 2006, we completed the acquisition of VasCon, LLC (“VasCon”), a privately held company engaged in the development and manufacture of vascular access and delivery devices. The acquisition of VasCon adds expertise in developing clinically advanced access and catheter systems to our core competencies and provides us with manufacturing capabilities that will facilitate cost reductions for a wide range of our products. In connection with the acquisition, we formed Micrus Design Technology, Inc. (“MDT”) to develop and manufacture neurovascular access and delivery products for us, including our family of Courier® microcatheters, Neuropath® guide catheters and our Ascent® Occlusion Balloon Catheter. On January 1, 2009, we merged MDT into Micrus Endovascular Corporation.

3

In October 2007, we entered into a Stock Purchase Agreement with The Cleveland Clinic Foundation (“The Cleveland Clinic”) and acquired ReVasc Technologies, Inc. (“ReVasc”), a wholly-owned subsidiary of The Cleveland Clinic. This acquisition provides us with an exclusive license to revascularization technology for the treatment of intra-cranial thrombus or clot which can also cause ischemic stroke. In January 2008, we entered into a license, development and commercialization agreement with Genesis Medical Interventional, Inc. (“Genesis”). Under the terms of the agreement, we licensed the rights to Genesis’ F.A.S.T. Funnel Catheter and clot retrieval system for the treatment of ischemic stroke.

In December 2007, we received regulatory approval to sell our stretch-resistant microcoils in Japan and in July 2008, we received approval from Ministry of Health, Labor and Welfare (“MHLW”) to sell our Cerecyte® microcoils in Japan. We currently market our products through a direct sales force in the United States, Canada, the United Kingdom, Germany, Austria and France. We market our products through a network of exclusive distributors in the rest of Europe, Latin America, Asia and the Middle East.

In fiscal 2008, we launched our Cashmere® microcoil systems and our Courier® ENZO® deflectable microcatheter. The Cashmere® is a conformable and stretch-resistant bare platinum or Cerecyte® microcoil designed to provide stable framing or filling of aneurysms that may require a softer microcoil, such as aneurysms with irregular shapes or ruptured aneurysms. The Courier® ENZO® deflectable microcatheter is designed to offer improved maneuverability through the brain’s tortuous vasculature and to enable in vivo repositioning of the microcatheter in the aneurysm, allowing physicians to more efficiently fill aneurysms, which may lead to improved outcomes. We believe that ENZO® is the only deflectable microcatheter available for use in the neurointerventional market.

In fiscal 2009, we launched the Neuropath® guide catheter, which combines robust proximal support with a highly flexible and visible tip designed to facilitate atraumatic vascular access. The Neuropath® guide catheter is used as a conduit for delivery of the microcatheter or other devices, such as coils, stents and balloons, to the aneurysm. We intend to continue to pursue this non-embolic product line expansion with the goal of increasing our revenue opportunity per procedure. We also launched the DeltaPaq™ microcoil system for the treatment of cerebral aneurysms in both bare platinum and Cerecyte® versions. Our DeltaPaq™ microcoil is based on the proprietary Delta Wind™ technology which is designed to enable physicians to achieve greater coil packing density within the aneurysm which may reduce the rate of recanalization and the need for re-treatment. The DeltaPaq™ microcoil system supplements our framing and finishing coils in the filling segment of the coil market. We also introduced a new detachment control box and remote control cable. The Enpower® Detachment Control Box features updated electronic controls, a new ergonomic interface as well as a single long life lithium ion battery system which obviates the need to replace batteries for each case. The remote cable enables physicians to detach the coil using an in-the-sterile-field control system. In fiscal 2009, we received both 510(k) clearances and CE Mark authorizations for our DeltaPlush microcoils, EnPower® Detachment Control System, Ascent® Occlusion Balloon Catheter and One2One™ family of guidewires.

In fiscal 2009, we also completed enrollment in the CCT, a trial which was designed to assess the differences in clinical outcomes between our Cerecyte microcoils and bare platinum microcoils. In October 2008, we also initiated the Presidio® And Cerecyte® (“PAC”) large and giant aneurysm study, which is a prospective registry designed to evaluate the differences in clinical outcomes between our Cerecyte® microcoils and bare platinum microcoils specifically in large and giant aneurysms.

In fiscal 2010, we launched our DeltaPlush™ microcoil, which has been designed to be our softest finishing coil. The DeltaPlush™ microcoil incorporates our exclusive Delta Wind™ technology resulting in a microcoil with the softness and flexibility to find and fill gaps, helping to provide superior finishing at the aneurysm neck.

In fiscal 2010, we also launched our Ascent® Occlusion Balloon Catheter which is intended for use in the blood vessels of the peripheral and neurovasculature where temporary occlusion is desired. The Ascent® balloon catheter enables physicians to use a vessel selective technique of temporary arterial occlusion which is useful in selectively stopping or controlling blood flow and assisting in the placement of coils in a wide neck aneurysm.

In fiscal 2010, we received regulatory approval from the Republic of Korea to sell our MicruSphere® and HeliPaq® microcoils.

On September 30, 2009, we entered into a Distribution Agreement (the “IDS Distribution Agreement”) with IDS (Hong Kong) Ltd. (“IDS”) pursuant to which IDS serves as our exclusive distributor of implantable and disposable medical devices used in the treatment of neurovascular diseases in Hong Kong and China. IDS will promote and market our products in Hong Kong and China and is required to purchase a certain amount of the products, in escalating quantities, over a five year period commencing upon receiving regulatory approval in order to maintain its exclusive distributor status in such territories. In connection with the IDS Distribution Agreement, we also entered into an agreement with IDS to provide marketing and sales support to IDS.

4

We plan to begin selling our products in China upon receiving regulatory and reimbursement approvals. The timing of these approvals is uncertain. We did not have any sales in China during fiscal 2010, but we currently anticipate selling our products in China in fiscal 2011.

We have executive offices in San Jose, California and sales offices in Switzerland and the United Kingdom as well as a development and manufacturing facility in Miramar, Florida. We were incorporated under the laws of the State of Delaware in 1996.

Information on revenues, gross profits and total assets for our business segments and by geographic area appears in Note 14 of the “Notes to Consolidated Financial Statements” for the year ended March 31, 2010, which are included in “Item 8 – Financial Statements and Supplementary Data” of this report and are incorporated herein by reference.

Industry Overview

Strokes can be either hemorrhagic stroke, most often caused by ruptured cerebral aneurysms, or ischemic stroke, caused by the narrowing or blockage of vessels within or leading to the brain. Both hemorrhagic and ischemic stroke often result in irreversible neurological impairment or death. According to the American Heart Association, stroke is the third leading cause of death in the United States. Patients who survive a stroke are often left with disabilities, including paralysis, coma, impaired cognition, decreased coordination, loss of visual acuity, loss of speech, loss of sensation or some combination of these conditions. A significant need for effective prevention and treatment of stroke exists because of the severity of the disorder, its prevalence in society, the shortcomings of current therapies and the high cost of treatment and care.

