Attached files

Table of Contents

As filed with the Securities and Exchange Commission on April 9, 2010

Registration No. 333-165200

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

AMENDMENT NO. 1

to

FORM S-1

REGISTRATION STATEMENT

UNDER

THE SECURITIES ACT OF 1933

Tower Automotive, LLC

to be converted as described herein to a corporation named

TOWER INTERNATIONAL, INC.

(Exact name of registrant as specified in its charter)

| Delaware | 3714 | 20-8879584 | ||

| (State or other jurisdiction of incorporation or organization) |

(Primary Standard Industrial Classification Code number) |

(I.R.S. Employer Identification Number) |

17672 Laurel Park Drive North, Suite 400E

Livonia, Michigan 48152

(248) 675-6000

(Address, including zip code, and telephone number, including area code, of registrant’s principal executive offices)

James Gouin

Chief Financial Officer

17672 Laurel Park Drive North, Suite 400E

Livonia, Michigan 48152

(248) 675-6000

(Name, address, including zip code and telephone number, including area code, of agent for service)

Please address a copy of all communications to:

| Peter H. Ehrenberg, Esq. Michael J. Reinhardt, Esq. Lowenstein Sandler PC 1251 Avenue of the Americas New York, New York 10020 (212) 262-6700 |

Joseph A. Hall, Esq. Davis Polk & Wardwell LLP 450 Lexington Avenue New York, New York 10017 (212) 450-4000 |

Approximate date of commencement of proposed sale to the public: As soon as practicable after this Registration Statement becomes effective.

If any of the securities being registered on this Form are to be offered on a delayed or continuous basis pursuant to Rule 415 under the Securities Act of 1933, check the following box. ¨

If this Form is filed to register additional securities for an offering pursuant to Rule 462(b) under the Securities Act, please check the following box and list the Securities Act registration statement number of the earlier effective registration statement for the same offering. ¨

If this Form is a post-effective amendment filed pursuant to Rule 462(c) under the Securities Act, check the following box and list the Securities Act registration statement number of the earlier effective registration statement for the same offering. ¨

If this Form is a post-effective amendment filed pursuant to Rule 462(d) under the Securities Act, check the following box and list the Securities Act registration statement number of the earlier effective registration statement for the same offering. ¨

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company. See the definitions of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act.

| Large accelerated filer ¨ | Accelerated filer ¨ | Non-accelerated filer x | Smaller reporting company ¨ | |||

| (Do not check if a smaller reporting company) |

The Registrant hereby amends this Registration Statement on such date or dates as may be necessary to delay its effective date until the Registrant shall file a further amendment which specifically states that this Registration Statement shall thereafter become effective in accordance with Section 8(a) of the Securities Act of 1933 or until the Registration Statement shall become effective on such date as the Commission, acting pursuant to said Section 8(a), may determine.

Table of Contents

The information in this prospectus is not complete and may be changed. We may not sell these securities until the registration statement filed with the Securities and Exchange Commission is effective. This prospectus is not an offer to sell these securities and it is not soliciting an offer to buy these securities in any jurisdiction where the offer or sale is not permitted.

Subject to Completion

Preliminary Prospectus dated April 9, 2010

| PROSPECTUS Shares |

Tower International, Inc.

Common Stock

This is Tower International, Inc.’s initial public offering. We are selling shares of our common stock.

We expect the public offering price to be between $ and $ per share. Currently, no public market exists for the shares. We intend to apply to have our shares listed on the New York Stock Exchange under the symbol “TOWR.”

Investing in our common stock involves risks that are described under “Risk Factors” beginning on page 15 of this prospectus.

| Per Share | Total | |||||

| Public offering price |

$ | $ | ||||

| Underwriting discount |

$ | $ | ||||

| Proceeds, before expenses, to us |

$ | $ | ||||

The underwriters may also purchase up to an additional shares from us, at the public offering price, less the underwriting discount, within 30 days from the date of this prospectus to cover over-allotments, if any.

Neither the Securities and Exchange Commission nor any state securities commission has approved or disapproved of these securities or determined if this prospectus is truthful or complete. Any representation to the contrary is a criminal offense.

The underwriters expect to deliver the shares against payment in New York, New York on or about , 2010.

| Goldman, Sachs & Co. | Citi |

The date of this prospectus is , 2010.

Table of Contents

| Page | ||

| 1 | ||

| 15 | ||

| 37 | ||

| 38 | ||

| 39 | ||

| 40 | ||

| 42 | ||

| 44 | ||

| Management’s Discussion and Analysis of Financial Condition and Results of Operations |

46 | |

| 78 | ||

| 96 | ||

| 101 | ||

| 123 | ||

| 126 | ||

| 128 | ||

| 133 | ||

| 137 | ||

| Material United States Federal Income and Estate Tax Considerations for Non-U.S. Holders |

139 | |

| 142 | ||

| 147 | ||

| 147 | ||

| 148 | ||

| F-1 |

You should rely only on the information contained in this prospectus or contained in any free writing prospectus approved by us or filed by us with the Securities and Exchange Commission (the “SEC”). Neither we, nor the underwriters, have authorized anyone to provide you with additional information or information different from that contained in this prospectus or in any such free writing prospectus. We are offering to sell, and seeking offers to buy, our common stock only in jurisdictions where offers and sales are permitted. The information contained in this prospectus is accurate only as of the date of this prospectus, regardless of the time of delivery of this prospectus or of any sale of our common stock.

Through and including , 2010 (the 25th day after the date of this prospectus), all dealers effecting transactions in these securities, whether or not participating in this offering, may be required to deliver a prospectus. This is in addition to a dealer’s obligation to deliver a prospectus when acting as an underwriter and with respect to an unsold allotment or subscription.

MARKET AND INDUSTRY DATA

Market and industry data used throughout this prospectus, including information relating to our relative position in the vehicle structural component and assemblies industry, is based on the good faith estimates of management, which in turn are based upon management’s review of internal surveys, independent industry surveys and publications and other publicly available information, including reports and information prepared by CSM Worldwide®, a global forecasting service for automotive production. The reports prepared by CSM Worldwide® are subscription-based.

i

Table of Contents

TRADEMARKS AND TRADE NAMES

We own or have rights to trademarks or trade names that we use in conjunction with the operation of our business. In addition, our name, logo and website name and address are our service marks or trademarks. Each trademark, trade name or service mark by any other company appearing in this prospectus belongs to its holder. Our principal trademark or trade name that we use is Tower Automotive®.

CORPORATE CONVERSION

Immediately prior to the consummation of this offering, we will convert from a Delaware limited liability company to a Delaware corporation and will change our name from Tower Automotive, LLC to Tower International, Inc. We refer to this transaction as the Corporate Conversion. See “Business—Our History and Corporate Structure—Our Corporate Conversion.”

ii

Table of Contents

The following summary is qualified in its entirety by, and should be read together with, the more detailed information and financial statements and related notes thereto appearing elsewhere in this prospectus. You should read the entire prospectus carefully, particularly the “Risk Factors” beginning on page 14 and our consolidated financial statements and the related notes thereto. In this prospectus, unless otherwise indicated or the context otherwise requires, references to (1) the terms “we,” “us,” “our,” the “Company,” “Tower” and “Tower Automotive” refer to Tower International, Inc. and its subsidiaries on a consolidated basis, (2) the term “CCM” refers only to Cerberus Capital Management, L.P. and (3) the term “Cerberus” refers to CCM and funds and accounts affiliated with CCM. The terms “Adjusted EBITDA” and “Adjusted EBITDA margin” are defined in footnotes 5 and 6 in “—Summary Consolidated Financial Data,” and the terms “Predecessor” and “Successor” are defined in “—Summary Consolidated Financial Data.”

