Attached files

| file | filename |

|---|---|

| EX-32.1 - EXHIBIT 32.1 - EVERGREEN ENERGY INC | a2197697zex-32_1.htm |

| EX-32.2 - EXHIBIT 32.2 - EVERGREEN ENERGY INC | a2197697zex-32_2.htm |

| EX-21.1 - EXHIBIT 21.1 - EVERGREEN ENERGY INC | a2197697zex-21_1.htm |

| EX-4.19 - EX-4.19 - EVERGREEN ENERGY INC | a2197697zex-4_19.htm |

| EX-12.1 - EX-12.1 - EVERGREEN ENERGY INC | a2197697zex-12_1.htm |

| EX-31.1 - EXHIBIT 31.1 - EVERGREEN ENERGY INC | a2197697zex-31_1.htm |

| EX-23.1 - EXHIBIT 23.1 - EVERGREEN ENERGY INC | a2197697zex-23_1.htm |

| EX-31.2 - EXHIBIT 31.2 - EVERGREEN ENERGY INC | a2197697zex-31_2.htm |

| EX-10.40 - EX-10.40 - EVERGREEN ENERGY INC | a2197697zex-10_40.htm |

| EX-10.42 - EX-10.42 - EVERGREEN ENERGY INC | a2197697zex-10_42.htm |

| EX-10.41 - EX-10.41 - EVERGREEN ENERGY INC | a2197697zex-10_41.htm |

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10-K

ý |

ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

|

For the fiscal year ended December 31, 2009 |

||

o |

TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

|

For the transition period from to |

||

Commission file number: 001-14176

EVERGREEN ENERGY INC.

(Exact Name of Registrant as specified in its Charter)

| Delaware (State or other jurisdiction of incorporation or organization) |

84-1079971 (IRS Employer Identification No.) |

|

1225 17th Street, Suite 1300 Denver, Colorado (Address of Principal Executive Offices) |

80202 (Zip Code) |

Registrant's Telephone Number, including area code: (303) 293-2992

Securities registered pursuant to Section 12(b) of the Act:

| Title of Each Class | Name of Exchange on Which Registered | |

|---|---|---|

| Common Stock, $.001 par value | NYSE Arca |

Securities registered pursuant to Section 12(g) of the Act: None

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes o No ý

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or section 15(d) of the Exchange Act. Yes o No ý

Indicate by check mark whether registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes ý No o

Indicated by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§ 232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes o No o

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of registrant's knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. ý

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer or a smaller reporting company. See the definitions of "large accelerated filer," "accelerated filer" and "smaller reporting company" in Rule 12b-2 of the Exchange Act.

| Large accelerated filer o | Accelerated filer ý | Non-accelerated filer o (Do not check if a smaller reporting company) |

Smaller reporting company o |

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act). Yes o No ý

The aggregate market value of the common stock held by non-affiliates of the registrant was $88,236,019 computed by reference to the closing price of the common stock on June 30, 2009, the last trading day of the registrant's most recently completed second fiscal quarter.

Indicate the number of shares outstanding of each of the issuer's classes of common stock, as of the latest practicable date.

| Class | Outstanding at March 26, 2010 | |

|---|---|---|

| Common Stock, $.001 par value | 201,295,116 shares |

DOCUMENTS INCORPORATED BY REFERENCE

| Document | Parts Into Which Incorporated | |

|---|---|---|

| Definitive Proxy Statement for the 2010 Annual Meeting | Part III |

2

CAUTIONARY STATEMENT ABOUT FORWARD-LOOKING STATEMENTS

This Annual Report on Form 10-K contains forward-looking statements that are not statements of historical fact and may involve a number of risks and uncertainties. These statements relate to analyses and other information that are based on forecasts of future results and estimates of amounts not yet determinable. These statements may also relate to our future prospects, developments and business strategies.

We have used the words "anticipate," "believe," "could," "estimate," "expect," "intend," "may," "will," "plan," "predict," "project" and similar terms and phrases, including references to assumptions, in this Annual Report on Form 10-K to identify forward-looking statements. These forward-looking statements are made based on expectations and beliefs concerning future events affecting us and are subject to uncertainties and factors relating to our operations and business environment, all of which are difficult to predict and many of which are beyond our control, that could cause our actual results to differ materially from those matters expressed in or implied by these forward-looking statements. The following factors are among those that may cause actual results to differ materially from our forward-looking statements:

- •

- general economic and industry conditions;

- •

- our history of losses, deficits and negative operating cash flows;

- •

- our substantial capital requirements and dependence on future financings and the sale of our equity securities to provide

capital to fund our operations;

- •

- our ability to complete the sale of Buckeye;

- •

- our limited operating history;

- •

- technical and operational problems at K-Fuel facilities;

- •

- uncertain market for GreenCert technology;

- •

- industry competition;

- •

- environmental and government regulation;

- •

- protection and defense of our intellectual property rights;

- •

- reliance on, and the ability to attract, key personnel;

- •

- inability to implement our acquisition strategy; and

- •

- other factors including those discussed under "Risk Factors" in Item 1A of this Annual Report on Form 10-K.

You should keep in mind that any forward-looking statement made by us in this Annual Report on Form 10-K or elsewhere speaks only as of the date on which we make it. New risks and uncertainties arise from time to time, and it is impossible for us to predict these events or how they may affect us. We have no duty to, and do not intend to, update or revise the forward-looking statements in this Annual Report on Form 10-K after the date of this filing, except as may be required by law. In light of these risks and uncertainties, you should keep in mind that any forward-looking statement made in this Annual Report on Form 10-K or elsewhere might not occur.

3

In this Annual Report on Form 10-K, we use the terms "Evergreen Energy," "we," "our," and "us" to refer to Evergreen Energy Inc. and its subsidiaries. C-Lock refers to our subsidiary C-Lock Technology, Inc. Buckeye refers to our subsidiary Buckeye Industrial Mining Co. All references to C-Lock®, GreenCert™, K-Fuel, K-Fuel®, K-Fuel process, K-Fuel refined coal, K-Fuel refineries, K-Direct®, K-Fuel Plants, K-Fuel facilities, K-Direct facilities and K-Direct® plants, refer to our patented processes and technologies explained in detail throughout this Annual Report on Form 10-K. All references to years, unless otherwise noted, refer to our fiscal year, which ends on December 31st.

We were founded in 1984 as a cleaner coal technology, energy production and environmental solutions company focused on developing our proprietary technologies. In the last two years, we have sharpened our focus on positioning us as a carbon technology company. We have developed two proprietary, patented, and potentially transformative green technologies: the GreenCert suite of software and services and K-Fuel. Our GreenCert technology is a scientifically accurate and scalable environment intelligence solution that measures greenhouse gases (or GHG) and other environmental costs enabling customers to manage and report their environmental assets and liabilities. GreenCert, built on IBM's Service-Oriented Architecture (or SOA), is an environment intelligence solution that provides customers the end-to-end visibility and traceability necessary to measure their complete environmental footprint. K-Fuel, our clean coal technology significantly improves the performance of low-rank coals yielding higher efficiency and lower emissions.