As noted above, hemorrhagic stroke is most often caused by the bulging or rupture of cerebral aneurysms. A cerebral aneurysm is an outward bulging of an artery in the brain that can develop at weak points in the arterial wall. In some cases, the patient will experience symptoms such as headache, blurred vision or dizziness as the aneurysm grows, but in many cases patients will have no symptoms. The most devastating complication of a cerebral aneurysm occurs when the aneurysm ruptures, decreasing blood flow to brain tissue and leading to increased pressure on the brain. Rupture of a cerebral aneurysm typically occurs suddenly and without warning, often leading to catastrophic brain injury or death.

Historically, patients diagnosed with a cerebral aneurysm that has ruptured or is determined to be at risk of rupturing underwent a craniotomy and aneurysmal clipping, a highly-invasive surgical procedure in which a neurosurgeon creates an opening in the skull, dissects or retracts brain tissue to gain access to the aneurysm, and places a metal clip at the base of the aneurysm to stop further blood flow into the aneurysm, halting its growth and preventing future rupture. This procedure is typically performed by a neurosurgeon at a specialized hospital or medical center. Aneurysmal clipping requires a lengthy recovery time and has the significant expense, morbidity and complication risks associated with a major neurosurgical procedure.

In the 1990s, interventional neuroradiologists and to a lesser extent endovascularly trained neurosurgeons, who collectively are referred to in the industry as “neurointerventionalists,” started using an alternative procedure to clipping, known as embolic coiling, to treat cerebral aneurysms. Rather than reaching the aneurysm by opening the skull to gain access to the aneurysm in an embolic coiling procedure, access is obtained through a catheterization procedure in which the physician inserts a guidewire followed by a catheter into the femoral artery of the upper leg and threads them under fluoroscopy through the arterial system to the brain and ultimately into the opening of the aneurysm. The neurointerventionalist then typically advances a number of embolic coils through the microcatheter to fill the aneurysm. Embolic coils are small platinum coils that typically range in size from approximately 1.5 mm to 20 mm and once advanced through the microcatheter and into the aneurysm, they successively fill the aneurysm. The multiple strands of microcoils effectively form a barrier at the neck of the aneurysm which decreases, stagnates or stops blood flow into the aneurysm, enabling formation of a clot and scar tissue which prevent further growth or rupture of the aneurysm. Since the mid-1990s, embolic coiling has become a widely accepted treatment for cerebral aneurysms because it is a less invasive procedure than surgical clipping and results in lower overall treatment cost, shorter recovery times, and less trauma to the patient.

In 2002, The Lancet, a leading medical journal, published the results of the ISAT, an independent, randomized clinical trial involving 2,143 patients in Europe, North America and Australia that compared surgical clipping with embolic coiling as a method of treating cerebral aneurysms. The ISAT concluded, based on a survey of patients published in The Lancet in October 2002, that among the patients participating in the trial, endovascular intervention with detachable platinum coils resulted in a 23% relative and 7% absolute reduction in the risk of major brain injury or death compared with neurosurgical clipping of the aneurysm at one year follow up. The seven-year follow up data published in The Lancet in September 2005 indicated a continued clinical advantage for patients who underwent coiling versus clipping procedures.

5

Market Opportunity

According to the American Heart Association, approximately 720,000 strokes occur annually in the United States. Ischemic stroke affects approximately 620,000 patients annually while hemorrhagic stroke affects approximately 100,000 patients. We believe that a majority of the hemorrhagic strokes are caused by cerebral aneurysms. We believe that embolic coiling is being used to treat approximately 45% of the patients diagnosed with cerebral aneurysms in the United States. Industry sources also indicate that approximately 65-70% of patients diagnosed with cerebral aneurysms in certain European countries are treated using embolic coiling procedures. We believe that embolic coiling procedures can be used to treat a similar percentage of patients with cerebral aneurysms in the United States as awareness grows among patients and physicians of the advantages of embolic coiling. Industry sources estimate that in Japan embolic coiling is growing at an annual rate of approximately 15% and in China coiling procedures appear to be growing at greater than 20% year over year. The latest industry sources further estimate that the worldwide sale of endovascular devices for the treatment of hemorrhagic stroke was between $600 million to $700 million in 2008.

We believe that growth drivers in the market for embolic coiling products include the overall trend towards less invasive procedures, an increasing number of neurointerventionalists trained to perform embolic coiling procedures, and the aging population in which aneurysms occur with greater frequency.

The key challenges of embolic coiling procedures are the following:

|

•

|

Access to the Aneurysm Site. Specialized products are required to access the complex vasculature of the brain, properly access the aneurysm site and perform a coiling procedure. These access products include microcatheters and guidewires. In order to navigate the complex vascular anatomy of the brain, access products must have enough column strength to be pushed significant distances through this vasculature, yet be flexible enough to travel to distal portions of the brain without injuring blood vessels.

|

|

•

|

Framing and Filling the Aneurysm. In order to effectively treat an aneurysm, the neurointerventionalist must fill the aneurysm with a sufficient volume of coils to disrupt and stagnate blood flow, which is required for aneurysm to ultimately heal. Aneurysms vary in shape and size and, consequently, neurointerventionalists seek an embolic coiling solution that enables coils to conform to the aneurysm’s shape and most effectively fill the aneurysm without requiring extensive manipulation of the coil. Coils that frame, or conform to, the aneurysm wall reduce the risk of rupture, thus decreasing the opportunity for procedural complications. Additionally, microcoils that safely permit the interventionalist to increase the packing density of the aneurysm, will likely lead to improved clinical outcomes.

|

|

•

|

Coverage of the Neck of the Aneurysm. It is important to effectively cover the neck of the aneurysm with coils to help reduce recanalization and improve the chances of a better clinical outcome.

|

|

•

|

Deployment. Once embolic coils are placed in the aneurysm, the neurointerventionalist must be able to quickly and reliably detach the coils from the device positioning unit (“DPU”) within the aneurysm. Unreliable detachment mechanisms can lead to inadvertent retraction of the embolic coil as the neurointerventionalist withdraws the positioning unit only to discover that the coil is still attached. Further, any delay in deployment may increase procedure time and its attendant risks.

|

|

•

|

Recanalization. Industry sources estimate that recanalization, or the continued or renewed growth of the aneurysm, occurs in approximately 15% to 25% of aneurysms treated with embolic coiling. Experts believe that one of the reasons for recanalization is due to inadequate filling of the aneurysm with the embolic coils. Studies have shown that while the recanalization rate is higher for patients treated with embolic coiling procedures compared to aneurysm clipping, embolic coiling has been demonstrated to be a safer treatment approach for aneurysms. Therefore, embolic coiling solutions that decrease recanalization rates and reduce the need for retreatment are highly desirable.

|

|

•

|

Risk of Rupture. Embolic coiling solutions that enhance safety and limit the risk of rupture or re-rupture in the treatment of aneurysms are also essential. Successful framing and filling of the aneurysm requires precise placement of the embolic coil. Neurointerventionalists seek embolic coiling solutions that minimize stress on the aneurysm wall in the course of placing or repositioning the coil in order to reduce the risk of rupture.

|

The Micrus Solution

We are focused on a broad range of cerebral vascular treatments and have developed a proprietary embolic coiling solution, stents and access products that are designed to effectively access and treat cerebral aneurysms and ischemic disease. Complementing our bare platinum microcoil product line, we have also developed a line of microcoils that incorporate bioactive filaments. In addition, we have recently introduced the proprietary DeltaPaq™ and DeltaPlush™ microcoil systems which are designed to enable physicians to achieve greater coil packing density and uniformity of coils at the aneurysm neck.