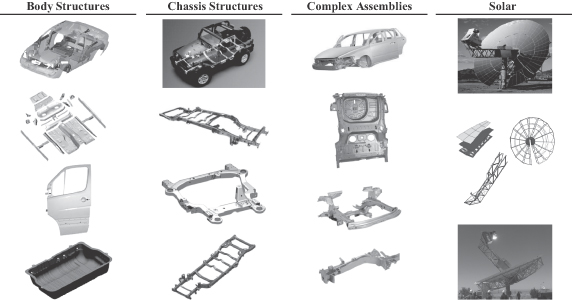

Our Company

We are a leading integrated global manufacturer of engineered structural metal components and assemblies primarily serving automotive original equipment manufacturers, or OEMs. We offer our automotive customers a broad product portfolio, supplying body-structure stampings, frame and other chassis structures, as well as complex welded assemblies, for small and large cars, crossovers, pickups and SUVs. We have also recently entered the utility-scale solar energy market with an agreement to supply large stamped mirror-facet panels and welded support structures. We refer to such agreement as our solar agreement.

| Product Offerings | ||||||

|

| ||||||

Our products are manufactured at 31 production facilities strategically located near our customers in North America, South America, Europe and Asia. We support our manufacturing operations through nine engineering and sales locations throughout the world. We are a disciplined, process-driven company with an experienced management team that has a history of implementing sustainable operational improvements. From January 1, 2008 through December 31, 2009, we achieved $195 million in manufacturing and purchasing cost reductions.

1

Table of Contents

We achieved these cost reductions in large part through successful implementation of Lean Six Sigma principles and rigorous application of global best practices. These cost reductions helped us achieve a 6% gross profit margin in 2009 during an historically challenging environment in the automotive industry. For the year ended December 31, 2009, we generated revenues of $1.6 billion and a net loss attributable to Tower Automotive, LLC of $(67.9) million. In addition, we had Adjusted EBITDA of $125 million and an Adjusted EBITDA margin of 7.6% for the year ended December 31, 2009.

We believe that our product capabilities, our geographic, customer and product diversification and the cost reductions that we achieved in 2008 and 2009 position us to benefit from a recovery in global automotive industry production. We also intend to leverage our program management and engineering expertise to pursue growth opportunities outside of our existing automotive markets, as demonstrated by our solar agreement.

Our Industry

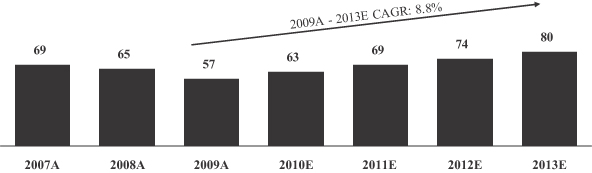

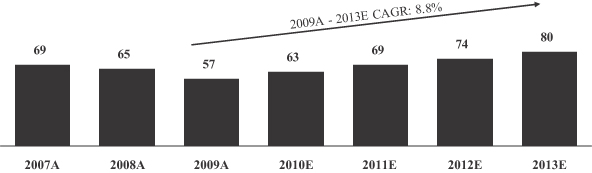

CSM Worldwide® projects significant growth in the global automotive market, with production expected to increase from 57 million units in 2009 to 80 million units by 2013.

CSM Worldwide® Global Light Vehicle Production Forecast (millions of units)

We believe OEMs produce a majority of their structural metal components and assemblies internally. While OEM policies differ and may be especially impacted by their own capacity utilization, the capital expenditures associated with internal production can be substantial. We believe that longer term, OEMs may outsource a greater proportion of their stamping requirements because of this capital and fixed-cost intensity and we may benefit from this shift in our customer preferences. In addition, we believe OEMs will increasingly favor global vehicle platforms supported by larger, more capable and financially strong suppliers. Given our global manufacturing footprint, competitive cost structure and integrated design, engineering and program management capabilities, we are well-positioned to take advantage of these potential opportunities.

2

Table of Contents

Our Competitive Strengths

Geographic Diversification

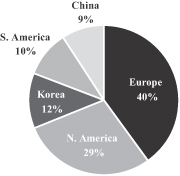

We are well-diversified geographically, which positions us to participate in growth opportunities as they occur over time around the world and mitigates the impact of regional production fluctuations on our business. These potential opportunities range from near-term cyclical volume recovery in North America and Europe to continued growth in emerging markets such as Brazil and China. Proximity to end customers is especially important in our business because size and weight make our products difficult and expensive to transport. Our geographic mix of 2009 revenues is shown below:

Geographic Mix (% of 2009 Revenues)

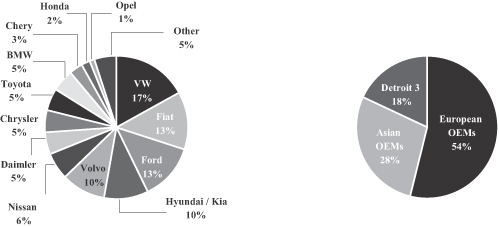

Customer Diversification

We have a well-diversified customer mix. In 2009, no single customer accounted for more than 17% of our revenues, and ten different OEMs individually accounted for 5% or more of our revenues. European OEMs were our biggest customer group in 2009, followed by Asian OEMs, with Detroit 3 OEMs representing the smallest group, at 18% of 2009 revenues. Ford accounted for approximately 70% of our 2009 Detroit 3 revenues. With this customer diversification, we believe we are well-positioned to participate in the anticipated automotive recovery, while also mitigating our exposure to any individual customer. The term “Detroit 3” refers collectively to Ford, General Motors and Chrysler and the term “European OEMs” includes Volvo and Opel.

Customer Mix (% of 2009 Revenues)

3

Table of Contents

Platform Diversification

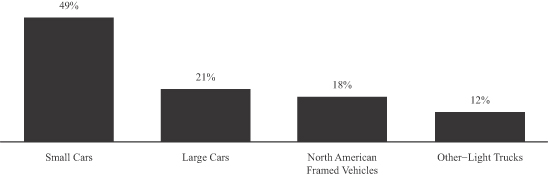

Our products are offered on a diverse mix of vehicle platforms, reflecting the balanced portfolio approach of our business model and the breadth of our product capabilities. We believe that our platform diversification provides us an opportunity to participate in an industry recovery without being overly exposed to a single vehicle model. We supply products to approximately 160 vehicle models globally. Our 10 largest vehicle models represented approximately 27% of our 2009 revenues.

Vehicle Segment Mix (% of 2009 Revenues)

See “Business—Our Competitive Strengths—Platform Diversification” for definitions of the terms “small cars,” “large cars” and “North American framed vehicles.”

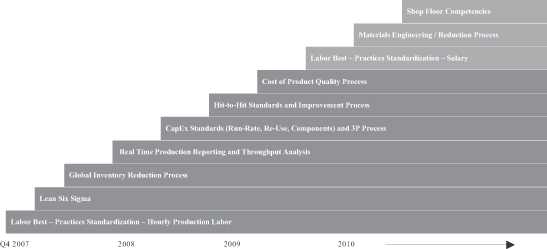

Competitive Cost Structure

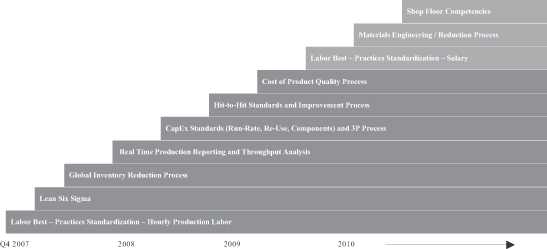

Based on the cost improvement actions we have taken and the results we have achieved, our experience in the automotive industry and our Adjusted EBITDA margins, we believe we have a competitive cost structure. During the Predecessor’s restructuring, while operating under bankruptcy protection, it achieved significant savings. For example, in North America the Predecessor reduced its manufacturing footprint from 23 to 12 plants, a 48% reduction. In addition, our average North American labor rate for hourly production workers, including wages and fringe benefits, was reduced by approximately 15%, to what we believe is a competitive level for our sector, and we froze our pension plan. We also capped our post-retirement healthcare liability to an amount which, at December 31, 2009, was $1.7 million. Following the acquisition of the Predecessor’s assets, we moved aggressively to improve productivity and manufacturing throughput to world-class standards to further improve our cost structure. We launched eight operating efficiency initiatives through 2009, we have scheduled two additional operating efficiency initiatives for launch in 2010 and we intend to implement other efficiency programs in the future to assist us in driving costs out of our manufacturing and procurement processes.

4

Table of Contents

Efficiency Initiatives

See “Business—Manufacturing and Operations” for a detailed explanation of this chart.

