Attached files

| file | filename |

|---|---|

| 8-K - DARLING INTERNATIONAL 8-K 11-2-2009 - DARLING INGREDIENTS INC. | form8-k.htm |

Investor

Presentation

Investor

Presentation

November

2009

NYSE:

DAR

2

Forward-Looking

Statements

This

presentation contains forward-looking statements regarding the

business

operations of Darling and the industry in which it operates. These statements are

identified by words such as “may,” “will,” “expect,” “believe,” “intend,” “anticipate,”

“should,” “estimate,” “continue,” and other words referring to events to occur in the

future. These statements reflect Darling's current view of future events and are

based on its assessment of, and are subject to, a variety of risks and uncertainties

beyond its control, including business and economic conditions in its existing

markets that could cause actual results to differ materially from those projected in

the forward-looking statements. Other risks and uncertainties regarding Darling,

its business and the industry in which it operates are referenced from time to time

in the Company's filings with the Securities and Exchange Commission. Darling is

under no obligation to (and expressly disclaims any such obligation to) update or

alter its forward-looking statements whether as a result of new information, future

events or otherwise.

operations of Darling and the industry in which it operates. These statements are

identified by words such as “may,” “will,” “expect,” “believe,” “intend,” “anticipate,”

“should,” “estimate,” “continue,” and other words referring to events to occur in the

future. These statements reflect Darling's current view of future events and are

based on its assessment of, and are subject to, a variety of risks and uncertainties

beyond its control, including business and economic conditions in its existing

markets that could cause actual results to differ materially from those projected in

the forward-looking statements. Other risks and uncertainties regarding Darling,

its business and the industry in which it operates are referenced from time to time

in the Company's filings with the Securities and Exchange Commission. Darling is

under no obligation to (and expressly disclaims any such obligation to) update or

alter its forward-looking statements whether as a result of new information, future

events or otherwise.

3

Over a

century old,

Darling International Inc.

is America’s leading provider

of rendering, recycling and

recovery solutions to the

nation’s food industry.

Darling International Inc.

is America’s leading provider

of rendering, recycling and

recovery solutions to the

nation’s food industry.

Founded in

1882

Headquartered

in Dallas, TX

1900

employees

Public since

1994

NYSE Listed

(DAR)

Largest independent

rendering company with

80 locations, 44 processing plants nationwide

80 locations, 44 processing plants nationwide

Reports under two

segments:

– Rendering

– Restaurant

services

Who

we are:

4

Essential

“Gate Keeper” for People & Planet

5

Composting - Volume would fill

10,000 new

Dallas Cowboy stadiums per year

Dallas Cowboy stadiums per year

Landfill - Volume

would reduce existing

US landfill space by 25% per year and

increase GHG emissions

US landfill space by 25% per year and

increase GHG emissions

Incineration - Cost prohibitive

and has

air quality issues

air quality issues

Digesting- Operationally

challenging

and capital intensive

and capital intensive

Burial - Potential

for ground and

surface water contamination

surface water contamination

Abandonment -Greatest threat

to

environment and human/animal health

environment and human/animal health

Without rendering…. we face critical issues using other methods of disposal:

6

Rendering…

invisible industry with massive scale

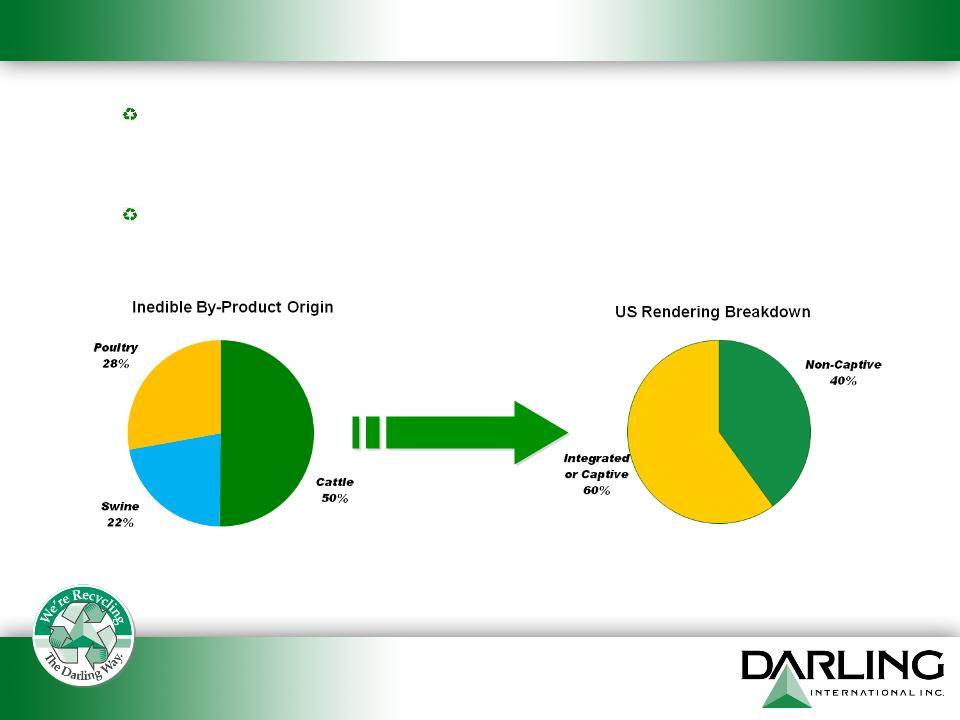

Animal and food

by-product recycling industry is “mission critical” in

the food supply chain and is the most efficient and environmentally

sound disposal alternative for a sustainable society.

the food supply chain and is the most efficient and environmentally

sound disposal alternative for a sustainable society.

Over 59 billion

pounds of inedible by-products generated annually

from meat packers, poultry processors and retail food stores.

from meat packers, poultry processors and retail food stores.