6

Our solutions have the following key features:

Anatomically Conforming Coils. Our proprietary spherical MicruSphere®, Cashmere® and Presidio® microcoils deploy into a three-dimensional configuration that assumes an aneurysm’s shape upon deployment and are designed to provide effective framing of the aneurysm. Our microcoils are designed to require limited manipulation during placement, thereby reducing the need for significant microcoil repositioning thus reducing potential for procedural complications.

Enhanced Coverage of the Neck of the Aneurysm. We believe that effective neck coverage reduces the rate of recanalization. Our microcoils are designed to facilitate coverage of the neck of the aneurysm in two ways. First, the three dimensional configuration of our spherical MicruSphere®, Cashmere® and Presidio® microcoils provide the framework to stabilize the neck of the aneurysm. Second, our DeltaPaq™ filling coils and UltiPaq® and DeltaPlush™ finishing coils are designed to be soft and flexible, permitting coverage across the neck of the aneurysm.

Unique Framing and Filling Technology Designed to Increase Packing Density. Our Presidio® microcoils are stretch resistant microcoils designed to deliver stable, predictable aneurysm framing and filling to increase coverage of the aneurysm wall and neck with a single coil deployment. In addition, we have introduced a completely new coil technology to the market, called “Delta Wind.” This unique triangular shaped primary wind allows the DeltaPaq™ and DeltaPlush™ to change directions every quarter of a millimeter, far surpassing the filling and finishing performance capabilities of traditional round primary wind coils. The Delta Wind™ technology is designed to increase packing density which previous published studies have suggested lower the risk of coil compaction and recanalization rates.

Proprietary Finishing Coils. Our UltiPaq® and DeltaPlush™ microcoils are extra-soft, stretch-resistant finishing coils used to provide additional aneurysm neck coverage and to more thoroughly fill in the aneurysm after placement of one or more MicruSphere®, Presidio®, Cashmere® and/or DeltaPaq™ microcoils. We launched our DeltaPlush™ microcoil in January 2010. DeltaPlush™ has been designed to be our softest finishing coil.

Deployment Technology. Our proprietary electronic microcoil deployment system employs a resistive heating fiber deployment mechanism that enables neurointerventionalists to quickly and reliably deploy the microcoil. Our electronic microcoil deployment system has been designed so that microcoil deployment time remains consistent regardless of the number of coils used in the procedure. We believe that our electronic microcoil deployment system enables neurointerventionalists to more rapidly deploy microcoils and generally reduce procedure time. We have also recently introduced a change to our DPU which we believe enhances clinical performance while reducing our manufacturing costs.

Bioactive Technology. Cerecyte® is our proprietary microcoil product line that incorporates filaments comprised of PGA within the lumen of the microcoils. MicruSphere®, Cashmere®, Presidio®, HeliPaq® and UltiPaq®, DeltaPaq™ and DeltaPlush™ are all available in Cerecyte® versions. We are conducting two post market studies, a prospective randomized trial and a registry, which could provide additional data regarding the potential benefits of Cerecyte®. Both the CCT and Cerecyte® Registry completed enrollment in fiscal 2009 and the data is being assembled for presentation and submission to peer review journals in fiscal 2011.

Balloon Assisted Coiling. Our Ascent® Occlusion Balloon Catheter is a coaxial dual lumen balloon catheter designed for use over any 0.014 inch guidewire. The 0.014 dual lumen catheter is designed to improve the stability of the balloon potentially resulting in a more effective and safer procedure. It is intended to be used for temporary vascular occlusion and to assist in delivery of microcoils into the aneurysm.

Stent Platform. Our PHAROS® stent is a rapid exchange balloon-delivered device which enables the neurointerventionalist to deliver and deploy a stent in one step, eliminating the need for pre-dilation of the constricted vasculature. We believe this feature may reduce overall procedural time and cost. We believe that the balloon catheter marker bands combined with the radiopacity of the stainless steel stent provide for excellent visibility resulting in improved placement accuracy of deployment. We also believe that the PHAROS® stent’s combination of Rapid Exchange Technology™ and a trackable tip will enable physicians to effectively access the tortuous and distal anatomy of the brain. In March 2006, we launched the PHAROS® stent in certain countries outside of the United States that recognize the CE Mark. In March 2008, we filed an IDE with the FDA for our next generation stent, the cobalt chromium steel PHAROS® Vitesse®, for the treatment of neurovascular stenosis. In July 2008, we received FDA conditional approval of our IDE for the PHAROS® VISSIT study which allowed us to initiate the study. In August 2009, the FDA granted approval of the VISSIT study. The VISSIT study is the first industry sponsored, randomized, prospective clinical trial designed to compare the clinical outcomes between patients who receive a stent for the treatment of their intracranial ischemic stenosis versus being treated with medical therapy. We are currently enrolling patients in our VISSIT IDE trial in the United States, Europe and China.

7

Improved Access Products. We launched an access product line which includes the Courier® line of microcatheters, the Ascent® Occlusion Balloon Catheter, the Neuropath® guide catheter and the Watusi® line of guidewires. We believe that our Courier® microcatheters provide neurointerventionalists with more predictable and secure access to the complex and distal anatomy of the cerebral vasculature. The Neuropath® guide catheter combines robust proximal support with a highly flexible and visible tip designed to facilitate atraumatic vascular access. The Neuropath® guide catheter is used as a conduit for delivery of the microcatheter or other devices such as coils to the aneurysm. We intend to continue to pursue this non-embolic product line expansion with the goal of increasing our revenue opportunity per procedure.

Micrus Strategy

Our objective is to develop and commercialize innovative, minimally invasive medical devices that provide a comprehensive solution to physicians for the treatment of hemorrhagic and ischemic stroke. The key elements of our strategy to achieve our objective include:

Expand Our Hemorrhagic Market Share through Continued Product Innovation. We believe that our microcoils, catheters, balloons, wires, and stents offer safer, more effective and less technically demanding treatment options for neurointerventionalists which have resulted in the rapid growth of our revenues. We believe that continued product innovations such as the introductions of our proprietary DeltaPaq™ and DeltaPlush™ microcoils, Cerecyte® line of bioactive microcoils, our Cashmere® microcoils, our Presidio® microcoils, our Ascent® Occlusion Balloon Catheter, our Courier® microcatheters and our Neuropath® guide catheters will allow us to further grow our market share. We are continuing to develop new technologies which we believe may further enhance aneurysm occlusion and reduce the rate of recanalization.

Increase Our Per-Procedure Revenues. 6% of our revenue for fiscal 2010 has come from the sale of non-embolic products. This product line expansion includes stents, microcatheters, balloons, guidewires and accessories.