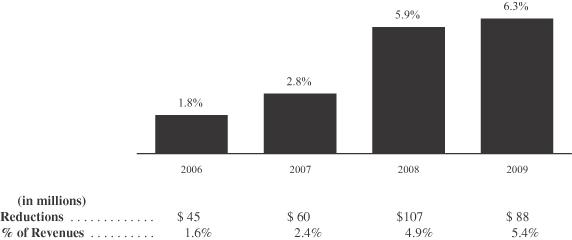

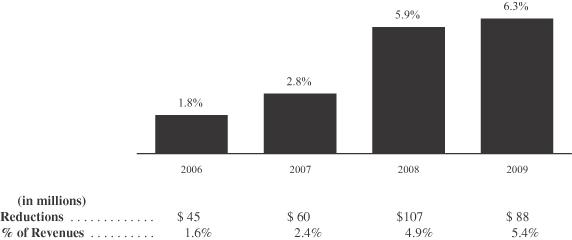

We measure our operating efficiencies in manufacturing and purchasing cost reductions as a percentage of our material and manufacturing costs. As a result of our process-driven initiatives, we significantly increased that annual percentage improvement from approximately 2% in 2006 to approximately 6% in 2009 resulting in $195 million in manufacturing and purchasing cost savings from January 1, 2008 through December 31, 2009. Our focus in 2010 and beyond is to retain the benefit of these achieved cost savings as anticipated volume recovery occurs.

Operating Efficiencies vs. Prior Year

(Manufacturing and Purchasing Cost Reductions as % of Manufacturing and Material Costs)

5

Table of Contents

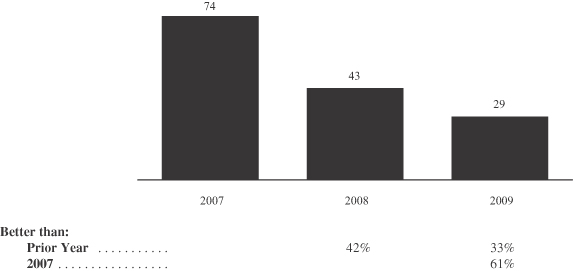

Good Quality

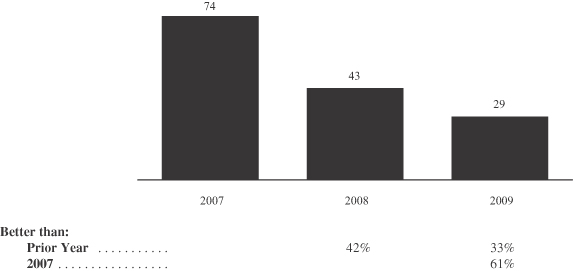

Through rigorous standardization of global best practices and major process improvements such as Lean Six Sigma, we have improved our quality results, with customer-reported defects per million parts, or PPM, down to 29 in 2009.

Customer-Reported PPM

Experienced Management Team

Our senior management team has substantial industry and related operational and financial experience. In addition, the eight executives comprising our executive leadership team have been in place as a cohesive group essentially since we acquired the Predecessor’s assets in 2007. Mark Malcolm, our Chief Executive Officer since August 2007, worked for 28 years in a broad variety of roles with Ford Motor Company. Mr. Malcolm then became a senior operational adviser for Cerberus, where he led a year-long due diligence effort prior to the acquisition of the Predecessor’s assets, assessing strengths and weaknesses and developing the business plan that we have executed since the acquisition. Our Chief Operating Officer, Michael Rajkovic, worked for Ford and Visteon prior to assuming officer positions at Goodyear and U.S. Can Corporation. Jim Gouin, our Chief Financial Officer, worked for 28 years at Ford, including as Vice President, Finance and Global Corporate Controller.

6

Table of Contents

Our Strategy

Our strategy is to strengthen our leadership position as a supplier to the global automotive industry and to expand opportunistically into non-automotive markets. We believe that our core strengths described above position us to continue to provide a high-quality, low-cost value proposition to our customers, enabling profitable growth. Specific strategic objectives include:

Revenue Growth

Our strategy for revenue growth has three main pillars: organic automotive growth, expansion into solar and other non-automotive markets, and opportunistic acquisitions and joint ventures.

Organic Automotive Growth: Although for planning purposes we are cautious about the pace of automotive industry recovery in 2010, we believe that vehicle growth will be above-average over the next three to five years. Having significantly improved our cost structure over the last two years, we believe that we are poised to benefit from an anticipated cyclical recovery in the European and North American markets and to grow in developing markets like Brazil and China. In terms of organic automotive growth, our planning assumption is that our growth will roughly track the growth in annual vehicle production. We will also strive to increase our share of business, principally through contract wins for new models developed by our existing customers and by expanding our customer base, while maintaining good geographic, customer and platform diversification.

Expansion into Solar and Other Non-Automotive Markets: We intend to leverage our integrated engineering, manufacturing and program-management expertise to pursue growth opportunities in non-automotive markets. The solar industry shows promise for us, as many applications require highly engineered large stampings and complex welded structural assemblies that must be produced in high volume at repeatable tight tolerances, similar to our product requirements in the automotive industry. To date, we have won a solar agreement initially entered into in August 2009 with expected lifetime revenues of approximately $ million over the term of this agreement, assuming that our customer secures the financing it requires to build its solar project. We expect that such funding will be obtained. The term of our solar agreement is five years, except that it will automatically extend if necessary to assure that a specified production volume threshold has been met. We expect that production will commence in late 2010 and that revenues will commence in 2011. We plan to invest approximately $30 to $35 million (net of government and other incentives) in 2010 to support this agreement, including investing in a new facility in the southwest United States that could provide a base for additional expansion. We expect that approximately one third of this investment will be expended in the first six months of 2010 and that the balance will be expended in the second half of 2010. We believe the solar industry in the United States and globally has the potential to grow at an average rate substantially greater than the trend rate for the automotive industry. Beyond solar, we believe there may be similar opportunities in the future to apply and extend our core skills in other industries, such as defense, wind or appliances.

Opportunistic Acquisitions and Joint Ventures: We intend to analyze and pursue acquisition opportunities where we believe we can add value and realize synergies by improving operating results through application of our processes, as demonstrated in our own business. We anticipate that the automotive structural metal components and assemblies sector will experience increased consolidation and believe that we are well-positioned to participate successfully in that evolution. We also intend to seek suitable partners to set up additional joint ventures in developing automotive markets, such as China, which we believe have above-average secular growth prospects. While we regularly participate in discussions with potential acquisition targets and joint venture partners, there are presently no specific agreements that have reached the stage where execution has become probable.

Continuous Process-Driven Operating Improvements

Our business philosophy and approach is grounded in the fundamental importance of building capabilities through ongoing process awareness and improvements. That focus and mindset applies to daily plant and cash reports, to detailed monthly business reviews, to our adoption and implementation of Lean Six Sigma principles,

7

Table of Contents

to our global inventory reduction process, to our internal controls, to our colleague engagement process that measures the involvement of our employees, and to many other critical governance and business processes employed and under development in our company. Near-term results must be delivered, but we strive to do so in a way that is repeatable and sustainable, strengthening our longer-term competitiveness to the ultimate benefit of our customers, colleagues, suppliers and stockholders.

Intense Focus on Cash Flow

We have a common focus and an alignment of incentives throughout our company on the importance of operating cash flow. For example, we track cash on a daily basis and our global bonus program is tied largely to cash flow metrics. This common focus and aligned incentive with respect to cash flow among all our colleagues helps create value for our stockholders. For example, inventories have been reduced from 23 average days on hand in December 2007 to approximately 13 average days on hand in December 2009.

Maintain a Sound Balance Sheet

We consider it critical to maintain a sound balance sheet in the cyclical automotive industry. That mindset and approach helped us weather the severe 2009 downturn without violating our loan covenants, and we intend to maintain this approach going forward. We anticipate reducing our leverage by applying a significant portion of the net proceeds from this offering to repay indebtedness.

Ownership

Prior to this offering, we will become a Delaware corporation and all of our outstanding capital stock will be owned by Tower International Holdings, LLC, a newly formed entity controlled by Cerberus that we sometimes refer to in this prospectus as our controlling stockholder.