Source:

NRA/Harvard Risk Assessment

35 million cattle

(49% of live wt. not used for human food)

100 million hogs

(44% not used for human food)

8 billion chickens

(37% not used for human food)

280 million turkeys

(36% not used for human food)

U.S.

Animal Agriculture Annual Production

7

How

it All Fits Together

RAW

MATERIAL

Tallow

Meat

& Bone

Grease

Hides

Leather

Shoes

Garments

Upholstery

Bio-

Fuels

Fuels

Animal

Feed

Feed

Pet

Food

Food

Poultry

Feed

Feed

Hog

Food

Food

Animal

Feed

Feed

Pet

Food

Food

Bio-

Fuels

Fuels

Soap

Linoleic

Acid

Acid

Oleic

Acid

Acid

Glycerin

Stearic

Acid

Acid

Fertilizer

Lubricants

Textiles

Plastics

Shampoo

Emulsifiers

Cleaners

Creams

Esters

Paints

Plastics

Lubricants

Inks

Glues

Solvents

Antifreeze

Explosives

Rubber

Plastics

Tires

Lubricants

Finished

Products

Products

Component

By-Products

By-Products

Component

By-Products

Applications

By-Products

Applications

8

9

Industry

Leader

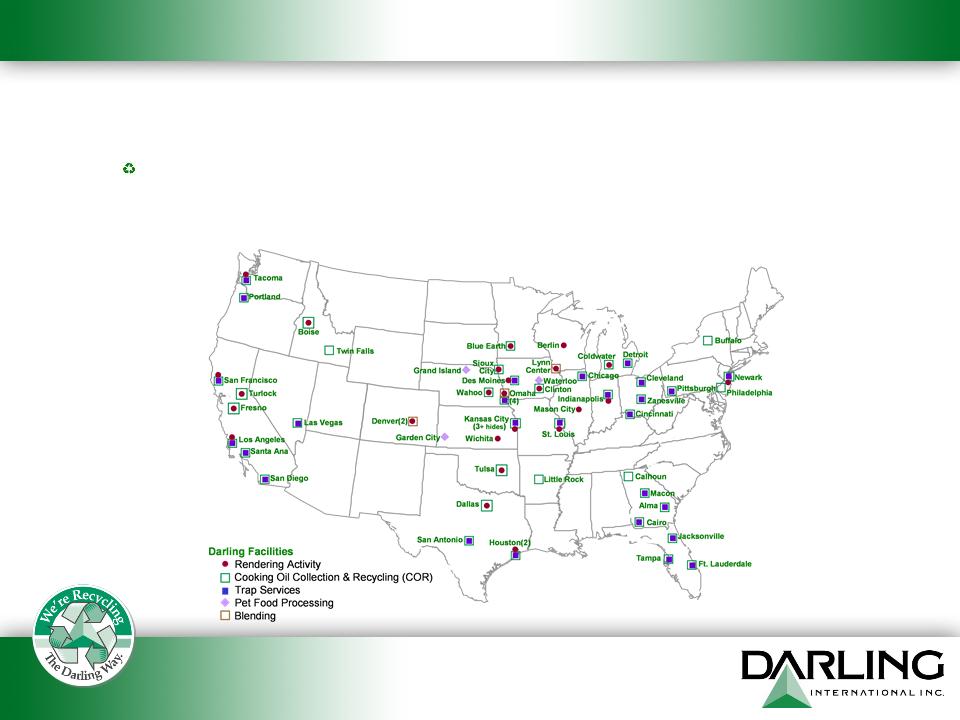

Only

recycling/rendering company with a national footprint operating in 42

states

- Network of 44 processing facilities from coast to coast

- Supported by 36 accumulation centers.

- Network of 44 processing facilities from coast to coast

- Supported by 36 accumulation centers.

A

national footprint with scale ……

10

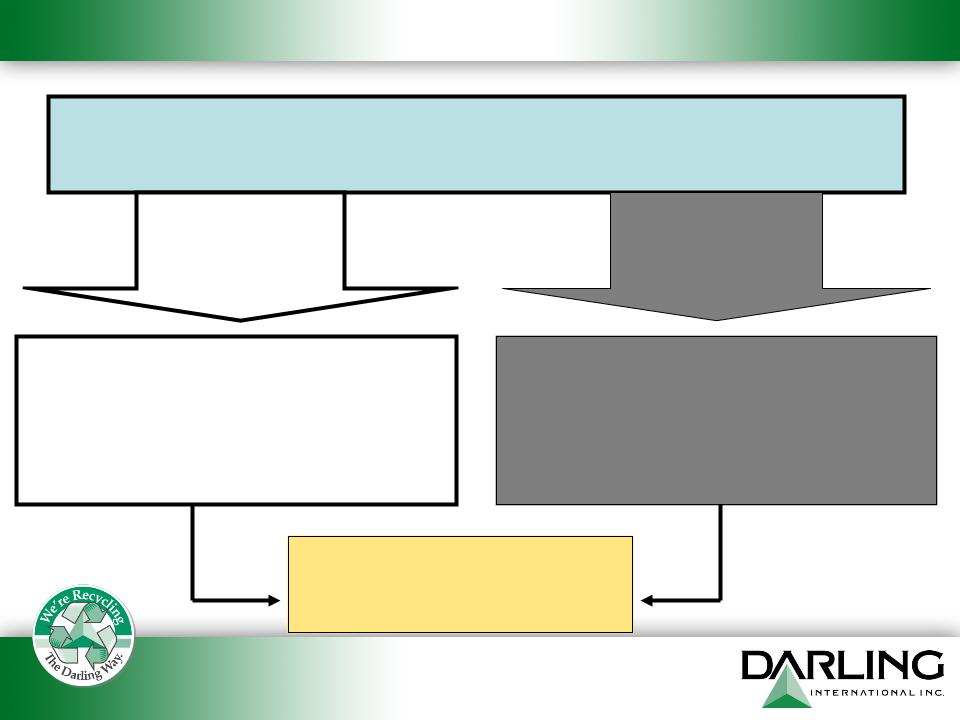

Reporting

Segments

Rendering

Rendering is the

process of recycling animal and food waste products into useful

commercial goods, including tallow, protein meals (meat and bone meal), yellow

grease, and hides.

commercial goods, including tallow, protein meals (meat and bone meal), yellow

grease, and hides.