Enter the Ischemic Stroke Market. In October 2007, we acquired an exclusive license to revascularization and clot retrieval technology for the treatment of ischemic stroke through the acquisition of ReVasc now known as ReVive™ SE, from The Cleveland Clinic. In January 2008, we entered into a license, development and commercialization agreement with Genesis. Under the terms of the agreement, we licensed the rights to Genesis’ F.A.S.T. Funnel Catheter and clot retrieval and revascularization system for the treatment of ischemic stroke. The Genesis technology is now known as ReVive™ CX. Through our agreement with Biotronik, we launched our first product addressing the ischemic stroke market, our PHAROS® stent. We intend to continue developing and acquiring additional stent platforms for this market. In March 2008, we filed an IDE with the FDA for our next generation stent, the PHAROS® Vitesse®, for the treatment of intracranial stenosis. We are currently enrolling patients in our VISSIT IDE trial in the United States, Europe and China.

Leverage Our Sales and Marketing Expansion. We intend to continue to expand our direct sales force in North America, Europe and Asia as necessary and further increase our presence in the Asian markets through distributors. This expansion should provide us access to more hospitals, garner more per-procedure revenues and expand our market share.

Continue to Penetrate Asian Markets. We believe that Japan and China represent significant potential markets for our products and, in March 2006, we launched our sales and marketing efforts in Japan through our distribution partner, Goodman. In December 2007, we received regulatory approval to sell our stretch-resistant microcoils in Japan and we received regulatory approval for our Cerecyte® microcoils in July 2008. We will begin selling our products in China with the assistance of our Chinese distributor IDS upon receiving regulatory and reimbursement approvals.

License or Acquire Complementary Products and Technologies. In addition to growing our business through internal product development efforts, we will continue to look for opportunities to license and/or acquire technologies to provide solutions for the treatment of a variety of cerebral vascular conditions. In July 2005, we acquired certain deflectable catheter technologies from Vascular FX. In January 2006, we entered into a license, development and distribution agreement with Biotronik, a company with stent design and manufacturing expertise, pursuant to which we collaborate with Biotronik to develop certain neurovascular stent products. This agreement provides us with the exclusive worldwide right to market stent products developed jointly by Biotronik and us. In November 2006, we acquired certain neurovascular catheter patent and process technology through the acquisition of VasCon. In October 2007, we acquired an exclusive license to revascularization technology for the treatment of ischemic stroke through the acquisition of ReVasc from The Cleveland Clinic. In January 2008, we entered into a license, development and commercialization agreement with Genesis. Under the terms of the agreement, we licensed the rights to Genesis’ F.A.S.T. Funnel Catheter and clot retrieval system for the treatment of ischemic stroke. In April 2008, we entered into a co-development agreement with Chemence Medical Products, Inc. (“Chemence”) to jointly develop a liquid embolic product for the treatment of cerebral aneurysms using Chemence’s cyanoacrylate technology, development capabilities and intellectual property. In August 2009, we entered into a license, development and commercialization agreement with Flexible Stenting Solutions, Inc (“FSS”) to jointly develop a flow diversion product for neurovascular indications using both Micrus and FSS technology, development capabilities and intellectual property.

8

In January 2010, we entered into an exclusive license and option agreement with Bay Street Medical, Inc. (“Bay Street”), which granted us a worldwide exclusive license and option to purchase intellectual property assets held by Bay Street related to its proprietary stent delivery and locking technology. By continuing to acquire complementary products, we believe that we can address a broader range of physician and patient needs.

Products

The following table shows our principal products and indicates significant applications for these products. Most of our products are intended for single use and are either disposed of or, in the case of microcoils, remain in the patient after the procedure. All of our products set forth in the following table have received CE Mark authorization and, except for our PHAROS® stent, are covered by the FDA 510(k) process.

|

Product Line

|

Sizes

|

Product Description

|

||

MicruSphere® Microcoil

|

2-18 mm diameter

|

Three-dimensional framing microcoil; stabilizes the aneurysm. Available in bare platinum and Cerecyte®.

|

||

Presidio® Microcoil

|

4-20 mm diameter

|

Framing and filling coil to deliver more neck and wall coverage in a single deployment. Available in Cerecyte®.

|

||

Cashmere® Complex Microcoil

|

2-12 mm diameter

|

Three-dimensional framing and filling complex coil for aneurysms which require a softer coil. Available in Cerecyte® and stretch resistant platinum.

|

||

DeltaPaq™ Microcoil

|

1.5-10 mm diameter, up to 25cm in length

|

Filling microcoil featuring the new Delta Wind triangular primary wind featuring natural deflection points allowing the coil to change direction more easily, facilitating greater packing density. Available in bare platinum and Cerecyte®.

|

9

|

Product Line

|

Sizes

|

Product Description

|

DeltaPlush™ Microcoil

|

1.5mm-4mm, up to 8cm in length

|

Designed for finishing, DeltaPlush™ microcoil incorporates our exclusive Delta Wind™ technology resulting in a 10 system microcoil with the softness and flexibility to find and fill empty gaps and open spaces, to help provide superior finishing at the aneurysm neck. Available in bare platinum and Cerecyte®.

|

UltiPaq® Microcoil

|

2-4 mm diameter

|

Finishing microcoil; soft, stretch resistant, pliable microcoil designed to complete filling of the aneurysm. Available in bare platinum and Cerecyte®.

|

||

HeliPaq® HeliPaq SR® Microcoil

|

HeliPaq® 2-20 mm diameter; HeliPaq SR® 2-10 mm diameter

|

Filling microcoil; occludes aneurysm following framing. Available in bare platinum and Cerecyte®.

|

||

InterPaq® Microcoil

|

4 and 6 mm diameter

|

Filling microcoil; occludes aneurysm following framing. Available in bare platinum.

|

||

Cerecyte® Microcoil

|

2-20 mm diameter

|

Available in MicruSphere®, Cashmere®, Presidio®, Ultipaq®, DeltaPaq™, DeltaPlush™ and HeliPaq SR®. Includes filaments comprised of PGA, a bioactive material.

|

||

Courier® ENZO® Microcatheter

|

.0170" and 0190” inner diameter and 150 cm length

|

Unique deflectable device used to deliver embolics into the aneurysm.

|

10

|

Product Line

|

Sizes

|

Product Description

|

Courier® Microcatheter

|

.0170” and .0190” inner diameter and 150 cm length

|

Device used to deliver embolics into the aneurysm.

|

||

Neuropath® Guide Catheter

|

5 and 6 french internal diameter and a 90 and 100cm length

|

The Neuropath® guide catheter uses Progressive Shaft Technology™ to facilitate the smooth delivery of multiple devices including microcatheters, balloons, guidewires and microcoils. It comes in a variety of tip shapes and sizes.

|

||

Watusi® Guidewire

|

.014” diameter and 205 cm length

|

Device used to guide catheters and other devices to the aneurysm or stenosis site.

|

||

PHAROS® Vitesse® Stent System

|

2.5 mm - 4.0 mm outer diameter and 8 mm – 20 mm length

|

For use as scaffolding of wide-neck aneurysms to ensure that the microcoil is not dislodged and for use in opening intracranial arteries that have narrowed.

|

||

Ascent® Balloon Catheter

|

4 mm diameter and higher. Multiple lengths

|

A coaxial dual lumen balloon catheter designed for use over any 0.014-inch guidewire. It is intended for use for temporary vascular occlusion and to assist in delivery of diagnostic and therapeutic agents.