Over the past year, we have been evaluating several alternatives related to our strategic positioning, including the potential sale of certain assets, including Buckeye. On March 12, 2010, we signed a definitive agreement with Rosebud Mining Company for the sale of certain net assets of both Buckeye and Evergreen, which we refer to as the "sale of Buckeye", for $27.9 million, in addition to the release of $5.0 million of cash reclamation bonds. Further, $2.8 million of the purchase price will be deposited into escrow for a period of twelve months to cover amounts payable to Rosebud pursuant to the indemnification provision of the sales agreement. The closing is not subject to a financing condition, but is subject to the satisfaction of customary closing conditions, including, among other matters, (i) accuracy of the representations and warranties and compliance with the covenants set forth in the agreement, each in all material respects, (ii) receipt of legally required regulatory approvals, and (iii) consents of certain governmental authorities and certain of Buckeye's specified contractual counterparties. The sale is expected to close in April 2010, but in any event no later than June 30, 2010. The proceeds from the sale of Buckeye will be used to retire the outstanding 2009 Notes including fees and accrued interest of $21.1 million, to fund related transaction expenses estimated at $2.5 million and for general working capital purposes.

With the sale of Buckeye we will be able to better focus our resources on core business activities, our GreenCert and K-Fuel technologies. We terminated the contemplated K-Fuel spin-off as previously announced. Concurrently, Evergreen-China Energy Technology Co., Ltd. ("Evergreen-China"), a Sino-US joint venture between Evergreen Energy and a Chinese investor, signed a letter of intent with a large Chinese integrated utility and chemical manufacturer to build a K-Fuel plant in Inner Mongolia to produce K-Fuel from low-ranked lignite feedstock.

As the business environment changes, our ongoing business plan may be altered. The following discussion addresses the current aspects of our business.

GreenCert

We are continuing the development of our GreenCert suite of software and services. GreenCert is an accurate and scalable environmental intelligence solution that quantifies greenhouse gas emission

4

avoidances and reductions and generates verifiable emissions offsets. GreenCert provides real-time, multiple method data analysis to increase accuracy and reduce uncertainty to quantify incremental improvements. GreenCert also enables enterprises to reduce overall costs via the identification of significant operational efficiencies, compliance and risk reduction and sustainability measures. We intend to sell GreenCert as an on-premise offering and as a hosted software as a service (or SaaS) solution, both with annual licensing and renewal fees.

GreenCert is a software framework that is both generally applicable to all industries and customizable for client and industry specifics and currently has two environmental intelligence solution sets: Energy/Utilities and Agriculture. The GreenCert Energy Solutions suite offers three levels: Reporting, Analytics and Enterprise. GreenCert Reporting contains baseline emissions tracking, an interface for emissions data entry, and base level reporting and dashboard capability. GreenCert Analytics offers reporting plus forward modeling and analysis tools. GreenCert Enterprise contains all of the components of GreenCert Analytics with the additional capability of an enterprise SOA solution which automates the quantification and verification of emission reductions. GreenCert Agriculture offers the unique ability to scientifically quantify, on a per field basis, soil carbon sequestration and generate terrestrial emission reduction offsets. GreenCert greenhouse gas consulting services are available to conduct environmental and efficiency assessments, to quantify footprints, and to provide utility, agricultural, and environmental expertise. All GreenCert products and services fall within the Enterprise Carbon Management solutions market as a broad class of solutions that cuts across industrial sectors to offer services, reporting, efficiency auditing, and emission reduction offsets for emitters of greenhouse gases.

Evergreen Energy's GreenCert solutions are designed to be indifferent to legislation and meet and/or exceed any governmental mandate. Our scientifically rigorous solutions contain a flexible information technology backbone which can be adapted to any regulatory environment. Regardless of any new legislation, the efficiency and accuracy improvement that are obtained within the GreenCert Energy Solution appeals to utilities and provides a platform to prepare for future legislative or regulatory changes. Greenhouse gas regulation of any form will only enhance the market appeal for our GreenCert products.

We have a three-phase plan to implement GreenCert at client locations. In the first phase, GreenCert quantifies the client's baseline emissions status and the accuracy of the methodology and data used. In the second phase, we assess and identify the capital expenditure and operating expense improvements that drive efficiencies within the client or specific plant and determines the GHG savings associated with those efficiency improvements. This phase also evaluates methods to reduce the uncertainty of the GHG measurement to improve accuracy. Combined, the first two phases deliver the GHG assessment and result in an understanding of the return on investment for employing the third phase. In this final phase, we deploy the site-specific, highly-customized solution that enables the quantification and monetization of the emissions reductions and efficiency improvements. The deployed solution then also enables further improvements to be quantified and monetized going forward.

We continue to identify potential future strategic partners for GreenCert, in addition to IBM Corp. and Enterprise Information Management Corp (or EIM), to assist in the development, testing and roll-out of its products. Potential partners include companies offering services or products such as: energy engineering consulting; power generation performance optimization; environmental consulting; and products relating to sensor systems and devices, data collection devices, or other products that support energy or power plant operations. On November 5, 2009, we announced that GreenCert was validated on IBM's Solution Architecture for Energy and Utilities (or SAFE) framework, the software technology backbone that makes a wide range of utility solutions possible by helping clients build a standards-based integrated platform across the clients' entire operations and energy value chain. GreenCert will be marketed across the globe through the SAFE framework validation. Also on November 5, 2009, we announced our partnership with Black & Veatch to deploy GreenCert to the

5

global power generation market. Black & Veatch expects to provide integrated emissions and performance management solutions by leveraging GreenCert for additional customer needs and requirements.

K-Fuel

Through our proprietary K-Fuel process we intend to meet the specific needs of public utility, industrial and international customers by providing economical solutions for energy supply, energy efficiency and compliance with environmental emission standards. Additional markets served by our K-Fuel process include mines looking to expand the market for their low rank coal by transforming it into a higher value fuel and chemical manufacturers using coal as a feedstock. Our K-Fuel process uses heat and pressure to physically and chemically transform high-moisture, low-Btu coals, such as sub-bituminous coal and lignite, into a more energy dense, energy efficient, lower-emission fuel. The inherent efficiency of higher Btu-lower moisture coal improves power plant performance and reduces emissions on a per kilowatt-hour-generated basis. We believe that China presents the best opportunity to develop the K-Fuel technology because of its plentiful reserves of high-moisture, low-Btu coals, its rapid growth in electric power demand and its lower construction and manufacturing costs. The goal of our K-Fuel technology is to transform those lower-rank coals into more efficient and environmentally compliant fuels in order to meet the increasing demand for energy in an optimal fashion. As mentioned above Evergreen-China continues discussions with a Chinese conglomerate for the potential construction of a K-Fuel plant in Inner Mongolia. See further discussion of the K-Fuel business under Business History.

Segments

Our segments include the GreenCert segment, the Plant segment, the Mining segment and the Technology segment. The GreenCert segment reflects activities related to the measurement of greenhouse gases and certification of environmental improvements such as carbon credits. The Plant segment primarily represents revenue and costs related to our Fort Union plant near Gillette, Wyoming, at which we suspended operations in March 2008. The Mining segment primarily represents our mining operations of our subsidiary Buckeye, and includes certain marketing capabilities such as an ash disposal facility and a coal preparation and blending facility. The Technology segment is comprised of all other operations that use, apply, own or otherwise advance our proprietary patented K-Fuel process, including our headquarters and related operations, around activities of KFx Technology, LLC, which holds the right to issue licenses of the K-Fuel technology. Corporate costs within our Technology segment are allocated to our other segments, generally based on a percentage of the number of employees, total segment operating expenses, or segment operating expenses plus segment capital expenditures. We will continue to evaluate how we manage our business and, as necessary, adjust our segment reporting accordingly.

Business Strategy

The principal elements of our long-term strategy are to focus our efforts and resources on building our GreenCert and K-Fuel businesses through a combination of organic growth, acquisitions and joint ventures and to complete the sale of our Buckeye operations. We plan to focus on the following strategies.