Restaurant

Services

Darling

is the only US provider of collection, storage, transport, and recycling

of

old grease on a national scale.

old grease on a national scale.

Rendering

Process

Grinding

Cooking

Defatting

Meal

Fat

11

Raw

Materials - turning this …

Offal

Bones and

fat

Blood

Animals dead on

arrival,

in transit or on farms

in transit or on farms

Feathers

12

…

into this

13

14

Rendering

Overview

Darling

operates a fleet of approx 960 trucks to collect raw materials from

approx

116,000 food service establishments, butcher shops, grocery stores, and

independent meat and poultry processors nationwide.

116,000 food service establishments, butcher shops, grocery stores, and

independent meat and poultry processors nationwide.

“Formula”

basis: Applied to approx

58% of Darling’s annual raw material

volume; cost is tied to published finished product commodity prices after

deducting a fixed service charge.

volume; cost is tied to published finished product commodity prices after

deducting a fixed service charge.

“Non-formula”

basis: Applied to remaining

volume; suppliers are either paid a

fixed price, are not paid, or are charged for the expense of collection, depending

on various economic and competitive factors

fixed price, are not paid, or are charged for the expense of collection, depending

on various economic and competitive factors

Darling

markets finished products worldwide.

Primarily BFT and YG, and also MBM, a protein;

Oils used in pet food, animal feed, soaps;

Oleo-chemical producers use oils to produce ingredients for paint,

rubber, paper, concrete, plastics;

MBM is used as high protein additives in pet food and animal feed

Primarily BFT and YG, and also MBM, a protein;

Oils used in pet food, animal feed, soaps;

Oleo-chemical producers use oils to produce ingredients for paint,

rubber, paper, concrete, plastics;

MBM is used as high protein additives in pet food and animal feed

Purchase

&

Collection

Collection

Risk

Management

& Pricing

Management

& Pricing

Marketing,

Sales &

Distribution

Sales &

Distribution

15

Restaurant

Services Overview

Basic cooking oil removal (COR) service

- Collection of used cooking oil from inside systems or

outside corrals

- Collection of used cooking oil from inside systems or

outside corrals

Premium service offered in conjunction with COR

- Self

contained used cooking oil storage system inside or

outside customer’s premises

outside customer’s premises

Grease trap maintenance and cleaning service

- Operates in 20 markets

- Customers represent FSEs, malls and industrial food processors

- Operates in 20 markets

- Customers represent FSEs, malls and industrial food processors

16

Cooking

Oil Removal

Bundled

services - Complete,

individualized used cooking oil collection and

recycling services nationwide through local

providers

individualized used cooking oil collection and

recycling services nationwide through local

providers

Environmental

compliance - Efficient,

reliable

pickup and disposal of non-recyclable waste

pickup and disposal of non-recyclable waste

17

CleanStar

Environmentally

safe and efficient - Used

cooking

oil is pumped directly into sealed, insulated CleanStar

storage tank with press of a button

oil is pumped directly into sealed, insulated CleanStar

storage tank with press of a button

Customer

choice - Option of inside or

outside

storage systems to fit customer needs

storage systems to fit customer needs

18

Torvac

(Trap)

Ongoing

maintenance - Provides

manpower,

equipment and expertise to find and fix grease

trap problems

equipment and expertise to find and fix grease

trap problems

Compliance

-

Removed material is tracked

and handled in a legal and environmentally

sound manner

and handled in a legal and environmentally

sound manner

19

National

Service Center

Darling’s

National Service Center (NSC) offers

complete service management for all cooking oil

removal, grease trap and rendering services.

complete service management for all cooking oil

removal, grease trap and rendering services.

Manages grease and

rendering related service needs.

Ensures compliance

for trap regulations and ordinances.

24 hr/day, 7

day/week high-quality customer service.

Web-based records

management system.