|

11

|

Product Line

|

Sizes

|

Product Description

|

||

EnPower® Detachment Control Box and Connecting Cable

|

|

Next-generation control box provides electronic control via a lithium ion battery and initiates detachment of our proprietary microcoil system. The EnPower® also features a remote cable which enables physicians to detach the coils from the patient field.

|

Microcoil Products

We offer a range of microcoils designed to enable neurointerventionalists to treat a wide variety of aneurysms. These include our MicruSphere®, Cashmere®, DeltaPaq™, DeltaPlush™ and Ultipaq® microcoil systems which are available in bare platinum and Cerecyte® versions, and the Presidio® line of microcoils which also incorporates our proprietary Cerecyte® technology. All of our microcoils utilize our rapid deployment system and perform certain specific functions:

|

•

|

Frame. Our MicruSphere®, Presidio® and Cashmere® microcoils are typically the first microcoils used by neurointerventionalists to frame the aneurysm. The MicruSphere® microcoil folds automatically into a spherical three-dimensional shape that conforms to the shape of the aneurysm. This conforming shape reduces the need for the clinician to manipulate and reposition the coil multiple times, shortens procedure time, and reduces the potential for complications. Additional microcoils may then be placed within the first microcoil in smaller sizes in an approach known as the “Russian doll technique,” sequentially filling the aneurysm.

|

|

•

|

Frame and Fill. Our Presidio® and Cashmere® microcoils feature longer lengths and their own unique shapes required to frame and fill the aneurysm. This can allow for more platinum to be deployed at the neck of the aneurysm, as well as greater packing density.

|

|

•

|

Fill. The DeltaPaq™ features a completely new coil technology, called “Delta Wind.” This unique triangular shaped primary wind allows the DeltaPaq™ to change directions rapidly, far surpassing traditional round primary winds. The Delta Wind technology is designed to increase packing density, which previous studies have suggested results in a reduction in recanalization. The DeltaPaq™ is available in both bare platinum and with Cerecyte. The Cashmere® microcoil is a stretch resistant complex coil which may also be used as a filling coil. The Cashmere® combines extra coil softness with a 3 dimensional secondary shape in a 14 system coil. Attributes of a 14 system coil help deliver more packing density per cm of coil compared with smaller system microcoils. Our proprietary DeltaPaq™, HeliPaq® and HeliPaq SR® products are filling microcoils used to fill gaps which may remain in the center of the aneurysm after placement of one or more of our MicruSphere® or Presidio® framing microcoils. Both the HeliPaq® and the HeliPaq SR® automatically form a helical shape upon deployment, which allows filling of complex gaps in the aneurysm. The HeliPaq SR® employs a stretch-resistant system designed to prevent the microcoil from stretching in an unwanted manner while being positioned in the aneurysm. InterPaq® microcoils are filling coils used in larger size aneurysms requiring a greater volume of coil mass in order to be adequately filled.

|

|

•

|

Finish. The DeltaPlush™ microcoil with “Delta Wind” technology is designed to be our softest finishing coil. The DeltaPlush™ is available in both bare platinum and with Cerecyte. Our UltiPaq® microcoil is an extra-soft, stretch-resistant finishing coil, used to provide additional aneurysm neck coverage and to more thoroughly fill in the aneurysm after placement of one or more MicruSphere®, Presidio®, Cashmere® and/or HeliPaq® microcoils.

|

|

•

|

Cerecyte®. Our proprietary Cerecyte® microcoil product line incorporates filaments comprised of PGA into most of our current line of microcoils — MicruSphere®, Presidio®, Cashmere®, DeltaPaq™, DeltaPlush™, HeliPaq®, HeliPaq SR® and UltiPaq®. Because the PGA filaments run through the center of our microcoils, our Cerecyte microcoils possess the same handling characteristics as our standard platinum microcoils.

|

12

In January 2009, we completed the enrollment of 500 patients in our CCT. The CCT is a prospective randomized multi-center trial which directly compares Micrus Cerecyte® bioactive microcoils to Micrus bare platinum microcoils for the treatment of intracranial aneurysms. We also completed the enrollment of 250 patients in our Cerecyte® Registry in January 2009. The Cerecyte® Registry is a prospective non-randomized United States multi-center registry designed to document the clinical and angiographic outcomes of intracranial aneurysms treated with our Cerecyte® bioactive coils. Data from these studies are being assembled for presentation and submission to peer review journals in fiscal 2011. Interim data from the CCT presented at the American Society of Neuroradiology in May 2010 suggest that our Cerecyte and bare platinum microcoils outperform the ISAT study published results for bare platinum coils in both investigator assessed angiographic occlusion rate and safety. The ISAT results are the industry’s benchmark.

PHAROS® and PHAROS® Vitesse® Balloon-Expandable Stent

Our PHAROS® stent is a balloon-delivered device which can be used both to treat ischemic disease and for scaffolding of wide-neck aneurysms to ensure that the microcoil is not dislodged. For the treatment of ischemic disease, our PHAROS® stent dilates intracranial arteries that have narrowed and allows the neurointerventionalist to deliver and deploy a stent in one step. We believe this feature will help reduce overall procedural time and cost. We believe that the balloon catheter marker bands combined with the radiopacity of the stent provide for excellent visibility resulting in improved accuracy of deployment.

We believe that PHAROS® Rapid Exchange Technology and trackable tip will enable a physician to access the tortuous and distal anatomy of the brain. In March 2006, we launched the PHAROS® stent in certain countries outside the United States that recognize the CE Mark. In March 2008, we filed an IDE with FDA for our next generation stent, the cobalt chromium steel PHAROS® Vitesse®, for the treatment of neurovascular stenosis. In July 2008, we received FDA conditional approval of our IDE for the VISSIT study of our next generation PHAROS® Vitesse® stent. In August 2009, we received approval for the study. The VISSIT study is the first industry sponsored, randomized, prospective clinical trial designed to compare the clinical outcomes between patients who are stented for intracranial ischemic stenosis versus treated with medical therapy. We are currently enrolling patients in our VISSIT IDE trial in the United States, Europe and China.