- •

- Develop and Market GreenCert. We believe there is opportunity both domestically and internationally to market, license and sell our environmental intelligence and greenhouse gas software solutions and services. We believe that there is a unique opportunity for these services around the world. As "cap-and-trade" and other cap and carbon taxation programs seeking to limit emissions take hold, the global trading of emission reduction offsets is expected to expand,

6

- •

- Enter into Strategic Arrangements, Leverage Distribution Channels and Advance Relationships with Original Equipment

Manufacturers (OEMs). We have strategic arrangements and believe there are additional opportunities to further expand GreenCert

through new relationships. Evergreen Energy has agreements with Foxconn Technology Group related to the Asia-Pacific Rim region and Crowley-Shindler in the Eastern European

region. Both of these relationships provide for the marketing and further licensing of GreenCert solutions within these geographic regions. As further described above, we have relationships with IBM,

EIM and Black & Veatch that we believe will present us opportunities to reach a broad-base of energy and utility customers. Our solutions require implementation services,

infrastructure for support and hardware and advisory services—we therefore believe that these relationships will present us opportunities to broaden the market reach of our solution by

using our partners' sales programs and sales channels.

- •

- Complete Assessments and Pilot Deployments and Enter into GreenCert Licensing

Agreements. We intend to complete assessments to determine and identify capital expenditure and operational improvements that result in

efficiency improvements and therefore GHG emissions reductions. After this initial phase, we expect to implement pilot deployments at specific, individual customer sites using customer data to

quantify these reductions and accurately determine the return on investment related to such improvements. Finally, we plan to license GreenCert as an on-premise offering and as a hosted

SaaS solution, both with annual licensing fees and renewal fees. Our solutions will require consulting and implementation services.

- •

- Pursue Strategic Growth Through Acquisitions and Joint

Ventures. We believe we are positioned to pursue selected acquisitions and attract industry joint venture partners to continue our

strategic development. Our investments in GreenCert and K-Fuel are consistent with our integrated technology strategy. We expect to pursue acquisitions of, or joint ventures with,

companies that have operations complementary to our business model and strategy.

- •

- Enter into K-Fuel Licensing Agreements. We

believe that there are potential opportunities to license our K-Fuel technology internationally to third parties principally in the Asia-Pacific Rim region due to its vast

reserves of low-rank coal, rapid economic growth and interest in upgrading that coal to meet its increasing appetite for electric power and use in industrial applications including

chemical manufacturing. Concurrently, Evergreen-China signed a Letter of Intent with a large Chinese integrated utility and chemical manufacturer to build a K-Fuel plant in

Inner Mongolia to produce K-Fuel from low ranked lignite feedstock.

- •

- Complete Sale of our Buckeye Subsidiary. As discussed above, we have entered into an agreement for the sale of Buckeye. Per the terms of the agreement, Rosebud Mining Company will purchase certain assets of both Buckeye and Evergreen, generating aggregate proceeds of $27.9 million, in addition to the release of $5.0 million of cash reclamation bonds. The transaction is subject to customary closing conditions and the completion by Rosebud of due diligence. The sale is expected to close in April 2010, but in any event no later than June 30, 2010.

along with the need for accurate and precise measurements of emissions and the verification of emissions offsets.

Competitive Strengths

We believe we are uniquely positioned in the energy market as a result of the following strengths:

- •

- Highly Accurate and Patented Solution. The GreenCert carbon information management software solution and services stand as an innovative software-based solution for the complex process of accurate, precise, transparent, verifiable and scientifically defensible quantification of greenhouse gases, emission reductions, and offsets. Uncertainties and costs associated with greenhouse gas

7

- •

- Scalable, Enterprise-wide Solution. We believe

that other greenhouse gas measurement methods are cumbersome and inadequate. They are expensive, ad-hoc and can be unreliable. The solutions from these companies focus on mandatory and

voluntary reporting of greenhouse gases. As such, they do not offer the ability to quantify incremental improvements as monetizable offsets, which is a unique feature of GreenCert. GreenCert is

positioned within the energy and utilities market segment to function as an integral middleware for plant operations to optimize efficiency and greenhouse gas management, not just as a reporting

solution.

- •

- Strong Base of Technical Experience and Expertise. We have developed an employee population that is highly qualified and experienced in our GreenCert solution and in carbon management. Our experience and expertise includes carbon measurement, carbon emission modeling, power generation, soil carbon sequestration, and nitrogen oxides and sulfur dioxide reduction analysis. In addition, we have developed strong relationships and strategic partners to support our GreenCert solution, including IBM, EIM, and Black and Veatch, each of which has significant experience in the development, marketing and sale of software solutions.

measurement remain key issues for the emerging global carbon marketplace. The Federal Trade Commission has held hearings on guidelines for the sale of "carbon credits" and Congress has held hearings and is considering legislation to enact federal oversight of carbon markets. Also, in 2009, the Environmental Protection Agency (or EPA) took actions to require reporting of GHG emission and to include best available control technology for GHG emissions when initiating or renewing permits under the Clean Air Act. See further discussion under "Environmental Regulation Affecting Our Market". Through GreenCert, we offer a scientifically defensible, intelligence software and system solution to accurately measure greenhouse gas emissions and create verifiable and certifiable emission reduction credits that is also designed to be indifferent to legislation enacted.

- •

- High Btu, Low Emission K-Fuel Refined Coal. We

have been able to convert thousands of tons of low-Btu sub-bituminous coals and lignites into K-Fuel refined coal, with higher Btu's and lower emissions, that is a

replacement for dwindling supplies of higher quality coals. The EPA will likely impose strict mercury emission rules on a plant-by-plant basis due to the U.S. Supreme

Court's rejection of a utility industry's appeal of a lower court ruling which vacated the "Clean Air Mercury Rule". Mercury reduction in coal is one of several environmental improvements where the

K-Fuel process performs exceedingly well. With key congressional committees working to enact a "cap-and-trade" greenhouse gas emission or other carbon taxation bill

in the future, and with groups of states rolling out regional limitations on sulfur dioxide, mercury, oxides of nitrogen and carbon dioxide emissions, K-Fuel's ability to reduce those

emissions, including a potential 8% carbon dioxide reduction, stands out as a marketplace advantage. We believe K-Fuel industrial customers that use our K-Fuel refined

coal or blended K-Fuel refined coal will be able to cost-effectively boost efficiency and will reduce these emissions without adding new, expensive, post-combustion

cleanup equipment. Power generating facilities that burn our K-Fuel refined coal or blended K-Fuel refined coal instead of unrefined high Btu coal are expected to realize lower

emissions and experience significant savings as a result of reducing the need to purchase carbon dioxide, sulfur dioxide, nitrogen oxide and mercury credits in order to comply with environmental

regulations.

- •

- Provide Flexibility in Feedstock. Coal-fired power plants and industrial users with post-combustion pollution controls may see improved pollution control performance by using our K-Fuel refined coal or blended K-Fuel refined coal and will benefit from the ability to use alternative feedstock

Our K-Fuel employees and consultants have a wide range of technical experience and expertise in refining coal, coal thermal upgrading, thermal processing, coal gasification, coal liquefaction, chemical engineering, power plant engineering and process engineering.

8

- •

- Key Industry Relationships. In GreenCert, not only have we built strong alliances with IBM, EIM and Black and Veatch, but also strategic marketing partners in Asia and Eastern Europe. K-Fuel also benefits from key industry relationships, which we believe will assist us in the development, deployment and marketing of our K-Fuel and GreenCert technologies.

in addition to their traditional feedstocks or to blend with their traditional feedstocks. We believe that Carbon Capturing and Storage Technology, or CCS, especially a class of clean coal technology that integrates coal gasification with carbon capture and storage referred to as IGCC-CCS, will perform better if the quality of its coal feedstock is upgraded through the K-Fuel process.