Concurrent with the closing of this offering, we will issue restricted stock units, or RSUs, to certain executive officers and directors under one of our benefit plans. These RSUs will be valued using the price of our common stock to the public in this offering. Immediately after this offering, Tower International Holdings, LLC will control approximately % (approximately % if the underwriters’ option to purchase additional shares is exercised in full) of our common stock.

Corporate Information

Our principal executive offices are located at 17672 Laurel Park Drive North, Suite 400E, Livonia, Michigan 48152, and our telephone number is (248) 675-6000. For information regarding our corporate history, see “Business—Company Overview—Our History and Corporate Structure.” Our website address is www.towerautomotive.com. The information contained on our website or that can be accessed through our website is not part of this prospectus, and investors should not rely on any such information in deciding whether to purchase our common stock.

8

Table of Contents

THE OFFERING

| Common stock we are offering. |

shares (or shares if the underwriters exercise their option to purchase additional shares in full). |

| Common stock to be outstanding after this offering |

shares (or shares if the underwriters exercise their option to purchase additional shares in full). |

| Use of proceeds |

The net proceeds to us from this offering will be approximately $ after deducting the underwriting discount and estimated expenses of this offering and assuming we sell the shares for $ per share, representing the midpoint of the range on the cover page of this prospectus. We intend to use the net proceeds of this offering to retire indebtedness and for working capital and general corporate purposes. |

| Dividend policy |

We do not intend to pay dividends on our common stock in the foreseeable future. See “Dividend Policy.” |

| Risk factors |

See “Risk Factors” and other information included in this prospectus for a discussion of factors you should carefully consider before deciding to invest in our common stock. |

| Proposed ticker symbol |

“TOWR” |

The number of shares of common stock outstanding after the offering is based on shares of common stock issuable pursuant to our Corporate Conversion and excludes shares reserved for issuance under RSUs to be issued to certain executive officers and directors pursuant to one of our benefit plans in connection with the consummation of this offering. The number of such RSUs to be granted will depend primarily upon the price of our common stock to the public in this offering. Assuming such price equals the mid-point of the price range as set forth on the cover page of this prospectus, we expect to grant approximately RSUs to certain executive officers and directors in connection with this offering. See “Compensation Discussion and Analysis—Components of Compensation—Equity-Based Incentive Awards —Long Term Incentive Compensation Awards.”

Unless otherwise indicated, all information contained in this prospectus assumes that the underwriters do not exercise their option to purchase up to additional shares of our common stock and assumes that our Corporate Conversion has been consummated.

For more detailed information regarding our common stock, see “Description of Capital Stock.”

9

Table of Contents

SUMMARY CONSOLIDATED FINANCIAL DATA

The following tables set forth (i) summary consolidated financial data of Tower Automotive, LLC, for periods after July 31, 2007, the date on which we acquired substantially all of the assets and assumed certain specific liabilities of Tower Automotive, Inc. and its United States subsidiaries in connection with the bankruptcy proceedings of Tower Automotive, Inc. and such subsidiaries and acquired the capital stock of substantially all of the foreign subsidiaries of Tower Automotive, Inc. and (ii) summary consolidated financial data of Tower Automotive, Inc. for periods on or before July 31, 2007. With respect to our financial data and throughout this prospectus, we refer to Tower Automotive, Inc. through July 31, 2007 as the Predecessor and we refer to Tower Automotive, LLC after July 31, 2007 as the Successor. The summary consolidated balance sheet data, the summary consolidated statement of operations data and the summary consolidated statement of cash flows data as of December 31, 2009 and for the periods ended December 31, 2009, 2008 and 2007 and July 31, 2007 have been derived from our audited consolidated financial statements and related notes included elsewhere in this prospectus.

Prior to the consummation of this offering, we will convert from a Delaware limited liability company to a Delaware corporation and will change our name from Tower Automotive, LLC to Tower International, Inc. We refer to this transaction as the Corporate Conversion. See “Business—Our History and Corporate Structure—Our Corporate Conversion.”

The summary consolidated financial data as of any date and for any period are not necessarily indicative of the results that may be achieved as of any future date or for any future period. As a result of the implementation of applicable accounting pronouncements relating to our acquisition of the Predecessor’s consolidated assets, the financial statements and financial data presented in this prospectus for dates and for periods ending on or before July 31, 2007 are not comparable with the financial statements and financial data presented in this prospectus for periods after July 31, 2007.

The following tables also set forth certain summary consolidated unaudited as adjusted balance sheet data as of December 31, 2009, giving effect to (i) the sale of shares of common stock by us in this offering at an assumed initial public offering price of $ per share (representing the midpoint of the range on the cover page of this prospectus) and (ii) the application of the net proceeds of this offering as described under “Use of Proceeds”, assuming that 100% of the net proceeds are used to repay indebtedness. The summary consolidated unaudited as adjusted balance sheet data is presented for informational purposes only and does not purport to represent what our financial condition actually would have been had these events occurred on the dates indicated or to project our financial condition as of any future date.

You should read the following summary financial data in conjunction with “Use of Proceeds,” “Selected Historical Consolidated Financial Data,” “Management’s Discussion and Analysis of Financial Condition and Results of Operations” and our consolidated financial statements and the related notes included elsewhere in this prospectus.

10

Table of Contents

Summary Consolidated Financial Data

| Successor | Predecessor(1) | |||||||||||||||

| Year Ended December 31 |

Five Months Ended December 31, 2007 |

Seven Months Ended July 31, 2007 |

||||||||||||||

| 2009 | 2008 | |||||||||||||||

| (in millions) | ||||||||||||||||

| Statement of Operations Data: |

||||||||||||||||

| Revenues |

$ | 1,634.4 | $ | 2,171.7 | $ | 1,086.1 | $ | 1,455.5 | ||||||||

| Cost of sales |

1,536.8 | 1,991.3 | 970.5 | 1,325.9 | ||||||||||||

| Gross profit |

97.6 | 180.4 | 115.6 | 129.6 | ||||||||||||

| Gross profit margin |

6.0 | % | 8.3 | % | 10.6 | % | 8.9 | % | ||||||||

| Selling, general and administrative expenses |

$ | 118.3 | $ | 138.6 | $ | 57.0 | $ | 77.3 | ||||||||

| Operating income/(loss) |

(36.9 | ) | 34.0 | 55.5 | 30.0 | |||||||||||

| Operating income/(loss) margin |

(2.3 | )% | 1.6 | % | 5.1 | % | 2.1 | % | ||||||||

| Interest expense, net. |

$ | 56.9 | $ | 60.2 | $ | 34.0 | $ | 65.5 | ||||||||

| Net income/ (loss) attributable to Tower Automotive, LLC |

(67.9 | ) | (52.3 | ) | 15.2 | (106.0 | )(2) | |||||||||

| Successor | Predecessor | |||||||||||||||

| Year Ended December 31 |

Five Months Ended December 31, 2007 |

Seven Months Ended July 31, 2007 |

||||||||||||||

| 2009 | 2008 | |||||||||||||||

| (in millions) | ||||||||||||||||

| Cash Flow Data: |

||||||||||||||||

| Net cash provided by (used in) |

||||||||||||||||

| Operating activities |

$ | 48.9 | $ | 200.6 | $ | 118.2 | $ | 18.3 | ||||||||

| Investing activities |

(86.0 | ) | (126.8 | ) | (676.3 | ) | (53.4 | ) | ||||||||

| Financing activities |

50.8 | (32.3 | ) | 651.4 | 53.0 | |||||||||||

| As of December 31, 2009 | ||||||||||||||||

| Actual | As Adjusted (Unaudited) |

|||||||||||||||

| (in millions) | ||||||||||||||||

| Balance Sheet Data: |

||||||||||||||||

| Cash and cash equivalents |

$ | 149.8 | ||||||||||||||

| Total assets |

1,334.4 | |||||||||||||||

| Total debt(3) |

669.5 | |||||||||||||||

| Redeemable preferred units(4) |

170.9 | — | ||||||||||||||

| Total members’/stockholders’ equity (deficit) |

(147.2 | ) | ||||||||||||||

| Successor | Predecessor | |||||||||||||||

| Year Ended December 31 |

Five Months Ended December 31, 2007 |

Seven Months Ended July 31, 2007 |

||||||||||||||

| 2009 | 2008 | |||||||||||||||

| (in millions) | ||||||||||||||||

| Other Financial Data: |

||||||||||||||||

| Adjusted EBITDA(5) |

$ | 125.0 | $ | 212.9 | $ | 123.6 | $ | 144.6 | ||||||||

| Adjusted EBITDA margin(6) |

7.6 | % | 9.8 | % | 11.4 | % | 9.9 | % | ||||||||

| Capital expenditures(7) |

$ | 78.9 | $ | 129.1 | (8) | $ | 39.4 | $ | 38.5 | |||||||

| As of December 31, 2009 | ||||||||||||||||

| Actual | As Adjusted (Unaudited) |

|||||||||||||||

| (in millions) | ||||||||||||||||

| Net debt(9) |

$ | 519.8 | ||||||||||||||

11

Table of Contents

| (1) | For information regarding our acquisition of the Predecessor’s business in 2007, see “Management’s Discussion and Analysis of Financial Condition and Results of Operations—Bases of Presentation—2007 Acquisition.” |