Sales

Recap

20

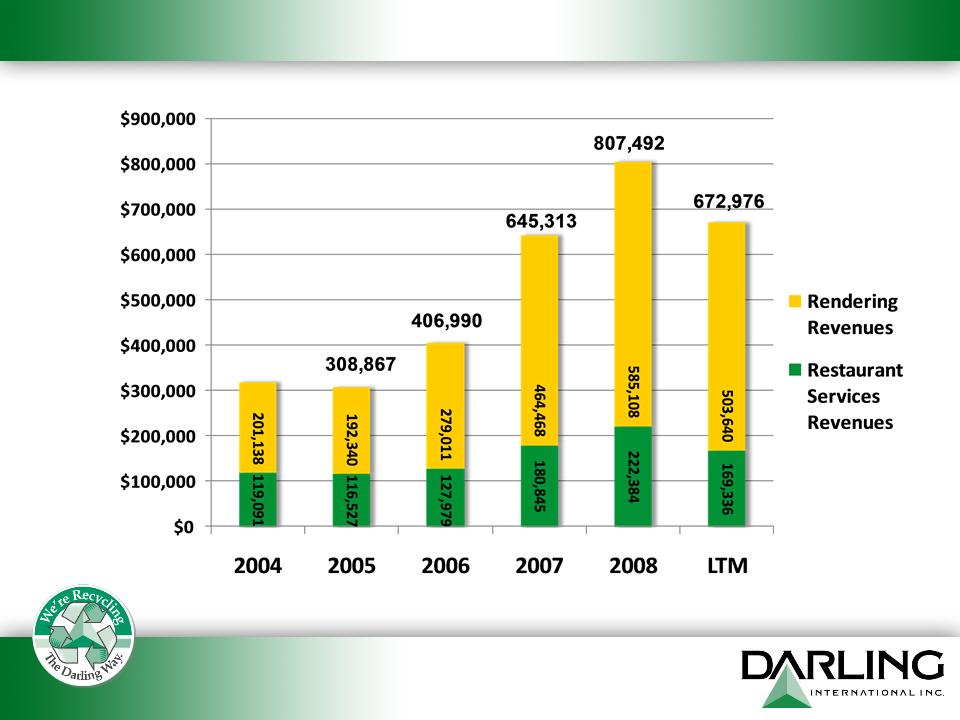

320,229

21

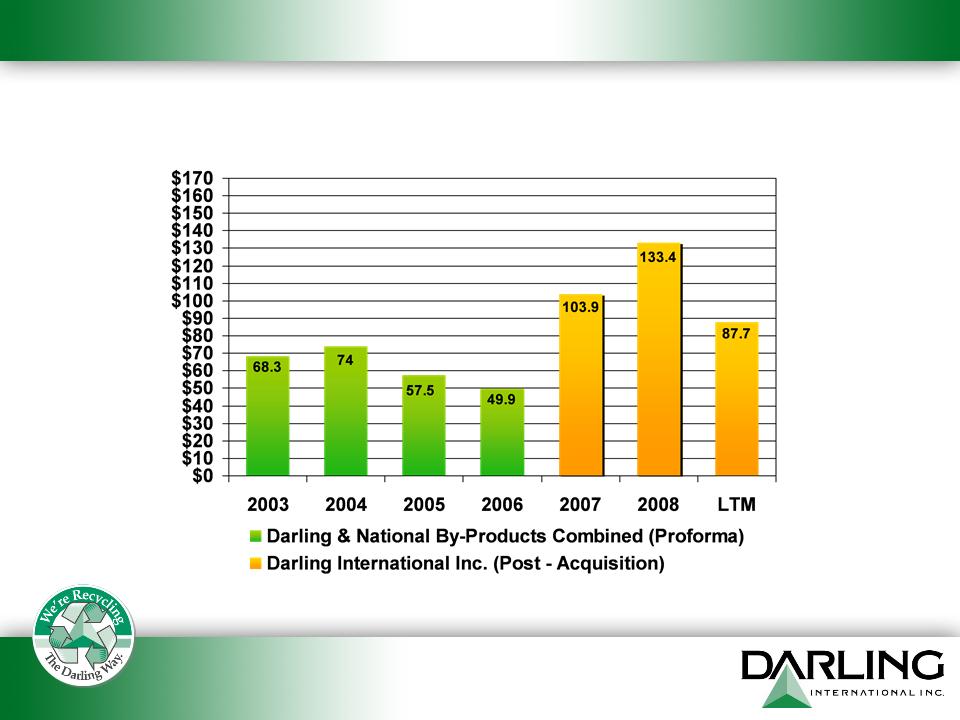

Operating

Cash Flows

(in

millions)