Access Products

We offer the following products:

|

•

|

Ascent® Balloon Catheter. The Ascent® Occlusion Balloon Catheter is a coaxial dual lumen balloon catheter designed for use over any 0.014 inch guidewire. The 0.014 dual lumen catheter is designed to improve the stability of the balloon, potentially resulting in a more effective and safer procedure. It is intended to be used for temporary vascular occlusion and to assist in delivery of microcoils and other therapeutic and diagnostic agents into the aneurysm.

|

|

•

|

Courier® Microcatheter. Our Courier® microcatheter is a device used to deliver microcoils to the aneurysm. Our Courier® microcatheter features our proprietary Endurance™ technology designed to enhance both tip shaping and tip shape retention, both of which are vital to optimal coil delivery. It is available in straight and pre-shaped configurations. Our Courier® Microcatheter has been designed to provide the neurointerventionalist with the ability to navigate the tortuous vasculature of the brain. The microcatheter’s design and hydrophilic coating enable a high level of stability, tip shape retention and overall tracking.

|

|

•

|

Neuropath® Guide catheter. The Neuropath® guide catheter uses Progressive Shaft Technology and facilitates the smooth delivery of multiple devices including microcatheters, balloons, guidewires and micro coils. It comes in a variety of tip shapes as well as varying sizes. It is currently available in a 5 and 6 french internal diameter and a 90 and 100cm length.

|

|

•

|

Courier® ENZO® Microcatheter. Introduced to the United States in September 2007 and to Europe in January 2008, the ENZO® deflectable tip microcatheter is designed to offer improved maneuverability through the brain’s tortuous vasculature and to enable in vivo repositioning of the microcatheter in the aneurysm, allowing physicians to more efficiently fill aneurysms, which may lead to improved outcomes. We believe that ENZO® is the only deflectable tip microcatheter available for use in the neurovascular market.

|

Microcoil Delivery System and Deployment Mechanism

In addition to the detachable microcoil, our microcoil delivery system is comprised of a DPU, a connecting cable and the EnPower® Detachment Control Box. Our DPU is a flexible catheter to which a Micrus microcoil is attached. Deployment of the microcoil occurs when the neurointerventionalist activates a resistive heater at the tip of the DPU, shearing the polyethylene fiber that holds the microcoil onto the DPU. Our deployment technology results in fast and reliable deployment of the microcoil from the DPU.

13

Sales and Marketing

We market our products to interventional neuroradiologists and neurosurgeons who generally practice at centers located in major metropolitan areas. There are currently approximately 300 - 400 neurointerventionalists in the United States who perform embolic coiling procedures. We believe that less than one-third of these physicians perform a substantial majority of the total number of embolic coiling procedures performed in the United States each year. We believe that a similar number of neurointerventionalists are practicing in Europe and Asia.

We have developed relationships with a number of these neurointerventionalists who perform a large number of cerebral vascular procedures. In fiscal 2010, a substantial portion of our product sales in the United States was to an estimated 118 hospitals. In order to encourage the continued adoption of our products, we believe that we need to continue to build and maintain relationships with these neurointerventionalists. We believe that these relationships are enhanced by the presence of our direct sales organization. Sales of embolic coiling products involve a long-term relationship between the sales representative and neurointerventionalist where the sales representative must initially be present for product demonstrations and to monitor procedures. We recruit our sales representatives based on their experience with minimally invasive devices and prior success in the medical device industry. We provide ongoing sales and product training to our employees and distributors and continually monitor their performance. We also market our products at various industry trade shows and conferences.

In the United States and Canada, we market our products through our direct sales force to neurointerventionalists, while in Europe, we rely on both a direct sales force and a distribution network. In Asia Pacific and Latin America, we market our products through a distribution network. We currently have a North American direct sales force of 34, a European direct sales force of 18, an Asia Pacific direct sales force of four and two direct sales people in Latin America. We may add clinical and sales support personnel at both the direct and distributor level in Asia Pacific and Europe to ensure a high level of global physician support for all our products. Our marketing group currently consists of 10 employees in North America and 4 employees in Europe.

We have entered into agreements with distributors in several European countries, as well as portions of the Middle East, Asia and Latin America. Our distributors are experienced in the interventional device markets and have relationships with leading neurointerventionalists and institutions in those countries. Our standard distribution agreement generally (i) provides our distributors with an exclusive right to distribute our products in a certain territory; (ii) restricts them from selling products that are competitive with our products for the limited duration of our agreement with them; (iii) obligates them to obtain the necessary authorizations, licenses and approvals to import, market and distribute our products within the applicable territory; and (iv) obligates them to promote and distribute our products within the applicable territory.

We believe that Japan represents a significant market for our products. On September 30, 2005, we entered into a five-year, exclusive distribution agreement with Goodman to promote and market our products in Japan. In February 2006, we received the requisite local regulatory approvals to sell certain of our products in Japan through Goodman, and the sale of such products in Japan commenced in March 2006. On September 20, 2007, we amended the distribution agreement with Goodman to, among other things, extend the duration of the distribution agreement to six years from the original date of the distribution agreement. In December 2007, we received regulatory approval to sell our stretch-resistant microcoils in Japan, and we received regulatory approval for our Cerecyte® microcoils in July 2008.

Information about our revenues from sales to unaffiliated customers is included in Note 14 of the “Notes to Consolidated Financial Statements,” which are included in “Item 8 – Financial Statements and Supplementary Data” of this report.

We generate revenues from sales to hospitals and third-party distributors. Once a sale has occurred, the customer has no right of return. We provide the customers with limited warranty privileges.

Goodman, our distributor in Japan, accounted for 12% of revenues for both years ended March 31, 2010 and 2009. No customer accounted for 10% or more of our revenues for the year ended March 31, 2008.

Research and Development

Our product development efforts are focused on designing microcoils, guidewires, microcatheters, balloons, thrombectomy devices and stents for the treatment of hemorrhagic and ischemic stroke. We are working to develop next generation microcoils to frame and fill the aneurysm more efficiently and thoroughly. Also under development are next-generation balloon expandable stents for the treatment of intracranial atherosclerosis, self-expanding stents and covered stents, as well as occlusion balloons to augment the treatment of aneurysms with microcoils.

14

Additionally, we are developing technologies to treat acute ischemic stroke. In October 2007, we acquired an exclusive license to revascularization and clot retrieval technology for the treatment of ischemic stroke, known as ReVive™ SE, through the acquisition of ReVasc from The Cleveland Clinic. In January 2008, we entered into a license, development and commercialization agreement with Genesis. Under the terms of the agreement, we licensed the rights to Genesis’ F.A.S.T. Funnel Catheter and clot retrieval and revascularization system, known as ReVive™ CX, for the treatment of ischemic stroke. In April 2008, we entered into a co-development agreement with Chemence to jointly develop a liquid embolic product for the treatment of cerebral aneurysms using Chemence’s cyanoacrylate technology, development capabilities and intellectual property. In August 2009, we entered into a license, development and commercialization agreement with FSS to jointly develop a flow diversion product for neurovascular indications using both Micrus and FSS technology, development capabilities and intellectual property. In January 2010, we entered into a license, development and commercialization agreement with Bay Street regarding their stent delivery system.

As of March 31, 2010, we had 37 full-time employees engaged in research and development activities. Research and development expenses for the fiscal years ended March 31, 2010, 2009 and 2008 were $10.4 million, $10.2 million and $13.7 million, respectively.

Biotronik Collaboration

In January 2006, we entered into a license, development and distribution agreement with Biotronik, pursuant to which we will collaborate with Biotronik to develop certain neurovascular products and we will be the exclusive worldwide distributor for jointly developed neurovascular products. Biotronik granted us an exclusive license to certain patents, know-how and other proprietary technology in the neurovascular field.