| (2) | Represents amounts attributable to the Predecessor. |

| (3) | Consists of short-term and long-term debt, current portion of long-term debt and capital lease obligations. |

| (4) | Represents preferred equity interests in Tower Automotive, LLC. Pursuant to the Corporate Conversion, these interests will be contributed to Tower International Holdings, LLC prior to the closing of this offering and thus will not represent obligations of Tower International, Inc. |

| (5) | Adjusted EBITDA is included in this prospectus, and in note 16 to our consolidated financial statements, because it is one of the principal factors upon which our management assesses operating performance. Our Chief Executive Officer measures the operating performance of our segments on the basis of Adjusted EBITDA. In addition to adjusting net income/(loss) to exclude interest expense, income taxes, depreciation and amortization, Adjusted EBITDA also adjusts net income/(loss) by excluding items or expenses as set forth below. Adjusted EBITDA is not a measure of operating performance defined in accordance with generally accepted accounting principles, or GAAP. However, our management believes that Adjusted EBITDA is useful to investors in evaluating our performance because it is a commonly used financial metric for measuring and comparing the operating performance of companies in our industry. We believe that the disclosure of Adjusted EBITDA offers an additional financial metric that, when coupled with our GAAP results and the reconciliation to our GAAP results presented below, provides a more complete understanding of our results of operations and the factors and trends affecting our business. |

| Adjusted EBITDA should not be considered as an alternative to net income/(loss) as an indicator of our operating performance, as an alternative to net cash provided by operating activities as a measure of liquidity, or as an alternative to any other measure prescribed by GAAP. The primary limitations associated with the use of Adjusted EBITDA as compared to GAAP results are (i) other companies in our industry may define EBITDA differently than we define Adjusted EBITDA and, as a result, our references to Adjusted EBITDA may not be comparable to similarly titled measures used by other companies in our industry and (ii) it excludes financial information that some may consider important in evaluating our operating performance. We compensate for these limitations by providing the following disclosure of the differences between Adjusted EBITDA and GAAP results, including providing a reconciliation of Adjusted EBITDA to GAAP results, to enable investors to perform their own analysis of our operating results. |

12

Table of Contents

Adjusted EBITDA is calculated as follows:

| Successor | Predecessor | |||||||||||||||

| Year Ended December 31 |

Five Months Ended December 31, 2007 |

Seven Months Ended July 31, 2007 |

||||||||||||||

| 2009 | 2008 | |||||||||||||||

| (in millions) |

||||||||||||||||

| Net income / (loss) attributable to Tower Automotive, LLC |

$ | (67.9 | ) | $ | (52.3 | ) | $ | 15.2 | $ | (106.0 | ) | |||||

| Adjustments: |

||||||||||||||||

| Depreciation and amortization |

$ | 147.7 | $ | 170.3 | $ | 61.3 | $ | 90.5 | ||||||||

| Interest expense, net |

56.9 | 60.2 | 34.0 | 65.5 | ||||||||||||

| Restructuring(a) |

13.4 | 4.8 | 1.8 | 22.4 | ||||||||||||

| Provision for income taxes |

(1.1 | ) | 19.5 | 10.4 | 15.0 | |||||||||||

| Chapter 11 and related reorganization items(b) |

— | — | — | 62.2 | ||||||||||||

| Other (income) / loss, net(c) |

(33.7 | ) | — | — | — | |||||||||||

| Non-controlling interest(d) |

8.9 | 6.6 | 3.0 | 5.4 | ||||||||||||

| Equity in joint ventures(e) |

— | — | (7.1 | ) | (12.4 | ) | ||||||||||

| Receivable factoring charges(f) |

0.8 | 0.7 | 1.6 | 1.7 | ||||||||||||

| Other adjustments(g) |

— | 3.1 | 3.4 | 0.3 | ||||||||||||

| Total adjustments |

$ | 192.9 | $ | 265.2 | $ | 108.4 | $ | 250.6 | ||||||||

| Adjusted EBITDA |

$ | 125.0 | $ | 212.9 | $ | 123.6 | $ | 144.6 | ||||||||

| (a) | Represents costs associated with facilities closures or permanent layoffs, including (i) closure and other exit costs and (ii) termination and severance payments. |

| (b) | Primarily represents professional fees and other costs associated with the Predecessor’s bankruptcy proceedings. |

| (c) | Represents gains associated with a reduction in our synthetic letter of credit facility and then a repurchase and retirement of a portion of our first lien term loan. |

| (d) | Represents the net income attributable to non-controlling partners in entities that we consolidate in our financial results, given the controlling nature of our interests in these entities. |

| (e) | Represents our portion of the net income of our non-controlled joint venture with Metalsa S.A. de C.V., or Metalsa, which we sold in December 2007. |

| (f) | Represents the discounts taken by our customers when making payments on our accounts receivable before the normal payment terms would require payment. We have excluded these amounts from Adjusted EBITDA because they represent a form of finance charge and finance charges have otherwise been excluded in calculating Adjusted EBITDA. |

| (g) | Other adjustments consist of one-time costs associated with discontinued operations for the period ended July 31, 2007; one-time costs associated with the acquisition of the assets of the Predecessor for the period ended December 31, 2007; and one-time costs associated with due diligence on a potential acquisition for the period ended December 31, 2008. |

| (6) | Represents Adjusted EBITDA divided by revenues. We believe that Adjusted EBITDA margin is useful to investors in evaluating our performance because Adjusted EBITDA is a commonly used financial metric for measuring and comparing the operating performance of companies in our industry. In addition, we use Adjusted EBITDA margin because we believe it is helpful to us and to investors when comparing our performance over various reporting periods on a consistent basis, as Adjusted EBITDA excludes items that we do not believe reflect our core operating performance. |

| (7) | Capital expenditures do not equal cash disbursed for purchases of property, plant, and equipment as presented in our consolidated statement of cash flows, and as shown in note 16 to our consolidated financial statements, include amounts paid and accrued during the periods presented. |

13

Table of Contents

| (8) | Includes $30.6 million of lease buyout payments that we paid in 2008 to terminate certain equipment leases in Europe and North America. Our Adjusted EBITDA improved by approximately $14.6 million per year as a result of these lease termination payments. |

| (9) | Represents total debt less cash and cash equivalents. We regard net debt as a useful measure of our outstanding debt obligations. Our use of the term “net debt” should not be understood to mean that we will use any cash on hand to repay debt. Net debt is calculated as follows: |

| Year Ended December 31, 2009 | ||||||

| Actual | As Adjusted (Unaudited) | |||||

| (in millions) | ||||||

| Total debt |

$ | 669.5 | ||||

| Cash and cash equivalents |

(149.8 | ) | ||||

| Net debt |

$ | 519.8 | ||||

14

Table of Contents

An investment in our common stock is subject to a number of risks. You should carefully consider the risks described below together with all the other information contained in this prospectus before deciding whether to purchase our common stock. If any of the following risks occurs, our business, financial condition, prospects and results of operations could be harmed. In such an event, the trading price of our common stock could decline and you may lose part or all of your investment.