Key

Financials

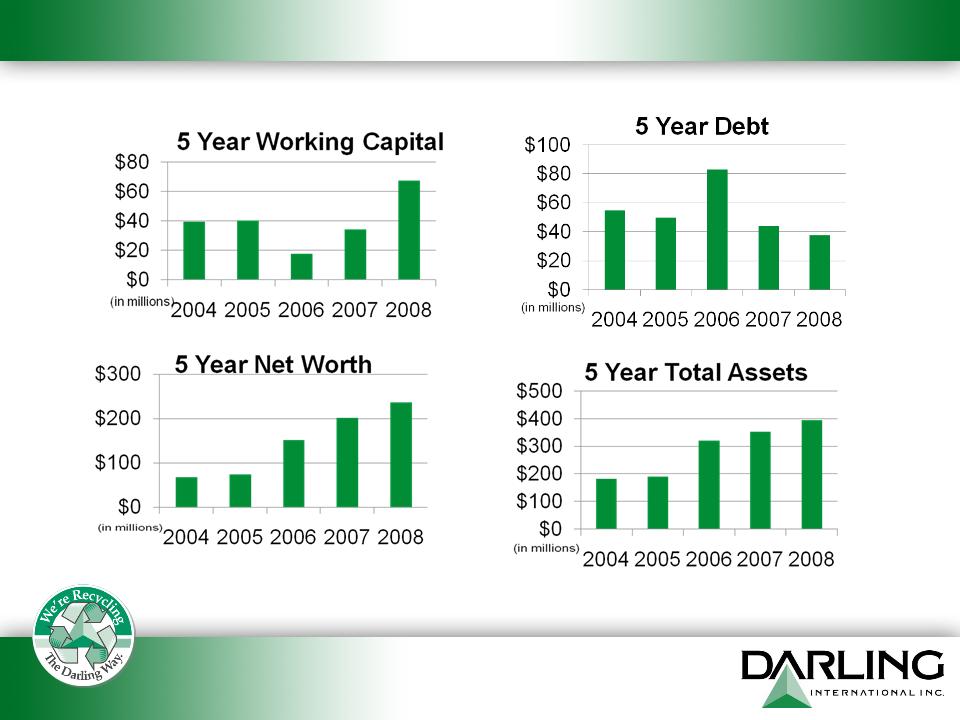

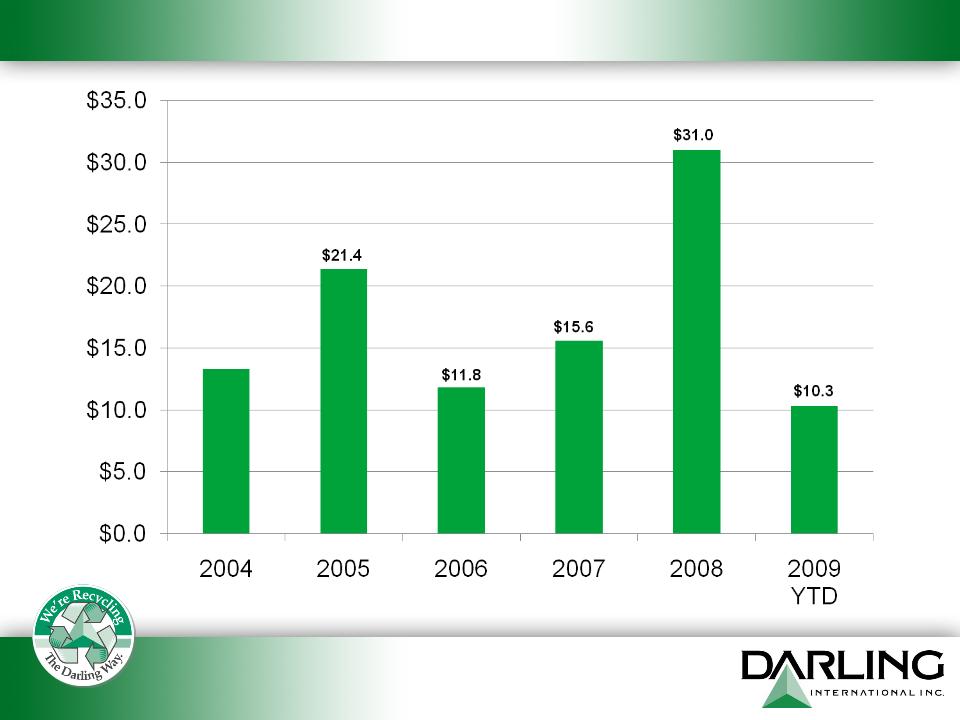

22

Capital

Expenditures

23

Millions

$13.3

Balance

Sheet

24

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

July

4, 2009

|

|

June

28, 2008

|

|

|

|

|

|

|

|

|

|

CASH

|

|

$ 57,786

|

|

$ 44,596

|

|

|

ACCOUNTS

RECEIVABLE

|

|

46,404

|

|

65,078

|

|

|

INVENTORIES

|

|

20,073

|

|

30,300

|

|

|

INCOME

TAXES REFUNDABLE

|

|

5,170

|

|

-

|

|

|

OTHER

CURRENT ASSETS

|

|

15,539

|

|

12,018

|

|

|

TOTAL

CURRENT ASSETS

|

|

144,972

|

|

151,992

|

|

|

|

|

|

|

|

|

|

PROPERTY,

PLANT & EQUIP

|

|

146,477

|

|

132,698

|

|

|

GOODWILL

|

|

66,958

|

|

71,856

|

|

|

OTHER

|

|

47,604

|

|

32,716

|

|

|

TOTAL

ASSETS

|

|

$ 406,011

|

|

$ 389,262

|

|

|

|

|

|

|

|

|

|

CURRENT

PORTION - DEBT

|

|

$ 5,000

|

|

$ 5,000

|

|

|

A/P

AND ACCRUED EXPENSES

|

|

61,290

|

|

70,139

|

|

|

TOTAL

CURRENT LIABILITIES

|

|

66,290

|

|

75,139

|

|

|

|

|

|

|

|

|

|

LONG-TERM

DEBT, LESS CURRENT

|

|

30,000

|

|

36,250

|

|

|

OTHER

LIABILITIES

|

|

54,117

|

|

28,361

|

|

|

TOTAL

LIABILITIES

|

|

150,407

|

|

139,750

|

|

|

|

|

|

|

|

|

|

STOCKHOLDERS'

EQUITY

|

|

255,604

|

|

249,512

|

|

|

TOTAL

LIABILITIES AND EQUITY

|

|

$ 406,011

|

|

$ 389,262

|

|

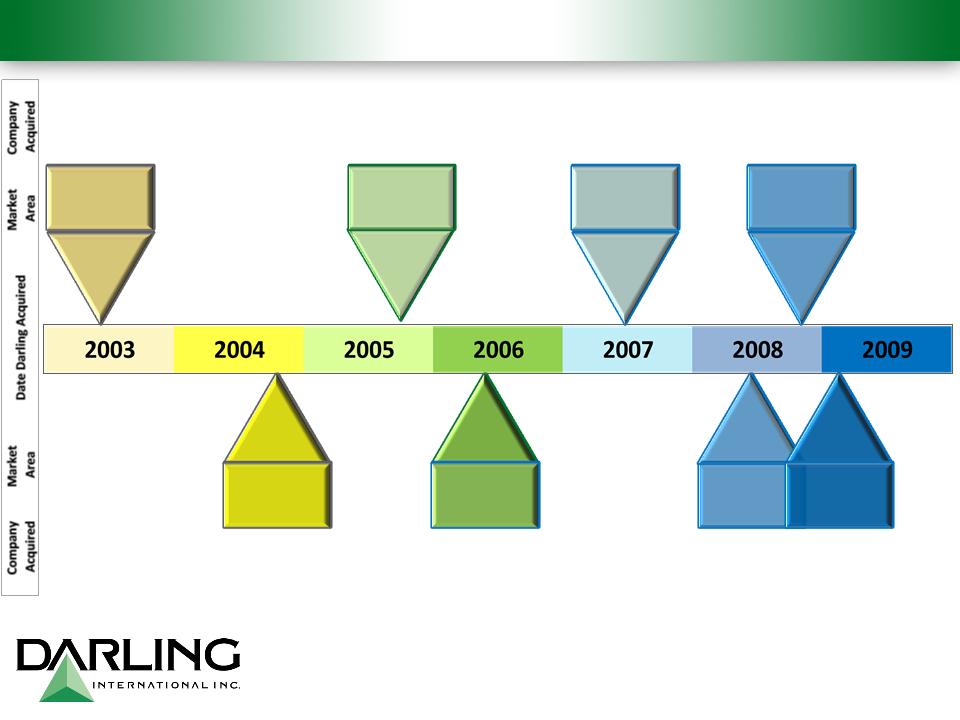

Core

Business Growth through Acquisition

25

March

03

03

Dec

04

04

May

06

06

July

07

07

Dec

08

08

Feb

09

09

Aug

08

08

Oct

05

05

Enviro

Vac,

Inc.

