Attached files

| file | filename |

|---|---|

| 8-K - COPANO ENERGY, L.L.C. FORM 8-K - Copano Energy, L.L.C. | form8-k.htm |

| EX-99.1 - COPANO ENERGY, L.L.C. PRESS RELEASE - Copano Energy, L.L.C. | ex99-2.htm |

NAPTP

Annual MLP Investor

Conference

May 12, 2010

Conference

May 12, 2010

NASDAQ: CPNO

Disclaimer

Statements made by

representatives of Copano Energy, L.L.C. (“Copano”) during this presentation

will

include “forward-looking statements,” as defined in the federal securities laws. All statements that

address activities, events or developments that Copano believes will or may occur in the future are

forward-looking statements. Underlying these statements are assumptions made by Copano’s

management based on their experience and perceptions of historical trends, current conditions,

expected future developments and other factors management believes are appropriate under the

circumstances.

include “forward-looking statements,” as defined in the federal securities laws. All statements that

address activities, events or developments that Copano believes will or may occur in the future are

forward-looking statements. Underlying these statements are assumptions made by Copano’s

management based on their experience and perceptions of historical trends, current conditions,

expected future developments and other factors management believes are appropriate under the

circumstances.

Whether future

results and developments will conform to Copano’s expectations is subject to a

number

of risks and uncertainties, many of which are beyond Copano’s control. If one or more of these risks or

uncertainties materializes, or if underlying assumptions prove incorrect, then Copano’s actual results

may differ materially from those implied or expressed by forward-looking statements made during this

presentation. These risks and uncertainties include the volatility of prices and market demand for

natural gas and natural gas liquids; Copano’s ability to complete any pending acquisitions and integrate

any acquired assets or operations; Copano’s ability to continue to obtain new sources of natural gas

supply; the ability of key producers to continue to drill and successfully complete and attach new

natural gas supplies; Copano’s ability to retain key customers; the availability of local, intrastate and

interstate transportation systems and other facilities to transport natural gas and natural gas liquids;

Copano’s ability to access sources of liquidity when needed and to obtain additional financing, if

necessary, on acceptable terms; the effectiveness of Copano’s hedging program; unanticipated

environmental or other liability; general economic conditions; the effects of government regulations and

policies; and other financial, operational and legal risks and uncertainties detailed from time to time in

the Risk Factors sections of Copano’s annual and quarterly reports filed with the Securities and

Exchange Commission.

of risks and uncertainties, many of which are beyond Copano’s control. If one or more of these risks or

uncertainties materializes, or if underlying assumptions prove incorrect, then Copano’s actual results

may differ materially from those implied or expressed by forward-looking statements made during this

presentation. These risks and uncertainties include the volatility of prices and market demand for

natural gas and natural gas liquids; Copano’s ability to complete any pending acquisitions and integrate

any acquired assets or operations; Copano’s ability to continue to obtain new sources of natural gas

supply; the ability of key producers to continue to drill and successfully complete and attach new

natural gas supplies; Copano’s ability to retain key customers; the availability of local, intrastate and

interstate transportation systems and other facilities to transport natural gas and natural gas liquids;

Copano’s ability to access sources of liquidity when needed and to obtain additional financing, if

necessary, on acceptable terms; the effectiveness of Copano’s hedging program; unanticipated

environmental or other liability; general economic conditions; the effects of government regulations and

policies; and other financial, operational and legal risks and uncertainties detailed from time to time in

the Risk Factors sections of Copano’s annual and quarterly reports filed with the Securities and

Exchange Commission.

Copano undertakes

no obligation to update any forward-looking statements, whether as a result of

new

information or future events.

information or future events.

2

Introduction

to Copano

Independent

midstream company founded in 1992

■ Best in class

service to customers

■ Entrepreneurial

approach

■ Focus on long-term

accretive growth

Provides midstream

services in multiple producing areas through

three operating segments

three operating segments

■ Texas

● South Texas

conventional and Eagle Ford Shale

● North Texas

Barnett Shale Combo play

■ Central and

Eastern Oklahoma

● Conventional,

Hunton De-Watering play and Woodford Shale

■ Rocky

Mountains

● Powder River

Basin

3

Key

Metrics

Service throughput

volumes approximate 1.8 Bcf/d of natural gas(1)

Over 6,700 miles

of active pipelines

8 natural gas

processing plants with over 1.1 Bcf/d of combined

processing capacity

processing capacity

One NGL

fractionation facility with total capacity of 22,000 Bbls/d

Equity market cap:

$1.6 billion(2)

Enterprise value:

$2.2 billion(2)

4

Based

on 1Q 2010 results. Includes

unconsolidated affiliates.

As

of May 7, 2010.