Competition

We believe our GreenCert solution is a first-of-its-kind, web-based platform that accurately measures incremental greenhouse gas emission reductions and can certify these environmental improvements as emission offsets to meet any regulatory environment. There are other companies that have developed systems that measure greenhouse gases and certify emission offsets, and our potential customer base can choose to use other Enterprise Carbon Management solutions instead of ours. In the last year a number of additional companies have entered the Enterprise Carbon Management solution space. According to Groom Energy there are 68 companies that have software packages for GHG/Enterprise Carbon Management Solutions and they anticipate the number of sellers to increase 600% by 2011.

Our K-Fuel refined coal is a coal with characteristics of low-moisture, high-Btu content and low sulfur dioxide, nitrogen oxides and mercury emissions. The known direct competitors for K-Fuel refined coal include other coal upgrading processes, other high-Btu coal, low sulfur coal and advanced pollution control technologies. The indirect competition to K-Fuel refined coal includes electrical generation from natural gas, nuclear fuel, oil, wind, bio-fuels, and other renewable energy sources. Potential customers could choose to install pollution equipment instead of using our K-Fuel refined coal and/or choose to inject additives to reduce emissions. These alternatives include equipment such as low-nitrogen oxide burners, over-fire air systems, selective catalytic reduction systems, sulfur scrubbers, fabric filters, electrostatic precipitators, mercury control technology, or other equipment and adding limestone or other chemicals to combustion and waste stream.

Intellectual Property

Our success depends in part on our ability to protect our intellectual property and to avoid infringement of the intellectual property of third parties. Our trademarked GreenCert solution embodies greenhouse gas measurement, certification and carbon information management software. The technology and patents provide for certification of emission offset reduction credits—essential to maximizing the value of credits in compliance and trading markets. We have the worldwide exclusive rights to various patents. The technology can be applied to measurements of any emissions offsets reduction or other environmental attributes. This proprietary process is web-based and has been integrated with IBM software products and tools.

The patents which cover earlier versions of our K-Fuel technology are near their expiration dates. Patents which cover newer versions of that technology expire from 2018 through 2024. Our most recently issued patent covers most of the aspects of our K-Fuel process as it is currently conducted. As we make modifications and improvements to our proprietary process, we continue to evaluate our patent protection. As new improvements result, we would anticipate the filing of additional patent applications.

9

Business History

We were founded in 1984. We incorporated under the laws of the state of Delaware in 1988. Our principal executive offices are located at 1225 17th Street, Suite 1300, Denver, Colorado 80202, and our telephone number is (303) 293-2992.

GreenCert. In December 2007, our subsidiary, C-Lock Technology, Inc., in conjunction with IBM and Enterprise Information Management, Inc. began developing a greenhouse gas solution called GreenCert. Certain aspects of GreenCert are patented and available to us through an exclusive licensing agreement. We continue to focus our efforts on further development and commercialization of our GreenCert solution.

K-Fuel. Over the past 25 years, we have been principally focused on the development of our K-Fuel technology. We have obtained multiple patents for different versions of the K-Fuel technology using a variety of methods to apply heat and pressure to process high moisture coal feedstocks. We have patents or patent applications for the K-Fuel technology issued or pending in the United States and various foreign countries. As we continue to develop and make enhancements to either technology or develop new technologies consistent with our business strategy, we anticipate expanding our patent coverage.

Multiple laboratory and test burn results have independently verified the effectiveness of the K-Fuel process at removing significant amounts of mercury from lower-rank coals. The amount of mercury reduction varies depending on the coal source. The K-Fuel process can reduce mercury by up to 70% in Wyoming Powder River Basin coal. Tests on Indonesian coal showed a 56% mercury reduction, and a test burn of blended K-Fuel at a western Pennsylvania power plant achieved an almost 82% mercury emission reduction at the stack when compared to the mercury content of the coal normally burned at that plant.

The current K-Fuel process applies heat and pressure to lower-rank coals with high water content, such as those found in Wyoming's Powder River Basin, to reduce moisture from approximately 30% in the low-Btu coal to 8%-14% in our K-Fuel refined coal. As a result, the heat value is boosted by 25% to 40%. The increase is variable depending on the type of coal processed and process conditions. We believe the process results in increased efficiency of the fuel needs in power generating, industrial and institutional facilities. Further, the K-Fuel process removes a significant amount of impurities from the lower-Btu coal, which we believe will allow the power generation industry and smaller industrial coal boilers to economically comply with increasingly stringent air emission standards and environmental regulations. The pre-combustion refinement of raw coal into K-Fuel refined coal reduces the mercury content, and upon combustion, sulfur dioxide and nitrogen oxides are also reduced. Our analysis also shows that burning K-Fuel refined coal with its increased efficiency will reduce carbon dioxide emissions by up to 8% on a per-kilowatt-hour generated basis.

We, along with Bechtel Power Corporation, have completed the modifications and improvements of the design and efficiency of the equipment used in the K-Fuel process. Bechtel and Evergreen's operations teams at our Fort Union plant near Gillette, Wyoming completed successful testing of new operational systems that will support construction of future K-Fuel refineries, including an enhanced standard processing tower design. We believe this work signals that we have resolved the most substantive technical challenges to scaling and fully commercializing our production process.

In March 2008, we suspended operations at our Fort Union plant in order to redirect constrained resources, both capital and human, to focus on the commercialization of this process in future K-Fuel

10

plants. Suspending production at Fort Union enabled us to reduce our cash expenditures. The significant resources invested in the Fort Union plant served four important purposes:

- •

- First, as an engineering and process improvement platform, the Fort Union plant allowed Evergreen and Bechtel engineers

and scientists to improve the performance of the K-Fuel process.

- •

- Second, Fort Union served as an important coal testing facility that allowed Evergreen to build a database of test results

from more than 100 coal types drawn from across the globe.

- •

- Third, Fort Union served as an important business development tool and production platform for thousands of tons of

K-Fuel used for marketing and test burn purposes.

- •

- Fourth, Fort Union served to produce K-Fuel at a commercial scale for customer test burns and purchase.

Through the construction and limited operation of our Fort Union facility, which is the first plant utilizing the current version of our technology, we sought to further develop the application of our proprietary K-Fuel technology. As previously stated, the Fort Union plant has realized virtually all of the goals and objectives which we set forth, except for continuous production, and we suspended operations at this site. Also, during the last five years we have completed numerous evaluations to further test and improve our K-Fuel refined coal and process. During the years ended December 31, 2009, 2008 and 2007, our research and development costs were approximately $49,000, $79,000, and $876,000, respectively.

In February 2007, we expanded our contractual relationship with Bechtel to assist with future designs of additional K-Fuel plants we may build or license. On September 19, 2007, we amended and restated our agreement with Bechtel. Through this new program management agreement, we committed to provide Bechtel with $1 billion in construction contracts through 2013. This restated agreement increases the scope of engineering, procurement and construction services which may be performed by Bechtel. Bechtel's services are available to oversee both technical development and implementation of new facilities and plants.