Under the terms of our agreement, we paid an up-front licensing fee of approximately $0.6 million to Biotronik and were required to make milestone payments to Biotronik upon receipt of approvals to market stent products we jointly developed for the treatment of neurovascular disease and royalty payments on the products sold. We are also required to pay Biotronik royalties equal to 15% of the actual net sales of our PHAROS® stent on a quarterly basis. In February 2006, Biotronik received CE Mark authorization for the PHAROS® stent intended for both the treatment of aneurysms and the treatment of ischemic diseases. As a consequence, we made milestone payments to Biotronik of approximately $0.7 million in both March and April 2006. We paid an additional cost associated with the PHAROS® stent development of $102,000 in the first quarter of fiscal 2007. Additionally, we have incurred royalties to Biotronik of approximately $318,000, $169,000 and $150,000 for the products sold in fiscal 2010, 2009 and 2008, respectively. There are no future milestone payments to Biotronik related to the PHAROS® stent. Additionally, we will continue to fund ongoing project development based on the terms of this agreement.

ReVasc Acquisition

In October 2007, we entered into a Stock Purchase Agreement (the “ReVasc Agreement”) with The Cleveland Clinic and acquired ReVasc, a wholly-owned subsidiary of The Cleveland Clinic for an aggregate up-front purchase price of $1.0 million. Pursuant to the ReVasc Agreement, we also agreed to pay The Cleveland Clinic up to $5.0 million in additional payments upon the achievement of certain milestones set forth in the ReVasc Agreement. This includes minimum milestone payments of at least $2.0 million due to The Cleveland Clinic by October 2010. The first milestone payment in the amount of $500,000 was paid in March 2008. In January 2010, we paid The Cleveland Clinic an additional milestone payment of $2.0 million, which did not count towards the minimum milestone payments.

ReVasc was a party to a license agreement with The Cleveland Clinic (the “ReVasc License Agreement”) pursuant to which The Cleveland Clinic granted ReVasc an exclusive license to its revascularization technology for the treatment of ischemic stroke. In connection with the acquisition, the parties amended the ReVasc License Agreement to provide, among other matters, for the payment to The Cleveland Clinic of certain royalties for sales of products based on the technology subject to the ReVasc License Agreement.

On December 7, 2007, we merged ReVasc into Micrus. Following the merger, Micrus became the direct recipient of the license of the revascularization technology from The Cleveland Clinic under the ReVasc License Agreement. The ReVasc technology is now known as ReVive™ SE.

Genesis Collaboration

In January 2008, we entered into a license, development and commercialization agreement with Genesis. Under the terms of the agreement, we licensed the rights to Genesis’ F.A.S.T. Funnel Catheter, a revascularization platform and clot retrieval system for the treatment of ischemic stroke. In fiscal 2011, we plan to finalize our development and validation work on these Ischemic products and intend to perform safety studies outside the United States. The transaction with Genesis includes an initial up-front payment of $0.8 million, a development milestone payment of $150,000, which was paid in October 2008, and royalties on potential future product sales. Additionally, we paid $277,000 and $351,000 in consulting fees to Genesis in fiscal 2010 and 2009, respectively, for the funnel catheter product development. The Genesis technology is now known as ReVive™ CX.

15

Disposition of Cardiac and Peripheral Catheter Platform Assets

In January 2008, we entered into an Asset Purchase and Supply Agreement (the “Merit Agreement”) with Merit Medical Systems, Inc. (“Merit”) pursuant to which we sold certain cardiac and peripheral catheter platform assets and technology (the “Merit Transaction”). The majority of the assets sold were originally acquired by us in November 2006 in connection with our purchase of VasCon. Pursuant to the Merit Agreement, we received an up-front payment of $1.5 million and received an additional $1.5 million in December 2008 upon the completion of our obligation to help Merit build a production line for coronary guide catheters. Under the terms of the Merit Agreement, we also agreed to manufacture and supply certain guide catheters to Merit for a period of up to one year following the closing. This obligation expired in January 2009, and we no longer supply guide catheters to Merit.

In connection with the Merit Transaction, we also entered into a license agreement granting Merit the right to use certain non-patented intellectual property in the cardiology and peripheral radiology fields and a non-competition agreement, whereby we agreed not to engage in certain competitive business activities in the fields of cardiology and peripheral radiology for a period of five years.

Our remaining obligations to Merit terminated on September 30, 2009 and therefore, the deferred gain of $1.9 million was recognized as other income in the quarter ended September 30, 2009.

Chemence Collaboration

In April 2008, we entered into a co-development agreement with Chemence to jointly develop a liquid embolic product for the treatment of cerebral aneurysms using Chemence’s cyanoacrylate technology, development capabilities and intellectual property. We will be responsible for overseeing the regulatory and clinical process and will be the exclusive worldwide distributor for the neurovascular product developed based on this collaborative agreement. Under the terms of the agreement, we have made an up-front payment of $100,000 to Chemence and will make additional payments of up to $200,000 upon achieving certain development milestones.

FSS Collaboration

In August 2009, we entered into a License, Development and Commercialization Agreement (the “FSS Agreement”) with FSS. Under the terms of the FSS Agreement, Micrus and FSS will jointly develop a flow diversion product for neurovascular indications using both Micrus and FSS technology, development capabilities and intellectual property. We will be responsible for overseeing the regulatory and clinical process and will manufacture neurovascular products developed under the terms of this collaborative agreement. The transaction included an initial up-front payment of $0.5 million, future development and regulatory milestone payments and royalties on potential future product sales. In March 2010, we amended the original agreement with FSS to expand the projects focus to include a non-flow diversion variation of the FSS stent platform for use as a neurovascular stent.

Bay Street Agreement

In January 2010, we entered into an Exclusive License and Option Agreement (the “Bay Street Agreement”) with Bay Street. Pursuant to the terms of the Bay Street Agreement, Bay Street granted us a worldwide exclusive license and option to purchase intellectual property assets held by Bay Street related to its proprietary stent delivery and locking technology (the “Bay Street Assets”). The transaction included an initial up-front payment of $0.5 million for a six month evaluation of the exclusive license. We have the option to extend the exclusive license for an additional six months upon paying to Bay Street an option payment of $0.5 million. We also have the option to purchase the Bay Street Assets before the option period ends pursuant to an Asset Purchase Agreement that will be an addendum to the Bay Street Agreement. Under the terms of the Asset Purchase Agreement, if we elect to purchase the Bay Street Assets, we would be required to pay an initial purchase payment of $1.0 million, a future sales-based milestone payment and royalties on future product sales.

Physician Advisors

We rely extensively on our physician advisors to advise us on our research and development efforts and to provide feedback on the clinical use of our products. Our advisors are experts in interventional neuroradiology and cerebral vascular diseases. We regularly consult with our physician advisors regarding our research and development efforts, preclinical trials and clinical trials.

16

Some of our physician advisors receive a consulting fee for providing services to Micrus. All of our physician advisors are reimbursed for reasonable expenses. In addition, our medical advisors receive compensation for clinical studies they conduct for us. All of our medical advisors are employed by other organizations and may have commitments to or have consulting arrangements with other companies, including our competitors, which may limit their availability to consult with us. Although these advisors may contribute significantly to our business, we generally do not expect them to devote more than a small portion of their time to us. We also routinely seek advice, input and feedback on our products and business from a larger broader group of physicians and advisors, some of whom may also receive appropriate compensation for their time and expert opinions.

Manufacturing

We manufacture and/or assemble, inspect, test and package all our proprietary microcoils and microcatheters at our headquarters in San Jose, California, or in Miramar, Florida. Most of our non-embolic products are manufactured in Miramar, Florida. As of March 31, 2010, we had 164 employees in manufacturing, quality control, manufacturing engineering and materials and logistics.