Copano’s

LLC Structure

5

Growth

Strategy

Goal: to become a

diversified midstream company with scale and

stability of cash flows, above-average returns on invested capital

and “investment-grade quality distributions”

stability of cash flows, above-average returns on invested capital

and “investment-grade quality distributions”

Key tenets of

growth strategy:

■ Execute on organic

growth opportunities around existing assets

■ Explore

opportunities beyond traditional gathering and processing

● Be more proactive

in seeking assets and opportunities

■ Reduce sensitivity

of cash flows to commodity price fluctuations

● Hedging

program

● Contracts -

increase fee-for-service component

6

Agenda

7

|

2010

Regional

Outlook |

Commodity

Prices and

Margin Sensitivities |

|

Financing

and

Commodity Risk Management |

Conclusions

|

2010

Outlook

Texas

■ North Texas:

Significant drilling and development activity in the Barnett Shale

Combo play

Combo play

■ South Texas: Ramp

up of Eagle Ford Shale directed drilling

Oklahoma

■ Moderate drilling

activity behind both the Hunton De-Watering and Woodford

Shale plays

Shale plays

Rocky

Mountains

■ Minimal new

drilling; flat volumes

8

Texas

Outlook

North

Texas

■ 9 rigs running in

the area with

as many as 4 more anticipated

later this year

as many as 4 more anticipated

later this year

● Leasing activity

also

continues

continues

■ Crude oil play

with associated

gas requiring a full slate of

midstream services

gas requiring a full slate of

midstream services

■ Based on producer

drilling

schedule, expect steady

increase in plant inlet volumes

in 2010

schedule, expect steady

increase in plant inlet volumes

in 2010

● Current spot

volumes of

approximately 38 MMcf/d vs.

1Q 2010 average volumes of

21 MMcf/d

approximately 38 MMcf/d vs.

1Q 2010 average volumes of

21 MMcf/d

9

Texas

Outlook

South

Texas

■ Fractionation

start-up at Houston Central complete

■ To date we have

connected 6 Eagle Ford Shale wells with a combined IP rate

of 40 MMcf/d with significant associated condensate

of 40 MMcf/d with significant associated condensate

■ Finalizing joint

venture agreements with Kinder Morgan for the western

portion of the Eagle Ford Shale

portion of the Eagle Ford Shale

■ Expect further

Eagle Ford Shale volume increases in 2Q 2010

10

Texas

Recent Developments

North

Texas

■ Recently executed

key producer

contract

contract

● Long-term

gathering, treating and

processing agreement

processing agreement

● Fee-for-service

contract

● Highly rated

producer

■ Additional 50

MMcf/d of compression

expected in service early 4Q 2010,

bringing total plant capacity to 100

MMcf/d

expected in service early 4Q 2010,

bringing total plant capacity to 100

MMcf/d

■ Approximately $30

million in expansion

capex for 2010 (compression and

pipelines)

capex for 2010 (compression and

pipelines)

■ $30 - $35 million

in fee-based cash flow

expected by year-end 2010 on an

annualized basis

expected by year-end 2010 on an

annualized basis

11

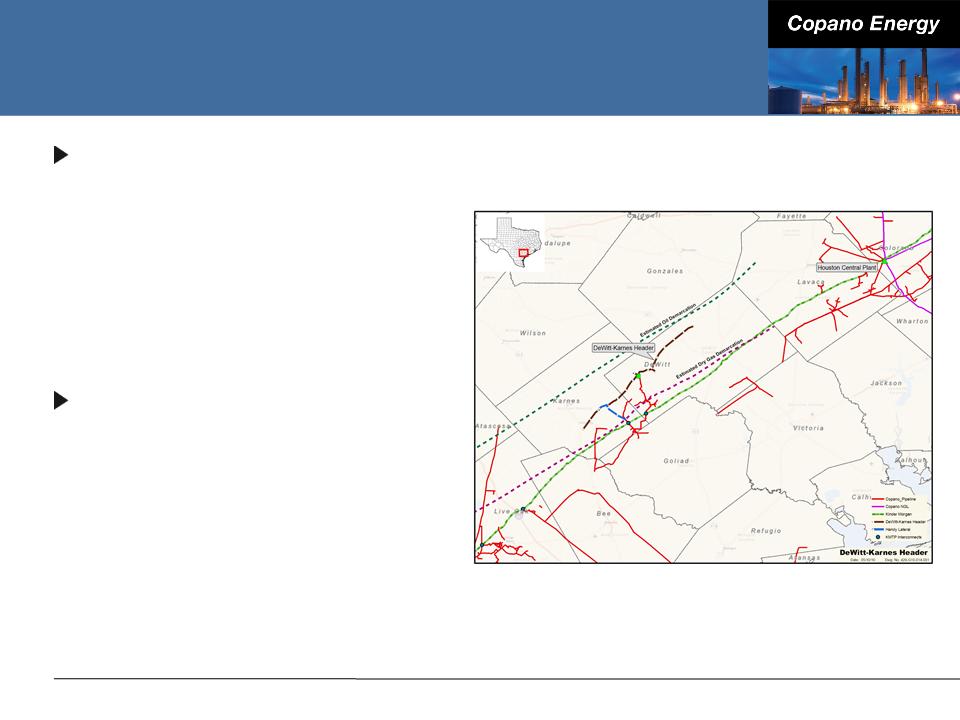

DeWitt-Karnes

Pipeline

Recently announced

DeWitt-

Karnes pipeline

Karnes pipeline

■ Targets rich Eagle

Ford Shale gas

■ 38 miles of 24”