Inc.

FL,

GA

KC

metro

NYC

metro

GA

GA

So

CA

TX

Burrows

Industries, Inc.

dba Minuteman Pumping

dba Minuteman Pumping

Ace

Grease

Service

Service

J&R

Rendering, Inc.

Rendering, Inc.

Southeastern

Maintenance &

Construction Inc.

Maintenance &

Construction Inc.

National

By-Products, LLC

By-Products, LLC

API

Recycling,

div of American

Proteins Inc.

div of American

Proteins Inc.

Boca

Transport, Inc.

Transport, Inc.

Midwest

US

US

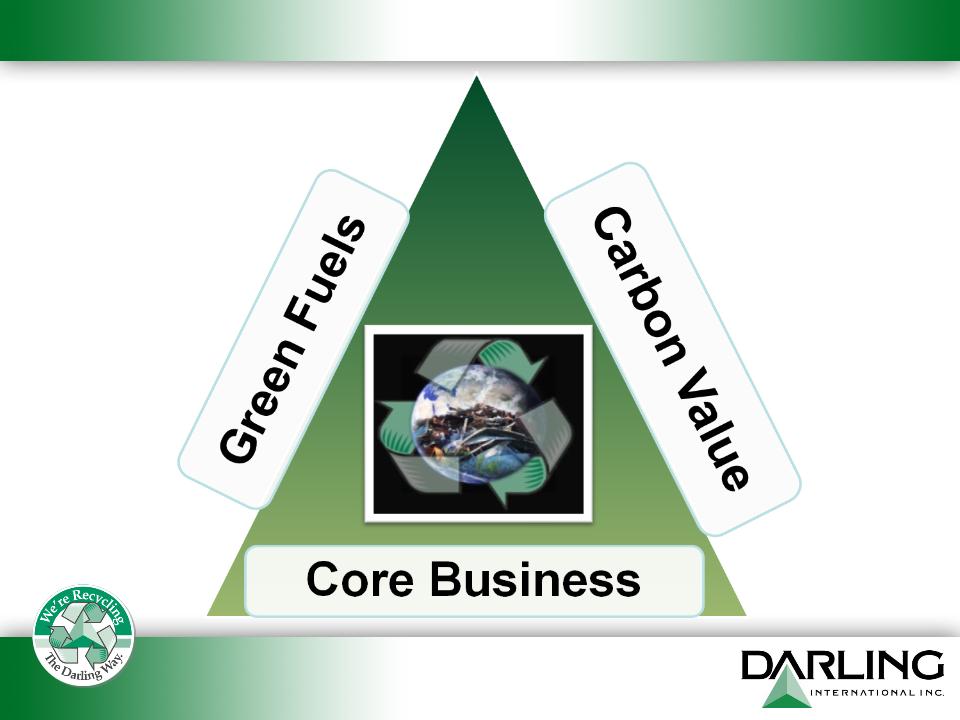

Darling

International Inc. - Triangle of Value

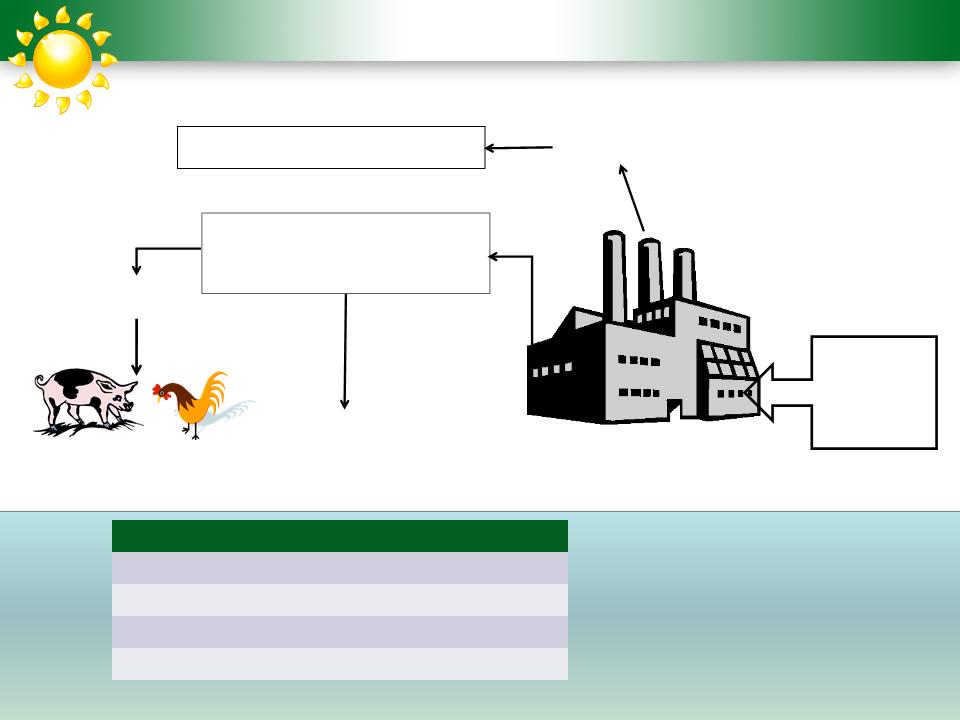

26

Darling

Captures and Recycles Carbon

(Emissions

per 1000 lb raw material)