Risk Factors Relating to Our Industry and Our Business

The recent deterioration in the global economy, the global credit markets and the financial services industry has severely and negatively affected demand for automobiles and automobile parts and our business, financial condition, results of operations and cash flows.

Demand for and pricing of our products are subject to economic conditions and other factors present in the various domestic and international markets where our products are sold. The level of demand for our products depends primarily upon the level of consumer demand for new vehicles that are manufactured with our products. The level of new vehicle purchases is cyclical, affected by such factors as general economic conditions, interest rates, consumer confidence, consumer preferences, patterns of consumer spending, fuel costs and the automobile replacement cycle.

The global economic crisis that has existed for at least the last two years and continues to exist has resulted in delayed and reduced purchases of durable consumer goods, such as automobiles. As a result, our OEM customers have significantly reduced their production. According to CSM Worldwide®, vehicle production during 2009 decreased by 32% and 43% in North America and by 20% and 25% in Europe, as compared to 2008 and 2007, respectively. This was the principal reason our revenues declined by $537 million, or 25%, from 2008 to 2009. These unprecedented conditions have had a severe and negative impact on our business, financial condition, results of operations and cash flows.

Further deterioration in the United States and world economies could exacerbate the difficulties experienced by our customers and suppliers in obtaining financing, which, in turn, could materially and adversely impact our business, financial condition, results of operations and cash flows.

Lending institutions have suffered and may continue to suffer losses due to their lending and other financial relationships, especially because of the general weakening of the global economy and the increased financial instability of many borrowers. Longer-term disruptions in the credit markets could further adversely affect our customers by making it increasingly difficult for them to obtain financing for their businesses and for their customers to obtain financing for automobile purchases. Our OEM customers typically require significant financing for their respective businesses. In addition, our OEM customers typically have related finance companies that provide financing to their dealers and customers. These finance companies have historically been active participants in the securitization markets, which have experienced severe disruptions during the global economic crisis. Our suppliers, as well as the other suppliers to our customers, may face similar difficulties in obtaining financing for their businesses. If capital is not available to our customers and suppliers, or if its cost is prohibitively high, their businesses would be negatively impacted, which could result in their restructuring or even reorganization/liquidation under applicable bankruptcy laws. Any such negative impact, in turn, could materially and negatively affect our company either through the loss of revenues to any of our customers so affected, or due to our inability to meet our commitments without excess expense resulting from disruptions in supply caused by the suppliers so affected.

A number of automobile manufacturers are, and over the last several years have been, facing severe financial difficulties. Many automobile manufacturers have undertaken significant restructuring actions in an effort to improve profitability and remain solvent. The current weaknesses in the capital markets combined with

15

Table of Contents

a slowdown in global automotive demand have increased the pressure on our customers and their cash reserves. Automobile manufacturers are burdened with substantial structural and embedded costs, such as facility overhead, pension expenses and healthcare costs, that have caused some manufacturers, including GM and Chrysler, to seek government financing and, ultimately, file for bankruptcy protection. Due to the declining economic situation, the United States government granted General Motors and Chrysler government loans to assist them in obtaining the necessary capital to continue to operate. In spite of the government programs, Chrysler filed for bankruptcy on April 30, 2009 and GM filed for bankruptcy on June 1, 2009. Chrysler and GM emerged from bankruptcy on June 10, 2009 and July 10, 2009, respectively. Other automakers are likewise experiencing difficulties from a weakened economy, tightening credit and reduced demand for their products. For example, certain automakers have sought and been granted government assistance in countries such as Germany, Sweden, Brazil, France, Britain, Portugal, Spain, and Canada in an attempt to sustain viability. We may be adversely affected by either a bankruptcy filing or merger or sale of an OEM. We cannot assure you that governmental responses to these disruptions will restore consumer confidence or improve the liquidity of the financial markets.

Given the significant decline in global automotive demand, many automotive suppliers have experienced a significant drop in their cash flow, which has caused certain of such companies to breach some of their debt covenants. Due to the tight credit market, there can be no assurance that these companies will be able to amend their debt covenants on commercially reasonable terms. This, in turn, may cause significant supply issues that could materially and adversely affect us.

Financial difficulties experienced by any major customer could have a material adverse impact on us if such customer were unable to pay for the products we provide or we experienced a loss of, or material reduction in, business from such customer. As a result of such difficulties, we could experience lost revenues, significant write-offs of accounts receivable, significant impairment charges or additional restructurings beyond the steps we have taken to date.

The automobile industry is highly cyclical and cyclical downturns in our domestic or international business segments negatively impact our business, financial condition, results of operations and cash flows.

The volume of automotive production in North America, Europe and the rest of the world has fluctuated, sometimes significantly from year-to-year, and such fluctuations give rise to fluctuations in demand for our products. Because we have significant fixed production costs, relatively modest declines in our customers’ production levels can have a significant adverse impact on our results of operations. Our results of operations have been negatively impacted over the last several years in part due to declines in North American production levels from prior periods. According to CSM Worldwide®, vehicle production during 2009 decreased by 32% and 43% in North America and by 20% and 25% in Europe as compared to 2008 and 2007, respectively.

The highly cyclical nature of the automotive industry presents a risk that is outside our control and that cannot be accurately predicted. For example, many believe that the current global economic crisis will continue throughout 2010 and we cannot assure you that we will be able to maintain or improve our results of operations in a stagnant or diminishing economic environment. Moreover, a number of factors that we cannot predict can and have impacted cyclicality in the past. Further decreases in demand for automobiles generally, or in the demand for our products in particular, could materially and adversely impact our business, financial condition, results of operations and cash flows.

Product recalls by OEMs could negatively impact their production levels and therefore have a material adverse impact on our business, financial condition, results of operations and cash flows.

There have recently been significant product recalls by some of the world’s largest automobile manufacturers. Toyota, for example, has engaged in a recall of some of its most popular models. Recalls may result in decreased production levels due to (i) an OEM focusing its efforts on addressing the problems underlying the recall, as opposed to generating new sales volume, and (ii) consumers’ electing not to purchase

16

Table of Contents

automobiles manufactured by the OEM initiating the recall, or by OEMs in general, while such recalls persist. Any reductions in OEM production volumes, especially those OEMs that are our existing customers, could have a material adverse impact on our business, financial condition, results of operations and cash flows.

Product liability claims could cause us to incur losses and damage our reputation.

Many of our products are critical to the structural integrity of a vehicle. As such, we face an inherent business risk of exposure to product liability claims in the event of the failure of our products to perform to specifications, or if our products are alleged to result in property damage, bodily injury or death. In addition, if any of our products are, or are alleged to be, defective, we may be required to participate in a recall involving those products. We are generally required under our customer contracts to indemnify our customers for product liability claims in respect of our products. In addition, we do not have insurance covering product recalls. Accordingly, we may be materially and adversely impacted by product liability claims.

The decreasing number of automotive parts customers could make it more difficult for us to compete favorably.

Our business, financial condition, results of operations and cash flows could be materially and adversely affected because the OEM customer base is consolidating. As a result, we are competing for business from fewer customers. Due to the cost focus of these major customers, we have been, and expect to continue to be, requested to reduce prices as part of our initial business quotations and over the life of contracts we have been awarded. We cannot be certain that we will be able to generate cost savings and operational improvements in the future that are sufficient to offset price reductions requested by customers and to make us profitable and position us to win additional business.

The decreasing number of automotive parts suppliers could make it more difficult for us to compete favorably.

Consolidation and bankruptcies among automotive parts suppliers are resulting in fewer and larger competitors who benefit from purchasing and distribution economies of scale. If we cannot compete favorably in the future with these larger suppliers, our business, financial condition, results of operations and cash flows could be adversely affected due to a reduction of, or inability to increase, revenues.

We may have difficulty competing favorably in the highly competitive automotive parts industry.