pipe - expected to

be in service by August 1, 2010

be in service by August 1, 2010

■ Anticipated 2010

capex -

approximately $45 million

approximately $45 million

Conducting

preliminary

engineering work to relocate

200 MMcf/d Lake Charles

plant to Houston Central

engineering work to relocate

200 MMcf/d Lake Charles

plant to Houston Central

12

Texas

Fractionation Facility

Responding to NGL

transportation and fractionation constraints

along the Texas Gulf Coast, Copano started its fractionator at

Houston Central

along the Texas Gulf Coast, Copano started its fractionator at

Houston Central

Utilizing Houston

Central’s fractionation unit and extensive

tailgate NGL pipelines, Copano began to deliver purity products

to market in April 2010

tailgate NGL pipelines, Copano began to deliver purity products

to market in April 2010

■ Total capacity of

22,000 Bbls/d

■ Approximate cost

of $17 million

■ Estimated

fee-based cash flow between $8 and $10 million on an

annualized basis at current throughput volumes

annualized basis at current throughput volumes

13

Oklahoma

Outlook

Rich

gas

(primarily Hunton De-Watering play)

■ Drilling activity

remains steady

■ 2 rigs currently

running in the Hunton and 7 rigs in other rich gas areas

■ Attractive

processing upgrade and low geologic risk

■ 2Q 2010 volumes

expected to be flat to slightly up vs. 1Q 2010

■ Burbank processing

plant in service 2Q 2010 (10 MMcf/d capacity)

Lean

gas

(primarily Woodford Shale and coalbed methane)

■ Drilling activity

in the Woodford Shale has recently increased

■ 5 rigs currently

running

■ 2Q 2010 volumes

expected to be slightly up from 1Q 2010

14

Oklahoma

Rich Gas vs. Lean Gas

15

Prices

as of 5/7/10

Full

value prior to deduction of Copano’s margin. Excludes

value of condensate and crude oil recovered by the producer at the

wellhead.

Implied

NGL prices are based on a six-year historical regression analysis.

Assumes

9 GPM gas with a Btu factor of 1.375 processed at Copano’s cryogenic plant, and

field fuel of 6.25%.

Assumes

unprocessed gas with a Btu factor of 1.0 and field fuel of

6%.