Rendering

Facility

573

kg

CO2 eq

avoided by recycling

avoided by recycling

64

kg CO2

Industrial

uses

and biofuels

and biofuels

Feed

|

Material

Darling recycles in a year:

|

|

|

Carbon Darling

captures, lb/year

|

1.23

billion

|

|

CO2 Darling avoids,

metric ton/year

|

2.1

million

|

|

CO2 emitted per metric

ton avoided

|

0.14 metric

ton

|

|

GHG avoided

,metric ton/year*

|

4

million

|

Atmospheric

CO2

*Avoided

when materials are rendered rather than composted, based on a study by Xu et

al., 2008

Animal

Byproducts

&

Mortalities

Byproducts

&

Mortalities

27

28

29

Darling

is uniquely positioned

A top producer of

animal fats and greases

“Similar to owning

the oil field”

Not a food oil (Food

vs. Fuel)

Mandates, subsidies,

and carbon credits

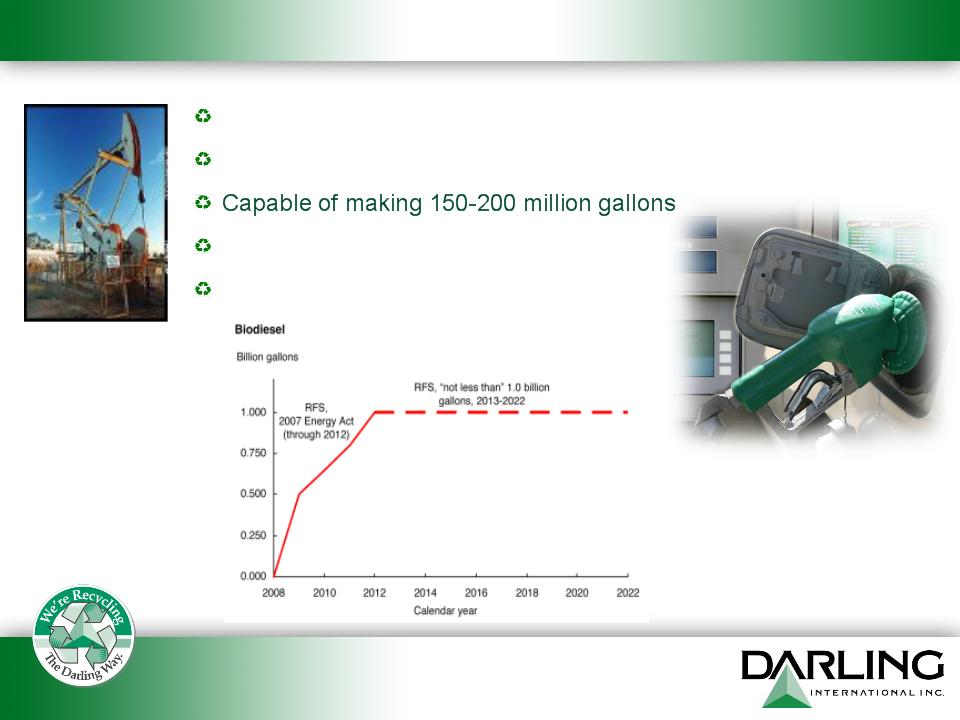

Source:

National Biodiesel Board.

Bio-diesel

has not been the solution so far for animal fats

Animal fat based bio-diesel (TME)

has not been embraced because of

cold flow properties… hard to handle in the

distribution system and variable quality.

|

|

Petro-Diesel

|

Biodiesel

(FAME)

|

Green

Diesel

|

|

NOx

Emission

|

Baseline

|

+

10

|

-10 to

0

|

|

Cetane

|

40-55

|

50-65

|

75-90

|

|

Cold flow

properties

|

Baseline

|

Poor

|

Excellent

|

|

Oxidative

stability

|

Baseline

|

Poor

|

Excellent

|

|

Energy

content

|

Baseline

|

Lower

|

Similar

|

30

Green

diesel may be a better solution?

Green diesel is a

bio fuel indistinguishable from petroleum diesel; it can be

blended to any proportion

blended to any proportion

Green diesel can be

used in any proportion within today’s infrastructure,

from pipelines and storage to gas pumps and automobiles

from pipelines and storage to gas pumps and automobiles

Green diesel has

excellent stability and is not oxygenated

Green diesel offers

superior cold flow properties making it more suitable for

very cold climate conditions

very cold climate conditions

Green diesel has

higher energy content per volume compared to biodiesel

The renewable diesel

process is feedstock flexible and will

produce green diesel with the same superior quality from a

wide variety of feedstock's, such as vegetable oils, tallow,

animal fats, greases & algae oils

produce green diesel with the same superior quality from a

wide variety of feedstock's, such as vegetable oils, tallow,

animal fats, greases & algae oils

Green diesel offers

lower fossil energy requirements and

reduction of green house gases and NOX emissions

reduction of green house gases and NOX emissions

31

Animal fat price is

determined by its value relative to corn!

Not a FOOD vs. FUEL

issue

Developing a new

customer alternative for DAR products

is essential to creating shareholder value.

is essential to creating shareholder value.

Mandated consumption

and blending requirement for

greenhouses gases

may alter the supply & demand enough

to

narrow the discount our products have enjoyed versus

soybean

oil.