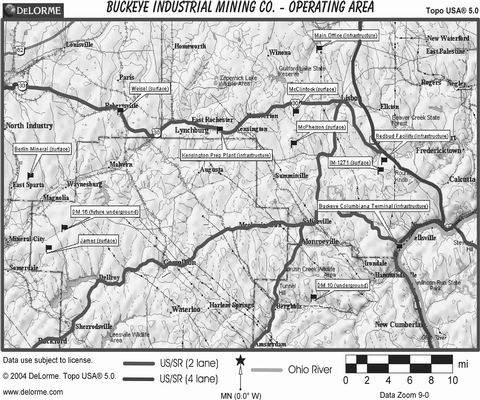

Buckeye. On April 3, 2006, we completed the acquisition of Buckeye for a total purchase price of $39.1 million, including cash paid, stock issued, liabilities assumed and costs incurred in the acquisition. Buckeye's primary business is to mine, process, blend and sell high-quality coal to electric utilities, industrial and institutional end users. Buckeye also operates one of the largest ash disposal facilities in the State of Ohio, disposing up to one million tons of dry and conditioned ash per year. On March 12, 2010, we signed a definitive agreement with Rosebud Mining Company for the sale of Buckeye for a purchase price of $27.9 million in cash payable at the closing of the transaction and the release of $5.0 million of reclamation bonds.

Customers

As of December 31, 2009, two customers from our Mining segment accounted for 20% and 18% of total accounts receivable and three customers in our Mining segment accounted for 18%, 16% and 15% of total revenues for 2009. As of December 31, 2008, two customers from our Mining segment accounted for 32% and 20% of total accounts receivable and two customers in our Mining segment accounted for 20% and 9% of total revenues for 2008. As of December 31, 2007, three customers from our Mining segment accounted for 27%, 18% and 13% of total accounts receivable while two customers in our Mining segment accounted for 32% and 13% of total revenues for 2007. We believe the loss of any one of these customers would not have a material adverse effect on our financial position because we believe we would be able to sell our production to other customers at prevailing market prices.

11

Through March 2010, Buckeye has presold, for delivery in 2010, approximately 338,000 tons of coal pursuant to long-term contracts, which expire through 2012. Buckeye has committed to deliver, in 2010, approximately 529,000 tons of coal pursuant to customer purchase orders. The prices are generally tied to published indices. The prices range from $41.00 to $95.00 per ton net of transportation with average current prices of approximately $57.42 per ton. The prices vary depending on the characteristics of the coal. Currently, 95% of Buckeye's anticipated coal sales in 2010 will be delivered from the pre-sold and committed tons.

Through March 2009, Buckeye had presold for delivery in 2009, approximately 335,000 tons of coal pursuant to long-term contracts, which expire through 2011. In 2009, Buckeye has committed to deliver approximately 375,000 tons of coal pursuant to customer purchase orders. The prices are generally tied to published indices. The prices range from $49.00 to $105.00 per ton net of transportation with an average current price of approximately $71.75 per ton. The prices vary depending on the characteristics of the coal.

Through March 2008, Buckeye had presold, for delivery in 2008, approximately 500,000 tons of coal pursuant to long-term contracts which expire through 2012, at prices tied to various published indices. We expected these prices to range from $35 to $59 per ton in 2008. Buckeye had presold 400,000 tons for delivery in 2007 at prices ranging from $34 to $55 per ton. Pursuant to existing contracts, Buckeye has presold approximately 800,000 tons of coal for delivery through 2012 at pricing which are tied to various indices. In 2008 Buckeye had committed to deliver approximately 200,000 tons of coal pursuant to customer purchase orders at prices tied to various indices, with the expected price ranging from $39 to $74 per ton.

Environmental Regulations Affecting our Market

The following summarizes federal, state, and international programs that may affect the market for our K-Fuel refined coal and for GreenCert products.

A. Federal Requirements:

- •

- National Ambient Air Quality

Standards. The Clean Air Act (CAA) requires that EPA set National Ambient Air Quality Standards (NAAQS), expressed as ambient

concentration levels based on levels "requisite to protect" human health and welfare. NAAQS are established for six specific criteria pollutants (ozone; particulate matter (PM) and fine PM which are

2.5 microns or smaller; sulfur dioxides; nitrogen oxides (NOx); lead; and carbon monoxide). The NAAQS set to protect human health is called the primary standard, while the NAAQS established to protect

welfare impacts, such as those on vegetation and visibility, is called the secondary standard. The primary standards have mandatory deadlines for attainment, whereas the secondary standards must be

met as soon as practicable. The CAA requires EPA to review and, if appropriate, revise the NAAQS every five years.

- •

- State Implementation Plans. Once a standard is finalized, States are required to develop State Implementation Plans (SIP) that demonstrate how areas within each state will attain NAAQS by using a combination of "state" and "federally" imposed controls and measures affecting emission sources. Depending on how far out of attainment a county or area is determined to be, different deadlines to reach attainment may be set. The SIP must be submitted to EPA for formal approval. As part of the SIP, emission standards are set for "state-controlled" sources, and enforced on businesses through construction and operating permits, on transportation systems, and sometimes on commercial and consumer product content. A number of States have imposed stationary source controls on existing and new sources that are more stringent than the federal NAAQS standards would require.

12

- •

- The Clean Air Act Acid Rain

Program. Title IV of the CAA separately regulates emissions of sulfur dioxide and nitrogen oxide from coal-fired power

generating facilities. Specifically, title IV set a goal of reducing sulfur dioxide emissions by 10 million tons below 1980 levels and imposed a two-phased tightening of

restrictions on fossil fuel-fired power plants. Phase I began in 1995 and focused primarily on coal-burning electric utility plants in the East and Midwest. In 2000,

Phase II began and this phase tightened the annual emissions' limits on larger higher emitting plants and set restrictions on smaller, cleaner plants fired by coal, oil, and gas. The Acid Rain

Program calls for a 2 million ton reduction in nitrogen oxide emission and focuses on one set of sources that emit nitrogen oxide: coal-fired electric utility boilers. Beginning in

January 2000, nitrogen oxide emissions are to be reduced 900,000 tons per year beyond the 1.2 million per year reduction set by the EPA in 1995. Coal-fired electric utility boilers

that are subject to the Acid Rain Program are required to report emissions of carbon dioxide along with their sulfur dioxide and nitrogen oxide emissions, but there is no required limit or control on

the carbon dioxide emissions.

- •

- Clean Air Interstate

Rule. The Clean Air Interstate Rule was finalized by the EPA in March 2005. Once fully implemented, this rule will reduce sulfur dioxide

emissions in 28 eastern states and the District of Columbia by more than 70% and nitrogen oxide emissions by more than 60% from the 2003 levels. Through the use of a

cap-and-trade approach, the rule promises to achieve substantial reduction of sulfur dioxide and nitrogen oxide emissions. Reduction of nitrogen oxide emissions began in

January 2009, which was followed by reductions of sulfur dioxide emissions in January 2010. The program will be fully implemented by January 2015. This rule has been set aside by the U.S. Court of

Appeals and the EPA is addressing that decision on remand.

- •

- Clean Air Mercury Rule. The U.S. Environmental Protection Agency, or EPA, finalized the Clean Air Mercury Rule, or CAMR, on March 15, 2005 to reduce mercury emissions from coal-fired power plants for the first time ever. Phase 1 of CAMR was set to go into effect on January 1, 2010. However, on February 8, 2008, the U.S. Circuit Court of Appeals for the District of Columbia vacated the rule, requiring the EPA to develop a new proposed utility mercury regulation. As a result of this ruling, it is likely that individual coal-fired boilers and power plants will be held to stringent levels of mercury emission reductions instead of averaging mercury emissions across multiple plants and across the country. EPA is currently developing air toxic emission standards for power plants under the Clean Air Act that are consistent with the U.S. Court of Appeals for the D. C. Circuit's decision and has stated its intention to finalize a regulation for coal and oil fired electric generating units in 2011.