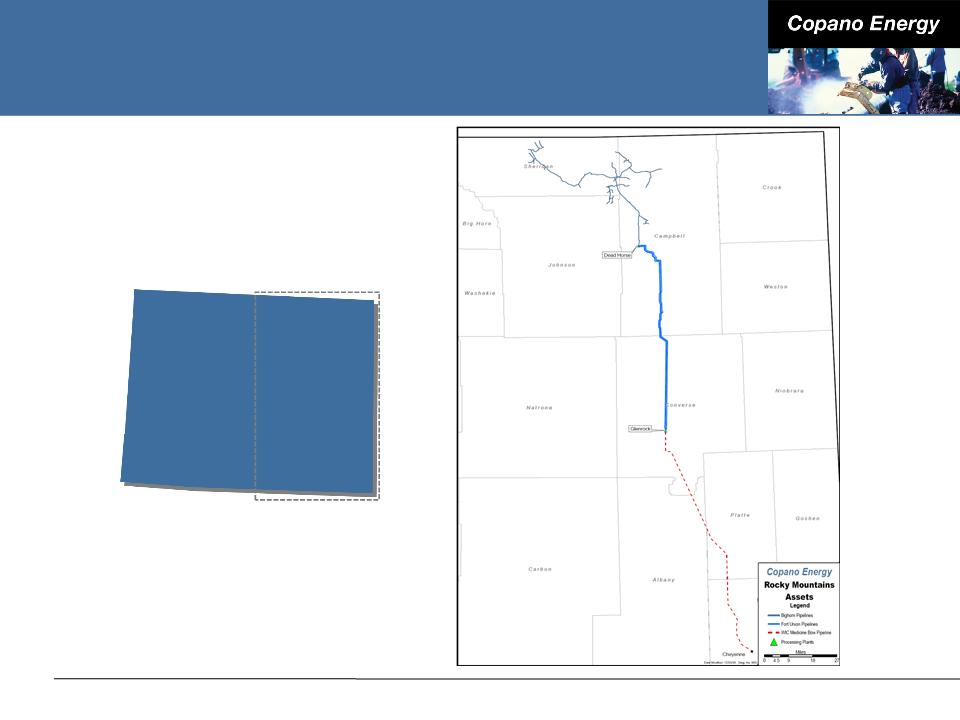

Rocky

Mountains Outlook

Drilling and

dewatering will be driven by commodity prices and

producer economics

producer economics

2Q 2010 volumes

expected to be slightly lower to flat vs. 1Q 2010

For Bighorn, 130

previously drilled wells can be connected with

minimal capital expenditures

minimal capital expenditures

■ An additional 70

drilled wells can be connected with moderate capital

expenditures

expenditures

2010 Adjusted

EBTIDA expected to be flat vs. 2009

■ Forward pricing

curve indicates drilling and dewatering activity should resume

this year and if this occurs, 2014 Adjusted EBITDA could double from current

levels

this year and if this occurs, 2014 Adjusted EBITDA could double from current

levels

16

Commodity

Prices and Margin Sensitivities

17

|

2010

Regional

Outlook |

Commodity

Prices and

Margin Sensitivities |

|

Financing

and

Commodity Risk Management |

Conclusions

|

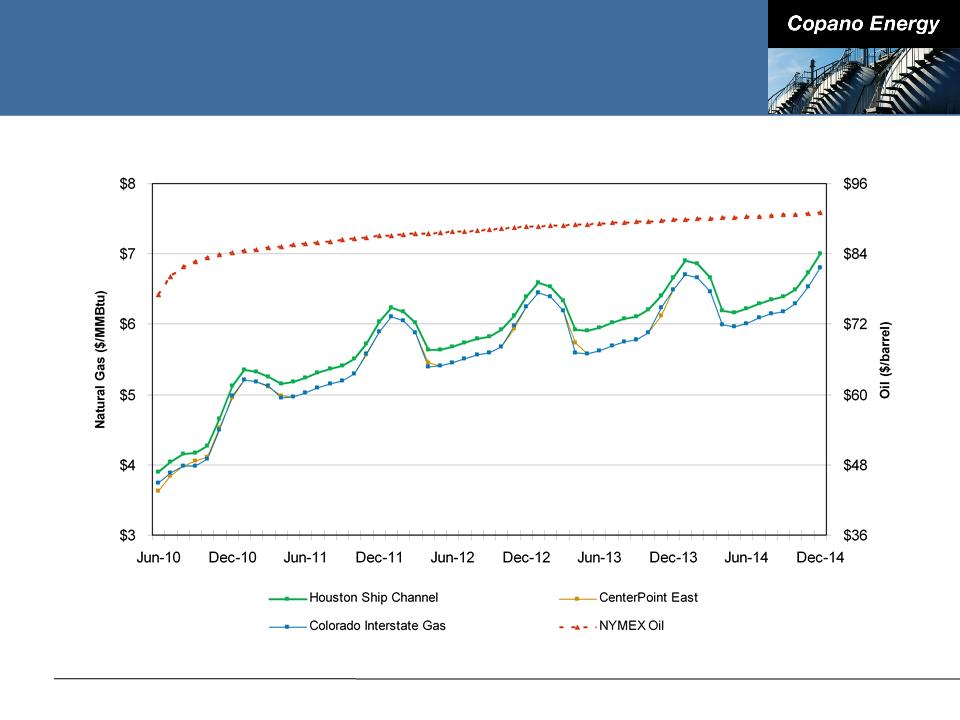

Historical

Commodity Prices

18

May-09

NGL prices are month-to-date through May 6, 2010.

NGL

prices for Jan-09 through Mar-10 are calculated based on the weighted-average

product mix for the period indicated. NGL

prices for Apr-10 through

May-10 are calculated based on the first quarter 2010 product mix.

May-10 are calculated based on the first quarter 2010 product mix.

Forward

Commodity Prices

19

Note:

Forward prices as of May 6, 2010

Combined

Commodity-Sensitive Segment

Margins and Hedging Settlements

Margins and Hedging Settlements

20

Financing

and Commodity Risk Management

21

|

2010

Regional

Outlook |

Commodity

Prices and

Margin Sensitivities |

|

Financing

and

Commodity Risk Management |

Conclusions

|

2010

Expansion Capex

Copano has

approximately $130 million(1) in approved

expansion

capital projects for 2010. Major areas of focus include:

capital projects for 2010. Major areas of focus include:

■ Eagle Ford Shale

and Houston Central processing plant in south Texas

● DeWitt-Karnes

pipeline

■ Saint Jo

processing plant and pipelines in north Texas

■ Additional

pipeline and processing capacity in Oklahoma

■ Expect capital to

be invested at a multiple of approximately 5x

Financing to be

consistent with Copano’s historical policy - balance

of debt and equity

of debt and equity

22

Includes

Copano’s net share for unconsolidated affiliates.