We have substantial design, manufacturing and applications engineering expertise in the development of small vessel access and delivery systems and intend to continue to leverage this expertise to develop new products. By designing and manufacturing most of the components of our products, we have been able to maintain greater control of quality and manufacturing process changes. Our microcoils are very small in size, ranging from 1.0 mm to 20.0 mm in diameter and are manufactured using microfabrication techniques. We have developed proprietary manufacturing technologies and processes in the areas of platinum memory shaping, metal fabrication, balloon fabrication and microcatheter and stent fabrication.

Trained product personnel assemble and test each of our components and products in controlled environment rooms. At various assembly stages each lot of product undergoes thorough testing to ensure compliance with applicable regulations, including Quality System Regulations (“QSR”) requirements in the United States and ISO 13485 certification standards in Europe. These standards specify the requirements necessary for a quality management system to consistently provide products that meet customer requirements and to include processes for achieving the outputs of the quality management system that are required in order to obtain a CE Mark to sell medical devices within the European Union. Our quality assurance group verifies that product fabrication and inspection process steps meet our stringent quality specifications and applicable regulatory requirements. Upon successful completion of these steps, the products are packaged, sterilized and prepared for shipment. We typically ship products as orders are received.

We have implemented quality control systems as part of our manufacturing processes, which we believe are in substantial compliance with United States Good Manufacturing Practices (“GMP”) or QSR requirements. Our San Jose facility has also been inspected by the California Department of Health Services on behalf of the State of California and under contract with the FDA, and is registered with the State of California to manufacture our products. We believe that we are in compliance with the FDA GMP for medical devices, and our facilities are subject to inspection by the FDA. The most recent of such inspections occurred in April 2010 in San Jose, California and in September 2007 in our Doral, Florida facility, prior to the relocation of that plant to Miramar, Florida. However, we cannot assure that we will remain in compliance with GMP and our failure to do so could have a material adverse effect on our business, operating results and financial condition.

We purchase the raw materials required for production from various qualified outside vendors. In addition, the deployment control box is manufactured by an outside supplier. We rely on single sources for some of our critical components, including the deployment control box, the platinum used to manufacture the microcoils and certain custom hypodermic tubing material. In addition, we have a sole source subcontract arrangement for sterilization services. We believe that we have alternative sources for most of the components purchased from single sources currently and generally maintain an adequate supply of products to avoid production interruptions. Where we do not have a qualified second source vendor for a product component and depending on the exact component, we believe that it would take us from two days to a month to either manufacture the product component ourselves or have a readily available new supply of the product component. Any unanticipated interruption in the supply of these components and services could have a material adverse effect on us.

Patents and Proprietary Rights

Our success depends in part on our ability to obtain and maintain proprietary protection for our products, technology and know-how, to operate without infringing on the proprietary rights of others and to prevent others from infringing our proprietary rights. Our policy is to seek protection of our proprietary position by filing United States and foreign patent applications to protect technology, inventions and improvements that are important to our business. We also rely on trade secrets, know-how and continuing technological innovation to develop and maintain our proprietary position. We hold 76 issued United States patents and 121 issued foreign patents expiring between 2015 and 2027. In addition, we have 37 United States and 66 foreign patent applications pending covering various aspects of our products and technology.

17

The issued patents relate, among other things, to subject matter in the following areas:

|

•

|

vaso-occlusive microcoils and devices, and methods for manufacturing such coils and devices;

|

|

•

|

microcoil deployment systems;

|

|

•

|

bioactive microcoils;

|

|

•

|

intracranial vascular stents;

|

|

•

|

catheters for neurovascular intervention;

|

|

•

|

embolic clot retrieval devices; and

|

|

•

|

bioactive material placement systems and methods.

|

In addition to developing our own technology, we have obtained licenses to certain patents and other intellectual property, including for materials used as coating on our guidewires and for certain types of coils. These licenses grant us the right to use the licensed patents to make, use and sell products that contain the licensed technology. We pay for these licenses through a combination of fixed payments and royalties on sales of covered products. Each of these licenses continues until expiration of the licensed patents. Payments under these license arrangements currently do not account for a material portion of our expenses.

Although we work aggressively to protect our technology, there is no assurance that any patents will be issued from current pending patent applications or from future patent applications. We also cannot assure that the scope of any patent protection will exclude competitors or provide competitive advantages to us, that any of our patents will be held valid if subsequently challenged, or others will not claim rights in or ownership of our patents and proprietary rights. Furthermore, there can be no assurance that others have not developed or will develop similar products, duplicate any of our products or design around our patents.

The medical device industry has been characterized by extensive litigation regarding patents and other intellectual property rights, and many companies in the industry have employed intellectual property litigation to gain a competitive advantage.

In addition to patents, we rely on trademark, trade secret and other intellectual property laws, nondisclosure agreements and other measures to protect our intellectual property rights. We believe that in order to have a competitive advantage, we must develop and maintain the proprietary aspects of our technologies. We require our employees, consultants and advisors to execute confidentiality agreements in connection with their employment, consulting or advisory relationships with us. We also require our employees, consultants and advisors who we expect to work on our products to agree to disclose and assign to us all inventions conceived while working for us, using our property or which relate to our business. Despite any measures taken to protect our intellectual property, unauthorized parties may attempt to copy aspects of our products or to obtain and use information that we regard as proprietary.

Competition

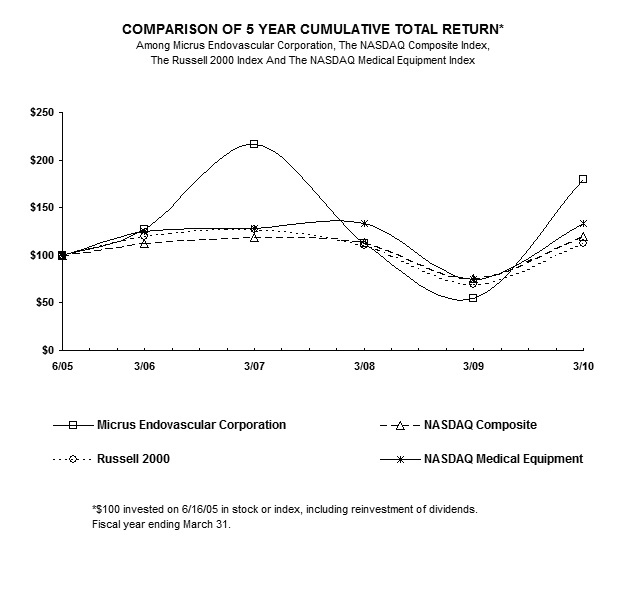

We compete primarily with the neurovascular division of Boston Scientific; Codman Neurovascular, a division of Johnson & Johnson; ev3 Inc and MicroVention, a division of Terumo. Boston Scientific, Codman Neurovascular and ev3 offer broad product lines consisting of embolic microcoils, microcatheters, stents, balloons and guidewires. Boston Scientific, Codman Neurovascular, ev3 and MicroVention currently market a variety of microcatheters which are compatible with our coil systems.