We believe that existing and proposed legislation and regulations could affect the profitability of fossil fuel-fired, and specifically coal-fired power generating facilities which can emit substantial levels of sulfur dioxide, nitrogen oxides, mercury and carbon dioxide into the environment. Regulation of these emissions can affect the market for our K-Fuel refined coal by imposing limits and caps on fossil fuel emissions. Regulation of carbon dioxide and other GHG's can also affect our GreenCert technology solutions by enhancing market opportunities. The most significant existing national legislation and regulations affecting our K-Fuel market include the Clean Air Act, the Clean Air Interstate Rule and the Clean Air Mercury Rule, which are implemented by the EPA as previously described.

While carbon dioxide and other GHG emissions are not regulated at the federal level at this time, the U.S. House of Representatives passed a bill in June 2009 which would amend the Clean Air Act to impose an economy-wide cap on GHG emissions and set up an emissions trading system to help mitigate control costs. The U.S. Senate introduced a similar bill in 2009, but action on this bill has been stalled. Currently it is uncertain whether Congress will complete legislation which would create a federal-level GHG cap-and-trade system this year.

13

In 2009, the EPA initiated two actions which could potentially affect K-Fuel and GreenCert products. The first EPA action was a regulation for the Mandatory Reporting of Greenhouse Gases. The final rule for this regulation was published in the Federal Register in October 2009. This regulation does not limit or control GHG emissions, but requires reporting of GHG emissions from coal-fired power plants and other large industrial facilities starting with the 2010 calendar year. The second EPA action was issuance of the proposed rule for the Prevention of Significant Deterioration and Title V Greenhouse Gas Tailoring Rule, also published in the Federal Register in October 2009. This rule, if finalized, would regulate GHG emissions from coal-fired power plants and other large industrial facilities by requiring that these installations include best available control technology for GHG emissions when initiating or renewing permits under the existing Clean Air Act. The EPA Administrator has recently stated (February 2010 letter to Senator Rockefeller) that it plans to phase in the GHG permit requirements over time starting in 2011 with large stationary sources.

In addition, the K-Fuel market will be affected by additional national policies including the EPA's Nitrogen Oxide State Implementation Plan Call, the EPA's National Ambient Air Quality Standards for ozone and fine particulate matter, and the Regional Haze Rules, which require emission controls for industrial facilities emitting air pollutants that reduce visibility by causing or contributing to regional haze.

B. State and Regional Requirements

State and regional policies will also impact our market. Important regional frameworks include The Regional Greenhouse Gas Initiative (RGGI), which requires reduction in carbon dioxide emissions from electric generating units, beginning in January 2009 in ten northeastern states. The Western Climate Initiative, a coalition including seven western states and four Canadian provinces as partners (although Arizona has recently announced that it will not continue to be a full partner), has developed a regional, economy-wide GHG cap-and-trade program, the first phase of which will start in 2012. In the Midwest, six states and one province are full members of the Midwestern Greenhouse Gas Reduction Accord with the aim of establishing a regional GHG cap-and-trade market system. Many states have at least nominal economy-wide greenhouse gas reduction targets. A number of these are based only on Executive Orders, so implementation is not assured. Many states have legislated greenhouse gas targets and/or utility performance standards including California, Connecticut, Illinois, Maine, Maryland, Massachusetts, Minnesota, Montana, New Jersey, Oregon, and Washington.

The GHG emission reduction target set by state legislation is more stringent than the target set by RGGI, a regional cap-and-trade program to which Maryland belongs. RGGI caps carbon dioxide emissions for electric utilities and will achieve a 10 percent reduction in emissions from 2009 levels by 2018. Maryland's legislation also has a broader scope than RGGI, covering sources across the economy except the manufacturing sector.

Many states also have mandatory GHG Reporting Requirements for utilities. For example, Washington, Oregon, California, New Mexico, Florida, Iowa, Wisconsin, North Carolina, Maryland, Delaware, Rhode Island, New Jersey, New York, Connecticut, Massachusetts, Vermont, New Hampshire, and Maine. All but 8 states have at least some voluntary reporting system, mostly through the Climate Registry. Many states are also implementing emission reduction policies more stringent than national policies with respect to mercury, SO2 and NOx and visibility,

C. International Markets

Markets for K-Fuel and GreenCert products are also influenced by international regulations. While the Kyoto Protocol to the UN Framework Convention on Climate Change (UNFCCC), to which the US is not a party, expires in 2012, negotiations are well underway for a successor treaty that will be more broadly-based. Of primary importance to future coal markets are the positions of China and

14

India, the two largest coal-based emerging economies. While both have resisted calls for firm greenhouse gas targets, both submitted voluntary commitments to the Copenhagen Accord, concluded in December 2009. India committed to a 20-25% reduction in the GHG intensity of its economy by 2020, compared to 2005, and China to a 40-45% reduction in conjunction with at least a 15% increase in renewable energy use. China in particular has been aggressively investing in renewable energy technologies such as wind and photovoltaic generation. At the same time, both countries are likely to remain heavy producers and consumers of coal-based energy for the foreseeable future, and increasing levels of environmental consciousness and regulation will likely heighten interest in the benefits of K-Fuel refined coal. The UNFCCC Clean Development Mechanism (CDM) provides market opportunities for GreenCert products in GHG reduction projects in developing countries such as China and India. Market opportunities in developed countries are provided by the UNFCCC Joint Implementation (JI) mechanism and the European Union Emissions Trading Scheme (EU ETS).

Environmental Regulations Affecting the Construction and Operation of our Plants and Mining of Coal

As a general matter, we are subject to a number of state and federal regulations that (i) seek to limit the amount of certain emissions into the environment, (ii) govern the handling and disposal of solid waste materials as well as potentially hazardous materials, and (iii) impose certain employee safety requirements. As we expand our operations we may become subject to more regulation. For example, if we build additional plants we may install coal-fueled electric generating units, which are subject to substantial federal, state, and local permitting requirements and more environmental regulation than gas- fueled electric generating units. Through our mining activities, we are also subject to additional regulations including the Coal Mine Health and Safety Act of 1969, the Federal Mine Safety and Health Act of 1977, the Black Lung Benefits Revenue Act of 1977 and other regulations that seek to protect the health and safety of employees.

In the United States, K-Fuel refined coal is not expected to be subject to unusual levels of local, state or federal regulation with respect to its transportation and distribution. However, any future production plants will require numerous permits, approvals and certificates from appropriate federal, state and local governmental agencies before construction of each facility can begin and will be required to comply with applicable environmental laws and regulations (including obtaining operating permits) once facilities begin production. The most significant types of permits that are typically required for commercial production facilities include an operating and construction permit and a wastewater discharge permit under the Clean Water Act, and a treatment, storage and disposal permit under the Resource Conservation and Recovery Act. Some federal programs have delegated regulatory authority to the states and as a result, facilities may be required to secure state permits. Finally, the construction of new facilities may require review under the National Environmental Policy Act, or a state equivalent, which requires analysis of environmental impacts and potentially, the implementation of measures to avoid or minimize these environmental impacts.

Any international K-Direct or K-Fuel plants will also be subject to various permitting and operational regulations specific to each country. International initiatives, such as the Kyoto Protocol, are expected to create increasing pressures on the electric power generation industry on a world-wide basis to reduce emissions of various pollutants, which management expects will create additional demand for our products and services.