Recent

Equity Offering

In March 2010

Copano sold approximately 7.45 million common

units in a public offering

units in a public offering

■ Approximately $164

million in net proceeds (including greenshoe)

■ Proceeds used to

reduce revolver borrowings, which ultimately will fund

expansion capex

expansion capex

■ Demonstrated

commitment to raising capital and maintaining liquidity

Enhances liquidity

available to fund expansion capex and balance

sheet

sheet

■ At March 31, 2010,

total liquidity of approximately $301 million

23

Hedging

Strategy

Option-based,

product-specific

2010 price exposed

volumes are well hedged

■ Between 70% and

80% of propane, butane, natural gasoline and condensate

price exposure is hedged

price exposure is hedged

■ Approximately 40%

of ethane price exposure is hedged

■ Expect $32 - $34

million of non-cash amortization expense in 2010 related to

option component of hedge portfolio

option component of hedge portfolio

So far in

2010:

■ Added ethane puts

for 2011 (net cost of approximately $0.7 million)

■ Added ethane,

propane, isobutane, normal butane and WTI puts for 2012 (net

cost of approximately $10.1 million)

cost of approximately $10.1 million)

2010 focus -

adding to 2012 hedging positions

24

Conclusions

25

|

2010

Regional

Outlook |

Commodity

Prices and

Margin Sensitivities |

|

Financing

and

Commodity Risk Management |

Conclusions

|

Conclusions

Growth projects

recently completed are expected to contribute to

increased total distributable cash flow in 2010

increased total distributable cash flow in 2010

■ Volumes at Saint

Jo plant increasing

■ Start-up of

fractionator at Houston Central plant

■ Burbank plant

in-service

■ Portions of

DeWitt-Karnes header in-service

Significant funnel

of growth opportunities

■ Expansion of Saint

Jo plant to 100 MMcf/d anticipated by early 4Q 2010

■ Completion of

DeWitt Karnes Header expected by mid-3Q 2010

■ Finalizing Kinder

Morgan joint venture in western Eagle Ford Shale

■ Other processing

plant expansions, fractionation expansion and additional

pipelines

pipelines

Ample liquidity

and access to capital to support growth initiatives

26

Appendix

27

Oklahoma

Assets

28

OKLAHOMA

South

Texas Assets

29

TEXAS

North

Texas Assets

30

TEXAS

Rocky

Mountains Assets

31

WYOMING

Processing

Modes

32

|

Full

Recovery

|

|

|

|

Texas and

Oklahoma - If the value of

recovered NGLs exceeds the fuel and gas shrinkage costs of recovering NGLs |

|

Ethane

Rejection

|

|

|

|

Texas and

Oklahoma - If the value of ethane

is less than the fuel and shrinkage costs to recover ethane (in Oklahoma, ethane rejection at Paden plant is limited by nitrogen rejection facilities) |

|

Conditioning

Mode

|

|

|

|

Texas - If

the value of recovered NGLs is less

than the fuel and gas shrinkage cost of recovering NGLs (available at Houston Central plant and at Saint Jo plant in North Texas) |

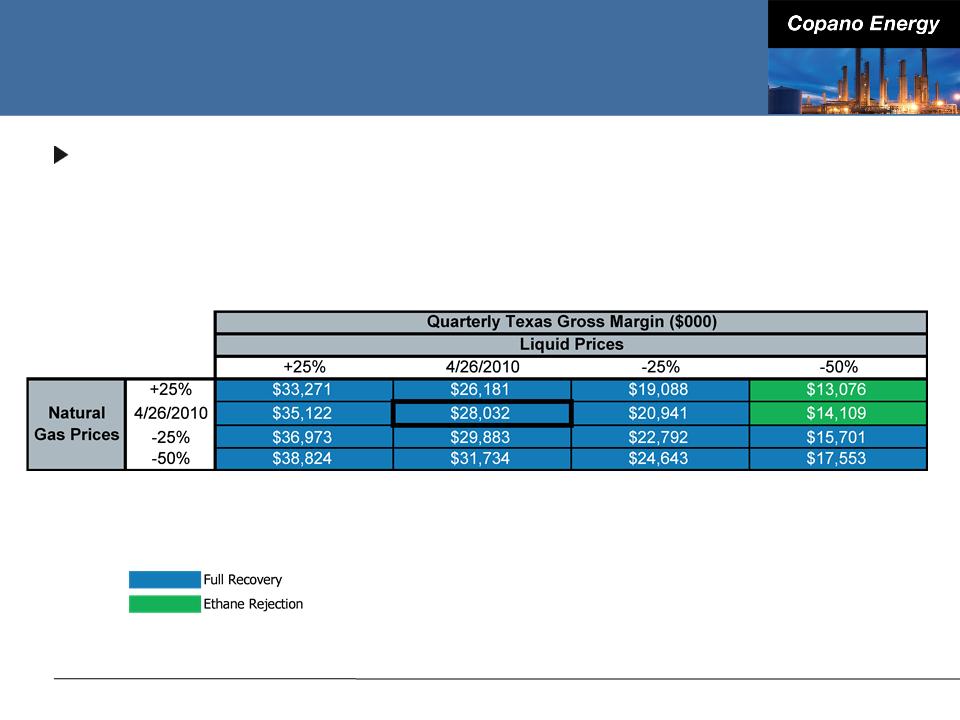

Commodity-Related

Margin Sensitivities

Matrix reflects 1Q

2010 wellhead and plant inlet volumes, adjusted

using Copano’s 2010 planning model

using Copano’s 2010 planning model

33

Note: Please

see Appendix for definitions of processing modes and additional

details.