The automotive parts industry is highly competitive. Although the overall number of competitors has decreased due to ongoing industry consolidation, we face significant competition within each of our major product areas, including from new competitors entering the markets that we serve, and from OEMs seeking to integrate vertically. The principal competitive factors include price, quality, global presence, service, product performance, design and engineering capabilities, new product innovation and timely delivery. We cannot assure you that we will be able to continue to compete favorably in these competitive markets or that increased competition will not have a material adverse effect on our business by reducing our ability to increase or maintain sales and profit margins. A number of our major OEM customers manufacture products which compete with our products. Our OEM customers tend to outsource less when they have idle capacity.

We principally compete for new business at the beginning of the development of new models and upon the redesign of existing models by major OEM customers. New model development generally begins three-to-five years prior to the marketing of such models to the public. Redesign of existing models begins during the life cycle of a platform, usually at least two-to-three years before the end of the platform’s life cycle. The failure to obtain new business on new models or to retain or increase business on redesigned existing models, could adversely affect our business, financial condition, results of operations, and cash flows. In addition, as a result of the relatively long lead times required for many of our structural components, it may be difficult in the short term for us to obtain new revenues to replace any unexpected decline in the sale of existing products.

17

Table of Contents

The inability for us, our customers and/or our suppliers to obtain and maintain sufficient debt financing, including working capital lines, and credit insurance may adversely affect our, our customers’ and our suppliers’ liquidity and financial condition.

Our working capital requirements can vary significantly, depending in part on the level, variability and timing of our customers’ worldwide vehicle production and the payment terms with our customers and suppliers. Our liquidity could also be adversely impacted if our suppliers were to suspend normal trade credit terms and require payment in advance or payment on delivery. If our available cash flows from operations are not sufficient to fund our ongoing cash needs, we would be required to look to our cash balances and availability for borrowings under our credit facilities to satisfy those needs, as well as potential sources of additional capital, which may not be available on satisfactory terms and in adequate amounts, if at all.

The current capital markets have made it difficult for companies, including ours, to raise and maintain the liquidity necessary to operate. While we believe that we have sufficient liquidity to operate, there can be no assurance that we, our customers and our suppliers will continue to have such ability. This may increase the risk that we cannot produce our products or will have to pay higher prices for our inputs. These higher prices may not be recovered in our selling prices.

Our suppliers often seek to obtain credit insurance based on the strength of the financial condition of our subsidiary with the payment obligation, which may be less robust than our consolidated financial condition. If we were to experience liquidity issues, our suppliers may not be able to obtain credit insurance and in turn would likely not be able to offer us payment terms that we have historically received. Our failure to receive such terms from our suppliers could have a material adverse effect on our liquidity.

We may incur material costs related to product warranties and other legal proceedings, which could have a material adverse impact on our business, financial condition, results of operations and cash flows.

If our warranty expense estimates differ materially from our actual claims, or if we are unable to estimate future warranty expense for new products, our business and financial results could be harmed. Currently, we have limited exposure to warranty claims with our present products and historically we have incurred limited expense in relation to warranty claims; however, as we transition to new products in the future, including within our solar business, we may incur substantial warranty expense related to these products.

From time to time, we are involved in legal proceedings, claims or investigations that are incidental to the conduct of our business. Some of these proceedings allege damages against us relating to environmental liabilities, personal injury claims, taxes, employment matters or commercial or contractual disputes.

We cannot assure you that the costs, charges and liabilities associated with these matters will not be material, or that those costs, charges and liabilities will not exceed any amounts reserved for them in our consolidated financial statements. In future periods, we could be subject to cash costs or non-cash charges to earnings if any of these matters is resolved unfavorably to us.

We are dependent on large customers for current and future revenues. The loss of any of these customers or the loss of market share by these customers could have a material adverse impact on us.

We depend on major vehicle manufacturers for our revenues. For example, during 2009, Volkswagen, Fiat and Ford accounted for 17%, 13% and 13% of our revenues, respectively. The loss of all or a substantial portion of our sales to any of our large-volume customers could have a material adverse effect on our business, financial condition, results of operations and cash flows by reducing cash flows and by limiting our ability to spread our fixed costs over a larger revenue base. We may make fewer sales to these customers for a variety of reasons, including, but not limited to:

| • | loss of awarded business; |

| • | reduced or delayed customer requirements; |

18

Table of Contents

| • | OEMs’ insourcing business they have traditionally outsourced to us; |

| • | strikes or other work stoppages affecting production by our customers; or |

| • | reduced demand for our customers’ products. |

See “—Further deterioration in the United States and world economies could exacerbate the difficulties experienced by our customers and suppliers in obtaining financing, which, in turn, could materially and adversely impact our business, financial condition, results of operations and cash flows.”

In addition, Ford recently announced the sale of Volvo Car Corporation to Geely, a privately-owned Chinese OEM. If the sale is consummated, the change in ownership may adversely impact our ability to win new business from Volvo. If the sale is not consummated, we cannot predict how Volvo will be operated in the future.

The loss of key customer platforms could materially and adversely affect our business.

Our typical sales contract with a customer provides for supplying that customer’s requirements for a particular platform, rather than manufacturing a specific quantity of components. Our revenues contracts generally run for the life of the platform, usually three to ten years, and do not require the purchase by our customers of any minimum number of components. The loss or significant reduction in demand for vehicles for which we produce components could have a material adverse effect on our existing and future revenues and net income. The loss of one or more significant platforms, or a significant decrease in purchases from us in respect of such platforms, could have a material adverse effect on our business, financial condition, results of operations and cash flows.

We may be unable to realize revenues represented by our awarded business, which could materially and adversely impact our business, financial condition, results of operations and cash flows.

The realization of future revenues from awarded business is inherently subject to a number of important risks and uncertainties, including the number of vehicles that our customers will actually produce, the timing of that production and the mix of options that our customers may choose. Prior to 2008, substantially all of our North American customers had slowed or maintained at relatively flat levels new vehicle production for several years. More recently, new vehicle production has decreased dramatically as a result of the global economic crisis. In addition, we have agreed with our customers, that during the course of our awarded business, and as sales volume increases, that we will lower the per unit cost of our products, and such savings will, in part, be passed on to our customers. Accordingly, we cannot assure you that we will realize any or all of the future revenues represented by our awarded business. Any failure to realize these revenues could have a material adverse effect on our business, financial condition, results of operations and cash flows.

In addition to not having a commitment from our customers regarding the minimum number of products they must purchase from us if we obtain awarded business, typically the terms and conditions of the agreements with our customers provide that they have the contractual right to unilaterally terminate our contracts with them with no notice or limited notice. If such contracts are terminated by our customers, our ability to obtain compensation from our customers for such termination is generally limited to the direct out-of-pocket costs that we incurred for raw materials and work-in-progress and in certain instances undepreciated capital expenditures.

We base a substantial part of our planning on the anticipated lifetime revenues of particular products. We calculate the lifetime revenues of a product by multiplying our expected price for a product by forecasted production volume during the length of time we expect the related vehicle to be in production. We use a third-party forecasting service, CSM Worldwide®, to provide long-term forecasts which allows us to determine how long a vehicle is expected to be in production. Lifetime revenues associated with a particular platform are not guaranteed and are not equivalent to backlog. If we over-estimate the production units or if a customer reduces

19

Table of Contents

its level of anticipated purchases of a particular platform as a result of reduced demand, our actual revenues for that platform may be substantially less than the lifetime revenues we had anticipated for that platform. See “—Our ability to recognize revenues from our agreement with Stirling Energy Systems, or SES, is subject to several risks, any one of which could materially and adversely impact our business, financial condition, results of operations and cash flows.”

Typically, it takes two to five years from the time a manufacturer awards a program until the program is launched and production begins. In many cases, we must commit substantial resources in preparation for production under awarded customer business well in advance of the customer’s production start date. Although we have been successful in recovering these costs under appropriate circumstances in the past, we cannot assure you that our results of operations will not be materially adversely impacted in the future if we are unable to recover these types of pre-production costs related to our customers’ cancellation of awarded business.

Shifts in demand away from light trucks and sport utility vehicles could materially and adversely impact our business, financial condition, results of operations and cash flows.

In our North American operations, we are heavily dependent on SUVs and pickup trucks, which accounted for approximately 61% of North American revenues in 2009. As fuel prices increased significantly during the first half of 2008, consumers began to shift their purchases from these types of vehicles to cross-over utility vehicles, or CUVs, and passenger cars. CUVs are vehicles built on car platforms but that have many features similar to a traditional SUV. While gas prices have moderated, there has not been a substantial shift back to SUVs and pickup trucks. These trends could adversely affect our North American operations as the product life cycles are long and it will take time to diversify the North American portfolio.