15

Employees

At March 12, 2010, we had 145 full-time employees of which 108 are employed at Buckeye.

Access to Information

Our web site address is www.evgenergy.com. We make available, free of charge on the Investor Info section of our web site, our Annual Report on Form 10-K, Quarterly Reports on Form 10-Q, Current Reports on Form 8-K, and all amendments to those reports, as soon as reasonably practicable after these reports are electronically filed with or furnished to the Securities and Exchange Commission. We also make available through our web site other reports electronically filed with the SEC under the Securities Exchange Act of 1934, including our proxy statements and reports filed by officers and directors under Section 16(a) of that Act. Additionally, we make available press releases and presentation material including slides and other investor information. We do not intend for information contained in our web site to be part of this Annual Report on Form 10-K.

In addition to risk and uncertainties in the ordinary course of business that are common to all businesses, important factors that are specific to our industry and our company could materially impact our future performance and results. We have provided below a list of these risk factors that should be reviewed when considering our business and securities. These are not all the risks we face, and other factors currently considered immaterial or unknown to us may impact our future operations.

Business Risks

Our financial condition continued to deteriorate during 2009. We have been evaluating several alternatives related to our strategic positioning, including the potential sale of Buckeye which is not strategic to the further development of our GreenCert or K-Fuel technologies. While we have investigated a number of financing alternatives, we have not yet obtained sufficient additional financing to complete our strategic positioning. In October 2009 we completed a financing deal totaling $7.0 million resulting in net proceeds of $5.0 million, excluding transaction costs, and again completed a financing deal in January 2010 totaling $8.7 million resulting in net proceeds of $8.0 million. We completed another financing transaction in March 2010 totaling $9.3 million and resulting in net proceeds of $5.0 million, excluding transaction costs. Further, in March 2010, we entered a definitive agreement regarding the sale of Buckeye, as described further below. Notwithstanding these financings and the contemplated sale of Buckeye; we continue to require additional capital.

As a result of the preceding,we are in need of capital. We are continuing to evaluate restructuring and capital raising alternatives—and to work towards the closing of the Buckeye assets. Without an additional influx of capital, we will not be able to pursue our business plan and may not be able to remain a going concern.

The contemplated sale of the Buckeye may not be consummated.

On March 12, 2010, we signed a definitive agreement with Rosebud Mining Company for the sale of Buckeye for $27.9 million, in addition to the release of $5.0 million of cash reclamation bonds. Further, $2.8 million of the purchase price will be deposited into escrow for a period of twelve months to cover amounts payable to Rosebud pursuant to the indemnification provision of the sales agreement. The closing is not subject to a financing condition, but is subject to the satisfaction of customary closing conditions, including, among other matters, (i) accuracy of the representations and warranties and compliance with the covenants set forth in the agreement, each in all material respects, (ii) receipt of legally required regulatory approvals, and (iii) consents of certain governmental authorities and certain of Buckeye's specified contractual counterparties. The sale is expected to close in April 2010, but in any

16

event no later than June 30, 2010. The proceeds from the sale of Buckeye will be used to retire the outstanding 2009 Notes including fees and accrued interest of $21.1 million, to fund related transaction expenses estimated at $2.5 million and for general working capital purposes.

If this transaction is not closed, we will need to reevaluate our strategy with respect to the Buckeye assets and identify another source of capital to retire the 2009 Notes. A failure to complete the sale of Buckeye could require us to immediately raise capital to pursue our business plan and remain a going concern.

We have a history of losses, deficits, and negative operating cash flows and will likely continue to incur losses in the future. Such losses may impair our ability to pursue our business plan and our independent registered public accounting firm has expressed substantial doubt over our ability to continue as a going concern.

We continue to incur operating losses and negative cash flows from operations for the foreseeable future. We have made, and will continue to make, substantial capital and other expenditures before we will have sufficient operating income and cash flow to recover all of our investments. We are not able to accurately estimate when, if ever, our cash flows from operating activities will increase sufficiently to cover these investments. Further, we may not achieve or maintain profitability or generate cash from operations in future periods. Our working capital (the amount by which our current assets exceed our current liabilities), accumulated deficit, net loss and cash (used in) provided by operating activities are as follows:

| |

December 31, | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| |

2009 | 2008 | 2007 | |||||||

| |

(in thousands) |

|||||||||

Working capital |

$ | (21,747 | ) | $ | 2,263 | $ | 45,580 | |||

Accumulated deficit |

(529,939 | ) | (473,303 | ) | (408,073 | ) | ||||

Net loss |

(58,537 | ) | (65,230 | ) | (204,676 | ) | ||||

Cash used in operating activities |

$ | (12,908 | ) | $ | (36,263 | ) | $ | (51,581 | ) | |

We have substantial capital requirements and as a result, we have been, and continue to be, dependent on financing activities or sales of our equity securities to fund our operating costs. The inability to raise funds through traditional financing means or sale of our equity securities may require us to sell assets to fund our operating costs.

As a result of negative cash flows from operations, we have been, and continue to be, dependent on financing activities and sales of our equity securities to fund the operating and substantial capital costs associated with our business. Our success is dependent on our ability to utilize existing resources and to generate sufficient cash flows to meet our obligations on a timely basis, to obtain financing or refinancing as may be required, to attain profitability, or a combination thereof. The continued economic downturn has had, and may continue to have, an impact on our business and our financial condition. In addition, the economic downturn may present significant challenges for us if conditions in the financial markets do not improve or continue to worsen. We have limited ability to access traditional bank loan financing in current market conditions. Further, our ability to access capital markets, for example, may be severely restricted at times when we need adequate funding to pay our existing indebtedness, pursue our business strategy, respond to changing business and economic conditions and competitive pressures, absorb negative operating results and fund our continuing operations, capital expenditures or increased working capital requirements. We may also need to sell assets to fund our operating costs to the extent that we are unable to raise adequate funds in the capital markets. Given the global recession, we may not be able to sell assets on favorable terms or at all.

17

We have a limited operating history as a technology solutions company, and our business and prospects should be considered in light of the risks and difficulties typically encountered by a company with a limited operating history.

You should consider our business and prospects in light of the risks and difficulties typically encountered by a company with a limited operating history. The specific risks include whether we will be able to:

- •

- enter into agreements to measure, quantify certify and verify carbon dioxide emissions or to license our GreenCert

technology;

- •

- enter into or maintain strategic partnerships with vendors and other parties to maximize our K-Fuel and

GreenCert technologies;

- •

- raise additional capital;

- •

- execute our business strategy;

- •

- accurately assess potential markets and effectively respond to competitive developments;

- •

- successfully market our products;

- •

- attract and retain customers for product sales;

- •

- attract and retain credit-worthy customers;

- •

- effectively manage expanding operations;

- •

- attract and retain key personnel; and

- •

- enter into agreements for the purpose of building K-Direct and K-Fuel plants or licensing of that technology;

We may not be successful in addressing these and other risks. As a result, our financial condition, results of operations and cash flows may be adversely affected.

Competition from other companies that have developed or may develop other systems that measure greenhouse gases and certify carbon credits, could adversely affect our competitive position. Further, competition could increase depending upon the level of regulation ultimately enacted in the United States and international markets, which could further adversely affect our competitive position.