Consists

of Texas and Oklahoma Segment gross margins.

Combined

Commodity-Sensitive Segment

Margins and Hedging Settlements

Margins and Hedging Settlements

34

Note:

Weighted

average NGL prices are based on Copano product mix for period

indicated.

Does

not include non-cash expenses included in Corporate and Other for purposes of

calculating Total Segment Gross Margin. See

Appendix for

reconciliation of Total Segment Gross Margin.

reconciliation of Total Segment Gross Margin.

Reflects

the average of April and May (as of May 6, 2010)

prices.

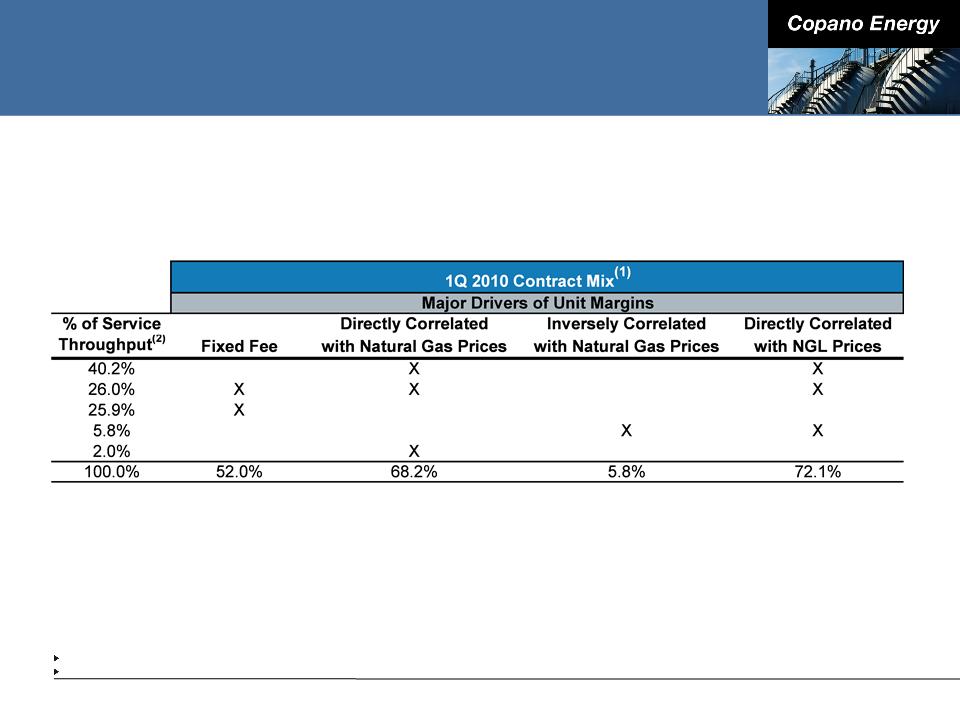

Oklahoma

Contract Mix

35

Source:

Copano Energy internal financial planning models for consolidated

subsidiaries.

Excludes

14,130 MMBtu/d service throughput for Southern Dome, a majority-owned

affiliate.

Oklahoma

Net Commodity Exposure

36

Note: See

explanation of processing modes in this Appendix. Values

reflect rounding.

Source: Copano

Energy internal financial planning models for consolidated

subsidiaries.

Ethane

rejection at Paden plant is limited by nitrogen rejection

facilities.

Reflects

impact of producer delivery point allocations, offset by field condensate

collection and stabilization.

Oklahoma

Commodity Price Sensitivities

Oklahoma segment

gross margins excluding hedge settlements

■ Matrix reflects 1Q

2010 volumes, adjusted using Copano’s 2010 planning

model

model

37

Texas

Contract Mix

38

Source: Copano

Energy internal financial planning models for consolidated

subsidiaries.

Excludes

66,764 MMBtu/d service throughput for Webb Duval, a majority-owned

affiliate.

Texas

Net Commodity Exposure

39

Note: See

explanation of processing modes in this Appendix.

Source: Copano

Energy internal financial planning models for consolidated subsidiaries. Based on

1Q 201 daily wellhead/plant inlet volumes.

Fractionation

at Houston Central processing plant permits significant reductions in ethane

recoveries in ethane rejection mode and full ethane rejection in

conditioning mode. To optimize profitability, plant operations can also be adjusted to partial recovery mode.

conditioning mode. To optimize profitability, plant operations can also be adjusted to partial recovery mode.

At

the Houston Central processing plant, pentanes+ may be sold as

condensate.