Our joint venture partners may have interests that are not consistent with those of the joint venture, thereby resulting in our joint venture failing to achieve the results we desire.

We have two joint ventures in China. In both instances, our joint venture partner is also affiliated with the largest customer of the joint venture. As such, these partners may negotiate on behalf of customers of the joint venture for sales terms that are not in the best interest of the joint venture. More specifically, when acting on behalf of a customer, our joint venture partners effectively receive 100% of the benefits of revenues terms, but when acting as a joint venture partner we must share with them any benefits received by the joint venture. This may create a misalignment of incentives between us and our joint venture partners that could have a material adverse impact on our business.

Our ability to recognize revenues from our agreement with Stirling Energy Systems, or SES, is subject to several risks, any one of which could materially and adversely impact our business, financial condition, results of operations and cash flows.

There are several risks directly associated with our solar agreement with SES. SES must secure significant financing in order to be in a position to purchase the products we have agreed to manufacture. There can be no assurances that financing will be made available to SES. In order for us to produce large stamped mirror-facet panels and welded support structures for SES, we must equip a facility for production that we will lease in Arizona. We may not be able to recover the costs we incur in establishing this facility if the contractual arrangement with SES is not a long-term success.

Based on a number of assumptions and subject to significant uncertainties and contingencies, including non-binding and uncertain volume estimates and pricing targets, we expect the SES contract to produce approximately $ million in revenues over the term of the agreement, assuming that SES secures the financing it requires to build its solar project. The term of the agreement is five years, except that it will automatically extend if necessary to assure that a specified production volume threshold has been met. There is no guarantee that the SES agreement will produce the expected revenues. SES is not required to purchase a

20

Table of Contents

minimum number of mirror-facet components and welded support structures from us. The revenues that we obtain from our solar agreement are entirely dependent on the sales that SES achieves for its products. Additionally, SES has the right to terminate the agreement with us if, among other reasons, the products we sell to SES are persistently and verifiably uncompetitive with the products sold by another company at similar volumes and with similar capital investment requirements. Under no circumstances should our revenue estimate be regarded as a representation or prediction that we will achieve or are likely to achieve any particular results. Additionally, we do not have prior experience manufacturing components for the solar industry and therefore cannot assure you that we will be able to produce solar components in mass volume or that our margins associated with solar revenues will be comparable to our margins in our automotive business.

We have agreed to provide a 3-year warranty on the products that we sell to SES. We will warrant to SES that, among other things, our products are free from defects, conform to specifications and have been manufactured in compliance with all applicable laws. Should the products we sell to SES be found to be defective or otherwise violate our warranties to SES, we could face significant expenses to comply with our SES warranty obligations.

The termination of, or damage to, one or more of our relationships with key third-party suppliers could have a material adverse effect on our business, financial condition, results of operations and cash flows.

We obtain raw materials and components, including some of our steel, from third-party suppliers. Any delay in receiving supplies could impair our ability to deliver products to our customers and, accordingly, could have a material adverse effect on our business, financial condition, results of operations and cash flows. Some of our suppliers are the sole source for a particular supply item. Loss of or damage to our relationships with these suppliers could have a material adverse effect on our business, financial condition, results of operations and cash flows.

Various factors could result in the termination of our relationship with any supplier or the inability of suppliers to continue to meet our requirements on favorable terms. For example, the volatility in the financial markets and uncertainty in the automotive sector could result in exposure related to the financial viability of certain of our key third-party suppliers. Severe financial difficulties at any of our major suppliers could have a material adverse effect on us if we were unable to obtain, on a timely basis, on similar economic terms, the quantity and quality of components and raw materials we require to produce our products. In response to financial pressures, suppliers may also exit certain business lines, or change the terms on which they are willing to provide raw material and components to us.

Disruptions in the automotive supply chain could have a material adverse effect on our business, financial condition, results of operations and cash flows.

The automotive supply chain has been faced with severe cash flow problems as a result of the significantly lower production of vehicles, increases in certain raw material, commodity and energy costs and restricted access to additional liquidity. Several automotive suppliers have filed for bankruptcy protection or ceased operations. Severe financial difficulties, including bankruptcy, of any automotive supplier could have a significant disruptive effect on the entire automotive industry, leading to, among other things, supply chain disruptions and labor unrest. For example, if a parts supplier were to cease operations, it could force the automotive manufacturers to whom the supplier provides parts to shut down their operations. This, in turn, could force other suppliers, including us, to shut down production at plants that are producing products for these automotive manufacturers.

The volatility of steel prices may adversely affect our results of operations.

We utilize steel and various purchased steel products in virtually all of our products. We refer to the “net steel impact” as the combination of the change in steel prices that are reflected in customer pricing, the change in

21

Table of Contents

the cost to procure steel from the mills, and the change in our recovery of scrap steel, which we refer to as offal. While we strive to achieve a neutral net steel impact over time, we are not always successful in achieving that goal. Changes in steel prices may affect our liquidity because of the time difference between our payment for our steel and our collection of cash from our customers. We tend to pay for replacement materials, which are more expensive when steel prices are rising, over a much shorter period. As a result, rising steel prices may cause us to draw greater than anticipated amounts from our credit lines to cover the cash flow cycle from our steel purchases to cash collection for related accounts receivable. This cash requirement for working capital is higher in periods when we are increasing our inventory quantities.

A by-product of our production process is the generation of offal. We typically sell offal in secondary markets, which are similar to the steel markets. We generally share our recoveries from sales of offal with our customers either through scrap sharing agreements, in cases where we are on resale programs, or in the product pricing that is negotiated regarding increases and decreases in the steel price in cases where we purchase steel directly from the mills. In either situation, we may be impacted by the fluctuation in scrap steel prices, either positive or negative, in relation to our various customer agreements. Since scrap steel prices generally increase and decrease as steel prices increase and decrease, our sale of offal may mitigate the severity of steel price increases and limit the benefits we achieve through steel price declines. Any dislocation in offal and steel prices could negatively affect our business, financial condition, results of operations and cash flows.

The seasonality we experience in our business may negatively impact our quarterly revenues.

Our business is seasonal. Our customers in Europe typically shut down vehicle production during portions of July or August and during one week in our fourth quarter. Our North American customers typically shut down vehicle production for approximately two weeks during July and for one week during December. Such seasonality may adversely affect our revenues during the third and fourth quarters of our fiscal year.

We have significant operating lease obligations and our failure to meet those obligations could adversely affect our business, financial condition, results of operations and cash flows.

We lease many of our manufacturing facilities and certain capital equipment. Our lease expense under these operating leases was $24.1 million for the year ended December 31, 2009. A failure to pay our lease obligations would constitute a default allowing the applicable landlord or lessor to pursue remedies available to it under our leases and applicable law, which could include taking possession of property that we utilize in our business and, in the case of facilities leases, evicting us. In addition, we are party to two master leases with entities affiliated with a single commercial real estate company that cover a number of our leased properties. These master leases require us to continue to perform under the leases with respect to certain properties that we are no longer using. Such obligations negatively impact our results of operations.

We may incur material costs related to plant closings, which could have a material adverse impact on our business, financial condition, results of operations and cash flows.

If we must close additional manufacturing locations because of loss of business or consolidation of manufacturing facilities, the employee severance, asset retirement and other costs, including reimbursement costs relating to public subsidies, to close these facilities may be significant. In certain locations that are subject to leases, we may continue to incur material costs consistent with the initial lease terms. Due to the current state of the global economy, there is no assurance that additional plants will not have to be closed. We continually attempt to align production capacity with demand, which may result in additional closures. Historically, we have incurred significant costs related to the closure of our facilities and can provide no assurance that such costs will not be material in the future.

Our ability to operate effectively could be impaired if we are unable to recruit and retain key personnel.

Our success depends, in part, on the efforts of our executive officers and other key senior managers and colleagues. Our senior management team has reoriented our business towards anticipated future demand and

22

Table of Contents