While we believe we have developed the only science-based method to accurately measure greenhouses gas emissions, other companies have developed less costly methodologies to measure these emissions. In addition, a number of companies are developing carbon measurement alternatives and many of these companies have greater resources than ours. Carbon measurement regulation, in both the United States and internationally, is evolving and there is no clear consensus on how carbon emissions should be measured. While we believe that our measurement tool is the most accurate tool because it is scientifically based, regulations could be enacted allowing for less precise methods and therefore, less costly methodologies to be applied. Further, there is a risk that our GreenCert technology will not be accepted by regulators and customers even though we believe it is compliant. Future revenues will be dependent upon our ability to identify and adapt to our competition and the changing regulatory environment.

We rely on key personnel and if we are unable to retain or attract qualified personnel, we may not be able to execute our business plan.

Our success is currently dependent on the performance of a small group of senior managers, key technical personnel and independent contractors that have a wide range of technical experience and

18

expertise. For K-Fuel, this experience and expertise includes coal refining, coal thermal upgrading, thermal processing, coal gasification, coal liquification and general plant operations, For GreenCert this expertise includes carbon measurement, carbon emission modeling, power generation, carbon sequestration and nitrogen oxides and sulfur dioxide reduction analysis. In addition, our business strategy will require us to attract and retain a substantially greater number of qualified personnel and/or hire additional contractors in these key areas. The inability to retain key managerial and technical personnel or attract and retain additional highly qualified managerial or technical personnel in the future could harm our business or financial condition.

Competition from other companies in the clean coal, alternative fuel and emission-reducing equipment industries, including competition resulting from deregulation in the United States power industry, could adversely affect our competitive position.

Competition in the clean coal, alternative fuel and emission-reducing equipment industries could impact our ability to generate revenue from our K-Fuel process. Many of these companies in the clean coal, alternative fuel technology and emission-reducing equipment industries have financial resources greater than ours. Providers of alternative or competing technologies in these industries may be subject to less regulation, or alternatively, may enjoy subsidies that provide them with increased financial strength, or make their products or services more attractive to energy consumers. Due to any of these competitive advantages, our existing and future competitors may be able to offer products more competitively priced and more widely available than ours. These companies also may have the resources to create new technologies and products that could make our process and products obsolete. Our future revenues may depend on our ability to address competition in these industries. In addition, deregulation in the United States power generating industry may result in increased competition from other producers of energy-efficient coal products, other clean fuel sources, and other products, services and technologies designed to provide environmental and operating cost benefits similar to those which we believe are available from our K-Fuel refined coal.

Overseas development of our K-Fuel and GreenCert businesses is subject to international risks, which could adversely affect our ability to license, construct overseas plants or profitably operate our businesses overseas.

We believe a portion of the growth opportunity for our businesses lies outside the United States. Doing business in foreign countries may expose us to many risks that are not present domestically. We lack significant experience dealing with such risks, including political, military, privatization, technology piracy, currency exchange and repatriation risks, and higher credit risks associated with customers. In addition, it may be more difficult for us to enforce legal obligations in foreign countries, and we may be at a disadvantage in any legal proceeding within the local jurisdiction. Local laws may also limit our ability to hold a majority interest in the projects that we develop.

If the national and world-wide financial downturn continues or intensifies it could adversely impact demand for our technology and products.

Continued market disruptions could cause broader economic downturns, which may lead to lower demand for our technology or products, increased incidence of customers' inability to pay their accounts, or insolvency of our customers, any of which could adversely affect our results of operations, liquidity, cash flows, and financial condition.

Our inability to adequately protect and defend our proprietary K-Fuel and GreenCert processes could harm our business, increase our costs and decrease sales of our products and services.

Our success depends, in part, upon our proprietary processes. We rely on a combination of patent, trademark and trade secret rights to establish and protect our proprietary rights. We currently have a

19

series of patents and patent applications on our K-Fuel process and our GreenCert technology. However, competitors may successfully challenge the validity or scope of one or more of our patents, or any future patents. These patents alone may not provide us with any significant competitive advantage. Further, while our most recently issued K-Fuel patent protection covers what we believe are the unique aspects of our K-Fuel process as it is currently conducted, not all of the claims we filed were allowed. An additional patent application has been filed to address the examiner's comments and we expect some of the revised claims to be allowed. While we continue our efforts regarding these claims there can be no assurance that we will be able to obtain patent protection in the United States or abroad to protect these or any other aspects of our intellectual property, or that, in the absence of any such patent protection, that the combination of additional methods that we currently employ to maintain the confidentiality of our processes will adequately safeguard our proprietary processes and information. If our intellectual property is not adequately protected, this may have a material adverse impact on our financial condition, results of operations, cash flows and future prospects.

Third parties could copy or otherwise obtain and use our technologies without authorization or develop similar technologies independently. The protection of our proprietary rights may be inadequate and our competitors could independently develop similar technology, duplicate our solutions, or design around any patents or other intellectual property rights we hold.

Any actions taken by us to enforce our patents or other property rights could result in significant expense as well as the diversion of management time and resources. In addition, detecting infringement and misappropriation of patents or intellectual property can be difficult, and there can be no assurance that we would detect any infringement or misappropriation of our proprietary rights. Even if we are able to detect infringement or misappropriation of our proprietary rights, litigation to enforce our rights could cause us to divert significant financial and human resources from our business operations, and may not ultimately be successful. If we are required to divert significant resources and time to the enforcement of our proprietary rights, even if the enforcement is successful, our business could be materially adversely affected.

Our success will depend on our ability to operate without infringing on or misappropriating the proprietary rights of others.

We may be sued for infringing or misappropriating the proprietary rights of others. Intellectual property litigation is costly, and, even if we prevail, the cost of such litigation could adversely affect our business. In addition, litigation is time consuming and could divert management attention and resources away from our business. If we do not prevail in any litigation, we could be required to stop the infringing activity and/or pay substantial damages. Under some circumstances, these damages could be triple the actual damages the patent holder incurs. If we have supplied infringing products to third parties for marketing or licensed third parties to manufacture, use or market infringing products, we may be obligated to indemnify these third parties for any damages they may be required to pay to the patent holder and for any losses the third parties may sustain themselves as the result of lost sales or damages paid to the patent holder.

If a third party holding rights under a patent successfully asserts an infringement claim with respect to any of our products or processes, we may be prevented from manufacturing or marketing our infringing product in the country or countries covered by the patent we infringe, unless we can obtain a license from the patent holder. Any required license might not be available to us on acceptable terms, or at all. Some licenses may be non-exclusive, and therefore, our competitors may have access to the same technology licensed to us. If we fail to obtain a required license or are unable to design around a patent, we may be unable to market future products, which could have a material adverse effect on our business.

20

Our acquisition activities may not be successful.

As part of our business strategy, we may make acquisitions of businesses and technologies. However, suitable acquisition candidates may not be available on terms and conditions we find acceptable. Further, acquisitions pose substantial risks to our financial condition, results of operations and cash flows. In pursuing acquisitions, we compete with other companies, many of which have greater financial and other resources to acquire attractive companies and properties. Even if future acquisitions are completed, the following are some of the risks associated with acquisitions:

- •

- the acquired businesses or properties may not produce revenues, earnings or cash flow at anticipated levels;

- •

- we may be unable to integrate acquired businesses successfully and realize anticipated economic, operational and other

benefits in a timely manner;

- •

- acquisitions could disrupt our ongoing business, distract management, divert resources and make it difficult to maintain

our current business standards, controls and procedures;

- •

- we may finance future acquisitions by issuing common stock for some or all of the purchase price, which could dilute the

ownership interests of our stockholders; and

- •

- we may incur additional debt related to future acquisitions.

Risks Relating to Our Debt, Our Common Stock and Other Risks.

Our debt obligations may affect our business, operating results and financial condition.