Texas

Commodity Price Sensitivities

Texas segment

gross margins excluding hedge settlements

■ Matrix reflects 1Q

2010 volumes and operating conditions, adjusted using

Copano’s 2010 planning model

Copano’s 2010 planning model

40

Rocky

Mountains Sensitivities

1Q 2010 Adjusted

EBITDA volume sensitivity (positive or negative

impact)

impact)

■ Bighorn: 10,000

MMBtu/d = $244,000(1)

■ Fort Union: 10,000

MMBtu/d = $70,000(1)

41

Note: See

this Appendix for reconciliation of Adjusted EBITDA. Values

reflect rounding.

Impact

on Adjusted EBITDA based on Copano’s interest in the unconsolidated

affiliate.

Hedging

Impact of Commodity Price

Sensitivities

Sensitivities

42

Liquidity

and Debt Facilities

At March 31,

2010:

■ Cash:

Approximately $54 million

■ $550 million

revolving credit facility

● Approximately $247

million available (limited by debt covenants)

● Remaining term:

approximately 2.6 years

● LIBOR + 200

bps

■ $582 million

senior notes

● $332,665,000 8 ⅛%

due 2016

● $249,525,000 7 ¾%

due 2018

● Weighted average

rate: 7.96%

● Weighted average

maturity: 6.9 years

43

Key

Debt Terms and Covenants

Senior Secured

Revolving Credit Facility

■ $550 million

facility with $100 million accordion

■ Maintenance

tests:

● 5x total debt to

defined EBITDA(1)

limitation

Ø 3.7x at March

31, 2010

● Minimum required

interest coverage 2.5x defined EBITDA

Ø 3.5x at March

31, 2010

● Defined EBITDA

adds back hedge amortization and other non-cash

expenses

expenses

■ Following an

acquisition, Copano may increase total debt to defined EBITDA

limitation to 5.5x for three quarters

limitation to 5.5x for three quarters

Senior

Notes

■ Incurrence

tests:

● Minimum defined

EBITDA to interest test of 2.00x for debt incurrence

● Minimum defined

EBITDA to interest test of 1.75x for restricted payments

● Defined EBITDA is

similar to that for credit facility

44

See

this Appendix for reconciliation of defined EBITDA, which is referred to in our

credit facility as “Consolidated EBITDA.”

Distribution

Outlook

45

Reconciliation

of Non-GAAP Financial

Measures

Measures

Segment

Gross Margin and Total Segment Gross Margin

We define segment

gross margin, with respect to a Copano operating segment, as segment revenue

less cost of sales. Cost of

sales includes the

following: cost of natural gas and NGLs purchased from third parties, cost of natural gas and NGLs purchased from affiliates, cost of crude oil purchased

from third parties, costs paid to third parties to transport volumes and costs paid to affiliates to transport volumes. Total segment gross margin is the

sum of the operating segment gross margins and the results of Copano’s risk management activities that are included in Corporate and other. We view

total segment gross margin as an important performance measure of the core profitability of our operations. Segment gross margin allows Copano’s

senior management to compare volume and price performance of the segments and to more easily identify operational or other issues within a

segment. The GAAP measure most directly comparable to total segment gross margin is operating income.

following: cost of natural gas and NGLs purchased from third parties, cost of natural gas and NGLs purchased from affiliates, cost of crude oil purchased

from third parties, costs paid to third parties to transport volumes and costs paid to affiliates to transport volumes. Total segment gross margin is the

sum of the operating segment gross margins and the results of Copano’s risk management activities that are included in Corporate and other. We view

total segment gross margin as an important performance measure of the core profitability of our operations. Segment gross margin allows Copano’s

senior management to compare volume and price performance of the segments and to more easily identify operational or other issues within a

segment. The GAAP measure most directly comparable to total segment gross margin is operating income.

46

Reconciliation

of Non-GAAP Financial

Measures

Measures

Adjusted

EBITDA

We define EBITDA as

net income (loss) plus interest expense, provision for income taxes and

depreciation and amortization expense. Because a portion

of our net income (loss) is attributable to equity in earnings (loss) from our equity investees (which include Bighorn, Fort Union, Webb Duval and

Southern Dome), our management also calculates Adjusted EBITDA to reflect the depreciation and amortization expense embedded in equity in

earnings (loss) from unconsolidated affiliates. Specifically, our management determines Adjusted EBITDA by adding to EBITDA (i) the amortization

expense attributable to the difference between our carried investment in each unconsolidated affiliate and the underlying equity in its net assets, (ii)

the portion of each unconsolidated affiliate’s depreciation and amortization expense, which is proportional to our ownership interest in that

unconsolidated affiliate and (iii) the portion of each unconsolidated affiliate’s interest and other financing costs, which is proportional to our ownership

interest in that unconsolidated affiliate.

of our net income (loss) is attributable to equity in earnings (loss) from our equity investees (which include Bighorn, Fort Union, Webb Duval and

Southern Dome), our management also calculates Adjusted EBITDA to reflect the depreciation and amortization expense embedded in equity in

earnings (loss) from unconsolidated affiliates. Specifically, our management determines Adjusted EBITDA by adding to EBITDA (i) the amortization

expense attributable to the difference between our carried investment in each unconsolidated affiliate and the underlying equity in its net assets, (ii)

the portion of each unconsolidated affiliate’s depreciation and amortization expense, which is proportional to our ownership interest in that

unconsolidated affiliate and (iii) the portion of each unconsolidated affiliate’s interest and other financing costs, which is proportional to our ownership

interest in that unconsolidated affiliate.