Highlights

to consider:

Bio-fuels

may be a game changer for DAR!

|

|

2006

|

2007

|

2008

|

3-Yr

Average

|

|

Per # price of

diesel fuel

|

.27

|

.30

|

.45

|

.34

|

|

Per # price of

animal fat/used grease

|

.16

|

.26

|

.31

|

.24

|

|

Price premium

as fuel before tax credit

|

.11

|

.04

|

.14

|

.10

|

|

Per # value of

tax credit

|

.14

|

.14

|

.14

|

.14

|

|

Price premium

as fuel after tax credit

|

.25

|

.18

|

.28

|

.24

|

Alters supply/demand

dynamic of animal fats/used grease

Darling fat is more

valuable as fuel than animal feed

|

|

Billions

of

Annual Lbs |

|

Demand as

animal feed

|

7.5

|

|

Demand as

industrial feedstock

|

2.1

|

|

Demand as food

ingredient

|

.4

|

|

U.S.

supply/demand fat’s and greases

|

10.0

|

32

33

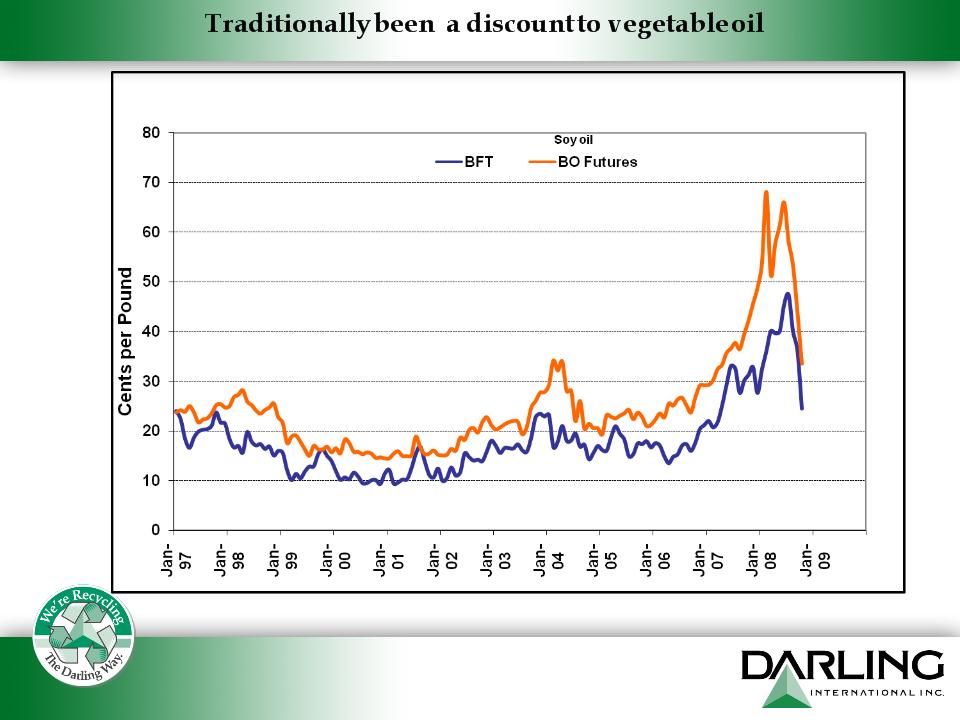

Bleachable

Fancy Tallow

Fancy Tallow

|

|

MMs

Annual |

|

Revenue renewable

diesel

|

$526

|

|

Other

products

|

30

|

|

Total

revenue

|

556

|

|

Input

cost

|

375

|

|

Plant

operating cost

|

39

|

|

Total

expenses

|

414

|

|

|

|

|

EBITDA

|

$142**

|

What

did Green Diesel economics in 2008 look like?

10,000

barrel/day plant

Earnings

Snapshot

34

**Assumes 2008

average market prices for the

respective products and inputs as published by

trade journals and may not be indicative of future

performance.

respective products and inputs as published by

trade journals and may not be indicative of future

performance.

Green

Diesel and the Carbon World

THE

CARBON FACTS

-

Each gallon of diesel fuel results in 22.2 #’s of carbon emissions

- Carbon reduction associated with animal fat/used cooking oil

green diesel between 70%-90%

10,000

BPD PLANT

U.S.

ANIMAL FAT

&

USED

GREASE

SUPPLY

Gallons

green diesel 125,000,000

X

#’s/gallon carbon reduction 18

=

Total #’s of carbon reduction 2,250,000,000

or

Metric

tonnes carbon credit 1,020,593

X

Assumed per tonne credit $35

=

Available income carbon credits $35,720,755

Gallons

green diesel 1,250,000,000

X

#’s/gallon carbon reduction 8

= Total #’s of carbon

reduction

22,500,000,000

or

Metric

tonnes carbon credit 10,205,933

X

Assumed per tonne credit 35

= Available income

carbon credits $357,207,655

Value

will most likely be created by

RIN’S

which will be indexed with

fuels having greater carbon reductions

receiving

premium pricing in market

Assumes

80%

35

DAR

& VLO have applied for DOE Loan Guarantee

Joint venture to

construct 10,000 barrel/ day “Green

Diesel Refinery”

Facility to have

pre-treatment capability for multi-feedstock flexibility,

but animal fats and used cooking oil are primary

but animal fats and used cooking oil are primary

St. Charles Site

Provides:

– Located on major

waterway for feedstock flexibility

– Located on petroleum

pipeline distribution system

– Located on hydrogen

supply pipeline system

Deal points we are

looking for:

– 50/50 equity

participation

– Supply at market of

fats and oils

– Finished products

(Diesel, Naphtha, and Propane) off take agreement

– RIN and

Carbon Credit stay with facility

36

37

The

RECYCLING COMPANY of YESTERDAY…

The

CARBON FRIENDLY

FUEL COMPANY

of TOMMORROW

CARBON FRIENDLY

FUEL COMPANY

of TOMMORROW