External users of

our financial statements such as investors, commercial banks and research

analysts use EBITDA or Adjusted EBITDA, and our

management uses Adjusted EBITDA, as a supplemental financial measure to assess:

management uses Adjusted EBITDA, as a supplemental financial measure to assess:

■ The financial

performance of our assets without regard to financing methods, capital structure

or historical cost basis;

■ The ability of our

assets to generate cash sufficient to pay interest costs and support our

indebtedness;

■ Our operating

performance and return on capital as compared to those of other companies in the

midstream energy sector, without regard to financing or capital

structure; and

structure; and

■ The viability of

acquisitions and capital expenditure projects and the overall rates of return on

alternative investment opportunities.

47

Reconciliation

of Non-GAAP Financial

Measures

Measures

Consolidated

EBITDA

EBITDA is also a

financial measure that, with negotiated pro forma adjustments relating to

acquisitions completed during

the period, is reported to our lenders as Consolidated EBITDA and is used to compute our financial covenants under our

senior secured revolving credit facility.

the period, is reported to our lenders as Consolidated EBITDA and is used to compute our financial covenants under our

senior secured revolving credit facility.

The following

table presents a reconciliation of the non-GAAP financial measure of

Consolidated EBITDA to the GAAP

financial measure of net income (loss):

financial measure of net income (loss):

48

Definitions

of Non-GAAP Financial Measures

Total

Distributable Cash Flow

We define total

distributable cash flow as net income plus: (i) depreciation, amortization and

impairment expense

(including amortization expense relating to the option component of our risk management portfolio); (ii) cash

distributions received from investments in unconsolidated affiliates and equity losses from such unconsolidated affiliates;

(iii) provision for deferred income taxes; (iv) the subtraction of maintenance capital expenditures; (v) the subtraction of

equity in earnings from unconsolidated affiliates and (vi) the addition of losses or subtraction of gains relating to other

miscellaneous non-cash amounts affecting net income for the period, such as equity-based compensation, mark-to-

market changes in derivative instruments, and our line fill contributions to third-party pipelines and gas imbalances.

Maintenance capital expenditures are capital expenditures employed to replace partially or fully depreciated assets to

maintain the existing operating capacity of our assets and to extend their useful lives, or other capital expenditures that

are incurred in maintaining existing system volumes and related cash flows.

(including amortization expense relating to the option component of our risk management portfolio); (ii) cash

distributions received from investments in unconsolidated affiliates and equity losses from such unconsolidated affiliates;

(iii) provision for deferred income taxes; (iv) the subtraction of maintenance capital expenditures; (v) the subtraction of

equity in earnings from unconsolidated affiliates and (vi) the addition of losses or subtraction of gains relating to other

miscellaneous non-cash amounts affecting net income for the period, such as equity-based compensation, mark-to-

market changes in derivative instruments, and our line fill contributions to third-party pipelines and gas imbalances.

Maintenance capital expenditures are capital expenditures employed to replace partially or fully depreciated assets to

maintain the existing operating capacity of our assets and to extend their useful lives, or other capital expenditures that

are incurred in maintaining existing system volumes and related cash flows.

Total

distributable cash flow is a significant performance metric used by senior

management to compare basic cash flows

generated by us (prior to the establishment of any retained cash reserves by our Board of Directors) to the cash

distributions we expect to pay our unitholders, and it also correlates with the metrics of our existing debt covenants.

Using total distributable cash flow, management can quickly compute the coverage ratio of estimated cash flows to

planned cash distributions. Total distributable cash flow is also an important non-GAAP financial measure for our

unitholders because it serves as an indicator of our success in providing a cash return on investment — specifically,

whether or not we are generating cash flow at a level that can sustain or support an increase in our quarterly distribution

rates. Total distributable cash flow is also used by industry analysts with respect to publicly traded partnerships and

limited liability companies because the market value of such entities’ equity securities is significantly influenced by the

amount of cash they can distribute to unitholders.

generated by us (prior to the establishment of any retained cash reserves by our Board of Directors) to the cash

distributions we expect to pay our unitholders, and it also correlates with the metrics of our existing debt covenants.

Using total distributable cash flow, management can quickly compute the coverage ratio of estimated cash flows to

planned cash distributions. Total distributable cash flow is also an important non-GAAP financial measure for our

unitholders because it serves as an indicator of our success in providing a cash return on investment — specifically,

whether or not we are generating cash flow at a level that can sustain or support an increase in our quarterly distribution

rates. Total distributable cash flow is also used by industry analysts with respect to publicly traded partnerships and

limited liability companies because the market value of such entities’ equity securities is significantly influenced by the

amount of cash they can distribute to unitholders.

49